Laser-Scribed Pencil Lead Electrodes for Amperometric Quantification of Indapamide

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reagents

2.2. Pencil-Lead Electrodes Laser Treatment

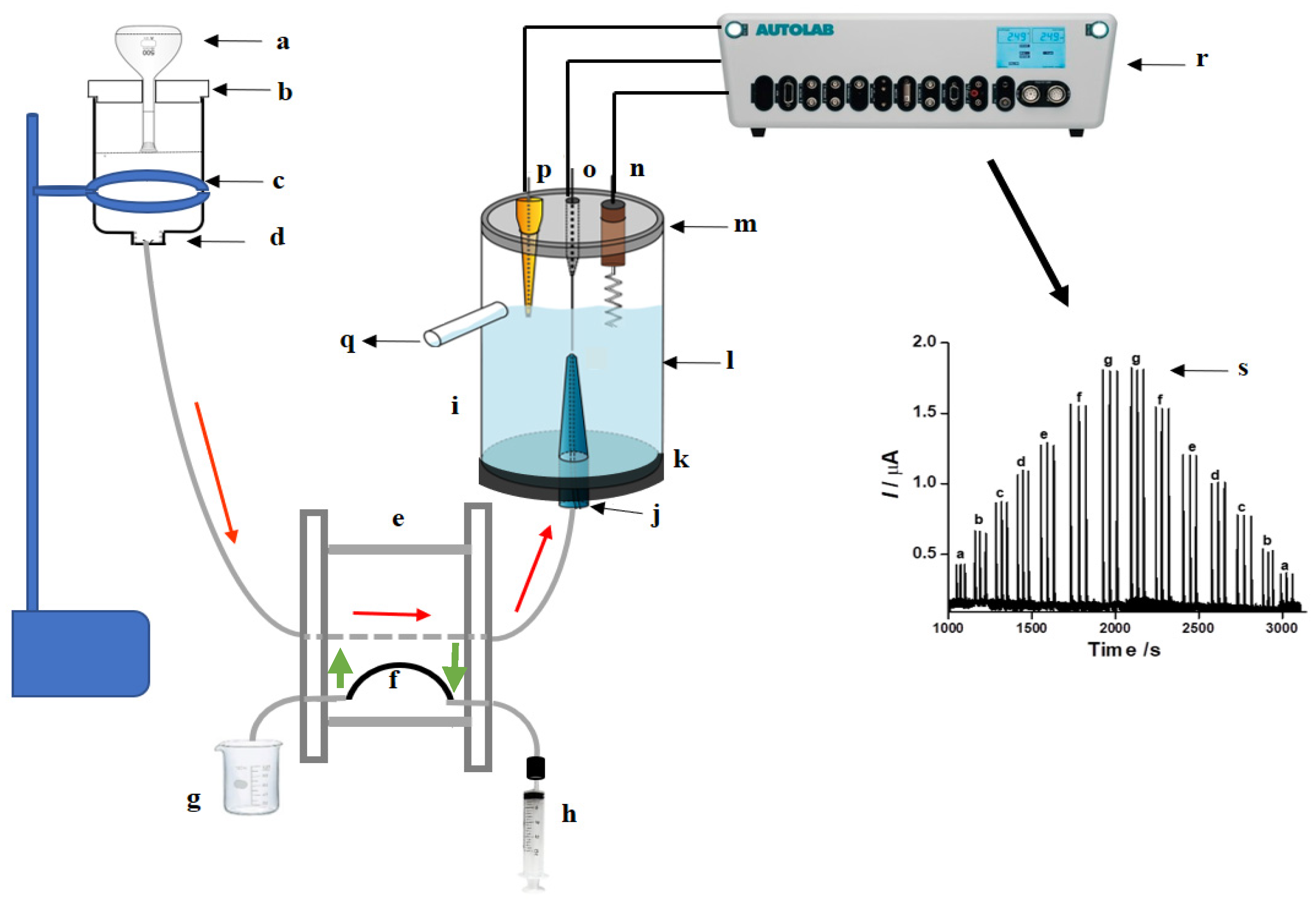

2.3. Electrochemical Measurements

