Abstract

Hydrocarbon reservoirs’ formation damage is one of the essential issues in petroleum industries that is caused by drilling and production operations and completion procedures. Ineffective implementation of drilling fluid during the drilling operations led to large volumes of filtrated mud penetrating into the reservoir formation. Therefore, pore throats and spaces would be filled, and hydrocarbon mobilization reduced due to the porosity and permeability reduction. In this paper, a developed model was proposed to predict the filtrated mud saturation impact on the formation damage. First, the physics of the fluids were examined, and the governing equations were defined by the combination of general mass transfer equations. The drilling mud penetration in the core on the one direction and the removal of oil from the core, in the other direction, requires the simultaneous dissolution of water and oil flow. As both fluids enter and exit from the same core, it is necessary to derive the equations of drilling mud and oil flow in a one-dimensional process. Finally, due to the complexity of mass balance and fluid flow equations in porous media, the implicit pressure-explicit saturation method was used to solve the equations simultaneously. Four crucial parameters of oil viscosity, water saturation, permeability, and porosity were sensitivity-analyzed in this model to predict the filtrated mud saturation. According to the results of the sensitivity analysis for the crucial parameters, at a lower porosity (porosity = 0.2), permeability (permeability = 2 mD), and water saturation (saturation = 0.1), the filtrated mud saturation had decreased. This resulted in the lower capillary forces, which were induced to penetrate the drilling fluid to the formation. Therefore, formation damage reduced at lower porosity, permeability and water saturation. Furthermore, at higher oil viscosities, due to the increased mobilization of oil through the porous media, filtrated mud saturation penetration through the core length would be increased slightly. Consequently, at the oil viscosity of 3 cP, the decrease rate of filtrated mud saturation is slower than other oil viscosities which indicated increased invasion of filtrated mud into the formation.

1. Introduction

Underbalanced drilling operations (henceforth; UBD) is considered as one of the drilling procedures in the drilling of hydrocarbon wells. In this process, the wellbore pressure is fewer than the formation of static pressure [1,2,3,4,5]. By drilling the well, fluid flow through the porous media has been increased, and the hydrocarbon could flow to the surface via wellbore annulus. The produced fluid through this process is diverted to some special separators, which was done by rotating head [6,7,8,9]. In situations where formation pressures are high enough, the wellbore pressure will be reduced by the utilization of low-density mud.

The advantages of UBD are as follows: to minimize the formation damage effect, to increase the penetration rate, to reduce lost circulation, to virtually eliminate differential sticking, and to reduce water loss and formation damage [10,11,12]. In contrast, there are some disadvantages to this technique which should be taken into consideration during the reservoir studies and optimization procedures. This technique is usually more expensive than other conventional methods, and it has safety issues during the drilling procedure [12,13,14,15]. Formation damage effects are considered as one of the substantial factors, performed by drilling and completion procedures. This resulted in the reduction in oil and gas recovery performances. UBD processes are the prominent performances to reduce the formation damage effect regarding the mud invasion (fluid filtrate and mud solids) through the fractured and permeable rock formations [15,16,17,18]. Salimi et al. (2010) investigated the crucial parameters, which were seriously influenced by the formation damage in UBD procedures. The parameters that they concentrated on were capillary pressure, oil viscosity, water relative permeability, and the saturation of initial water [19]. In this paper, a numerical model was developed to consider different reservoir characteristics of porosity, permeability, water saturation and oil viscosity that are of crucial in reservoir planning and management. Xiao et al. (2019) presented a probability model to investigate the impact of porosity, relative roughness, fractal dimensions, and pores diameters on the effective thermal conductivity of porous media. They found that the tortuosity fractal dimension and relative roughness increase resulted in a decrease in porous media’s effective thermal conductivity [20]. Xiao et al. (2019) proposed a novel fractal solution to investigate the Kozney–Carman constant and permeability of the fibrous porous medium. According to their results, absolute permeability has been increased by the increase in porosity and particle diameter; however, it is decreased with the increase in the tortuosity fractal dimension [21]. Long et al. (2018) developed a perforation-erosion model to estimate specific erosion parameters that are dependent on the abrasion mechanisms. To provide a successful limited entry treatment, they incorporate the model with a nonplanar hydraulic-fracturing simulator to anticipate relevant perforation-number distributions at different clusters [22].

Bennion and Thomas (1994) investigated the different parameters which significantly impacted the formation damage. They experimentally investigated six different types of reservoir rocks in laboratory condition to consider the crucial parameters in the formation damage. They concluded that cross-sectional area, equilibrium pressure, which is defined as the pressure difference between drilling mud and formation, oil viscosity, water saturation, and wellbore pressure considerably influenced the formation damage [23]. In this paper, oil viscosity effect was analyzed and it was concluded that the oil viscosity increase resulted in the reduction in filtrated mud saturation. Byrne and Patey (2003) had investigated different crucial parameters which significantly influenced the formation damage in hydrocarbon reservoirs. According to their findings, reservoir geology is one of the significant factors of formation damage. This parameter includes some rock characteristics such as clay type, permeability, and the size of fine particles. They concluded that drawdown pressure is another useful parameter which can impact the formation damage procedure by facilitating the fine mobilization through porous media in high pressure. Therefore, pore throats would be plugged and have caused formation damage [24]. Sedaghatzadeh et al. (2016) investigated the profound impact of borehole inclination, particle aggregation, and nanoparticle geometry on the reservoir formation damage. According to their results, the damage degree and quality of mud cake are common and essential factors that caused the production of aggregated particles. Furthermore, the increase in well inclination has led to an increase in skin factor that is effectively related to the geometry of the particle. These parameters would be of importance during the design of the drilling fluid before drilling performances to reduce the formation damage effect [25].

Shi et al. (2018) proposed a new experimental and numerical method which is known as coiled tubing partial underbalanced drilling (henceforth; CT-PUBD) to enhance the penetration rate in the hard rock formation. They estimated the considerable influence of drilling speed, pressure loss, cutting migration, and cleaning hole efficiency in UBD operations to optimize the procedures. According to the results of their studies, CT-PUBD is shown as an efficient way that was close to the wellbore conditions and provide safe maintenance around the wellbore. Moreover, this technique could provide better hole-cleaning efficiency and enhance the penetration rate more than other conventional techniques [26]. Ezeakacha, C. P et al. (2018) investigated the considerable influence of water base mud invasion for different lithologies of formation rock and how it affected the formation damage issue in the dynamic conditions of the well during underbalanced drilling operations. They consider the critical parameters of lithological rock type, porous media heterogeneity, and the temperature and diameter of pore throats on the formation damage in a dynamic wellbore condition. They found that porosity and permeability are two substantial factors that can efficiently control the damage propensity and mud invasion in porous media. Furthermore, temperature increase has an inverse effect on the permeability reduction by the rise of fine mobilizations and cross-flow for mud solids in pore throats. Therefore, a temperature increase has a negative impact on the formation damage control, as it reduces the permeability [27].

