Abstract

The compaction of asphalt mixture is crucial to the performance of the pavement. However, the mix design (i.e., porosity, aggregate size distribution, binder content), which is based on compaction results, remains largely empirical. It is difficult to relate the aggregate size distribution and the asphalt binder properties to the compaction curve in both the field and laboratory compaction of asphalt mixtures. In this paper, the author proposes a simple mathematical model from the perspective of granular physics to predict the compaction of asphalt mixtures. In this model, the compaction process is divided into two mechanisms: (i) viscoplastic deformation of an ordered granular-fluid assembly, and (ii) the transition from an ordered system to a disordered system due to particle rearrangement. This model could take into account both the viscous properties of the asphalt binder and the grain size distributions of the aggregates, where the viscous deformation is calculated with a proposed governing equation and the particle rearrangement effect is solved using simple DEM simulations. This model is calibrated based on the Superpave gyratory compaction tests in the pavement lab, and the R-squares of model predictions are all above 0.95. The model results are compared with experimental data to show that it can provide good predictions for the experiments, suggesting its potential for enhancing the design of asphalt mixtures.

Keywords:

mathematical modeling; granular physics; asphalt mixtures; compaction; discrete element method MSC:

70F40; 74D99; 76A10; 37J70; 37N15

1. Introduction

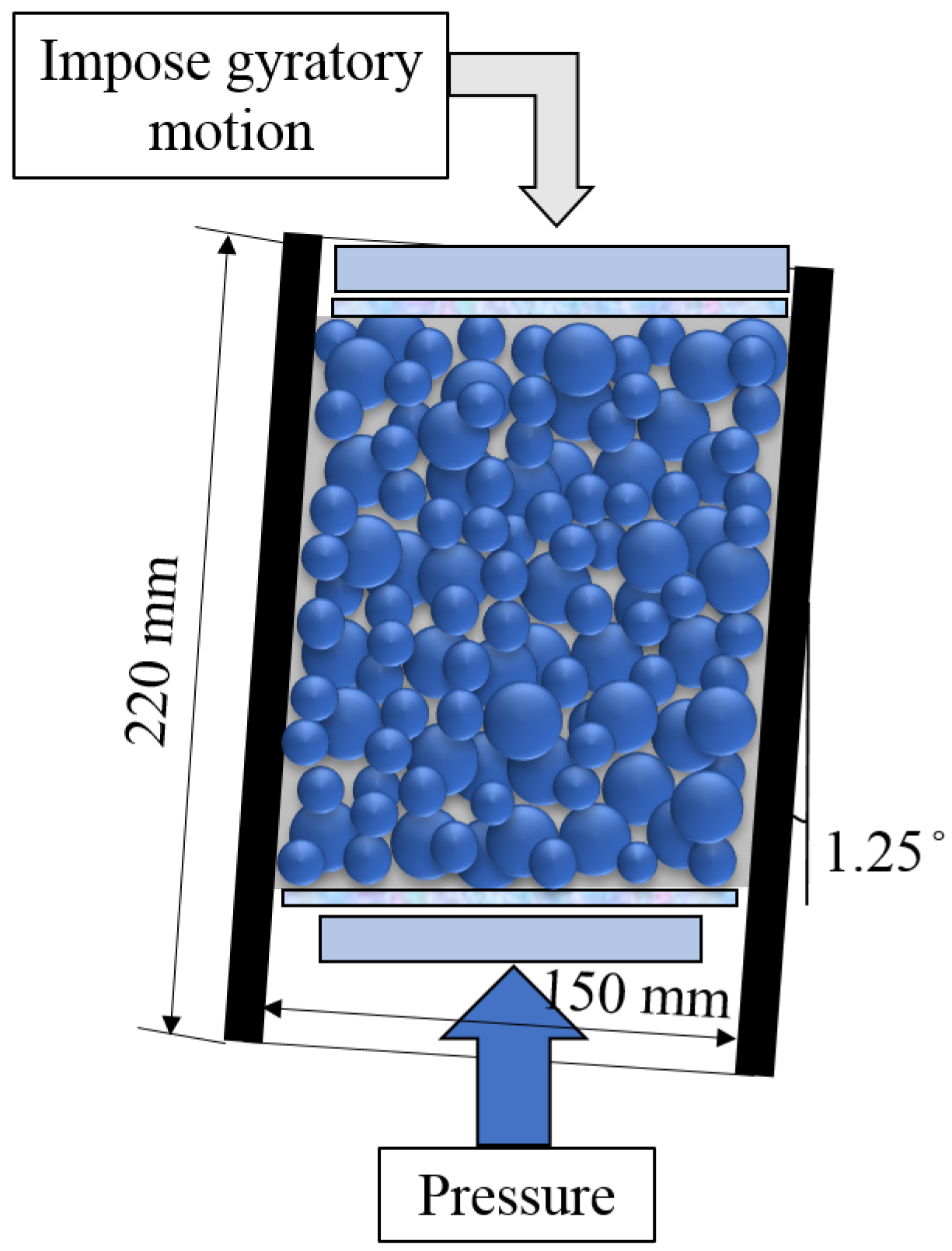

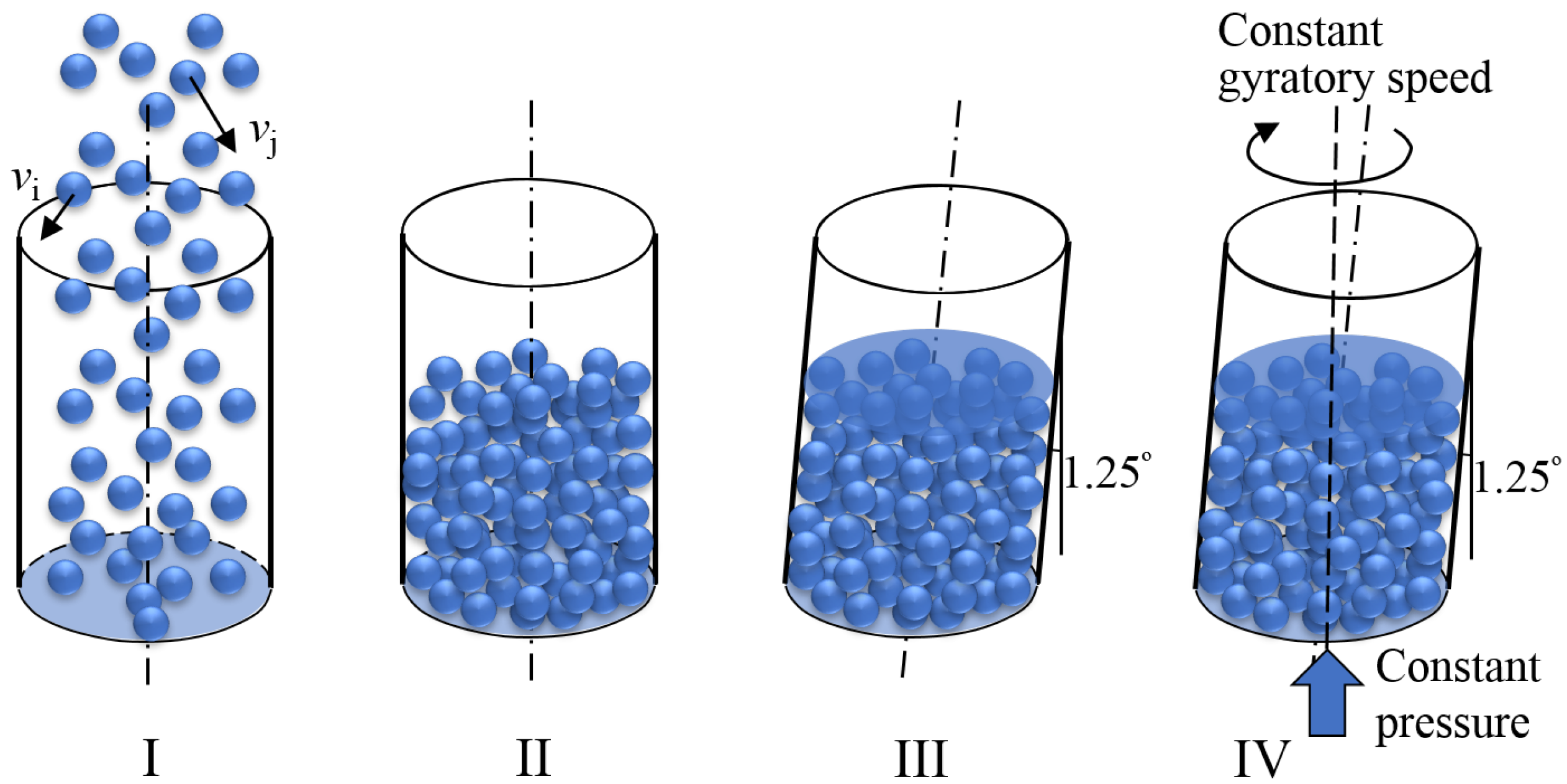

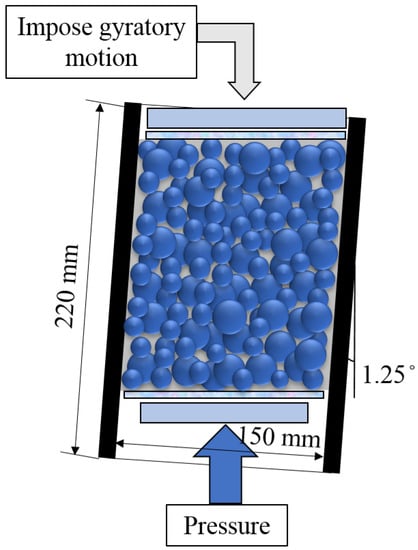

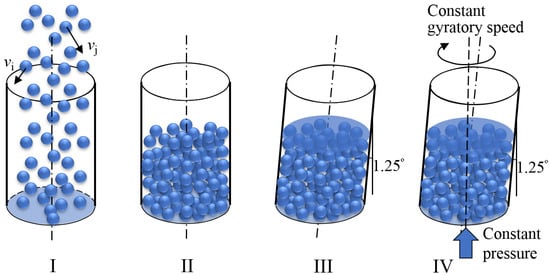

Hot-mixed asphalt is ubiquitous in the pavement industry. The performance of asphalt mixtures is largely influenced by air voids. Thus, reasonable porosity is needed after the compaction process. To simplify the problem and address the methodology proposed in this paper, we focused on the laboratory compaction of asphalt mixtures, instead of various compaction methods in the field. In the laboratory, to represent the similar volume properties of the field compaction, a variety of laboratory compaction methods have been developed, among which, the Superpave gyratory compactor (SGC) plays an important role in studying the compaction behavior and mechanical properties of asphalt mixtures [1]. In this study, we use a Brovold Superpave gyratory compactor for the experimental part. The compactor has a cylindrical ring, a top plate to provide gyratory motion, and a bottom plate (pushed by the loading system) to offer constant pressure (Figure 1 and Figure 2). Usually, the asphalt mixtures will be compacted with a gyratory speed of 30 rpm (or rps) and a pressure of 600 kPa. The gyratory angle is 1.25° (or ). We calculate the average shear rate during compaction as .