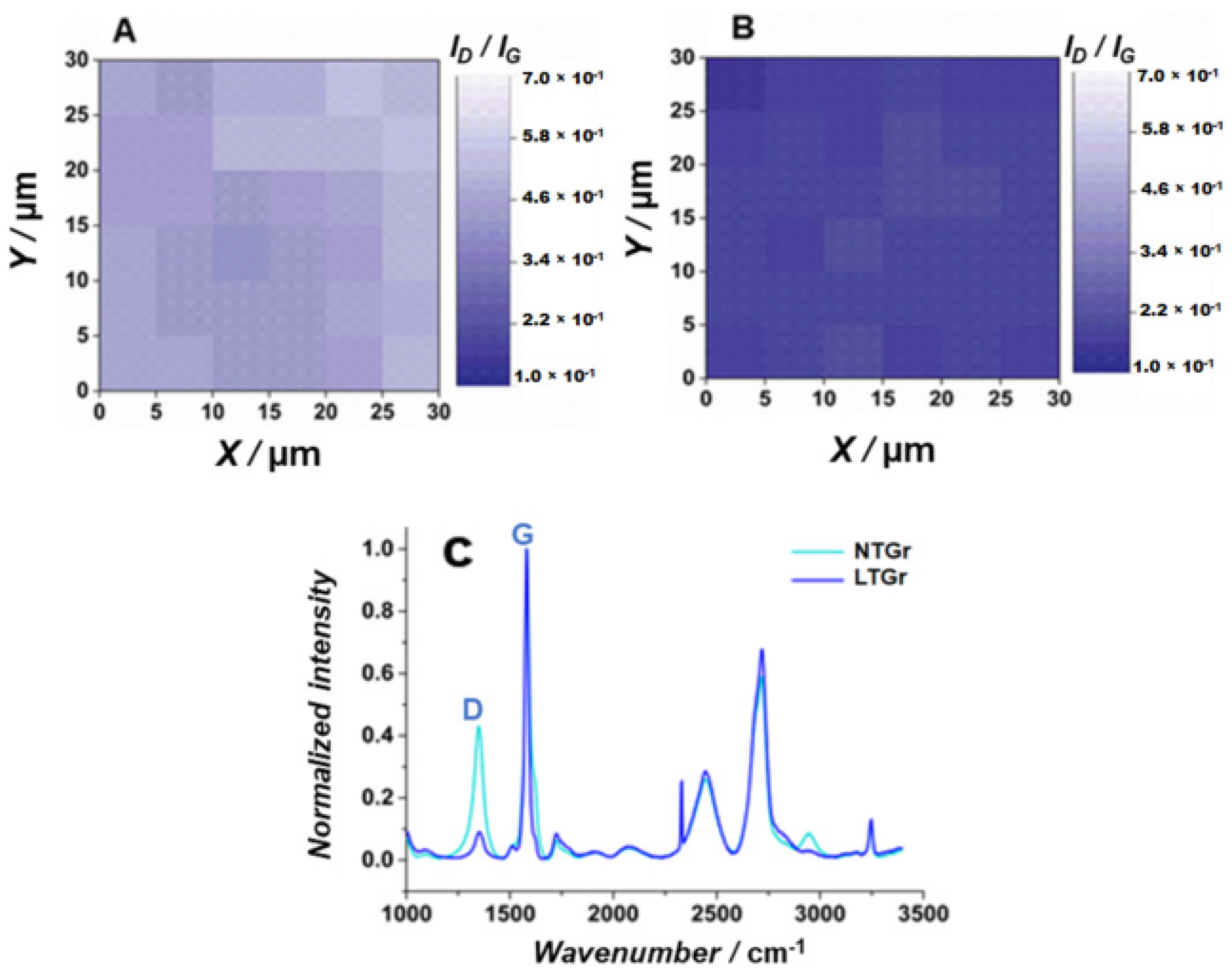

2.4. Raman Spectroscopy

2.5. Scanning Electron Microscopy

2.6. Flow Injection Analysis (FIA)

3. Results and Discussion

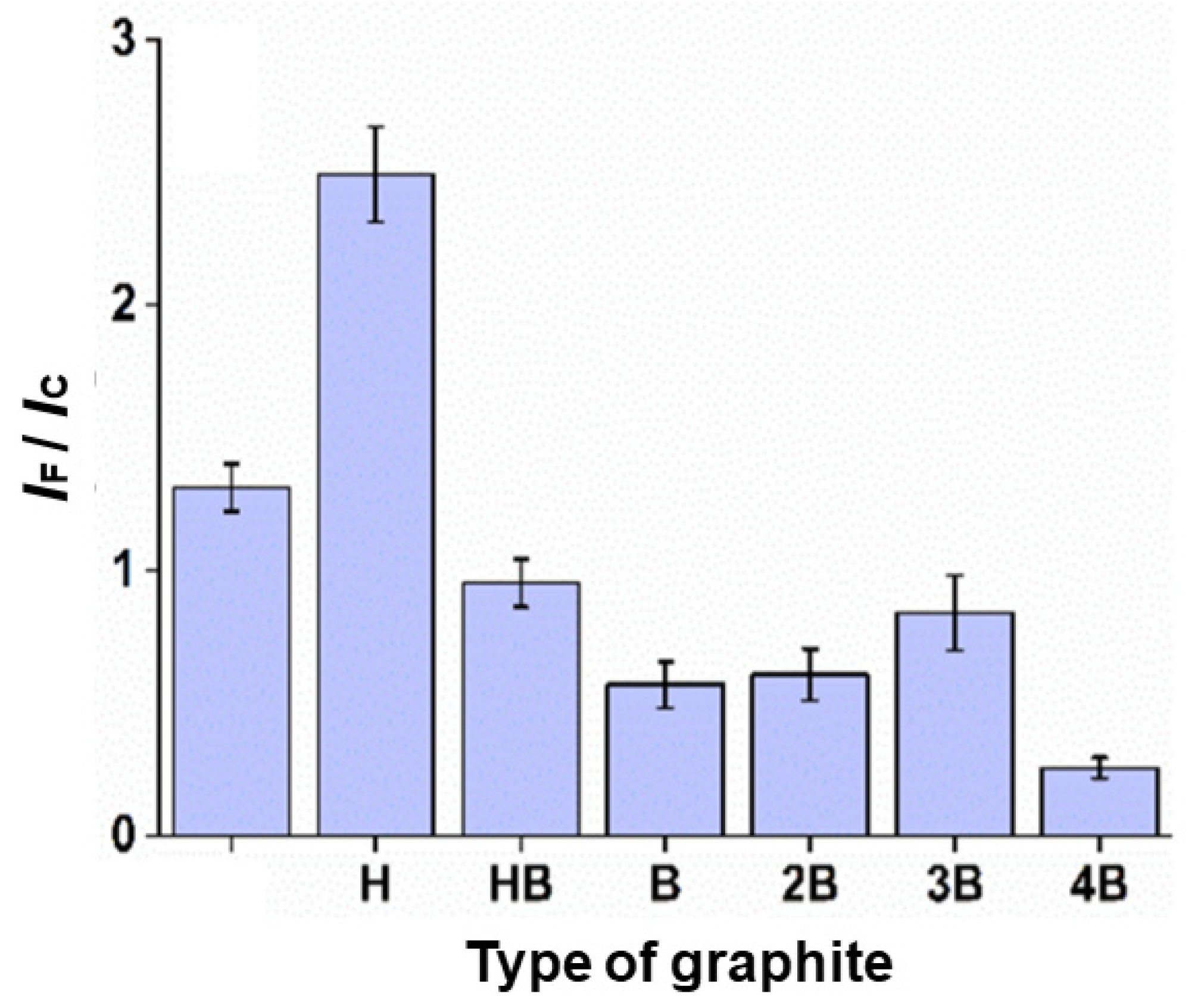

3.1. Fabrication of the Laser-Scribing-Treated Pencil-Lead Electrode

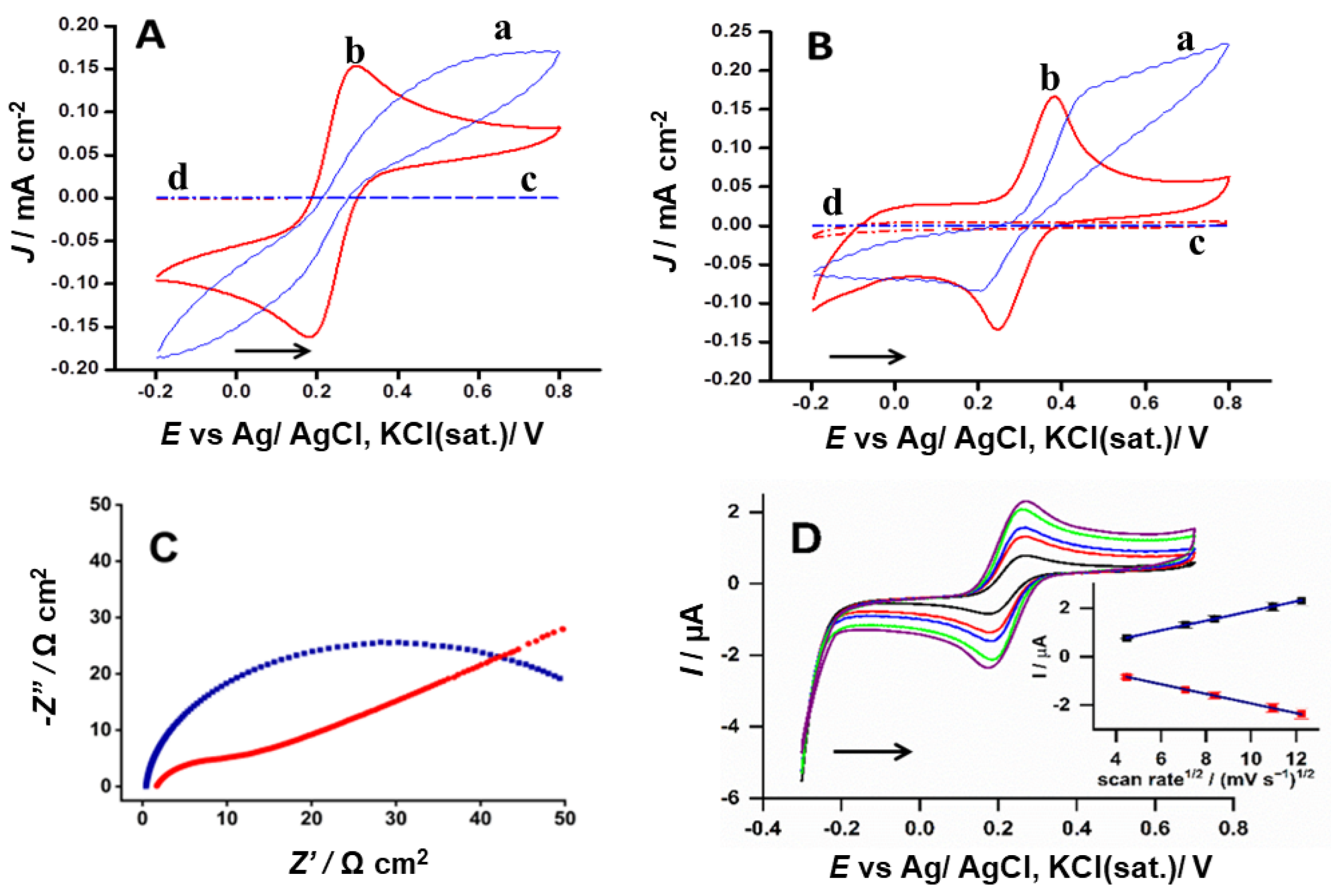

3.2. Laser-Treated Pencil Lead Characterization

3.3. Amperometric Detection of Indapamide Using the FIA Technique

3.3.1. Optimization of System Conditions FIA

3.3.2. FIA Parameters for Quantification of Indapamide

3.3.3. Quantification of Indapamide in Synthetic Urine

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ameku, W.A.; Negahdary, M.; Lima, I.S.; Santos, B.G.; Oliveira, T.G.; Paixão, T.R.L.C.; Angnes, L. Laser-Scribed Graphene-Based Electrochemical Sensors: A Review. Chemosensors 2022, 10, 505. [Google Scholar] [CrossRef]

