Mathematical Formulations for Asynchronous Parallel Disassembly Planning of End-of-Life Products

Abstract

1. Introduction

- (1)

- A nonlinear mathematical model is formulated to demonstrate the APDP.

- (2)

- Four MILP formulations are developed based on the nonlinear model.

- (3)

- The branch-and-cut algorithm of the CPLEX solver is employed to search for exact solutions. The results demonstrate that the exact solutions of three MILP models are able to improve the current best solutions in the test instances.

2. Literature Review

3. Problem Description

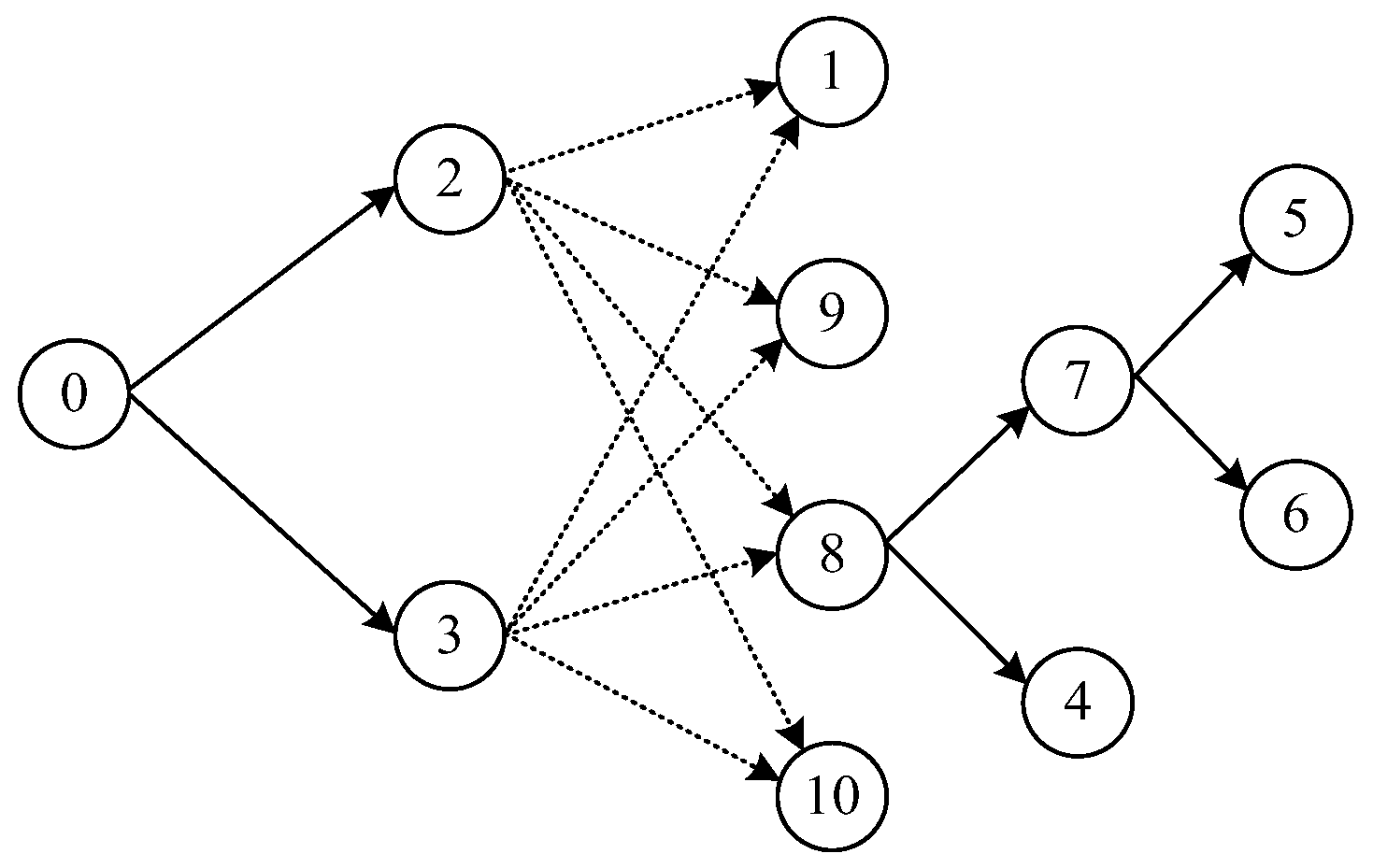

3.1. Representation of DP

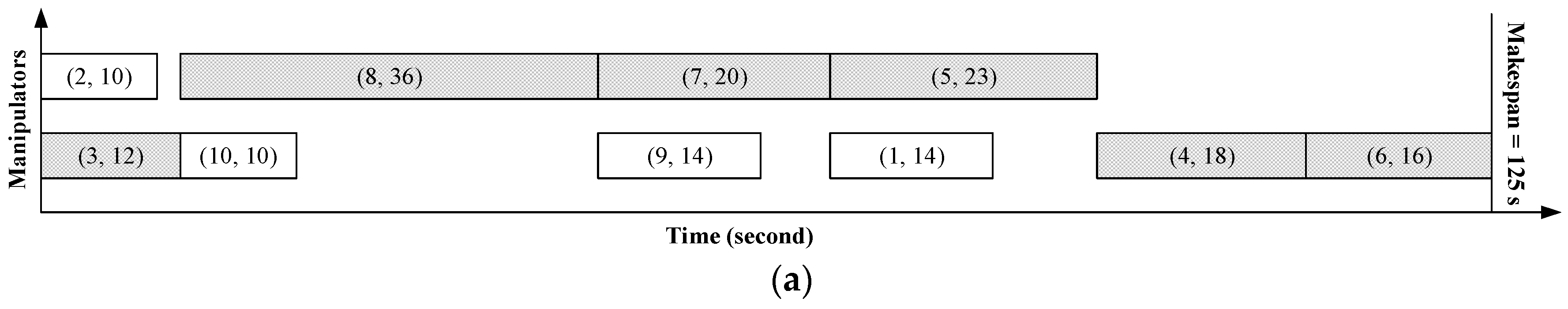

3.2. Synchronous Parallel Disassembly and Asynchronous Parallel Disassembly

- AND precedence and OR precedence relationships are ensured.

- Work area collisions among manipulators are considered.

- Once a part begins, it cannot be interrupted.

- Each part is exactly removed once by one manipulator.

- Disassembly times of parts are determined in advance.

- A manipulator can remove at most one part at the same time.

4. MILP Modeling of APDP

| the number of parts | |

| position indices of manipulators, where | |

| the number of manipulators | |

| the disassembly time of part | |

| index set of AND predecessors of part | |

| index set of OR predecessors of part | |

| index set of parts that have work area collisions with part in the parallel disassembly process | |

| a large positive number | |

| a binary decision variable, , if part occupies position of the disassembly sequence of manipulator ; otherwise, | |

