Metal Oxide-Based Sensors for Ecological Monitoring: Progress and Perspectives

Abstract

1. Introduction

2. Environmental Monitoring by Metal Oxides Sensors

2.1. H2

2.2. COx

2.3. SOx

2.4. NOx

2.5. CH4

2.6. Summary of Semiconductor Metal Oxide Gas Sensors to H2, COx, NOx, SOx, and CH4 Gases

3. Multisensor Systems/e-Nose Based on Metal Oxides for Environmental Monitoring

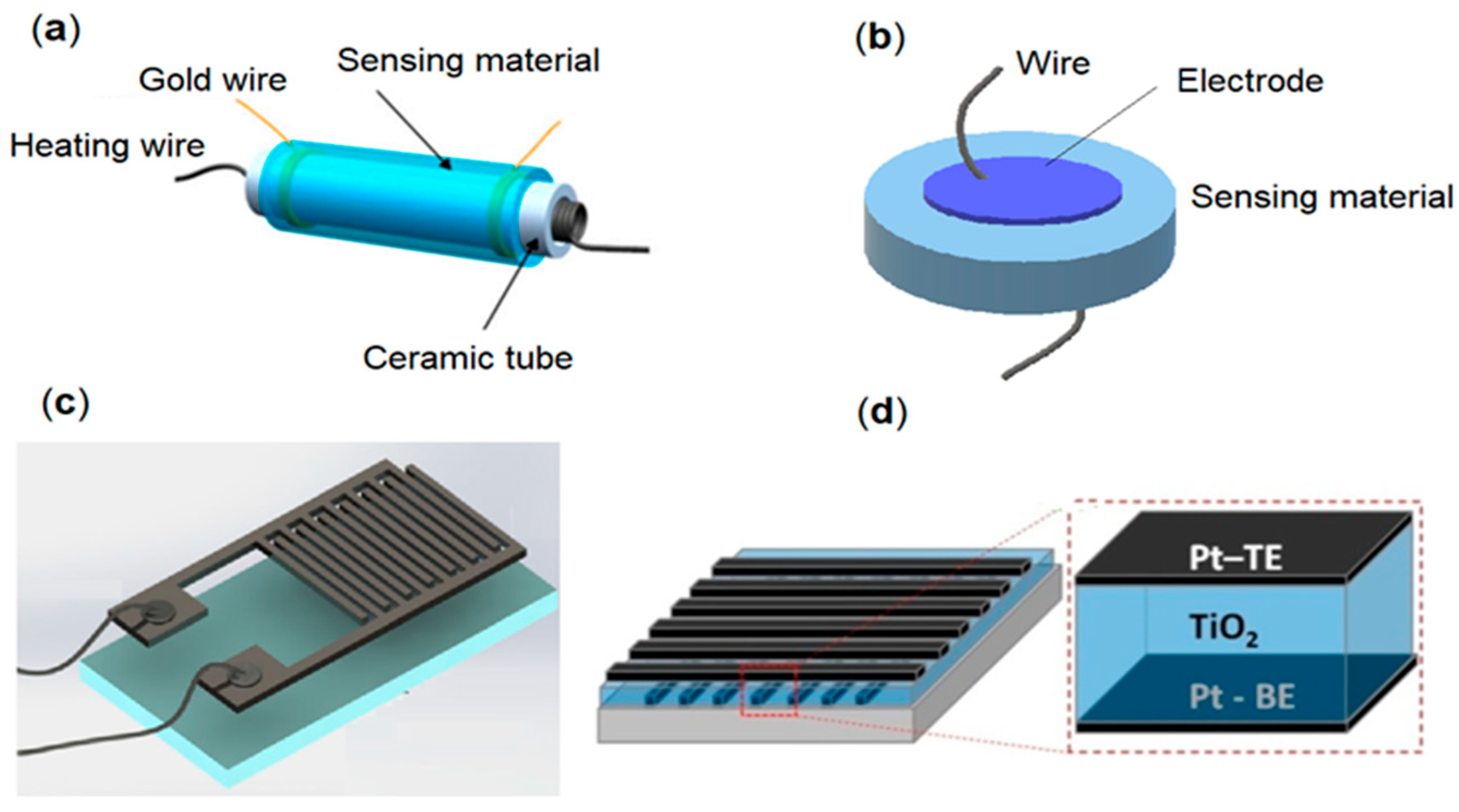

4. Configuration and Geometry of Metal Oxide Sensors

5. Detection Mechanism and Parameters Affecting the Sensitivity/Selectivity of the Sensors

5.1. Detection Models of Gas-Sensing Processes

5.2. Parameters Affecting Sensor’s Performance

5.3. Methods of Processing Sensor Signals to Improve Sensitivity/Selectivity of the Sensors

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Uma, S.; Shobana, M.K. Metal oxide semiconductor gas sensors in clinical diagnosis and environmental monitoring. Sens. Actuators A Phys. 2023, 349, 114044. [Google Scholar] [CrossRef]

- Dontsova, T.A.; Nahirniak, S.V.; Astrelin, I.M. Metaloxide nanomaterials and nanocomposites of ecological purpose. J. Nanomater. 2019, 2019, 5942194. [Google Scholar] [CrossRef]

- Burgués, J.; Marco, S. Environmental chemical sensing using small drones: A review. Sci. Total Environ. 2020, 748, 141172. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Zheng, Z. Electronic noses based on metal oxide semiconductor sensors for detecting crop diseases and insect pests. Comput. Electron. Agric. 2022, 197, 106988. [Google Scholar] [CrossRef]

- Nahirniak, S.; Dontsova, T.; Lapinsky, A.; Tereshkov, M.; Singh, R. Soil and soil breathing remote monitoring: A short review. Biosyst. Divers. 2020, 28, 350–356. [Google Scholar] [CrossRef]

- Nanotechnology-Based E-Noses: Fundamentals and Emerging Applications; Woodhead Publishing Series in Electronic and Optical Materials; Elsevier: Cambridge, UK, 2023; 457p.

- An, Y.; Tian, Y.; Wei, C.; Tao, Y.; Xi, B.; Xiong, S.; Feng, J.; Qian, Y. Dealloying: An effective method for scalable fabrication of 0D, 1D, 2D, 3D materials and its application in energy storage. Nano Today 2021, 37, 101094. [Google Scholar] [CrossRef]

- Galstyan, V.; Moumen, A.; Kumarage, G.W.C.; Comini, E. Progress towards chemical gas sensors: Nanowires and 2D semiconductors. Sens. Actuators B Chem. 2022, 357, 131466. [Google Scholar] [CrossRef]

- Ortiz-Casas, B.; Galdámez-Martínez, A.; Gutiérrez-Flores, J.; Ibañez, A.B.; Panda, P.K.; Santana, G.; de la Vega, H.A.; Suar, M.; Rodelo, C.G.; Kaushik, A.; et al. Bio-acceptable 0D and 1D ZnO nanostructures for cancer diagnostics and treatment. Mater. Today 2021, 50, 533–569. [Google Scholar] [CrossRef]

- Nagirnyak, S.V.; Lutz, V.A.; Dontsova, T.; Astrelin, I.M. The effect of the synthesis conditions on morphology of tin (IV) oxide obtained by vapor transport method. In Nanophysics, Nanophotonics, Surface Studies, and Applications; Fesenko, O., Yatsenko, L., Eds.; Springer Proceedings in Physics; Springer: Berlin/Heidelberg, Germany, 2016; Volume 183, pp. 331–341. [Google Scholar]

- Masuda, Y. Recent advances in SnO2 nanostructure based gas sensors. Sens. Actuators B Chem. 2022, 364, 131876. [Google Scholar] [CrossRef]

- Dey, A. Semiconductor metal oxide gas sensors: A review. Mater. Sci. Eng. B 2018, 229, 206–217. [Google Scholar] [CrossRef]

- Kaur, N.; Singh, M.; Comini, E. One-dimensional nanostructured oxide chemoresistive sensors. Langmuir 2020, 36, 6326–6344. [Google Scholar] [CrossRef] [PubMed]

- Nagirnyak, S.V.; Lutz, V.A.; Dontsova, T.A. Synthesis and characterization of tin (IV) oxide obtained by chemical vapor deposition method. Nanoscale Res. Lett. 2016, 11, 343. [Google Scholar] [CrossRef]

- Chen, L.; Yu, Q.; Pan, C.; Song, Y.; Dong, H.; Xie, X.; Li, Y.; Liu, J.; Wang, D.; Chen, X. Chemiresistive gas sensors based on electrospun semiconductor metal oxides: A review. Talanta 2022, 246, 123527. [Google Scholar] [CrossRef]

- Dontsova, T.A.; Nagirnyak, S.V.; Zhorov, V.V.; Yasiievych, Y.V. SnO2 nanostructures: Effect of processing parameters on their structural and functional properties. Nanoscale Res. Lett. 2017, 12, 332. [Google Scholar] [CrossRef]

- Paul, R.; Das, B.; Ghosh, R. Novel approaches towards design of metal oxide based hetero-structures for room temperature gas sensor and its sensing mechanism: A recent progress. J. Alloys Compd. 2023, 941, 168943. [Google Scholar] [CrossRef]

- Wang, J.; Shen, H.; Xia, Y.; Komarneni, S. Light-activated room-temperature gas sensors based on metal oxide nanostructures: A review on recent advances. Ceram. Int. 2021, 47, 7353–7368. [Google Scholar] [CrossRef]

- Latif, U.; Dickert, F.L. Graphene hybrid materials in gas sensing applications. Sensors 2015, 15, 30504–30524. [Google Scholar] [CrossRef]

- Calise, F.; D’Accadia, M.D.; Santarelli, M.; Lanzini, A.; Ferrero, D. (Eds.) Solar Hydrogen Production: Processes, Systems and Technologies; Academic Press: Cambridge, MA, USA, 2019; 560p. [Google Scholar]

