Research on On-Line Monitoring System of Hydraulic Actuator of Combine Harvester

Abstract

:1. Introduction

2. Experimental Methods

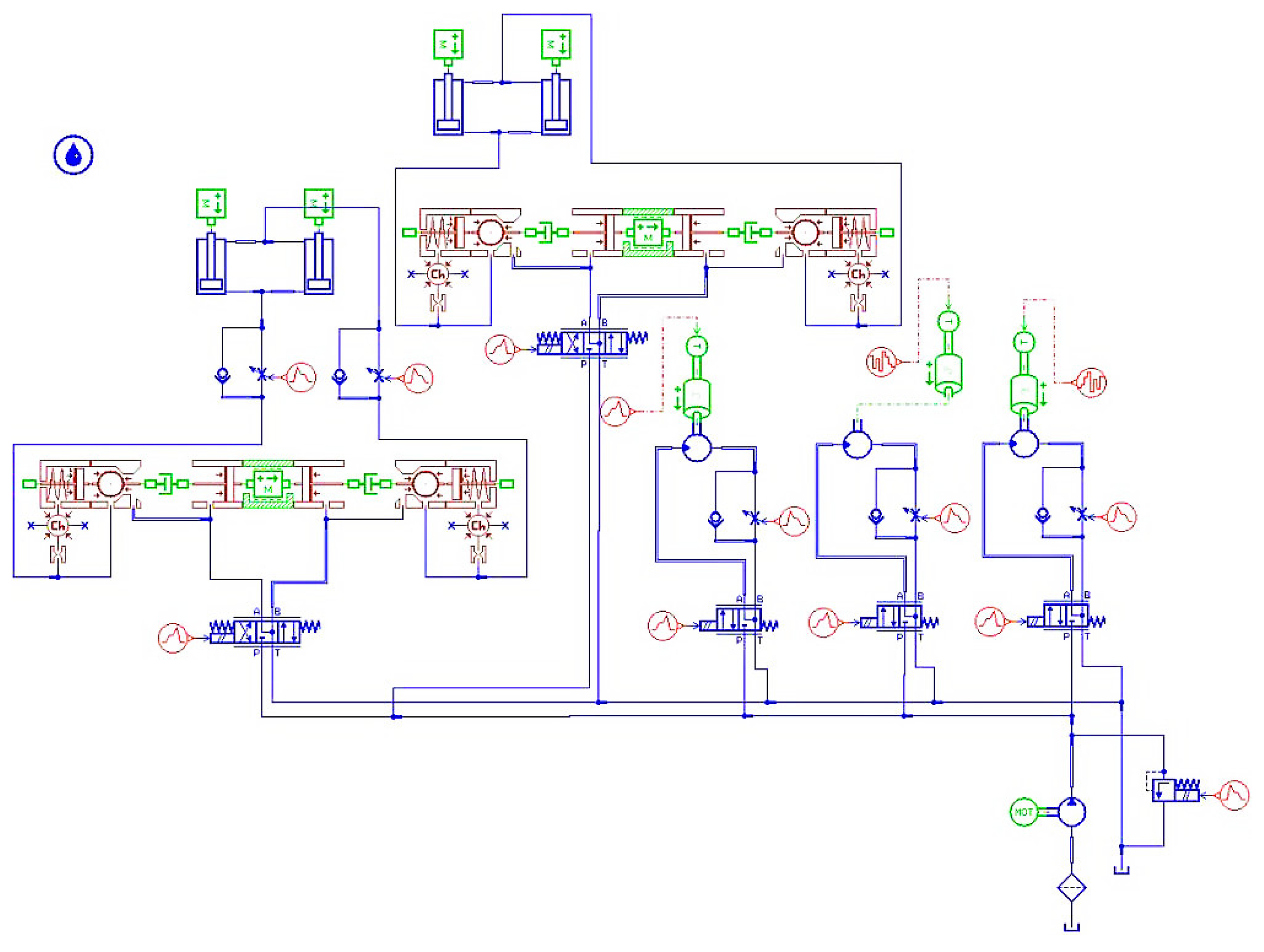

2.1. Mathematical Model of Hydraulic System

2.2. Simulation Test Analysis

2.3. Design of On-Line Monitoring System

2.3.1. Design of Monitoring Points and Monitoring Parameters

2.3.2. Software Design of On-Line Monitoring System

2.4. Fault Judgment and Alarm Program Design

2.5. Experiment

3. Results

3.1. Experimental Results of Working Condition Parameters

3.2. Experimental Results of Fault Diagnosis

4. Discussion of Experimental Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Reinke, R.; Dankowicz, H.; Phelan, J. A dynamic rain flow model for a mass flow yield sensor on a combine. Precis. Agric. 2011, 12, 732–749. [Google Scholar] [CrossRef]

