Polyethylene and Semiconducting Polymer Blends for the Fabrication of Organic Field-Effect Transistors: Balancing Charge Transport and Stretchability

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Measurements and Characterization

2.3. Polymer Blend Preparation

2.4. Device Fabrication and Characterization

2.5. Transfer-Printed Organic Field-Effect Transistor Fabrication

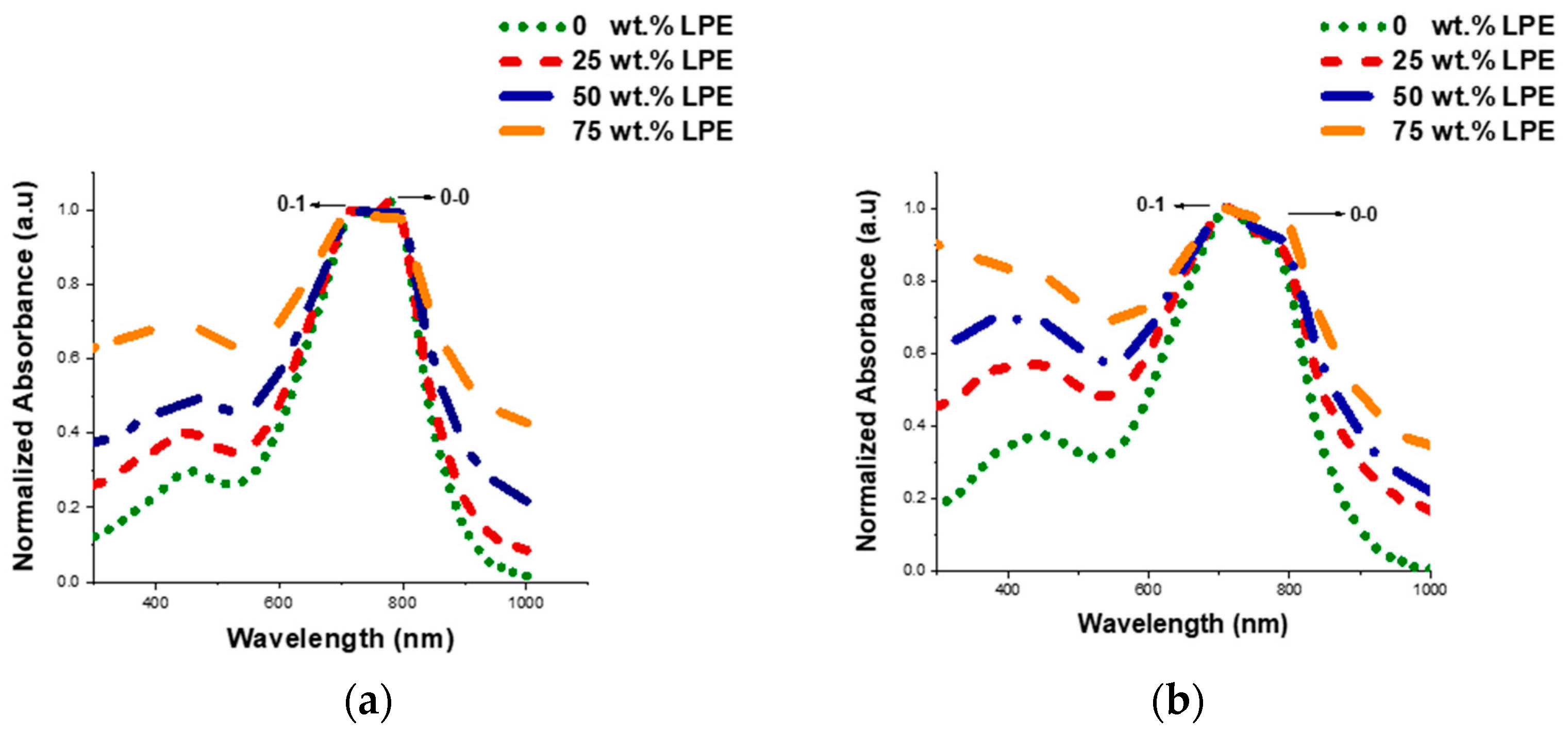

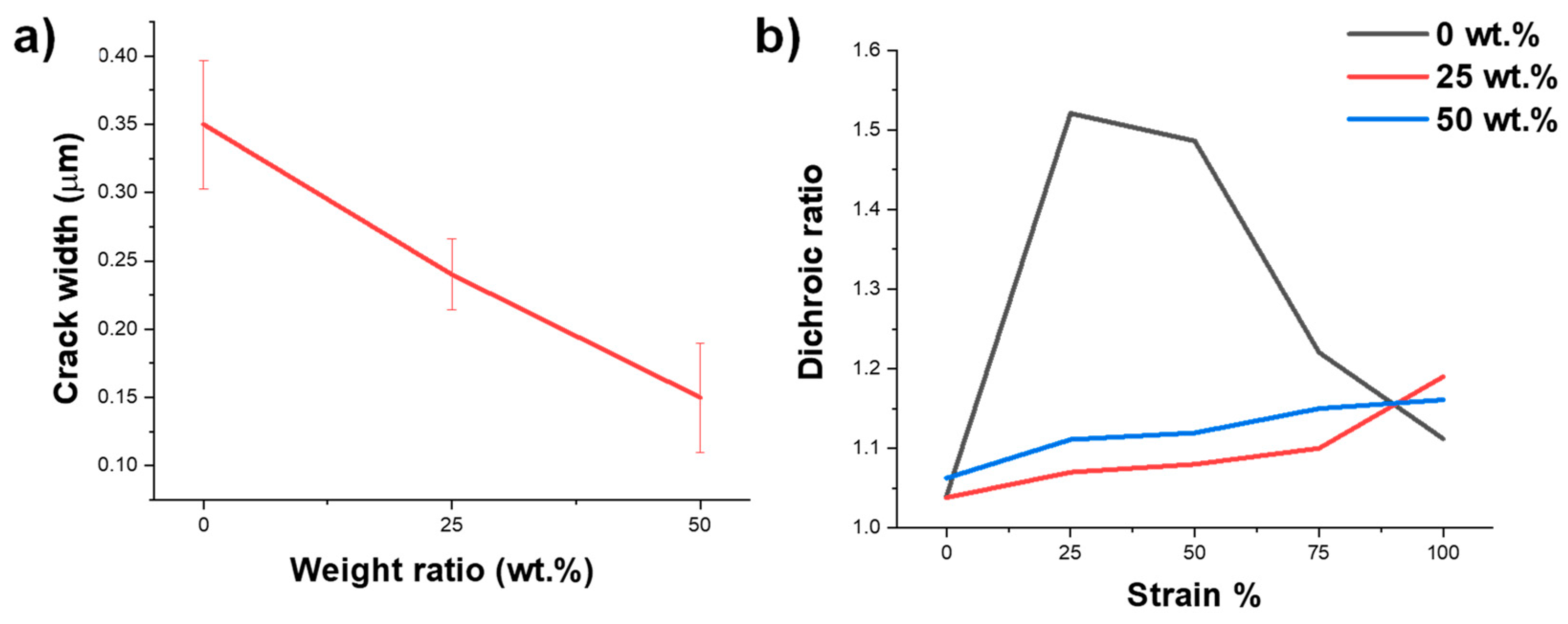

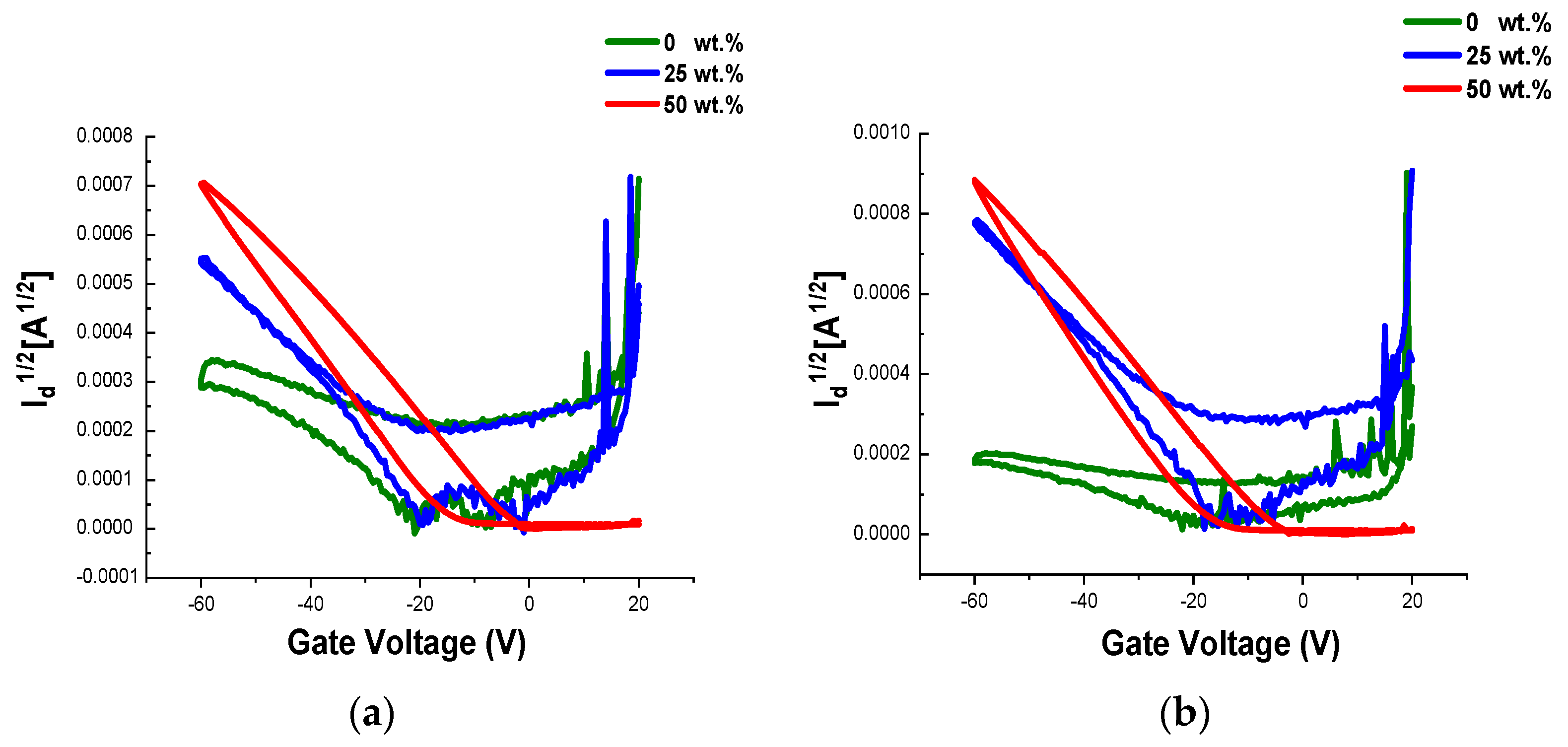

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Markovic, G.; Visakh, P.M. 1-Polymer Blends: State of Art. In Recent Developments in Polymer Macro, Micro and Nano Blends; Visakh, P.M., Markovic, G., Pasquini, D., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 1–15. [Google Scholar]

- Paul, D.R.; Barlow, J.W. Polymer Blends. J. Macromol. Sci. Part C 1980, 18, 109–168. [Google Scholar] [CrossRef]

- Yu, L.; Dean, K.; Li, L. Polymer Blends and Composites from Renewable Resources. Prog. Polym. Sci. 2006, 31, 576–602. [Google Scholar] [CrossRef]

