Hybrid Deep Neural Network Approaches for Power Quality Analysis in Electric Arc Furnaces

Abstract

1. Introduction

2. Related Works

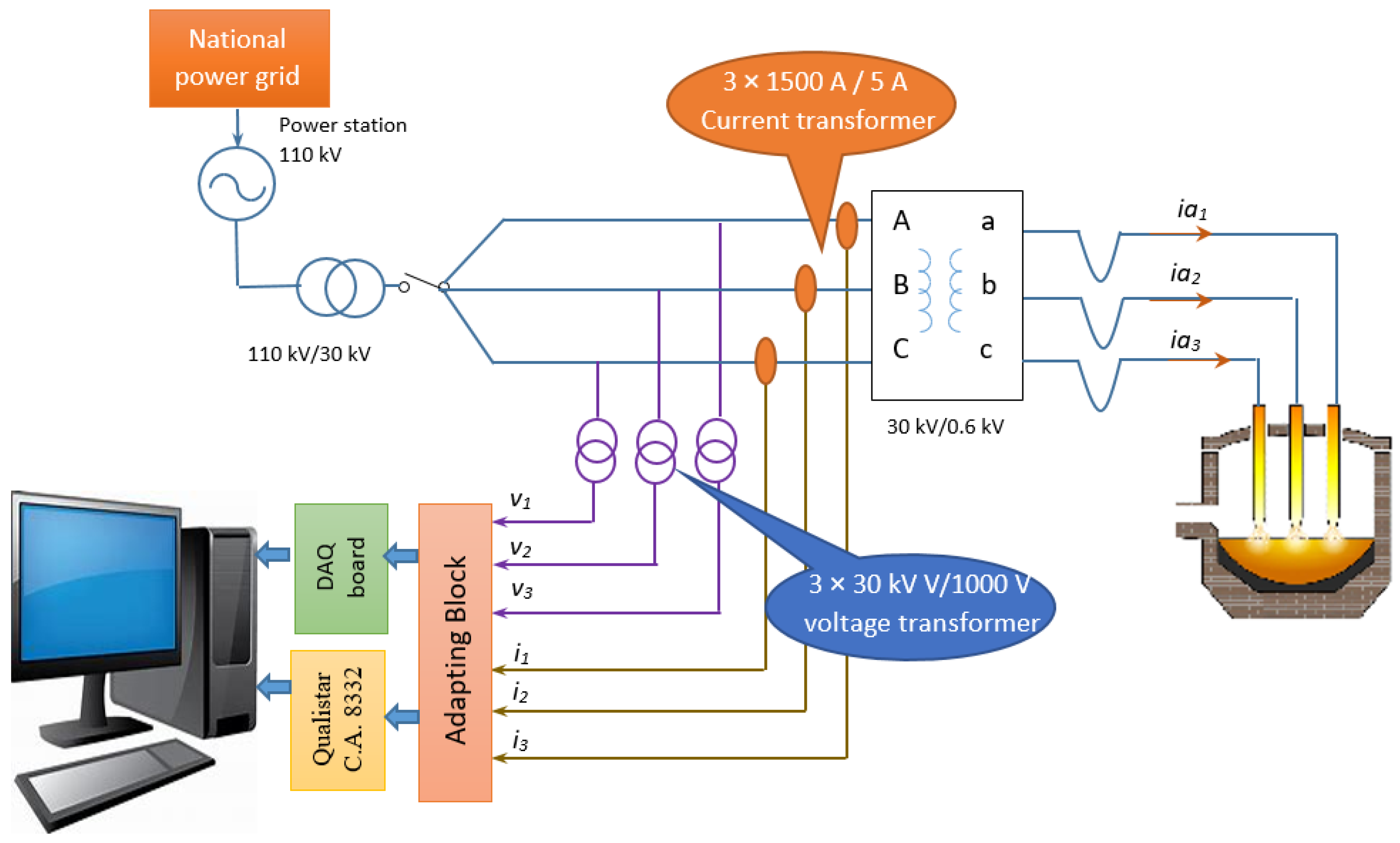

3. Materials and Methods

- The voltage measurement channel’s maximum operating frequency is 15 KHz, which matches the cutoff frequency of the isolation amplifier and alternating current amplifier assembly. The nonlinearity error in the voltage measurement process in the 1000 V range is less than 1% in the frequency range of 15 KHz.

- The nonlinearity error in the current measurement process is within 0.5% of the frequency range of the current transducer, which is in the frequency range of 100 KHz.