The analysis of bottom hole formations is essential in the prediction of the fragmentation mechanism. Liu et al. (2019) proposed a coupled simulation modelling to investigate the profound impact of drilling mud pressure, overburden pressure impacts, temperature, horizontal in situ stresses, and pore pressure on the distribution of existing stresses in bottom hole formations. According to their findings, by the administration of air drilling fluid, bottom hole formations would be broken by the increase in well depth, and the drilling fluid pressure has a significant influence. As this pressure increases, breaking the bottom hole formations becomes more difficult. Moreover, they concluded that, by the increase in temperature difference, drilling fluid pressure, and well depth, the maximum bottom hole formations’ principal stress increases [28].

Zhang J. (2017) investigated the profound impact of porosity and permeability on the filtrated invasion depth as a numerical model. His findings showed that in higher porosities and permeabilities, the invasion depth of filtrated mud increased, as also indicated in the results of this model [29]. As porosity and permeability correlated together according to the findings of Costa A. (2006), a higher filtrated saturation of drilling fluid occurred with higher values of porosity and permeability, as indicated in Section 3.1 and Section 3.2. This issue is indicated in the results of this paper, and by the increase in porosity and permeability, filtrated mud saturation increased. The correlation between the two parameters is as follows [30]

where R is the core radius, is the porosity and is the tortuosity.

In this paper, a developed model to predict filtrated mud saturation impact on the formation damage were numerically analyzed. As the mass balance and fluid flow equations in porous media are difficult to solve, the implicit pressure explicit saturation method was used to address the mentioned issue more accurately. Four crucial parameters of porosity, permeability, water saturation, and oil viscosity, were considered in this model to predict the filtrated mud saturation. As in previous investigations, there was only a laboratory or experimental test, that was done only in operational processes, to consider formation damage. As a consequence, the developed model was compared with laboratory data to provide a comprehensive understanding, before implementing the operational processes, which might be expensive enough.

2. Methodology

In this part of the study, an analytical model is presented to simulate the influence of drilling mud in UBD procedures due to spontaneous imbibition processes. First, by examining the physics of the fluids, the governing equations are defined by combining the general mass transfer equations; then, a numerical simulation method and algorithm are finally implemented. The drilling mud penetration in the core on the one direction and the removal of oil from the core, in the other direction, requires the simultaneous dissolution of water and oil flow. Since both fluids enter and exit from the same core (which is equivalent to actual conditions in the well), it is necessary to derive the equations of drilling mud and oil flow in a one-dimensional process. The oil and drilling mud equations in the porous medium are obtained by combining the mass stability equation and the Darcy equation. The general mass balance for each phase is as follows

Although UBD procedures do not have any effect on formation degradation, capillary forces can still penetrate the drilling fluid into the pore spaces. If formation wettability type is hydrophilic, this phenomenon will increase the aqueous penetration of base drilling mud into the pore spaces. The extent and strength of this influence in UBD procedures are due to the hydrophilic strength of the formation. The more hydrophilic the formation, the more the drilling mud will penetrate the formation. Equations (1) and (2) cannot be analytically solved because of the extreme dependence of the coefficients of these equations on saturation and pressure. As a result, the above equations should be solved by numerical analysis. Finite difference method was utilized to solve the partial equations numerically. Thereby, two continuous partitions in the problem-solving domain were solved by discrete nodes. The coefficients of the mentioned equations are saturation and pressure. Therefore, the implicit pressure-explicit saturation (IMPES) method was administered to solve Equations (1) and (2). The final form of this equation is derived as follows

Consequently, in this paper, a developed model was proposed to predict the filtrated mud saturation impact on the formation damage. First, the physics of the fluids were examined, and the governing equations were defined by the combination of general mass transfer equations. The drilling mud penetration in the core on the one direction and the removal of oil from the core, in the other direction, requires the simultaneous dissolution of water and oil flow. As both fluids enter and exit from the same core, it is necessary to derive the equations of drilling mud and oil flow in a one-dimensional process. Finally, due to the complexity of mass balance and fluid flow equations in porous media, the implicit pressure-explicit saturation method was used to solve the equations simultaneously. The Matlab codes that are used in this paper are provided as a Supplementary Information file.

Experimental Section

As every analytical model needs to be validated by experimental evaluation or field test data, one laboratory dataset, done by Khakshour, M. 2010 [31], was taken into consideration in the developed model. One of the accurate methods to measure the filtration mud saturation through the length of core samples is an x-ray CT scan. CT is defined according to the Hounsfield unit, normalized as a water adsorption coefficient in linear form. Therefore, CT is calculated as the following equation in which μ is the gamma-ray damping factor and x is the desired fluid that is used in the calculations. In this study, x is the drilling fluid that is focused on its penetration in the formation.

In this method, log data from production well for each sample are used in CT scan correlations in Equation (5) to measure the water saturation [29,30].

When the porosity is defined, the saturation of each phase should be measured accurately according to CT scan data. Akin and Kovscek (1999) proposed the following correlations to measure oil and water saturation according to the CT scan data in laboratory condition [27]. Then, filtrated mud saturation was calculated sequentially, as there was a three-phase of oil, water, and mud occupying the pore spaces

where is the mud filtration saturation. The following parameters, used for validation of the model, are statistically explained in Table 1.

Table 1.

Required parameters for modelling according to the provided core samples for CT scan method.

3. Results and Discussion

In this part of the study, crucial parameters, which significantly affect the filtrated mud saturation, were compared together. The following items of porosity, permeability, saturation, and oil viscosity were analyzed. The initial conditions that were assumed in the proposed model are: K = 3 mD, = 1.05 cP, = 1.5 cP, φ = 20%.

