Development of a Semi-Empirical Model for Droplet Size Determination of a Three-Channel Spray Nozzle for Pellet Coating Based on the Optical Method Concept

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials: Polymeric Dispersions and Their Rheology

2.1.1. Surface Tension

2.1.2. Viscosity

2.1.3. Density

2.2. Design of Experiment and Dimensional Analysis to Support the Experimental Setup

- -

- Solvents: water, acetone, ethanol, and mixture of ethanol and water

- -

- Polymer used and its w/w%:

- ○

- Hypromellose: 6.5–9.3

- ○

- Ethylcellulose: 4.0

- ○

- Copolymer of acrylic and methacrylic acid: 1.8–10.0

- -

- Viscosity (η): 0.3–225 mPas

- -

- Surface tension (λ): 23.7–72.0 mN/m

- -

- Density (): 790–1030 kg/m3

- -

- Dispersion flow (M): 12–160 g/min

- -

- Atomization air pressure (pa): 1.1–3.1 bar

- -

- Microclimate air pressure (pm): 0.1–2.6 bar

2.3. Droplet Size Measurements

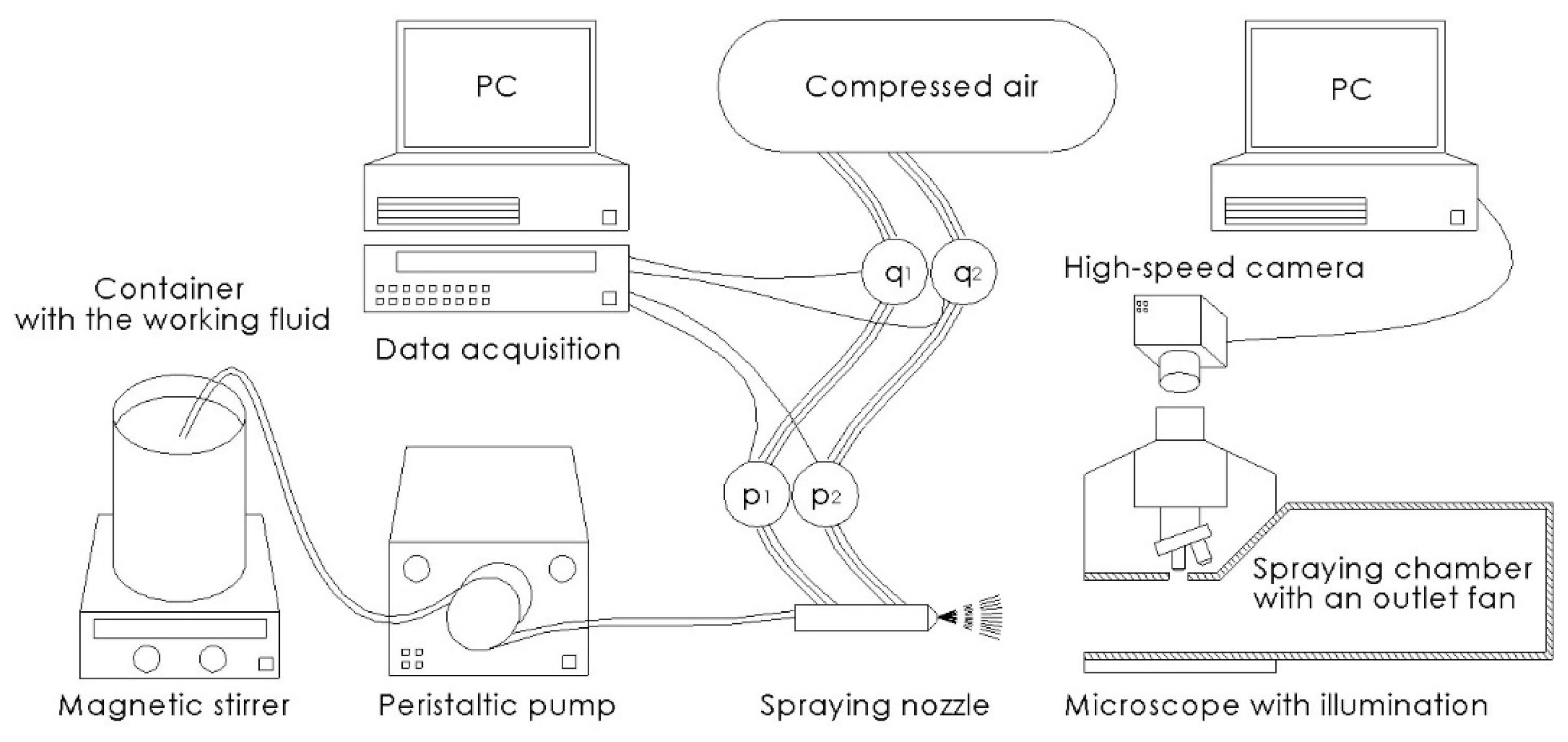

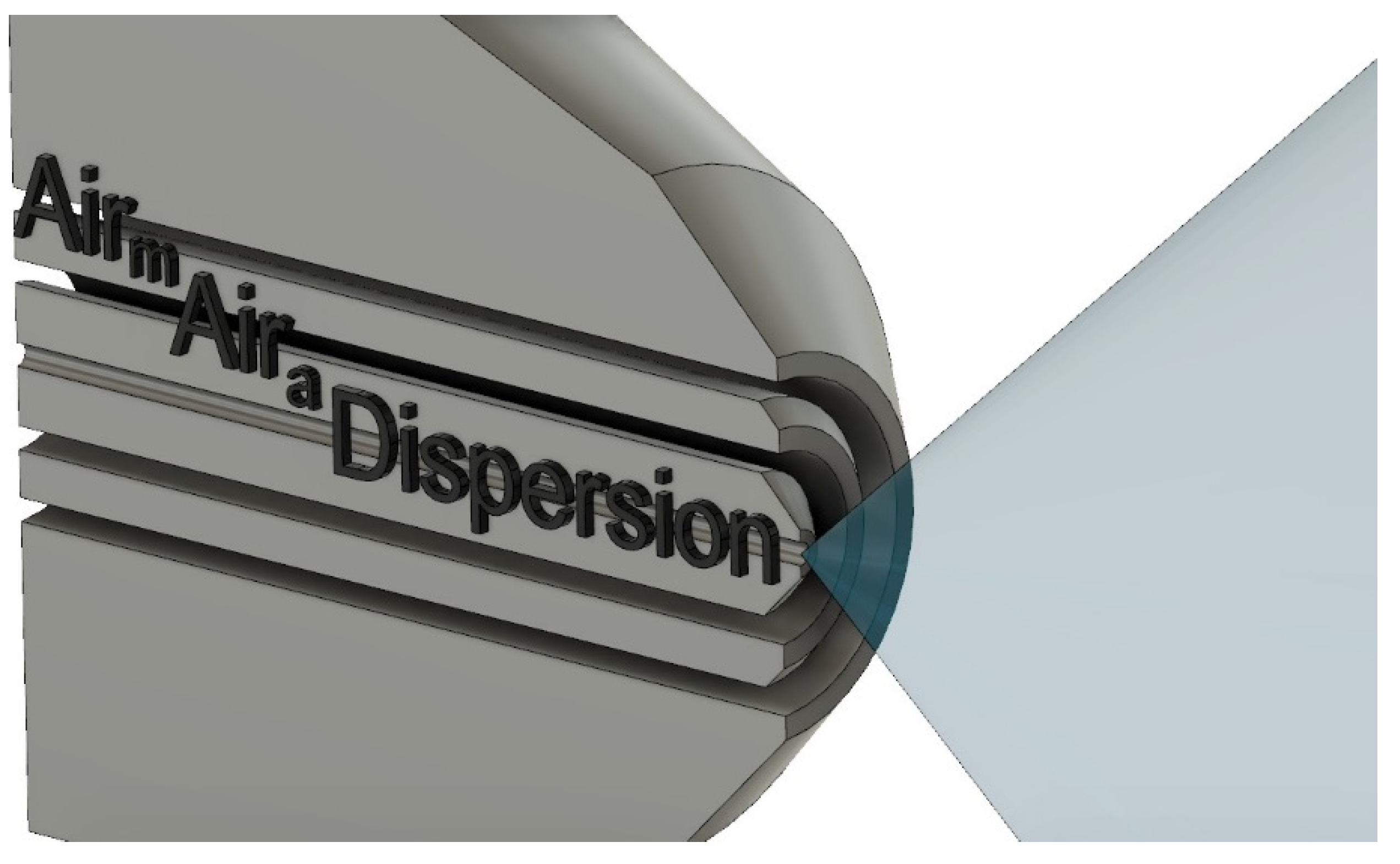

2.3.1. Experimental Setup

2.3.2. Image Analysis

3. Results and Discussion

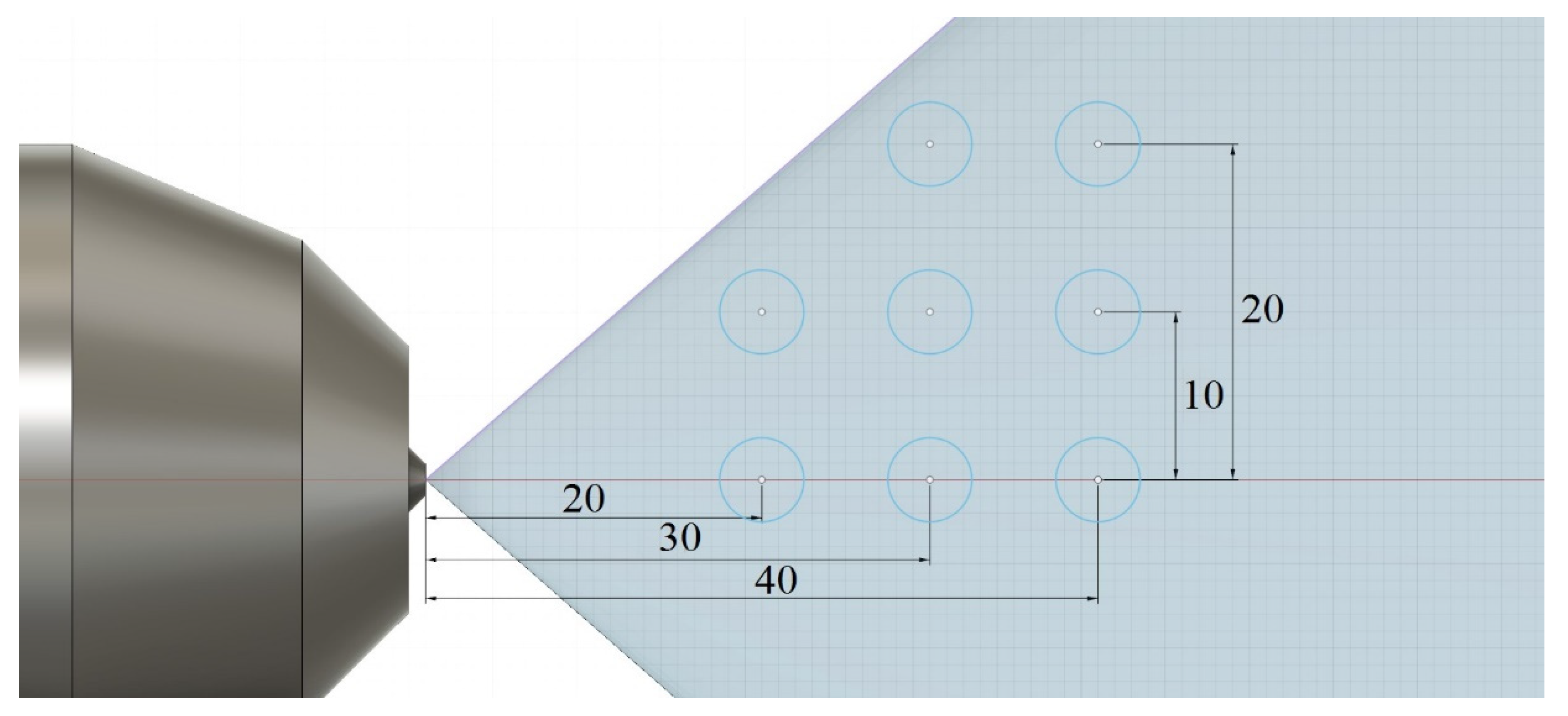