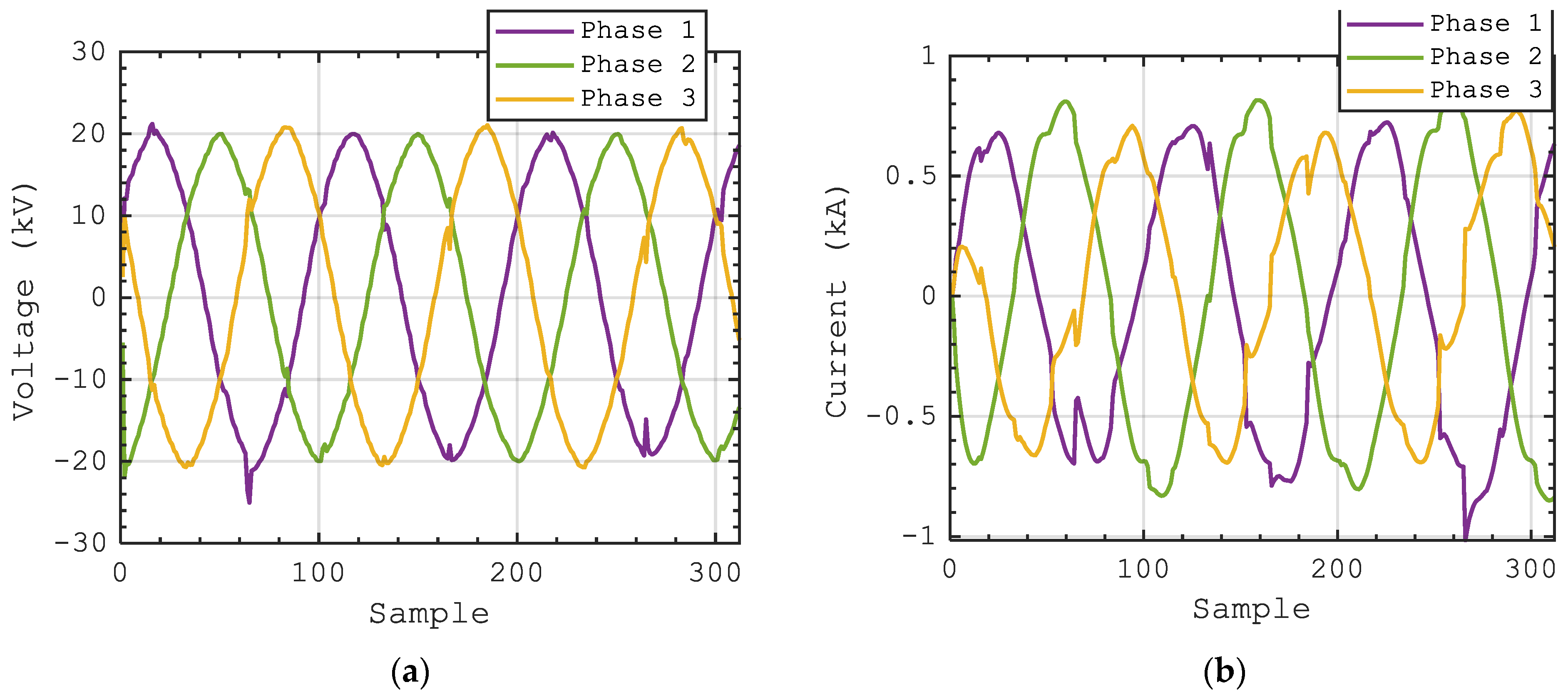

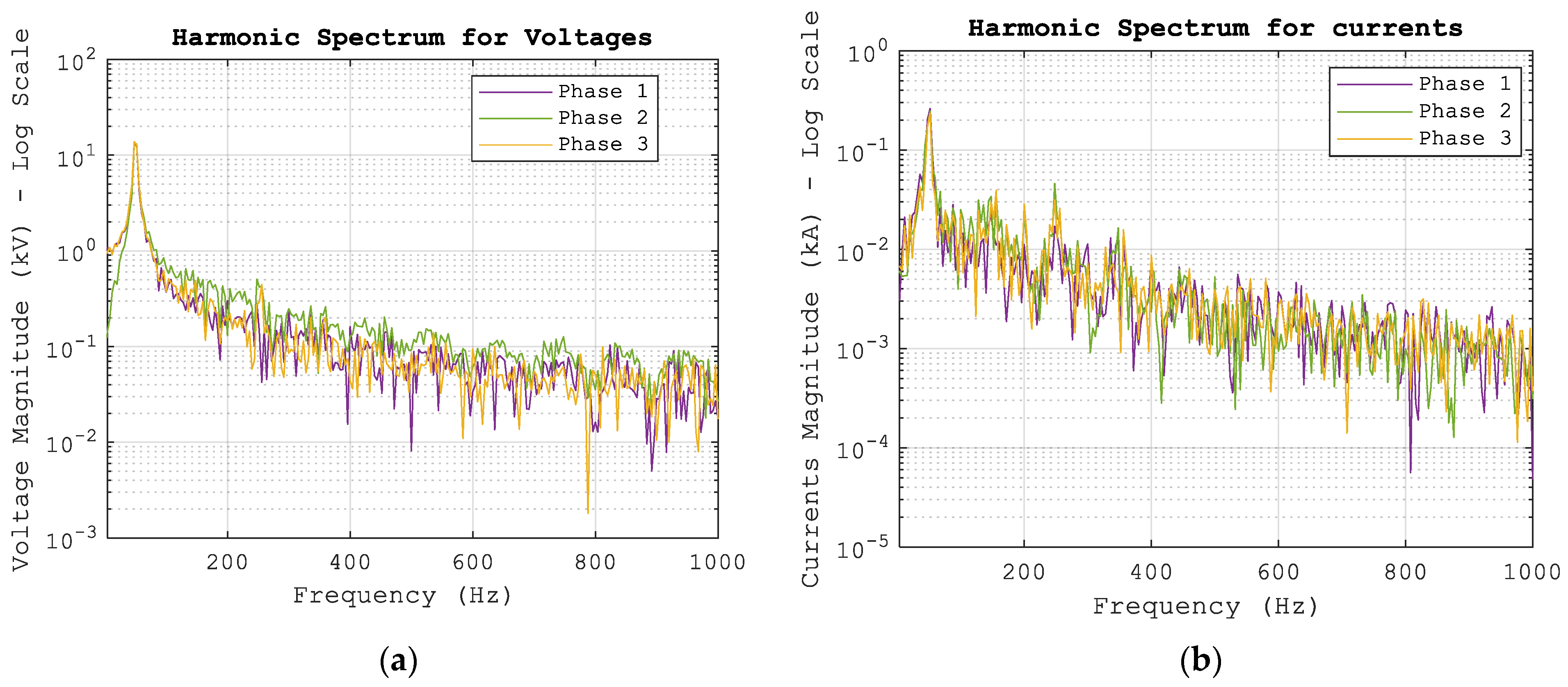

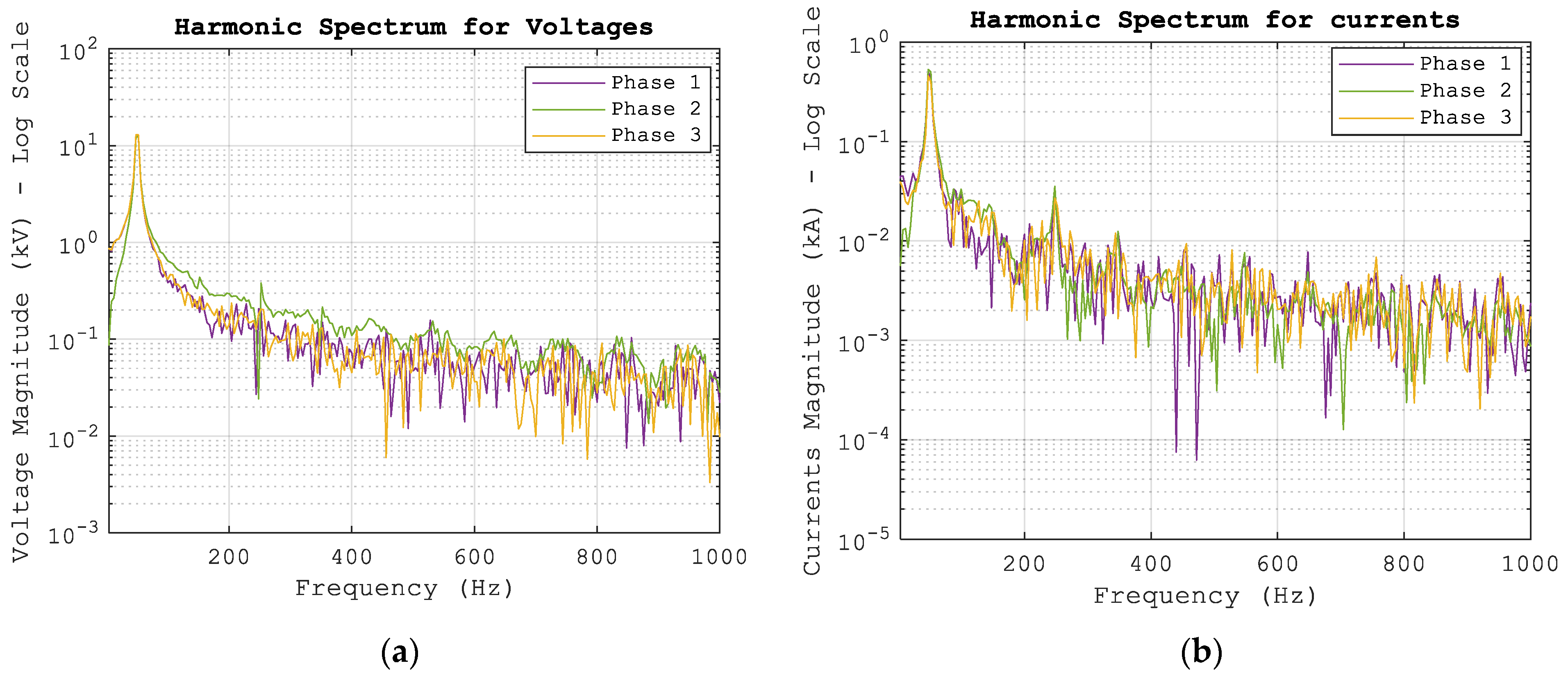

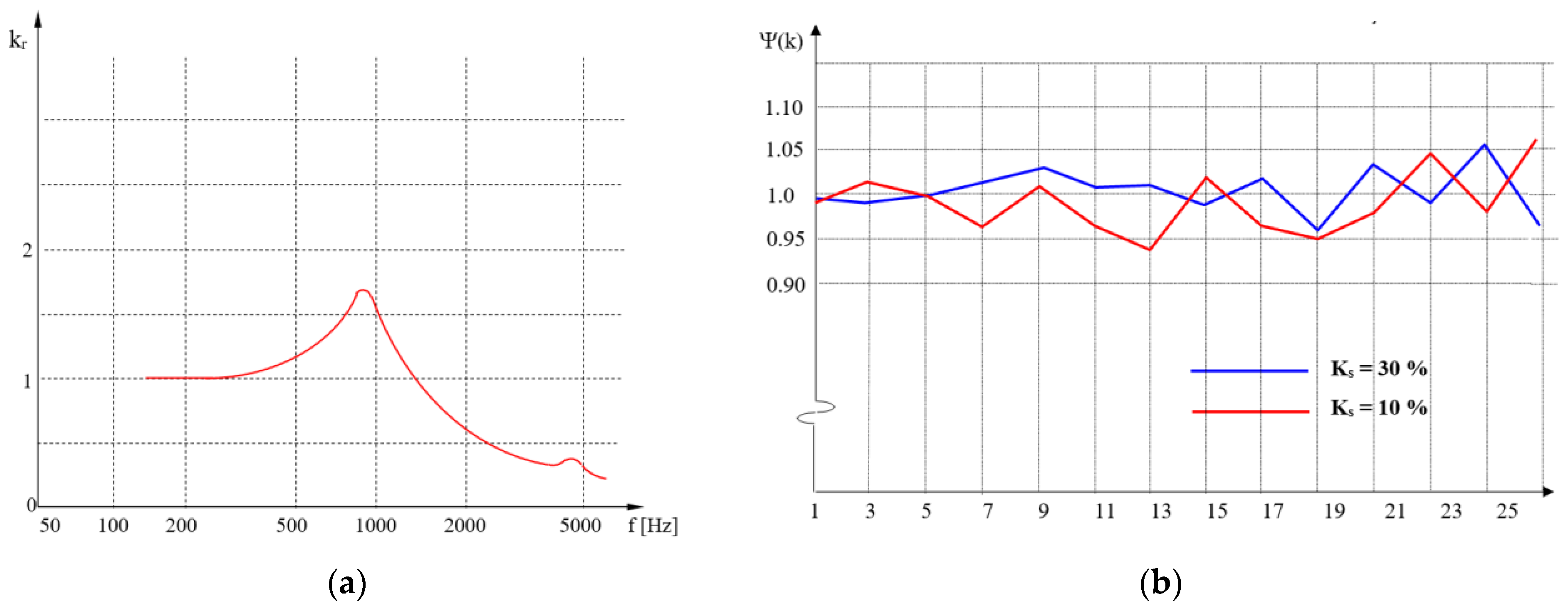

3.1. Power Quality Analyze

3.1.1. The Power Quality Indicators in the Context on an EAF

3.1.2. Harmonic Voltage

3.1.3. Harmonic Current

3.1.4. The RMS Voltage

3.1.5. The RMS Current

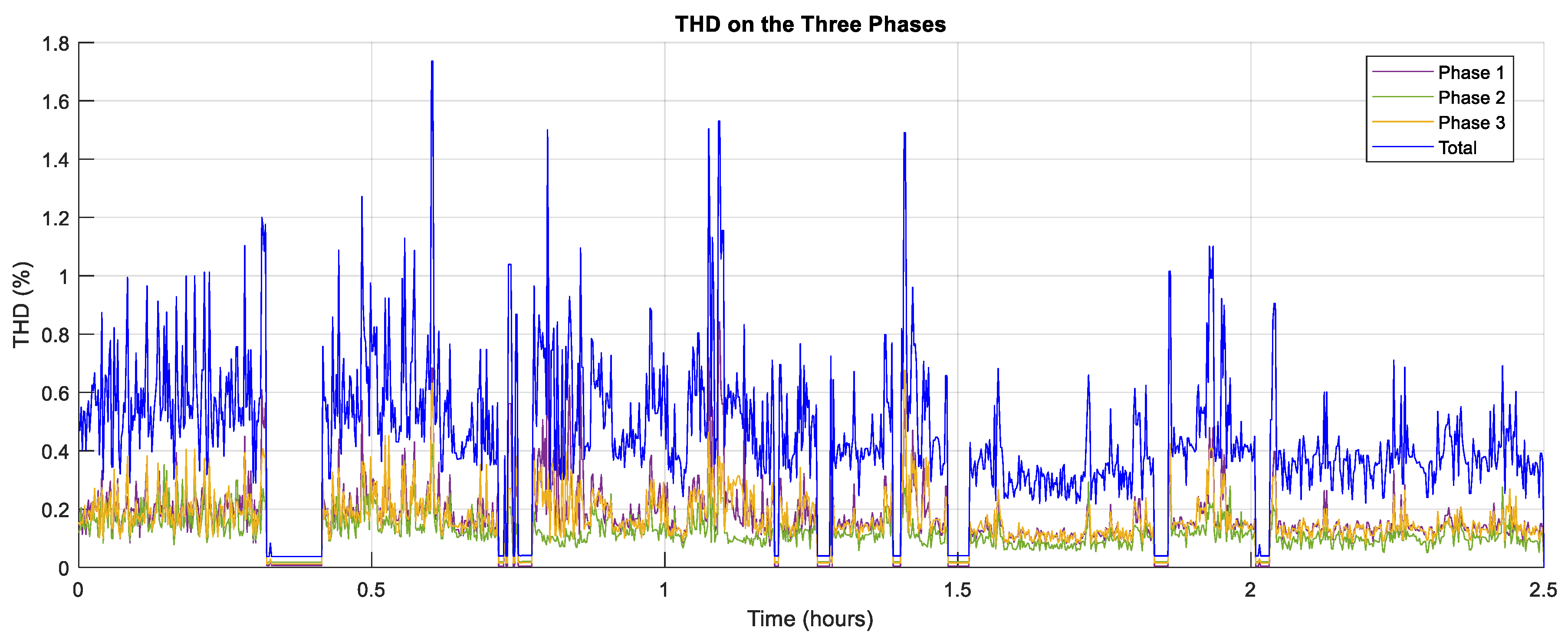

3.1.6. The Total Harmonic Distortion (THD)

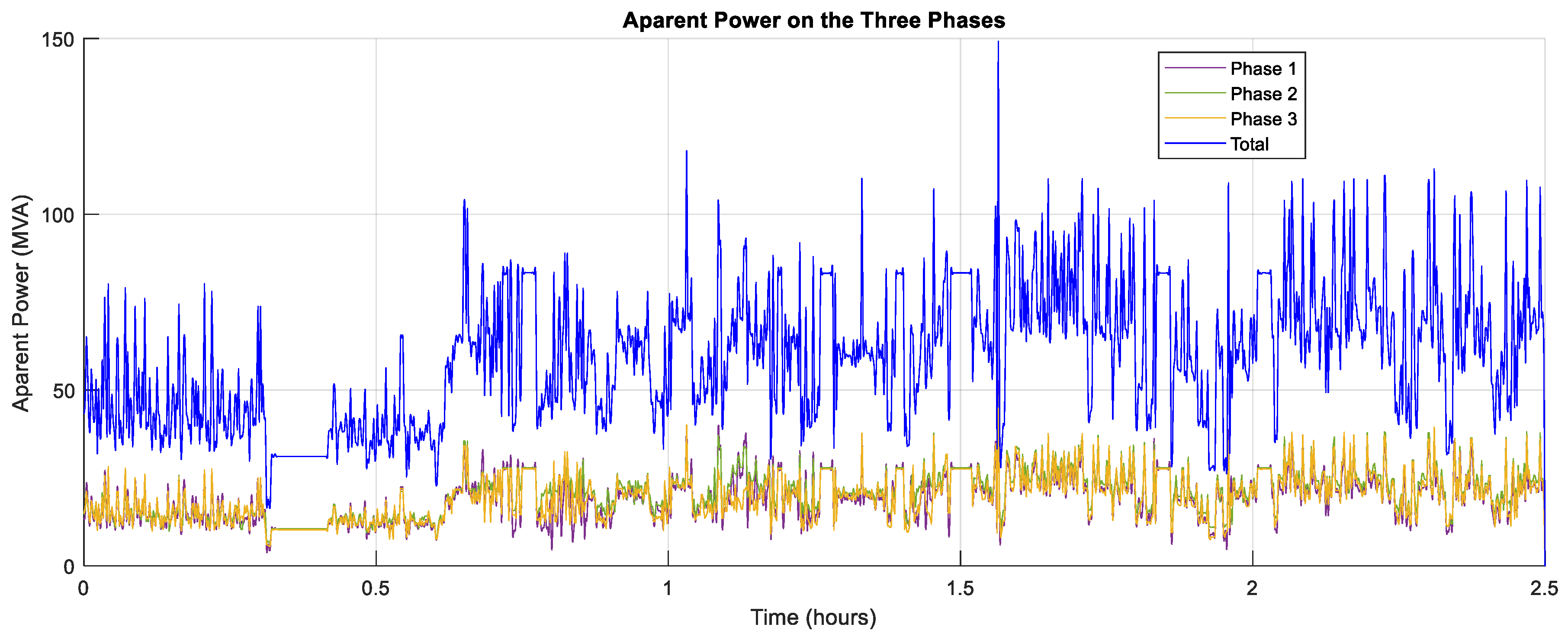

3.1.7. The Apparent Power (S)

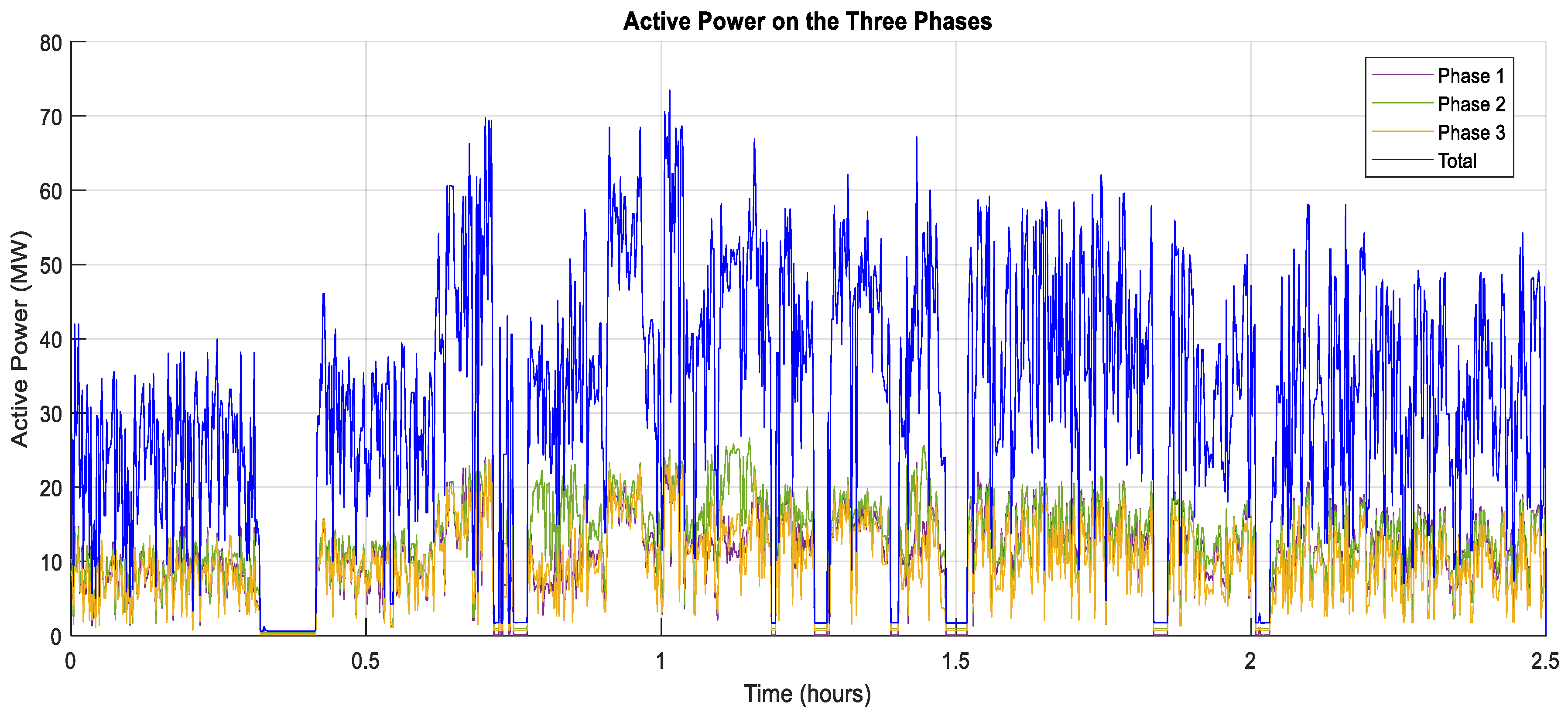

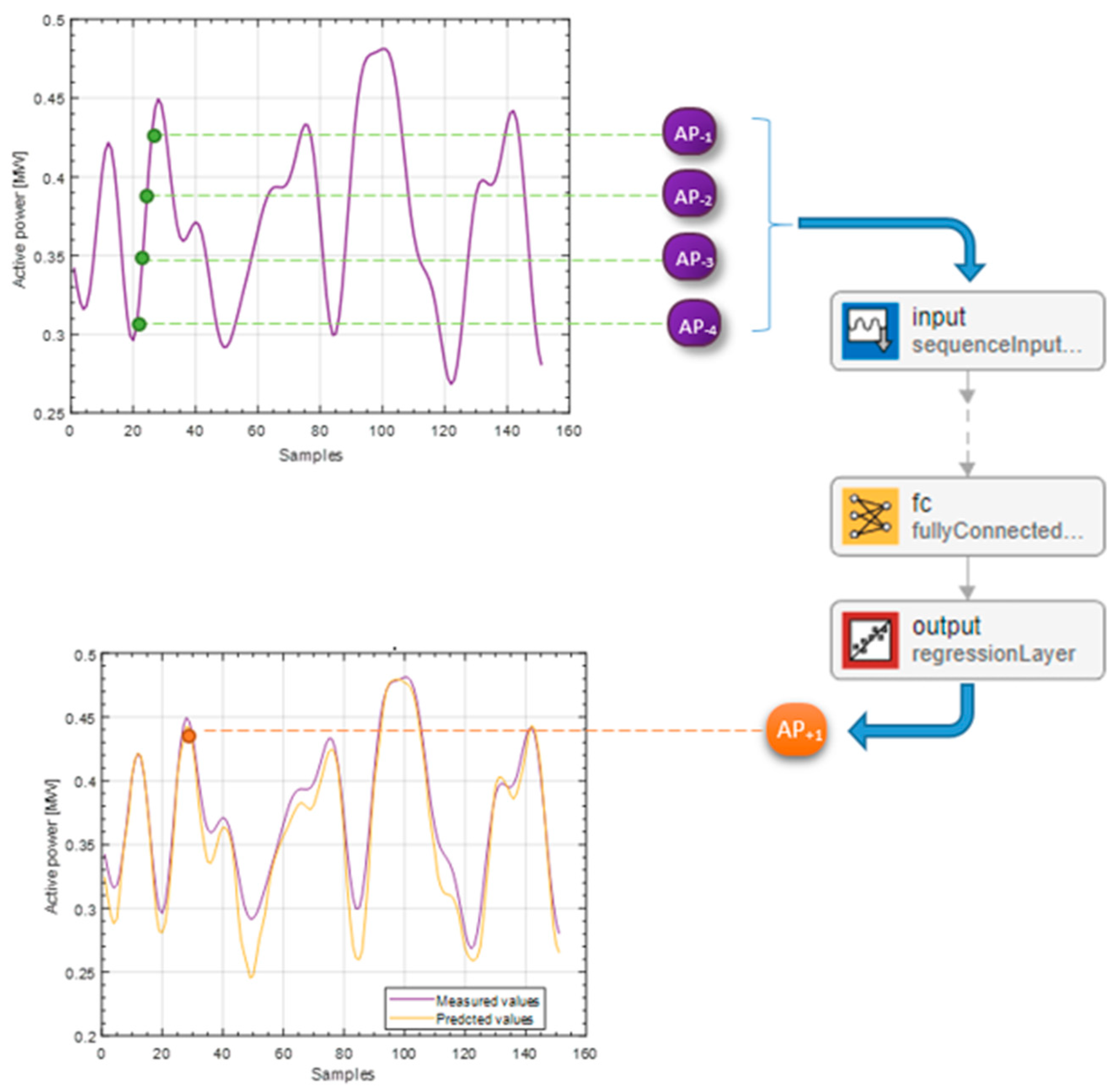

3.1.8. The Active Power (P)

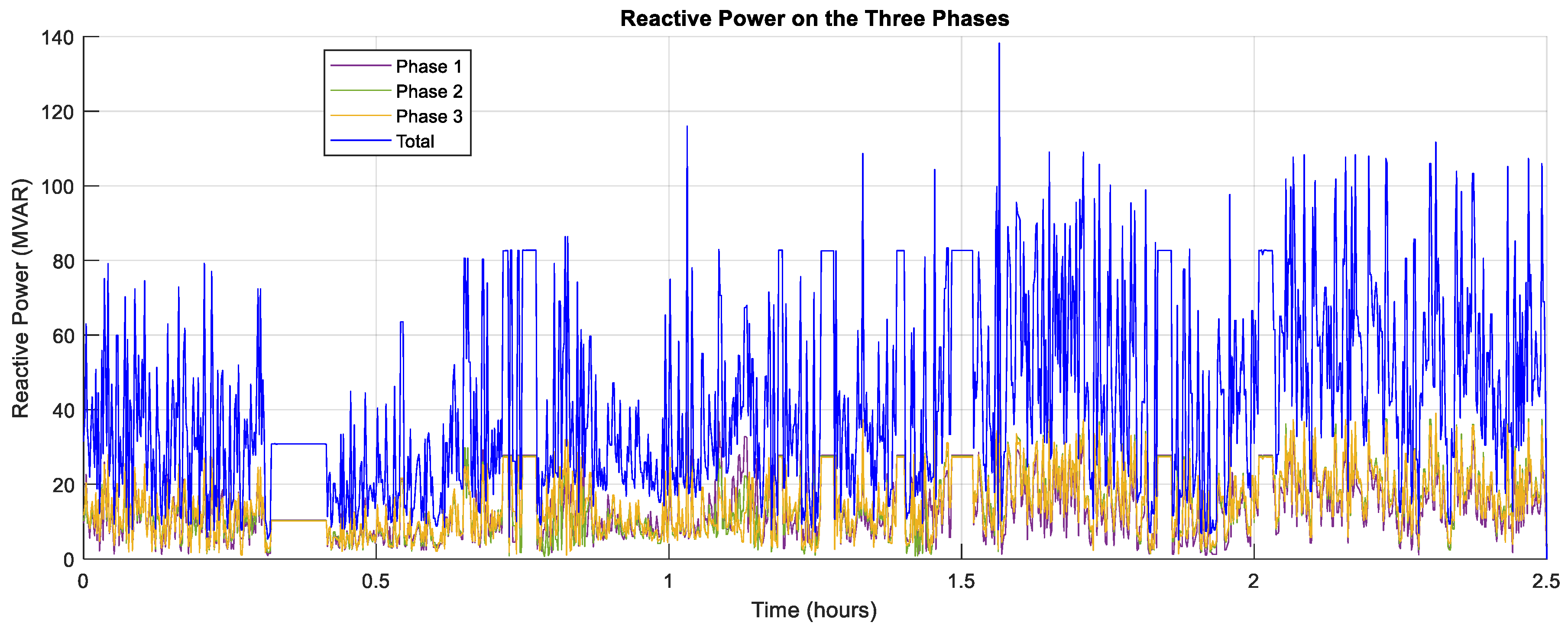

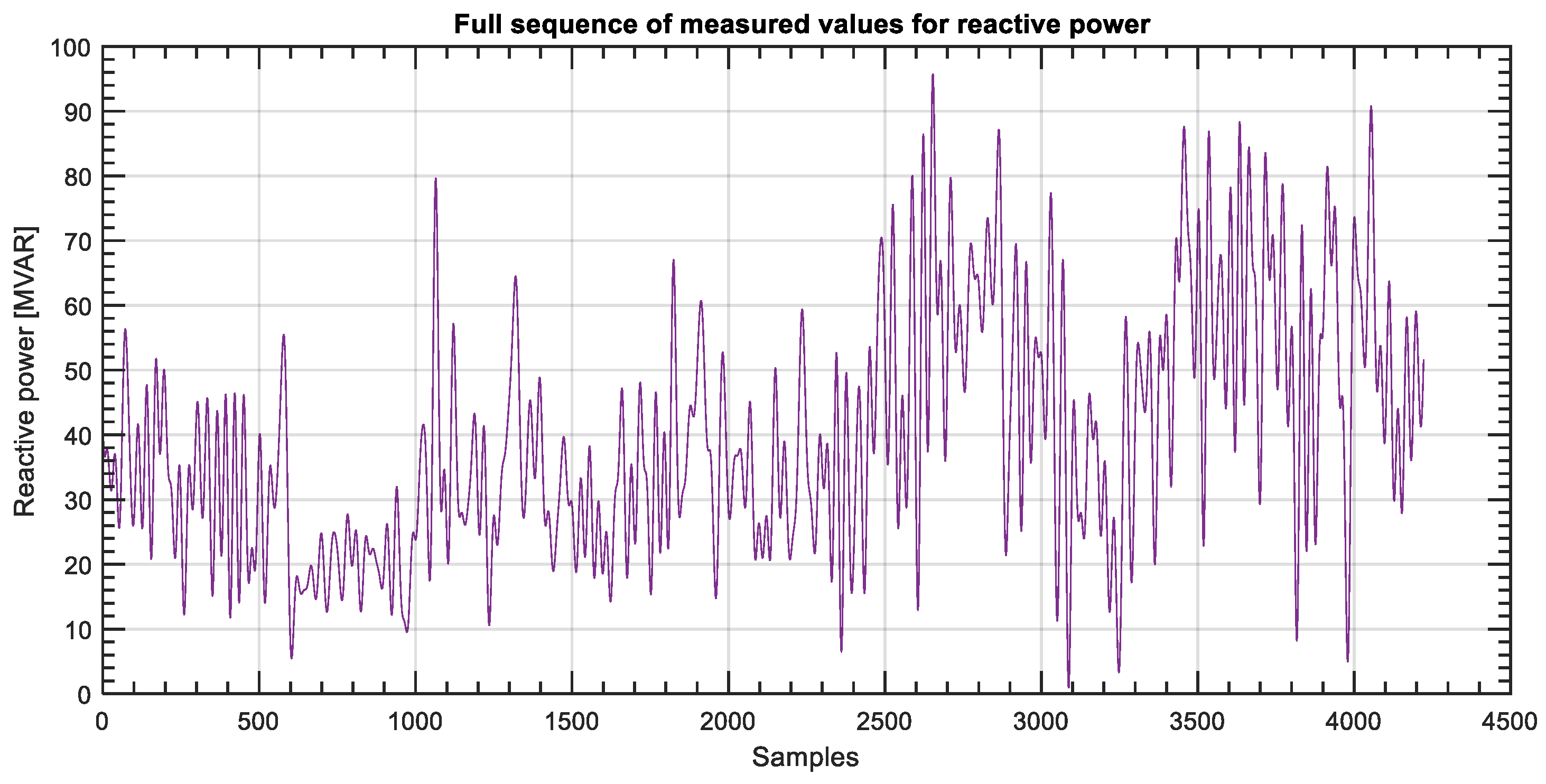

3.1.9. The Reactive Power (Q)

3.1.10. The Distorted Power (D)

3.2. The Error Measure Analysis

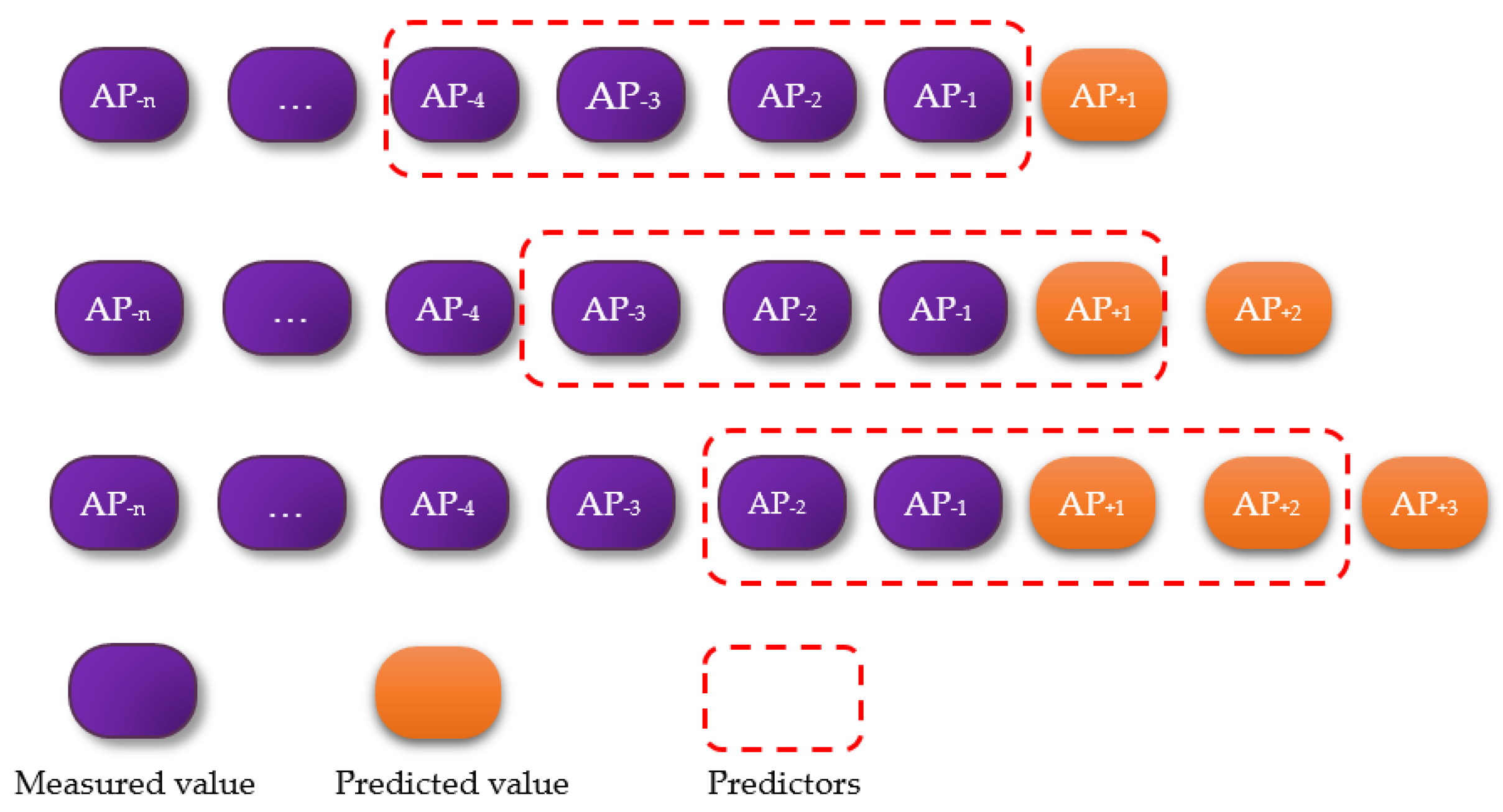

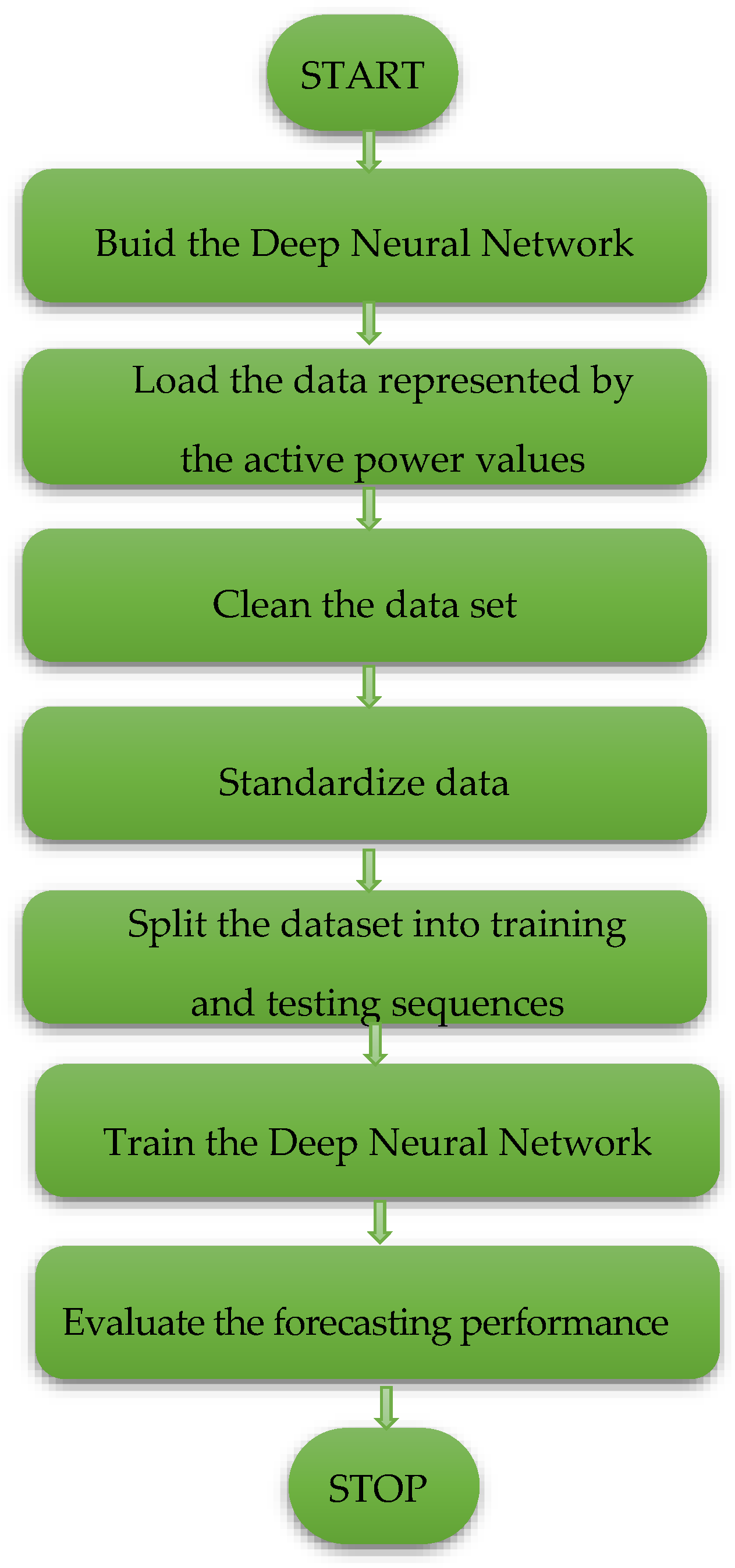

3.3. Hybrid Deep Neural Network in Analyzing Power Quality of EAF

3.4. Performance Indicators

3.4.1. Mean Absolute Percentage Error (MAPE)

3.4.2. Symmetric Mean Absolute Percentage Error (SMAPE)

3.4.3. Root Mean Square Error (RMSE)

3.4.4. Mean Absolute Error (MAE)

3.4.5. R2 Coefficient

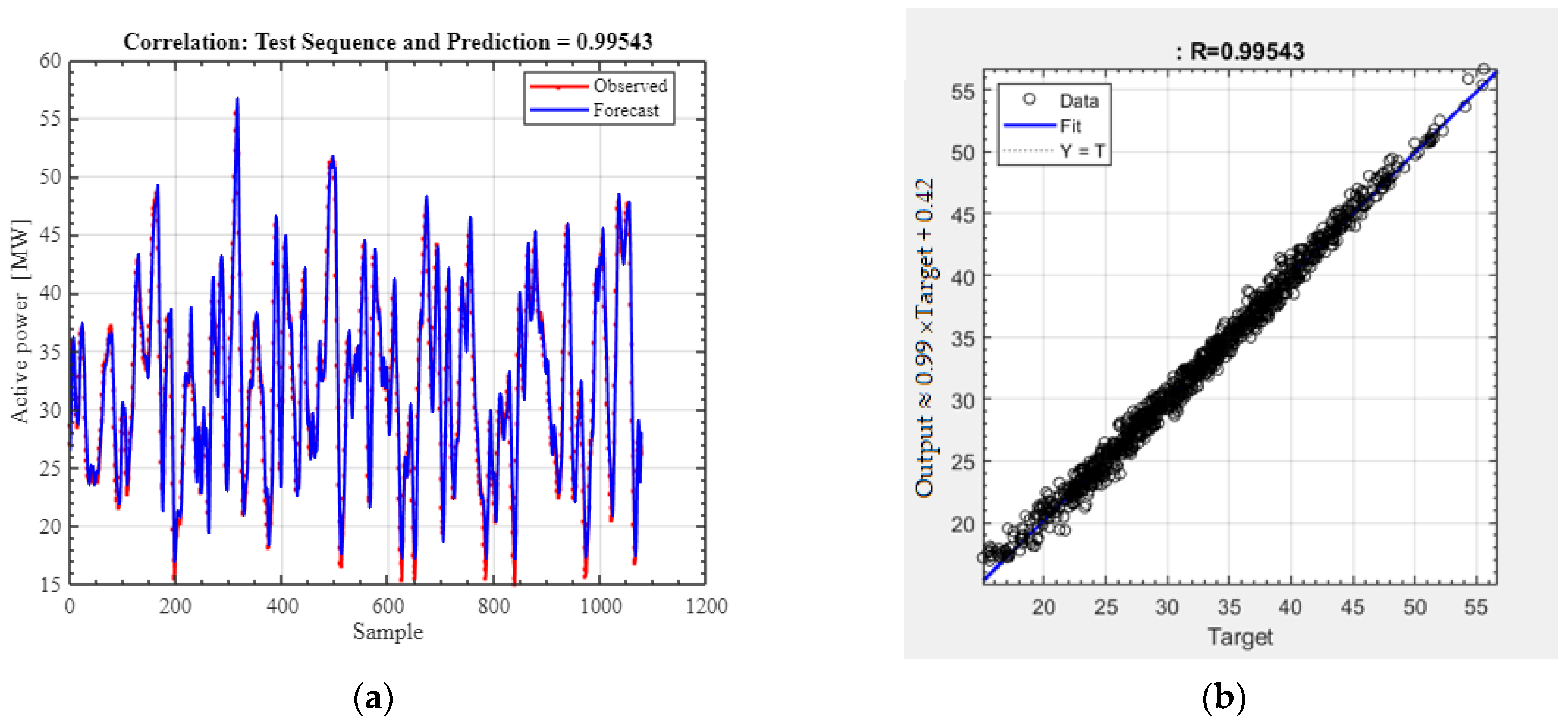

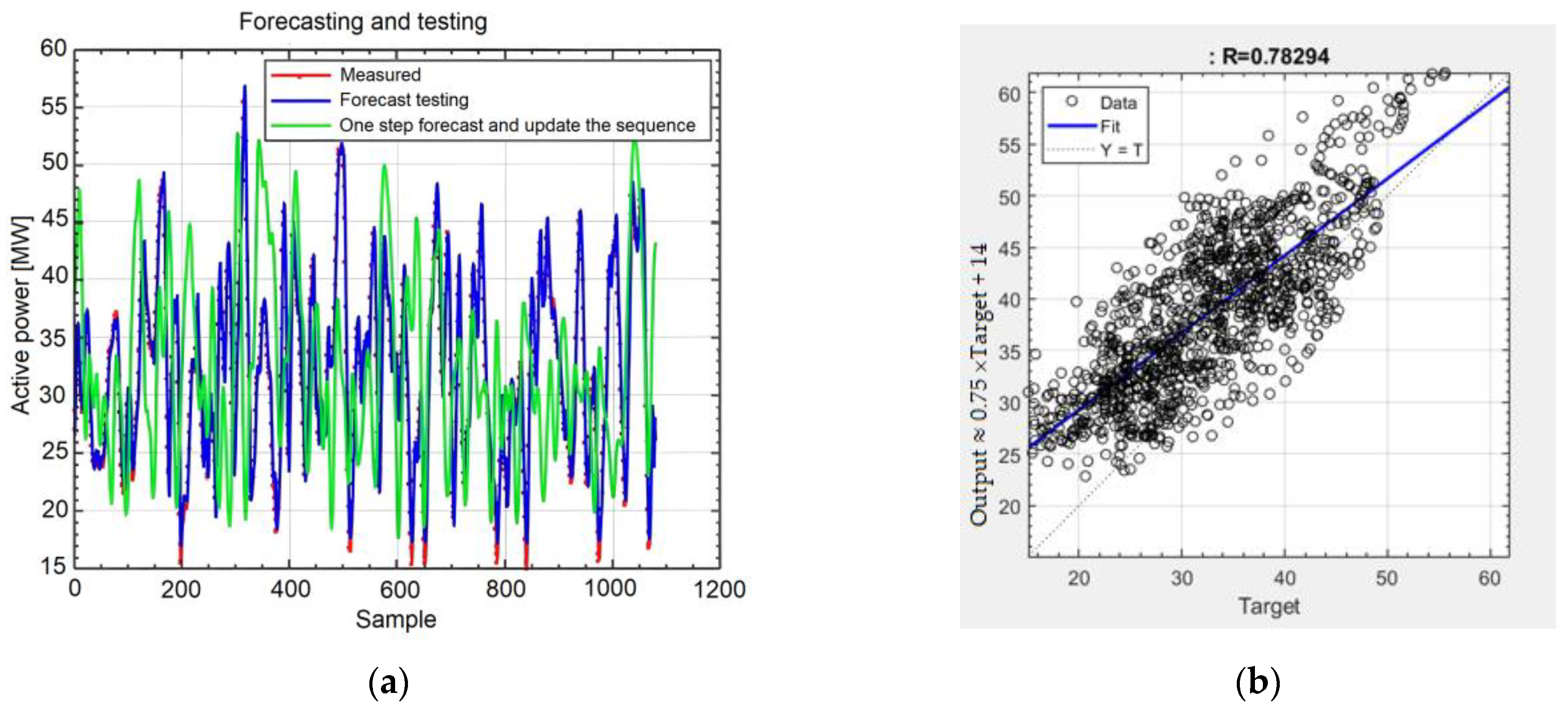