- Nowotny, J.; Veziroglu, T.N. Impact of hydrogen on the environment. Int. J. Hydrogen Energy 2011, 36, 13218–13224. [Google Scholar] [CrossRef]

- Xu, M.; Peng, B.; Zhu, X.; Guo, Y. Multi-gas detection system based on non-dispersive infrared (NDIR) spectral technology. Sensors 2022, 22, 836. [Google Scholar] [CrossRef] [PubMed]

- Ravishankara, A.R.; Daniel, J.S.; Portmann, R.W. Nitrous oxide (N2O): The dominant ozone-depleting substance emitted in the 21st century. Science 2009, 326, 123–125. [Google Scholar] [CrossRef] [PubMed]

- OECD. Environment at a Glance 2013: OECD Indicators; OECD Publishing: Paris, France, 2013; 108p. [Google Scholar] [CrossRef]

- Dhall, S.; Mehta, B.R.; Tyagi, A.K.; Sood, K. A review on environmental gas sensors: Materials and technologies. Sens. Int. 2021, 2, 100116. [Google Scholar] [CrossRef]

- Kholod, N.; Evans, M.; Pilcher, R.C.; Roshchanka, V.; Ruiz, F.; Coté, M.; Collings, R. Global methane emissions from coal mining to continue growing even with declining coal production. J. Clean. Prod. 2020, 256, 120489. [Google Scholar] [CrossRef]

- Sachin, N.; Sanjit, M.; Ali, M.; Sang, К. Metal oxide ceramic gas sensors. Encycl. Mater. Electron. 2023, 1, 452–462. [Google Scholar]

- Nikolić, M.; Milovanović, V.; Vasiljevic, Z.; Stamenkovic, Z. Semiconductor gas sensors: Materials, technology, design and application. Sensors 2020, 2020, 6694. [Google Scholar] [CrossRef]

- Zhu, L.-Y.; Ou, L.-X.; Mao, L.-W.; Wu, X.; Liu, Y.; Lu, H.-L. Advances in noble metal-decorated metal oxide nanomaterials for chemiresistive gas sensors: Overview. Nano-Micro Lett. 2023, 15, 89. [Google Scholar] [CrossRef]

- Sohal, M.K.; Mahajan, A.; Gasso, S.; Nahirniak, S.V.; Dontsova, T.A.; Singh, R.C. Rare earth-tuned oxygen vacancies in gadolinium-doped tin oxide for selective detection of volatile organic compounds. J. Mater. Sci. Mater. Electron. 2020, 31, 8446–8455. [Google Scholar] [CrossRef]

- Zegebreal, L.T.; Tegegne, N.A.; Hone, F.G. Recent progress in hybrid conducting polymers and metal oxide nanocomposite for room-temperature gas sensor applications: A Review. Sens. Actuators A Phys. 2023, 359, 114472. [Google Scholar] [CrossRef]

- Bhati, V.S.; Kumar, M.; Banerjee, R. Gas sensing performance of 2D nanomaterials/metal oxide nanocomposites: A review. J. Mater. Chem. C 2021, 9, 8776–8806. [Google Scholar] [CrossRef]

- Potyrailo, R.A.; Go, S.; Sexton, D.; Li, X.; Alkadi, N.; Kolmakov, A.; Amm, B.; St-Pierre, R.; Scherer, B.; Nayeri, M.; et al. Extraordinary performance of semiconducting metal oxide gas sensors using dielectric excitation. Nat. Electron. 2020, 3, 280–289. [Google Scholar] [CrossRef]

- Gu, H.; Wang, Z.; Hu, Y. Hydrogen gas sensors based on semiconductor oxide nanostructures. Sensors 2012, 12, 5517–5550. [Google Scholar] [CrossRef] [PubMed]

- Ren, Q.; Cao, Y.-Q.; Arulraj, D.; Liu, C.; Wu, D.; Li, W.; Li, A. Review—Resistive-type hydrogen sensors based on zinc oxide nanostructures. J. Electrochem. Soc. 2020, 167, 067528. [Google Scholar] [CrossRef]

- Hossain, M.K.; Drmosh, Q.A. Noble metal-decorated nanostructured zinc oxide: Strategies to advance chemiresistive hydrogen gas sensing. Chem. Rec. 2022, 22, e202200090. [Google Scholar] [CrossRef] [PubMed]

- Dontsova, T.; Yanushevska, O.; Nahirniak, S.; Kutuzova, A.; Krymets, G.; Smertenko, P. Characterization of commercial TiO2 P90 modified with ZnO by the impregnation method. J. Chem. 2021, 2021, 9378490. [Google Scholar] [CrossRef]

- Nahirniak, S.V.; Dontsova, T.A.; Chen, Q. Sensing properties of SnO2-MWCNTs nanocomposites towards H2. Mol. Cryst. Liq. Cryst. 2018, 674, 48–58. [Google Scholar] [CrossRef]

- Chang, C.W.; Liu, I.P.; Yao, P.C.; Lin, K.W.; Hsu, W.C.; Liu, W.C. Hydrogen detecting characteristics of a palladium nanoparticle/indium gallium oxide based sensor. Sens. Actuators B Chem. 2023, 393, 134240. [Google Scholar] [CrossRef]

- Nguyen, T.T.D.; Dao, D.V.; Kim, D.S.; Lee, H.L.; Oh, S.Y.; Lee, I.H.; Yu, Y.T. Effect of core and surface area toward hydrogen gas sensing performance using Pd@ZnO core-shell nanoparticles. J. Colloid Interface Sci. 2021, 587, 252–259. [Google Scholar] [CrossRef] [PubMed]

- Le, H.J.; Dao, V.D.; Yu, Y.T. Superfast and efficient hydrogen gas sensor using PdAualloy@ZnO core–shell nanoparticles. J. Mater. Chem. A 2020, 8, 12968–12974. [Google Scholar] [CrossRef]

- Hübert, T.; Boon-Brett, L.; Black, V.; Banach, U. Hydrogen sensors—A review. Sens. Actuators B Chem. 2011, 157, 329–352. [Google Scholar] [CrossRef]

- Kim, S.H.; Yun, K.S. Room-temperature hydrogen gas sensor composed of palladium thin film deposited on NiCo2O4 nanoneedle forest. Sens. Actuators B Chem. 2023, 376, 132958. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, C.; Zheng, B.; Geng, X.; Debliquy, M. Hydrogen sensors based on noble metal doped metal-oxide semiconductor: A review. Int. J. Hydrogen Energy 2017, 42, 20386–20397. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, K.; Liu, K.; Xu, J.; Zheng, Z. Metal oxide resistive sensors for carbon dioxide detection. Coord. Chem. Rev. 2022, 472, 214758. [Google Scholar] [CrossRef]

- Lupan, O.; Chow, L.; Shishiyanu, S.; Monaico, E.; Shishiyanu, T.; Sontea, V.; Cuenya, B.R.; Naitabdi, A.; Park, S.; Schulte, A. Nanostructured zinc oxide films synthesized by successive chemical solution deposition for gas sensor applications. Mater. Res. Bull. 2009, 44, 63–69. [Google Scholar] [CrossRef]

- Kanaparthi, S.; Singh, V. Chemiresistive sensor based on zinc oxide nanoflakes for CO2 detection. ACS Appl. Nano Mater. 2019, 2, 700–706. [Google Scholar] [CrossRef]

- Mahajan, S.; Jagtap, S. Metal-oxide semiconductors for carbon monoxide (CO) gas sensing: A review. Appl. Mater. Today 2020, 18, 100483. [Google Scholar] [CrossRef]

- Fine, G.F.; Cavanagh, L.M.; Afonja, A.; Binions, R. Metal oxide semi-conductor gas sensors in environmental monitoring. Sensors 2010, 10, 5469–5502. [Google Scholar] [CrossRef] [PubMed]

- Tereshkov, M.; Dontsova, T.; Yanushevska, O.; Dusheiko, M.; Smertenko, P. Solution composition and temperature impact on physicochemical properties of synthesized zinc oxide. Appl. Nanosci. 2022, 12, 2523–2532. [Google Scholar] [CrossRef]

- Bagheri, F.; Haratizadeh, H. UV-activated CO2 sensor based on ZnO nanoparticles at low temperatures. Mater. Sci. Semicond. Process. 2022, 141, 106422. [Google Scholar] [CrossRef]

- Zhou, Q.; Zeng, W.; Chen, W.; Xu, L.; Kumar, R.; Umar, A. High sensitive and low-concentration sulfur dioxide (SO2) gas sensor application of heterostructure NiO-ZnO nanodisks. Sens. Actuators B Chem. 2019, 298, 126870. [Google Scholar] [CrossRef]

- Tyagi, P.; Sharma, A.; Tomar, M.; Gupta, V. Metal oxide catalyst assisted SnO2 thin film based SO2 gas sensor. Sens. Actuators B Chem. 2016, 224, 282–289. [Google Scholar] [CrossRef]

- Pan, Q.; Yang, Z.; Wang, W.; Zhang, D. Sulfur dioxide gas sensing at room temperature based on tin selenium/tin dioxide hybrid prepared via hydrothermal and surface oxidation treatment. Rare Met. 2020, 40, 1588–1596. [Google Scholar] [CrossRef]

- Chaitra, U.; Ali, A.; Viegas, A.E.; Kekuda, D.; Rao, K.M. Growth and characterization of undoped and aluminium doped zinc oxide thin films for SO2 gas sensing below threshold value limit. Appl. Surf. Sci. 2019, 496, 143724. [Google Scholar] [CrossRef]