| a binary decision variable,, if part is removed by manipulator ; otherwise, | |

| a binary decision variable, , if part is removed immediately before part by manipulator ; otherwise, | |

| a binary decision variable, , if part is removed before (adjacent or non-adjacent) part ; otherwise, , part is removed before (adjacent or non-adjacent) part | |

| a continuous decision variable, the starting time of disassembling part | |

| a continuous decision variable, the time when manipulator starts to remove the part | |

| a continuous decision variable, the maximum completion time (makespan) of the disassembly process |

4.1. Model 1

4.2. Model 2

4.3. Model 3

4.4. Model 4

5. Computational Results

5.1. Comparisons of MILP Models

5.1.1. Size Complexity

5.1.2. Computational Complexity

5.2. Result Comparisons with IGA

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Ren, Y.; Zhang, C.; Zhao, F.; Tian, G.; Lin, W.; Meng, L.; Li, H. Disassembly line balancing problem using interdependent weights-based multi-criteria decision making and 2-Optimal algorithm. J. Clean. Prod. 2018, 174, 1475–1486. [Google Scholar] [CrossRef]

- Colledani, M.; Battaïa, O. A decision support system to manage the quality of End-of-Life products in disassembly systems. CIRP Ann. Manuf. Technol. 2016, 65, 41–44. [Google Scholar] [CrossRef]

- Ren, Y.; Tian, G.; Zhao, F.; Yu, D.; Zhang, C. Selective cooperative disassembly planning based on multi-objective discrete artificial bee colony algorithm. Eng. Appl. Artif. Intell. 2017, 64, 415–431. [Google Scholar] [CrossRef]