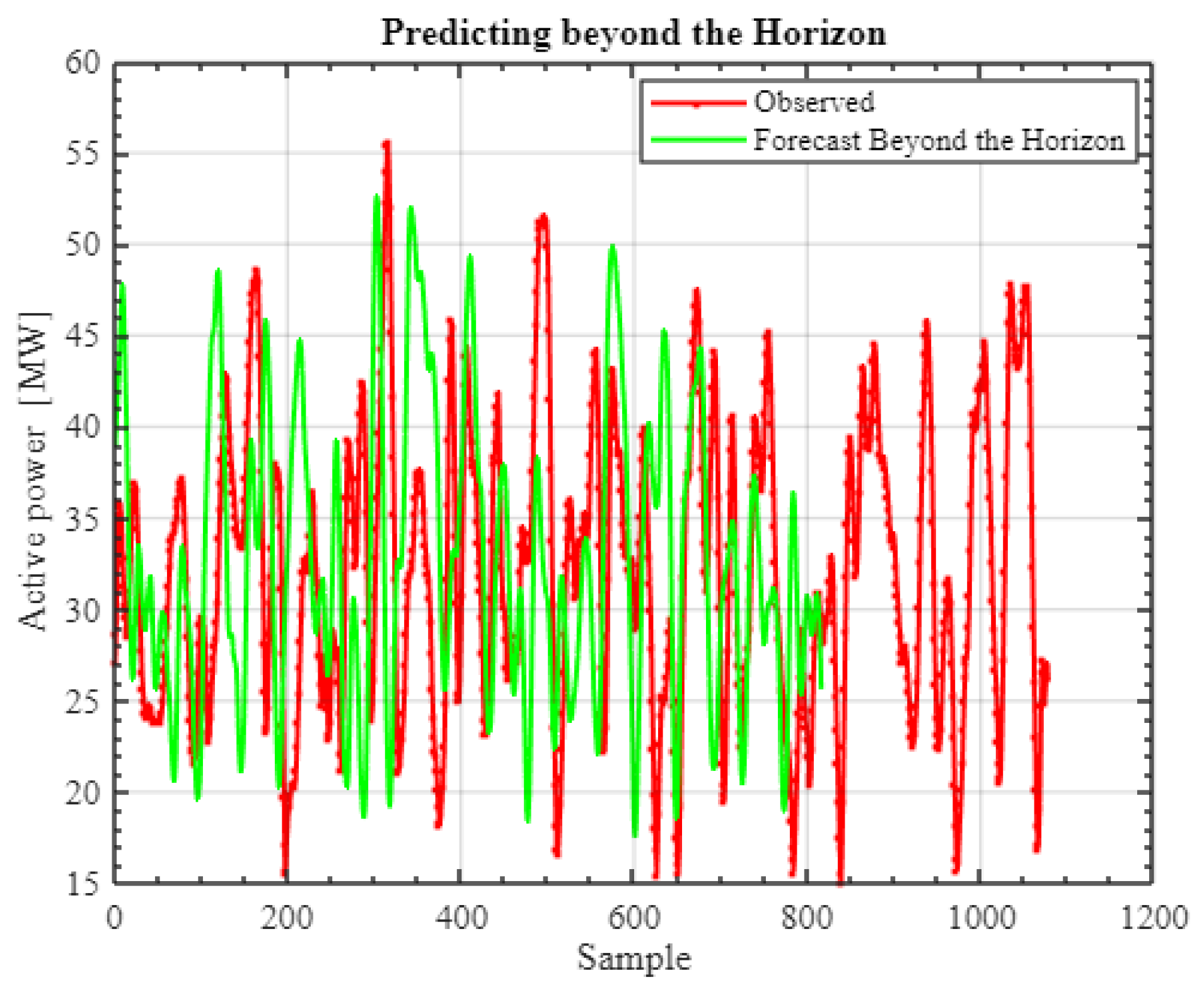

4. Results

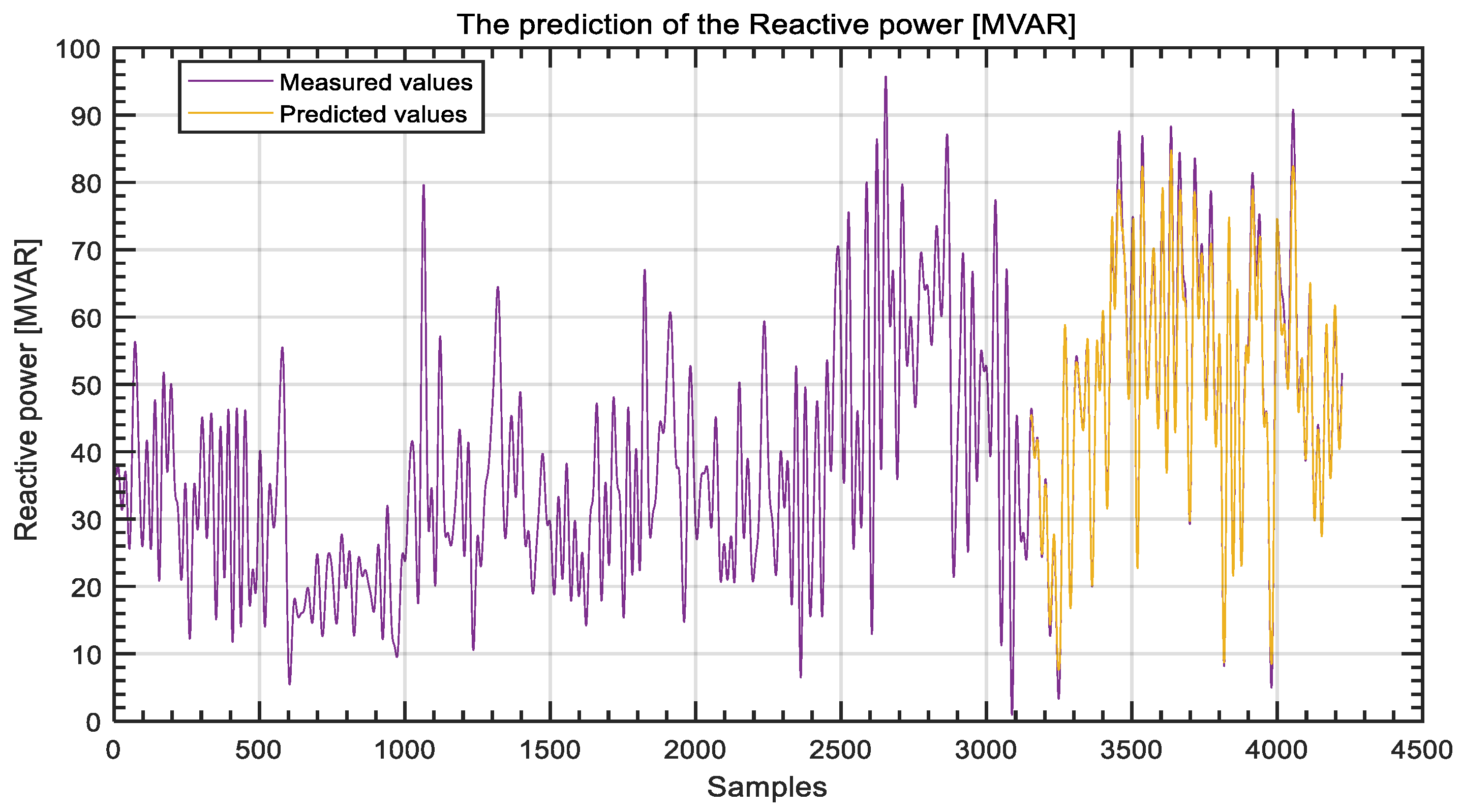

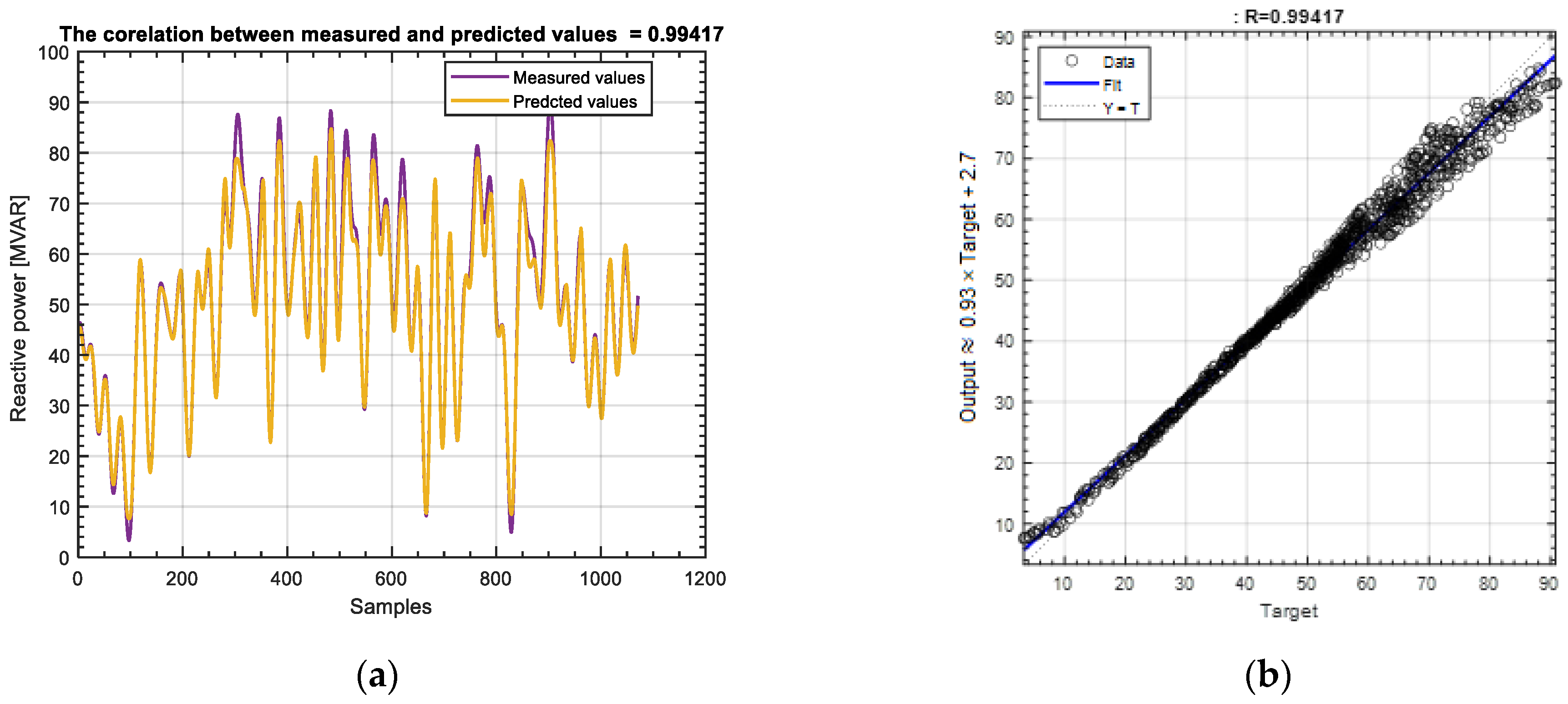

- The ratio used for splitting training and testing data is as follows: 0.6 to 0.85.

- The number of precedents samples is as follows: between 200 and 500.

- The steps for multi-step prediction and horizon are as follows: between 500 and 1000.

5. Discussion

6. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ANN | Artificial Neural Networks |

| AP | Active Power |

| CNN | Convolutional Neural Network |

| DL | Deep Learning |

| EAF | Electric Arc Furnace |

| GRU | Gated Recurrent Unit |

| LSTM | Long Short-Term Memory |

| MAE | Mean Absolute Error |

| PCC | Point of Common Coupling |

| PF | Power Factor |

| PQ | Power Quality |

| RMSE | Root Mean Square Error |

| RNN | Recurrent Neural Networks |

| sMAPE | Symmetric Mean Absolute Percentage Error |

| SVC | Static Var Compensator |

| THD | Total Harmonic Distortion |

References

- Uz-Logoglu, E.; Salor, O.; Ermis, M. Online Characterization of Interharmonics and Harmonics of AC Electric Arc Furnaces by Multiple Synchronous Reference Frame Analysis. IEEE Trans. Ind. Appl. 2016, 52, 2673–2683. [Google Scholar] [CrossRef]

