Omega-3 Fatty Acid Retention and Oxidative Stability of Spray-Dried Chia–Fish-Oil-Prepared Microcapsules

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Raw Material

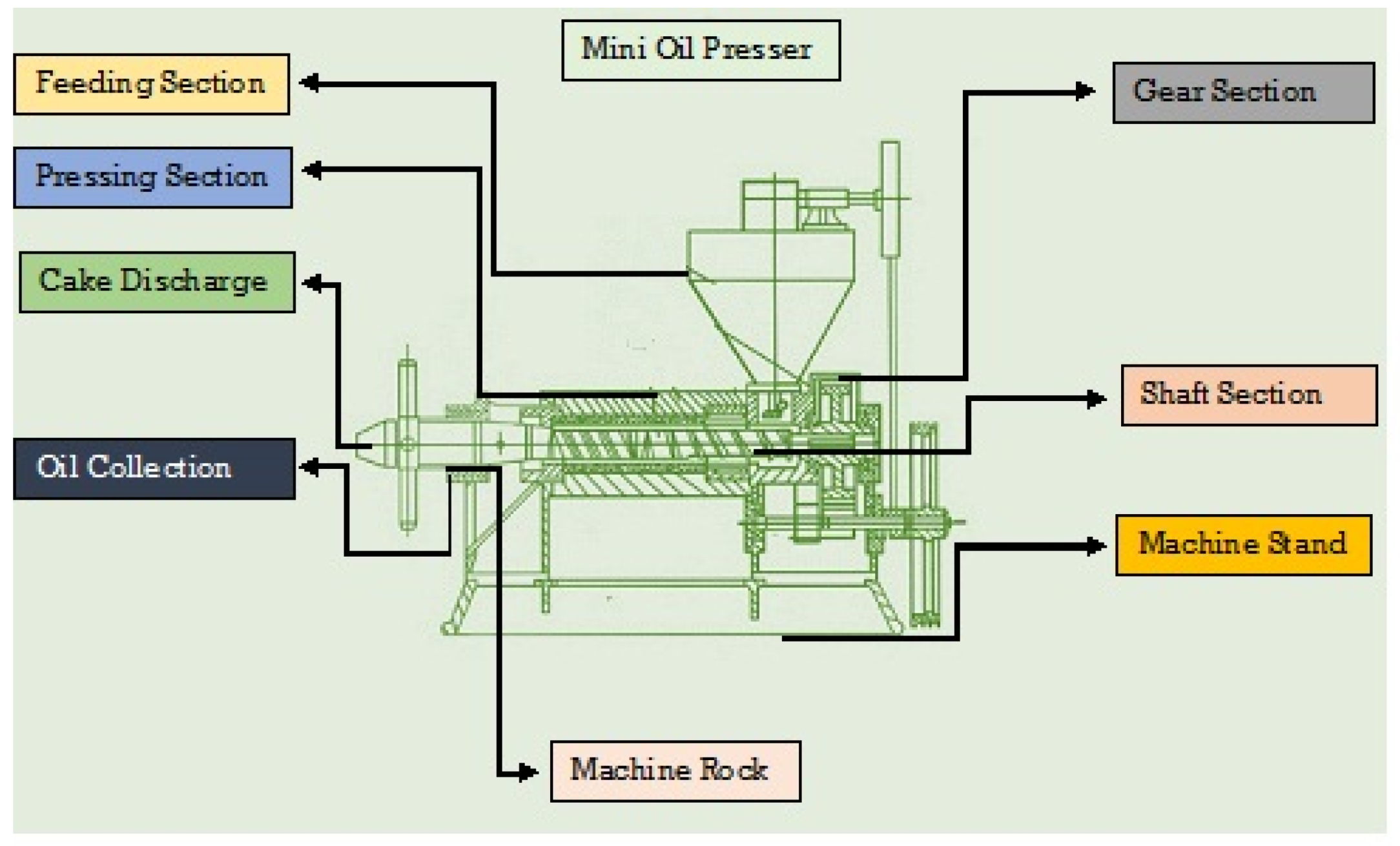

2.2. Chia Seed Oil Extraction

2.3. Fish Oil (FO) Extraction

2.4. Characteristics of the Extracted Oil

2.4.1. Fatty Acid Composition

2.4.2. Free Fatty Acids (FFAs)

2.4.3. Peroxide Value (PV)

2.5. Preparation of Emulsion

2.6. Spray Drying of the Omega-3-Enriched Oil

2.7. Optimization of Spray-Dried Microcapsules (SDM)

2.8. Statistical Analysis

3. Results

3.1. Fatty Acid Composition of the Extracted Oil

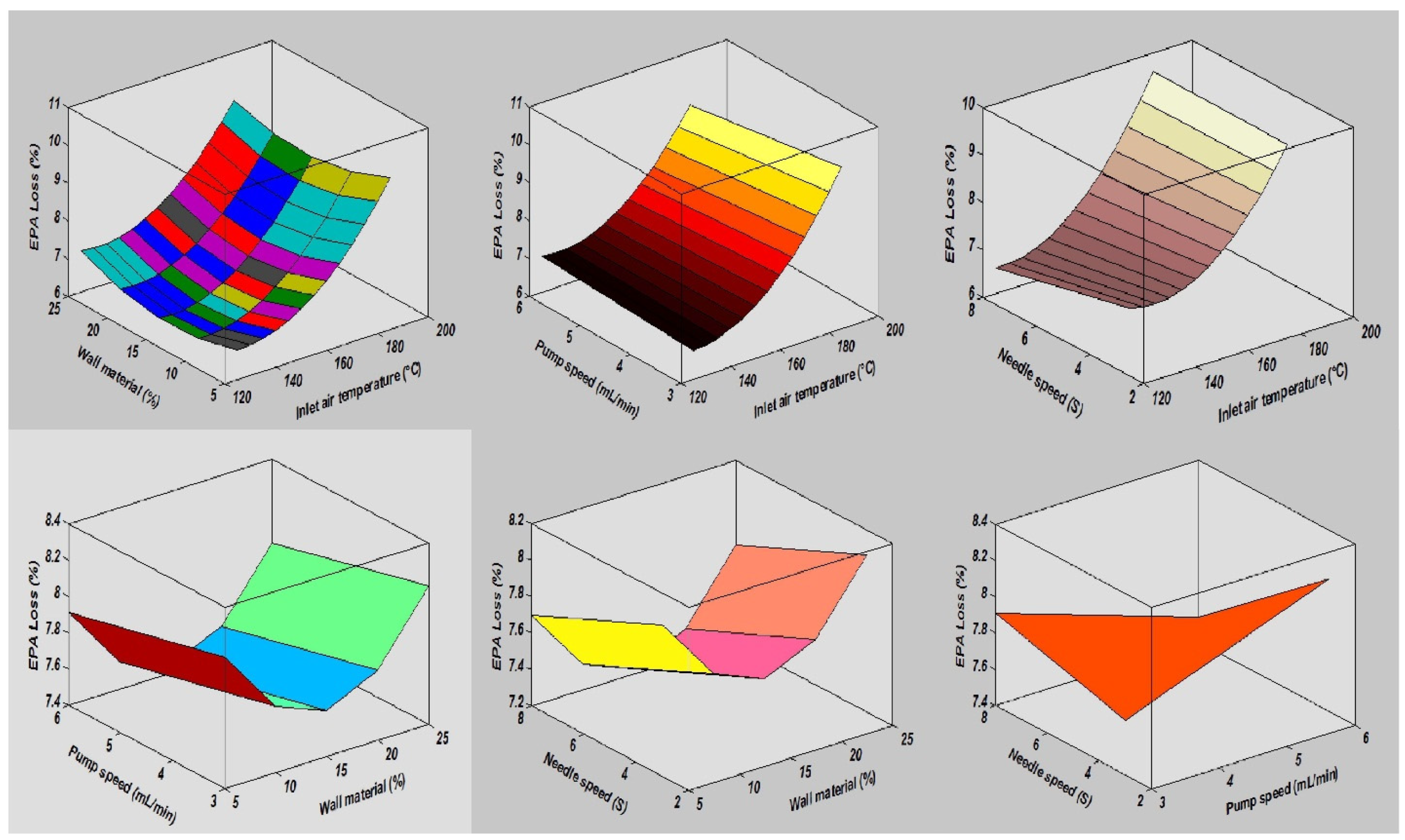

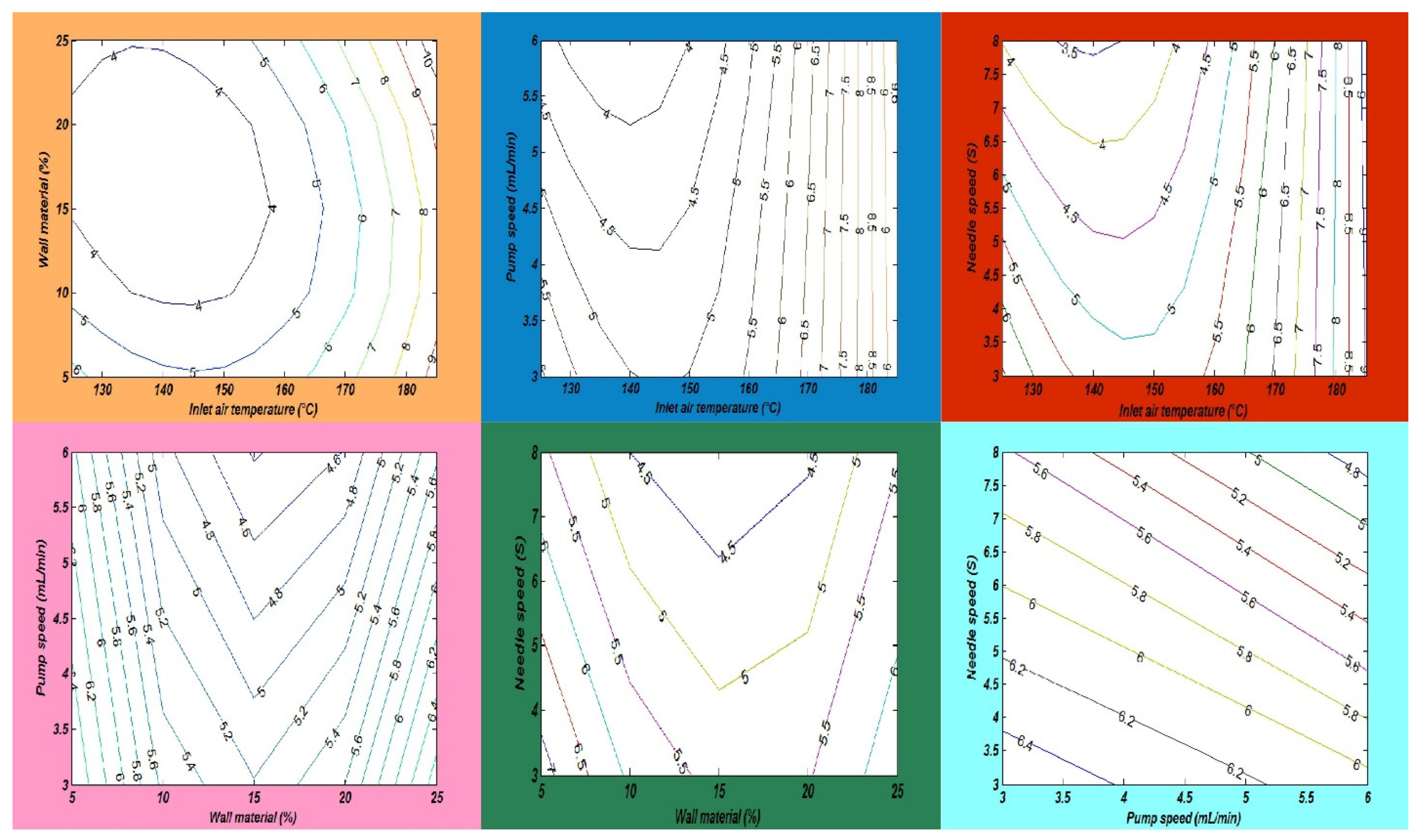

3.2. Optimization of Spray-Dried Microcapsules

3.2.1. Fatty Acid Composition

3.2.2. Oxidative Stability

