Methods for Calibrating the Electrochemical Quartz Crystal Microbalance: Frequency to Mass and Compensation for Viscous Load

Abstract

1. Introduction

2. Materials and Methods

2.1. Theory

2.2. Material

2.3. Electrochemical Quartz Crystal Microbalance

2.4. Potentiostat

3. Results and Discussion

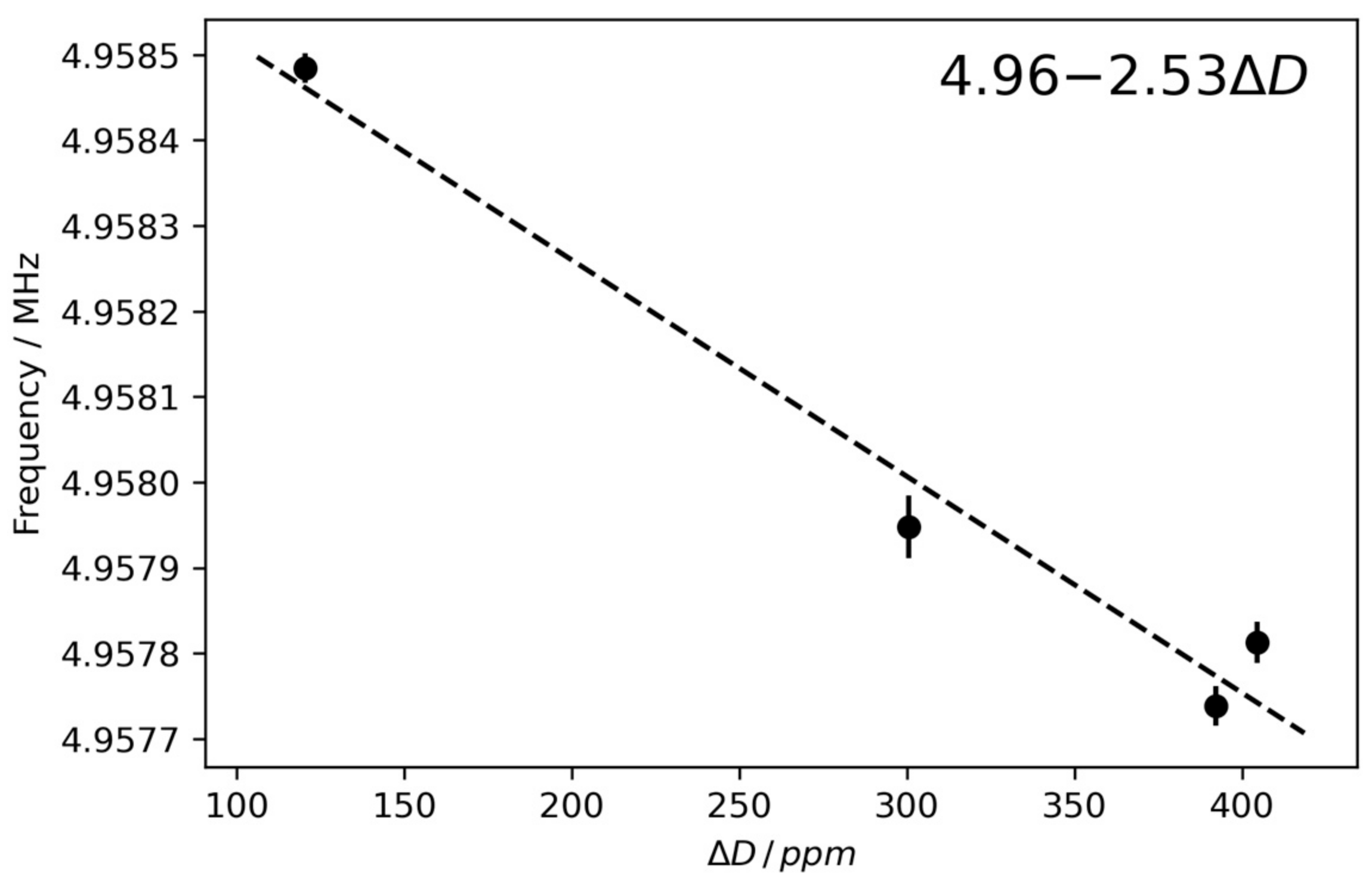

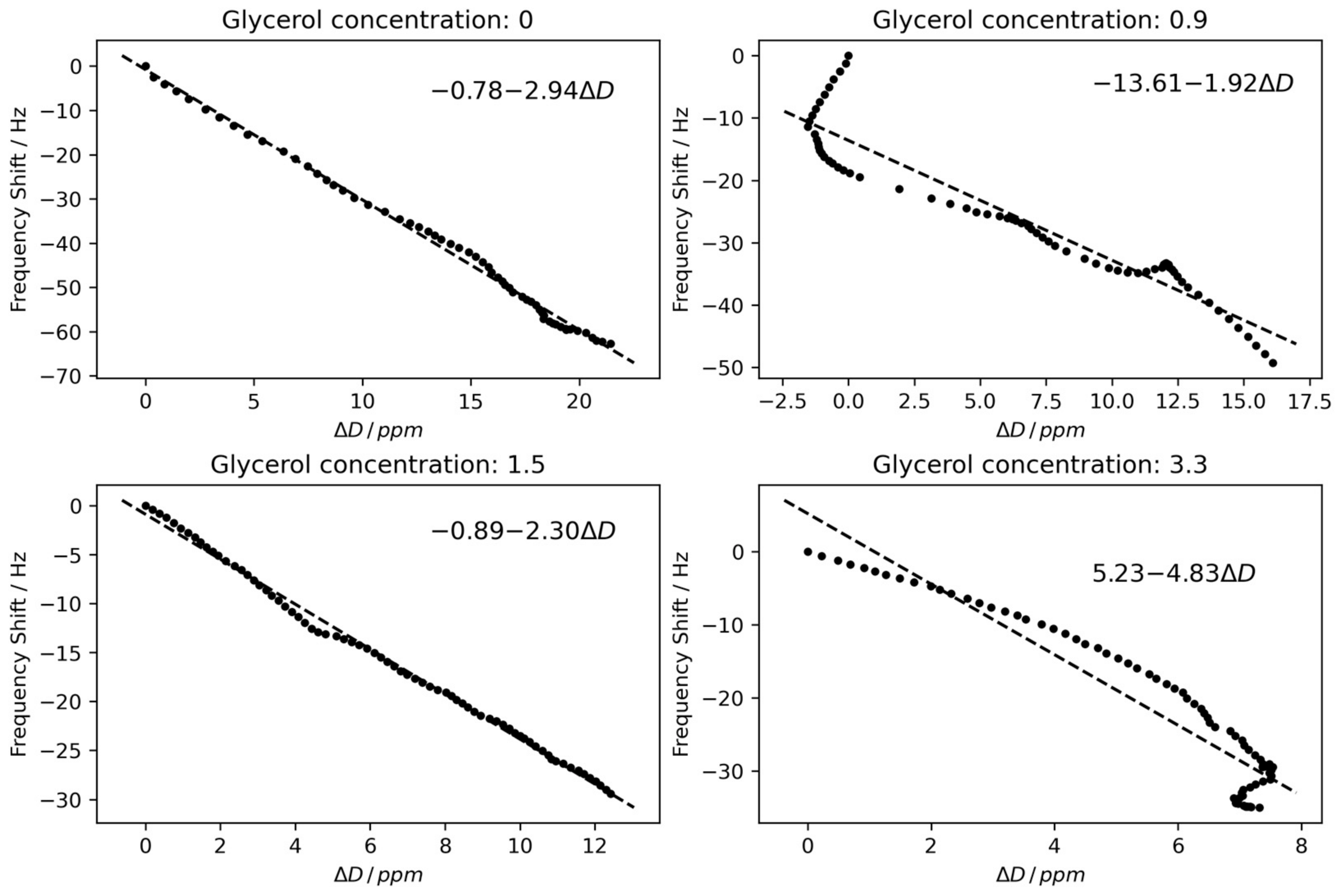

3.1. Calibration in a Water–Glycerol Mixture

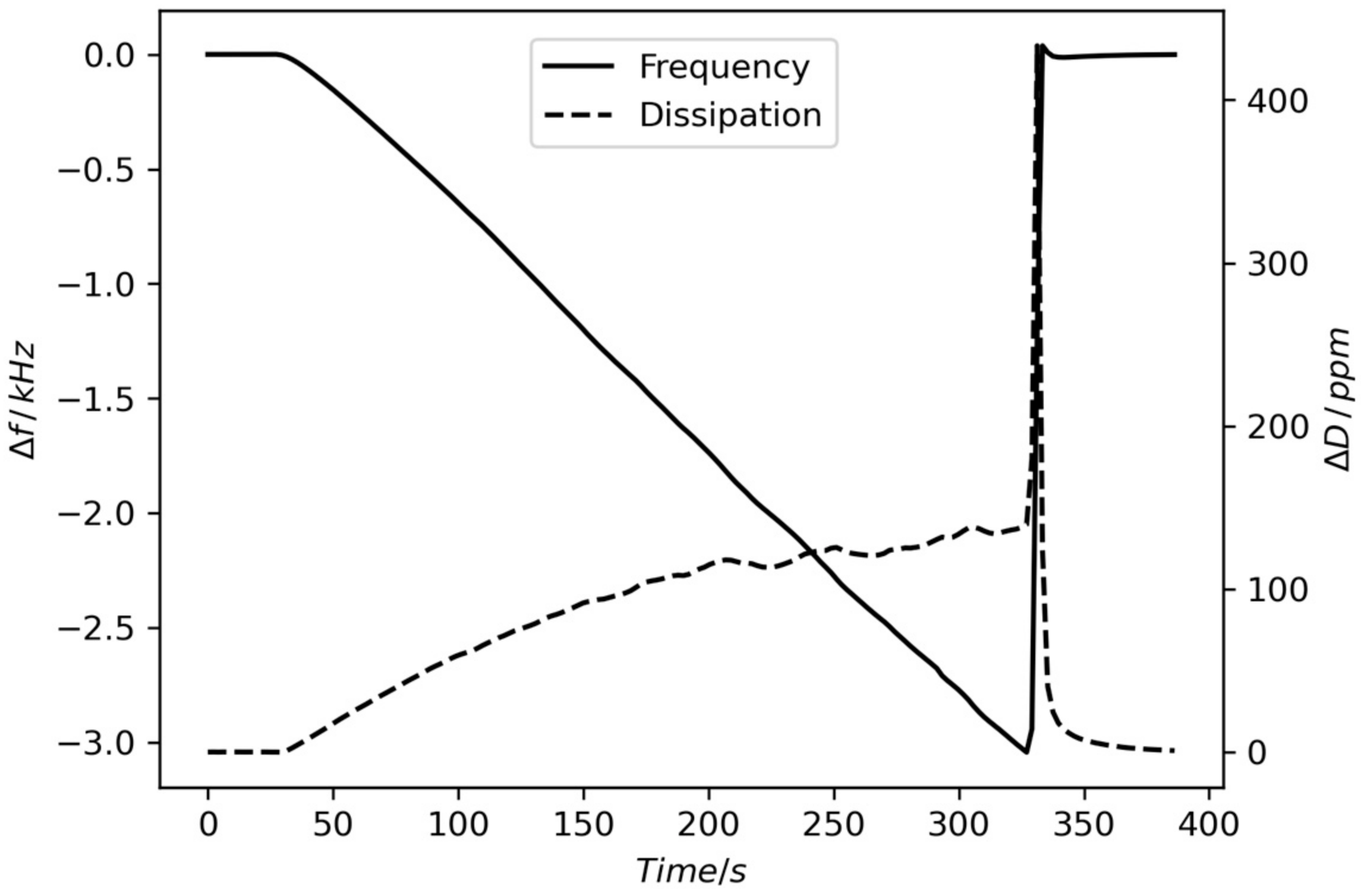

3.2. Calibration of Mass Coefficient and Viscous Load Using Galvanostatic Plating

4. Conclusions

- (1)

- The crystal is exposed to a series of water–glycerol mixtures where no adsorption is occurring. This makes it possible to determine the frequency contribution from the viscous load for a comparatively wide range of viscosities.

- (2)

