The Composite Grid Method for Singular Problems of Partial Differential Equations

Abstract

1. Introduction

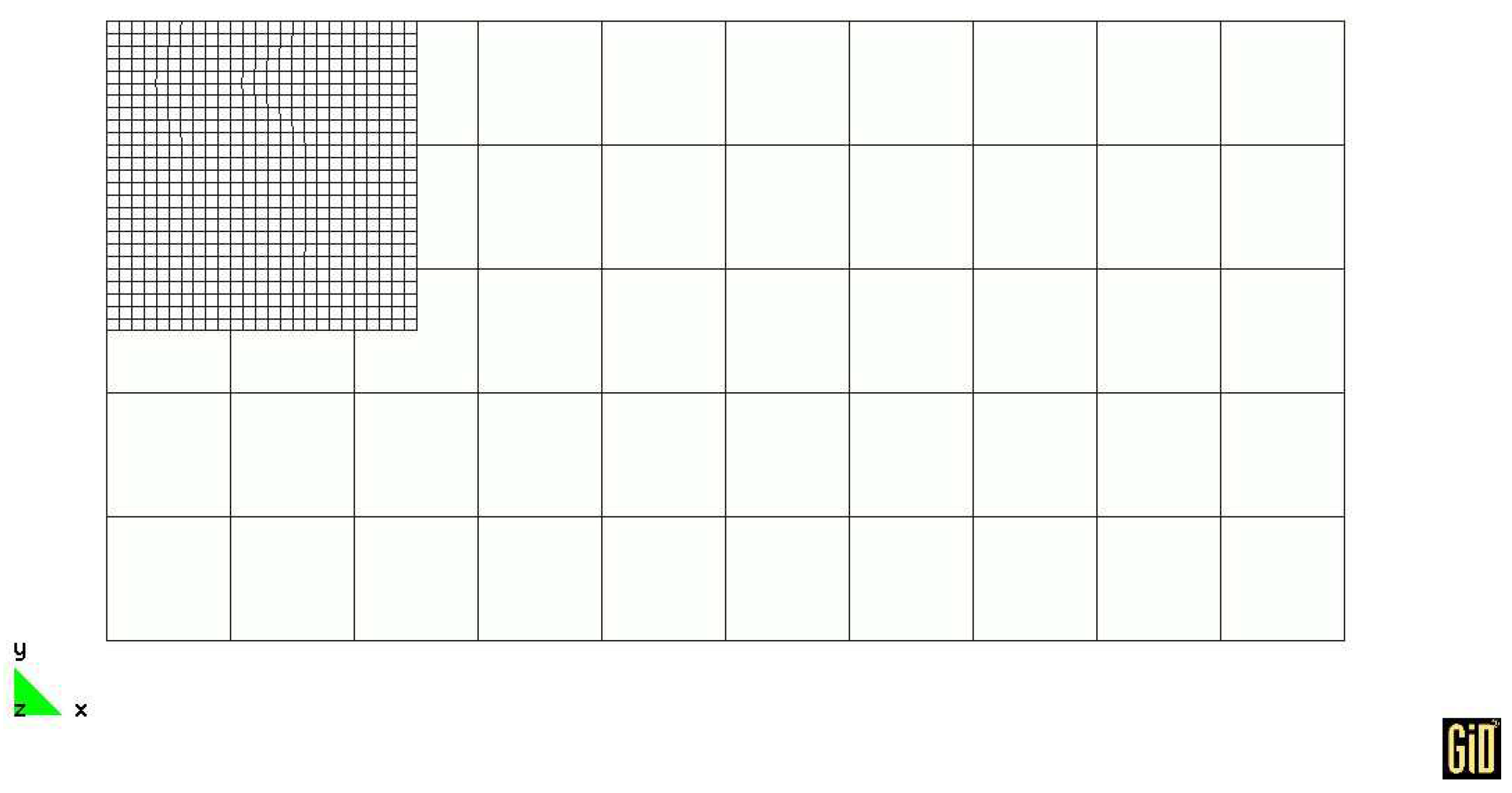

2. Composite Grid Method

2.1. Algorithm Description

2.2. Algorithm Scheme

3. Numerical Example

3.1. Elliptical Homogeneous Boundary Value Problems

3.2. The Simulation of Laser Welding

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Furzeland, R.M.; Verwer, J.G.; Zegeling, P.A. A numerical study of three moving-grid methods for one-dimensional partial differential equations which are based on the method of lines. J. Comput. Phys. 1990, 89, 349–388. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, L.; Zhang, X. Two-Grid method for nonlinear parabolic equations by expanded mixed finite element methods. Numer. Methods Partial. Differ. Equations 2013, 29, 1238–1256. [Google Scholar] [CrossRef]

- Williamson, D.L. The evolution of dynamical cores for global atmospheric models. J. Meteorol. Soc. Jpn. 2007, 85, 241–269. [Google Scholar] [CrossRef]

- Chesshire, G.; Henshaw, W.D. Composite overlapping meshes for the solution of partial differential equations. J. Comput. Phys. 1990, 90, 1–64. [Google Scholar] [CrossRef]