- Mendes, L.F.; Pradela-Filho, L.A.; Paixão, T.R.L.C. Polyimide Adhesive Tapes as a Versatile and Disposable Substrate to Produce CO2 Laser-Induced Carbon Sensors for Batch and Microfluidic Analysis. Microchem. J. 2022, 182, 107893. [Google Scholar] [CrossRef]

- Kavai, M.S.; de Lima, L.F.; de Araujo, W.R. A Disposable and Low-Cost Laser-Scribed Graphene Electrochemical Sensor for Simultaneous Detection of Hydroquinone, Paracetamol and Methylparaben. Mater. Lett. 2023, 330, 133211. [Google Scholar] [CrossRef]

- Devi, M.; Wang, H.; Moon, S.; Sharma, S.; Volker Strauss, V. Laser-Carbonization—A Powerful Tool for Micro-Fabrication of Patterned Electronic Carbons. Adv. Mater. 2023, 35, 2211054. [Google Scholar]

- Richter, E.M.; Rocha, D.P.; Cardoso, R.M.; Keefe, E.M.; Foster, C.W.; Munoz, R.A.A.; Banks, C.E. Complete Additively Manufactured (3D-Printed) Electrochemical Sensing Platform. Anal. Chem. 2019, 91, 12844–12851. [Google Scholar] [CrossRef] [PubMed]

- Murilo Santhiago, M.; Strauss, M.; Pereira, M.P.; Chagas, A.S.; Bufon, C.C.B. Direct Drawing Method of Graphite onto Paper for High-Performance Flexible Electrochemical Sensors. ACS Appl. Mater. Interfaces 2017, 9, 11959–11966. [Google Scholar] [CrossRef] [PubMed]

- Alba, A.F.; Totoricaguena-Gorriño, J.; Sánchez-Ilárduya, M.B.; Ruiz-Rubio, L.; Vilas-Vilela, J.L.; Lanceros-Méndez, S.; del Campo, F.J. Laser-Activated Screen-Printed Carbon Electrodes for Enhanced Dopamine Determination in the Presence of Ascorbic and Uric Acid. Electrochim. Acta 2021, 399, 139374. [Google Scholar] [CrossRef]

- Kaneko, S.; Shimizu, Y.; Rachi, T.; Kato, C.; Tanaka, S.; Naganuma, Y.; Katakura, T.; Satoh, K.; Ushiyama, M.; Konuma, S.; et al. Multigraphene Growth on Lead-Pencil Drawn Sliver Halide Print Paper Irradiated by Scanning Femtosecond Laser. Jpn. J. Appl. Phys. 2015, 55, 01AE24. [Google Scholar] [CrossRef]

- Annu; Sharma, S.; Jain, R.; Raja, A.N. Review—Pencil Graphite Electrode: An Emerging Sensing Material. J. Electrochem. Soc. 2019, 167, 037501. [Google Scholar] [CrossRef]

- David, I.G.; Popa, D.-E.; Buleandra, M. Pencil Graphite Electrodes: A Versatile Tool in Electroanalysis. J. Anal. Methods Chem. 2017, 2017, e1905968. [Google Scholar] [CrossRef]

- Ameku, W.A.; Ataide, V.N.; Costa, E.T.; Gomes, L.R.; Napoleão-Pêgo, P.; William Provance, D.; Paixão, T.R.L.C.; Salles, M.O.; De-Simone, S.G. A Pencil-Lead Immunosensor for the Rapid Electrochemical Measurement of Anti-Diphtheria Toxin Antibodies. Biosensors 2021, 11, 489. [Google Scholar] [CrossRef]

- Bataillard, A.; Schiavi, P.; Sassard, J. Pharmacological Properties of Indapamide. Clin Pharmacok. 1999, 37, 7–12. [Google Scholar] [CrossRef] [PubMed]