- Tyagi, P.; Sharma, A.; Tomar, M.; Gupta, V. Efficient detection of SO2 gas using SnO2 based sensor loaded with metal oxide catalysts. Procedia Eng. 2014, 87, 1075–1078. [Google Scholar] [CrossRef]

- Kang, X.; Deng, N.; Yan, Z.; Pan, Y.; Sun, W.; Zhang, Y. Resistive-type VOCs and pollution gases sensor based on SnO2: A review. Mater. Sci. Semicond. Process. 2022, 138, 106246. [Google Scholar] [CrossRef]

- Fu, Y.; Li, J.; Xu, H. SnO2 recycled from tin slime for enhanced SO2 sensing properties by NiO surface decoration. Mater. Sci. Semicond. Process. 2020, 114, 105073. [Google Scholar] [CrossRef]

- Stoycheva, T.; Vallejos, S.; Blackman, C.S.; Moniz, S.J.A.; Calderer, J.; Correig, X. Important considerations for effective gas sensors based on metal oxide nanoneedles films. Sens. Actuators B Chem. 2012, 161, 406–413. [Google Scholar] [CrossRef]

- Liu, H.; Wan, J.; Fu, Q.; Li, M.; Luo, W.; Zheng, Z.; Cao, H.; Hu, Y.; Zhou, D. Tin oxide films for nitrogen dioxide gas detection at low temperatures. Sens. Actuators B Chem. 2013, 177, 460–466. [Google Scholar] [CrossRef]

- Liu, T.; Jia, X.; Qiao, L.; Yang, J.; Wang, S.; Li, Y.; Shao, D.; Feng, L.; Song, H. Conductometric NO2 gas sensors achieved by design of Ti3C2Tx @ZnO heterostructures for application around 80 °C. Sens. Actuators B Chem. 2023, 390, 133908. [Google Scholar] [CrossRef]

- Afzal, A.; Cioffi, N.; Sabbatini, L.; Torsi, L. NOx sensors based on semiconducting metal oxide nanostructures: Progress and perspectives. Sens. Actuators B Chem. 2012, 171–172, 25–42. [Google Scholar] [CrossRef]

- Sohal, M.K.; Mahajan, A.; Gasso, S.; Nahirniak, S.; Dontsova, T. Modification of SnO2 surface oxygen vacancies through Er doping for ultralow NO2 detection. Mater. Res. Bull. 2020, 133, 111051. [Google Scholar] [CrossRef]

- Srivastava, S. Study of gas sensor detection for NOX Gas: A review. Mater. Today Proc. 2021, 37, 3709–3712. [Google Scholar] [CrossRef]

- Trung, T.D.; Toan, N.V.; Tong, P.V.; Duy, N.V.; Hoa, N.D.; Hieu, N.V. Synthesis of single-crystal SnO2 nanowires for NOx gas sensors application. Ceram. Int. 2012, 38, 6557–6563. [Google Scholar] [CrossRef]

- Zhao, S.; Shen, Y.; Zhou, P.; Hao, F.; Xu, X.; Gao, S.; Wei, D.; Ao, Y.; Shen, Y. Enhanced NO2 sensing performance of ZnO nanowires functionalized with ultra-fine In2O3 nanoparticles. Sens. Actuators B Chem. 2020, 308, 127729. [Google Scholar] [CrossRef]

- Kang, Y.; Yu, F.; Zhang, L.; Wang, W.; Chen, L.; Li, Y. Review of ZnO-based nanomaterials in gas sensors. Solid State Ion. 2021, 360, 115544. [Google Scholar] [CrossRef]

- Lux, K.C.; Hot, J.; Fau, P.; Bertron, A.; Kahn, M.L.; Ringot, E.; Fajerwerg, K. Nano-gold decorated ZnO: An alternative photocatalyst promising for NOx degradation. Chem. Eng. Sci. 2023, 267, 118377. [Google Scholar]

- Nundy, S.; Eom, T.; Kang, J.; Suh, J.; Cho, M.; Park, J.S.; Lee, H.J. Flower-shaped ZnO nanomaterials for low-temperature operations in NOX gas sensors. Ceram. Int. 2020, 46, 5706–5714. [Google Scholar] [CrossRef]

- Xia, Y.; Xu, L.; He, S.; Zhou, L.; Wang, M.; Wang, J.; Komarneni, S. UV-activated WS2/SnO2 2D/0D heterostructures for fast and reversible NO2 gas sensing at room temperature. Sens. Actuators B Chem. 2022, 364, 131903. [Google Scholar] [CrossRef]

- Chakrabarty, P.; Banik, M.; Gogurla, N.; Santra, S.; Ray, S.K.; Mukherjee, R. Light trapping-mediated room-temperature gas sensing by ordered ZnO nano structures decorated with plasmonic Au nanoparticles. ACS Omega 2019, 4, 12071–12080. [Google Scholar] [CrossRef]

- Chen, R.; Wang, J.; Xia, Y.; Xiang, L. Near infrared light enhanced room-temperature NO2 gas sensing by hierarchical ZnO nanorods functionalized with PbS quantum dots. Sens. Actuators B Chem. 2018, 255, 2538–2545. [Google Scholar] [CrossRef]

- Peterson, P.J.D.; Aujla, A.; Grant, K.H.; Brundle, A.G.; Thompson, M.R.; Hey, J.V.; Leigh, R.J. Practical use of metal oxide semiconductor gas sensors for measuring nitrogen dioxide and ozone in urban environments. Sensors 2017, 17, 1653. [Google Scholar] [CrossRef]

- Aldhafeeri, T.R.; Fowler, M.; Vrolyk, R.; Pope, M.A.; Fowler, M. A review of methane gas detection sensors: Recent developments and future perspectives. Inventions 2020, 5, 28. [Google Scholar] [CrossRef]

- Basu, S.; Basu, P.K. Nanocrystalline metal oxides for methane sensors: Role of noble metals. J. Sens. 2009, 2009, 861968. [Google Scholar] [CrossRef]

- De Lacy Costello, B.P.J.; Ewen, R.J.; Ratcliffe, N.M.; Richards, M. Highly sensitive room temperature sensors based on the UV-LED activation of zinc oxide nanoparticles. Sens. Actuators B Chem. 2008, 134, 945–952. [Google Scholar] [CrossRef]

- Aghagoli, Z.; Ardyanian, M. Synthesis and study of the structure, magnetic, optical and methane gas sensing properties of cobalt doped zinc oxide microstructures. J. Mater. Sci. Mater. Electron. 2018, 29, 7130–7141. [Google Scholar] [CrossRef]

- Bhattacharyya, P.; Basu, P.K.; Saha, H.; Basu, S. Fast response methane sensor using nanocrystalline zinc oxide thin films derived by sol–gel method. Sens. Actuators B Chem. 2007, 124, 62–67. [Google Scholar] [CrossRef]

- Wang, Y.; Meng, X.; Yao, M.; Sun, G.; Zhang, Z. Enhanced CH4 sensing properties of Pd modified ZnO nanosheets. Ceram. Int. 2019, 45, 13150–13157. [Google Scholar] [CrossRef]

- Li, H.Y.; Shu-Na, Z.; Zang, S.Q.; Li, J. Functional metal–organic frameworks as effective sensors of gases and volatile compounds. Chem. Soc. Rev. 2020, 49, 6364–6401. [Google Scholar] [CrossRef]

- Yuan, Z.; Han, E.; Meng, F.; Zuo, K. Detection and identification of volatile organic compounds based on temperature-modulated ZnO sensors. IEEE Trans. Instrum. Meas. 2020, 69, 4533–4544. [Google Scholar] [CrossRef]

- Luan, Z.; Zeng, W.; Li, Y. A non-oxygen adsorption mechanism for hydrogen detection of nanostructured SnO2 based sensors. Mater. Res. Bull. 2019, 109, 108–116. [Google Scholar]

- Choi, K.-S.; Chang, S.-P. Effect of structure morphologies on hydrogen gas sensing by ZnO nanotubes. Mater. Lett. 2018, 230, 48–52. [Google Scholar] [CrossRef]

- Kumar, M.; Kumar, R.; Rajamani, S.; Ranwa, S.; Fanetti, M.; Valant, M.; Kumar, M. Efficient room temperature hydrogen sensor based on UV-activated ZnO nano-network. Nanotechnology 2017, 28, 365502. [Google Scholar] [CrossRef]

- Fan, F.; Zhang, J.; Li, J.; Zhang, N.; Hong, R.; Deng, X.; Tang, P.; Li, D. Hydrogen sensing properties of Pt-Au bimetallic nanoparticles loaded on ZnO nanorods. Sens. Actuators B Chem. 2017, 241, 895–903. [Google Scholar] [CrossRef]

- Geng, X.; Luo, Y.; Zheng, B.; Zhang, C. Photon assisted room-temperature hydrogen sensors using PdO loaded WO3 nanohybrids. Int. J. Hydrogen Energy 2017, 42, 6425–6434. [Google Scholar] [CrossRef]

- Mobtakeran, S.; Habashyani, S.; Çoban, Ö.; Budak, H.F.; Kasapoğlu, A.E.; Gür, E. Effect of growth pressure on sulfur content of RF-magnetron sputtered WS2 films and thermal oxidation properties of them toward using Pd decorated WO3 based H2 gas sensor. Sens. Actuators B Chem. 2023, 381, 133485. [Google Scholar] [CrossRef]

- Li, G.; Du, K.; Wang, X.; Wang, X.; Chen, B.; Qiu, C.; Xu, J. Pd nanoparticles decorated SnO2 ultrathin nanosheets for highly sensitive H2 sensor: Experimental and theoretical studies. Int. J. Hydrogen Energy 2023, 50, 761–771. [Google Scholar] [CrossRef]