- Nikolaev, A.A.; Anokhin, V.V.; Lozhkin, I.A. Estimation of accuracy of chosen SVC power for steel-making arc furnace. In Proceedings of the 2016 2nd International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), Chelyabinsk, Russia, 19–20 May 2016; pp. 1–5. [Google Scholar] [CrossRef]

- Brandão, D.A.D.L.; Parreiras, T.M.; Pires, I.A.; Braz de J. Cardoso, F. Electric Arc Furnace Reactive Compensation System Using Zero Harmonic Distortion Converter. IEEE Trans. Ind. Appl. 2022, 58, 6833–6841. [Google Scholar] [CrossRef]

- Jebaraj, B.S.; Bennet, J.; Kannadasan, R.; Alsharif, M.H.; Kim, M.K.; Aly, A.A.; Ahmed, M.H. Power Quality Enhancement in Electric Arc Furnace Using Matrix Converter and Static VAR Compensator. Electronics 2021, 10, 1125. [Google Scholar] [CrossRef]

- Ghiormez, L.; Panoiu, M.; Panoiu, C.; Rob, R. Electric Arc Model in PSCAD—EMTDC as embedded component and the dependency of the desired Active Power. In Proceedings of the 2016 IEEE 14th International Conference on Industrial Informatics (INDIN), Poitiers, France, 19–21 July 2016; pp. 351–356. [Google Scholar]

- Balouji, E.; Salor, Ö.; McKelvey, T. Deep Learning Based Predictive Compensation of Flicker, Voltage Dips, Harmonics and Interharmonics in Electric Arc Furnaces. IEEE Trans. Ind. Appl. 2022, 58, 4214–4224. [Google Scholar] [CrossRef]