Figure 1.

Sketch of the Brovold Superpave gyratory compactor.

Figure 2.

Sketch of the compaction process using the Brovold Superpave gyratory compactor.

Experimentally, Consuegra et al. [2] compared different laboratory compactors to field compaction and provided evaluations for each compactor based on their ability to produce mixtures with engineering properties similar to those achieved in the field. The study concluded that the gyratory compactor performed relatively better compared to other compaction methods. Additionally, Hunter et al. [3] analyzed the impact of the compaction mode on the mechanical performance of asphalt mixtures. They found that both gyratory and vibratory compaction could result in stiffer specimens compared to mixtures compacted in the field. In terms of designing asphalt mixtures using laboratory compactors, Blankenship et al. [4] proposed a rational method that relates the number of gyrations to various traffic levels and different climates. However, even the laboratory compaction process tends to be random, and the compaction behavior is governed by a number of factors, such as binder content, binder type, temperature, loading method, aggregate grain size distributions, aggregate shapes, etc. Stakston et al. [5] investigated the influence of the angularity of fine aggregates on the compaction behavior of asphalt mixtures, which indicated that a higher fine aggregate angularity may lead to higher resistance to compaction. Delgadillo and Bahia [6], however, analyzed the influences of both temperature and pressure on the behaviors of both laboratory and field compaction levels and found that the compaction was not reduced dramatically when the temperature was reduced from 125 °C to 75 °C.

While much of the research on asphalt compaction has primarily focused on qualitatively analyzing factors that may influence gyratory compaction behavior, relatively few studies have quantitatively investigated compaction behavior. Awed et al. [7] proposed a method for predicting the laboratory compaction behavior of asphalt mixtures, providing a phenomenological tool for compaction prediction. They established a connection between the air void ratio and parameters, such as the gradation scale parameter, gradation shape parameter, and asphalt content. Their model also converged to a logarithmic law, as shown in the following equation [7].

where is the air void ratio, is the number of gyrations, and a and b are parameters empirically determined by material parameters.

Numerical models have been employed to predict the compaction behavior of asphalt mixtures; these modeling efforts can be categorized into two major categories: continuum-based modeling and discrete-based models. Guler et al. [8] proposed a modified model based on an existing poro-elasto-plasticity model to simulate the deformation of hot-mixed asphalt during the compaction process. Their model primarily considers material plasticity and changes in porosity, while the explicit consideration of asphalt binder viscosity was not included. In a recent study, Masad et al. [9,10,11] proposed a thermodynamics-based viscoplastic constitutive model that accounts for the viscous effect of asphalt binder. The model was calibrated using Superpave gyratory compaction tests and used to predict the field compaction of asphalt mixtures. Continuum-based models serve as efficient tools for large-scale prediction of asphalt mixture compaction. However, these models heavily rely on phenomenological constitutive laws and may not explicitly capture the influence of individual material constituents on the compaction behavior of asphalt mixtures. They may also fail to predict the influence of particle-scale dynamics, such as aggregate size distribution, aggregate shape, and binder viscosity, on the overall compaction process.

On the other hand, discrete-based models, such as the discrete element method (DEM), have the unique advantage of explicitly modeling particle-scale dynamics. Wang et al. [12] used the DEM to model the asphalt compaction, where the asphalt mixtures were treated as an assembly of dry particles and the inter-particle interaction was described by the Hertz–Mindlin contact law alone. In recent DEM simulations of Superpave gyratory compaction and vibratory compaction [13,14], the Burger contact law, characterized by mechanical tests of asphalt mastic, was utilized to describe the forces between aggregates. In this study, when two particles were in contact, the interactions between them were calculated based on Burger’s model of asphalt mastic, which ignored the elastic contact of solid aggregates themselves. The results under-predicted the air void ratio for a given compaction effort. Further, Man et al. [15] proposed a two-scale particle-based model to simulate the gyratory compaction of asphalt mixture, where the coarse aggregate interactions were represented by normal and tangential rate-dependent forms using rheology theory of dense granular-fluid systems.

Theoretically, the asphalt mixtures, at high temperatures, can be seen as granular materials (aggregates) with interstitial viscous fluid (asphalt binder) [15,16,17]. Thus, the compaction of asphalt mixtures can follow the research on the compaction of granular materials. In past decades, physicists were interested in the general compaction or relaxation of mono-dispersed or bi-dispersed granular materials [18]. Although the compaction behavior of mono- or bi-dispersed granular materials differs from the behavior of the compaction of asphalt mixtures, the underlying physics should be similar and transferable. The microscopic analyses of granular materials during compaction induced by tapping or vibrating have been studied [18,19], and the relationship between collective microscopic structure and the compaction dynamics has been explained [20,21]. Several equations or models for describing the compaction behavior were proposed based on multiple time-scale assumptions [19,22,23], among which, Knight et al. [19] proposed a logarithmic equation to better fit the compaction behavior of mono-dispersed granular materials.

where is the volume fraction of granular materials at time t, is the final volume fraction when time goes to infinity, is the difference between and the initial volume fraction , B, and are fitting parameters. This form was motivated by the observation, as stated in References [19,24], of large time intervals characterized by a logarithmically slow relaxation in the time evolution of density for compacted granular materials.

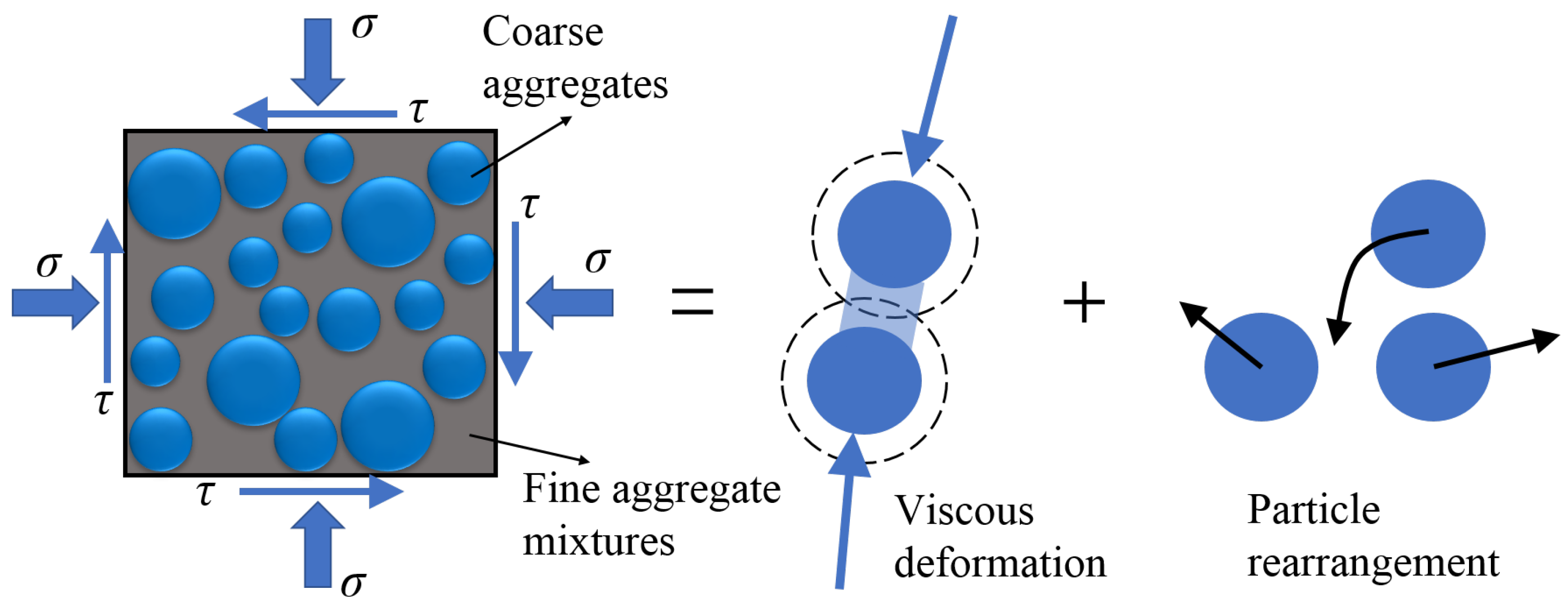

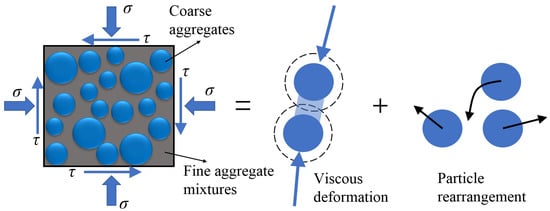

In this paper, our aim is to establish a connection between the compaction of granular materials and the compaction behavior of asphalt mixtures. We also take into account the viscoplastic deformation caused by air voids, the viscosity of the asphalt binder, and the wide grain size distribution. To simplify the analysis of this paper, we consider the asphalt mixture as a mixture of coarse aggregates (aggregate with size mm) and fine aggregate mixtures (FAM, a mixture of asphalt binder and fine aggregates). In this study, the deformation of the asphalt mixture during compaction is divided into two parts: (i) the deformation caused by the viscoplastic behavior of the FAM, and (ii) the deformation due to the particle rearrangement. On the one hand, we consider the viscoplasticity of the FAM using a rheological model of granular-fluid systems. The effective frictional coefficient of the granular system, denoted as , is calculated by combining the inertial number, , and the viscous number, . The macroscopic deformation of the asphalt mixture resulting from FAM viscoplasticity can be calculated using a simple ordinary differential equation (ODE). On the other hand, the deformation of asphalt mixtures due to particle rearrangements can be generalized from granular compaction and calibrated using experimental results obtained from gyratory compaction. This allows us to establish a straightforward mathematical model that incorporates granular physics in the prediction of asphalt mixture compaction. This paper is organized in the following way. First, after the introduction in Section 1, we describe the model framework for predicting the compaction behavior of asphalt mixtures in Section 2. Then, this model is calibrated with several experiments obtained in the laboratory in Section 3. In Section 4, the model is validated by comparing its results with other experimental findings. Finally, concluding remarks are drawn in Section 5.

2. Model Description

The motivation of this paper is to understand the compaction behavior of asphalt mixtures from the viewpoint of granular materials. However, as a granular material, the asphalt mixture is far too complicated because of complex aggregate shapes and a wide range of particle sizes. To tackle such a problem, certain simplifications are necessary.

- As stated, the asphalt mixture is divided into two parts: coarse aggregates (aggregates larger than 2.36 mm) and a fine aggregate matrix (a mixture of asphalt binder and fine aggregates <2.36 mm).