3.1. Definition of Measuring Conditions

3.2. Statistical Analysis

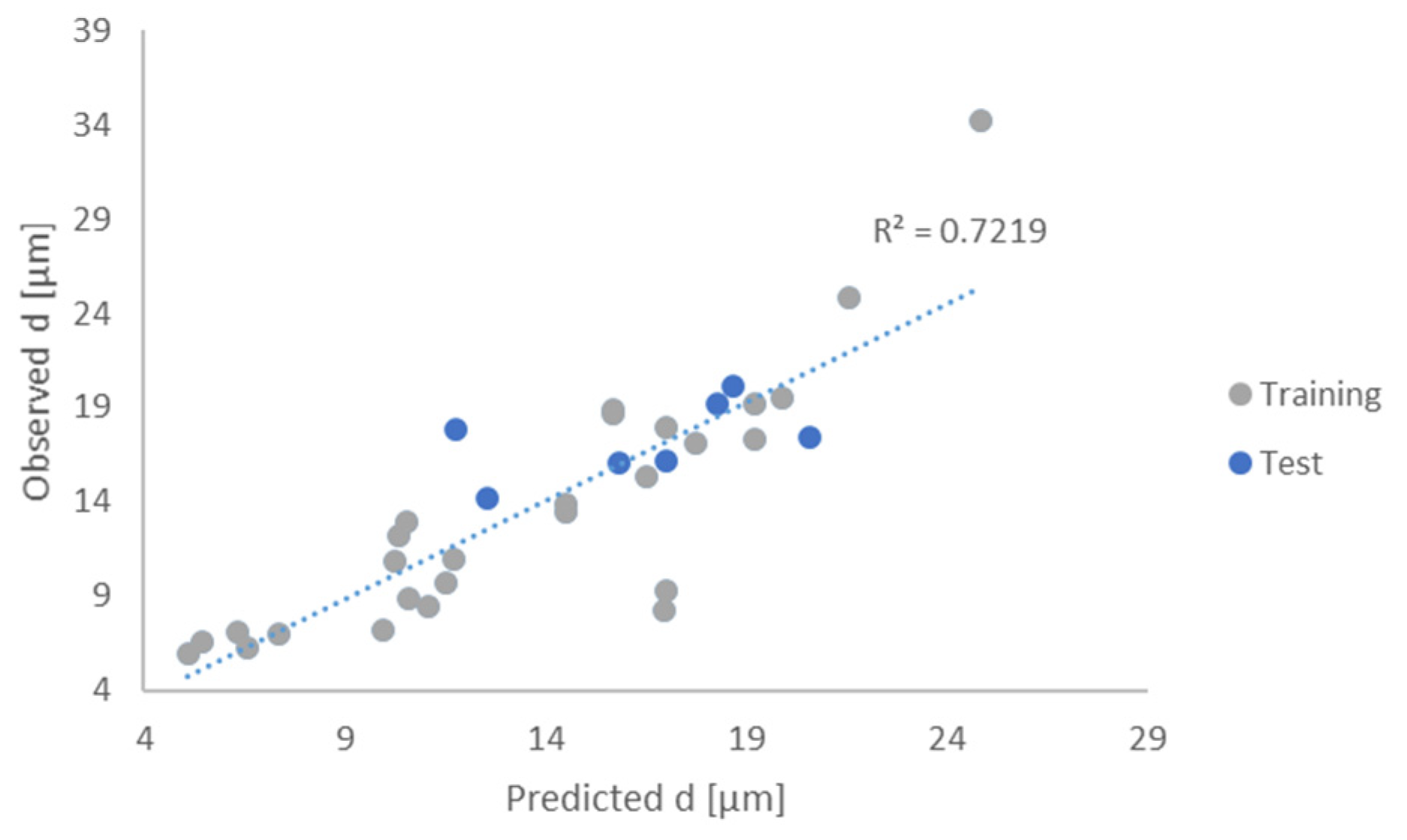

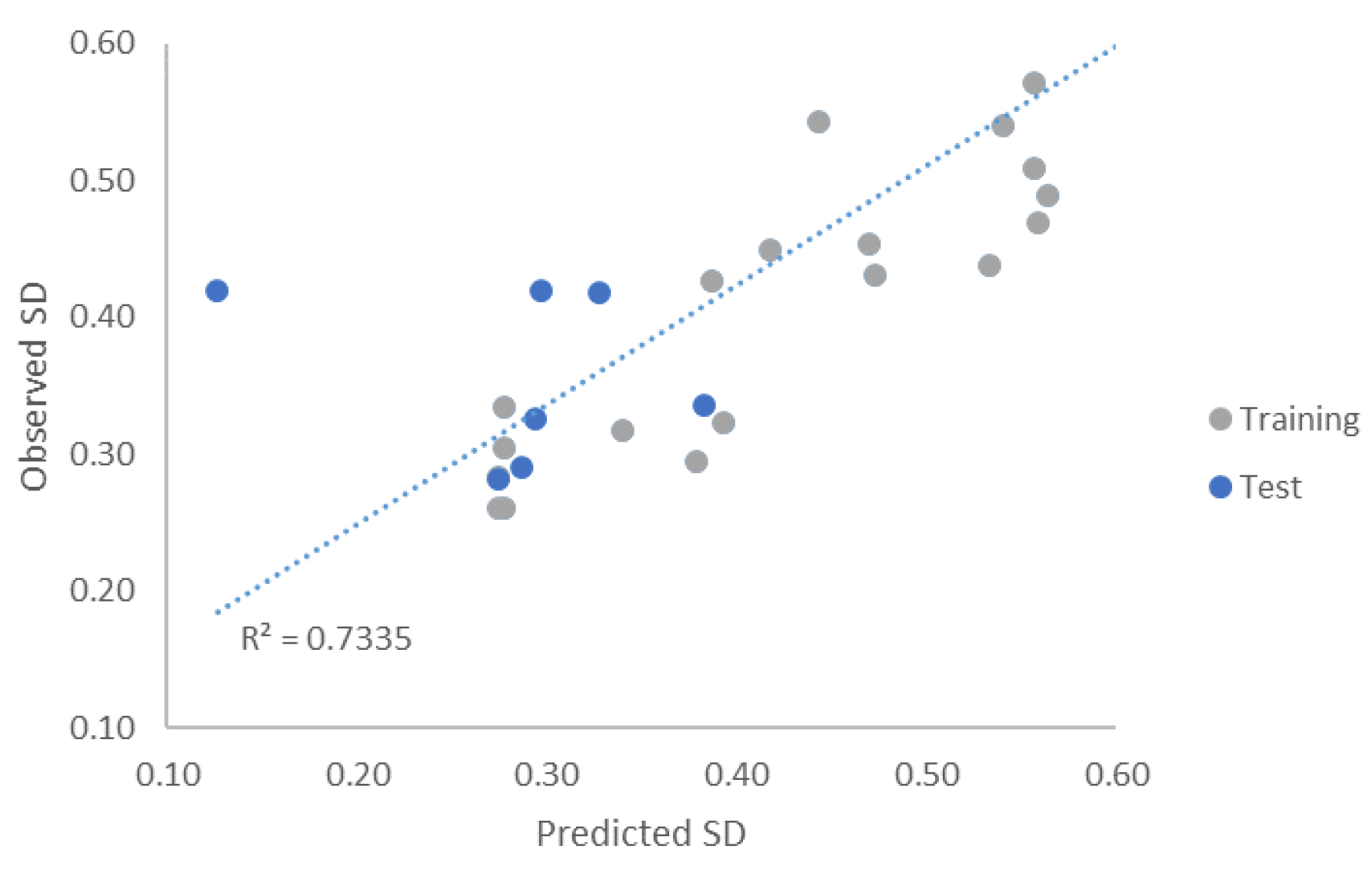

3.3. Model Construction

3.4. Simplification of Generated Models, Extraction of Basic Physio Chemical Influences, and Comparison with N–T

- The majority of the influences of the parameters are comparable: M and λ exhibit a positive correlation, whereas , pa, and pm show a negative correlation with droplet size.

- The influence of viscosity has a negative correlation with droplet size based on our results and has a positive correlation with droplet size based on the N–T. However, based on the experimental results in this study, the influence of viscosity is much lower compared with the N–T equation, which was also emphasized by other authors [39].

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gabrielsson, J.; Lindberg, N.O.; Lundstedt, T. Multivariate methods in pharmaceutical applications. J. Chemom. 2002, 16, 141–160. [Google Scholar] [CrossRef]