- Nooshabadi AM, E.; Sadeghi, S.; Hashemi-Dezaki, H. Optimal Electric Arc Furnace Model’s Characteristics Using Genetic Algorithm and Particle Swarm Optimization and Comparison of Various Optimal Characteristics in DIgSILENT and EMTP-RV. Int. Trans. Electr. Energy Syst. 2022, 2022, 9952315. [Google Scholar] [CrossRef]

- Babaei, Z.; Samet, H.; Jalil, M. Enhanced models with time-series coefficients used for electric arc furnace. IET Gener. Transm. Distrib. 2023, 17, 2301–2316. [Google Scholar] [CrossRef]

- Babaei, Z.; Samet, H. Optimized time varying parameters of the power balance equation model for electric arc furnaces. IET Gener. Transm. Distrib. 2024, 18, 779–792. [Google Scholar] [CrossRef]

- Marulanda-Durango, J.; Zuluaga-Ríos, C. A meta-heuristic optimization-based method for parameter estimation of an electric arc furnace model. Results Eng. 2023, 17, 100850. [Google Scholar] [CrossRef]

- Marulanda-Durango, J.; Escobar-Mejía, A.; Alzate-Gómez, A.; Álvarez-López, M. A Support Vector machine-Based method for parameter estimation of an electric arc furnace model. Electr. Power Syst. Res. 2021, 196, 107228. [Google Scholar] [CrossRef]