- It is also possible to obtain the influence of viscous load on the frequency shift by following initial oscillations during a stabilization phase of the experiment where no adsorption is occurring. This allows us to determine the viscous load for a specific quartz/solution couple, i.e., to use a calibration specific to each experiment. This approach is, however, limited to a narrow range in dissipation and frequency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Levi, M.D.; Daikhin, L.; Aurbach, D.; Presser, V. Quartz Crystal Microbalance with Dissipation Monitoring (EQCM-D) for in-situ studies of electrodes for supercapacitors and batteries: A mini-review. Electrochem. Commun. 2016, 67, 16–21. [Google Scholar] [CrossRef]

- Levi, M.D.; Shpigel, N.; Sigalov, S.; Dargel, V.; Daikhin, L.; Aurbach, D. In Situ Porous Structure Characterization of Electrodes for Energy Storage and Conversion by EQCM-D: A Review. Electrochim. Acta 2017, 232, 271–284. [Google Scholar] [CrossRef]

- Leimbach, M.; Tschaar, C.; Schmidt, U.; Bund, A. Electrochemical characterization of chromium deposition from trivalent solutions for decorative applications by EQCM and near-surface pH measurements. Electrochim. Acta 2018, 270, 104–109. [Google Scholar] [CrossRef]

- Valero-Vidal, C.; Igual-Muñoz, A.; Olsson, C.-O.A.; Mischler, S. Adsorption of BSA on Passivated CoCrMo PVD Alloy: An EQCM and XPS Investigation. J. Electrochem. Soc. 2012, 159, C233. [Google Scholar] [CrossRef]

- Buttry, D.A.; Ward, M.D. Measurement of interfacial processes at electrode surfaces with the electrochemical quartz crystal microbalance. Chem. Rev. 1992, 92, 1355. [Google Scholar] [CrossRef]

- Olsson, C.-O.A.; Landolt, D.C. Analytical Methods in Corrosion Science and Engineering; Marcus, P., Mansfeld, F., Eds.; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Sauerbrey, G. Verwendung von Schwingquarzen zur Wägung danner Schichten und zur Mikrowägung. Z. Phys. 1959, 155, 206–222. [Google Scholar] [CrossRef]

- Voinova, M.V.; Rodahl, M.; Jonson, M.; Kasemo, B. Viscoelastic Acoustic Response of Layered Polymer Films at Fluid-Solid Interfaces: Continuum Mechanics Approach. Phys. Scr. 1999, 59, 391–396. [Google Scholar] [CrossRef]

- Fernandez, R.; Calero, M.; Reiviakine, I.; Garcia, J.V.; Rocha-Gaso, M.I.; Arnau, A.; Jimenez, Y. High Fundamental Frequency (HFF) Monolithic Resonator Arrays for Biosensing Applications: Design, Simulations, Experimental Characterization. IEEE Sens. J. 2020, 21, 284–295. [Google Scholar] [CrossRef]