- Huang, J.; Kaul, G.; Cai, C.; Chatlapalli, R.; Hernandez-Abad, P.; Ghosh, K.; Nagi, A. Quality by design case study: An integrated multivariate approach to drug product and process development. Int. J. Pharm. 2009, 382, 23–32. [Google Scholar] [CrossRef] [PubMed]

- Korakianiti, E.; Rekkas, D. Statistical thinking and knowledge management for quality-driven design and manufacturing in pharmaceuticals. Pharm. Res. 2011, 28, 1465–1479. [Google Scholar] [CrossRef]

- Mitchell, M. Determining criticality—Process parameters and quality attributes part III: Process control strategies—Criticality throughout the lifecycle. BioPharm Int. 2014, 27, 26–35. [Google Scholar]

- Juckers, A.; Knerr, P.; Harms, F.; Strube, J. Advanced process analytical technology in combination with process modeling for endpoint and model parameter determination in lyophilization process design and optimization. Processes 2021, 9, 1600. [Google Scholar] [CrossRef]

- Missaghi, S.; Fassihi, R. A novel approach in the assessment of polymeric film formation and film adhesion on different pharmaceutical solid substrates. AAPS PharmSciTech 2004, 5, 32–39. [Google Scholar] [CrossRef] [Green Version]

- Aliseda, A.; Hopfinger, E.J.; Lasheras, J.C.; Kremer, D.M.; Berchielli, A.; Connolly, E.K. Atomization of viscous and non-newtonian liquids by a coaxial, high-speed gas jet. Experiments and droplet size modeling. Int. J. Multiph. Flow 2008, 34, 161–175. [Google Scholar] [CrossRef] [Green Version]

- Marković, S.; Poljanec, K.; Kerč, J.; Horvat, M. In-Line NIR monitoring of key characteristics of enteric coated pellets. Eur. J. Pharm. Biopharm. 2014, 88, 847–855. [Google Scholar] [CrossRef] [PubMed]

- Hîrjau, M.; Miron, D.S.; Anut, V.; Lupuliasa, D.; Ghica, M.V.; Jinga, V.; Dinu-Pîrvu, C.E. Evaluation of experimental multi-particulate polymer-coated drug delivery systems with meloxicam. Coatings 2020, 10, 490. [Google Scholar] [CrossRef]

- Vesey, C.; Cronlein, J.; Breuer, A.; Gerstner, S. Fluid Bed Nozzle Spray Characterization of an Aqueous Ethylcellulose Dispersion for Particle Taste-Masking Applications. AAPS Poster Reprint. 2014. Available online: https://www.colorcon.com/es/products-formulation/all-products/download/312/2928/34?method=view (accessed on 13 September 2020).