- Ren, Y.; Zhang, C.; Zhao, F.; Xiao, H.; Tian, G. An asynchronous parallel disassembly planning based on genetic algorithm. Eur. J. Oper. Res. 2018, 269, 647–660. [Google Scholar] [CrossRef]

- Zhang, X.F.; Zhang, S.Y. Product cooperative disassembly sequence planning based on branch-and-bound algorithm. Int. J. Adv. Manuf. Technol. 2010, 51, 1139–1147. [Google Scholar] [CrossRef]

- Kara, S.; Pornprasitpol, P.; Kaebernick, H. Selective Disassembly Sequencing: A Methodology for the Disassembly of End-of-Life Products. CIRP Ann. Manuf. Technol. 2006, 55, 37–40. [Google Scholar] [CrossRef]

- Xiu, F.Z.; Gang, Y.; Zhi, Y.H.; Cheng, H.P.; Guo, Q.M. Parallel disassembly sequence planning for complex products based on fuzzy-rough sets. Int. J. Adv. Manuf. Technol. 2014, 72, 231–239. [Google Scholar]

- Smith, S.; Hung, P.-Y. A novel selective parallel disassembly planning method for green design. J. Eng. Des. 2015, 26, 283–301. [Google Scholar] [CrossRef]

- Pistolesi, F.; Lazzerini, B. TeMA: A Tensorial Memetic Algorithm for Many-Objective Parallel Disassembly Sequence Planning in Product Refurbishment. IEEE Trans. Ind. Inform. 2019, 15, 3743–3753. [Google Scholar] [CrossRef]

- Ren, Y.; Zhang, C.; Zhao, F.; Triebe, M.J.; Meng, L. An MCDM-Based Multiobjective General Variable Neighborhood Search Approach for Disassembly Line Balancing Problem. IEEE Trans. Syst. Man Cybern. Syst. 2020, 50, 3770–3783. [Google Scholar] [CrossRef]

- Feng, Y.; Zhou, M.; Tian, G.; Li, Z.; Zhang, Z.; Zhang, Q.; Tan, J. Target Disassembly Sequencing and Scheme Evaluation for CNC Machine Tools Using Improved Multiobjective Ant Colony Algorithm and Fuzzy Integral. IEEE Trans. Syst. Man Cybern. Syst. 2019, 49, 2438–2451. [Google Scholar] [CrossRef]

- Hsu, H.-P. A Fuzzy Knowledge-Based Disassembly Process Planning System Based on Fuzzy Attributed and Timed Predicate/Transition Net. IEEE Trans. Syst. Man Cybern. Syst. 2016, 47, 1800–1813. [Google Scholar] [CrossRef]

- Tang, Y. Learning-Based Disassembly Process Planner for Uncertainty Management. IEEE Trans. Syst. Man Cybern. Part A Syst. Hum. 2008, 39, 134–143. [Google Scholar] [CrossRef]

- Tang, Y.; Zhou, M. Fuzzy-Petri-net based disassembly planning considering human factors. IEEE Trans. Syst. Man Cybern. A Syst. 2004, 26, 718–726. [Google Scholar] [CrossRef]

- Güngör, A.; Gupta, S.M. Disassembly sequence plan generation using a branch-and-bound algorithm. Int. J. Prod. Res. 2001, 39, 481–509. [Google Scholar] [CrossRef]

- Ren, Y.; Yu, D.; Zhang, C.; Tian, G.; Meng, L.; Zhou, X. An improved gravitational search algorithm for profit-oriented partial disas-sembly line balancing problem. Int. J. Prod. Res. 2017, 55, 7302–7316. [Google Scholar] [CrossRef]

- Johnson, M.R.; Wang, M.H. Economical evaluation of disassembly operations for recycling, remanufacturing and reuse. Int. J. Prod. Res. 1998, 36, 3227–3252. [Google Scholar] [CrossRef]

- Kang, J.-G.; Lee, D.-H.; Xirouchakis, P.; Persson, J.-G. Parallel Disassembly Sequencing with Sequence-Dependent Operation Times. CIRP Ann. 2001, 50, 343–346. [Google Scholar] [CrossRef]

- Lambert, A. Optimizing disassembly processes subjected to sequence-dependent cost. Comput. Oper. Res. 2007, 34, 536–551. [Google Scholar] [CrossRef]