- Song, Z.; Zhang, L.; Zhou, Q.; Zhang, Z.; Dong, Z.; Nie, L.; Liu, Q.; Pan, G. In-Situ synthesis of needle-like PdO-decorated NiO thin films on Al2O3 substrates for high-performance H2 sensors. Ceram. Int. 2022, 48, 31746–31754. [Google Scholar] [CrossRef]

- Karuppasamy, K.; Sharma, A.; Vikraman, D.; Lee, Y.A.; Sivakumar, P.; Korvink, J.G.; Kim, H.S.; Sharma, B. Room-temperature response of MOF-derived Pd@PdO core shell/γ-Fe2O3 microcubes decorated graphitic carbon based ultrasensitive and highly selective H2 gas sensor. J. Colloid Interface Sci. 2023, 652, 692–704. [Google Scholar] [CrossRef] [PubMed]

- More, M.S.; Bodkhe, G.A.; Ingle, N.N.; Singh, F.; Tsai, M.L.; Kim, M.; Shirsat, M.D. Metal-organic framework (MOF)/reduced graphene oxide (rGO) composite for high performance CO sensor. Solid-State Electron. 2023, 204, 108638. [Google Scholar] [CrossRef]

- Krivetskiy, V.; Efitorov, A.; Arkhipenko, A.; Vladimirova, S.; Rumyantseva, M.; Dolenko, S.; Gaskov, A. Selective detection of individual gases and CO/H2 mixture at low concentrations in air by single semiconductor metal oxide sensors working in dynamic temperature mode. Sens. Actuators B Chem. 2018, 254, 502–513. [Google Scholar] [CrossRef]

- Fort, A.; Mugnaini, M.; Rocchi, S.; Vignoli, V.; Comini, E.; Faglia, G.; Ponzoni, A. Metal-oxide nanowire sensors for CO detection: Characterization and modeling. Sens. Actuators B Chem. 2010, 148, 283–291. [Google Scholar] [CrossRef]

- Brosha, E.L.; Mukundan, R.; Brown, D.R.; Garzon, F.H.; Visser, J.H.; Zanini, M.; Zhou, Z.; Logothetis, E.M. CO/HC sensors based on thin films of LaCoO3 and La0.8Sr0.2CoO3−δ metal oxides. Sens. Actuators B Chem. 2000, 69, 171–182. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, D.; Pan, Q.; Wang, T.; Chen, F. Gas sensing performance of carbon monoxide sensor based on rod-shaped tin diselenide/MOFs derived zinc oxide polyhedron at room temperature. Sens. Actuators B Chem. 2022, 371, 132481. [Google Scholar] [CrossRef]

- Wu, R.; Tian, L.; Li, H.; Liu, H.; Luo, J.; Tian, X.; Hua, Z.; Wu, Y.; Fan, S. A selective methane gas sensor based on metal oxide semiconductor equipped with an on-chip microfilter. Sens. Actuators B Chem. 2022, 359, 131557. [Google Scholar] [CrossRef]

- Shwetha, H.R.; Sharath, S.M.; Guruprasad, B.; Rudraswamy, S.B. MEMS based metal oxide semiconductor carbon dioxide gas sensor. Micro Nano Eng. 2022, 16, 100156. [Google Scholar] [CrossRef]

- Keerthana, S.; Rathnakannan, K. Room temperature operated carbon dioxide sensor based on silver doped zinc oxide/cupric oxide nanoflowers. Sens. Actuators B Chem. 2023, 378, 133181. [Google Scholar] [CrossRef]

- Thomas, T.; Kumar, Y.; Ramón, J.A.R.; Agarwal, V.; Guzmán, S.S.; Pushpan, R.R.S.; Loredo, S.L.; Sanal, K.C. Porous silicon/α-MoO3 nanohybrid based fast and highly sensitive CO2 gas sensors. Vacuum 2021, 184, 109983. [Google Scholar] [CrossRef]

- Miao, F.; Wu, H.; Tao, B.; Zang, Y. A passive-chipless LC carbon dioxide sensor with non-contact ZnO/CuO/RGO nanocomposites at room temperature. Vacuum 2023, 215, 112261. [Google Scholar] [CrossRef]

- Wang, X.; Su, J.; Chen, H.; Li, G.; Shi, Z.; Zou, H.; Zou, X. Ultrathin In2O3 nanosheets with uniform mesopores for highly sensitive nitric oxide detection. ACS Appl. Mater. Interfaces 2017, 9, 16335–16342. [Google Scholar] [CrossRef]

- Liu, B.; Luo, Y.; Li, K.; Wang, H.; Gao, L.; Duan, G. Room-temperature NO2 gas sensing with ultra-sensitivity activated by ultraviolet light based on SnO2 monolayer array film. Adv. Mater. Interfaces 2019, 6, 1900376. [Google Scholar] [CrossRef]

- Shen, Y.; Zhong, X.; Zhang, J.; Li, T.; Zhao, S.; Cui, B.; Wei, D.; Zhang, Y.; Wei, K. In-situ growth of mesoporous In2O3 nanorod arrays on a porous ceramic substrate for ppb-level NO2 detection at room temperature. Appl. Surf. Sci. 2019, 498, 143873. [Google Scholar] [CrossRef]

- Hu, J.; Zou, C.; Su, Y.; Li, M.; Ye, X.; Cai, B.; Kong, E.S.-W.; Liu, Y. Light-assisted recovery for a highly-sensitive NO2 sensor based on RGO-CeO2 hybrids. Sens. Actuators B Chem. 2018, 270, 119–129. [Google Scholar] [CrossRef]

- Chinh, N.D.; Quang, N.D.; Lee, H.; Hien, T.T.; Hieu, N.M.; Kim, D.; Kim, C.; Kim, D. NO gas sensing kinetics at room temperature under UV light irradiation of In2O3 nanostructures. Sci. Rep. 2016, 6, 3506. [Google Scholar] [CrossRef]

- Zhang, Q.; Xie, G.; Xu, M.; Su, Y.; Tai, H.; Du, H.; Jiang, Y. Visible light-assisted room temperature gas sensing with ZnO-Ag heterostructure nanoparticles. Sens. Actuators B Chem. 2018, 259, 269–281. [Google Scholar] [CrossRef]

- Wang, C.Y.; Hong, Z.S.; Wu, R.J. Promotion effect of Pt on a SnO2–WO3 material for NOx sensing. Phys. E Low-Dimens. Syst. Nanostructures 2015, 69, 191–197. [Google Scholar] [CrossRef]

- Cao, Z.; Gao, Q.; Zhou, M.; Li, X.; Wang, Q. LaNiTiO3-SE-based stabilized zirconium oxide mixed potentiometric SO2 gas sensor. Ceram. Int. 2022, 48, 9269–9276. [Google Scholar] [CrossRef]

- Zeng, S.; Zhang, Y.; Zhang, Y.; Li, Y.; Tang, C.; Li, K.; Sun, J.; Deng, T. A novel room temperature SO2 gas sensor based on TiO2/rGO buried-gate FET. Microelectron. Eng. 2022, 263, 111841. [Google Scholar] [CrossRef]

- Zhang, B.; Sun, J.; Gao, P.-X. Single bimodular sensor for differentiated detection of multiple oxidative gases. Adv. Mater. Technol. 2020, 5, 1901152. [Google Scholar] [CrossRef]

- Manikandan, V.; Vigneselvan, S.; Petrila, L.; Mane, R.S.; Singh, A.; Sobczak, K.; Chandrasekaran, J. Long-lasting stability and low-concentration SO2 gas detection aptitude of Sn-doped alumina sensors. Mater. Chem. Phys. 2022, 291, 126691. [Google Scholar]

- Li, R.; Wang, S.; Li, S.; Zhao, F.; Dong, T.; He, P.; Yu, L.; Miao, J.; Fan, X. Cu-doped flower-like SnO2 architecture toward promoting SO2 detection: Fast equilibrium and low trace monitoring. Sens. Actuators B Chem. 2023, 390, 133953. [Google Scholar] [CrossRef]

- Boudiba, A.; Zhang, C.; Bittencourt, C.; Umek, P.; Olivier, M.G.; Snyders, R.; Debliquy, M. SO2 Gas Sensors based on WO3 nanostructures with different morphologies. Procedia Eng. 2012, 47, 1033–1036. [Google Scholar] [CrossRef]

- Nguyen, T.V.; Luong, N.A.; Nguyen, V.T.; Pham, A.T.; Le, A.T.; To, T.L.; Nguyen, V.Q. Effect of the phase composition of iron oxide nanorods on SO2 gas sensing performance. Mater. Res. Bull. 2021, 134, 111087. [Google Scholar] [CrossRef]

- Das, S.; Girija, K.G.; Debnath, A.K.; Vatsa, R.K. Enhanced NO2 and SO2 sensor response under ambient conditions by polyol synthesized Ni doped SnO2 nanoparticles. J. Alloys Compd. 2021, 854, 157276. [Google Scholar] [CrossRef]

- Thangamani, G.J.; Pasha, S.K.K. Titanium dioxide (TiO2) nanoparticles reinforced polyvinyl formal (PVF) nanocomposites as chemiresistive gas sensor for sulfur dioxide (SO2) monitoring. Chemosphere 2021, 275, 129960. [Google Scholar] [CrossRef] [PubMed]

- He, X.; Ying, Z.; Wen, F.; Li, L.; Zheng, X.; Zheng, P.; Wang, G. MoS2-doped spherical SnO2 for SO2 sensing under UV light at room temperature. Mater. Sci. Semicond. Process. 2021, 134, 105997. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, Y.; Meng, X.; Zhang, Z.; Cao, J. A gas sensor based on Ag-modified ZnO flower-like microspheres: Temperature-modulated dual selectivity to CO and CH4. Surf. Interfaces 2021, 24, 101110. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Y.; Sun, X.; Wang, Y.; Li, M.; Cao, J.; Qin, С. Enhanced CH4 sensing performances of g-C3N4 modified ZnO nanospheres sensors under visible-light irradiation. Mater. Res. Bull. 2023, 165, 112290. [Google Scholar] [CrossRef]