- Čerňan, M.; Müller, Z.; Tlustý, J.; Valouch, V. An improved SVC control for electric arc furnace voltage flicker mitigation. Int. J. Electr. Power Energy Syst. 2021, 129, 106831. [Google Scholar] [CrossRef]

- Babaei, Z.; Samet, H.; Jalil, M. An innovative approach considering active power and harmonics for modeling the electric arc furnace along with analyzing time-varying coefficients based on ARMA models. Int. J. Electr. Power Energy Syst. 2023, 153, 109377. [Google Scholar] [CrossRef]

- Laketic, N.; Radakovic, J.; Majtal, Z. Power factor correction of electric arc furnace using active and passive compensation. In Proceedings of the 2017 International Symposium on Power Electronics (Ee), Novi Sad, Serbia, 19–21 October 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Klimas, M.; Grabowski, D. Application of long short-term memory neural networks for electric arc furnace modeling. Appl. Soft Comput. 2023, 145, 110574. [Google Scholar] [CrossRef]

- Balouji, E.; Salor, Ö.; McKelvey, T. Predictive Compensation of EAF Flicker, Voltage Dips Harmonics and Interharmonics Using Deep Learning. In Proceedings of the 2021 IEEE Industry Applications Society Annual Meeting (IAS), Vancouver, BC, Canada, 10–14 October 2021; pp. 1–10. [Google Scholar] [CrossRef]