- Edis, E.B.; Ilgin, M.A.; Edis, R.S. Disassembly line balancing with sequencing decisions: A mixed integer linear programming model and extensions. J. Clean. Prod. 2019, 238, 117826. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, C.; Shao, X.; Ren, Y.; Ren, C. Mathematical modelling and optimisation of energy-conscious hybrid flow shop scheduling problem with unrelated parallel machines. Int. J. Prod. Res. 2018, 57, 1119–1145. [Google Scholar] [CrossRef]

- Pistolesi, F.; Lazzerini, B.; Mura, M.D.; Dini, G. EMOGA: A Hybrid Genetic Algorithm with Extremal Optimization Core for Multi-objective Disassembly Line Balancing. IEEE Trans. Ind. Inform. 2018, 14, 1089–1098. [Google Scholar] [CrossRef]

- Sanchez, B.; Haas, C. A novel selective disassembly sequence planning method for adaptive reuse of buildings. J. Clean. Prod. 2018, 183, 998–1010. [Google Scholar] [CrossRef]

- Seo, K.-K.; Park, J.-H.; Jang, D.-S. Optimal Disassembly Sequence Using Genetic Algorithms Considering Economic and Environmental Aspects. Int. J. Adv. Manuf. Technol. 2001, 18, 371–380. [Google Scholar] [CrossRef]

- Kongar, E.; Gupta, S.M. Disassembly sequencing using genetic algorithm. Int. J. Adv. Manuf. Technol. 2005, 30, 497–506. [Google Scholar] [CrossRef]

- Tian, G.; Zhou, M.; Chu, J. A Chance Constrained Programming Approach to Determine the Optimal Disassembly Sequence. IEEE Trans. Autom. Sci. Eng. 2013, 10, 1004–1013. [Google Scholar] [CrossRef]

- Tian, G.; Zhou, M.; Li, P. Disassembly Sequence Planning Considering Fuzzy Component Quality and Varying Operational Cost. IEEE Trans. Autom. Sci. Eng. 2017, 15, 748–760. [Google Scholar] [CrossRef]

- Kheder, M.; Trigui, M.; Aifaoui, N. Disassembly sequence planning based on a genetic algorithm. Proc. Inst. Mech. Eng. Part C: J. Mech. Eng. Sci. 2014, 229, 2281–2290. [Google Scholar] [CrossRef]

- Guo, X.; Liu, S.; Zhou, M.; Tian, G. Dual-Objective Program and Scatter Search for the Optimization of Disassembly Sequences Subject to Multiresource Constraints. IEEE Trans. Autom. Sci. Eng. 2017, 15, 1091–1103. [Google Scholar] [CrossRef]

- Kalayci, C.B.; Gupta, S.M. Artificial bee colony algorithm for solving sequence-dependent disassembly line balancing problem. Expert Syst. Appl. 2013, 40, 7231–7241. [Google Scholar] [CrossRef]

- Lu, Q.; Ren, Y.; Jin, H.; Meng, L.; Li, L.; Zhang, C.; Sutherland, J.W. A hybrid metaheuristic algorithm for a profit-oriented and ener-gy-efficient disassembly sequencing problem. Robot. Cim. Int. Manuf. 2020, 61, 101828. [Google Scholar] [CrossRef]

- Tian, G.; Ren, Y.; Feng, Y.; Zhou, M.; Zhang, H.; Tan, J. Modeling and Planning for Dual-Objective Selective Disassembly Using and/or Graph and Discrete Artificial Bee Colony. IEEE Trans. Ind. Inform. 2018, 15, 2456–2468. [Google Scholar] [CrossRef]

- Li, W.; Xia, K.; Gao, L.; Chao, K.-M. Selective disassembly planning for waste electrical and electronic equipment with case studies on liquid crystaldisplays. Robot. Comput. Manuf. 2013, 29, 248–260. [Google Scholar] [CrossRef]

- Wang, K.; Li, X.; Gao, L.; Garg, A. Partial disassembly line balancing for energy consumption and profit under uncertainty. Robot. Comput. Manuf. 2019, 59, 235–251. [Google Scholar] [CrossRef]

- Zhang, B.; Pan, Q.-K.; Gao, L.; Li, X.; Meng, L.-L.; Peng, K.-K. A multiobjective evolutionary algorithm based on decomposition for hybrid flowshop green scheduling problem. Comput. Ind. Eng. 2019, 136, 325–344. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, C.; Shao, X.; Ren, Y. MILP models for energy-aware flexible job shop scheduling problem. J. Clean. Prod. 2018, 210, 710–723. [Google Scholar] [CrossRef]