- Zhang, R.; Hoffmann, T.; Tsotsas, E. Novel technique for coating of fine particles using fluidized bed and aerosol atomizer. Processes 2020, 8, 1525. [Google Scholar] [CrossRef]

- Mueller, R.; Kleinebudde, P. Comparison of a laboratory and a production coating spray gun with respect to scale-up. AAPS PharmSciTech 2007, 8, E21–E31. [Google Scholar] [CrossRef] [Green Version]

- Ehlers, H.; Larjo, J.; Antikainen, O.; Räikkönen, H.; Heinämäki, J.; Yliruusi, J. In Situ droplet size and speed determination in a fluid-bed granulator. Int. J. Pharm. 2010, 391, 148–154. [Google Scholar] [CrossRef]

- Seo, A.; Holm, P.; Schafer, T. Effects of droplet size and type of binder on the agglomerate growth mechanisms by melt agglomeration in a fluidised bed. Eur. J. Pharm. Sci. 2002, 16, 95–105. [Google Scholar] [CrossRef]

- Debevec, V.; Ljubin, T.S.; Jeraj, Ž.; Peterka, T.R.; Bratuž, B.; Gašperlin, D.; Srčič, S.; Horvat, M. Step-Wise approach to developing a scale-independent design space for functional tablet coating process. Drug Dev. Ind. Pharm. 2020, 46, 566–575. [Google Scholar] [CrossRef] [PubMed]

- Dennison, T.J.; Smith, J.; Hofmann, M.P.; Bland, C.E.; Badhan, R.K.; Al-Khattawi, A.; Mohammed, A.R. Design of experiments to study the impact of process parameters on droplet size and development of non-invasive imaging techniques in tablet coating. PLoS ONE 2016, 11, e0157267. [Google Scholar] [CrossRef]

- Gauno, M.H.; Larsen, C.C.; Vilhelmsen, T.; Moller-Sonnergaard, J.; Wittendorff, J.; Rantanen, J. Evaluation of droplet size distributions using univariate and multivariate approaches. Pharm. Dev. Technol. 2013, 18, 926–934. [Google Scholar] [CrossRef] [PubMed]

- Shafer, M.R.; Bovey, H. Applications of Dimensional Analysis to Spray-Nozzle Performance Data. J. Res. Natl. Bur. Stand. 1954, 52, 141–147. [Google Scholar] [CrossRef]

- Schoefer, O.; Worts, T. Control of fluidized bed granulation, estimation of droplet size of atomized binder solution. Arch. Pharm. Chem. Sci. 1977, 2, 178–193. [Google Scholar]

- Thybo, P.; Hovgaard, L.; Andersen, S.K.; Lindeløv, J.S. Droplet size measurements for spray dryer scale-up. Pharm. Dev. Technol. 2008, 13, 93–104. [Google Scholar] [CrossRef] [PubMed]

- Mandato, S.; Rondet, E.; Delaplace, G.; Barkouti, A.; Galet, L.; Accart, P.; Ruiz, T.; Cuq, B. Liquids’ atomization with two different nozzles: Modeling of the effects of some processing and formulation conditions by dimensional analysis. Powder Technol. 2012, 224, 323–330. [Google Scholar] [CrossRef] [Green Version]

- Petit, J.; Méjean, S.; Accart, P.; Galet, L.; Schuck, P.; Le Floch-Fouéré, C.; Delaplace, G. A dimensional analysis approach for modelling the size of droplets formed by bi-fluid atomisation. J. Food Eng. 2015, 149, 237–247. [Google Scholar] [CrossRef]

- Lefebvre, A.H.; Mcdonell, V.G. Atomization and Sprays; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Dumouchel, C.; Yongyingsakthavorn, P.; Cousin, J. Light multiple scattering correction of laser-diffraction spray drop-size distribution measurements. Int. J. Multiph. Flow 2009, 35, 277–287. [Google Scholar] [CrossRef]

- Medendorp, J.; Bric, J.; Connelly, G.; Tolton, K.; Warman, M. Development and beyond: Strategy for long-term maintenance of an online laser diffraction particle size method in a spray drying manufacturing process. J. Pharm. Biomed. Anal. 2015, 112, 79–84. [Google Scholar] [CrossRef]

- Bian, J.; Zhang, D.; Sun, R.; Wu, Y.; Tian, W.; Su, G.H.; Qiu, S. Experimental study on spray characteristics of pressure-swirl nozzle in China advanced PWR containment. Nucl. Eng. Des. 2019, 350, 158–175. [Google Scholar] [CrossRef]

- Song, J.G.; Cain, J.; Lee, C.C. Liquid Jets in Subsonic Air Crossflow at Elevated Pressure. J. Eng. Gas Turbines Power 2015, 137, 041502. [Google Scholar] [CrossRef]

- Kong, L.; Lan, T.; Chen, J.; Wang, K.; Sun, H. Breakup processes and droplet characteristics of liquid jets injected into low-speed air crossflow. Processes 2020, 8, 676. [Google Scholar] [CrossRef]