- Itoh, A.; Ichihashi, M. A frequency of the quartz crystal microbalance (QCM) that is not affected by the viscosity of a liquid. Meas. Sci. Technol. 2008, 19, 075205. [Google Scholar] [CrossRef]

- Itoh, A.; Ichihashi, M. Separate measurement of the density and viscosity of a liquid using a quartz crystal microbalance based on admittance analysis (QCM-A). Meas. Sci. Technol. 2010, 22, 015402. [Google Scholar] [CrossRef]

- Olsson, C.-O.A.; Igual-Muñoz, A.N.; Mischler, S. Adsorption of organic matter on titanium surfaces with nano- and micro-scale roughness studied with the electrochemical quartz crystal microbalance dissipation technique. Biointerphases 2021, 16, 051001. [Google Scholar] [CrossRef]

- Kanazawa, K.K.; Gordon, J.G. Frequency of a quartz microbalance in contact with liquid. Anal. Chem. 1985, 57, 1770–1771. [Google Scholar] [CrossRef]

- Galliano, F.; Olsson, C.-O.A.; Landolt, D. Flow Cell for EQCM Adsorption Studies. J. Electrochem. Soc. 2003, 150, B504–B511. [Google Scholar] [CrossRef]

- Kelly, J.J.; Rahman, K.M.A.; Durning, C.J.; West, A.C. Effect of Current Distribution on Quartz Crystal Microbalance Measurements. J. Electrochem. Soc. 1998, 145, 492–497. [Google Scholar] [CrossRef]

| Latin | ||

|---|---|---|

| Acurr | Working Electrode sensing area | 1.14 cm2 |

| Aosc | Oscillating area, mass- and dissipation sensing | 0.26 cm2 |

| Cs | Sauerbrey constant | g s or g Hz−1 |

| ΔD | Dissipation change, energy loss per osc. Cycle | ppm |

| fm | Frequency change related to mass | Hz |

| f0 | Base frequency | ≈5 MHz |

| F | Faraday Constant | 96,485 C mol−1 |

| k | Proportionality constant | MHz or Hz ppm−1 |

| I | Plating current | A |

| i | Plating current density | A cm−2 |

| MCu | Molar mass of copper | 63.54 g mol−1 |

| Δm | Mass change | ng |

| n | Valence number | 2 |

| t | Time | s |

| Greek | ||

| ρq | Quartz density | 2.65 g cm−3 |

| ρl | Water density at 37 °C | 0.99327 g cm−3 |

| μq | Quartz shear modulus | 2.956 × 1011 g cm−1 s−2 |

| ηl | Dynamic viscosity of water at 37 °C | 8.92 N s cm−2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olsson, C.-O.A.; Igual-Muñoz, A.N.; Mischler, S. Methods for Calibrating the Electrochemical Quartz Crystal Microbalance: Frequency to Mass and Compensation for Viscous Load. Chemosensors 2023, 11, 456. https://doi.org/10.3390/chemosensors11080456

Olsson C-OA, Igual-Muñoz AN, Mischler S. Methods for Calibrating the Electrochemical Quartz Crystal Microbalance: Frequency to Mass and Compensation for Viscous Load. Chemosensors. 2023; 11(8):456. https://doi.org/10.3390/chemosensors11080456

Chicago/Turabian StyleOlsson, Claes-Olof A., Anna Neus Igual-Muñoz, and Stefano Mischler. 2023. "Methods for Calibrating the Electrochemical Quartz Crystal Microbalance: Frequency to Mass and Compensation for Viscous Load" Chemosensors 11, no. 8: 456. https://doi.org/10.3390/chemosensors11080456

APA StyleOlsson, C.-O. A., Igual-Muñoz, A. N., & Mischler, S. (2023). Methods for Calibrating the Electrochemical Quartz Crystal Microbalance: Frequency to Mass and Compensation for Viscous Load. Chemosensors, 11(8), 456. https://doi.org/10.3390/chemosensors11080456