3.3. Model Fitting

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nagy, K.; Tiuca, I.D. Importance of fatty acids in physiopathology of human body. In Fatty Acids; IntechOpen: London, UK, 2017. [Google Scholar]

- Kaur, N.; Chugh, V.; Gupta, A.K. Essential fatty acids as functional components of foods—A review. J. Food Sci. Technol. 2014, 51, 2289–2303. [Google Scholar] [CrossRef] [PubMed]

- Valdivia-López, M.Á.; Tecante, A. Chia (Salvia hispanica): A review of native Mexican seed and its nutritional and functional properties. Adv. Food Nutr. Res. 2015, 75, 53–75. [Google Scholar] [PubMed]

- Parker, J.; Schellenberger, A.N.; Roe, A.L.; Oketch-Rabah, H.; Calderón, A.I. Therapeutic perspectives on chia seed and its oil: A review. Planta Med. 2018, 84, 606–612. [Google Scholar] [CrossRef] [PubMed]

- Nadeem, M.; Imran, M. Chia (Salvia hispanica) Oil. In Fruit Oils: Chemistry and Functionality; Springer: Cham, Switzerland, 2019; pp. 303–316. [Google Scholar]

- Zeb, J.; Tufail, S.; Saboohi, N.; Samuel, Z.; Azeem, A.; Amir, Y.; Akram, S. Effect of Varying Levels of Lipids and Proteins on the Growth Indices and Fatty Acid Profile of Labeo rohita (Rohu). Pak. J. Zool. 2021, 54, 615–623. [Google Scholar] [CrossRef]

- Chughtai, M.I.; Maqbool, U.; Ahmed, R. Compositional properties of three freshwater carp species grown in brackish water. J. Microbiol. Biotechnol. Food Sci. 2021, 2021, 532–535. [Google Scholar]

- Manuelli, M.; Della, G.L.; Cena, H. Enriching diet with n-3 PUFAs to help prevent cardiovascular diseases in healthy adults: Results from clinical trials. Int. J. Mol. Sci. 2017, 18, 1552. [Google Scholar] [CrossRef]

- Ghosh, N.; Bhattacharyya, D.K. Effect of heating time and heat on the physicochemical and antioxidative property of fish (Labeo rohita) skin oil. Int. J. Pharm. Pharmac. Sci. 2019, 11, 87–89. [Google Scholar] [CrossRef][Green Version]

- Ghosh, N.; Roy, M.; Bhattacharyya, D.K. Formulation, production, and characterization of nutritionally enriched spread product with blends of fish skin (Labeo rohita) oil and chia seed (Salvia hispanica) oil. In Advances in Bioprocess Engineering and Technology; Springer: Singapore, 2021; pp. 209–217. [Google Scholar]

- Ismail, A.; Bannenberg, G.; Rice, H.B.; Schutt, E.; MacKay, D. Oxidation in EPA-and DHA-rich oils: An overview. Lipid Technol. 2016, 28, 55–59. [Google Scholar] [CrossRef]

- Catala, A. Fatty Acids; BoD–Books on Demand: Rejika, Crotia, 2017. [Google Scholar]