- Xu, H.; Shao, Z.; Chen, F. Data-Driven Compartmental Modeling Method for Harmonic Analysis—A Study of the Electric Arc Furnace. Energies 2019, 12, 4378. [Google Scholar] [CrossRef]

- Severoglu, N.; Salor, O. Statistical Models of EAF Harmonics Developed for Harmonic Estimation Directly From Waveform Samples Using Deep Learning Framework. IEEE Trans. Ind. Appl. 2021, 57, 6730–6740. [Google Scholar] [CrossRef]

- Panoiu, M.; Ghiormez, L.; Panoiu, C. Adaptive Neuro-Fuzzy System for Current Prediction in Electric Arc Furnaces. Adv. Intell. Syst. Comput. 2015, 1, 423–437. [Google Scholar] [CrossRef]

- Panoiu, M.; Panoiu, C.; Sora, I.; Osaci, M. Simulation results on the reactive power compensation process on electric arc furnace using PSCAD-EMTDC. Int. J. Model. Identif. Control 2007, 2, 250. [Google Scholar] [CrossRef]

- Panoiu, M.; Panoiu, C.; Sora, I.; Osaci, M. Using a model based on linearization of the current-voltage characteristic for electric arc simulation. In Proceedings of the 16th IASTED International Conference on Applied Simulation and Modelling, Palma de Mallorca, Spain, 29-31 August 2007; pp. 99–103. Available online: http://dl.acm.org/citation.cfm?id=1659062 (accessed on 1 February 2024).