- The coarse aggregates are considered as spherical particles with material properties identical to real aggregates. The median size of coarse aggregates is denoted as .

- The fine aggregate matrix can be seen as thick coatings on the surface of coarse aggregates.

- The FAM itself behaves as a granular-fluid system with an average particle size equal to the median particle size of the fine aggregates, . The constitutive relationship of the FAM follows the same rheology as proposed by Trulsson et al. in References [17,25].

Firstly, a portion of the deformation during the compaction process arises from the deformation of FAM coatings when two coarse aggregates approach each other. Secondly, as the asphalt mixture approaches random loose packing, the particles desire to rearrange themselves to form a more stable packing. As compaction proceeds, the effect of particle rearrangement gradually becomes important. As seen in Figure 3, two types of deformation are observed during the compaction process. Initially, the FAM usually acts as a coating on the coarse aggregate, preventing two adjacent particles from coming toward each other, resulting in viscous deformation of the whole mixture. On the other hand, as the solid fraction of aggregate packing increases, particle rearrangement starts to play a significant role. The particles oscillate during compaction, creating a free space for other particles to move inside and help the whole mixture form a denser state. Thus, the following equation can be obtained:

where is the volume fraction of the asphalt mixture at time t, is the volume fraction of the asphalt mixture due to viscous deformation at time t, and is the change of volume fraction due to the rearrangement of particles at time t. Here, the effect of particle rearrangement is considered the increment on top of viscous deformations.

Figure 3.

Two parts of the deformation during the compaction of asphalt mixtures: (1) viscous deformation; (2) particle rearrangement.

We note that the behavior of the FAM follows the rheology of granular fluid-like systems (or slurries) proposed by Trulsson et al. in Reference [25], where the frictional rheology of a granular-fluid system is governed by a dimensionless number, , and is called the inertial number, and is called the viscous number. Here, is the normal stress and is the dynamic viscosity of the interstitial fluid. In this section, to build a reasonable model framework, we are going to discuss these two compaction sources.

2.1. Viscoplastic Deformation Induced by FAM

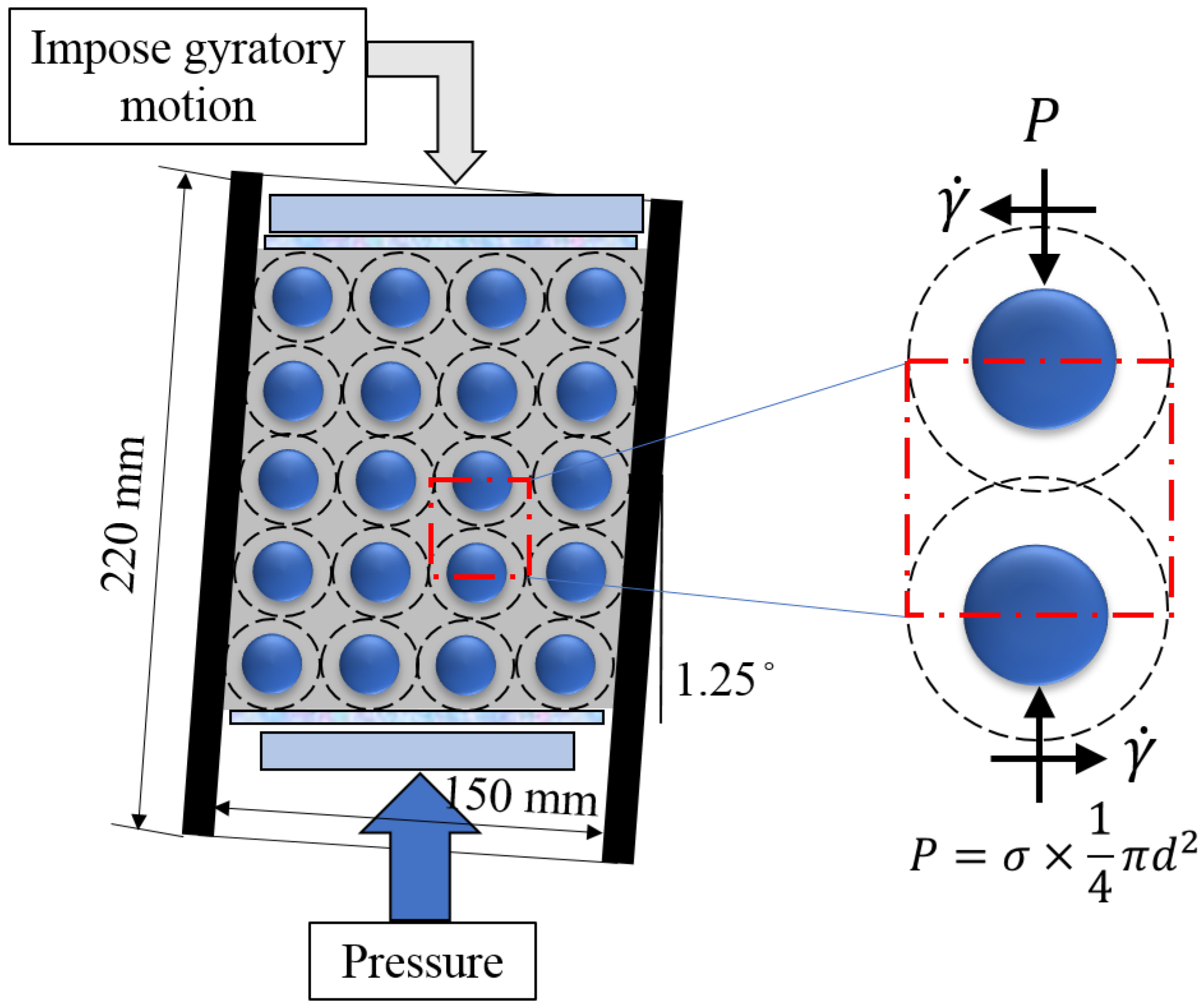

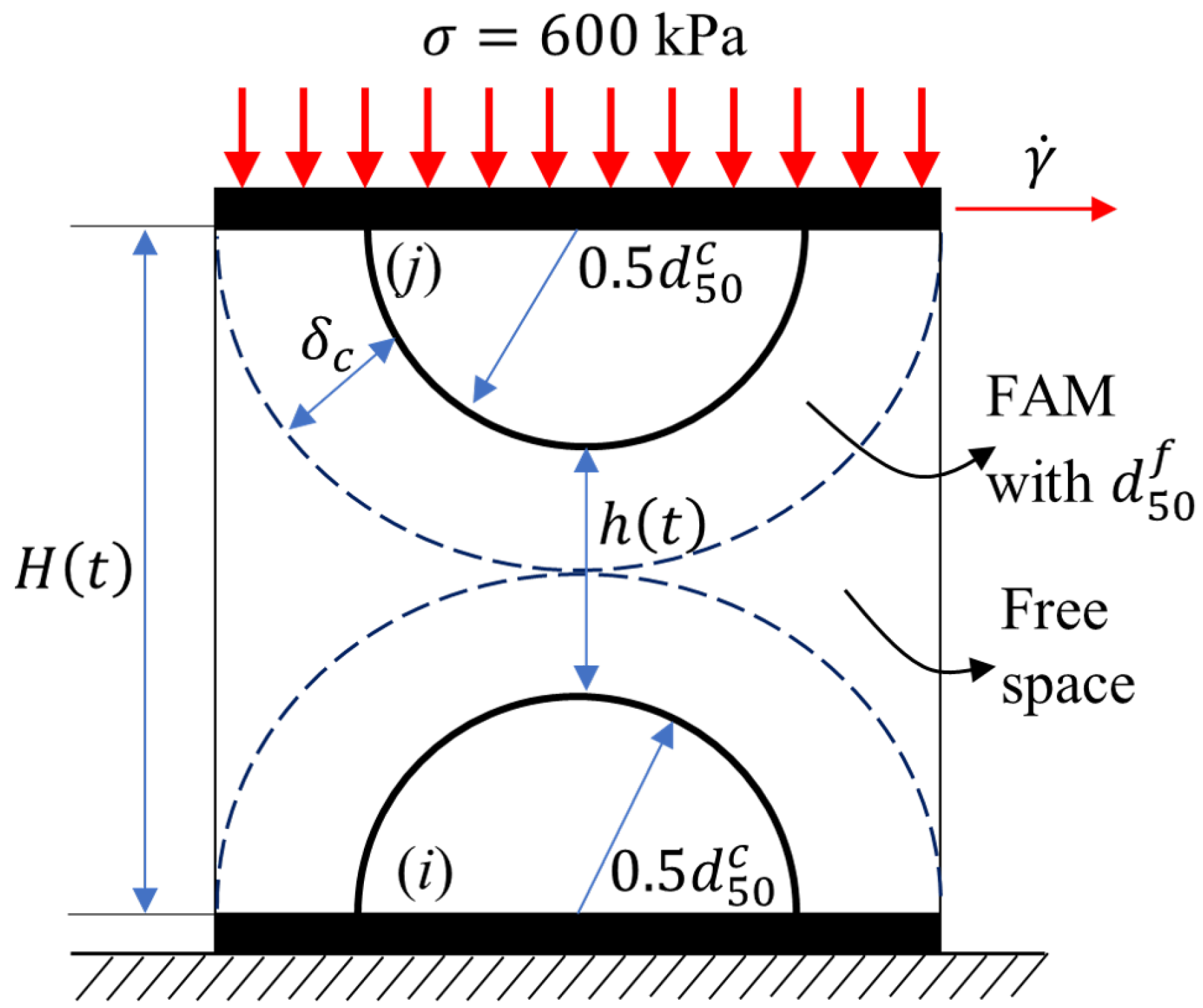

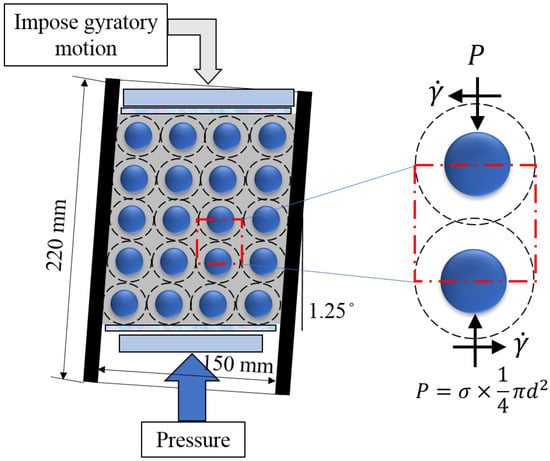

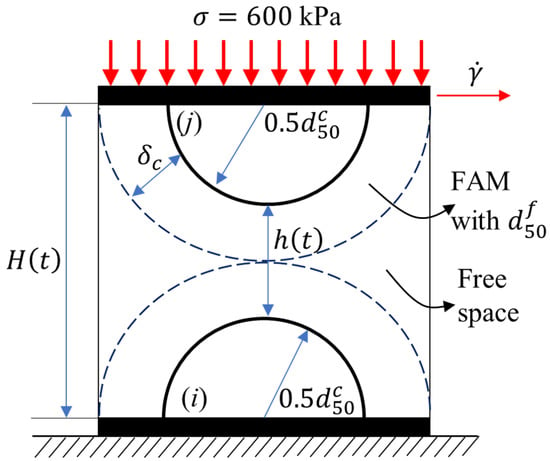

To calculate the viscoplastic deformation induced by the FAM, the asphalt mixture is simplified to have an ordered crystal-like structure as shown in Figure 4. The forces acting on two adjacent aggregates can be calculated based on the effective viscosity and thickness of the FAM coatings. Because a crystal-like structure is used to simplify the asphalt mixture, the problem becomes one-dimensional. The fundamental element of the crystal-like structure is shown in Figure 5.