- Mittal, V. Encapsulation Nanotechnologies; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Moghadam, F.V.; Pourahmad, R.; Mortazavi, A.; Davoodi, D.; Azizinezhad, R. Use of fish oil nanoencapsulated with gum arabic carrier in low fat probiotic fermented milk. Food Sci. Anim. Resour. 2019, 39, 309. [Google Scholar] [CrossRef]

- Kwak, H.S. Nano-and Microencapsulation for Foods; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Anandharamakrishnan, C. Spray Drying Techniques for Food Ingredient Encapsulation; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Santos, D.; Maurício, A.C.; Sencadas, V.; Santos, J.D.; Fernandes, M.H.; Gomes, P.S. Spray Drying: An Overview; Pignatello, R., Ed.; Biomaterials-Physics and Chemistry-New Edition; InTech: London, UK, 2018; pp. 9–35. [Google Scholar]

- Salaün, F. Microencapsulation: Processes, Technologies and Industrial Applications; BoD–Books on Demand: London, UK, 2019. [Google Scholar]

- Mohammed, N.K.; Tan, C.P.; Manap, Y.A.; Muhialdin, B.J.; Hussin, A.S.M. Spray drying for the encapsulation of oils—A review. Molecules 2020, 25, 3873. [Google Scholar] [CrossRef]

- Pourashouri, P.; Shabanpour, B.; Razavi, S.H.; Jafari, S.M.; Shabani, A.; Aubourg, S.P. Impact of wall materials on physicochemical properties of microencapsulated fish oil by spray drying. Food Bioprocess Technol. 2014, 7, 2354–2365. [Google Scholar] [CrossRef]

- Bordón, M.G.; Alasino, N.P.; Martínez, V.; Peter, R.G.; Iturralde, R.; Ribotta, P.D.; Martínez, M.L. Influence of the spray drying operating conditions on the estimated drying kinetics of emulsion single droplets and the properties of microencapsulated chia oil. Powder Technol. 2021, 383, 302–317. [Google Scholar] [CrossRef]

- Rahim, M.A.; Imran, M.; Khan, M.K.; Ahmad, M.H.; Ahmad, R.S. Impact of spray drying operating conditions on encapsulation efficiency, oxidative quality, and sensorial evaluation of chia and fish oil blends. J. Food Process. Preserv. 2021, 16, 16248. [Google Scholar] [CrossRef]

- Dijkstra, A.J. The purification of edible oils and fats. Lipid Technol. 2013, 25, 271–273. [Google Scholar] [CrossRef]

- Quero-Jiménez, P.C.; Felipe, L.A.A.; López, L.R. Oil extraction and derivatization method: A review. Open Access J. Sci. 2020, 4, 110–120. [Google Scholar] [CrossRef]

- Kostik, V.; Memeti, S.; Bauer, B. Fatty acid composition of edible oils and fats. J. Hyg. Eng. Des. 2013, 4, 112–116. [Google Scholar]

- American Oil Chemists’ Society. Official Methods and Recommended Practices of the AOCS; American Oil Chemists’ Society: Urbana, IL, USA, 1997. [Google Scholar]

- AOCS. Determination of Oil Content in Oilseeds; American Oil Chemists’ Society: Urbana, IL, USA, 2000. [Google Scholar]

- AOAC (Association of Analytical Chemists). Official Method 965.33 Peroxide Value in Oils and Fats/Pearson’s Composition and Analysis of Foods, 9th ed.; Association of Analytical Chemists: Rockville, MD, USA, 2000; p. 64. [Google Scholar]

- Low, L.K. Analysis of oils: Determination of peroxide value. In Laboratory Manual on Analytical Methods and Procedures for Fish and Fish Products; Marine Fisheries Research Department, Southeast Asian Fisheries Development Center: Samut Prakan, Thailand, 1992. [Google Scholar]