- Castro, P.M.; Grossmann, I.E. Generalized Disjunctive Programming as a Systematic Modeling Framework to Derive Scheduling Formulations. Ind. Eng. Chem. Res. 2012, 51, 5781–5792. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, C.; Shao, X.; Zhang, B.; Ren, Y.; Lin, W. More MILP models for hybrid flow shop scheduling problem and its extended problems. Int. J. Prod. Res. 2019, 58, 3905–3930. [Google Scholar] [CrossRef]

- Pan, C.-H. A study of integer programming formulations for scheduling problems. Int. J. Syst. Sci. 1997, 28, 33–41. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, C.; Zhang, B.; Ren, Y. Mathematical Modeling and Optimization of Energy-Conscious Flexible Job Shop Scheduling Problem with Worker Flexibility. IEEE Access 2019, 7, 68043–68059. [Google Scholar] [CrossRef]

- Castro, P.M.; Zeballos, L.J.; Méndez, C.A. Hybrid time slots sequencing model for a class of scheduling problems. AIChE J. 2011, 58, 789–800. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, C.; Ren, Y.; Zhang, B.; Lv, C. Mixed-integer linear programming and constraint programming formulations for solving distributed flexible job shop scheduling problem. Comput. Ind. Eng. 2020, 142, 106347. [Google Scholar] [CrossRef]

- Meng, L.; Gao, K.; Ren, Y.; Zhang, B.; Sang, H.; Zhang, C. Novel MILP and CP Models for Distributed Hybrid Flowshop Scheduling Problem with Se-quence-Dependent Setup Times. Swarm Evol. Comput. 2022, 71, 101058. [Google Scholar] [CrossRef]

| Models | Model 1 | Model 2 | Model 3 | Model 4 |

|---|---|---|---|---|

| Binary variables | , | |||

| Constraint sets | (2)–(3), (5)–(11) | (2)–(3), (5)–(10), (13)–(16) | (6)–(10), (17), (20)–(21) | (6)–(10), (22)–(24), (26)–(27) |

| Continuous variables | , | , , | , | , |

| Nm | Case | Model 1 | Model 2 | Model 3 | Model 4 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NBV | NC | NCV | NBV | NC | NCV | NBV | NC | NCV | NBV | NC | NCV | ||

| 2 | 1 | 244 | 2504 | 12 | 244 | 610 | 34 | 79 | 262 | 12 | 288 | 190 | 13 |

| 2 | 968 | 20,503 | 23 | 968 | 2197 | 67 | 275 | 1013 | 23 | 1056 | 622 | 24 | |

| 3 | 2458 | 83,593 | 36 | 2458 | 5331 | 106 | 673 | 2535 | 36 | 2598 | 1455 | 37 | |

| 4 | 3216 | 125,140 | 41 | 3216 | 6898 | 121 | 876 | 3302 | 41 | 3376 | 1867 | 42 | |

| 3 | 1 | 365 | 3735 | 12 | 365 | 894 | 45 | 90 | 372 | 12 | 431 | 203 | 13 |

| 2 | 1452 | 30,710 | 23 | 1452 | 3251 | 89 | 297 | 1475 | 23 | 1584 | 646 | 24 | |

| 3 | 3683 | 125,312 | 36 | 3683 | 7919 | 141 | 708 | 3725 | 36 | 3893 | 1492 | 37 | |

| 4 | 4816 | 187,619 | 41 | 4816 | 10,256 | 161 | 916 | 4862 | 41 | 5056 | 1909 | 42 | |

| 4 | 1 | 486 | 4966 | 12 | 486 | 1178 | 56 | 101 | 482 | 12 | 574 | 216 | 13 |

| 2 | 1936 | 40,917 | 23 | 1936 | 4305 | 111 | 319 | 1937 | 23 | 2112 | 670 | 24 | |

| 3 | 4908 | 167,031 | 36 | 4908 | 10,507 | 176 | 743 | 4915 | 36 | 5188 | 1529 | 37 | |

| 4 | 6416 | 250,098 | 41 | 6416 | 13,614 | 201 | 956 | 6422 | 41 | 6736 | 1951 | 42 | |