Figure 4.

Simplification of the viscous deformation induced by the FAM coatings on the surfaces of coarse aggregates.

Figure 5.

Computational cell for calculating the change of volume fraction due to the viscous deformation of the FAM coatings, based on which we can form the differential equation for calculating the motion of particles so that we could also calculate the volume fraction versus time.

The deformation can be calculated using a computational cell shown in Figure 5. The problem is to solve the motion of particle j under a pressure of kPa and a shear rate of . The acting load on particle j is introduced by the compaction pressure. We have two parts of resistance forces: (1) a squeeze-induced lubrication force, and (2) shear-induced viscous resistance force. Thus, we can obtain the following equations:

where x is the displacement of particle j, and are the normal and tangential effective viscosities of the FAM, is the effective volume of FAM between two coarse aggregates, is the thickness of the FAM coating, which can be calculated based on the volume ratio between coarse aggregates and the FAM, is the effective coefficient calculated based on the effective volume of FAM, and is the effective radius of adjacent particles (here, ). In Figure 5, is the distance between the centers of two particles at time t, and is the initial value of H. is the distance between the surfaces of two particles at time t, and is the initial value of h. The right-hand side of this equation represents forces subjected to the particle, i.e., the loading force, the normal shear-induced viscous force, and the effective squeeze-induced lubrication force. The first term represents the loading, which is the multiplication of pressure and the acting area. The second term is the normal viscous effect due to the shear granular-fluid systems, where is the normal viscous force and is the effective area. The third term is the effective lubrication force and is calculated based on Reference [26].

The constitutive relationship of the FAM coating follows the rheology of granular-fluid systems proposed in References [16,25,27]. Thus, we could first calculate the frictional rheology (effective frictional coefficient, , and solid fraction, ) of the FAM with the following equations.

where, according to [16,27], , , , , , are the fitting parameters. We can then calculate the normal and tangential effective viscosities accordingly [16].

where is the dynamic viscosity of the asphalt binder at the compaction temperature.

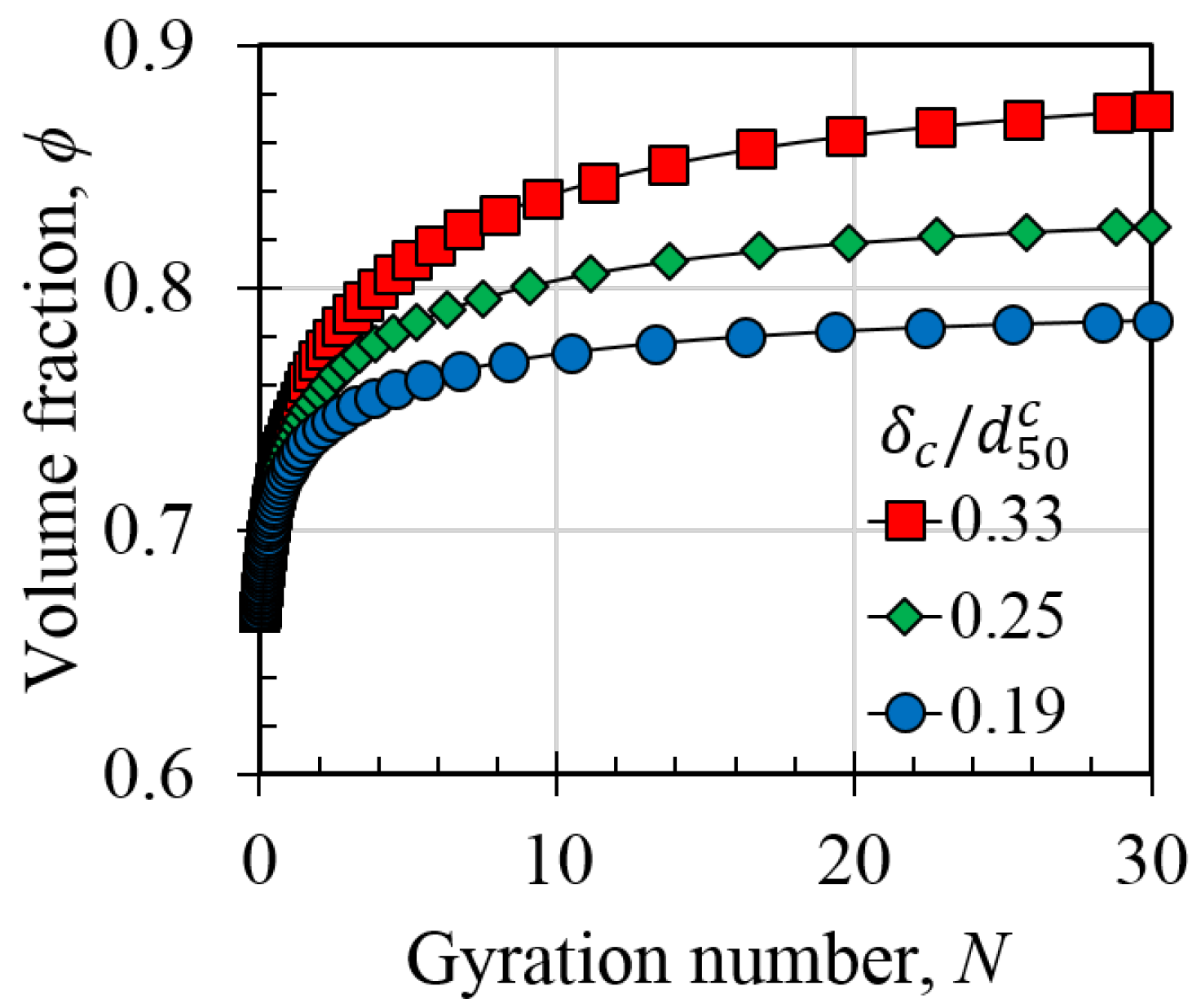

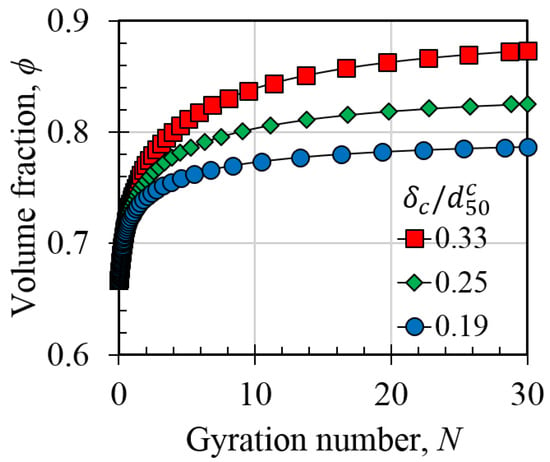

Based on the rheology of granular-fluid systems proposed by Trulsson et al. [25], the calculated normal and tangential effective viscosities can be applied to the ordinary differential equation (ODE) in Equation (4a). This ODE can be solved using the MATLAB internal function ode45s(). After the calculation, the relationship between the displacement x and time t can be obtained. Then we could convert the displacement to the volume fraction of asphalt mixtures and convert the time to gyration numbers (). To test the results of the ODE, three different coating thicknesses (three different mass ratios between the FAM and coarse aggregates) are chosen. Figure 6 shows the relationship between the volume fraction of the ordered asphalt mixtures, , and the number of gyrations, N. It shows that, as we increase the amount of the FAM (which leads to the increase of the FAM coating thickness), the compaction volume fraction can be improved accordingly.

Figure 6.

Comparison of the volume fraction/gyration number relationship as we change the thickness of the FAM coating.

2.2. Rearrangement of Aggregates

In the previous section, we observed that based on the viscoplastic deformation of the FAM coating, the volume fraction of the asphalt mixture could not exceed 90%. This leads us to the next step, which is to consider the rearrangement of particles. While we approached the problem theoretically with several simplifications in the previous section, we do not have theoretical tools available to deal with particle rearrangement. Therefore, we employ the discrete element method (DEM) to simulate the gyratory compaction behavior of granular materials with interstitial fluid. However, asphalt mixtures consist of particles with a wide range of sizes, and modeling each particle size individually would be time-consuming. Hence, we make certain assumptions: (1) The efficiency of particle rearrangement is solely governed by the loading conditions (pressure, shear rate, etc.) and the particle size distribution. (2) During the compaction process of asphalt mixtures, unlike bi-dispersed surface granular flows, no segregation occurs, which aligns with experimental observations [28]. (3) The overall particle rearrangement effect of different sizes can be accounted for by applying mixture theory. (4) The compaction behavior of each size group of particles is governed by the mean size of that particular group.

