Integrated Photonic Sensors for the Detection of Toxic Gasses—A Review

Abstract

:1. Introduction

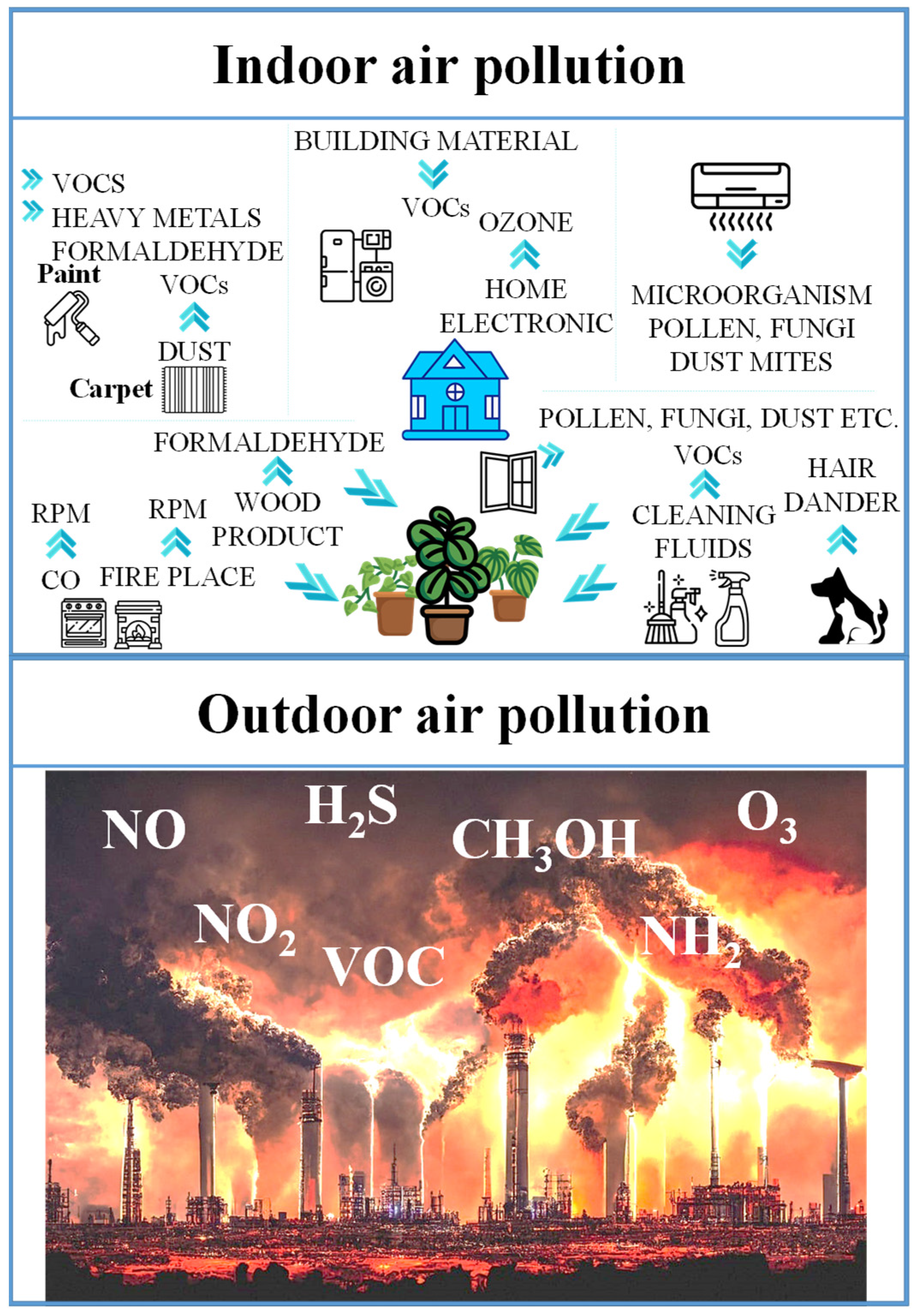

2. Indoor and Outdoor Toxic Gasses

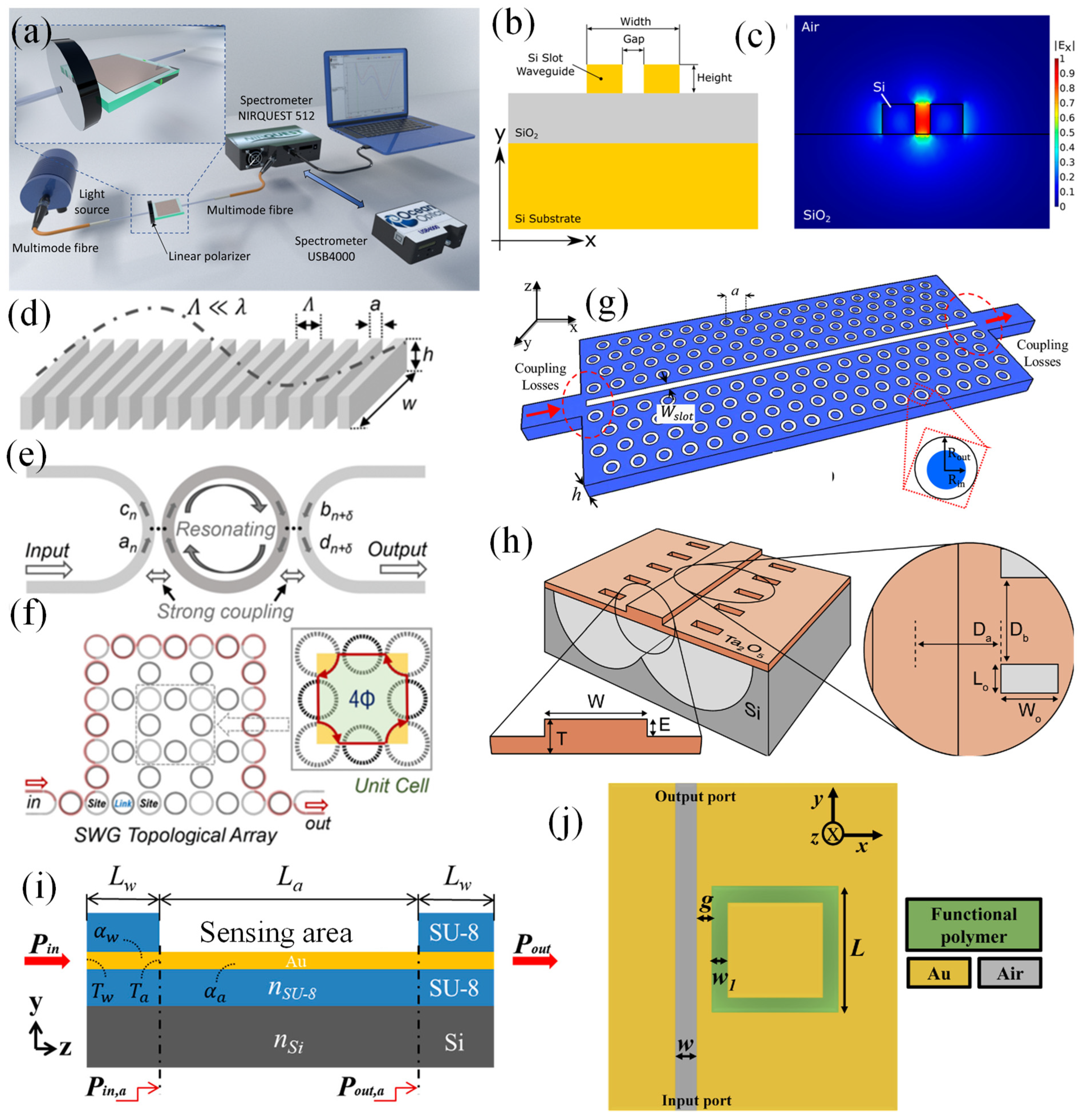

3. Types of Optical WG Architectures Widely Used for Gas Sensing

4. Two Widely Employed Gas Sensing Mechanisms

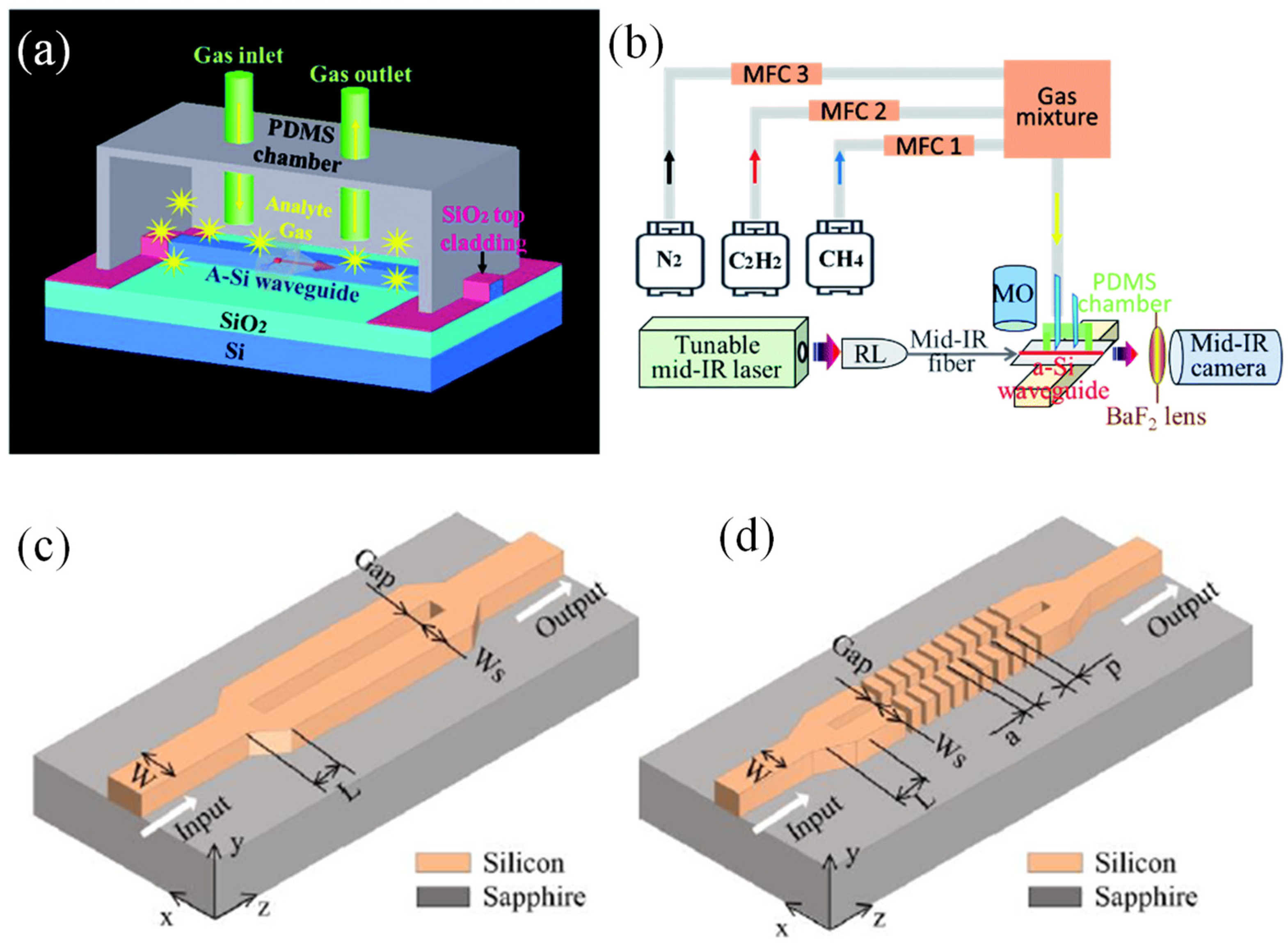

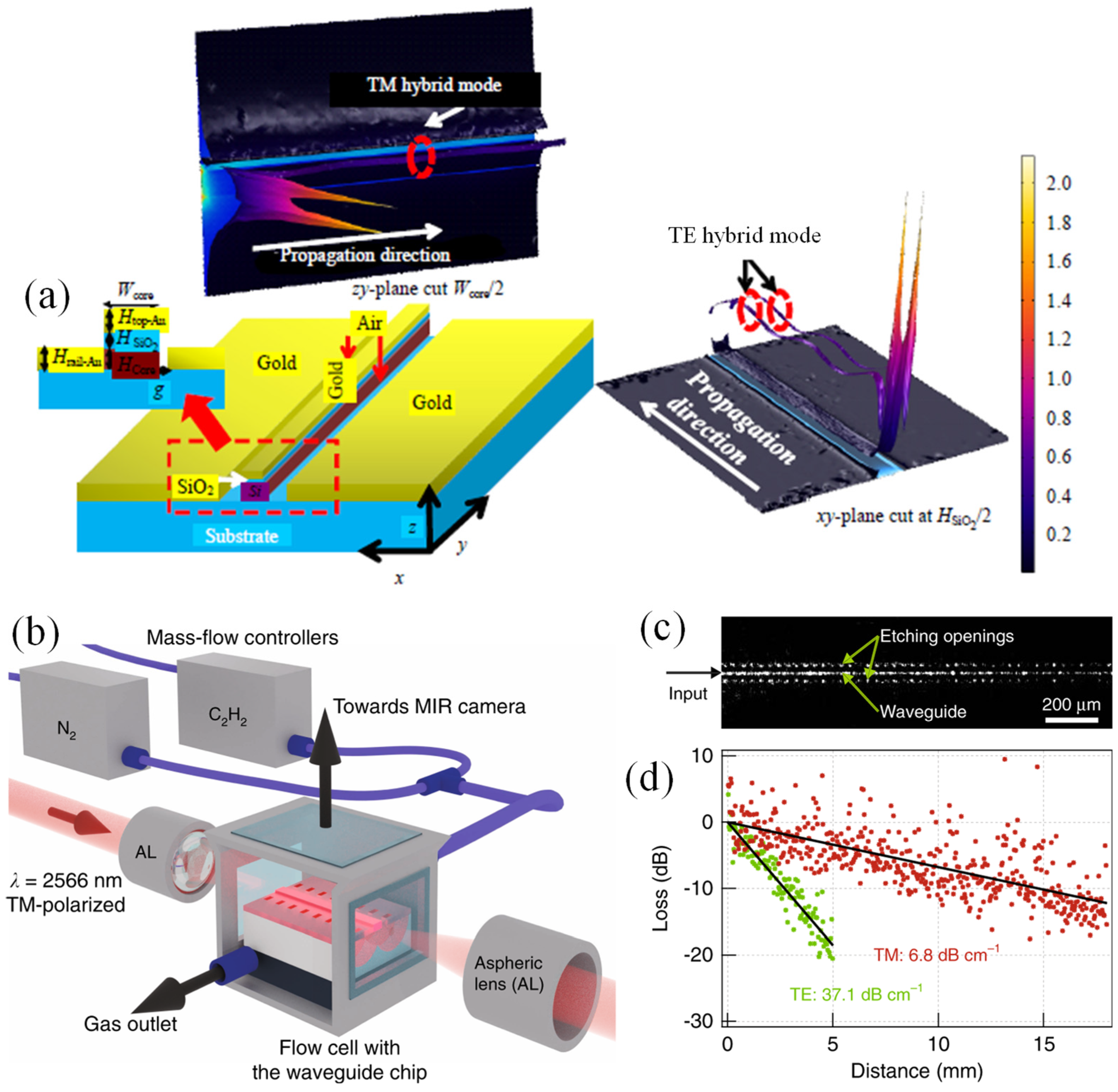

4.1. Gas Sensors Based on the Mechanism of EFA

| WG Configuration | Gas | Wavelength (µm) | EFR/Sensitivity/LOD | Ref. |

|---|---|---|---|---|

| Slot WG | N2O | 2.86 | 46% | [71] |

| HPWG | CH4 | 3.392 | 3 dB power reduction for 60% of gas | [94] |

| Slot | CO2 | 4.23 | 6.66 × 10−5 ppm−1 | [77] |

| SWGS | CO2 | 4.23 | 2.60 × 10−5 ppm−1 | [77] |

| Suspended membrane WG | Athylene | 2.566 | 7 ppm | [82] |

| Slot and double HPWG | CH4 | 3.39 | 3 dB power decay for 20–22% of gas | [48] |