| Nm | Case | Model 1 | Model 2 | Model 3 | Model 4 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CS | CPU (s) | Gap | CS | CPU (s) | Gap | CS | CPU (s) | Gap | CS | CPU (s) | Gap | ||

| 2 | 1 | 89 | 2.18 | 0 | 89 | 0.37 | 0 | 89 | 0.03 | 0 | 89 | 0.20 | 0 |

| 2 | 25.5 | 600 | 29.41 | 20.5 | 484.26 | 0 | 20.5 | 1.67 | 0 | 20.5 | 1.61 | 0 | |

| 3 | - | 600 | - | 1727 | 600 | 16.33 | 1726 | 600 | 13.04 | 1726 | 600 | 16.28 | |

| 4 | - | 600 | - | - | 600 | - | 365 | 600 | 6.85 | 384 | 600 | 24.74 | |

| 3 | 1 | 89 | 0.81 | 0 | 89 | 0.14 | 0 | 89 | 0.03 | 0 | 89 | 0.08 | 0 |

| 2 | 20 | 600 | 10.0 | 20 | 179.28 | 0 | 20 | 0.91 | 0 | 20 | 0.27 | 0 | |

| 3 | - | 600 | - | 1445 | 169.65 | 0 | 1445 | 3.25 | 0 | 1445 | 548.67 | 0 | |

| 4 | - | 600 | - | - | 600 | - | 338 | 600 | 5.92 | 338 | 600 | 14.50 | |