- Mak, H.W.L. Improved Remote Sensing Algorithms and Data Assimilation Approaches in Solving Environmental Retrieval Problems; Hong Kong University of Science and Technology: Hong Kong, China, 2019. [Google Scholar]

- Takemura, K.; Ishioka, K.; Shige, S. Development of a non-hydrostatic atmospheric model using the Chimera grid method for a steep terrain. Atmos. Sci. Lett. 2016, 17, 109–114. [Google Scholar] [CrossRef]

- Tao, L.; Jimin, S.; Zhenbao, L. Domain Decomposition Methods—New Numerical Techniques for Solving PDE; Science Press: Beijing, China, 1992. (In Chinese) [Google Scholar]

- Mote, C.D. Global-local finite element. Int. J. Numer. Methods Eng. 1971, 3, 565–574. [Google Scholar] [CrossRef]

- Zhu, K.; Zheng, X.; Zhang, C. The behavior of interlocked ortho-grid composite sandwich structure subjected to low-velocity impact. Compos. Struct. 2023, 304, 116399. [Google Scholar] [CrossRef]

- Lebon, F. Two-grid method for regularized frictional elastostatics problems. Eng. Comput. 1995, 12, 657–664. [Google Scholar] [CrossRef]

- Cai, Z.; McCormick, S. On the accuracy of the finite volume element method for diffusion equations on composite grids. Siam J. Numer. Anal. 1990, 27, 636–655. [Google Scholar] [CrossRef]

- Xu, J.; Park, U. The auxiliary space method and optimal multigrid preconditioning techniques for unstructureed grids. Computing 1996, 56, 215–235. [Google Scholar] [CrossRef]

- Xu, J.; Zhou, A. Local and parallel finite element Algorithms based on two-grid discretizations. Math. Comp. 2000, 69, 881–909. [Google Scholar] [CrossRef]

- Liang, G. FEPG User’s Manual; 2008.

- Beijing FEGENSOFT Co., Ltd. FEPG Reference Manual—Finite Element Method Based on FEPG; Beijing FEGENSOFT Co., Ltd.: Beijing, China, 2005. [Google Scholar]

- Chikin, P.; Chinbo, L.; Tsimin, S. On the computational aspects of the fast adaptive composite grid method for solving second order elliptic equations. J. Numer. Methods Comput. Appl. 1994, 4, 293–298. [Google Scholar]

- Guoming, H.; Jian, Z.; Jian Qang, L. Dynamic simulation of the temperature field of stainless steel laser welding. Mater. Des. 2007, 28, 240–245. [Google Scholar] [CrossRef]

- Shui, W.; Nielsen, M.P. Solving Navier-Stokes equation by mixed interpolation method. J. Southeast Univ. 2006, 22, 93–95. [Google Scholar]

- Su, W.; Haiyan, Z.; Yu, W. A new model in numerical simulation of high energy beam welding. Trans. China Weld. Inst. 2004, 25, 91–94. [Google Scholar]

| Grid Type | General FEM | CGM | |||

|---|---|---|---|---|---|

| Genuine Solution | Mesh Size | Error | Mesh Size of Fine Grid | Error | |

| A 0.00469 | A 0.00458 | ||||

| B 0.00790 | B 0.00779 | ||||

| C 0.00801 | C 0.00790 | ||||

| A 0.2275 | D 0.00229 | D 0.00229 | |||

| B 0.3536 | E 0.00070 | E 0.00070 | |||

| C 0.5493 | A 0.00170 | A 0.00149 | |||

| D 0.7277 | B 0.00309 | B 0.00298 | |||

| E 0.8777 | C 0.00230 | C 0.00229 | |||

| D 0.00081 | D 0.00079 | ||||

| E 0.00020 | E 0.00020 | ||||

| Time Step | 1 | 2 | 10 | 15 | 30 | 45 | 60 | |

|---|---|---|---|---|---|---|---|---|

| Temperature | ||||||||

| (general FEM) | 471.982 | 887.121 | 2949.38 | 2184.16 | 880.003 | 443.312 | 352.915 | |

| (CGM) | 474.085 | 892.313 | 2971.35 | 2183.30 | 867.932 | 439.152 | 350.282 | |

| 0.004456 | 0.005853 | 0.007449 | 0.000394 | 0.013717 | 0.009384 | 0.007461 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, H.; Xie, Y. The Composite Grid Method for Singular Problems of Partial Differential Equations. Mathematics 2023, 11, 3385. https://doi.org/10.3390/math11153385

Ye H, Xie Y. The Composite Grid Method for Singular Problems of Partial Differential Equations. Mathematics. 2023; 11(15):3385. https://doi.org/10.3390/math11153385

Chicago/Turabian StyleYe, Hai, and Yajun Xie. 2023. "The Composite Grid Method for Singular Problems of Partial Differential Equations" Mathematics 11, no. 15: 3385. https://doi.org/10.3390/math11153385

APA StyleYe, H., & Xie, Y. (2023). The Composite Grid Method for Singular Problems of Partial Differential Equations. Mathematics, 11(15), 3385. https://doi.org/10.3390/math11153385