- Scheme, R. IFRA analytical method: Determination of the peroxide value. Int. Fragr. Assoc. Rep. 2011, 17, 1–5. [Google Scholar]

- Hamilton, R.J. Lipid Analysis in Oils and Fats; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Lavanya, M.N.; Kathiravan, T.; Moses, J.A.; Anandharamakrishnan, C. Influence of spray-drying conditions on microencapsulation of fish oil and chia oil. Dry Technol. 2019, 38, 279–292. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Muhammad, I.; Muhammad, N.; Manzoor, M.F.; Amna, J.; Zafar, A.; Akhtar, M.N.; Yasir, H. Fatty acids characterization, oxidative perspectives and consumer acceptability of oil extracted from pre-treated chia (Salvia hispanica L.) seeds. Lipids Health Dis. 2016, 15, 162. [Google Scholar]

- Ivanovs, K.; Blumberga, D. Extraction of fish oil using green extraction methods: A short review. Energy Procedia 2017, 128, 477–483. [Google Scholar] [CrossRef]

- Hu, M.; Jacobsen, C. Oxidative Stability and Shelf Life of Foods Containing Oils and Fats; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Tocher, D.R.; Glencross, B.D. Lipids and fatty acids. In Dietary Nutrients, Additives, and Fish Health; John Wiley & Sons: Hoboken, NJ, USA, 2015; pp. 47–94. [Google Scholar]

- Bruno, S.F.; Kudre, T.G.; Bhaskar, N. Impact of pretreatment-assisted enzymatic extraction on recovery, physicochemical and rheological properties of oil from Labeo rohita head. J. Food Process Eng. 2019, 42, 12990. [Google Scholar] [CrossRef]

- Ixtaina, V.Y.; Martínez, M.L.; Spotorno, V.; Mateo, C.M.; Maestri, D.M.; Diehl, B.W.; Tomás, M.C. Characterization of chia seed oils obtained by pressing and solvent extraction. J. Food Comp. Anal. 2011, 24, 166–174. [Google Scholar] [CrossRef]

- Ghafoor, K.; Ahmed, I.A.M.; Özcan, M.M.; Al-Juhaimi, F.Y.; Babiker, E.E.; Azmi, I.U. An evaluation of bioactive compounds, fatty acid composition and oil quality of chia (Salvia hispanica L.) seed roasted at different temperatures. Food Chem. 2020, 333, 127531. [Google Scholar] [CrossRef] [PubMed]

- Abad, A.; Shahidi, F. Compositional characteristics and oxidative stability of chia seed oil (Salvia hispanica L.). Food Prod. Process. Nutr. 2020, 2, 9. [Google Scholar] [CrossRef]

- Ghena, M.; Amany, M.B. Chia (Salvia hispanica L.) Seed oil a new source of omega-3. Plant Arch. 2020, 20, 2678–2683. [Google Scholar]

- Souza, M.F.; Francisco, C.R.L.; Sanchez, J.L.; Guimarães-Inácio, A.; Valderrama, P.; Bona, E.; Gonçalves, O.H. Fatty acids profile of chia oil-loaded lipid microparticles. Braz. J. Chem. Eng. 2017, 34, 659–669. [Google Scholar] [CrossRef]

- Carrillo, W.; Cardenas, M.; Carpio, C.; Morales, D.; Alvarez, M.; Silva, M. Content of nutrients component and fatty acids in chia seeds (Salvia hispanica L.) cultivated in Ecuador. Asian J. Pharm. Clin. Res. 2018, 11, 1–4. [Google Scholar]

- Da Silva Marineli, R.; Moraes, É.A.; Lenquiste, S.A.; Godoy, A.T.; Eberlin, M.N.; Maróstica, M.R., Jr. Chemical characterization and antioxidant potential of Chilean chia seeds and oil (Salvia hispanica L.). LWT-Food Sci. Technol. 2014, 59, 1304–1310. [Google Scholar] [CrossRef]