- Dutta, D.; Fruitwala, H.; Kohli, A.; Weiss, R.A. Polymer Blends Containing Liquid Crystals: A Review. Polym. Eng. Sci. 1990, 30, 1005–1018. [Google Scholar] [CrossRef]

- McNeill, C.R.; Greenham, N.C. Conjugated-Polymer Blends for Optoelectronics. Adv. Mater. 2009, 21, 3840–3850. [Google Scholar] [CrossRef]

- Shaw, P.E.; Wolfer, P.; Langley, B.; Burn, P.L.; Meredith, P. Impact of Acceptor Crystallinity on the Photophysics of Nonfullerene Blends for Organic Solar Cells. J. Phys. Chem. C 2014, 118, 13460–13466. [Google Scholar] [CrossRef]

- Claudia Arias, A. Vertically Segregated Polymer Blends: Their Use in Organic Electronics. J. Macromol. Sci. Part C 2006, 46, 103–125. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, Y.H.; Ha, Y.H.; Kwon, J.; Pyo, S.; Kim, Y.-H.; Hyoung Lee, W. Semiconducting/Insulating Polymer Blends with Dual Phase Separation for Organic Field-Effect Transistors. RSC Adv. 2017, 7, 7526–7530. [Google Scholar] [CrossRef] [Green Version]

- Riera-Galindo, S.; Leonardi, F.; Pfattner, R.; Mas-Torrent, M. Organic Semiconductor/Polymer Blend Films for Organic Field-Effect Transistors. Adv. Mater. Technol. 2019, 4, 1900104. [Google Scholar] [CrossRef]

- Zhu, S.; Liu, Y.; Rafailovich, M.H.; Sokolov, J.; Gersappe, D.; Winesett, D.A.; Ade, H. Confinement-Induced Miscibility in Polymer Blends. Nature 1999, 400, 49–51. [Google Scholar] [CrossRef]

- Yim, K.-H.; Zheng, Z.; Friend, R.H.; Huck, W.T.S.; Kim, J.-S. Surface-Directed Phase Separation of Conjugated Polymer Blends for Efficient Light-Emitting Diodes. Adv. Funct. Mater. 2008, 18, 2897–2904. [Google Scholar] [CrossRef]

- Xu, J.; Wang, S.; Wang, G.-J.N.; Zhu, C.; Luo, S.; Jin, L.; Gu, X.; Chen, S.; Feig, V.R.; To, J.W.F.; et al. Highly Stretchable Polymer Semiconductor Films through the Nanoconfinement Effect. Science 2017, 355, 59–64. [Google Scholar] [CrossRef]

- Ko, J.; Kim, Y.; Kang, J.S.; Berger, R.; Yoon, H.; Char, K. Enhanced Vertical Charge Transport of Homo- and Blended Semiconducting Polymers by Nanoconfinement. Adv. Mater. 2020, 32, 1908087. [Google Scholar] [CrossRef]

- Nikzad, S.; Wu, H.-C.; Kim, J.; Mahoney, C.M.; Matthews, J.R.; Niu, W.; Li, Y.; Wang, H.; Chen, W.-C.; Toney, M.F.; et al. Inducing Molecular Aggregation of Polymer Semiconductors in a Secondary Insulating Polymer Matrix to Enhance Charge Transport. Chem. Mater. 2020, 32, 897–905. [Google Scholar] [CrossRef]

- Liu, D.; Ding, Z.; Wu, Y.; Liu, S.F.; Han, Y.; Zhao, K. In Situ Study of Molecular Aggregation in Conjugated Polymer/Elastomer Blends toward Stretchable Electronics. Macromolecules 2022, 55, 297–308. [Google Scholar] [CrossRef]

- Zhang, G.; McBride, M.; Persson, N.; Lee, S.; Dunn, T.J.; Toney, M.F.; Yuan, Z.; Kwon, Y.-H.; Chu, P.-H.; Risteen, B.; et al. Versatile Interpenetrating Polymer Network Approach to Robust Stretchable Electronic Devices. Chem. Mater. 2017, 29, 7645–7652. [Google Scholar] [CrossRef]