- Tshabalala, Z.P.; Swart, H.C.; Motaung, D.E. Fabrication of TiO2 nanofibers based sensors for enhanced CH4 performance induced by notable surface area and acid treatment. Vacuum 2021, 187, 110102. [Google Scholar] [CrossRef]

- Han, L.; Zhang, S.; Zhang, B.; Zhang, B.; Wang, Y.; Bala, H.; Zhang, Z. Dual-selective detection of CO and CH4 based on hierarchical porous In2O3 nanoflowers with Pd modification. J. Mater. 2022, 8, 545–555. [Google Scholar] [CrossRef]

- Zhang, S.; Li, J.; Han, L.; Zhang, B.; Wang, Y.; Zhang, Z. Preparation of porous NiO/In2O3 nanoflower-like composites and their dual selectivity for CO/CH4. Mater. Res. Bull. 2023, 165, 112332. [Google Scholar] [CrossRef]

- Vatandoust, L.; Habibi, A.; Naghshara, H.; Sajedeh Mohammadi Aref, S.M. Fabrication and investigation of TiO1.5/ZnO nanocomposite nanosensor for detection of CO and CH4 gases. Surf. Interfaces 2022, 31, 102001. [Google Scholar] [CrossRef]

- Mishra, V.N.; Agarwal, R.P. Sensitivity, response and recovery time of SnO2 based thick-film sensor array for H2, CO, CH4 and LPG. Microelectron. J. 1998, 29, 861–874. [Google Scholar] [CrossRef]

- Mounasamy, V.; Mani, G.K.; Ponnusamy, D.; Tsuchiya, K.; Reshma, P.R.; Prasad, A.K.; Madanagurusamy, S. Investigation on CH4 sensing characteristics of hierarchical V2O5 nanoflowers operated at relatively low temperature using chemiresistive approach. Anal. Chim. Acta 2020, 1106, 148–160. [Google Scholar] [CrossRef]

- Nahirniak, S.; Dontsova, T.; Astrelin, I. Directional synthesis of SnO2-based nanostructures for use in gas sensors. In Nanochemistry, Biotechnology, Nanomaterials, and Their Applications. NANO 2017; Springer Proceedings in Physics; Springer: Berlin/Heidelberg, Germany, 2018; Volume 214, pp. 233–245. [Google Scholar]

- Dontsova, T.; Nahirniak, S.; Linyucheva, O.; Tereshkov, M.; Mahajan, A.; Singh, R.C. Physicochemical properties of Tin (IV) oxide synthesized by different methods and from different precursors. Appl. Nanosci. 2022, 12, 1155–1168. [Google Scholar] [CrossRef]

- Sviderskyi, A.; Nahirniak, S.; Yashchenko, T.; Dontsova, T.; Kalinowski, S. Properties of TiO2 and SnO2 in a state of different dispersion and morphology. In Proceedings of the NAP-2018, 2018 IEEE 8th International Conference on Nanomaterials: Applications and Properties (NAP), Zatoka, Ukraine, 9–14 September 2018; 01NNPT13-1-4. [Google Scholar]

- Yashchenko, T.; Sviderskyi, A.; Nahirniak, S.; Dontsova, T.; Kalinowski, S. Electrical properties and sensitivity of SnO2 nanostructures to organic compounds. Nanosistemi Nanomater. Nanotehnologii 2021, 19, 53–70. [Google Scholar]

- Korotcenkov, G. Current trends in nanomaterials for metal oxide-based conductometric gas sensors: Advantages and limitations. Part 1: 1D and 2D Nanostructures. Nanomaterials 2020, 10, 1392. [Google Scholar] [CrossRef]

- Xue, S.; Cao, S.; Huang, Z.; Yang, D.; Zhang, G. Improving gas-sensing performance based on MOS nanomaterials: A Review. Materials 2021, 14, 4263. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.; Chase, M.; Jung, J.; Kim, H.-D. Correlation between sensing accuracy and read margin of a memristor-based NO gas sensor array estimated by neural network analysis. ACS Sens. 2023, 8, 2105–2114. [Google Scholar] [CrossRef] [PubMed]

- Kang, M.; Cho, I.; Park, J.; Jeong, J.; Lee, K.; Lee, B.; Henriquez, D.D.O.; Yoon, K.; Park, I. High accuracy real-time multi-gas identification by a batch-uniform gas sensor array and deep learning algorithm. ACS Sens. 2022, 7, 430–440. [Google Scholar] [CrossRef]

- The Main Sources of Air Pollution. Available online: https://www.breeze-technologies.de/blog/main-sources-of-air-pollution/ (accessed on 31 July 2023).

- Capelli, L.; Sironi, S.; Del Rosso, R. Electronic noses for environmental monitoring applications. Sensors 2014, 14, 19979–20007. [Google Scholar] [CrossRef]

- EN 13725:2003; Air Quality: Determination of Odor Concentration by Dynamic Olfactometry. Comitee Europeen de Normalisation: Brussels, Belgium, 2007.

- Bourgeois, W.; Romain, A.-C.; Nicolas, J.; Stuetz, R.M. The use of sensor arrays for environmental monitoring: Interests and limitations. J. Environ. Monit. 2003, 5, 852–860. [Google Scholar] [CrossRef]

- Betty, C.A.; Choudhury, S.; Girija, K.G. Reliability studies of highly sensitive and specific multi-gas sensor based on nanocrystalline SnO2 film. Sens. Actuators B 2014, 193, 484–491. [Google Scholar] [CrossRef]

- Abbas, M.N.; Moustafa, G.A.; Gopel, W. Multicomponent analysis of some environmentally important gases using semiconductor tin oxide sensors. Anal. Chim. Acta 2001, 431, 181–194. [Google Scholar] [CrossRef]

- Özmet, A.; Dogan, E. Design of a portable e-nose instrument for gas classifications. IEEE Trans. Instrum. Meas. 2009, 58, 3609–3618. [Google Scholar]

- Helli, O.; Siadat, M.; Lumbreras, M. Qualitative and quantitative identification of H2S/NO2 gaseous components in different reference atmospheres using a metal oxide sensor array. Sens. Actuators B Chem. 2004, 103, 403–408. [Google Scholar] [CrossRef]

- Lee, D.S.; Jung, J.K.; Lim, J.W.; Huh, J.S.; Lee, D.D. Recognition of volatile organic compounds using SnO2 sensor array and pattern recognition analysis. Sens. Actuators B Chem. 2001, 77, 228–236. [Google Scholar] [CrossRef]

- Barisci, J.N.; Wallace, G.G.; Andrews, M.K.; Partridge, A.C.; Harris, P.D. Conduction polymer sensors for monitoring aromatic hydrocarbons using an electronic nose. Sens. Actuators B Chem. 2002, 84, 252–257. [Google Scholar] [CrossRef]

- De Vito, S.; Massera, E.; Piga, A.; Martinotto, L.; di Francia, G. On field calibration of an electronic nose for benzene estimation in an urban pollution monitoring scenario. Sens. Actuators B Chem. 2008, 129, 750–757. [Google Scholar] [CrossRef]

- Romain, A.-C.; Andre, P.; Nicolas, J. Three years experiment with the same tin oxide sensor array for identification of malodorous sources in the environment. Sens. Actuators B 2002, 84, 271–277. [Google Scholar] [CrossRef]

- Cho, J.H.; Kim, Y.W.; Na, K.J.; Jeon, G.J. Wireless electronic nose system for real-time quantitative analysis of gas mixture using micro-gas sensor array and neuro-fuzzy network. Sens. Actuators B Chem. 2008, 134, 104–111. [Google Scholar] [CrossRef]

- Dentoni, L.; Capelli, L.; Sironi, S.; del Rosso, R.; Zanetti, S.; Della Torre, M. Development of an electronic nose for environmental odour monitoring. Sensors 2012, 12, 14363–14381. [Google Scholar] [CrossRef]

- Reddy, B.K.; Borse, P.H. Review—Recent material advances and their mechanistic approaches for room temperature chemiresistive gas sensors. J. Electrochem. Soc. 2021, 168, 057521. [Google Scholar] [CrossRef]

- Dadkhan, M.; Tulliani, J.-M. Nanostructured metal oxide semiconductors towards greenhouse gas detection. Chemosensors 2022, 10, 57. [Google Scholar] [CrossRef]

- Lee, S.P. Electrodes for semiconductor gas sensors. Sensors 2017, 17, 683. [Google Scholar] [CrossRef] [PubMed]

- Adeyemo, A.; Mathew, J.; Jabir, A.; Di Natele, C.; Martinelli, E.; Ottavi, M. Efficient sensing approaches for high-density memristor sensor array. J. Comput. Electron. 2018, 17, 1285–1296. [Google Scholar] [CrossRef]

- Liu, J.; Han, T.; Sun, B.; Kong, L.; Jin, Z.; Huang, X.; Liu, J.; Meng, F. Catalysis-based cataluminiscent and conductometric gas sensors: Sensing nanomaterials, mechanism, applications and perspectives. Catalysis 2016, 6, 210. [Google Scholar]

- Haidry, A.A.; Ebach-Stahl, A.; Saruhan, B. Effect of Pt/TiO2 interface on room temperature hydrogen sensing performance of memristor type Pt/TiO2/Pt structure. Sens. Actuators B Chem. 2017, 253, 1043–4054. [Google Scholar] [CrossRef]

- Bhat, P.; Kumar, S.K.N. Evaluation of IDE-based flexible thin film ZnO sensor for VOC sensing in a custom designed gas chamber at room temperature. J. Mater. Sci. Mater. Electron. 2022, 33, 1529–1541. [Google Scholar] [CrossRef]