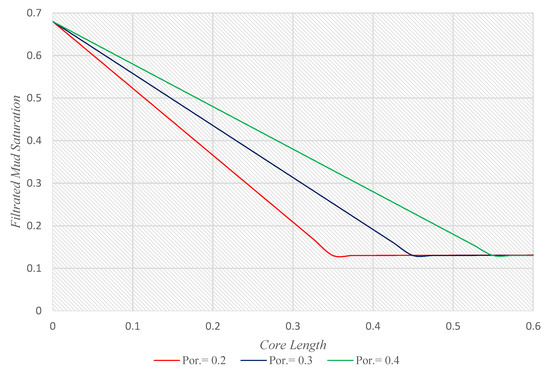

3.1. Porosity Effect

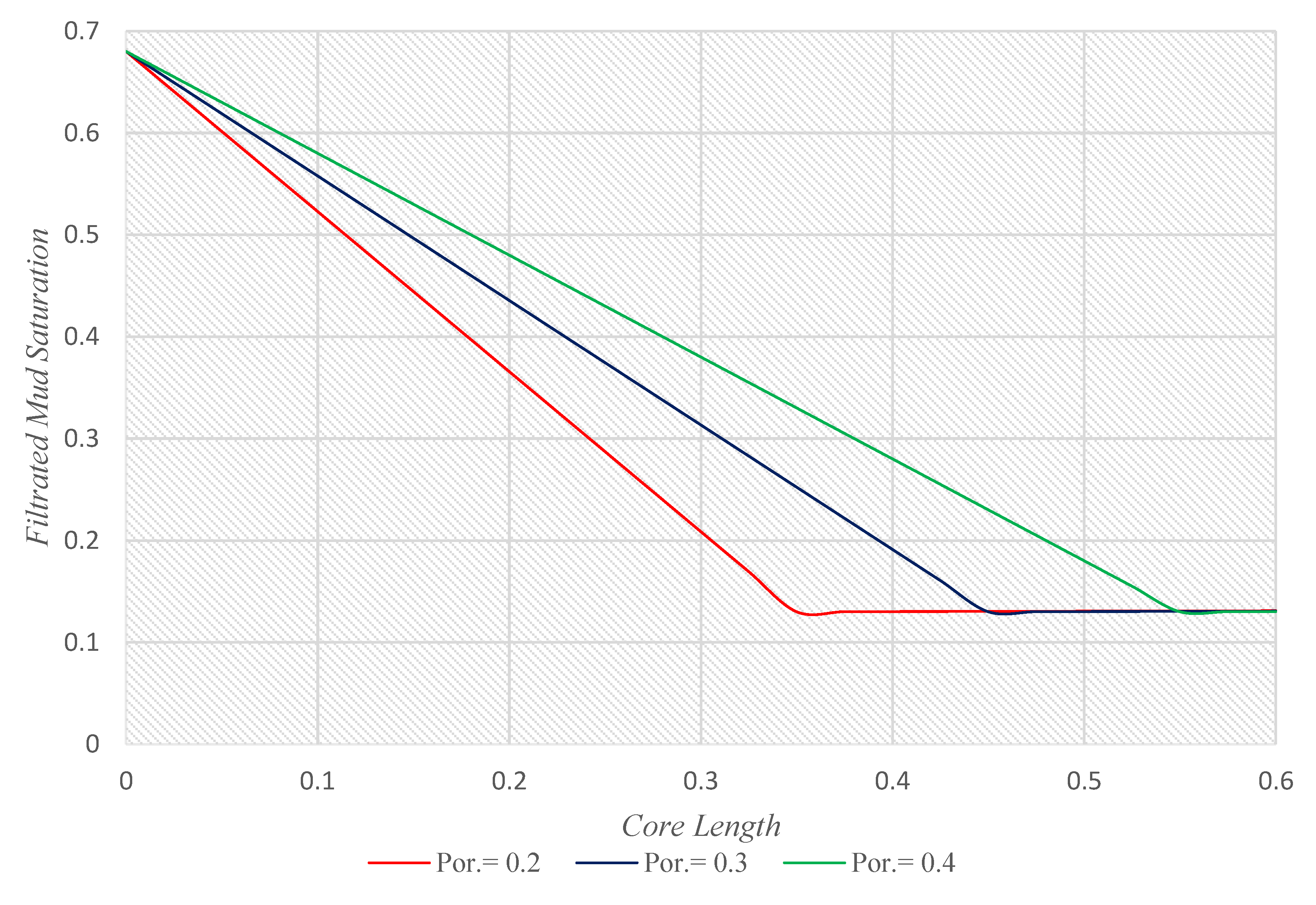

Porosity is defined as the ratio of pore volumes to the bulk volume, which is a dimensionless parameter. It is used to describe the oil mobilization through porous media. Therefore, higher porosities indicated more oil mobilization through porous media, as they have more pore connections and throats and oil can mobilize more efficiently than lower porosities. As porosity is one of the crucial parameters to define the fluid flow mobilization in the porous media, it is necessary to provide a sensitivity analysis on this parameter to nurture a better understanding of filtrated mud saturation in different porosities. To do this, three different percentages of porosity of 20%, 30% and 40% were considered in the proposed model. The reason for selecting these ranges for porosity is that most of the hydrocarbon reservoirs worldwide have an average porosity between 0.01–0.43. As is evident in Figure 1, for all three porosity values, the filtrated mud saturation started from approximately 0.7. This means that the maximum saturation for filtrated mud is about 0.7. By increasing the core length, saturation will be decreased slightly to reach its minimum value of relatively 0.1. At lower porosities, due to the fewer pore spaces through the bulk volume, the filtrated mud saturation decrease through the core length would be slightly more. Therefore, at the porosity of 0.2, the filtrated mud saturation decrease is slower than other porosities, which resulted in the capillary pressure reduction when the drilling fluid intended to penetrate the formation. Zhang J. (2017) investigated the profound impact of porosity and permeability on the filtrated invasion depth as a numerical model. His findings showed that, at higher porosities and permeabilities, the invasion depth of filtrated mud had increased, which was also indicated in the results of this model [32].

Figure 1.

Porosity effect on the filtrated mud saturation.