- Zhang, S.; Cheng, Y.-H.; Galuska, L.; Roy, A.; Lorenz, M.; Chen, B.; Luo, S.; Li, Y.-T.; Hung, C.-C.; Qian, Z.; et al. Tacky Elastomers to Enable Tear-Resistant and Autonomous Self-Healing Semiconductor Composites. Adv. Funct. Mater. 2020, 30, 2000663. [Google Scholar] [CrossRef]

- Selivanova, M.; Coady, M.J.; Pignanelli, J.; Ocheje, M.U.; Schlingman, K.; Malik, A.; Prado, M.; Rondeau-Gagné, S. Crack Propagation and Electronic Properties of Semiconducting Polymer and Siloxane-Urea Copolymer Blends. Flex. Print. Electron. 2020, 5, 035001. [Google Scholar] [CrossRef]

- Chang, M.; Su, Z.; Egap, E. Alignment and Charge Transport of One-Dimensional Conjugated Polymer Nanowires in Insulating Polymer Blends. Macromolecules 2016, 49, 9449–9456. [Google Scholar] [CrossRef]

- Sauter, D.W.; Taoufik, M.; Boisson, C. Polyolefins, a Success Story. Polymers 2017, 9, 185. [Google Scholar] [CrossRef] [Green Version]

- Xie, K.; Xu, J.; Liu, P. Effect of ligands in TiCl3(OAr) catalysts for ethylene polymerization: Computational and experimental studies. Appl. Surf. Sci. 2018, 461, 175–181. [Google Scholar] [CrossRef]

- Xie, K.; Xu, S.; Hao, W.; Wang, J.; Huang, A.; Zhang, Y. Surface effect of the MgCl2 support in Ziegler–Natta catalyst for ethylene polymerization: A computational study. Appl. Surf. Sci. 2022, 589, 153002. [Google Scholar] [CrossRef]

- Su, E.; Gao, W.; Hu, X.; Zhang, C.; Zhu, B.; Jia, J.; Huang, A.; Bai, Y. Preparation of Ultrahigh Molecular Weight Polyethylene/Graphene Nanocomposite In Situ Polymerization via Spherical and Sandwich Structure Graphene/Sio2 Support. Nanoscale Res. Lett. 2018, 13, 105. [Google Scholar] [CrossRef] [PubMed]

- Selivanova, M.; Chuang, C.-H.; Billet, B.; Malik, A.; Xiang, P.; Landry, E.; Chiu, Y.-C.; Rondeau-Gagné, S. Morphology and Electronic Properties of Semiconducting Polymer and Branched Polyethylene Blends. ACS Appl. Mater. Interfaces 2019, 11, 12723–12732. [Google Scholar] [CrossRef] [PubMed]

- Selivanova, M.; Zhang, S.; Billet, B.; Malik, A.; Prine, N.; Landry, E.; Gu, X.; Xiang, P.; Rondeau-Gagné, S. Branched Polyethylene as a Plasticizing Additive to Modulate the Mechanical Properties of π-Conjugated Polymers. Macromolecules 2019, 52, 7870–7877. [Google Scholar] [CrossRef]

- Wu, Y.; Ocheje, M.U.; Mechael, S.S.; Wang, Y.; Landry, E.; Gu, X.; Xiang, P.; Carmichael, T.B.; Rondeau-Gagné, S. From Chlorinated Solvents to Branched Polyethylene: Solvent-Induced Phase Separation for the Greener Processing of Semiconducting Polymers. Adv. Electron. Mater. 2022, 8, 2100928. [Google Scholar] [CrossRef]

- Zalesskiy, S.S.; Ananikov, V.P. Pd2(dba)3 as a Precursor of Soluble Metal Complexes and Nanoparticles: Determination of Palladium Active Species for Catalysis and Synthesis. Organometallics 2012, 31, 2302–2309. [Google Scholar] [CrossRef]