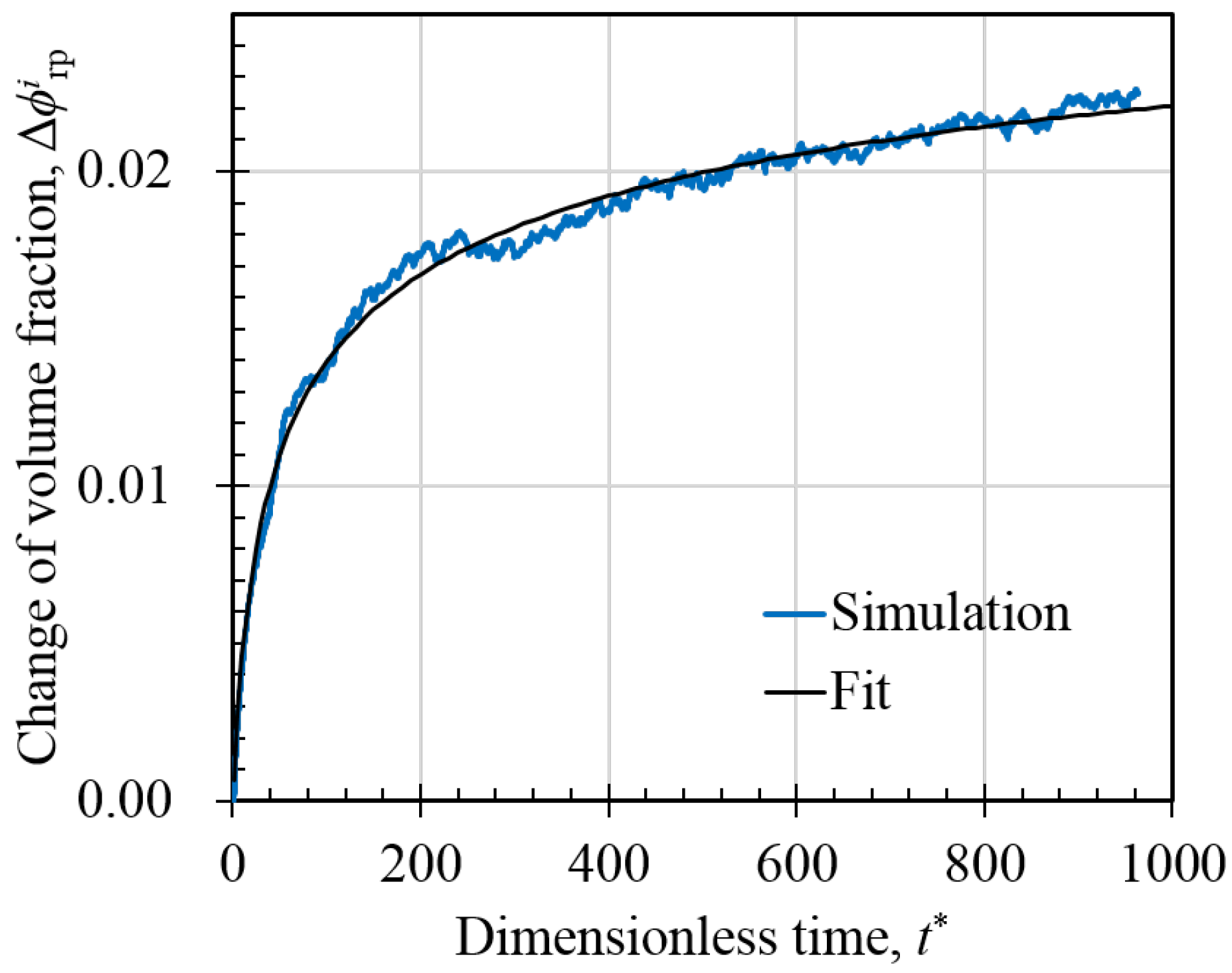

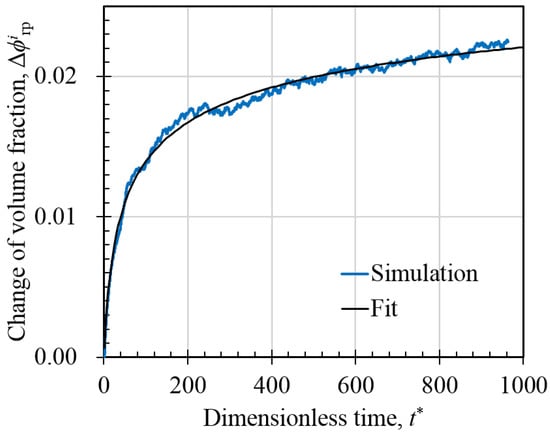

Based on these assumptions, we can use the discrete element method (DEM) to simulate the gyratory compaction of a mono-dispersed granular-fluid system in a Superpave gyratory compactor configuration, as shown in Figure 1. We compact the granular materials with particle diameters mm using constant pressure of 600 kPa, gyratory speed of 30 rpm, and a gyratory angle of 1.25°; the viscosity of the interstitial fluid is set to be equal to 250 cP. To simplify the analyses, we neglected the effect of interstitial fluid on particle rearrangement. All the dimensional parameters will be normalized using average particle radius, , the mass of average-size particles, , and gravitational acceleration, g. Thus, the compaction time, t, can be non-dimensionalized as , where is the dimensionless time. In Figure 7, we plot the relationship between dimensionless time, , and the change of solid fraction of granular materials during the compaction. Here, the change of solid fraction can be seen as the effect of particle rearrangement. The compaction curve in Figure 7 can be fitted with the following equation:

where represents the change in volume fraction for the compaction of particles with specific average grain sizes, and denotes the dimensionless time. This fitting curve is derived from Equation (2).

Figure 7.

Relationship between the solid fraction of particle rearrangement and the dimensionless time, .

The fitting curve mentioned above can only be applied to quantify a monodisperse granular assembly. To capture the overall effect of particle rearrangement considering the entire grain size distribution, we implemented a concept known as mixture theory. The aggregates are divided into different-sized groups based on the results of sieving tests. Each group size is defined by adjacent sieve sizes ( and ), and the mean size of each group is calculated as with . On the one hand, using the mean size of each size group, we can calculate the compaction behavior of each group, denoted as , where is a function of particle size. On the other hand, we can determine the mass ratio of each group size based on the sieving test, denoted as . By combining these quantities, we can obtain the total particle rearrangement effect by considering the grain size distribution of the aggregates

where is the number of aggregate-sized groups identified in the sieving test.

2.3. Redistribution of Particle Rearrangement

In previous sections, we analyzed the contributions of both viscous deformation and particle rearrangement to the overall compaction process. In this process, we treat the viscous contribution as the foundation of the change of solid fraction and regard the particle rearrangement effect as the increment. However, due to the existence of the viscous effect, the particle rearrangement may not occur in the same way that we calculated; thus, the two parts of contributions cannot be added together directly. In this section, we propose a redistribution function of the particle rearrangement to reshape the curve of .

The basic idea is that at the beginning of compaction, due to the significant influence of viscous deformation described in the previous section, the effect of particle rearrangement is comparatively smaller than what was observed in the DEM simulations. Consequently, we aim to reduce the influence of particle rearrangement during the initial stages of compaction while gradually increasing its impact toward the end. To address this, we propose the following equation to capture the redistribution of particle rearrangement.

where is the balancing point, which depends on the grain size distribution, and N is the gyration number. Once we know the viscosity of the asphalt binder at the compaction temperature and the grain size distribution of the aggregate, the relationship between and the grain size distribution is the only parameter we need to calibrate. In the end, if we combine the contributions from both the viscous deformation and the particle rearrangement, we can obtain the following relationship between the volume fraction of asphalt mixtures, , and the compaction time, t, to describe the whole gyratory compaction process of asphalt mixtures:

3. Model Calibration

The model we propose requires information on the viscosity of the asphalt binder and the sieving analysis results of the aggregates. With these inputs, we can calculate both the viscous deformation and the particle rearrangement effect during the compaction process of asphalt mixtures. However, to account for the redistribution of the particle rearrangement effect, the parameter needs to be calibrated using experiments. In this section, we present experimental results to determine a suitable value for this parameter.

3.1. Materials and Experiments for Model Calibration

In this study, our main focus is to capture the influence of aggregate grain size distributions. To achieve this, we conducted seven sets of compaction experiments with different grain size distributions in order to calibrate the redistribution of the particle rearrangement effect. For these experiments, we utilized the same type of asphalt binder (PG64-22) without any additives. As previously stated, in our analysis of viscous deformation, we utilized the viscosity of the asphalt binder measured at 135 °C and 20 rpm using a rotational viscometer. The obtained viscosity value for the asphalt binder was approximately 250 cP.

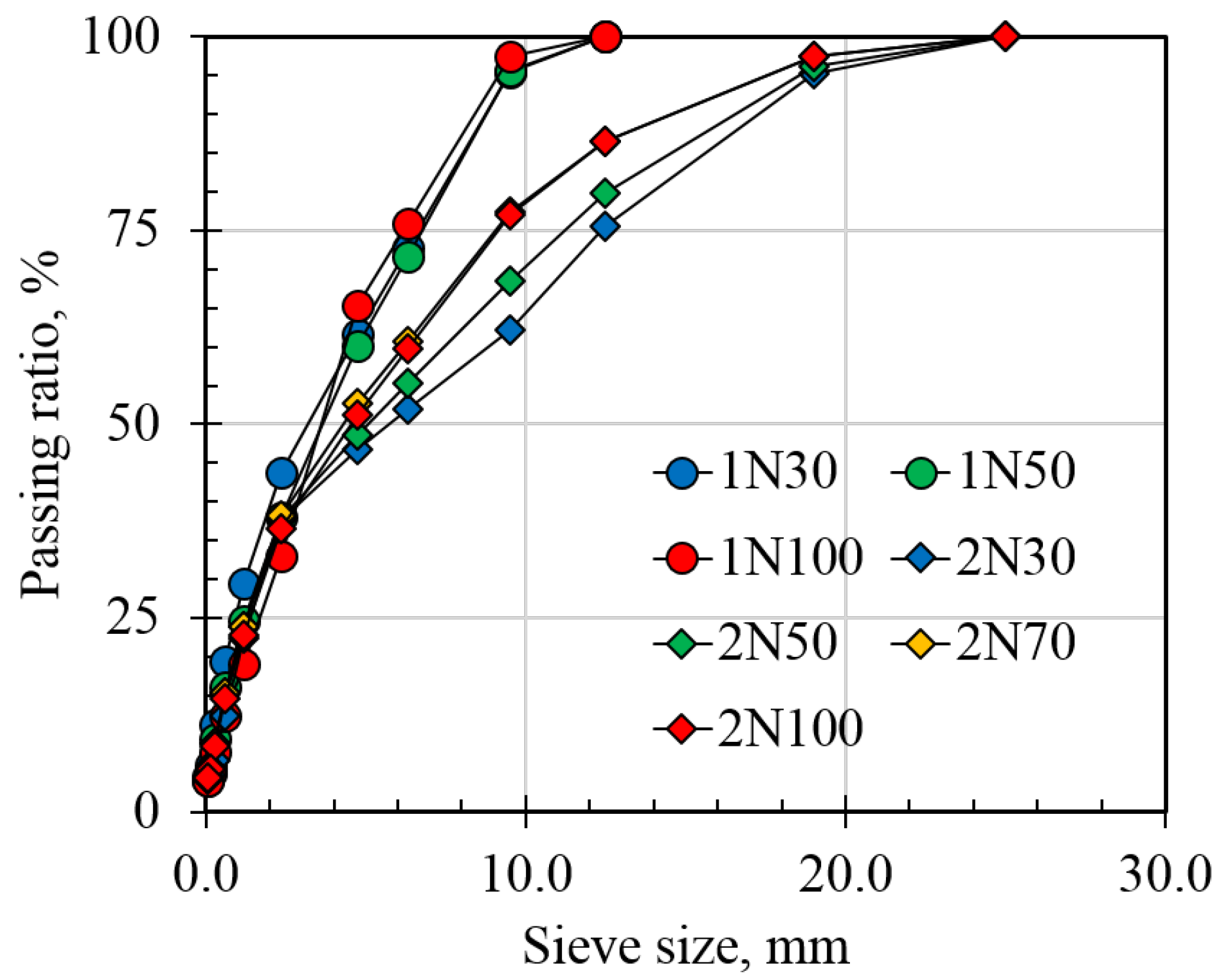

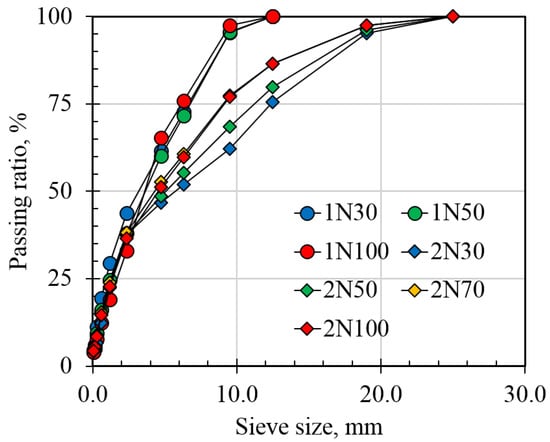

We acquired aggregates from two sources: river sand and quarry gravel. We show the size distributions of seven sets of aggregates in Figure 8. Four sets of aggregates have maximum diameter of 12.5 mm, while three sets of aggregates have a maximum diameter of 25 mm. During the experiment, we first put all the materials into an oven set to a temperature of 140 °C. After remaining in the oven for one hour, materials were transferred to the mixer to be mixed for 180 s. To compact the asphalt mixtures in a laboratory, we used the Brovold Superpave gyratory compactor (Figure 1). This experimental apparatus can compact asphalt mixtures at constant pressure and a constant shear rate. Following the standard compaction procedure [29], we set the compaction pressure at 600 kPa, the gyratory angle at 1.25°, and the gyratory speed at 30 rpm.