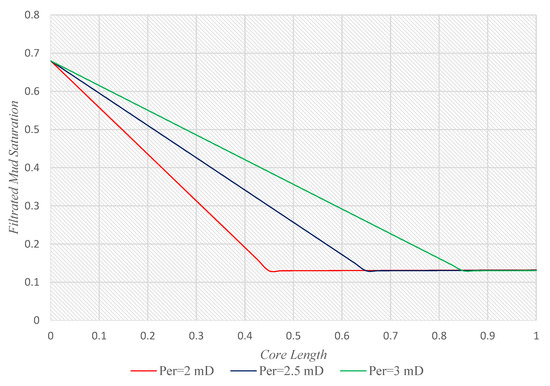

3.2. Permeability Effect

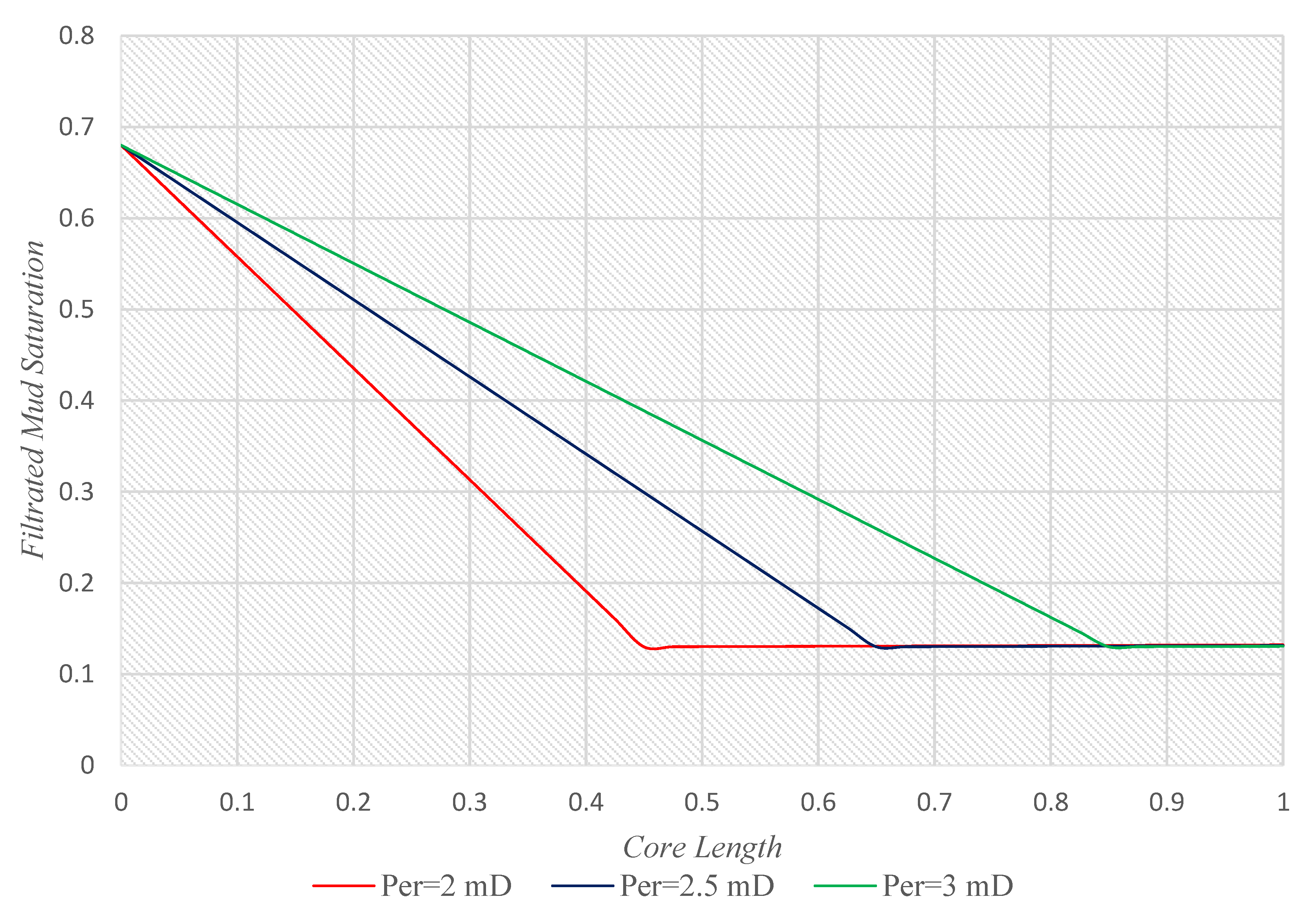

Permeability is defined as the fluid ability to flow through porous rocks, which mainly depended on the porosity. As permeability is one of the crucial parameters to define the fluid transfer conductivity in the porous media, it is necessary to provide a sensitivity analysis on this parameter to nurture a better understanding of filtrated mud saturation in different porosities. To do this, three different permeabilities of 2, 2.5, 3 mD were considered in the developed model. It is shown in Figure 2, for all three permeability values, the filtrated mud saturation started from approximately 0.7. It means that the maximum saturation for filtrated mud is about 0.7. By increasing the core length, saturation will be decreased gradually to reach its minimum value of relatively 0.1. At lower permeabilities, due to the more fluid transfer conductivity through the porous media, the filtrated mud saturation decrease through the core length would be slightly more. Therefore, at the permeability of 2 mD, the decrease rate of filtrated mud saturation is slower than other permeabilities, which indicated the significant dependency of this parameter on the size of pore diameters, which is known as porosity. Moreover, in low permeabilities, regarding the lower capillary forces’ ability to penetrate drilling fluid to the formation, the formation damage will be decreased. As porosity and permeability correlated together according to the findings of Costa A. (2006), higher filtrated saturation of drilling fluid occurred in higher values of porosity and permeability, as indicated in Section 3.1 and Section 3.2 [33].

Figure 2.

Permeability Effect on the filtrated mud saturation.