- Chaffman, M.; Heel, R.C.; Brogden, R.N.; Speight, T.M.; Avery, G.S. Indapamide. A Review of Its Pharmacodynamic Properties and Therapeutic Efficacy in Hypertension. Drugs 1984, 28, 189–235. [Google Scholar] [CrossRef] [PubMed]

- Cadwallader, A.B.; De La Torre, X.; Tieri, A.; Botrè, F. The Abuse of Diuretics as Performance-Enhancing Drugs and Masking Agents in Sport Doping: Pharmacology, Toxicology and Analysis. Brit. J. Pharm. 2010, 161, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Dossi, N.; Toniolo, R.; Piccin, E.; Susmel, S.; Pizzariello, A.; Bontempelli, G. Pencil-Drawn Dual Electrode Detectors to Discriminate Between Analytes Comigrating on Paper-Based Fluidic Devices but Undergoing Electrochemical Processes with Different Reversibility. Electroanalysis 2013, 25, 2515–2522. [Google Scholar] [CrossRef]

- Akanda, M.R.; Sohail, M.; Aziz, M.A.; Kawde, A.N. Recent Advances in Nanomaterial-Modified Pencil Graphite Electrodes for Electroanalysis. Electroanalysis 2016, 28, 408–424. [Google Scholar] [CrossRef]

- Stradolini, F.; Kilic, T.; Di Consiglio, A.; Ozsoz, M.; De Micheli, G.; Carrara, S. Long-Term Monitoring of Propofol and Fouling Effect on Pencil Graphite Electrodes. Electroanalysis 2018, 30, 1363–1369. [Google Scholar] [CrossRef]

- Shahzadi, M.; Nisar, S.; Kim, D.-K.; Sarwar, N.; Rasheed, A.; Ahmad, W.; Afzal, A.M.; Imran, M.; Assiri, M.A.; Shahzad, Z.M.; et al. Highly Efficient, Non-Covalent Functionalization of CVD-Graphene via Novel Pyrene-Based Supporter Construct. Chemosensors 2023, 11, 83. [Google Scholar] [CrossRef]

- Celiešiūtė, R.; Trusovas, R.; Niaura, G.; Švedas, V.; Račiukaitis, G.; Ruželė, Ž.; Pauliukaite, R. Influence of the Laser Irradiation on the Electrochemical and Spectroscopic Peculiarities of Graphene-Chitosan Composite Film. Electrochim. Acta 2014, 132, 265–276. [Google Scholar] [CrossRef]

- Li, Z.; Li, K.; Wang, S.; Teng, C. Covalent Patterning of Graphene for Controllable Functionalization from Microscale to Nanoscale: A Mini-Review. Front. Chem. 2022, 10, 829614. [Google Scholar] [CrossRef]

- Kim, J.; Ahn, D.; Sun, J.; Park, S.; Cho, Y.; Park, S.; Ha, S.; Ahn, S.; Kim, Y.A.; Park, J.-J. Vertically and Horizontally Drawing Formation of Graphite Pencil Electrodes on Paper by Frictional Sliding for a Disposable and Foldable Electronic Device. ACS Omega 2021, 6, 1960–1970. [Google Scholar] [CrossRef]

- Lenner, M.; Kaplan, A.; Huchon, C.; Palmer, R.E. Ultrafast Laser Ablation of Graphite. Phys. Rev. B 2009, 79, 184105. [Google Scholar] [CrossRef]

- Sokolov, D.A.; Shepperd, K.R.; Orlando, T.M. Formation of Graphene Features from Direct Laser-Induced Reduction of Graphite Oxide. J. Phys. Chem. Lett. 2010, 1, 2633–2636. [Google Scholar] [CrossRef]

- Pedrotti, J.J.; Angnes, L.; Gutz, I.G.R. Miniaturized Reference Electrodes with Microporous Polymer Junctions. Electroanalysis 1996, 8, 673–675. [Google Scholar] [CrossRef]

- Legorburu, M.J.; Alonso, R.M.; Jiménez, R.M. Electrochemical Oxidation of the Diuretic Indapamide. Electroanalysis 1996, 8, 280–284. [Google Scholar] [CrossRef]