Figure 8.

Grain size distribution of aggregates.

The height of the mixture was measured after each gyration. To calculate the volume fraction of the asphalt mixture at each gyration number based on the position of the bottom plate of the compactor, we also need to measure both the theoretical maximum specific gravity, , and the bulk specific gravity of the mix, , which were conducted based on ASTM D2041 and ASTM D2726 [30,31]. Based on the recorded position of the bottom plate, and the measured and , the volume fraction (, where was the volume fraction of the compacted asphalt mixture, and was the air void ratio of the compacted asphalt mixture) can be calculated in the software attached to the Superpave gyratory compactor. The relationship between and the gyration number can be obtained accordingly.

3.2. Comparison between Model and Experimental Results

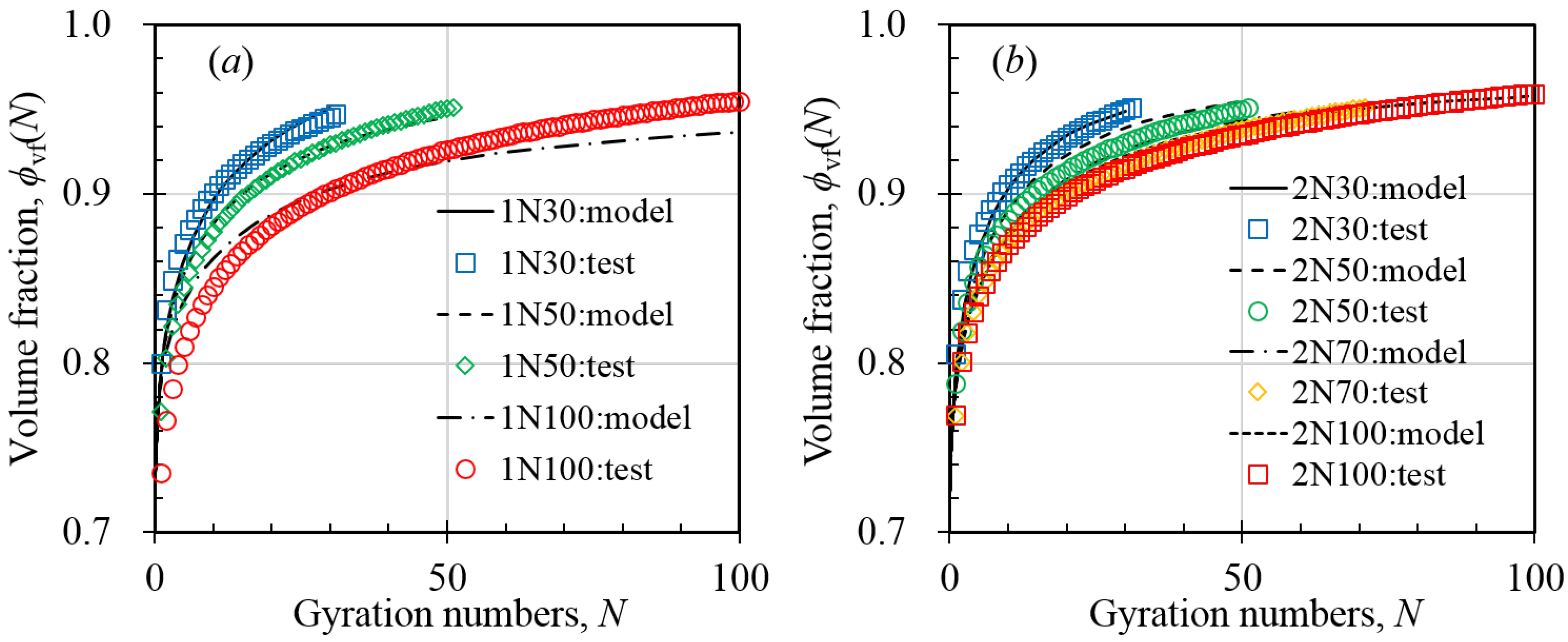

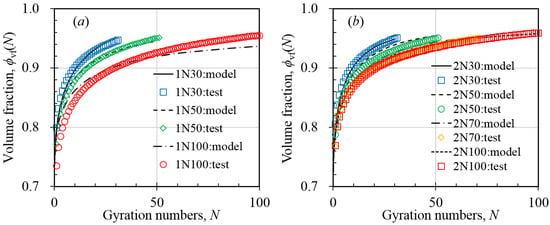

Markers with different colors in Figure 9 represent the experimental results obtained with different grain size distributions. It is evident from the figure that the compaction behavior is greatly influenced by the grain size distribution of aggregates. By comparing the experimental results with the characteristic parameters of the grain size distributions, such as the mass ratio between fine aggregates and coarse aggregates, and the median aggregate sizes, we can conclude that a higher proportion of fine aggregates and a smaller median aggregate size could result in better compaction outcomes.

Figure 9.

Comparison between experimental results and the results obtained from the proposed mathematical model: (a) results for 1N30, 1N50, and 1N100; (b) results for 2N30, 2N50, and 2N100.

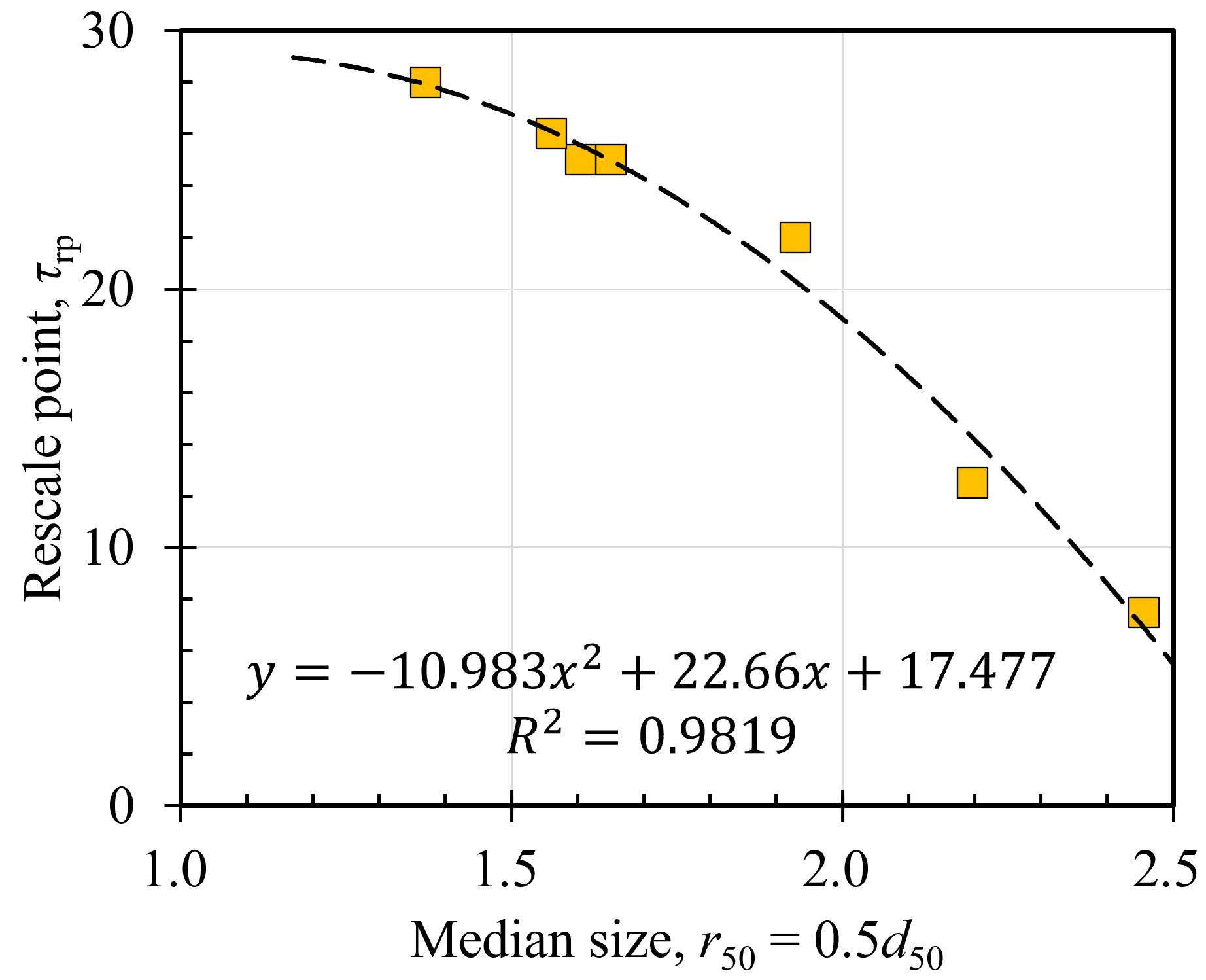

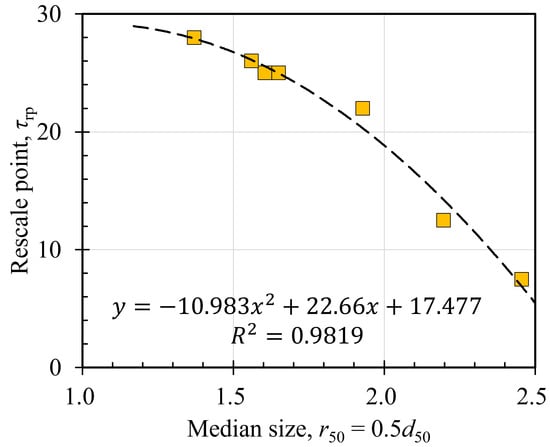

As previously stated, our objective is to find the relationship between the balancing point, , and the grain size distribution for the model calibration. Thus, we first obtain the best fit (with a specific ) for the experimental results, which are plotted as curves with different curve types (in Figure 9, curves represent model results and markers represent experimental results). Then, we plot the fitted balance point, , against the median aggregate size (radius), (Figure 10). We find that the relationship between and can be described using the parabolic equation shown in Figure 10.