- Mikolasek, M.; Meri, J.; Chymo, F.; Ondrejka, P.; Rehacek, V.; Predanocy, M.; Kostic, I.; Hotovy, I. Novel Cu2O gas sensor prepared by potentiostatic electrodeposition on IDE electrodes. J. Physics Conf. Ser. 2019, 1319, 012009. [Google Scholar] [CrossRef]

- Plecenik, T.; Moško, M.; Haidry, A.A.; Ďurina, P.; Truchlý, M.; Grančič, B.; Gregor, M.; Roch, T.; Satrapinskyy, L.; Mošková, A.; et al. Fast high-sensitive room-temperature semiconductor gas sensor based on nanoscale Pt-TiO2-Pt sandwich. Sens. Actuators B 2015, 207, 351–361. [Google Scholar] [CrossRef]

- Vidiš, M.; Plecenik, T.; Moškp, M.; Tomašec, S.; Roch, T.; Satrapinskyy, L.; Grančič, B.; Plecenik, A. Gasistor: A memristor based gas-triggered switch and gas sensor with memory. Appl. Phys. Lett. 2019, 115, 093504. [Google Scholar] [CrossRef]

- Nagirnyak, S.V.; Dontsova, T.A. Gas sensor device creation. In Proceedings of the NAP-2017, 2017 IEEE 7th International Conference on Nanomaterials: Applications and Properties (NAP), Odessa, Ukraine, 10–15 September 2017. 01NNPT13-1-4. [Google Scholar]

- Feng, S.; Farha, F.; Li, Q.; Wan, Y.; Xu, Y.; Zhang, T.; Ning, H. Review on smart gas sensing technology. Sensors 2019, 19, 3760. [Google Scholar] [CrossRef]

- Shaalan, N.M.; Yamazaki, T.; Kikuta, T. Effect of micro-electrode geometry on NO2 gas-sensig characteristics of one-dimensional tin dioxide nanostructure microsensors. Sens. Actuators B 2011, 156, 784–790. [Google Scholar] [CrossRef]

- Tamaki, J.; Mayaji, A.; Makinodan, J.; Ogura, S.; Konishi, S. Effect of micro-gap electrode on detection of dilute NO2 using WO3 thin film microsensors. Sens. Actuators B Chem. 2005, 108, 202–206. [Google Scholar] [CrossRef]

- Nguyen Mihn, Q.; Tong, H.D.; Kuijk, A.; van de Bent, F.; Beekman, P.; van Rijn, C.J.M. Gas sensing performance at room temperature of nanogap interdigitated electrodes for detection of acetone at low concentration. RSC Adv. 2017, 7, 50279. [Google Scholar]

- Miyaji, A.; Ogura, S.; Konishi, S.; Tamaki, J. Effect of micro-gap electrode in nitrogen dioxide sensor using tungsten oxide thin film. Electrochem. Soc. Proc. 2004, 2004-09, 201–204. [Google Scholar]

- Prajesh, R.; Goyal, V.; Saini, V.; Bhargava, J.; Sharma, A.; Agarwal, A. Effect of IDE placement on response in metal oxide gas sensors. Mater. Res. Express 2018, 5, 096415. [Google Scholar] [CrossRef]

- Ji, H.; Zeng, W.; Li, Y. Gas sensing mechanisms of metal oxide semiconductors: A focus review. Nanoscale 2019, 11, 22664–22684. [Google Scholar] [CrossRef]

- Li, T.; Zeng, W.; Long, H.; Wang, Z. Nanosheet-assembled hierarchical SnO2 nanostructures for efficient gas-sensing applications. Sens. Actuators B Chem. 2016, 231, 120–128. [Google Scholar] [CrossRef]

- Xiao, X.; Liu, L.; Ma, J.; Ren, Y.; Cheng, X.; Zhu, Y.; Zhao, D.; Elzatahry, A.A.; Alghamdi, A.; Deng, Y. Ordered mesoporous tin oxide semiconductors with large pores and crystallized walls for high-performance gas sensing. ACS Appl. Mater. Interfaces 2018, 10, 1871–1880. [Google Scholar] [CrossRef]

- Van Dang, T.; Hoa, N.D.; Van Duy, N.; Van Hieu, N. Chlorine gas sensing performance of on-chip grown ZnO, WO3, and SnO2 nanowire sensors. ACS Appl. Mater. Interfaces 2016, 8, 4828–4837. [Google Scholar] [CrossRef]

- Yamazoe, N. New approaches for improving semiconductor gas sensors. Sens. Actuators B Chem. 1991, 5, 7–19. [Google Scholar] [CrossRef]

- Ansari, S.G.; Boroojerdian, P.; Sainkar, S.R.; Karekar, R.N.; Aiyer, R.C.; Kulkarni, S.A. Grain size fffects on H2 gas sensitivity of thick film resistor using SnO2 nanoparticles. Thin Solid Film. 1997, 295, 271–276. [Google Scholar] [CrossRef]

- Baraton, M.-I.; Merhari, L. Influence of the particle size on the surface reactivity and gas sensing properties of SnO2 nanopowders. Mater. Trans. 2001, 42, 1616–1622. [Google Scholar] [CrossRef]

- Das, S.; Mojumder, S.; Saha, D.; Pal, M. Influence of major parameters on the sensing mechanism of semiconductor metal oxide based chemiresistive gas aensors: A review focused on personalized healthcare. Sens. Actuators B Chem. 2022, 352, 131066. [Google Scholar] [CrossRef]

- Hwang, S.-H.; Kim, Y.K.; Hong, S.H.; Lim, S.K. Effect of the morphology and electrical property of metal-deposited ZNO nanostructures on CO gas sensitivity. Nanomaterials 2020, 10, 2124. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.; Choi, P.G.; Itoh, T.; Masuda, Y. Morphology control technique of ZnO by hydroxide ion supply rate and its effect on the ppt-level gas sensors. J. Am. Ceram. Soc. 2023, 106, 5944–5954. [Google Scholar] [CrossRef]

- Yao, K.; Caruntu, D.I.; Cao, B.; O’Connor, C.J.; Zhou, W. Investigation of gas-sensing performance of SnO2 nanoparticles with different morphologies. IEEE Trans. Nanotechnol. 2010, 9, 630–633. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, C. Oxygen vacancy engineering on cerium oxide nanowires for room-temperature linalool detection in rice aging. J. Adv. Ceram. 2022, 11, 1559–1570. [Google Scholar] [CrossRef]

- Liu, J.; Chen, S.; Liu, Y.; Zhao, B. Progress in preparation, characterization, surface functional modification of graphene oxide: A review. J. Saudi Chem. Soc. 2022, 26, 101560. [Google Scholar] [CrossRef]

- Bae, K.L.; Kim, J.; Lim, C.K.; Nam, K.M.; Song, H. Colloidal zinc oxide-copper(I) oxide nanocatalysts for selective aqueous photocatalytic carbon dioxide conversion into methane. Nat. Commun. 2017, 8, 1156. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.E.; Lim, C.K.; Park, H.J.; Song, H.; Choi, S.-Y.; Lee, D.-S. ZnO–CuO core-hollow cube nanostructures for highly sensitive acetone gas sensors at the ppb level. ACS Appl. Mater. Interfaces 2020, 12, 35688–35697. [Google Scholar] [CrossRef]

- Yu, Q.; Kong, W.; Zhang, Y.; Li, X.; Xu, Y. Morphology-controllable synthesis of hierarchical hollow GaFeO3 microcubes with selective triethylamine gas-sensing properties. Ceram. Int. 2022, 48, 4554–4562. [Google Scholar] [CrossRef]

- Wang, C.-X.; Yin, L.; Zhang, L.; Xiang, D.; Gao, R. Metal oxide gas sensors: Sensitivity and influencing factors. Sensors 2010, 10, 2088–2106. [Google Scholar] [CrossRef]

- Neri, G. First fifty years of chemoresistive gas sensors. Chemosensors 2015, 3, 1–20. [Google Scholar] [CrossRef]

- Meixner, H.; Lampe, U. Metal oxide sensors. Sens. Actuators B Chem. 1996, 33, 198–202. [Google Scholar] [CrossRef]

- Zhang, M.; Yuan, Z.; Shen, J.; Zheng, C. Improvement and mechanism for the fast response of a Pt/TiO2 gas sensor. Sens. Actuators B Chem. 2010, 148, 87–92. [Google Scholar] [CrossRef]

- Ghosh, A.; Maity, A.; Banerjee, R.; Majumder, S.B. Volatile organic compound sensing using copper oxide thin films: Addressing the cross sensitivity issue. J. Alloys Compd. 2017, 692, 108–118. [Google Scholar] [CrossRef]

- Kamarudin, K.; Bennetts, V.H.; Mamduh, S.H.; Visvanathan, R.; Yeon, A.S.A.; Shakaff, A.Y.M.; Zakaria, A.; Abdullah, A.; Kamarudin, L.M. Cross-sensitivity of metal oxide gas sensor to ambient temperature and humidity: Effects on gas distribution mapping. Am. Inst. Phys. 2017, 1808, 020025. [Google Scholar]

- Neri, G.; Leonardi, S.G.; Latino, M.; Donato, N.; Baek, S.; Conte, D.E.; Russo, P.A.; Pinna, N. Sensing behavior of SnO2/reduced graphene oxide nanocomposites toward NO2. Sens. Actuators B Chem. 2013, 179, 61–68. [Google Scholar] [CrossRef]

- Fan, S.; Srivastava, A.K.; Dravid, V.P. UV-activated room-temperature gas sensing mechanism of polycrystalline ZnO. Appl. Phys. Lett. 2009, 95, 142106. [Google Scholar] [CrossRef]