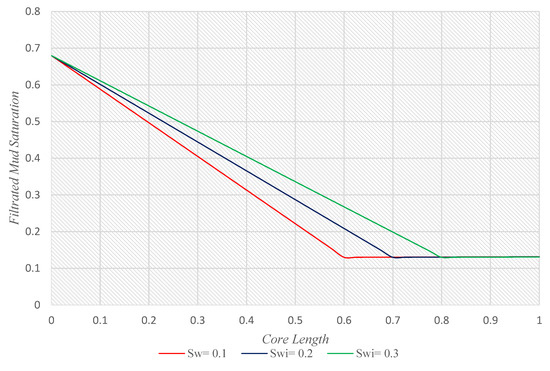

3.3. Water Saturation Effect

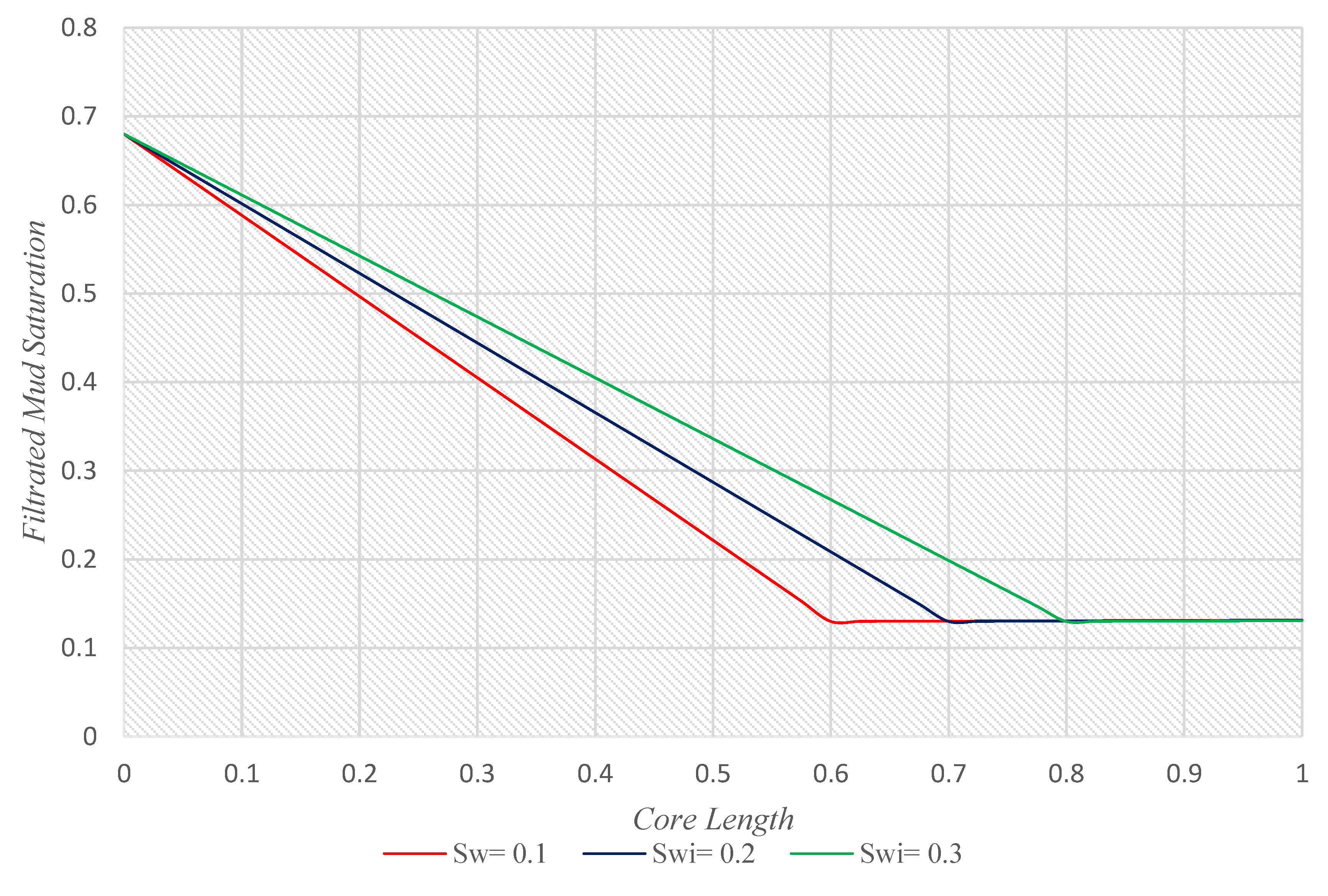

As water saturation is one of the crucial parameters to define the fluid volume in the porous media, it is necessary to provide a sensitivity analysis of this parameter to nurture a better understanding of filtrated mud saturation in different porosities. To do this, three different percentages of water saturation of 10%, 20%, 30% were considered in the developed model. It is shown in Figure 3, for all three water saturation values, the filtrated mud saturation started from approximately 0.7. This means that the maximum saturation for filtrated mud is about 0.7. By increasing the core length, saturation will be decreased gradually to reach its minimum value of relatively 0.1. At lower water saturations, due to the presence of greater water volume through the porous media, the filtrated mud saturation decrease through the core length would be slightly more. Therefore, at the water saturation of 0.1, the decrease rate of filtrated mud saturation is slower than other water saturations, which indicated the greater invasion of filtrated mud to the formation. Moreover, in lower water saturations, regarding the lower capillary forces that are able to penetrate drilling fluid into the formation, the formation damage will be decreased.

Figure 3.

Water Saturation Effect on the filtrated mud saturation.