Figure 10.

The relationship between and the median radius .

Thus, we associated each part of the compaction contribution to the properties of the asphalt binder and grain size distributions. The calibrated model could be used to predict the gyratory compaction behavior of asphalt mixtures in the future.

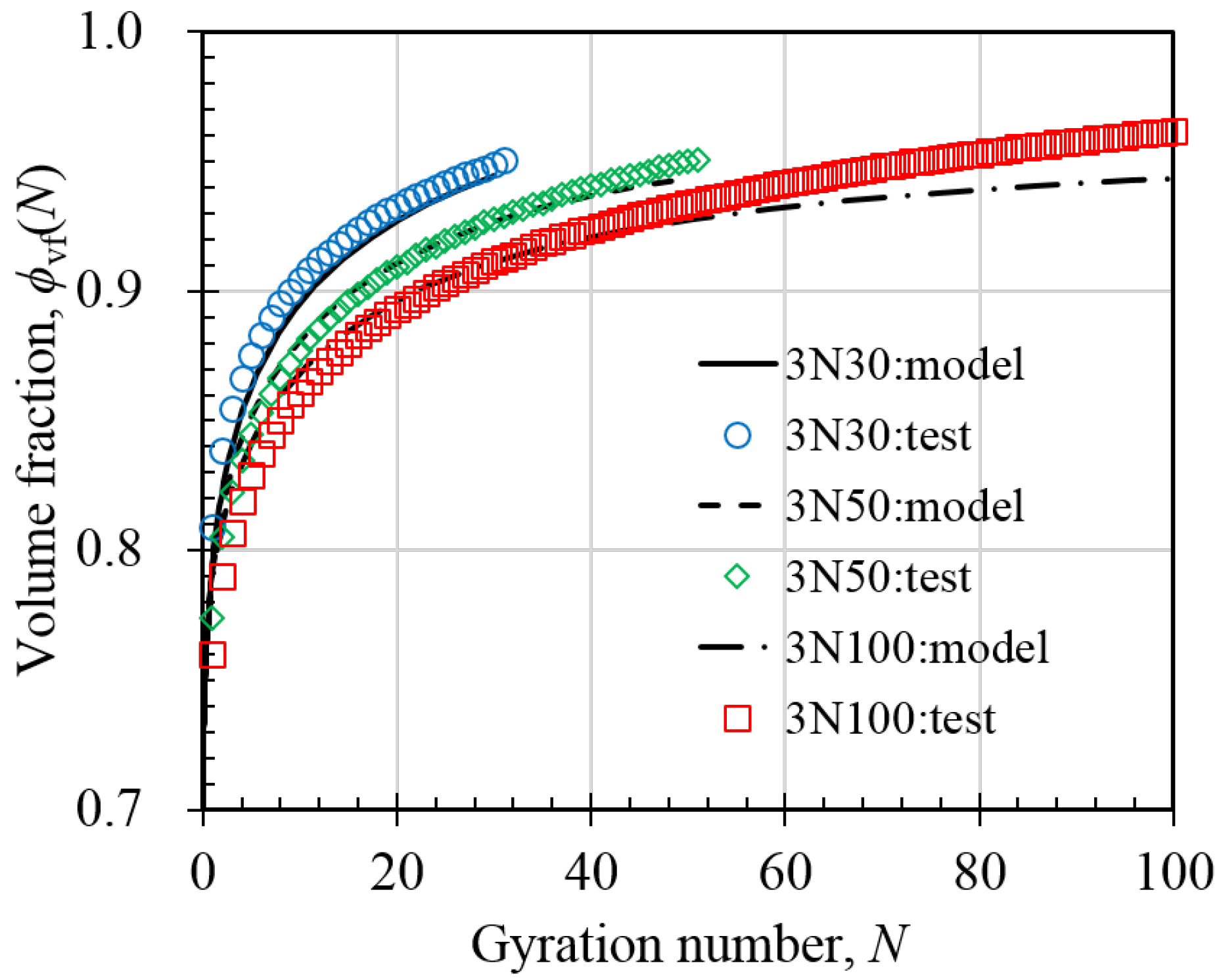

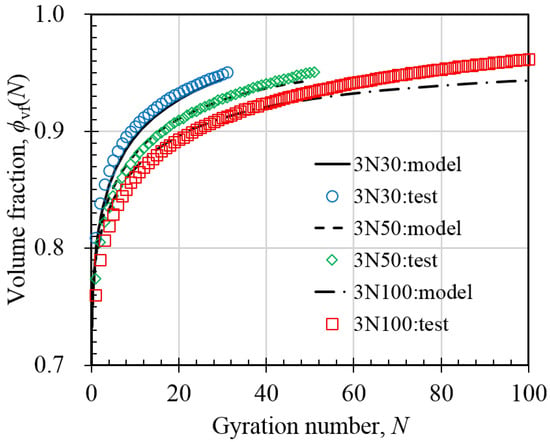

4. Model Validation and Further Discussions

This model can be validated using a set of different compaction experiments (3N30, 3N50, 3N100) with a maximum aggregate size of 12.5 mm. The overall size distributions for these experiments are provided in Table 1. Each compaction test has a different grain size distribution, a different percentage of fine aggregate mixtures, a different median radius, and a calculated balance point for particle rearrangement. By utilizing the material information, we can apply the model discussed in the previous sections. The validation of the model will be successful if the model predictions align with the corresponding experimental results.

Table 1.

Mix design of the model validation experiments.

The validation experiments follow the same procedure as those in the calibration experiments. For each experiment, we first prepared the asphalt binder and the aggregate mixture by placing them in an oven set at a temperature of 140 °C for 1 h. Then, we mixed them in a mixer for 3 min. We also used a Brovold Superpave gyratory compactor to compact the hot mixture and record the calculated void ratio for every gyration during the compaction. The volume fraction of the asphalt mixture could then be calculated as one minus the porosity of the system calculated by the compactor.

In Figure 11, we show both the experimental results (markers) and the model predictions (lines). Generally, the predictions align well with the experimental results, indicating that this simple model can roughly capture the compaction behavior of hot mixed asphalt. However, the model slightly underpredicts the final volume fraction of compaction. For compaction 3N30, the final experimental volume fraction is 0.948, while the model prediction is 0.944, with an R-squared value of approximately 0.964. For compaction 3N50, the final experimental and predicted volume fractions are 0.95 and 0.944, respectively, resulting in an R-squared value of 0.978. For compaction 3N100, the final experimental and predicted volume fractions are 0.96 and 0.945, respectively. Although there is a larger deviation in this case, the prediction remains reasonable, with an R-squared value of 0.954. Moreover, this model could help us understand the compaction mechanism of asphalt mixtures. Previously, we considered the compaction deformation of asphalt mixtures as the result of air voids being squeezed in porous media and simulated the process using porous media mechanical models. In our model, we reversed the thinking; instead of investigating the deformation brought by the change of air voids, we put priority on the solid-fluid mixture itself.

Figure 11.

Results of model validations.