- Kumar, R.; Liu, X.; Zhang, J.; Kumar, M. Room-temperature gas sensors under photoactivation: From metal oxides to 2D materials. Nano-Micro Lett. 2020, 12, 164. [Google Scholar] [CrossRef]

- Lee, J.H.; Kim, J.-Y.; Mirzaei, A.; Nam, M.-S.; Kim, H.W.; Kim, S.S. Room-temperature detection of acetone gas by PANI/NiO-loaded TiO2 nanoparticles under UV irradiation. Sens. Actuators B Chem. 2023, 374, 132850. [Google Scholar] [CrossRef]

- Pedowitz, M.; Kim, S.; Lewis, D.I.; Uppalapati, B.; Khan, D.; Bayram, F.; Koley, G.; Daniels, K.M. Fast selective sensing of nitrogen-based gases utilizing δ-MnO2-epitaxial graphene-silicon carbide heterostructures for room temperature gas sensing. J. Microelectromech. Syst. 2020, 29, 846–852. [Google Scholar] [CrossRef]

- Shin, D.H.; Choi, Y.S.; Park, S.-J.; Yeo, C.-S.; Park, Y.Y.; Jun, S.; Lee, S.-K.; Kim, T.-W.; Bae, S.; Hong, B.H. Fast and complete recovery of TMDs-decorated RGO fiber gas sensors at room temperature. Appl. Surf. Sci. 2022, 578, 151832. [Google Scholar] [CrossRef]

- Moumen, A.; Kumarage, W.G.C.; Comini, E. P-type metal oxide semiconductor thin films: Synthesis and chemical sensor applications. Sensors 2022, 22, 1359. [Google Scholar] [CrossRef]

- Abdullah, A.N.; Kamarudin, L.M.; Adom, A.H.; Zakaria, S.A.; Juffry, Z.H.M.; Bennetts, V.H. Correction model for metal oxide sensor drift caused by ambient temperature and humidity. Sensors 2022, 22, 3301. [Google Scholar] [CrossRef]

- Nair, S.S.; Illyaskutty, N.; Tam, B.; Yazaydin, A.O.; Emmerich, K.; Steudel, A.; Hashem, T.; Schöttner, L.; Wöll, C.; Kohler, H.; et al. ZnO@ZIF-8: Gas sensitive core-shell hetero-structures show reduced cross-sensitivity to humidity. Sens. Actuators B Chem. 2020, 304, 127184. [Google Scholar] [CrossRef]

- Spagnoli, E.; Fabbri, B.; Gaiardo, A.; Valt, M.; Ardit, M.; Krik, S.; Cruciani, G.; Della Ciana, M.; Vanzetti, L.; Vola, G.; et al. Design of a metal-oxide solid solution for selective detection of ethanol with marginal influence by humidity. Sens. Actuators B Chem. 2022, 370, 132426. [Google Scholar] [CrossRef]

- Schipani, F.; Miller, D.B.; Ponce, M.A.; Aldao, C.M.; Akbar, S.A.; Morris, P.A. Electrical characterization of semiconductor oxide-based gas sensors using impedance spectroscopy: A review. Rev. Adv. Sci. Eng. 2016, 5, 86–105. [Google Scholar] [CrossRef]

- Ratan, S.; Kumar, C.; Kumar, A.; Jarwal, D.K.; Mishra, A.K.; Upadhyay, R.K.; Singh, A.P.; Jit, S. Room temperature high hydrogen gas response in Pd/TiO2/Si/Al capacitive sensor. Micro Nano Lett. 2020, 15, 632–635. [Google Scholar] [CrossRef]

- Marimuthu, G.; Nguyen, B.S.; Pham, V.T.; Nguyen, V.H.; Tran, V.M.; Sivashanmugan, K.; Pazhanivel, T. Novel NiCo2O4/MWCNTs nanocomposite with flake-like architecture as room temperature capacitive-type NH3 gas sensor. Mater. Lett. 2021, 283, 128814. [Google Scholar] [CrossRef]

- Schipani, F.; Miller, D.B.; Ponce, M.A.; Aldao, C.M.; Akbar, S.A.; Morris, P.A.; Xu, J. Conduction mechanisms in SnO2 single-nanowire gas sensors: An impedance spectroscopy study. Sens. Actuators B Chem. 2017, 241, 99–108. [Google Scholar] [CrossRef]

- Lee, S.; Jin, J.; Baek, J.; Lee, J.; Chae, H. Readout integrated circuit for small-sized and low-power gas sensor based on HEMT device. Sensors 2021, 21, 5637. [Google Scholar] [CrossRef] [PubMed]

- Drix, D.; Schmuker, M. Resolving fast gas transients with metal oxide sensors. ACS Sens. 2021, 6, 688–692. [Google Scholar] [CrossRef] [PubMed]

- Burgués, J.; Hernandez, V.; Lilienthal, A.J.; Marco, S. Smelling nano aerial vehicle for gas source localization and mapping. Sensors 2019, 19, 478. [Google Scholar] [CrossRef]

- Acharyya, S.; Jana, B.; Nag, S.; Saha, G.; Guha, P.K. Single resistive sensor for selective detection of multiple VOCs employing SnO2 hollowspheres and machine learning algorithm: A proof of concept. Sens. Actuators B Chem. 2020, 321, 128484. [Google Scholar] [CrossRef]

- Liu, T.; Guo, L.; Wang, M.; Su, C.; Wang, D.; Dong, H.; Chen, J.; Wu, W. Review on algorithm design in electronic noses: Challenges, status, and trends. Intell. Comput. 2023, 2, 0012. [Google Scholar] [CrossRef]

- Casey, J.G.; Collier-Oxandale, A.; Hannigan, M. Performance of artificial neural networks and linear models to quantify 4 trace gas species in an oil and gas production region with low-cost sensors. Sens. Actuators B Chem. 2019, 283, 504–514. [Google Scholar] [CrossRef]

| Target Gas/Concentration | SMO/Mode of Signal Transmission | Synthesis Technique/Particle Morphology | Sensor Parameters | Ref. |

|---|---|---|---|---|

| H2 100 ppm | Pd35Au65@ZnO/ chemoresistive | Hydrothermal route/core-shell nanoparticles | Response: 80% Response/recovery time: 0.6/12 min Detection limit: N/A Operating temperature: 300 °C | [41] |

| H2 400 ppm | SnO2/ chemoresistive | Hydrothermal/nanosheet-assembled nanoflowers | Response: 22 Response/recovery time: ~15/~17 s Detection limit: N/A Operating temperature: 350 °C | [82] |

| H2 100 ppm | ZnO/ chemoresistive | Electrospinning, RF sputtering/ porous nanotubes | Response: 1.48 Response/recovery time: ~50/~200 s Detection limit: N/A Operating temperature: 200 °C | [83] |

| H2 5 ppm | Au-decorated ZnO/ chemoresistive | Thermal CVD/ nano-network | Response: 21.5% Response/recovery time: 4/24 s Detection limit: N/A Operating temperature: 150 °C | [84] |

| H2 250 ppm | Pt-Au@ZnO/ chemoresistive | Hydrothermal/bimetallic nanoparticles, nanorods | Response: 157.4 Response time: 115 s Detection limit: 50 ppm Operating temperature: 130 °C | [85] |

| H2 40 ppm | PdO/WO3 nanohybrids/ chemoresistive | Hydrothermal/nanorods | Response: 8.02 Response/recovery time: 2.1/5.8 min Detection limit: 5 ppm Operating temperature: 200–250 °C | [86] |

| H2 1000 ppm | Pd-decorated WO3/ chemoresistive | Magnetron sputtering method/films | Response: 586 Response/recovery time: 360/90 s Detection limit: N/A Operating temperature: 200 °C | [87] |

| H2 20 ppm | Pd-decorated SnO2/ chemoresistive | Hydrothermal/nanosheets | Response: 75 Response/recovery time: 21/13 s Detection limit: N/A Operating temperature: 220 °С | [88] |

| H2 50 ppm | PdO-decorated NiO/ chemoresistive | Ultrasonic spray pyrolysis/ needle-like thin films | Response: 82 Response/recovery time: 53/78 s Detection limit: 500 ppb Operating temperature: 250 °С | [89] |

| H2 100 ppm | Pd@PdO/ γ-Fe2O3@GC Heterostructures/ chemoresistive | Solvothermal/core-shells, microcubes | Response: 96.2 Response/recovery time: 21/29 s Detection limit: 500 ppb Operating temperature: RT | [90] |

| CO 25 ppm | NiO-MOF/rGO/ chemoresistive | Hydrothermal method/nanoparticle aggregates | Response: 30 Response/recovery time: 30/70 s Detection limit: N/A Operating temperature: RT | [91] |

| CO 50 ppm | SnO2-PdOx/ chemoresistive | Sol-gel method/nanoparticle aggregates | Response: 3.8 Response/recovery time: N/A Detection limit: 7.33 ppm Operating temperature: 500 °C | [92] |

| CO 300 ppm | SnO2 nanowires/ chemoresistive | Evaporation-condensation process, with vapor–liquid– solid growth mechanism/nanowires | Response: 1.8 Response/recovery time: 200/800 s Detection limit: N/A Operating temperature: 250 °C | [93] |

| CO 330 ppm | La0.8Sr0.2CoO3/potentiometric | Radio frequency magnetron sputtering/thin films | Response: 15 Response/recovery time: 120/3000 s Detection limit: 10 ppm Operating temperature: 600 °С | [94] |

| CO 200 ppm | ZnO/SnSe2/ chemoresistive | Hydrothermal method/ rod-shaped, polyhedral nanostructures | Response: 14.8 Response/recovery time: 19/13 s Detection limit: 10 ppm Operating temperature: RT | [95] |