3.4. Oil Viscosity Effect

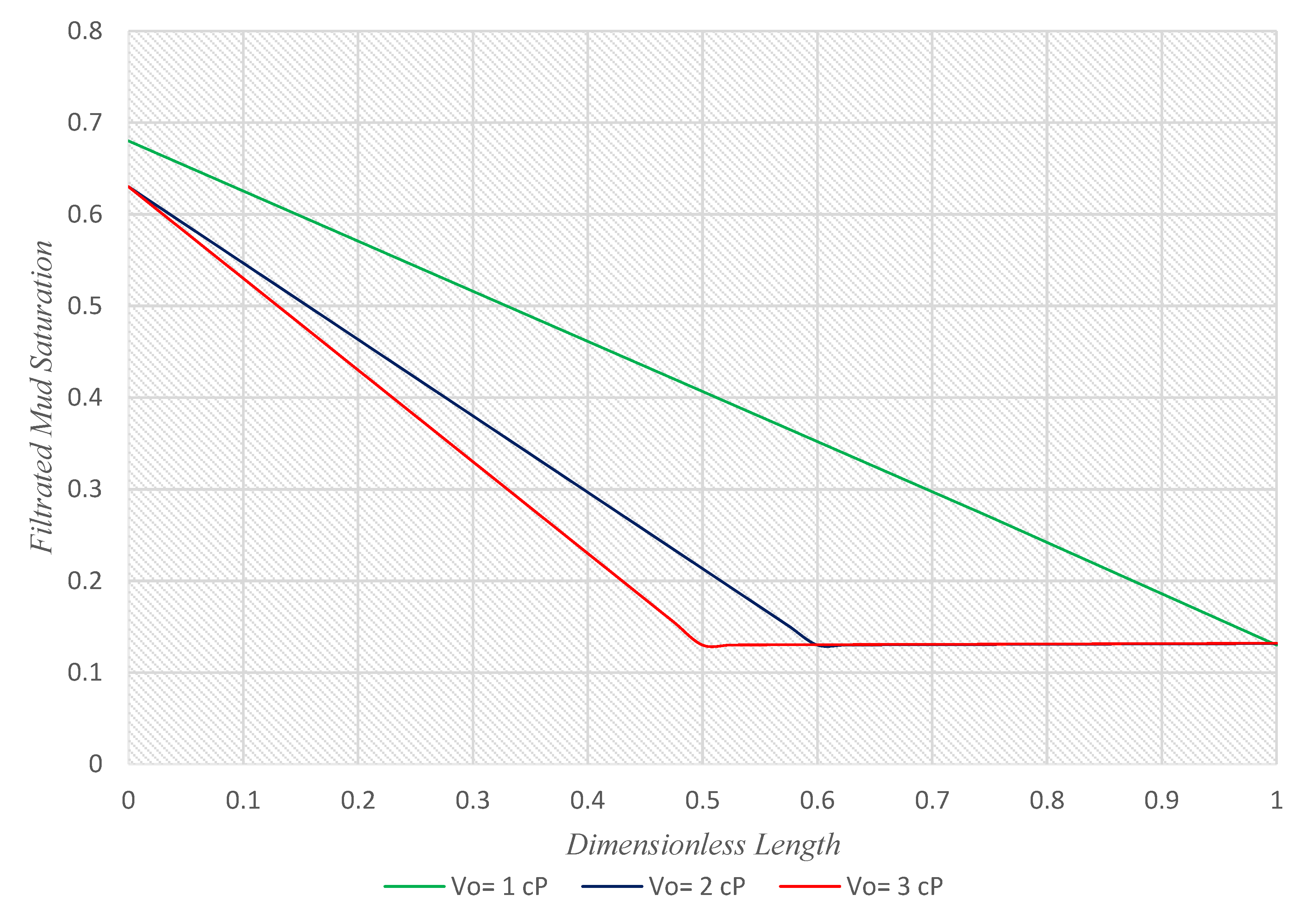

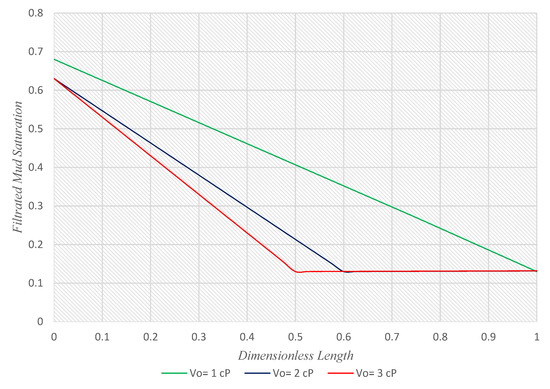

As oil viscosity is one of the crucial parameters to define the presence of oil and other phases in porous media, it is necessary to provide a sensitivity analysis on this parameter to nurture a better understanding of filtrated mud saturation in different viscosities. To do this, three different percentages of oil viscosity 1 cP, 2 cP, and 3 cP, were considered in the developed model. As can be seen in Figure 4, for all three oil viscosity values, the filtrated mud saturation started from approximately 0.7. This means that the maximum saturation for filtrated mud is about 0.7. By increasing the core length, saturation will be decreased gradually to reach its minimum value of relatively 0.1. At higher oil viscosities, due to the greater mobilization of oil through the porous media, the filtrated mud saturation decrease through the core length would be slightly more. Therefore, at the oil viscosity of 3 cP, the decrease rate of filtrated mud saturation is slower than other oil viscosities, which indicated the invasion of more filtrated mud into the formation. Moreover, in high oil viscosities, regarding the lower capillary forces’ ability to penetrate drilling fluid into the formation, the formation damage will be decreased. Effect of oil viscosity was investigated by Bennion & Thomas (1994). They concluded that oil viscosity increase was considerably influenced the formation damage and led to a decrease in the filtrated mud saturation that is discussed in the proposed model [23].

Figure 4.

Oil viscosity effect on the filtrated mud saturation.

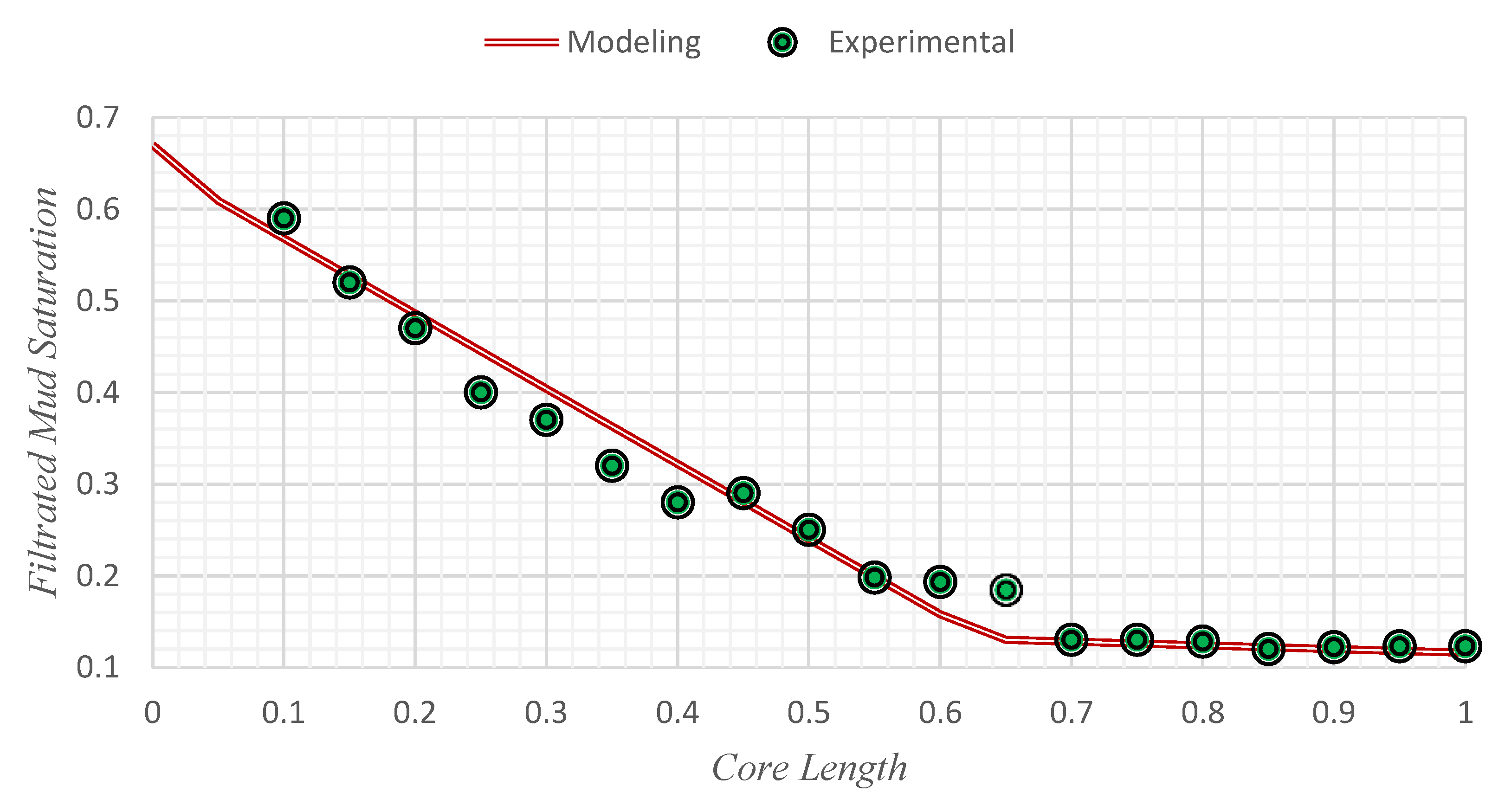

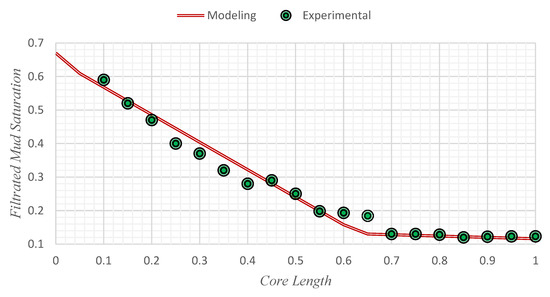

3.5. The Validity of the Proposed Model

In previous parts, different crucial parameters and their differentiation on the filtrated mud saturation were considered in the proposed model. To validate the proposed model, it should be compared with field data. To do this, CT data which was taken from one of the Iranian’s oilfield to validate the model were administered. As is shown in Figure 5, the results of the developed model were in good agreement with the CT data. Therefore, the proposed model would be a useful tool for reservoir and formation studies before field test operations [28].