| Dual HPWG | CH4 | 3.392 | 0.0715 mW/gas conc. | [79] |

| Strip WG | CO2 | 4.26 | 14–16% | [83] |

| Ridge WG | CH4 | 3.39 | 55% | [33] |

| Rib WG | CO | 4.67 | >30% | [95] |

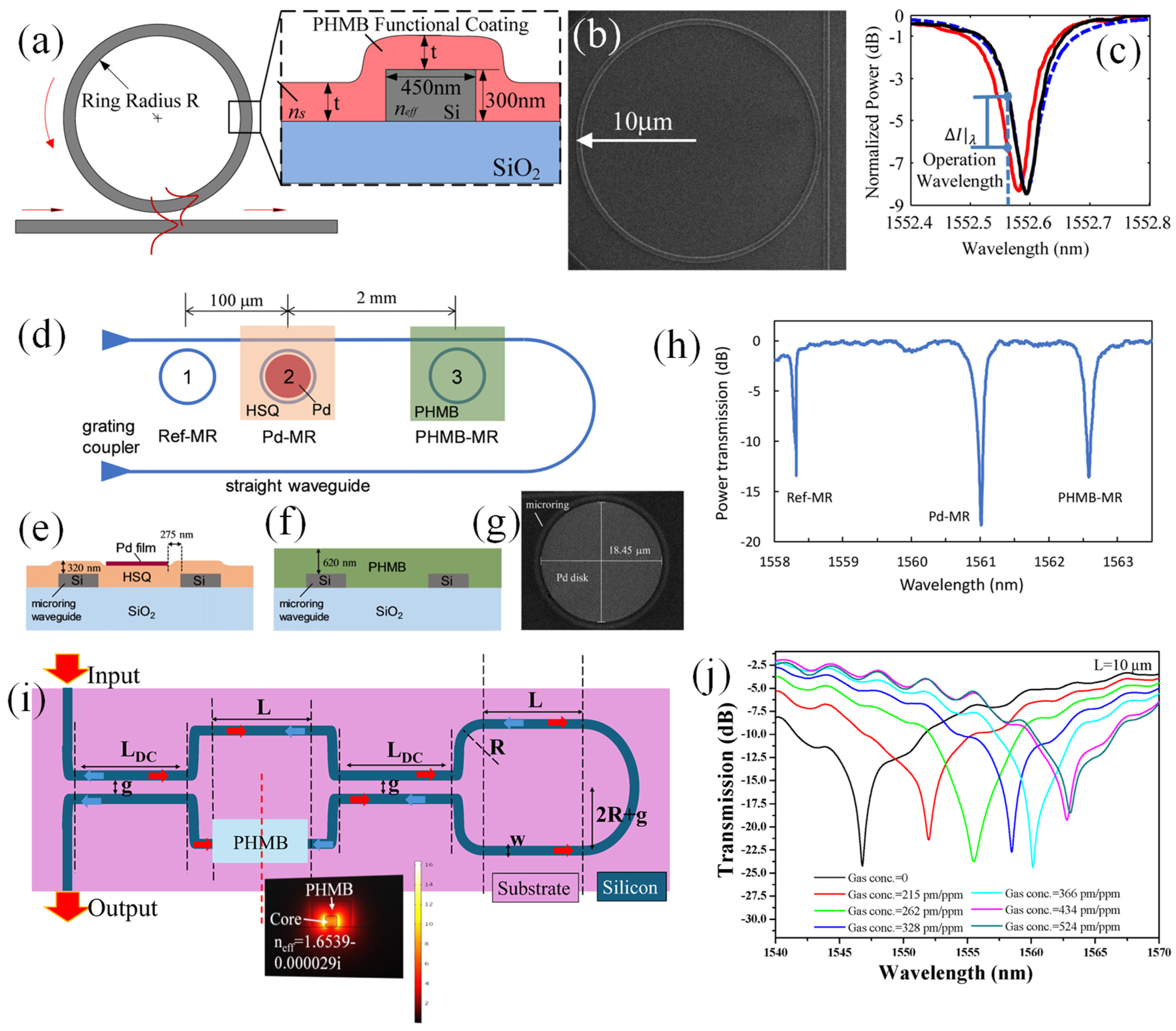

4.2. Gas Sensors Based on the Mechanism of Wavelength Interrogation Method

| Platform | Sensor Design | Sensing Material | Gas | Sensitivity/LOD | Ref. |

|---|---|---|---|---|---|

| SOI | MRR array | Pd and PHMB | H2 and CO2 | 9.15 × 10−4 pm/ppm for H2 and 1.44 × 10−3 pm/ppm for CO2 | [96] |

| SOI | RR | PbSe | CO2 | 10 ppm | [107] |

| SOI | RR | - | VOC | 1.7 pm/1000 ppm | [108] |

| SOI | LT-MZI structure | PHMB | CO2 | 74.78 pm/ppm | [28] |

| Plasmonic | MIM WG based square ring cavity | PHMB | CO2 | 135.95 pm/ppm | [70] |

| Plasmonic | MIM WG based E-shaped cavity | Methane sensitive membrane | CH4 | −12.017 nm/% | [109] |

5. Other Kinds of Photonic Gas Sensors

5.1. MS-Based Gas Sensors

5.2. Optical Fiber-Based Gas Sensors

5.3. Photoacoustic Spectroscopy (PAS) Gas Sensors

6. Research towards Developing Commercial Gas Sensor Products

7. Fabrication Methods of Integrated Photonic Sensors

8. Challenges and Prospects

9. Concluding Remarks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, J.; Viciano-Tudela, S.; Parra, L.; Lacuesta, R.; Lloret, J. Evaluation of Suitability of Low-Cost Gas Sensors for Monitoring Indoor and Outdoor Urban Areas. IEEE Sens. J. 2023, 23, 20968–20975. [Google Scholar] [CrossRef]

- Yang, L.; Zheng, G.; Cao, Y.; Meng, C.; Li, Y.; Ji, H.; Chen, X.; Niu, G.; Yan, J.; Xue, Y.; et al. Moisture-resistant, stretchable NOx gas sensors based on laser-induced graphene for environmental monitoring and breath analysis. Microsyst. Nanoeng. 2022, 8, 78. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Jung, Y.; Sung, S.H.; Lee, G.; Kim, J.; Seong, J.; Shim, Y.-S.; Jun, S.C.; Jeon, S. High-performance gas sensor array for indoor air quality monitoring: The role of Au nanoparticles on WO3, SnO2, and NiO-based gas sensors. J. Mater. Chem. A 2021, 9, 1159–1167. [Google Scholar] [CrossRef]

- Cao, J.; Chen, Q.; Wang, X.; Zhang, Q.; Yu, H.D.; Huang, X.; Huang, W. Recent Development of Gas Sensing Platforms Based on 2D Atomic Crystals. Research 2021, 2021, 9863038. [Google Scholar] [CrossRef] [PubMed]

- Kendler, S.; Zuck, A. The Challenges of Prolonged Gas Sensing in the Modern Urban Environment. Sensors 2020, 20, 5189. [Google Scholar] [CrossRef] [PubMed]

- Yaqoob, U.; Younis, M.I. Chemical Gas Sensors: Recent Developments, Challenges, and the Potential of Machine Learning—A Review. Sensors 2021, 21, 2877. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Cheng, S.; Liu, H.; Hu, S.; Zhang, D.; Ning, H. A Survey on Gas Sensing Technology. Sensors 2012, 12, 9635–9665. [Google Scholar] [CrossRef] [PubMed]

- Padvi, M.N.; Moholkar, A.V.; Prasad, S.R.; Prasad, N.R. A Critical Review on Design and Development of Gas Sensing Materials. Eng. Sci. 2021, 15, 20–37. [Google Scholar] [CrossRef]

- Eranna, G.; Joshi, B.C.; Runthala, D.P.; Gupta, R.P. Oxide Materials for Development of Integrated Gas Sensors—A Comprehensive Review. Crit. Rev. Solid State Mater. Sci. 2004, 29, 111–188. [Google Scholar] [CrossRef]

- Sihag, S.; Dahiya, R.; Rani, S.; Berwal, P.; Jatrana, A.; Sisodiya, A.K.; Sharma, A.; Kumar, V. Low ppm NO2 detection through advanced ultrasensitive copper oxide gas sensor. Discov. Nano 2024, 19, 107. [Google Scholar] [CrossRef]

- Hu, Q.; Solomon, P.; Österlund, L.; Zhang, Z. Nanotransistor-based gas sensing with record-high sensitivity enabled by electron trapping effect in nanoparticles. Nat. Commun. 2024, 15, 5259. [Google Scholar] [CrossRef]

- Dey, A. Semiconductor metal oxide gas sensors: A review. Mater. Sci. Eng. B 2018, 229, 206–217. [Google Scholar] [CrossRef]

- Goel, N.; Kunal, K.; Kushwaha, A.; Kumar, M. Metal oxide semiconductors for gas sensing. Eng. Rep. 2023, 5, e12604. [Google Scholar] [CrossRef]

- He, Y.; Jiao, M. A Mini-Review on Metal Oxide Semiconductor Gas Sensors for Carbon Monoxide Detection at Room Temperature. Chemosensors 2024, 12, 55. [Google Scholar] [CrossRef]

- Symons, E.A. Catalytic Gas Sensors. In Gas Sensors: Principles, Operation and Developments; Sberveglieri, G., Ed.; Springer: Dordrecht, The Netherlands, 1992; pp. 169–185. [Google Scholar] [CrossRef]

- Gentry, S.J.; Jones, T.A. The role of catalysis in solid-state gas sensors. Sens. Actuators 1986, 10, 141–163. [Google Scholar] [CrossRef]

- Wu, L.; Zhang, T.; Wang, H.; Tang, C.; Zhang, L. A Novel Fabricating Process of Catalytic Gas Sensor Based on Droplet Generating Technology. Micromachines 2019, 10, 71. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Wu, R.; Liu, H.-B.; Han, L.-Y.; Yuan, W.-J.; Hua, Z.-Q.; Fan, S.-R.; Wu, Y. A novel catalytic-type gas sensor based on alumina ceramic substrates loaded with catalysts and printed electrodes. Chin. J. Anal. Chem. 2021, 49, 93–101. [Google Scholar] [CrossRef]