| 4 | 1 | 89 | 0.42 | 0 | 89 | 0.16 | 0 | 89 | 0.05 | 0 | 89 | 0.06 | 0 |

| 2 | 18 | 346.31 | 0 | 18 | 50.5 | 0 | 18 | 0.20 | 0 | 18 | 0.25 | 0 | |

| 3 | - | 600 | - | 1445 | 204.92 | 0 | 1445 | 0.91 | 0 | 1445 | 345.54 | 0 | |

| 4 | - | 600 | - | - | 600 | - | 305 | 600 | 1.97 | 310 | 600 | 6.77 | |

| Mean | 429.14 | 6.57 | 290.77 | 1.18 | 200.59 | 0.49 | 274.72 | 1.69 | |||||

| Opt | 5 | 8 | 8 | 8 | |||||||||

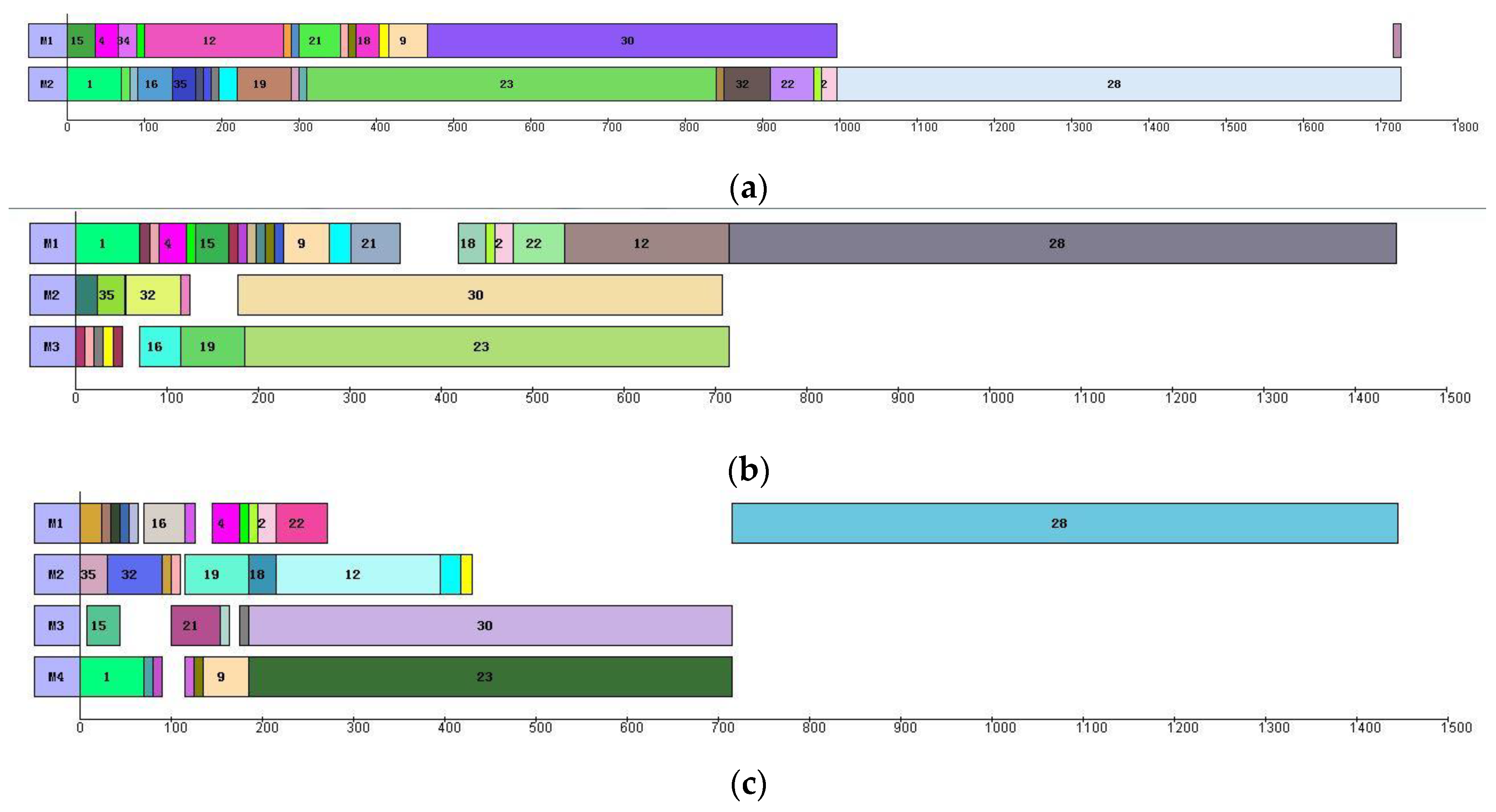

| Case | Nm | Solution | |

|---|---|---|---|

| 3 | 2 | M1:15,4,34,5,12,29,33,21,8,10,18,6,9,30,14 M2:1,13,31,16,35,24,20,7,11,19,26,17,23,25,32,22,3,2,27,28 | 1726 |

| 3 | M1:1,13,20,4,5,15,29,24,26,25,10,31,9,11,21,18,3,2,22,12,27,28 M2:34,35,32,17,30 M3:14,8,7,6,33,16,19,23 | 1445 | |

| 4 | M1:34,33,24,29,25,16,13,4,5,3,2,22,27,28 M2:35,32,20,8,19,18,12,11,6 M3:15,21,14,7,30 M4:1,31,26,17,10,9,23 | 1445 | |