- Liang, Z.; Li, Y.; Zhao, Z. Structure optimization of a grain impact piezoelectric sensor and its application for monitoring separation losses on tangential-axial combine harvesters. Sensors 2015, 15, 1496–1517. [Google Scholar] [CrossRef] [Green Version]

- Deng, L.L.; Li, Y.M. Current situation and development trend of rice combine harvester in China. Res. Agric. Mech. 2001, 2, 4–6. [Google Scholar]

- Xia, L.Q.; Liang, X.X.; Wei, L.G. Research progress of automatic monitoring system for combine harvester. Agric. Mach. 2013, 19, 141–144. [Google Scholar]

- Dębska, A.; Bieniek, J.; Fabrykowski, E. Exploitation assessment of New Holland CX780 combine harvester. Agric. Eng. 2016, 20, 43–51. [Google Scholar] [CrossRef]

- Lu, W.T.; Zhang, L.J.; Zhang, D.X. Research status of combine harvester monitoring system. Res. Agric. Mech. 2014, 36, 256–259. [Google Scholar]

- Liang, X.X. Research on Automatic Monitoring System of Combine Harvester; China Academy of Agricultural Mechanization: Beijing, China, 2013. [Google Scholar]

- Dong, Q.J.; Wang, M.; Jin, H.J. Application of on-line detection system in construction machinery. Constr. Mech. 2016, 37, 66–67. [Google Scholar]

- Ling, Y.J.; Lu, R.F.; Liao, Y.M. Grand View of combine harvester market. Agric. Mach. Mark. 2016, 4, 30–31. [Google Scholar]

- Chen, Q.W.; Han, Z.D.; Cui, J.W. Development status and trend analysis of self-propelled grain combine harvester. China Agric. Sci. Technol. Herald 2015, 17, 109–114. [Google Scholar]

- Craessaerts, G.; Baerdemaeker, J.D.; Saeys, W. Fault diagnostic systems for agricultural machinery. Biosyst. Eng. 2010, 106, 26–36. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.F.; Wang, Y.H. Design of remote video monitoring system for combine operation. Meas. Control. Technol. 2017, 12, 115–119. [Google Scholar]

- Ren, H.X. Application and development trend of automatic control in combine harvester. Mod. Agric. Equip. 2004, 6, 57–60. [Google Scholar]

- Zheng, S.Y.; Chen, J.; Li, Y.M. Multisensor signal acquisition and data processing system of combine harvester. J. Agric. Mach. 2011, 63 (Suppl. S1), 107–111. [Google Scholar]

- Yang, Y.X.; Xu, L.P.; Ren, D.Z. Design of condition detection system for excavator hydraulic system based on Virtual Instrument Technology. Mach. Tool Hydraul. 2012, 40, 133–135. [Google Scholar]

- Zhang, H.P.; Pan, S.L. Study on working efficiency of combine harvester. Agric. Dev. Equip. 2017, 5, 132–134. [Google Scholar]

- Wen, H.; Yao, C.F. The fault of hydraulic system and trouble-shooting. Appl. Mech. Mater. 2014, 46, 1121–1124. [Google Scholar] [CrossRef]

- Wang, L.T.; Zhu, S.X.; Lin, G.Z. Several new technologies of modern combine harvester. Mod. Agric. 2014, 3, 58–59. [Google Scholar]

- Chen, J.; Wang, X.L.; Wang, Y.F. Monitoring system for main parts working condition of combine harvester based on Android mobile phone. J. Agric. Mach. 2016, 47 (Suppl. S1), 203–207. [Google Scholar]

- Chen, H.F.; Guo, H.; Zhang, X.J. Application status and development trend of hydrostatic technology in agricultural machinery. Xinjiang Agric. Mech. 2016, 2, 11–13. [Google Scholar]

- Xu, K. Blockage Fault Diagnosis and Alarm System for Combine Harvester Based on BPNN and DS Theory. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2016. [Google Scholar]

- Xiong, S.H. Study on the State Monitoring System of Combine Harvester. Master’s Thesis, Shanghai Jiaotong University, Shanghai, China, 2018. [Google Scholar]

- Dong, S.; Yuan, C.H.; Gu, C. Research summary of intelligent agricultural machinery control platform based on multi-disciplinary technology integration. J. Agric. Eng. 2017, 38, 1–11. [Google Scholar]

- Hu, Y.X.; Yan, C.L. Application of data mining technology in quality control of agricultural machinery. J. Agric. Mach. 2007, 38, 153–156. [Google Scholar]