- Williams, D.E. Electrochemical sensors for environmental gas analysis. Curr. Opin. Electrochem. 2020, 22, 145–153. [Google Scholar] [CrossRef]

- Lakhmi, R.; Viricelle, J.-P.; Alrammouz, R.; Rieu, M. From the Modeling of an Electrochemical YSZ-Based Gas Sensor Used in Electrolysis Mode. Sensors 2024, 24, 658. [Google Scholar] [CrossRef]

- Khan, M.A.H.; Rao, M.V.; Li, Q. Recent Advances in Electrochemical Sensors for Detecting Toxic Gases: NO2, SO2 and H2S. Sensors 2019, 19, 905. [Google Scholar] [CrossRef]

- Iliev, I.; Kaisheva, A. Electrochemical gas biosensors. In Frontiers in Biosensorics II: Practical Applications; Scheller, F.W., Schubert, F., Fedrowitz, J., Eds.; Birkhäuser: Basel, Switzerland, 1997; pp. 87–98. [Google Scholar] [CrossRef]

- Dhall, S.; Mehta, B.R.; Tyagi, A.K.; Sood, K. A review on environmental gas sensors: Materials and technologies. Sens. Int. 2021, 2, 100116. [Google Scholar] [CrossRef]

- Ariannejad, M.M.; Akbari, E.; Hanafi, E. Silicon sub-wavelength grating resonator structures for gas sensor. Superlattices Microstruct. 2020, 142, 106506. [Google Scholar] [CrossRef]

- Shahbaz, M.; Butt, M.A.; Piramidowicz, R. Breakthrough in Silicon Photonics Technology in Telecommunications, Biosensing, and Gas Sensing. Micromachines 2023, 14, 1637. [Google Scholar] [CrossRef] [PubMed]

- Chandra, V.; Ranjan, R. Performance analysis of different slot waveguide structures for evanescent field based gas sensor applications. Opt. Quantum Electron. 2021, 53, 457. [Google Scholar] [CrossRef]

- Potyrailo, R.A.; Scherer, B.; Brewer, J.; Ruffalo, R. Boosting stability of photonic multi-gas sensors. In Proceedings of the 2022 IEEE Sensors, Dallas, TX, USA, 30 October–2 November 2022; pp. 1–4. [Google Scholar] [CrossRef]

- Butt, M.A. Loop-Terminated Mach-Zehnder Interferometer Integrated with Functional Polymer for CO2 Gas Sensing. Appl. Sci. 2024, 14, 4714. [Google Scholar] [CrossRef]

- Aksnes, A. Photonic Sensors for Health and Environmental Monitoring. In Sensors for Environment, Health and Security; Baraton, M.-I., Ed.; Springer: Dordrecht, The Netherlands, 2009; pp. 191–203. [Google Scholar] [CrossRef]

- Butt, M.A.; Voronkov, G.S.; Grakhova, E.P.; Kutluyarov, R.V.; Kazanskiy, N.L.; Khonina, S.N. Environmental Monitoring: A Comprehensive Review on Optical Waveguide and Fiber-Based Sensors. Biosensors 2022, 12, 1038. [Google Scholar] [CrossRef] [PubMed]

- De, A.; Kalita, D. Bio-Fabricated Gold and Silver Nanoparticle Based Plasmonic Sensors for Detection of Environmental Pollutants: An Overview. Crit. Rev. Anal. Chem. 2023, 53, 672–688. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Al Husseini, D.; Li, J.; Lin, Z.; Sukhishvili, S.; Coté, G.L.; Gutierrez-Osuna, R.; Lin, P.T. Detection of volatile organic compounds using mid-infrared silicon nitride waveguide sensors. Sci. Rep. 2022, 12, 5572. [Google Scholar] [CrossRef] [PubMed]

- Butt, M.A.; Degtyarev, S.A.; Khonina, S.N.; Kazanskiy, N.L. An evanescent field absorption gas sensor at mid-IR 3.39 μm wavelength. J. Mod. Opt. 2017, 64, 1892–1897. [Google Scholar] [CrossRef]

- Rose, J.J.; Wang, L.; Xu, Q.; McTiernan, C.F.; Shiva, S.; Tejero, J.; Gladwin, M.T. Carbon Monoxide Poisoning: Pathogenesis, Management, and Future Directions of Therapy. Am. J. Respir. Crit. Care Med. 2017, 195, 596–606. [Google Scholar] [CrossRef]

- Ngoc, L.T.N.; Park, D.; Lee, Y.-C. Human Health Impacts of Residential Radon Exposure: Updated Systematic Review and Meta-Analysis of Case–Control Studies. Int. J. Environ. Res. Public Health 2023, 20, 97. [Google Scholar] [CrossRef]

- David, E.; Niculescu, V.-C. Volatile Organic Compounds (VOCs) as Environmental Pollutants: Occurrence and Mitigation Using Nanomaterials. Int. J. Environ. Res. Public Health 2021, 18, 13147. [Google Scholar] [CrossRef]

- Peterson, W.H.; Burris, R.H.; Sant, R.; Little, H.N. Toxic Gases in Silage, Production of Toxic Gas (Nitrogen Oxides) in Silage Making. J. Agric. Food Chem. 1958, 6, 121–126. [Google Scholar] [CrossRef]

- Pangeni, R.P.; Timilsina, B.; Oli, P.R.; Khadka, S.; Regmi, P.R. A multidisciplinary approach to accidental inhalational ammonia injury: A case report. Ann. Med. Surg. 2022, 82, 104741. [Google Scholar] [CrossRef] [PubMed]

- Bocci, V. Ozone as Janus: This Controversial Gas Can Be Either Toxic or Medically Useful. Mediat. Inflamm. 2004, 13, 3–11. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Zhou, X.; Wang, C.; Zhou, H. Environmental and human health impacts of volatile organic compounds: A perspective review. Chemosphere 2023, 313, 137489. [Google Scholar] [CrossRef]

- Jiang, J.; Chan, A.; Ali, S.; Saha, A.; Haushalter, K.J.; Lam, W.-L.M.; Glasheen, M.; Parker, J.; Brenner, M.; Mahon, S.B.; et al. Hydrogen Sulfide—Mechanisms of Toxicity and Development of an Antidote. Sci. Rep. 2016, 6, 20831. [Google Scholar] [CrossRef]

- Anjana, N.S.; Amarnath, A.; Nair, M.V.H. Toxic hazards of ammonia release and population vulnerability assessment using geographical information system. J. Environ. Manag. 2018, 210, 201–209. [Google Scholar] [CrossRef]

- Ho, W.F.; Chan, H.P.; Yang, K.L. Planar Optical Waveguide Platform for Gas Sensing Using Liquid Crystal. IEEE Sens. J. 2013, 13, 2521–2522. [Google Scholar] [CrossRef]

- Vitoria, I.; Gallego, E.E.; Melendi-Espina, S.; Hernaez, M.; Zamarreño, C.R.; Matías, I.R. Gas Sensor Based on Lossy Mode Resonances by Means of Thin Graphene Oxide Films Fabricated onto Planar Coverslips. Sensors 2023, 23, 1459. [Google Scholar] [CrossRef]

- Zheng, L.; Keppler, N.; Zhang, H.; Behrens, P.; Roth, B. Planar Polymer Optical Waveguide with Metal-Organic Framework Coating for Carbon Dioxide Sensing. Adv. Mater. Technol. 2022, 7, 2200395. [Google Scholar] [CrossRef]

- Dominguez, I.; Del Villar, I.; Fuentes, O.; Corres, J.M.; Matias, I.R. Dually nanocoated planar waveguides towards multi-parameter sensing. Sci. Rep. 2021, 11, 3669. [Google Scholar] [CrossRef] [PubMed]

- Barrios, C.A.; Bañuls, M.J.; González-Pedro, V.; Gylfason, K.B.; Sánchez, B.; Griol, A.; Maquieira, A.; Sohlström, H.; Holgado, M.; Casquel, R. Label-free optical biosensing with slot-waveguides. Opt. Lett. 2008, 33, 708–710. [Google Scholar] [CrossRef] [PubMed]

- Butt, M.A.; Piramidowicz, R. Standard slot waveguide and double hybrid plasmonic waveguide configurations for enhanced evanescent field absorption methane gas sensing. Photonics Lett. Pol. 2022, 14, 10–12. [Google Scholar] [CrossRef]

- Passaro, V.M.N.; Dell’Olio, F.; Ciminelli, C.; Armenise, M.N. Efficient Chemical Sensing by Coupled Slot SOI Waveguides. Sensors 2009, 9, 1012. [Google Scholar] [CrossRef] [PubMed]

- Barrios, C.A. Optical Slot-Waveguide Based Biochemical Sensors. Sensors 2009, 9, 4751–4765. [Google Scholar] [CrossRef] [PubMed]