- Yu, H.; Park, K.H.; Song, I.; Kim, M.-J.; Kim, Y.-H.; Oh, J.H. Effect of the Alkyl Spacer Length on the Electrical Performance of Diketopyrrolopyrrole-Thiophene Vinylene Thiophene Polymer Semiconductors. J. Mater. Chem. C 2015, 3, 11697–11704. [Google Scholar] [CrossRef]

- Ito, Y.; Virkar, A.A.; Mannsfeld, S.; Oh, J.H.; Toney, M.; Locklin, J.; Bao, Z. Crystalline Ultrasmooth Self-Assembled Monolayers of Alkylsilanes for Organic Field-Effect Transistors. J. Am. Chem. Soc. 2009, 131, 9396–9404. [Google Scholar] [CrossRef]

- Wu, H.-C.; Benight, S.J.; Chortos, A.; Lee, W.-Y.; Mei, J.; To, J.W.F.; Lu, C.; He, M.; Tok, J.B.-H.; Chen, W.-C.; et al. Rapid and Facile Soft Contact Lamination Method: Evaluation of Polymer Semiconductors for Stretchable Transistors. Chem. Mater. 2014, 26, 4544–4551. [Google Scholar] [CrossRef]

- Chen, S.; Meng, Y.; Li, Y.; Qu, B.; Zhuo, D. Effect of the Length and Branching Point of Alkyl Side Chains on DPP-Thieno[3,2-b]Thiophene Copolymers for Organic Thin-Film Transistors. Opt. Mater. 2019, 88, 500–507. [Google Scholar] [CrossRef]

- Ocheje, M.U.; Charron, B.P.; Cheng, Y.-H.; Chuang, C.-H.; Soldera, A.; Chiu, Y.-C.; Rondeau-Gagné, S. Amide-Containing Alkyl Chains in Conjugated Polymers: Effect on Self-Assembly and Electronic Properties. Macromolecules 2018, 51, 1336–1344. [Google Scholar] [CrossRef]

- Kang, S.-H.; Lee, H.R.; Dutta, G.K.; Lee, J.; Oh, J.H.; Yang, C. A Role of Side-Chain Regiochemistry of Thienylene–Vinylene–Thienylene (TVT) in the Transistor Performance of Isomeric Polymers. Macromolecules 2017, 50, 884–890. [Google Scholar] [CrossRef]

- Moliton, A.; Hiorns, R.C. Review of Electronic and Optical Properties of Semiconductingπ-Conjugated Polymers: Applications in Optoelectronics. Polym. Int. 2004, 53, 1397–1412. [Google Scholar] [CrossRef]

- Schroeder, B.C.; Kurosawa, T.; Fu, T.; Chiu, Y.-C.; Mun, J.; Wang, G.-J.N.; Gu, X.; Shaw, L.; Kneller, J.W.E.; Kreouzis, T.; et al. Taming Charge Transport in Semiconducting Polymers with Branched Alkyl Side Chains. Adv. Funct. Mater. 2017, 27, 1701973. [Google Scholar] [CrossRef] [Green Version]

- Ge, F.; Wei, S.; Liu, Z.; Wang, G.; Wang, X.; Zhang, G.; Lu, H.; Cho, K.; Qiu, L. Tailoring Structure and Field-Effect Characteristics of Ultrathin Conjugated Polymer Films via Phase Separation. ACS Appl. Mater. Interfaces 2018, 10, 9602–9611. [Google Scholar] [CrossRef]

- Sun, B.; Hong, W.; Aziz, H.; Li, Y. Diketopyrrolopyrrole-Based Semiconducting Polymer Bearing Thermocleavable Side Chains. J. Mater. Chem. 2012, 22, 18950. [Google Scholar] [CrossRef]