Figure 5.

The validity of the proposed model with field data.

4. Conclusions

Formation damage effects are considered as one of the substantial factors, which were performed by drilling and completion procedures. They have led to reduced oil and gas recovery performances. In this paper, a developed model was proposed to predict the filtrated mud saturation impact on the formation damage. As the mass balance and fluid flow equations in porous media are difficult to solve, the implicit pressure explicit saturation method was used to address the mentioned issue more accurately. Four crucial parameters of oil viscosity, water saturation, permeability and porosity were sensitivity analyzed in this model to predict the filtrated mud saturation. To validate the model with field data, a collection of CT data was used to compare with the proposed model. They indicated that there was a good match between the model and CT data. Determination of filtrated mud saturation is one of the essential factors for petroleum industries to predict the formation damage during the underbalanced drilling operation. Therefore, accurate prediction of this parameter would eliminate the unnecessary expenses of fishing tools, directional wells to trap the damaged zone, and drilling inefficiencies during drilling operations. Due to the high costs and time-consuming process of the CT scan method to measure filtrated mud saturation, the proposed model in this study would help petroleum industries to predict filtrated mud saturation analytically and consider the effect of different parameters without high expenditures on CT scan tests. The main conclusions of this paper are as follows.

At lower porosities due to the fewer pore spaces through the bulk volume, the filtrated mud saturation decrease through the core length would be slightly more. Therefore, at the porosity of 0.2, the filtrated mud saturation decrease is slower than other porosities, which resulted in the capillary pressure reduction when the drilling fluid intended to penetrate the formation.

At lower permeabilities, due to the more fluid transfer conductivity through the porous media, the filtrated mud saturation decrease through the core length would be slightly more. Therefore, at the permeability of 2 mD, the decrease rate of filtrated mud saturation is slower than other permeabilities, which indicated the significant dependency of this parameter on the size of pore diameters, which is known as porosity.

At lower water saturations, due to the presence of more water volume through the porous media, the filtrated mud saturation decrease through the core length would be slightly more. Therefore, at the water saturation of 0.1, the decrease rate of filtrated mud saturation is slower than other water saturations, which indicated the invasion of more filtrated mud in the formation.

At higher oil viscosities, due to the mobilization of more oil through the porous media, the filtrated mud saturation decrease through the core length would be slightly more. Therefore, at the oil viscosity of 3 cP, the decrease rate of filtrated mud saturation is slower than other oil viscosities, which indicates the invasion of more filtrated mud into the formation.

Supplementary Materials

The following are available online at https://www.mdpi.com/2227-7390/8/7/1057/s1.

Author Contributions

Conceptualization, A.D.; Formal analysis, X.Z.; Methodology, M.Z.; Resources, X.Z.; Software, A.D.; Supervision, A.D.; Validation, M.Z.; Visualization, L.Y.; Writing–original draft, L.Y.; Writing–review & editing, A.D. All authors have read and agreed to the published version of the manuscript.

Funding

There is no financial support provided by any specific governmental and institutional organization to complete this manuscript.

Acknowledgments

MOE (Ministry of Education in China) Project of Humanities and Social Sciences (No. 16YJC790140).

Conflicts of Interest

The authors declare that they have no conflicts of interest.

Nomenclature

| Nomenclature | |

| B | Capillary pressure parameter |

| c | Coefficients of the penetration |

| Dm | Maximum value of the penetration coefficient |

| K | Absolute permeability |

| kr | Relative permeability |

| n | Coefficients of the penetration |

| P | Pressure |

| Pi | Formation initial pressure |

| S | Saturation |

| u | Velocity |

| Greek letters | |

| Porosity | |

| Tortuosity | |

| ρ | Density |

| φ | Cross-Section porosity |

| μ | Viscosity |

References

- Pedersen, T.; Godhavn, J.-M. Linear multivariable control of underbalanced-drilling operations. SPE Drill. Completion 2017, 32, 301–311. [Google Scholar] [CrossRef]

- Pedersen, T.; Aarsnes, U.J.F.; Godhavn, J.-M. Flow and pressure control of underbalanced drilling operations using NMPC. J. Process. Control. 2018, 68, 73–85. [Google Scholar] [CrossRef]

- Davarpanah, A.; Shirmohammadi, R.; Mirshekari, B.; Aslani, A. Analysis of hydraulic fracturing techniques: Hybrid fuzzy approaches. Arab. J. Geosci. 2019, 12, 402. [Google Scholar] [CrossRef]

- Davarpanah, A.; Mirshekari, B.; Behbahani, T.J.; Hemmati, M. Integrated production logging tools approach for convenient experimental individual layer permeability measurements in a multi-layered fractured reservoir. J. Pet. Technol. 2018, 8, 743–751. [Google Scholar] [CrossRef]

- Ojha, K.; Saxena, A.; Pathak, A. Underbalanced drilling and its advancements: An overview. J. Pet. Eng. Technol. 2019, 4, 37–51. [Google Scholar]

- Davarpanah, A.; Mirshekari, B. Mathematical modeling of injectivity damage with oil droplets in the waste produced water re-injection of the linear flow. Eur. Phys. J. Plus. 2019, 134, 180. [Google Scholar] [CrossRef]

- Davarpanah, A. The feasible visual laboratory investigation of formate fluids on the rheological properties of a shale formation. Environ. Sci. Technol. 2019, 16, 4783–4792. [Google Scholar] [CrossRef]

- Shi, H.; Song, H.; Zhao, H.; Chen, Z. Numerical Study of a Flow Field Near the Bit for a Coiled-Tubing Partial Underbalanced Drilling Method. J. Energy Resour. Technol. 2019, 141. [Google Scholar] [CrossRef]

- Davarpanah, A.; Mirshekari, B.; Razmjoo, A. A parametric study to numerically analyze the formation damage effect. Energy Explor. Exploit. 2020, 38, 555–568. [Google Scholar] [CrossRef]