| CO 500 ppm | Pt-SnO2/ chemoresistive | Chemical oxidation in solution/nanoparticles | Response: 4.8 Response/recovery time: 1/3 min Detection limit: 50 ppm Operating temperature: 350 °C | [96] |

| CO2 400 ppm | BaTiO3-CuO/ chemoresistive | Plasma enhanced chemical vapor deposition/films | Response: 54 Response/recovery time: 30/230 min Detection limit: N/A Operating temperature: 300 °C | [97] |

| CO2 1000 ppm | Ag doped ZnO/CuO nanoflowers/ chemoresistive | Hydrothermal Method/nanoflowers | Response: 18.4 Response/recovery time: 2.5–4.4/3.1–5.4 min Detection limit: 150 ppm Operating temperature: RT | [98] |

| CO2 100 ppm | MoO3 nanorods/ chemoresistive | Vacuum thermal evaporation/nanorods | Response: 15 Response/recovery time: 8/40 s Detection limit: 50 ppm Operating temperature: 250 °C | [99] |

| CO2 500 ppm | ZnO/CuO/RGO nanocomposite/ radio frequency identification | Hydrothermal method/nanorods | Response: 1.9 Response/recovery time: 19.1/32.5 s Detection limit: N/A Operating temperature: RT | [100] |

| NO2 5 ppm | WS2/SnO2/ optoelectronic | RT aqueous self-assembly/quantum dot-decorated nanosheets heterostructure | Response: 430% Response/recovery time: 10/9 s Detection limit: N/A Operating temperature: RT | [70] |

| NOx 6 ppm | Au-decorated ZnO/ chemoresistive | Colloidal templating/1D nanorods | Response: 78% Response/recovery time: 110/100 s Detection limit: 550 ppb Operating temperature: RT | [71] |

| NO2 1 ppm | ZnO/PbS nanocomposite/ chemoresistive | Hydrolysis/ nanorods | Response: 118–122% Response/recovery time: 3/4 min Detection limit: 26 ppb Operating temperature: RT | [72] |

| NOx 10 ppm | In2O3/ chemoresistive | Hydrothermal/mesoporous nanosheets | Response: 213 Response/recovery time: 4/9 s Detection limit: 10 ppb Operating temperature: 120 °C | [101] |

| NO2 5 ppm | SnO2/ chemoresistive | Hydrothermal/ hollow nanospheres | Response: 5 Response/recovery time: 7/25 s Detection limit: 0.1 ppm Operating temperature: RT | [102] |

| NO2 800 ppb | In2O3/ chemoresistive | Hydrothermal/nanorods | Response: 14.9 Response/recovery time: 14/32 s Detection limit: N/A Operating temperature: RT | [103] |

| NO2 10 ppm | rGO-CeO2/ chemoresistive | Solvothermal/nanosheets, nanocrystals | Response: 4.59 Response/recovery time: 100/258 s Detection limit: 0.3 ppm Operating temperature: RT | [104] |

| NO 50 ppm | In2O3/ chemoresistive | Co-arc-discharge/nanoparticles | Response: 40 Response/recovery time: 10 s/4 min Detection limit: N/A Operating temperature: RT | [105] |

| NO2 5 ppm | Ag-decorated ZnO/ chemoresistive | Modified polymer-network gel route/nanoparticles | Response: 1.545 Response/recovery time: 150/50 s Detection limit: <500 ppb Operating temperature: RT | [106] |

| NO 1000 ppm | Pt/SnO2-WO3/ chemoresistive | Calcination method/nanoparticle aggregates | Response: 3.3 Response/recovery time: 40/206 s Detection limit: 10 ppm Operating temperature: RT | [107] |

| SO2 5 ppm | LaNiTiO3/potentiometric | Sol-gel method/nanoparticle aggregates | Response: 27.5 Response/recovery time: 40/206 s Detection limit: 0.05 ppm Operating temperature: 510 °С | [108] |

| SO2 20 ppm | TiO2/rGO nanocomposite/ chemoresistive | Calcination method/thin film | Response: 3.47 Response/recovery time: 456/134 s Detection limit: N/A Operating temperature: RT | [109] |

| SO2 50 ppm | ZnO/ chemoresistive | Microwave-assisted hydrothermal/ nanorods | Response: ~100 Response/recovery time: N/A Detection limit: 5 ppm Operating temperature: 200 °C | [110] |

| SO2 300 ppm | Sn-doped Al2O3/ chemoresistive | The microwave irradiation method/nanoparticles | Response: 78.14 Response/recovery time: 17/200 s Detection limit: 10 ppm Operating temperature: 250 °C | [111] |

| SO2 5 ppm | Cu-SnO2/ chemoresistive | Hydrothermal method/nanosheets | Response: 4 Response/recovery time: 14/17 s Detection limit: 1 ppm Operating temperature: 300 °C | [112] |

| SO2 5 ppm | WO3/ chemoresistive | Hydrothermal method/ nanoparticles | Response: 50 Response/recovery time: 18/11 s Detection limit: 1 ppm Operating temperature: 260 °C | [113] |

| SO2 20 ppm | γ-Fe2O3/surface acoustic wave | Chemical precipitation method/ nanorods | Response: 35 Response/recovery time: 65/65 s Detection limit: 2.5 ppm Operating temperature: RT | [114] |

| SO2 10 ppm | Ni doped SnO2/ chemoresistive | Low temperature polyol route/ nanoparticles | Response: 6 Response/recovery time: 50/~2000 s Detection limit: 3 ppm Operating temperature: RT | [115] |

| SO2 600 ppm | PVF/TiO2/ chemoresistive | Solution casting technique/ nanocomposites | Response: 83.75 Response/recovery time: 66/107 s Detection limit: 40 ppm Operating temperature: 150 °C | [116] |

| SO2 15 ppm | SnO2/MoS2 heterostructure/ chemoresistive | Hydrothermal method/ nanospheres | Response: 12 Response/recovery time: ~300/~600 s Detection limit: 1 ppm Operating temperature: RT | [117] |

| CH4 100 ppm | Pd modified ZnO/ chemoresistive | Hydrothermal method/nanosheets | Response: 8.65 Response/recovery time: ~700/~250 s Detection limit: N/A Operating temperature: 200 °C | [79] |

| CH4 1000 ppm | Pt-SnO2/ chemoresistive | Chemical oxidation in solution/ nanoparticles | Response: 65.6 Response/recovery time: 1/3 min Detection limit: 200 ppm Operating temperature: 350 °C | [96] |

| CH4 5000 ppm | Ag-modified ZnO/ chemoresistive | Solvothermal route/flower-like microspheres | Response: 20.15 Response/recovery time: 118/119 s Detection limit: N/A Operating temperature: 200 °C | [118] |

| CH4 1000 ppm | ZnO/g-C3N4 composites/ chemoresistive | Precipitation-calcination route/ nanospheres | Response: 6.89 Response/recovery time: ~700/~300 s Detection limit: 500 ppm Operating temperature: RT | [119] |

| CH4 60 ppm | TiO2/ chemoresistive | Hydrothermal method/ nanofibers | Response: 57 Response/recovery time: 99/162 s Detection limit: 5 ppm Operating temperature: RT | [120] |

| CH4 1000 ppm | Pd/In2O3/ chemoresistive | Hydrothermal method/ nanoflowers | Response: 1.16 Response/recovery time: 13/27 s Detection limit: N/A Operating temperature: 340 °C | [121] |

| CH4 1000 ppm | NiO-modified In2O3/ chemoresistive | Hydrothermal method/flower-like structure | Response: 1.3 Response/recovery time: 33/64 s Detection limit: N/A Operating temperature: 350 °C | [122] |

| CH4 1000 ppm | TiO1.5/ZnO/ chemoresistive | DC magnetron sputtering/ nanoparticles | Response: 1.2 Response/recovery time: 430/228 s Detection limit: N/A Operating temperature: 300 °C | [123] |

| CH4 400 ppm | Pd-doped SnO2/ chemoresistive | Screen printing/ thick films | Response: 60 Response/recovery time: 8/73 s Detection limit: 50 ppm Operating temperature—350 °C | [124] |

| CH4 50 ppm | V2O5/ chemoresistive | DC magnetron sputtering technique/hierarchical nanostructures | Response: ~8 Response/recovery time: ~600/~550 s Detection limit: N/A Operating temperature: 100 °С | [125] |

| Parameter/Specificity | Example |

|---|---|

| Application type | Qualitative/Quantitative analysis |

| Measurement type | Continuous/Discrete |

| Device location | In situ/Remote |

| Environmental | Controlled/Variable, Harsh/Normal |

| Power | Autonomous/Mains |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tereshkov, M.; Dontsova, T.; Saruhan, B.; Krüger, S. Metal Oxide-Based Sensors for Ecological Monitoring: Progress and Perspectives. Chemosensors 2024, 12, 42. https://doi.org/10.3390/chemosensors12030042

Tereshkov M, Dontsova T, Saruhan B, Krüger S. Metal Oxide-Based Sensors for Ecological Monitoring: Progress and Perspectives. Chemosensors. 2024; 12(3):42. https://doi.org/10.3390/chemosensors12030042

Chicago/Turabian StyleTereshkov, Mykhail, Tetiana Dontsova, Bilge Saruhan, and Svitlana Krüger. 2024. "Metal Oxide-Based Sensors for Ecological Monitoring: Progress and Perspectives" Chemosensors 12, no. 3: 42. https://doi.org/10.3390/chemosensors12030042

APA StyleTereshkov, M., Dontsova, T., Saruhan, B., & Krüger, S. (2024). Metal Oxide-Based Sensors for Ecological Monitoring: Progress and Perspectives. Chemosensors, 12(3), 42. https://doi.org/10.3390/chemosensors12030042