- Charron, B.P.; Ocheje, M.U.; Selivanova, M.; Hendsbee, A.D.; Li, Y.; Rondeau-Gagné, S. Electronic Properties of Isoindigo-Based Conjugated Polymers Bearing Urea-Containing and Linear Alkyl Side Chains. J. Mater. Chem. C 2018, 6, 12070–12078. [Google Scholar] [CrossRef]

- Luzio, A.; Nübling, F.; Martin, J.; Fazzi, D.; Selter, P.; Gann, E.; McNeill, C.R.; Brinkmann, M.; Hansen, M.R.; Stingelin, N.; et al. Microstructural Control Suppresses Thermal Activation of Electron Transport at Room Temperature in Polymer Transistors. Nat. Commun. 2019, 10, 3365. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Ocheje, M.U.; Luo, S.; Ehlenberg, D.; Appleby, B.; Weller, D.; Zhou, D.; Rondeau-Gagné, S.; Gu, X. Probing the Viscoelastic Property of Pseudo Free-Standing Conjugated Polymeric Thin Films. Macromol. Rapid Commun. 2018, 39, 1800092. [Google Scholar] [CrossRef]

- Sirringhaus, H.; Wilson, R.J.; Friend, R.H.; Inbasekaran, M.; Wu, W.; Woo, E.P.; Grell, M.; Bradley, D.D.C. Mobility Enhancement in Conjugated Polymer Field-Effect Transistors through Chain Alignment in a Liquid-Crystalline Phase. Appl. Phys. Lett. 2000, 77, 406–408. [Google Scholar] [CrossRef]

- Brinkmann, M.; Hartmann, L.; Biniek, L.; Tremel, K.; Kayunkid, N. Orienting Semi-Conducting π-Conjugated Polymers. Macromol. Rapid Commun. 2014, 35, 9–26. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Alesadi, A.; Mason, G.T.; Chen, K.-L.; Freychet, G.; Galuska, L.; Cheng, Y.-H.; Onge, P.B.J.S.; Ocheje, M.U.; Ma, G.; et al. Molecular Origin of Strain-Induced Chain Alignment in PDPP-Based Semiconducting Polymeric Thin Films. Adv. Funct. Mater. 2021, 31, 2100161. [Google Scholar] [CrossRef]

- Heikenfeld, J.; Jajack, A.; Rogers, J.; Gutruf, P.; Tian, L.; Pan, T.; Li, R.; Khine, M.; Kim, J.; Wang, J.; et al. Wearable Sensors: Modalities, Challenges, and Prospects. Lab. Chip 2018, 18, 217–248. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Okabe, Y. Development and Application of Low-Temperature Curable Isotropic Conductive Adhesive Toward to Fabrication in IoT Generation; IntechOpen: London, UK, 2017. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kulatunga, P.; Yousefi, N.; Rondeau-Gagné, S. Polyethylene and Semiconducting Polymer Blends for the Fabrication of Organic Field-Effect Transistors: Balancing Charge Transport and Stretchability. Chemosensors 2022, 10, 201. https://doi.org/10.3390/chemosensors10060201

Kulatunga P, Yousefi N, Rondeau-Gagné S. Polyethylene and Semiconducting Polymer Blends for the Fabrication of Organic Field-Effect Transistors: Balancing Charge Transport and Stretchability. Chemosensors. 2022; 10(6):201. https://doi.org/10.3390/chemosensors10060201

Chicago/Turabian StyleKulatunga, Piumi, Nastaran Yousefi, and Simon Rondeau-Gagné. 2022. "Polyethylene and Semiconducting Polymer Blends for the Fabrication of Organic Field-Effect Transistors: Balancing Charge Transport and Stretchability" Chemosensors 10, no. 6: 201. https://doi.org/10.3390/chemosensors10060201

APA StyleKulatunga, P., Yousefi, N., & Rondeau-Gagné, S. (2022). Polyethylene and Semiconducting Polymer Blends for the Fabrication of Organic Field-Effect Transistors: Balancing Charge Transport and Stretchability. Chemosensors, 10(6), 201. https://doi.org/10.3390/chemosensors10060201