- Li, X.; Ma, H.; Zhao, H.; Gao, D.; Lu, B.; Ding, S.; Gong, D.; Ma, Z. Study on the model for predicting maximum allowable measured depth of a horizontal well drilled with underbalanced operation. J. Pet. Sci. Eng. 2020, 191, 107104. [Google Scholar] [CrossRef]

- Davarpanah, A.; Mirshekari, B. Effect of formate fluids on the shale stabilization of shale layers. Energy Rep. 2019, 5, 987–992. [Google Scholar] [CrossRef]

- Mendes Sales, I.; Alexandre Martinello, I.; Couto Lemgruber Kropf, T.; Mesquita Caetano, L.; Alonso Fernandes, A.; Loures Sa, L. Wireline Logging in Managed Pressure Drilling Well on a DP Rig. In Proceedings of the IADC/SPE Managed Pressure Drilling and Underbalanced Operations Conference and Exhibition, Amsterdam, The Netherlands, 9–10 April 2019. [Google Scholar]

- Rabbani, E.; Davarpanah, A.; Memariani, M. An experimental study of acidizing operation performances on the wellbore productivity index enhancement. J. Pet. Technol. 2018, 8, 1243–1253. [Google Scholar] [CrossRef]

- Davarpanah, A. Feasible analysis of reusing flowback produced water in the operational performances of oil reservoirs. Environ. Sci. Pollut. Res. 2018, 25, 35387–35395. [Google Scholar] [CrossRef]

- Okwu, M.O.; Nwachukwu, A.N. A review of fuzzy logic applications in petroleum exploration, production and distribution operations. J. Pet. Explor. Prod. Technol. 2019, 9, 1555–1568. [Google Scholar] [CrossRef]

- Santos, H.; Queiroz, J. How effective is underbalanced drilling at preventing formation damage? In Proceedings of the SPE International Symposium on Formation Damage Control, Lafayette, LA, USA, 23–24 February 2000. [Google Scholar]

- Qutob, H. Underbalanced drilling; remedy for formation damage, lost circulation, & other related conventional drilling problems. In Proceedings of the Abu Dhabi International Conference and Exhibition, Abu Dhabi, UAE, 10–13 October 2004. [Google Scholar]

- Salehi, S.; Hareland, G.; Nygaard, R. Numerical simulations of wellbore stability in under-balanced-drilling wells. J. Pet. Sci. Eng. 2010, 72, 229–235. [Google Scholar] [CrossRef]

- Salimi, S.; Ghalambor, A.; Tronvoll, J.; Andersen, K.I. A Simple Analytical Approach to Simulate Underbalanced-drilling in Naturally Fractured Reservoirs—The Effect of Short Overbalanced Conditions and Time Effect. Energies 2010, 3, 1639–1653. [Google Scholar] [CrossRef]

- Xiao, B.; Wang, W.; Zhang, X.; Long, G.; Fan, J.; Chen, H.; Deng, L. A novel fractal solution for permeability and Kozeny-Carman constant of fibrous porous media made up of solid particles and porous fibers. Powder Technol. 2019, 349, 92–98. [Google Scholar] [CrossRef]

- Xiao, B.; Wang, S.; Wang, Y.; Jiang, G.; Zhang, Y.; Chen, H.; Liang, M.; Long, G.; Chen, X. Effective thermal conductivity of porous media with roughened surfaces by Fractal-Monte Carlo simulations. Fractals 2020, 28, 2050029. [Google Scholar] [CrossRef]

- Long, G.; Liu, S.; Xu, G.; Wong, S.W.; Chen, H.; Xiao, B. A Perforation-Erosion Model for Hydraulic-Fracturing Applications. SPE Prod. Oper. 2020, 33, 770–783. [Google Scholar] [CrossRef]

- Bennion, D.; Thomas, F. Underbalanced drilling of horizontal wells: Does it really eliminate formation damage? In Proceedings of the SPE Formation Damage Control Symposium, Lafayette, LA, USA, 7–10 February 1994. [Google Scholar]

- Byrne, M.; Patey, I. Formation Damage Laboratory Testing—A Discussion of Key Parameters, Pitfalls and Potential. In Proceedings of the SPE European Formation Damage Conference, Hague, The Netherlands, 13–14 May 2003; p. 9. [Google Scholar]

- Sedaghatzadeh, M.; Shahbazi, K.; Ghazanfari, M.H.; Zargar, G. The impact of nanoparticles geometry and particle size on formation damage induced by drilling nano-fluid during dynamic filtration. J. Nano Res. 2016, 43, 81–97. [Google Scholar] [CrossRef]

- Shi, H.-Z.; Ji, Z.-S.; Zhao, H.-Q.; Song, H.-Y.; Chen, Z.-L.J. Investigations into the coiled tubing partial underbalanced drilling (CT-PUBD) technique for drilling hard formations. Pet. Sci. 2018, 15, 830–840. [Google Scholar] [CrossRef]

- Ezeakacha, C.P.; Salehi, S.; Ghalambor, A.; Bi, H. Investigating Impact of Rock Type and Lithology on Mud Invasion and Formation Damage. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 7–9 February 2018; p. 15. [Google Scholar]

- Liu, W.; Zhou, Y.; Zhu, X.; Meng, X.; Liu, M.; Wahab, M.A. Numerical modelling of bottom-hole rock in underbalanced drilling using thermo-poroelastoplasticity model. Struct. Eng. Mech. 2019, 69, 537–545. [Google Scholar]

- Perrin, J.-C.; Benson, S. An experimental study on the influence of sub-core scale heterogeneities on CO2 distribution in reservoir rocks. Transport. Porous Media 2010, 82, 93–109. [Google Scholar] [CrossRef]

- Akin, S.; Kovscek, A. Imbibition studies of low-permeability porous media. In Proceedings of the SPE Western Regional Meeting, Anchorage, AL, USA, 26–27 May 1999. [Google Scholar]

- Khakshour, M. Experimental Investigation of Formation Damage in UBD. Master’s Thesis, Petroleum University of Technology, Ahwaz, Iran, 2010. [Google Scholar]

- Zhang, J. Effects of porosity and permeability on invasion depth during drilling mud-filtrate invading into a reservoir dynamically. In Proceedings of the 7th International Conference on Education, Management, Information and Mechanical Engineering (EMIM 2017), Shenyang, China, 28–30 April 2017; Atlantis Press: Paris, France, 2017. [Google Scholar]

- Costa, A. Permeability-porosity relationship: A reexamination of the Kozeny-Carman equation based on a fractal pore-space geometry assumption. Geophys. Res. Lett. 2006, 33. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).