- Gao, F. Research on Monitoring Device for Main Working Parts of Combine Harvester. Master’s Thesis, Zhejiang University, Hangzhou, China, 2012. [Google Scholar]

- Guo, S.G.; Ren, L.J.; Wang, G.Z. Virtual instrument system based on LabVIEW and PCI-1710. Instrum. Technol. Sens. 2011, 10, 35–37. [Google Scholar]

- Yang, Y.X. Design and Research of Excavator Hydraulic System State Detection System Based on LabVIEW. Master’s Thesis, Henan University of Science and Technology, Luoyang, China, 2012. [Google Scholar]

- Nikeshin, A.V.; Shnitman, V.Z. Testing the conformance of implementations of the EAP protocol and its methods to internet specifications. Program. Comput. Softw. 2019, 45, 417–423. [Google Scholar]

- Ying, L.; Kun, W. Study on fault diagnosis and load feedback control system of combine harvester. In Proceedings of the Seventh International Conference on Electronics and Information Engineering, Nanjing, China, 17–18 September 2016. [Google Scholar]

- Yu, C.S. Research on Remote Fault Diagnosis System of Combine Harvester Based on Fuzzy Neural Network. Master’s Thesis, Hubei University of Technology, Wuhan, China, 2019. [Google Scholar]

- Wang, F.Z.; Zhang, J.N.; Li, R.C.; Wei, L.G.; Han, X.; Liu, Y.C. Design of on-line monitoring and fault early warning system for peanut combined harvester. J. Agric. Mach. 2015, 46 (Suppl. S1), 69–73. [Google Scholar]

- Li, Z. Research on Remote Monitoring Platform and Fault Analysis of Combine Harvester. Master’s Thesis, Hubei University of Technology, Wuhan, China, 2019. [Google Scholar]

| Name | Value |

|---|---|

| Pump delivery (mL/r) | 175 |

| Rated speed of pump (r/min) | 2500 |

| System pressure (MPa) | 20 |

| Diameter of cylinder of cutting table (mm) | 150 |

| Cylinder piston rod diameter (mm) | 40 |

| Oil cylinder load (Kg) | 400 |

| Diameter of cylinder of rotary wheel (mm) | 80 |

| Cylinder piston rod diameter (mm) | 30 |

| Oil cylinder load (Kg) | 100 |

| Motor displacement of threshing drum (mL/r) | 55 |

| Displacement of rotary wheel motor (mL/r) | 35 |

| Motor displacement of screw conveyor (mL/r) | 20 |

| Fault Category | SVM0 | SVM1 | SVM2 | SVM3 |

|---|---|---|---|---|

| SVM0 | 1 | 0 | 0 | 0 |

| SVM1 | 0 | 1 | 0 | 0 |

| SVM2 | 0 | 0 | 1 | 0 |

| SVM3 | 0 | 0 | 0 | 1 |

| Fault Location | Artificially Set Fault | Fault Phenomenon |

|---|---|---|

| Header auger | Reduce header height and increase travel speed | The rotating speed decreases and the straw accumulates |

| Conveying trough | Adjust the drive belt tensioner | The speed decreases and the feed auger is blocked |

| Threshing drum | Moderate throttle operation of the engine to increase the forward speed | The speed slows down and the belt rubs violently with the pulley |

| Job Failure | Number of Tests | Correct Number of Alarms | Number of Alarm Errors | Alarm Accuracy |

|---|---|---|---|---|

| Auger blocked | 100 | 93 | 7 | 93% |

| Conveyor chute blocked | 100 | 97 | 3 | 97% |

| Threshing drum blocked | 200 | 199 | 1 | 99.5% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, R.; Cheng, Y.; Xu, J.; Li, Y.; Ding, X.; Zhao, S. Research on On-Line Monitoring System of Hydraulic Actuator of Combine Harvester. Processes 2022, 10, 35. https://doi.org/10.3390/pr10010035

Li R, Cheng Y, Xu J, Li Y, Ding X, Zhao S. Research on On-Line Monitoring System of Hydraulic Actuator of Combine Harvester. Processes. 2022; 10(1):35. https://doi.org/10.3390/pr10010035

Chicago/Turabian StyleLi, Ruichuan, Yi Cheng, Jikang Xu, Yanchao Li, Xinkai Ding, and Shan Zhao. 2022. "Research on On-Line Monitoring System of Hydraulic Actuator of Combine Harvester" Processes 10, no. 1: 35. https://doi.org/10.3390/pr10010035

APA StyleLi, R., Cheng, Y., Xu, J., Li, Y., Ding, X., & Zhao, S. (2022). Research on On-Line Monitoring System of Hydraulic Actuator of Combine Harvester. Processes, 10(1), 35. https://doi.org/10.3390/pr10010035