- Laube, N.; Mohr, B.; Hesse, A. Laser-Probe-Based Investigation of the Evolution of Particle Size Distributions of Calcium Oxalate Particles Formed in Artificial Urines. J. C. Grow. 2001, 233, 367–374. [Google Scholar] [CrossRef]

- Oliveira, T.G.; Santos, B.G.; Gonçalves, J.M.; Angnes, L. Amperometric Detection of Indapamide on Glassy Carbon Electrode. Electroanalysis 2023, 35, e202200441. [Google Scholar] [CrossRef]

- Salamanca-Neto, C.A.R.; Yoshida, F.A.; Sartori, E.R.; Moraes, J.T. Boron-Doped Diamond Electrode: A Modification-Free Platform for Sensitive Square-Wave Voltammetric Determination of Indapamide Hydrochloride. Anal. Methods 2018, 10, 3347–3352. [Google Scholar] [CrossRef]

- Radi, A.-E.; Eissa, S. Electrochemical Study of Indapamide and Its Complexation with β-Cyclodextrin. J. Incl. Phenom. Macrocycl. Chem. 2011, 71, 95–102. [Google Scholar] [CrossRef]

- Radi, A. Stripping Voltammetric Determination of Indapamide in Serum at Castor Oil-Based Carbon Paste Electrodes. J. Pharm. Biom. Anal. 2001, 24, 413–419. [Google Scholar] [CrossRef]

- Radi, A. Adsorptive Cathodic Stripping Voltammetric Determination of Indapamide as Copper Complex at a Hanging Mercury Drop Electrode. Chem. Anal. 2003, 48, 273–281. [Google Scholar]

| Technique | Electrode | LOD mol L−1 | Linear Range mol L−1 | Reference |

|---|---|---|---|---|

| SWV | BDDE | 5.6 × 10−8 | 9.9 × 10−8–4.3 × 10−6 | [28] |

| SWAD | HMDE | 2.9 × 10−11 | 2.0 × 10−12–2.0 × 10−7 | [29] |

| ACSV | HMDE | 5.0 × 10−9 | 2.0 × 10−8–2.0 × 10−7 | [30] |

| AS | CPE | 5.0 × 10−9 | 5.0 × 10−8–1.0 × 10−7 | [31] |

| DPV | CPE | 1.0 × 10−7 | 6.0 × 10−7–2.0 × 10−5 | [25] |

| FIA-amperometric | GCE | 3.0 × 10−7 | 2.0 × 10−6–2.5 × 10−5 | [27] |

| FIA-amperometric | LTGr | 5.0 × 10−7 | 1.0 × 10−5–7.0 × 10−5 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, T.G.; Lima, I.S.; Ameku, W.A.; Gonçalves, J.M.; Souza, R.S.; Toma, H.E.; Angnes, L. Laser-Scribed Pencil Lead Electrodes for Amperometric Quantification of Indapamide. Chemosensors 2023, 11, 574. https://doi.org/10.3390/chemosensors11120574

Oliveira TG, Lima IS, Ameku WA, Gonçalves JM, Souza RS, Toma HE, Angnes L. Laser-Scribed Pencil Lead Electrodes for Amperometric Quantification of Indapamide. Chemosensors. 2023; 11(12):574. https://doi.org/10.3390/chemosensors11120574

Chicago/Turabian StyleOliveira, Thawan G., Irlan S. Lima, Wilson A. Ameku, Josué M. Gonçalves, Rodrigo S. Souza, Henrique E. Toma, and Lúcio Angnes. 2023. "Laser-Scribed Pencil Lead Electrodes for Amperometric Quantification of Indapamide" Chemosensors 11, no. 12: 574. https://doi.org/10.3390/chemosensors11120574

APA StyleOliveira, T. G., Lima, I. S., Ameku, W. A., Gonçalves, J. M., Souza, R. S., Toma, H. E., & Angnes, L. (2023). Laser-Scribed Pencil Lead Electrodes for Amperometric Quantification of Indapamide. Chemosensors, 11(12), 574. https://doi.org/10.3390/chemosensors11120574