- Ranacher, C.; Consani, C.; Jannesari, R.; Grille, T.; Jakoby, B. Numerical Investigations of Infrared Slot Waveguides for Gas Sensing. Proceedings 2018, 2, 799. [Google Scholar] [CrossRef]

- Torrijos-Morán, L.; Griol, A.; García-Rupérez, J. Experimental study of subwavelength grating bimodal waveguides as ultrasensitive interferometric sensors. Opt. Lett. 2019, 44, 4702–4705. [Google Scholar] [CrossRef] [PubMed]

- Awasthi, K.; Malviya, N.; Kumar, A. Silicon Subwavelength Grating Slot Waveguide based Optical Sensor for Label Free Detection of Fluoride Ion in Water. IETE Tech. Rev. 2024, 41, 341–352. [Google Scholar] [CrossRef]

- Kazanskiy, N.L.; Khonina, S.N.; Butt, M.A. Subwavelength Grating Double Slot Waveguide Racetrack Ring Resonator for Refractive Index Sensing Application. Sensors 2020, 20, 3416. [Google Scholar] [CrossRef]

- Tu, Z.; Gao, D.; Zhang, M.; Zhang, D. High-sensitivity complex refractive index sensing based on Fano resonance in the subwavelength grating waveguide micro-ring resonator. Opt. Express 2017, 25, 20911–20922. [Google Scholar] [CrossRef] [PubMed]

- Arledge, K.E.; Uchoa, B.; Zou, Y.; Weng, B. Topological sensing with photonic arrays of resonant circular waveguides. Phys. Rev. Res. 2021, 3, 033106. [Google Scholar] [CrossRef]

- Si, G.; Teo, E.J.; Bettiol, A.A.; Teng, J.; Danner, A.J. Suspended slab and photonic crystal waveguides in lithium niobate. J. Vac. Sci. Technol. B 2010, 28, 316–320. [Google Scholar] [CrossRef]

- Butt, M.A.; Khonina, S.N.; Kazanskiy, N.L. Recent advances in photonic crystal optical devices: A review. Opt. Laser Technol. 2021, 142, 107265. [Google Scholar] [CrossRef]

- Kassa-Baghdouche, L.; Cassan, E. Sensitivity analysis of ring-shaped slotted photonic crystal waveguides for mid-infrared refractive index sensing. Opt. Quantum Electron. 2019, 51, 328. [Google Scholar] [CrossRef]

- Rostamian, A.; Midkiff, J.; Yoo, K.M.; Cheng, Y.; Chakravarty, S.; Chen, R. Mid-Infrared Trace Gas Sensing Using Photonic Crystal Waveguides. In Proceedings of the 2019 IEEE Photonics Society Summer Topical Meeting Series (SUM), Ft. Lauderdale, FL, USA, 8–10 July 2019; pp. 1–2. [Google Scholar] [CrossRef]

- Peng, Z.; Huang, Y.; Zheng, K.; Zheng, C.; Pi, M.; Zhao, H.; Ji, J.; Min, Y.; Liang, L.; Song, F.; et al. Slow-light-enhanced on-chip 1D and 2D photonic crystal waveguide gas sensing in near-IR with an ultrahigh interaction factor. Photonics Res. 2023, 11, 1647–1656. [Google Scholar] [CrossRef]

- Goyal, A.K.; Pal, S. Design and simulation of high sensitive photonic crystal waveguide sensor. Optik 2015, 126, 240–243. [Google Scholar] [CrossRef]

- Butt, M.A.; Kazansky, N.L. SOI Suspended membrane waveguide at 3.39 µm for gas sensing application. Photonics Lett. Pol. 2020, 12, 67–69. [Google Scholar] [CrossRef]

- Vlk, M.; Datta, A.; Alberti, S.; Murugan, G.S.; Aksnes, A.; Jágerská, J. Free-standing tantalum pentoxide waveguides for gas sensing in the mid-infrared. Opt. Mater. Express 2021, 11, 3111–3124. [Google Scholar] [CrossRef]

- Yoo, K.M.; Midkiff, J.; Rostamian, A.; Chakravarty, S.; Chen, R.T. Suspended Membrane InGaAs Photonic Crystal Waveguides for ammonia sensing at λ = 6.15 μm. In Proceedings of the 2019 Conference on Lasers and Electro-Optics (CLEO), San Jose, CA, USA, 5–10 May 2019; Optica Publishing Group: San Jose, CA, USA, 2019; p. STh1F.6. [Google Scholar] [CrossRef]

- Yoo, K.M.; Midkiff, J.; Rostamian, A.; Chung, C.; Dalir, H.; Chen, R.T. InGaAs Membrane Waveguide: A Promising Platform for Monolithic Integrated Mid-Infrared Optical Gas Sensor. ACS Sens. 2020, 5, 861–869. [Google Scholar] [CrossRef]

- Butt, M.A.; Khonina, S.N.; Kazanskiy, N.L. Plasmonics: A Necessity in the Field of Sensing—A Review (Invited). Fiber Integr. Opt. 2021, 40, 14–47. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, F.; Gao, Y.; Zhang, D.; Sun, X.; Berini, P. Straight Long-Range Surface Plasmon Polariton Waveguide Sensor Operating at λ0 = 850 nm. Sensors 2020, 20, 2507. [Google Scholar] [CrossRef] [PubMed]

- Kazanskiy, N.L.; Khonina, S.N.; Butt, M.A. Plasmonic sensors based on Metal-insulator-metal waveguides for refractive index sensing applications: A brief review. Phys. E Low-Dimens. Syst. Nanostruct. 2020, 117, 113798. [Google Scholar] [CrossRef]

- Khonina, S.N.; Kazanskiy, N.L.; Butt, M.A.; Kaźmierczak, A.; Piramidowicz, R. Plasmonic sensor based on metal-insulator-metal waveguide square ring cavity filled with functional material for the detection of CO2 gas. Opt. Express 2021, 29, 16584–16594. [Google Scholar] [CrossRef] [PubMed]

- Joshi, K.; Meena, B.L.; Gehlot, K. Performance of silicon-on-insulator and silicon-on-sapphire based evanescent field gas sensor operating at 2.86 µm. AIP Conf. Proc. 2023, 2768, 020023. [Google Scholar] [CrossRef]

- Butt, M.A.; Shahbaz, M.; Piramidowicz, R. Racetrack Ring Resonator Integrated with Multimode Interferometer Structure Based on Low-Cost Silica–Titania Platform for Refractive Index Sensing Application. Photonics 2023, 10, 978. [Google Scholar] [CrossRef]

- Kazanskiy, N.L.; Butt, M.A.; Khonina, S.N. Carbon Dioxide Gas Sensor Based on Polyhexamethylene Biguanide Polymer Deposited on Silicon Nano-Cylinders Metasurface. Sensors 2021, 21, 378. [Google Scholar] [CrossRef] [PubMed]

- Butt, M.A.; Kazanskiy, N.L.; Khonina, S.N. On-chip symmetrically and asymmetrically transformed plasmonic Bragg grating formation loaded with a functional polymer for filtering and CO2 gas sensing applications. Measurement 2022, 201, 111694. [Google Scholar] [CrossRef]

- Ma, W.; Xing, J.; Wang, R.; Rong, Q.; Zhang, W.; Li, Y.; Zhang, J.; Qiao, X. Optical Fiber Fabry–Perot Interferometric CO2 Gas Sensor Using Guanidine Derivative Polymer Functionalized Layer. IEEE Sens. J. 2018, 18, 1924–1929. [Google Scholar] [CrossRef]

- Kazanskiy, N.L.; Khonina, S.N.; Butt, M.A. Advancement in Silicon Integrated Photonics Technologies for Sensing Applications in Near-Infrared and Mid-Infrared Region: A Review. Photonics 2022, 9, 331. [Google Scholar] [CrossRef]

- Song, Y.; Li, B.; Zhang, H.; Li, M.; Li, Q.; He, J.-J. Silicon Waveguide Sensors for Carbon Dioxide Gas Sensing in the Mid-Infrared Region. Photonics 2023, 10, 120. [Google Scholar] [CrossRef]

- Butt, M.A. Dielectric Waveguide-Based Sensors with Enhanced Evanescent Field: Unveiling the Dynamic Interaction with the Ambient Medium for Biosensing and Gas-Sensing Applications—A Review. Photonics 2024, 11, 198. [Google Scholar] [CrossRef]

- Khonina, S.N.; Kazanskiy, N.L.; Butt, M.A. Evanescent Field Ratio Enhancement of a Modified Ridge Waveguide Structure for Methane Gas Sensing Application. IEEE Sens. J. 2020, 20, 8469–8476. [Google Scholar] [CrossRef]

- Consani, C.; Ranacher, C.; Tortschanoff, A.; Grille, T.; Irsigler, P.; Jakoby, B. Evanescent-Wave Gas Sensing Using an Integrated Thermal Light Source. Proceedings 2017, 1, 550. [Google Scholar] [CrossRef]