- Lee, K.; Sallam, K.A.; Faeth, G.M.; Diez, F.J.; Aalburg, C. Primary Breakup of Turbulent Round Liquid Jets in Uniform Crossflows. AIAA J. 2007, 45, 1907–1916. [Google Scholar] [CrossRef]

- Lee, K.H.; Lee, C.H.; Lee, C.S. An experimental study on the spray behavior and fuel distribution of GDI injectors using the entropy analysis and PIV method. Fuel 2004, 83, 971–980. [Google Scholar] [CrossRef]

- Wu, Z.; Zhu, Z.; Huang, Z. An experimental study on the spray structure of oxygenated fuel using laser-based visualization and particle image velocimetry. Fuel 2006, 85, 1458–1464. [Google Scholar] [CrossRef]

- Nukiyama, Y.; Tanasawa, S. Experiments on the atomization of liquids in an air stream. Trans. Soc. Mech. Eng. Jpn. 1939, 5, 68–75. [Google Scholar]

- Lefebvre, A.H.; Miller, D. The Development of an Air Blast Atomizer for Gas Turbine Application; College of Aeronautics Report Aero 193; College of Aeronautics Cranfield: Cranfield, UK, 1966. [Google Scholar]

- Rizkalla, A.H.; Lefebvre, A. The influence of air and liquid properties on air blast atomization. ASME J. Fluids Eng. 1975, 97, 316–320. Available online: http://ir.obihiro.ac.jp/dspace/handle/10322/3933 (accessed on 13 September 2020). [CrossRef]

- Scheer, I.W.; Beaumont, C. A New Quality Methodology and Metrics for Spray Pattern Analysis. At. Sprays 2011, 21, 189–202. [Google Scholar] [CrossRef]

- Muliadi, A.R.; Sojka, P.E.; Sivathanu, Y.R.; Lim, J. A comparison of Phase Doppler Analyzer (dual-PDA) and optical patternator data for twin-fluid and pressure-swirl atomizer sprays. J. Fluids Eng. Trans. ASME 2010, 132, 0614021. [Google Scholar] [CrossRef]

- Smyth, H.; Brace, G.; Barbour, T.; Gallion, J.; Grove, J.; Hickey, A.J. Spray pattern analysis for metered dose inhalers: Effect of actuator design. Pharm. Res. 2006, 23, 1591–1596. [Google Scholar] [CrossRef]

- Fischer, C.; Jaskulski, M.; Tsotsas, E. Inline method of droplet and particle size distribution analysis in dilute disperse systems. Adv. Powder Technol. 2017, 28, 2820–2829. [Google Scholar] [CrossRef]

- Groom, S.; Schaldach, G.; Ulmer, M.; Walzel, P.; Berndt, H. Adaptation of a new pneumatic nebulizer for sample introduction in ICP spectrometry. J. Anal. At. Spectrom. 2005, 20, 169–175. [Google Scholar] [CrossRef]

- Canals, A.; Hernandis, V.; Browner, R.F. Experimental evaluation of the Nukiyama-Tanasawa equation for pneumatic nebulisers used in plasma atomic emission spectrometry. J. Anal. At. Spectrom. 1990, 5, 61–66. [Google Scholar] [CrossRef]

- Gupta, G.S.; Sarkar, S.; Chychko, A.; Teng, L.D.; Nzotta, M.; Seetharaman, S. Process Concept for Scaling-Up and Plant Studies. Treatise Process Met. 2014, 3, 1100–1144. [Google Scholar] [CrossRef]

- Sonin, A.A. A generalization of the ∏-theorem and dimensional analysis. Proc. Natl. Acad. Sci. USA 2004, 101, 8525–8526. [Google Scholar] [CrossRef] [Green Version]

- Enßlin, S. Development and Characterization of High Dosed Layered Pellets with Polyvinyl Based Film Coats for Modified Release Applications in Waiblingen. Martin-Luther-Universität Halle-Wittenberg. 2009. Available online: http://d-nb.info/1024937887/34 (accessed on 13 September 2020).

- Melegari, C. Study of Different Technologies for Film Coating of Drug Layered Pellets Using Ethylcellulose as Functional Polymer. 2016. Available online: https://core.ac.uk/download/pdf/76520468.pdf (accessed on 13 September 2020).

- Aulton, M.; Cole, G.; Hogan, J. Solution properties and atomization in film coating. In Pharmaceutical Coating Technology; CRC Press: London, UK, 1995. [Google Scholar] [CrossRef]

- Lefebvre, A.H. Some recent development in twin-fluid atomization. Part. Part. Syst. Charact. 1996, 13, 205–216. [Google Scholar] [CrossRef]

- Lefebvre, A.H. Twin-Fluid Atomization: Factors Influencing Mean Drop Size. At. Sprays. 2014, 2, 101–119. [Google Scholar] [CrossRef]

- Lefebvre, A.H. Airblast atomization. Prog. Energy Combust. Sci. 1980, 6, 233–261. [Google Scholar] [CrossRef]