- Kalair, A.; Abas, N.; Kalair, A.; Saleem, Z.; Khan, N. Review of harmonic analysis, modeling and mitigation techniques. Renew. Sustain. Energy Rev. 2017, 78, 1152–1187. [Google Scholar] [CrossRef]

- Kontogiannis, D.; Bargiotas, D.; Daskalopulu, A. Minutely Active Power Forecasting Models Using Neural Networks. Sustainability 2020, 12, 3177. [Google Scholar] [CrossRef]

- Lee, C.; Jeong, D.; Jang, Y.; Bae, S.; Oh, J.; Lim, S. A Hybrid Deep Neural Network Model for Photovoltaic Generation Power Prediction. In Proceedings of the 2022 25th International Conference on Electrical Machines and Systems (ICEMS), Chiang Mai, Thailand, 29 November–2 December 2022. [Google Scholar] [CrossRef]

- Succetti, F.; Rosato, A.; Panella, M. An adaptive embedding procedure for time series forecasting with deep neural networks. Neural Netw. 2023, 167, 715–729. [Google Scholar] [CrossRef] [PubMed]

- Succetti, F.; Rosato, A.; Araneo, R.; Panella, M. Deep Neural Networks for Multivariate Prediction of Photovoltaic Power Time Series. IEEE Access 2020, 8, 211490–211505. [Google Scholar] [CrossRef]

- Anu Shalini, T.; Sri Revathi, B. Power Generation Forecasting Using Deep Learning CNN-based BILSTM Technique for Renewable Energy Systems. J. Intell. Fuzzy Syst. 2022, 43, 8247–8262. [Google Scholar] [CrossRef]

- Yazici, I.; Beyca, O.F.; Delen, D. Deep-learning-based short-term electricity load forecasting: A real case application. Eng. Appl. Artif. Intell. 2022, 109, 104645. [Google Scholar] [CrossRef]

- Panoiu, M.; Panoiu, C.; Ivascanu, P. Power Factor Modelling and Prediction at the Hot Rolling Mills’ Power Supply Using Machine Learning Algorithms. Mathematics 2024, 12, 839. [Google Scholar] [CrossRef]

- Iordan, A.-E. An Optimized LSTM Neural Network for Accurate Estimation of Software Development Effort. Mathematics 2024, 12, 200. [Google Scholar] [CrossRef]

| No. of Sample | The Powers without Corrections | The Powers with Corrections | εS (%) | εP (%) | εQ (%) | εD (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S | P | Q | D | S | P | Q | D | |||||

| 20 | 41.46 | 27.11 | 29.94 | 9.34 | 41.08 | 26.82 | 29.64 | 9.47 | 0.92 | 1.07 | 1.04 | −1.43 |

| 200 | 44.21 | 19.46 | 38.00 | 11.46 | 43.79 | 19.26 | 37.62 | 11.47 | 0.95 | 1.04 | 1.03 | −0.07 |

| 860 | 38.59 | 36.95 | 8.17 | 7.56 | 38.22 | 36.57 | 8.09 | 7.61 | 0.95 | 1.02 | 0.94 | −0.60 |

| 1600 | 49.49 | 37.03 | 24.76 | 21.56 | 49.01 | 36.66 | 24.52 | 21.36 | 0.99 | 1.01 | 1.00 | 0.92 |

| 2320 | 68.58 | 49.70 | 45.63 | 12.33 | 67.93 | 49.20 | 45.16 | 12.40 | 0.97 | 1.02 | 1.02 | −0.56 |

| 2800 | 64.94 | 49.90 | 39.70 | 12.29 | 64.32 | 49.40 | 39.29 | 12.33 | 0.97 | 1.01 | 1.03 | −0.29 |

| 3200 | 72.25 | 48.63 | 52.43 | 10.29 | 71.55 | 48.14 | 51.90 | 10.42 | 0.97 | 1.01 | 1.03 | −1.27 |

| 3600 | 55.80 | 51.35 | 18.63 | 11.40 | 55.27 | 50.83 | 18.43 | 11.46 | 0.96 | 1.02 | 1.06 | −0.51 |

| 4000 | 63.92 | 50.09 | 37.33 | 13.56 | 63.32 | 49.58 | 36.95 | 13.61 | 0.96 | 1.02 | 1.03 | −0.37 |

| 4480 | 33.04 | 29.94 | 12.19 | 6.81 | 32.72 | 29.64 | 12.07 | 6.80 | 0.96 | 1.00 | 0.99 | 0.11 |

| Number of Previous Samples | Ratio between Training and Testing | RMSE | sMAPE | MAE | R |

|---|---|---|---|---|---|

| 300 | 0.6 | 3.314413 | 0.020381 | 2.640818 | 0.932784 |

| 0.65 | 3.113631 | 0.019159 | 2.363491 | 0.933585 | |

| 0.7 | 2.772064 | 0.017979 | 2.249753 | 0.942575 | |

| 0.75 | 2.554321 | 0.017291 | 2.027032 | 0.954922 | |

| 0.8 | 2.703436 | 0.017741 | 2.144316 | 0.944628 | |

| 0.85 | 2.197355 | 0.014936 | 1.80319 | 0.96907 | |

| 320 | 0.6 | 4.427475 | 0.026606 | 3.51508 | 0.905221 |

| 0.65 | 3.215631 | 0.020395 | 2.519334 | 0.929615 | |

| 0.7 | 3.325819 | 0.021575 | 2.632571 | 0.929156 | |

| 0.75 | 3.446187 | 0.02241 | 2.784356 | 0.911974 | |

| 0.8 | 2.446932 | 0.016907 | 1.993812 | 0.956757 | |

| 0.85 | 2.075665 | 0.013437 | 1.568379 | 0.97342 | |

| 340 | 0.6 | 3.63967 | 0.022252 | 2.872954 | 0.924098 |

| 0.65 | 3.751916 | 0.024204 | 2.982398 | 0.906847 | |

| 0.7 | 3.643837 | 0.024214 | 2.936227 | 0.904302 | |

| 0.75 | 2.882581 | 0.019911 | 2.403643 | 0.937951 | |

| 0.8 | 2.856469 | 0.018973 | 2.289497 | 0.939664 | |

| 0.85 | 2.796537 | 0.018814 | 2.187657 | 0.946595 | |

| 360 | 0.6 | 4.565411 | 0.026749 | 3.511043 | 0.886226 |

| 0.65 | 4.003983 | 0.02621 | 3.219417 | 0.879203 | |

| 0.7 | 3.487623 | 0.022634 | 2.744349 | 0.906444 | |

| 0.75 | 3.294766 | 0.021581 | 2.638397 | 0.921039 | |

| 0.8 | 3.451286 | 0.023981 | 2.81407 | 0.912688 | |

| 0.85 | 2.496078 | 0.016638 | 2.030982 | 0.963686 | |

| 380 | 0.6 | 4.361974 | 0.026913 | 3.450132 | 0.88018 |

| 0.65 | 4.15275 | 0.026569 | 3.352146 | 0.890026 | |

| 0.7 | 4.017251 | 0.026412 | 3.229326 | 0.878045 | |

| 0.75 | 3.067461 | 0.020094 | 2.431549 | 0.931187 | |

| 0.8 | 3.756365 | 0.025836 | 3.055964 | 0.895678 | |

| 0.85 | 3.014232 | 0.019905 | 2.437175 | 0.940705 | |

| 400 | 0.6 | 4.966194 | 0.030891 | 3.987687 | 0.856531 |

| 0.65 | 4.139194 | 0.02705 | 3.318692 | 0.868059 | |

| 0.7 | 3.686925 | 0.023995 | 2.897578 | 0.892862 | |

| 0.75 | 3.810963 | 0.023953 | 2.93027 | 0.894915 | |

| 0.8 | 3.470194 | 0.023951 | 2.837146 | 0.913756 | |

| 0.85 | 2.800888 | 0.018161 | 2.234741 | 0.943493 |

| The Power Quality Indicator | Number of Previous Samples | Ratio between Training and Testing | RMSE | sMAPE | MAE | R |

|---|---|---|---|---|---|---|

| Reactive power | 300 | 0.65 | 4.013783 | 0.056213 | 3.523698 | 0.896213 |

| 0.7 | 4.026241 | 0.036312 | 3.429386 | 0.876654 | ||

| 400 | 0.65 | 3.568147 | 0.030571 | 2.853147 | 0.916471 | |

| 0.7 | 3.643837 | 0.044214 | 3.295413 | 0.900214 | ||

| Distorted power | 300 | 0.65 | 3.985413 | 0.025468 | 2.985466 | 0.902145 |

| 0.7 | 4.153654 | 0.065413 | 3.254687 | 0.894123 | ||

| 400 | 0.65 | 2.292016 | 0.009181 | 1.576199 | 0.995645 | |

| 0.7 | 2.983621 | 0.016243 | 2.014785 | 0.985464 | ||

| THD | 300 | 0.65 | 0.061189 | 0.031250 | 0.048770 | 0.903144 |

| 0.7 | 0.072546 | 0.046524 | 0.042158 | 0.956477 | ||

| 400 | 0.65 | 0.069962 | 0.035276 | 0.053137 | 0.965752 | |

| 0.7 | 0.071456 | 0.021589 | 0.053177 | 0.972147 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Panoiu, M.; Panoiu, C. Hybrid Deep Neural Network Approaches for Power Quality Analysis in Electric Arc Furnaces. Mathematics 2024, 12, 3071. https://doi.org/10.3390/math12193071

Panoiu M, Panoiu C. Hybrid Deep Neural Network Approaches for Power Quality Analysis in Electric Arc Furnaces. Mathematics. 2024; 12(19):3071. https://doi.org/10.3390/math12193071

Chicago/Turabian StylePanoiu, Manuela, and Caius Panoiu. 2024. "Hybrid Deep Neural Network Approaches for Power Quality Analysis in Electric Arc Furnaces" Mathematics 12, no. 19: 3071. https://doi.org/10.3390/math12193071

APA StylePanoiu, M., & Panoiu, C. (2024). Hybrid Deep Neural Network Approaches for Power Quality Analysis in Electric Arc Furnaces. Mathematics, 12(19), 3071. https://doi.org/10.3390/math12193071