- Butt, M.A.; Khonina, S.N.; Kazanskiy, N.L. Enhancement of evanescent field ratio in a silicon strip waveguide by incorporating a thin metal film. Laser Phys. 2019, 29, 076202. [Google Scholar] [CrossRef]

- Vlk, M.; Datta, A.; Alberti, S.; Yallew, H.D.; Mittal, V.; Murugan, G.S.; Jágerská, J. Extraordinary evanescent field confinement waveguide sensor for mid-infrared trace gas spectroscopy. Light Sci. Appl. 2021, 10, 26. [Google Scholar] [CrossRef] [PubMed]

- Ranacher, C.; Consani, C.; Vollert, N.; Tortschanoff, A.; Bergmeister, M.; Grille, T.; Jakoby, B. Characterization of Evanescent Field Gas Sensor Structures Based on Silicon Photonics. IEEE Photonics J. 2018, 10, 2700614. [Google Scholar] [CrossRef]

- Wei, S.; Haggren, T.; Li, Z.; Tan, H.H.; Jagadish, C.; Tricoli, A.; Fu, L. Ultrasensitive Indium Phosphide Nanomembrane Wearable Gas Sensors. Energy Environ. Mater. 2024, e12763. Available online: https://onlinelibrary.wiley.com/doi/full/10.1002/eem2.12763 (accessed on 7 June 2024). [CrossRef]

- Rosborough, V.; Fridlander, J.; Sang, F.; Gambini, F.; Brunelli, S.T.; Chen, J.R.; Kawa, S.; Numata, K.; Stephen, M.; Coldren, L.; et al. Photonic Integration for Low Size, Weight, and Power (SWaP) Remote Gas Spectroscopy. In OSA Optical Sensors and Sensing Congress 2021 (AIS, FTS, HISE, SENSORS, ES); Optica Publishing Group: Washington, DC, USA, 2021; p. ETu6D.2. [Google Scholar] [CrossRef]

- Shahriar, R.; Hassan, O.; Alam, M.K. Adsorption of gas molecules on buckled GaAs monolayer: A first-principles study. RSC Adv. 2022, 12, 16732–16744. [Google Scholar] [CrossRef]

- Xie, K.; Zhang, X.; Zhang, X.; Jin, H.; Jian, J. A slot microring sensor with feedback spiral waveguide for trace gas CH4 sensing in mid-infrared region. Optoelectron. Lett. 2019, 15, 1–5. [Google Scholar] [CrossRef]

- Mere, V.; Selvaraja, S.K. Germanium-on-Glass Waveguides for Mid-IR Photonics. In International Conference on Fibre Optics and Photonics; Optica Publishing Group: Washington, DC, USA, 2016; p. Th3A-18. Available online: https://opg.optica.org/abstract.cfm?uri=photonics-2016-Th3A.18 (accessed on 31 January 2024).

- Soref, R. Mid-Infrared Photonics in Silicon and Germanium. Nat. Photonics 2010, 4, 495–497. [Google Scholar] [CrossRef]

- Kim, S.; Han, J.H.; Shim, J.P.; Kim, H.J.; Choi, W.J. Verification of Ge-on-Insulator Structure for a Mid-Infrared Photonics Platform. Opt. Mater. Express 2018, 8, 440–451. [Google Scholar] [CrossRef]

- Dong, M.; Zheng, C.; Miao, S.; Zhang, Y.; Du, Q.; Wang, Y.; Tittel, F.K. Development and Measurements of a Mid-Infrared Multi-Gas Sensor System for CO, CO2 and CH4 Detection. Sensors 2017, 17, 2221. [Google Scholar] [CrossRef] [PubMed]

- Yebo, N.A.; Lommens, P.; Hens, Z.; Baets, R. An Integrated Optic Ethanol Vapor Sensor Based on a Silicon-on-Insulator Microring Resonator Coated with a Porous ZnO Film. Opt. Express 2010, 18, 11859–11866. [Google Scholar] [CrossRef] [PubMed]

- Jin, T.; Zhou, J.; Tai, P. Real-time and non-destructive hydrocarbon gas sensing using mid-infrared integrated photonic circuits. RSC Adv. 2020, 10, 7452–7459. [Google Scholar] [CrossRef] [PubMed]

- Kazanskiy, N.L.; Khonina, S.N.; Butt, M.A. Polarization-Insensitive Hybrid Plasmonic Waveguide Design for Evanescent Field Absorption Gas Sensor. Photonic Sens. 2021, 11, 279–290. [Google Scholar] [CrossRef]

- Butt, M.A.; Khonina, S.N.; Kazanskiy, N.L. Modelling of Rib channel waveguides based on silicon-on-sapphire at 4.67 μm wavelength for evanescent field gas absorption sensor. Optik 2018, 168, 692–697. [Google Scholar] [CrossRef]

- Mi, G.; Horvath, C.; Van, V. Silicon photonic dual-gas sensor for H2 and CO2 detection. Opt. Express 2017, 25, 16250–16259. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.-Y.; Hu, H.-W.; Chiou, J.-C.; Yung, K.-F.; Kan, C.-W. Poly(hexamethylene biguanide) hydrochloride (PHMB)-based materials: Synthesis, modification, properties, determination, and application. Polym. Chem. 2023, 14, 5226–5252. [Google Scholar] [CrossRef]

- Silicon Microring Refractometric Sensor for Atmospheric CO2 Gas Monitoring’. Available online: https://opg.optica.org/oe/fulltext.cfm?uri=oe-24-2-1773&id=335762 (accessed on 4 May 2024).

- Virji, S.; Huang, J.; Kaner, R.B.; Weiller, B.H. Polyaniline Nanofiber Gas Sensors: Examination of Response Mechanisms. Nano Lett. 2004, 4, 491–496. [Google Scholar] [CrossRef]

- Kroutil, J.; Laposa, A.; Povolny, V.; Klimsa, L.; Husak, M. Gas Sensor with Different Morphology of PANI Layer. Sensors 2023, 23, 1106. [Google Scholar] [CrossRef] [PubMed]

- Fratoddi, I.; Venditti, I.; Cametti, C.; Russo, M.V. Chemiresistive polyaniline-based gas sensors: A mini review. Sens. Actuators B Chem. 2015, 220, 534–548. [Google Scholar] [CrossRef]

- Jain, A.; Nabeel, A.N.; Bhagwat, S.; Kumar, R.; Sharma, S.; Kozak, D.; Hunjet, A.; Kumar, A.; Singh, R. Fabrication of polypyrrole gas sensor for detection of NH3 using an oxidizing agent and pyrrole combinations: Studies and characterizations. Heliyon 2023, 9, e17611. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Lefferts, M.J.; Armitage, B.I.; Murugappan, K.; Castell, M.R. Polypyrrole Percolation Network Gas Sensors: Improved Reproducibility through Conductance Monitoring during Polymer Growth. ACS Appl. Polym. Mater. 2022, 4, 2536–2543. [Google Scholar] [CrossRef] [PubMed]

- Bhatt, C.M.; Jampana, N. Comparative studies on electrical properties of Polypyrrole based gas sensor. In Proceedings of the 2011 IEEE Sensors Applications Symposium, San Antonio, TX, USA, 22–24 February 2011; pp. 131–135. [Google Scholar] [CrossRef]

- Nagashima, K.; Kamaya, M.; Ishii, E. Electrochemical gas sensors using electrolytic films of poly(ethylene oxide)/Zn, Cu, Ni trifluoromethane sulphonates for flow injection analysis of nitrogen dioxide. Sens. Actuators B Chem. 1992, 9, 149–154. [Google Scholar] [CrossRef]

- Nagashima, K.; Meguro, K.; Hobo, T. A galvanic gas sensor using poly (ethylene oxide) complex of silver trifluoromethane sulphonate electrolyte. Fresenius J. Anal. Chem. 1990, 336, 571–574. [Google Scholar] [CrossRef]

- Khanloo, A.S.H.; Sarraf, M.J.; Rostami, A.; Dolatyari, M. Micro ring CO2 gas sensor using PbSe quantum dots. Opt. Quantum Electron. 2023, 55, 882. [Google Scholar] [CrossRef]

- Zhang, G.; Feng, X.L.; Liedberg, B.; Liu, A.Q. Gas Sensor for Volatile Organic Compounds Detection Using Silicon Photonic Ring Resonator. Procedia Eng. 2016, 168, 1771–1774. [Google Scholar] [CrossRef]

- Zhao, H.; Du, J.; Wang, S.; Wang, X.; Zhang, T.; Yu, R.; Chi, Z.; Wang, B. Triple narrow-spectrum enhanced multiparameter sensor based on asymmetric MIM waveguide for gas and liquid sensing. Opt. Laser Technol. 2024, 175, 110754. [Google Scholar] [CrossRef]