- Hede, P.D.; Bach, P.; Jensen, A.D. Two-Fluid spray atomisation and pneumatic nozzles for fluid bed coating/agglomeration purposes: A review. Chem. Eng. Sci. 2008, 63, 3821–3842. [Google Scholar] [CrossRef]

| Ref. | Statistical Approach | No. of Factors | Dispersion Properties | Type of Nozzle | Exp. Scale | No. of Exp. | Method for Droplet Size Determination | Field of Research | Drawbacks |

|---|---|---|---|---|---|---|---|---|---|

| Thybo et al. (2008) | Least squares analysis | 5 | Newtonian | 2 | Pilot, production | 166 | Malvern laser diffraction, volume-based | Pharmacy, spray drying |

|

| Petit et al. (2015) | DA + MLR | 7 (DA) | Newtonian | GEA | No data | 134 | Spraytec laser diffraction, volume-based | Food engineering |

|

| Aliseda et al. (2008) | No data | No data | Non-Newtonian | PF28100NB | No data | No data | Phase-Doppler particle analyzer, volume-based | Pharmacy, film coating |

|

| Vesey et al. (2014) | DoE | 3 | Non-Newtonian | Schlick 970, 0/4 | Laboratory, production | 34 | Phase-Doppler, volume-based | Pharmacy, film coating |

|

| Mueller and Kleinebudde (2007) | DoE | 4 | Newtonian | 970/7-1 S75 ABC, 930/7-1 S35 ABC | Laboratory, production | 27 | Phase-Doppler particle analyzer, volume-based | Pharmacy, film coating |

|

| Gauno et al. (2013) | ANOVA + PCA | 3 | Newtonian | Glatt 1-050-00190 X171 | Laboratory | 48 | Malvern laser diffraction, volume-based | Pharmacy, film coating (Wurster) |

|

| Dennison et al. (2016) | DoE | 3 | Newtonian | 1/8 JJAU-SS | Laboratory | 17 | Real time laser diffraction, volume-based | Pharmacy, film coating |

|

| Schoefer and Worts (1977) | Not used, single experiments compared | 4 | Newtonian * | 941-943/7 | Pilot | 160 | Photo-micrographs of droplets collected on oil-covered slides | Pharmacy, fluid bed granulation |

|

| Viscosity [mPas] | Surface Tension (1) [mN/m] | Density (1) [kg/m3] | |

|---|---|---|---|

| Acetone | 0.306 | 24.5 ± 0.11 | 790 ± 0 |

| Water | 0.894 | 72.0 | 1000 |

| 9.3 w/w% hypromellose in ethanol and water (9:1) | 225 | 26.9 ± 0.17 | 880 ± 20 |

| 6.5 w/w% hypromellose in ethanol | 75.2 | 25.8 ± 0.13 | 830 ± 0 |

| 10.0 w/w% copolymer of acrylic and methacrylic acid in ethanol | 16 | 24.0 ± 0.06 | 840 ± 0 |

| 1.8 w/w% copolymer of acrylic and methacrylic acid in ethanol | 2.2 | 23.7 ± 0.02 | 810 ± 10 |

| 4.0 w/w% ethylcellulose in ethanol | 10.6 | 24.3 ± 0.04 | 830 ± 20 |

| 6.5 w/w% hypromellose in water | 50.4 | 47.0 ± 0.44 | 1030 ± 0 |

| Exp. Name | [kg/m3] | η [Ns/m2] | λ [N/m] | M [g/min] | pa [bar] | pm [bar] | lnα | lnβ | lnγ | lnδ | d [µm] | E[ln(d10/D)] | SD[ln(d10/D)] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N1 | 880 | 0.225 | 0.0269 | 20 | 2.6 | 0.2 | −4.18 | −0.579 | −2.55 | −9.36 | 6.99 | −5.37 | 0.658 |