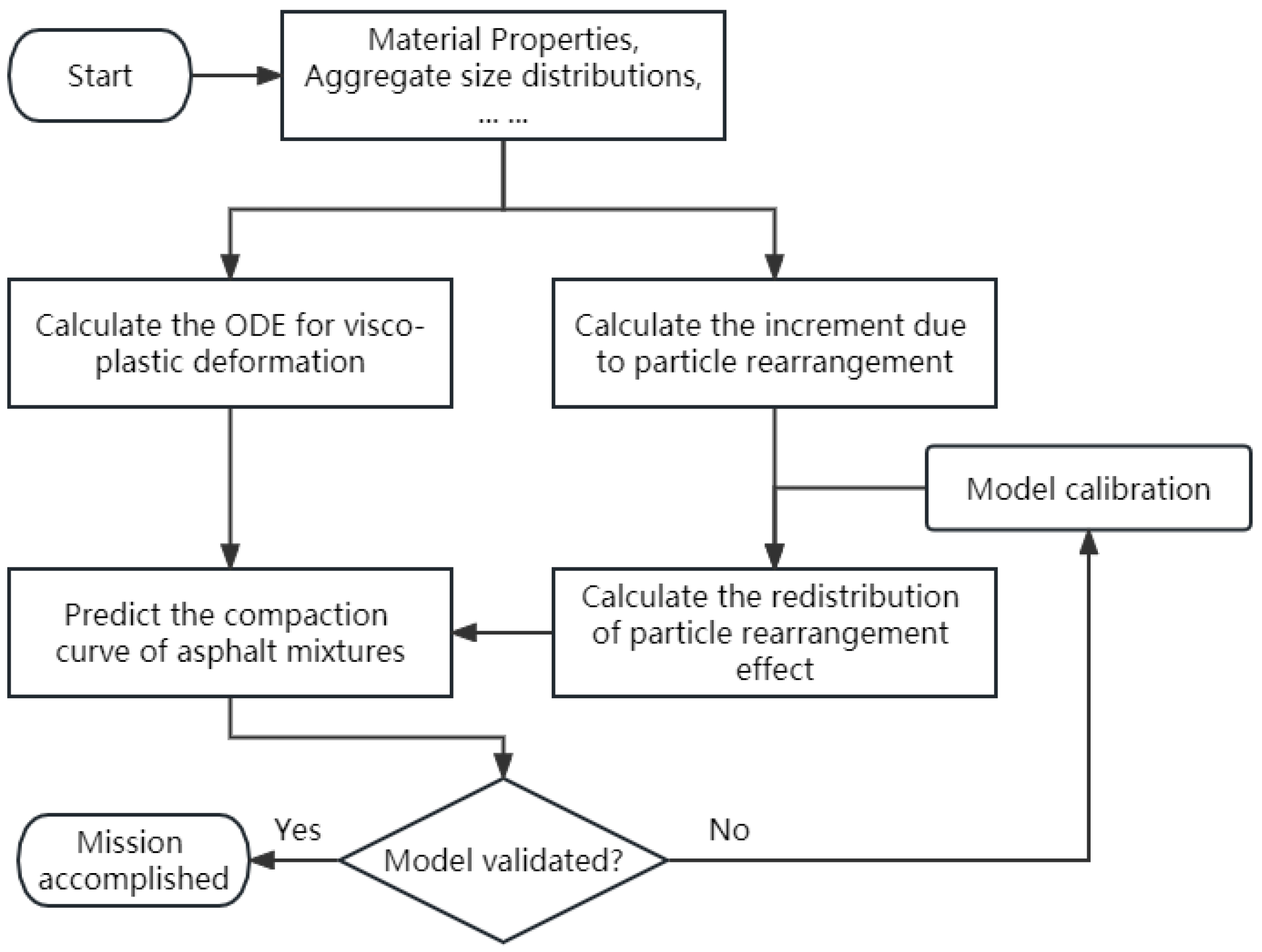

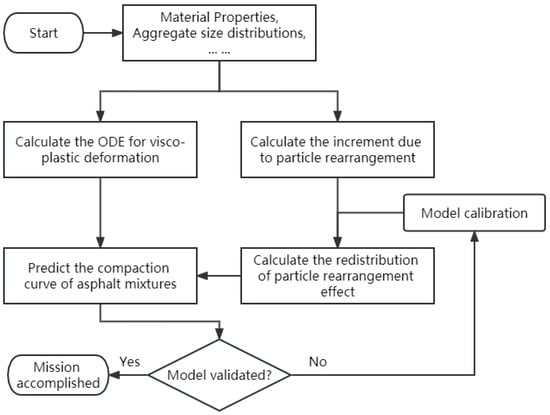

This model confirms the importance of the grain size distribution of aggregates on the compaction results. With this model, we can observe that increasing the mass of the fine aggregate matrix could help improve the compaction efficiency by influencing the viscoplastic deformations during the compaction process. Moreover, a reasonable grain size distribution could also benefit the particle rearrangement effect. However, it is important to acknowledge that this model is still relatively preliminary and requires more experimental data for calibration and validation. The entire process of this mathematical model can be summarized in a flowchart shown in Figure 12.

Figure 12.

Flowchart of the mathematical model for the gyratory compaction of asphalt mixtures.

5. Conclusions

This paper presents a simple mathematical model for predicting the compaction behavior of asphalt mixtures in a Superpave gyratory compactor. In contrast to previous phenomenological models that fitted compaction curves using different equations and considered compaction as the deformation of air voids, our approach divides the compaction deformation into two parts: (1) viscoplastic deformation of the fine aggregate mixture (FAM) due to the presence of the asphalt binder, and (2) particle rearrangement resulting from compaction excitation. The viscous deformation is numerically solved using a theoretical differential equation, while the particle rearrangement effect is quantified through discrete element method (DEM) simulations of monodisperse granular materials and mixture theory. The model can be calibrated based on experimental results to account for the non-uniformly distributed redistribution effect of particle rearrangements, and it is further validated using a different set of experiments.

This mathematical model is still a rudimentary model. Part of the model is still based on phenomenological behaviors and shows the lack of deep physical understanding. Moreover, the particle rearrangement is calculated based on the compaction of monodisperse dry granular systems, which neglects the influence of the interstitial fluid and particle size distributions. Although this method is preliminary, it provides a functional tool for predicting the gyratory compaction process of asphalt mixtures. With this model, we can calculate the compaction deformation based on the mix design of asphalt mixtures, which is both time-saving and economical for the pavement industry. Furthermore, the model has the potential to be improved with more experimental data to enable predictions of field compaction of asphalt mixtures.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy.

Acknowledgments

The author would like to acknowledge the help from K.M. Hill, J.-L. Le, and M. Marasteanu for the discussions about the model’s framework. The author also thanks the Saint Anthony Fall Laboratory at the University of Minnesota for computing resources provided.

Conflicts of Interest

The author declares no conflict of interest.

References

- Mallick, R.B. Use of Superpave gyratory compactor to characterize hot-mix asphalt. Transp. Res. Rec. 1999, 1681, 86–96. [Google Scholar] [CrossRef]

- Consuegra, A.E.; Little, D.N.; Von Quintus, H.; Burati, J. Comparative Evaluation of Laboratory Compaction Devices Based on Their Ability to Produce Mixtures with Engineering Properties Similar to Those Produced in the Field. Master’s Thesis, Texas A&M University, College Station, TX, USA, 1988. [Google Scholar]

- Hunter, A.E.; McGreavy, L.; Airey, G.D. Effect of compaction mode on the mechanical performance and variability of asphalt mixtures. J. Transp. Eng. 2009, 135, 839–851. [Google Scholar] [CrossRef]

- Blankenship, P.B.; Mahboub, K.C.; Huber, G.A. Rational Method for Laboratory Compaction of Hot-Mix Asphalt (with Discussion and Closure); Transportation Research Record; Transportation Research Board: Washington, DC, USA, 1994; Volume 1454. [Google Scholar]

- Stakston, A.D.; Bahia, H.U.; Bushek, J.J. Effect of fine aggregate angularity on compaction and shearing resistance of asphalt mixtures. Transp. Res. Rec. 2002, 1789, 14–24. [Google Scholar] [CrossRef]

- Delgadillo, R.; Bahia, H.U. Effects of temperature and pressure on hot mixed asphalt compaction: Field and laboratory study. J. Mater. Civ. Eng. 2008, 20, 440–448. [Google Scholar] [CrossRef]

- Awed, A.; Kassem, E.; Masad, E.; Little, D. Method for predicting the laboratory compaction behavior of asphalt mixtures. J. Mater. Civ. Eng. 2015, 27, 04015016. [Google Scholar] [CrossRef]

- Guler, M.; Bosscher, P.J.; Plesha, M.E. A porous elasto-plastic compaction model for asphalt mixtures with parameter estimation algorithm. In Recent Advances in Materials Characterization and Modeling of Pavement Systems; American Society of Civil Engineers: Reston, VA, USA, 2004; pp. 126–143. [Google Scholar]

- Koneru, S.; Masad, E.; Rajagopal, K. A thermomechanical framework for modeling the compaction of asphalt mixes. Mech. Mater. 2008, 40, 846–864. [Google Scholar] [CrossRef]

- Masad, E.; Scarpas, A.; Alipour, A.; Rajagopal, K.R.; Kasbergen, C. Finite element modelling of field compaction of hot mix asphalt. Part I: Theory. Int. J. Pavement Eng. 2016, 17, 13–23. [Google Scholar] [CrossRef]

- Masad, E.; Scarpas, A.; Rajagopal, K.R.; Kassem, E.; Koneru, S.; Kasbergen, C. Finite element modelling of field compaction of hot mix asphalt. Part II: Applications. Int. J. Pavement Eng. 2016, 17, 24–38. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, B.; Wang, D.; Yue, Z. Fundamental mechanics of asphalt compaction through FEM and DEM modeling. In Analysis of Asphalt Pavement Materials and Systems: Engineering Methods; American Society of Civil Engineers: Reston, VA, USA, 2007; pp. 45–63. [Google Scholar]

- Chen, J.; Huang, B.; Shu, X. Air-void distribution analysis of asphalt mixture using discrete element method. J. Mater. Civ. Eng. 2012, 25, 1375–1385. [Google Scholar] [CrossRef]

- Chen, J.; Huang, B.; Shu, X.; Hu, C. DEM simulation of laboratory compaction of asphalt mixtures using an open source code. J. Mater. Civ. Eng. 2014, 27, 04014130. [Google Scholar] [CrossRef]

- Man, T.; Le, J.L.; Marasteanu, M.; Hill, K.M. Two-Scale Discrete Element Modeling of Gyratory Compaction of Hot Asphalt. J. Eng. Mech. 2022, 148, 04021140. [Google Scholar] [CrossRef]

- Man, T. Rheology of Granular-Fluid Systems and Its Application in the Compaction of Asphalt Mixtures. Ph.D. Thesis, University of Minnesota, Minneapolis, MN, USA, 2019. [Google Scholar]

- Man, T.; Hill, K. Granular-slurry rheology and asphalt compaction. In Proceedings of the EPJ Web of Conferences, Powders & Grains, Buenos Aires, Argentina, 5, 13, 21, 29 July and 6 August 2021; EDP Sciences: Les Ulis, France, 2021; Volume 249, p. 09010. [Google Scholar] [CrossRef]

- Mehta, A.; Barker, G. The dynamics of sand. Rep. Prog. Phys. 1994, 57, 383. [Google Scholar] [CrossRef]

- Knight, J.B.; Fandrich, C.G.; Lau, C.N.; Jaeger, H.M.; Nagel, S.R. Density relaxation in a vibrated granular material. Phys. Rev. E 1995, 51, 3957. [Google Scholar] [CrossRef] [PubMed]

- Pouliquen, O.; Belzons, M.; Nicolas, M. Fluctuating particle motion during shear induced granular compaction. Phys. Rev. Lett. 2003, 91, 014301. [Google Scholar] [CrossRef]

- Mehta, A.; Barker, G.; Luck, J. Cooperativity in sandpiles: Statistics of bridge geometries. J. Stat. Mech. Theory Exp. 2004, 2004, P10014. [Google Scholar] [CrossRef]

- Barker, G.; Mehta, A. Transient phenomena, self-diffusion, and orientational effects in vibrated powders. Phys. Rev. E 1993, 47, 184. [Google Scholar] [CrossRef]

- Philippe, P.; Bideau, D. Compaction dynamics of a granular medium under vertical tapping. EPL Europhys. Lett. 2002, 60, 677. [Google Scholar] [CrossRef]

- Nowak, E.R.; Knight, J.B.; Ben-Naim, E.; Jaeger, H.M.; Nagel, S.R. Density fluctuations in vibrated granular materials. Phys. Rev. E 1998, 57, 1971. [Google Scholar] [CrossRef]

- Trulsson, M.; Andreotti, B.; Claudin, P. Transition from the viscous to inertial regime in dense suspensions. Phys. Rev. Lett. 2012, 109, 118305. [Google Scholar] [CrossRef]

- Pitois, O.; Moucheront, P.; Chateau, X. Liquid bridge between two moving spheres: An experimental study of viscosity effects. J. Colloid Interface Sci. 2000, 231, 26–31. [Google Scholar] [CrossRef]

- Man, T.; Feng, Q.; Hill, K. Rheology of Thickly-Coated Granular-Fluid Systems. arXiv 2018, arXiv:1812.07083. [Google Scholar]

- Brown, E.; Collins, R.; Brownfield, J. Investigation of Segregation of Asphalt Mixtures in the State of Georgia; Transportation Research Record; Transportation Research Board: Washington, DC, USA, 1989; Volume 1217. [Google Scholar]

- ASTM/D6925-15; Standard Test Method for Preparation and Determination of the Relative Density of Asphalt Mix Specimens by Means of the Superpave Gyratory Compactor. American Society for Testing and Materials: West Conshohocken, PA, USA, 2015.

- ASTM/D2041-11; Standard Test Method for Theoretical Maximum Specific Gravity and Density of Bituminous Paving Mixtures. American Society for Testing and Materials: West Conshohocken, PA, USA, 2011.

- ASTM/D2726-17; Standard Test Method for Bulk Specific Gravity and Density of Non-Absorptive Compacted Asphalt Mixtures. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).