- Kazanskiy, N.L.; Khonina, S.N.; Butt, M.A. Recent Development in Metasurfaces: A Focus on Sensing Applications. Nanomaterials 2023, 13, 118. [Google Scholar] [CrossRef]

- Chatterjee, S.; Shkondin, E.; Takayama, O.; Fisher, A.; Fraiwan, A.; Gurkan, U.A.; Lavrinenko, A.V.; Strangi, G. Hydrogen gas sensing using aluminum doped ZnO metasurfaces. Nanoscale Adv. 2020, 2, 3452–3459. [Google Scholar] [CrossRef] [PubMed]

- Butt, M.A.; Khonina, S.N.; Kazanskiy, N.L.; Piramidowicz, R. Hybrid metasurface perfect absorbers for temperature and biosensing applications. Opt. Mater. 2022, 123, 111906. [Google Scholar] [CrossRef]

- Nugroho, F.A.A.; Bai, P.; Darmadi, I.; Castellanos, G.W.; Fritzsche, J.; Langhammer, C.; Rivas, J.G.; Baldi, A. Inverse designed plasmonic metasurface with parts per billion optical hydrogen detection. Nat. Commun. 2022, 13, 5737. [Google Scholar] [CrossRef] [PubMed]

- Danila, O.; Gross, B.M. Towards Highly Efficient Nitrogen Dioxide Gas Sensors in Humid and Wet Environments Using Triggerable-Polymer Metasurfaces. Polymers 2023, 15, 545. [Google Scholar] [CrossRef] [PubMed]

- Meng, J.; Balendhran, S.; Sabri, Y.; Bhargava, S.K.; Crozier, K.B. Smart mid-infrared metasurface microspectrometer gas sensing system. Microsyst. Nanoeng. 2024, 10, 74. [Google Scholar] [CrossRef] [PubMed]

- Kim, I.; Kim, W.-S.; Kim, K.; Ansari, M.A.; Mehmood, M.Q.; Badloe, T.; Kim, Y.; Gwak, J.; Lee, H.; Kim, Y.-K.; et al. Holographic metasurface gas sensors for instantaneous visual alarms. Sci. Adv. 2021, 7, eabe9943. [Google Scholar] [CrossRef] [PubMed]

- Tabassum, S.; Nayemuzzaman, S.; Kala, M.; Kumar Mishra, A.; Mishra, S.K. Metasurfaces for Sensing Applications: Gas, Bio and Chemical. Sensors 2022, 22, 6896. [Google Scholar] [CrossRef] [PubMed]

- Kazanskiy, N.L.; Khonina, S.N.; Butt, M.A. Metasurfaces: Shaping the future of photonics. Sci. Bull. 2024, 69, 1607–1611. [Google Scholar] [CrossRef] [PubMed]

- Warken, F.; Vetsch, E.; Meschede, D.; Sokolowski, M.; Rauschenbeutel, A. Ultra-sensitive surface absorption spectroscopy using sub-wavelength diameter optical fibers. Opt. Express 2007, 15, 11952–11958. [Google Scholar] [CrossRef]

- Potyrailo, R.A.; Hobbs, S.E.; Hieftje, G.M. Near-Ultraviolet Evanescent-Wave Absorption Sensor Based on a Multimode Optical Fiber. Anal. Chem. 1998, 70, 1639–1645. [Google Scholar] [CrossRef]

- Benito-Peña, E.; Valdés, M.G.; Glahn-Martínez, B.; Moreno-Bondi, M.C. Fluorescence based fiber optic and planar waveguide biosensors. A review. Anal. Chim. Acta 2016, 943, 17–40. [Google Scholar] [CrossRef] [PubMed]

- Epstein, J.R.; Walt, D.R. Fluorescence-based fibre optic arrays: A universal platform for sensing. Chem. Soc. Rev. 2003, 32, 203–214. [Google Scholar] [CrossRef] [PubMed]

- Ding, L.; Gong, P.; Xu, B.; Ding, Q. An Optical Fiber Sensor Based on Fluorescence Lifetime for the Determination of Sulfate Ions. Sensors 2021, 21, 954. [Google Scholar] [CrossRef] [PubMed]

- Thompson, R.B. Fluorescence-Based Fiber-Optic Sensors. In Topics in Fluorescence Spectroscopy: Principles; Lakowicz, J.R., Ed.; Springer: Boston, MA, USA, 2002; pp. 345–365. [Google Scholar] [CrossRef]

- Wolfbeis, O.S.; Posch, H.E. Fibre-optic fluorescing sensor for ammonia. Anal. Chim. Acta 1986, 185, 321–327. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, Z.; Cai, C.; Yang, Z.; Qi, Z.-M. Surface plasmon resonance gas sensor with a nanoporous gold film. Opt. Lett. 2022, 47, 4155–4158. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, F.; Han, Z.; Cheng, P.; Ding, Z. Research Advances on Fiber-Optic SPR Sensors with Temperature Self-Compensation. Sensors 2023, 23, 644. [Google Scholar] [CrossRef] [PubMed]

- Allsop, T.; Neal, R. A Review: Application and Implementation of Optic Fibre Sensors for Gas Detection. Sensors 2021, 21, 6755. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Gan, L.; Guo, X. Optical Fiber-Based Gas Sensing for Early Warning of Thermal Runaway in Lithium-Ion Batteries. Adv. Sens. Res. 2023, 2, 2300055. [Google Scholar] [CrossRef]

- Xiong, S.; Yin, X.; Wang, Q.; Xia, J.; Chen, Z.; Lei, H.; Yan, X.; Zhu, A.; Qiu, F.; Chen, B.; et al. Photoacoustic Spectroscopy Gas Detection Technology Research Progress. Appl. Spectrosc. 2024, 78, 139–158. [Google Scholar] [CrossRef]

- Yang, T.; Chen, W.; Wang, P. A review of all-optical photoacoustic spectroscopy as a gas sensing method. Appl. Spectrosc. Rev. 2021, 56, 143–170. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, L.; Zhang, L.; Yin, X.; Huan, H.; Zhang, L.; Shao, X. A compact portable photoacoustic spectroscopy sensor for multiple trace gas detection. J. Appl. Phys. 2022, 131, 174501. [Google Scholar] [CrossRef]

- Qiao, S.; He, Y.; Sun, H.; Patimisco, P.; Sampaolo, A.; Spagnolo, V.; Ma, Y. Ultra-highly sensitive dual gases detection based on photoacoustic spectroscopy by exploiting a long-wave, high-power, wide-tunable, single-longitudinal-mode solid-state laser. Light Sci. Appl. 2024, 13, 100. [Google Scholar] [CrossRef]

- Qiao, S.; Qu, Y.; Ma, Y.; He, Y.; Wang, Y.; Hu, Y.; Yu, X.; Zhang, Z.; Tittel, F.K. A Sensitive Carbon Dioxide Sensor Based on Photoacoustic Spectroscopy with a Fixed Wavelength Quantum Cascade Laser. Sensors 2019, 19, 4187. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.L.; Tian, C.W.; Liu, Q.; Chang, J.; Zhang, Q.D.; Zhu, C.G. Wavelength modulation technique-based photoacoustic spectroscopy for multipoint gas sensing. Appl. Opt. 2018, 57, 2909–2914. [Google Scholar] [CrossRef]

- Elia, A.; Di Franco, C.; Lugarà, P.M.; Scamarcio, G. Photoacoustic Spectroscopy with Quantum Cascade Lasers for Trace Gas Detection. Sensors 2006, 6, 1411. [Google Scholar] [CrossRef]

- Patimisco, P.; Scamarcio, G.; Tittel, F.K.; Spagnolo, V. Quartz-Enhanced Photoacoustic Spectroscopy: A Review. Sensors 2014, 14, 6165. [Google Scholar] [CrossRef]

- Hänsel, A.; Heck, M.J.R. Feasibility of Telecom-Wavelength Photonic Integrated Circuits for Gas Sensors. Sensors 2018, 18, 2870. [Google Scholar] [CrossRef]

- Hänsel, A.; Adamu, A.I.; Markos, C.; Feilberg, A.; Bang, O.; Heck, M.J.R. Integrated Ammonia Sensor Using a Telecom Photonic Integrated Circuit and a Hollow Core Fiber. Photonics 2020, 7, 93. [Google Scholar] [CrossRef]

- Butt, M.A. Integrated Optics: Platforms and Fabrication Methods. Encyclopedia 2023, 3, 824–838. [Google Scholar] [CrossRef]

- Liaros, N.; Fourkas, J.T. Ten years of two-color photolithography [Invited]. Opt. Mater. Express 2019, 9, 3006. [Google Scholar] [CrossRef]

- Crowell, J.E. Chemical methods of thin film deposition: Chemical vapor deposition, atomic layer deposition, and related technologies. J. Vac. Sci. Technol. A 2003, 21, S88–S95. [Google Scholar] [CrossRef]

- Joyce, B.A. Molecular beam epitaxy-fundamentals and current status. Contemp. Phys. 1990, 31, 195–197. [Google Scholar] [CrossRef]