| N10 | 880 | 0.225 | 0.0269 | 113 | 1.3 | 0.1 | −2.10 | −0.579 | −2.54 | −8.67 | 11.0 | −4.87 | 0.626 |

| N11 | 790 | 0.000306 | 0.0245 | 12 | 1.1 | 0.2 | −4.21 | 12.4 | −1.72 | −8.61 | 7.17 | −5.25 | 0.509 |

| N12 | 790 | 0.000306 | 0.0245 | 100 | 1.1 | 0.1 | −2.09 | 12.4 | −2.48 | −8.61 | 13.5 | −4.93 | 0.822 |

| N13 | 880 | 0.225 | 0.0269 | 14 | 1.3 | 1.3 | −4.19 | −0.579 | −0.0038 | −8.67 | 5.96 | −5.40 | 0.449 |

| N14 | 880 | 0.225 | 0.0269 | 113 | 1.3 | 1.3 | −2.11 | −0.579 | −0.0123 | −8.67 | 8.87 | −5.05 | 0.543 |

| N15 | 790 | 0.000306 | 0.0245 | 12 | 1.1 | 1.1 | −4.21 | 12.42 | −0.00274 | −8.59 | 12.9 | −4.85 | 0.838 |

| N17 | 830 | 0.0752 | 0.0258 | 70 | 3.1 | 0.9 | −2.99 | 1.51 | −1.24 | −9.58 | 9.32 | −4.267 | 0.305 |

| N18 | 830 | 0.0752 | 0.0258 | 70 | 3.1 | 0.9 | −2.99 | 1.51 | −1.24 | −9.58 | 8.25 | −4.44 | 0.261 |

| N19 | 830 | 0.0686 | 0.026 | 70 | 3.1 | 0.9 | −2.99 | 1.71 | −1.23 | −9.57 | 18.0 | −4.26 | 0.335 |

| N2 | 880 | 0.225 | 0.0269 | 160 | 2.6 | 0.2 | −2.10 | −0.579 | −2.56 | −9.36 | 9.65 | −5.00 | 0.592 |

| N20 | 1000 | 0.000894 | 0.0720 | 113 | 1.3 | 0.1 | −2.17 | 11.6 | −2.58 | −7.68 | 24.8 | −4.12 | 0.701 |

| N3 | 790 | 0.000306 | 0.0245 | 18 | 2.2 | 0.2 | −4.15 | 12.4 | −2.57 | −9.29 | 7.11 | −5.28 | 0.540 |

| N4 | 790 | 0.000306 | 0.0245 | 141 | 2.2 | 0.2 | −2.10 | 12.4 | −2.55 | −9.30 | 12.2 | −4.77 | 0.611 |

| N5 | 880 | 0.225 | 0.0269 | 20 | 2.6 | 2.6 | −4.18 | −0.579 | −0.00653 | −9.36 | 6.29 | −5.36 | 0.469 |

| N6 | 880 | 0.225 | 0.0269 | 160 | 2.6 | 2.6 | −2.10 | −0.579 | −0.00769 | −9.36 | 10.9 | −4.92 | 0.613 |

| N7 | 790 | 0.000306 | 0.0245 | 18 | 2.2 | 2.2 | −4.15 | 12.4 | −0.00226 | −9.29 | 8.50 | −5.05 | 0.453 |

| N8 | 790 | 0.000306 | 0.0245 | 141 | 2.2 | 2.2 | −2.08 | 12.4 | 0.0128 | −9.28 | 17.1 | −4.35 | 0.438 |

| N9 | 880 | 0.225 | 0.0269 | 14 | 1.3 | 0.1 | −4.19 | −0.579 | −2.56 | −8.66 | 6.58 | −5.30 | 0.431 |

| C19 | 840 | 0.016 | 0.02395 | 20 | 2.6 | 0.2 | −4.16 | 4.55 | −2.57 | −9.48 | 29.0 | −3.82 | 0.445 |

| C20 | 810 | 0.0022 | 0.02366 | 20 | 2.6 | 2.0 | −4.14 | 8.47 | −0.276 | −9.49 | 18.9 | −4.25 | 0.427 |

| C21 | 870 | 0.216 | 0.02709 | 113 | 1.3 | 0.2 | −2.10 | −0.50 | −1.88 | −8.67 | 18.7 | −4.21 | 0.295 |

| C22 | 790 | 0.000306 | 0.02448 | 113 | 1.3 | 0.6 | −2.05 | 12.42 | −0.868 | −8.77 | 34.2 | −3.73 | 0.571 |

| C23 | 840 | 0.016 | 0.02395 | 113 | 1.3 | 1.3 | −2.08 | 4.55 | 0 | −8.79 | 19.5 | −4.23 | 0.489 |

| C24 | 1000 | 0.000894 | 0.07197 | 60 | 1.3 | 0.1 | −2.79 | 11.6 | −2.55 | −7.67 | 13.9 | −4.49 | 0.323 |

| C25 | 1000 | 0.000894 | 0.07197 | 30 | 1.3 | 1.3 | −3.49 | 11.6 | 0.00766 | −7.68 | 15.3 | −4.39 | 0.318 |

| C26 | 830 | 0.0106 | 0.02426 | 40 | 1.3 | 0.4 | −3.11 | 5.37 | −1.18 | −8.77 | 17.3 | −4.28 | 0.283 |

| C27 | 830 | 0.0106 | 0.02426 | 40 | 1.3 | 0.4 | −3.11 | 5.37 | −1.18 | −8.77 | 19.2 | −4.17 | 0.260 |

| Exp. name | [kg/m3] | η [Ns/m2] | λ [N/m] | M [g/min] | pa [bar] | pm [bar] | Exp. d [µm] | Model Prediction Diameter [µm] | Model Prediction SMD [µm] | Exp. SMD [µm] | Calculation of SMD by N-T [µm] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| D2 | 870 | 0.216 # | 0.0271 | 70 | 2.49 | 0.4 | 17.8 | 11.8 | 14.6 | 25.3 | 138 |

| D5 | 840 | 0.0160 | 0.0240 | 70 | 2.51 | 0.41 | 19.2 | 18.3 | 21.8 | 45.6 | 51.5 |

| D10 | 830 | 0.0106 | 0.0243 | 70 | 2.5 | 0.41 | 20.1 | 18.7 | 22.2 | 25.5 | 45.4 |

| X2 | 830 | 0.0686 | 0.0260 | 10 | 0.5 | 0.1 | 14.2 | 12.5 | 12.9 | 19.4 | 29.4 |

| X7 | 1030 | 0.0504 | 0.0470 | 70 | 2.51 | 0.4 | 16.1 | 15.8 | 18.7 | 19.3 | 54.9 |

| X8 | 1030 | 0.0504 | 0.0470 | 140 | 2.49 | 0.4 | 17.4 | 20.6 | 27.6 | 23.5 | 132 |

| X9 | 1030 | 0.0504 | 0.0470 | 70 | 3.11 | 0.9 | 16.2 | 17.0 | 19.7 | 19.1 | 54.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vidovič, S.; Bizjak, A.; Sitar, A.; Horvat, M.; Janković, B.; Golobič, I. Development of a Semi-Empirical Model for Droplet Size Determination of a Three-Channel Spray Nozzle for Pellet Coating Based on the Optical Method Concept. Processes 2022, 10, 86. https://doi.org/10.3390/pr10010086

Vidovič S, Bizjak A, Sitar A, Horvat M, Janković B, Golobič I. Development of a Semi-Empirical Model for Droplet Size Determination of a Three-Channel Spray Nozzle for Pellet Coating Based on the Optical Method Concept. Processes. 2022; 10(1):86. https://doi.org/10.3390/pr10010086

Chicago/Turabian StyleVidovič, Sara, Alan Bizjak, Anže Sitar, Matej Horvat, Biljana Janković, and Iztok Golobič. 2022. "Development of a Semi-Empirical Model for Droplet Size Determination of a Three-Channel Spray Nozzle for Pellet Coating Based on the Optical Method Concept" Processes 10, no. 1: 86. https://doi.org/10.3390/pr10010086

APA StyleVidovič, S., Bizjak, A., Sitar, A., Horvat, M., Janković, B., & Golobič, I. (2022). Development of a Semi-Empirical Model for Droplet Size Determination of a Three-Channel Spray Nozzle for Pellet Coating Based on the Optical Method Concept. Processes, 10(1), 86. https://doi.org/10.3390/pr10010086