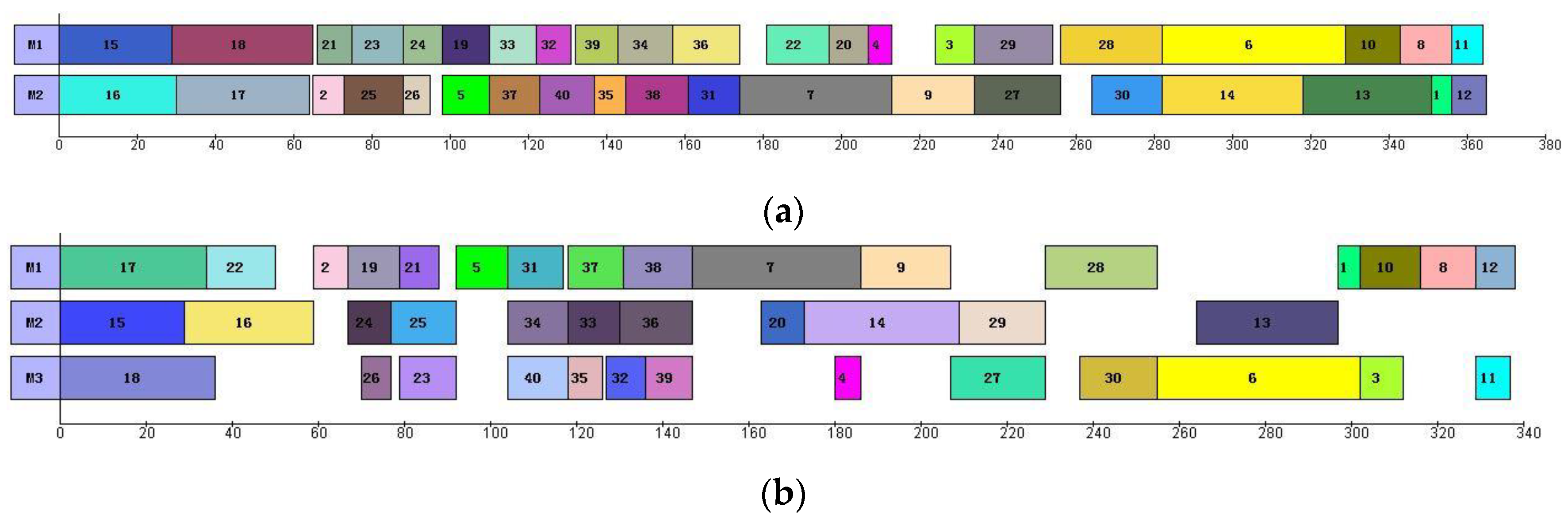

| 4 | 2 | M1:15,18,21,23,24,19,33,32,39,34,36,22,20,4,3,29,28,6,10,8,11 M2:16,17,2,25,26,5,37,40,35,38,31,7,9,27,30,14,13,1,12 | 365 |

| 3 | M1:17,22,2,19,21,5,31,37,38,7,9,28,1,10,8,12 M2:15,16,24,25,34,33,36,20,14,29,13 M3:18,26,23,40,35,32,39,4,27,30,6,3,11 | 338 | |

| 4 | M1:15,2,26,25,5,34,38,7,9,30,29,6,10,8,12 M2:17,40,36,13 M3:18,24,20,32,31,39,22,14,3 M4:16,23,35,33,37,19,21,4,28,27,1,11 | 305 |

| Case | Nm | IGA | Model 1 | Model 2 | Model 3 | Model 4 | ||

|---|---|---|---|---|---|---|---|---|

| Best | Average | Worst | ||||||

| 1 | 2 | 89 | 90.3 | 93 | 89 | 89 | 89 | 89 |

| 3 | 89 | 89 | 89 | 89 | 89 | 89 | 89 | |

| 4 | 89 | 89 | 89 | 89 | 89 | 89 | 89 | |

| 2 | 2 | 20.5 | 20.8 | 21 | 25.5 | 20.5 | 20.5 | 20.5 |

| 3 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | |

| 4 | 18 | 18 | 18 | 18 | 18 | 18 | 18 | |

| 3 | 2 | 1728 | 1731.9 | 1736 | - | 1727 | 1726 | 1726 |

| 3 | 1505 | 1516.6 | 1525 | - | 1445 | 1445 | 1445 | |

| 4 | 1445 | 1454.9 | 1467 | - | 1445 | 1445 | 1445 | |

| 4 | 2 | 400 | 414.8 | 426 | - | - | 365 | 384 |

| 3 | 342 | 350.5 | 357 | - | - | 338 | 338 | |

| 4 | 306 | 312.8 | 317 | - | - | 305 | 310 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, L.; Zhang, B.; Ren, Y.; Sang, H.; Gao, K.; Zhang, C. Mathematical Formulations for Asynchronous Parallel Disassembly Planning of End-of-Life Products. Mathematics 2022, 10, 3854. https://doi.org/10.3390/math10203854

Meng L, Zhang B, Ren Y, Sang H, Gao K, Zhang C. Mathematical Formulations for Asynchronous Parallel Disassembly Planning of End-of-Life Products. Mathematics. 2022; 10(20):3854. https://doi.org/10.3390/math10203854

Chicago/Turabian StyleMeng, Leilei, Biao Zhang, Yaping Ren, Hongyan Sang, Kaizhou Gao, and Chaoyong Zhang. 2022. "Mathematical Formulations for Asynchronous Parallel Disassembly Planning of End-of-Life Products" Mathematics 10, no. 20: 3854. https://doi.org/10.3390/math10203854

APA StyleMeng, L., Zhang, B., Ren, Y., Sang, H., Gao, K., & Zhang, C. (2022). Mathematical Formulations for Asynchronous Parallel Disassembly Planning of End-of-Life Products. Mathematics, 10(20), 3854. https://doi.org/10.3390/math10203854