- Butt, M.A.; Tyszkiewicz, C.; Karasiński, P.; Zięba, M.; Hlushchenko, D.; Baraniecki, T.; Kazmierczak, A.; Piramidowicz, R.; Guzik, M.; Bachmatiuk, A. Development of a low-cost silica-titania optical platform for integrated photonics applications. Opt. Express 2022, 30, 23678. [Google Scholar] [CrossRef] [PubMed]

- Butt, M.A.; Tyszkiewicz, C.; Wojtasik, K.; Karasiński, P.; Kaźmierczak, A.; Piramidowicz, R. Subwavelength Grating Waveguide Structures Proposed on the Low-Cost Silica–Titania Platform for Optical Filtering and Refractive Index Sensing Applications. Int. J. Mol. Sci. 2022, 23, 6614. [Google Scholar] [CrossRef] [PubMed]

- Ober, C.K.; Käfer, F.; Yuan, C. Recent developments in photoresists for extreme-ultraviolet lithography. Polymer 2023, 280, 126020. [Google Scholar] [CrossRef]

- Aassime, A.; Hamouda, F. Conventional and Un-Conventional Lithography for Fabricating Thin Film Functional Devices. In Modern Technologies for Creating the Thin-Film Systems and Coatings; IntechOpen: London, UK, 2017; Available online: https://www.intechopen.com/chapters/53135 (accessed on 5 July 2024).

- Chen, Y. Nanofabrication by electron beam lithography and its applications: A review. Microelectron. Eng. 2015, 135, 57–72. [Google Scholar] [CrossRef]

- Hohn, F.J. Electron beam lithography: Its applications. J. Vac. Sci. Technol. B Microelectron. Process. Phenom. 1989, 7, 1405–1411. [Google Scholar] [CrossRef]

- Ferstl, M. Reactive ion etching: A versatile fabrication technique for micro-optical elements. In Diffractive Optics and Micro-Optics; Optica Publishing Group: Kailua-Kona, HI, USA, 1998; p. DTuD.21. [Google Scholar] [CrossRef]

- Schmitt, J.; Meier, A.; Wallrabe, U.; Völklein, F. Reactive ion etching (CF4/Ar) and ion beam etching of various glasses for diffractive optical element fabrication. Int. J. Appl. Glass Sci. 2018, 9, 499–509. [Google Scholar] [CrossRef]

- Tolpygo, S.K.; Bolkhovsky, V.; Weir, T.J.; Wynn, A.; Oates, D.E.; Johnson, L.M.; Gouker, M.A. Advanced Fabrication Processes for Superconducting Very Large-Scale Integrated Circuits. IEEE Trans. Appl. Supercond. 2016, 26, 1–10. [Google Scholar] [CrossRef]

- Morrison, S.R. Selectivity in semiconductor gas sensors. Sens. Actuators 1987, 12, 425–440. [Google Scholar] [CrossRef]

- Tonezzer, M.; Izidoro, S.C.; Moraes, J.P.A.; Dang, L.T.T. Improved Gas Selectivity Based on Carbon Modified SnO2 Nanowires. Front. Mater. 2019, 6, 277. [Google Scholar] [CrossRef]

- Barik, P.; Pradhan, M. Selectivity in trace gas sensing: Recent developments, challenges, and future perspectives. Analyst 2022, 147, 1024–1054. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Feng, Z.; Zhang, Y.; Han, D.; Ma, J.; Chai, X.; Sang, S. Highly sensitive and low detection limit NO2 gas sensor based on In2O3 nanoparticles modified peach kernel-like GaN composites. Sens. Actuators B Chem. 2023, 382, 133452. [Google Scholar] [CrossRef]

- Hänsel, A.; Heck, M.J.R. Opportunities for photonic integrated circuits in optical gas sensors. J. Phys. Photonics 2020, 2, 012002. [Google Scholar] [CrossRef]

- Qin, J.; Jiang, S.; Wang, Z.; Cheng, X.; Li, B.; Shi, Y.; Tsai, D.P.; Liu, A.Q.; Huang, W.; Zhu, W. Metasurface Micro/Nano-Optical Sensors: Principles and Applications. ACS Nano 2022, 16, 11598–11618. [Google Scholar] [CrossRef]

- Allsop, T.; Arif, R.; Neal, R.; Kalli, K.; Kundrát, V.; Rozhin, A.; Culverhouse, P.; Webb, D.J. Photonic gas sensors exploiting directly the optical properties of hybrid carbon nanotube localized surface plasmon structures. Light Sci. Appl. 2016, 5, e16036. [Google Scholar] [CrossRef]

| WG Architecture | Description | Sensitivity | Ease of Fabrication |

|---|---|---|---|

| Planar WGs | Flat WGs typically fabricated on a substrate. | Moderate, limited interaction with evanescent field. | High, with well-established fabrication processes. |

| Rib WGs | WGs with a raised ridge structure on the substrate. | Enhanced compared to planar due to increased evanescent field. | Moderate, requires etching process. |

| Ridge WGs | Similar to rib WGs but with more pronounced confinement and elevation. | Higher sensitivity than rib WGs. | Moderate, requires etching process. |

| Slot WGs | Narrow slot between two high-index regions, creating strong field confinement. | High, strong interaction of the evanescent field in the slot. | Moderate, precise fabrication needed for narrow slot. |

| Plasmonic WGs | Utilize surface plasmon resonances at metal–dielectric interfaces for guiding light. | Very high, due to strong field enhancement at interfaces. | Complex, requires nanofabrication and precise metal deposition. |

| Hybrid Plasmonic WGs | Combine dielectric and plasmonic WGs to enhance field confinement and propagation length. | High, combining benefits of both dielectric and plasmonic fields. | Complex, advanced fabrication techniques for hybrid structures. |

| Subwavelength Grating WGs | Use periodic structures with subwavelength features for guiding light. | High, strong interaction with periodic structures. | Moderate to complex, requires precise control over grating patterns. |

| Suspended Membrane WGs | WGs suspended in air or another medium to maximize interaction with the environment. | Very high, maximum evanescent field exposure. Highly suitable for gas sensing. | Complex, requires suspension techniques and careful handling. |

| Gas | Absorption Wavelengths (µm) | Absorption Wavenumbers (cm−1) |

|---|---|---|

| Carbon Dioxide (CO2) | 4.26, 14.99, 15.45 | 2349, 667, 648 |

| Methane (CH4) | 3.31, 7.66 | 3020, 1305 |

| Water Vapor (H2O) | 2.66, 6.27 | 3756, 1596 |

| Nitrous Oxide (N2O) | 4.50, 7.80 | 2222, 1282 |

| Ozone (O3) | 9.60, 14.24 | 1042, 702 |

| Sulfur Dioxide (SO2) | 7.34, 8.72 | 1363, 1147 |

| Ammonia (NH3) | 2.97, 9.22 | 3368, 1085 |

| Carbon Monoxide (CO) | 4.67 | 2143 |

| Nitric Oxide (NO) | 5.30, 5.44 | 1887, 1838 |

| Formaldehyde (HCHO) | 5.72, 9.60 | 1750, 1042 |

| Deposition Method | Features | Cost | Materials | Film Quality |

|---|---|---|---|---|

| CVD | Uses chemical reactions of vapor-phase precursors at elevated temperatures. | Moderate to High | Semiconductors, dielectrics, metals | High-quality, uniform films with good adhesion. |

| PECVD | Utilizes plasma to enhance chemical reactions, allowing for lower temperatures. | Moderate to High | Dielectrics, semiconductors | High-quality films, often with improved properties due to plasma. |

| ALD | Sequential self-limiting reactions for precise thickness control at atomic scale. | High | Oxides, nitrides, metals, semiconductors | Extremely high-quality, ultra-thin, and uniform films. |

| MBE | Uses a beam of atoms or molecules directed at the substrate in an ultra-high vacuum. | Very High | Semiconductors, oxides | Very high-quality, crystalline films with atomic precision. |

| Dip-Coating Process | Substrate is dipped into a solution and then withdrawn at a controlled rate to form a thin film. | Low | Polymers, oxides, glasses | Variable quality, dependent on solution properties and withdrawal speed. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Butt, M.A.; Piramidowicz, R. Integrated Photonic Sensors for the Detection of Toxic Gasses—A Review. Chemosensors 2024, 12, 143. https://doi.org/10.3390/chemosensors12070143

Butt MA, Piramidowicz R. Integrated Photonic Sensors for the Detection of Toxic Gasses—A Review. Chemosensors. 2024; 12(7):143. https://doi.org/10.3390/chemosensors12070143

Chicago/Turabian StyleButt, Muhammad A., and Ryszard Piramidowicz. 2024. "Integrated Photonic Sensors for the Detection of Toxic Gasses—A Review" Chemosensors 12, no. 7: 143. https://doi.org/10.3390/chemosensors12070143