- Basuny, A.M.; Arafat, S.M.; Hikal, D.M. Chia (Salvia hispanica L.) seed oil rich in omega-3 fatty acid: A healthy alternative for milk fat in ice milk. Food Nutr. Sci. 2021, 12, 479–493. [Google Scholar] [CrossRef]

- Ghosh, N.; Roy, M.; Ghosh, M.; Bhattacharyya, D.K. Study on physicochemical and antioxidant properties of blend of fish skin (Labeo rohita) oil and chia seed (Salvia hispanica) oil. In Biotechnology and Biological Sciences; CRC Press: London, UK, 2019; pp. 121–126. [Google Scholar]

- Raatz, S.; Bibus, D. Fish and Fish Oil in Health and Disease Prevention; Academic Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Varnham, A. Seed Oil: Biological Properties, Health Benefits and Commercial Applications; Nova Science Publishers: New York, NY, USA, 2014. [Google Scholar]

- Skulas-Ray, A.C.; Kris-Etherton, P.M.; Harris, W.S.; Vanden, H.J.P.; Wagner, P.R.; West, S.G. Dose-response effects of omega-3 fatty acids on triglycerides, inflammation, and endothelial function in healthy persons with moderate hypertriglyceridemia. Am. J. Clin. Nutr. 2011, 93, 243–252. [Google Scholar] [CrossRef]

- Bentsen, H. Dietary polyunsaturated fatty acids, brain function and mental health. Microb. Ecol. Health Dis. 2017, 28, 1281916. [Google Scholar] [CrossRef]

- Balić, A.; Vlašić, D.; Žužul, K.; Marinović, B.; Bukvić, M.Z. Omega-3 versus omega-6 polyunsaturated fatty acids in the prevention and treatment of inflammatory skin diseases. Int. J. Mol. Sci. 2020, 21, 741. [Google Scholar] [CrossRef]

- Azizian, H.; Kramer, J.K.; Winsborough, S. Factors influencing the fatty acid determination in fats and oils using Fourier transform near-infrared spectroscopy. Eur. J. Lipid Sci. Technol. 2007, 109, 960–968. [Google Scholar] [CrossRef]

- Karthik, P.; Anandharamakrishnan, C. Enhancing omega-3 fatty acids nanoemulsion stability and in-vitro digestibility through emulsifiers. J. Food Eng. 2016, 187, 92–105. [Google Scholar] [CrossRef]

- Fernandes, S.S.; Greque, L.; Santos, M.D.F.C.; de Novais, L.M.; D’Oca, C.D.; Prentice, C.; Salas-Mellado, M.D.L.M. Effect of the spray drying conditions on the physicochemical and structural characteristics and the stability of chia oil microparticles. J. Appl. Polym. Sci. 2021, 138, 51015. [Google Scholar] [CrossRef]

- Ali, M.; Imran, M.; Khan, M.K.; Ahmad, M.H.; Muhammad, N. Functional and Oxidative Quality Characterization of Spray-Dried Omega-3-Enriched Milk Powder. J. Food Qual. 2021, 2021, 6693960. [Google Scholar] [CrossRef]

- Javed, A.; Imran, M.; Ahmad, N.; Hussain, A.I. Fatty acids characterization and oxidative stability of spray dried designer egg powder. Lipids Health Dis. 2018, 17, 282. [Google Scholar] [CrossRef]

- Botrel, D.A.; Borges, S.V.; Yoshida, M.I.; Feitosa, J.P.D.A.; Fernandes, R.V.D.B.; de Souza, H.J.B.; de Paula, R.C.M. Properties of spray-dried fish oil with different carbohydrates as carriers. J. Food Sci. Technol. 2017, 54, 4181–4188. [Google Scholar] [CrossRef]

- Babushkina, E.A.; Belokopytova, L.V.; Grachev, A.M.; Meko, D.M.; Vaganov, E.A. Variation of the hydrological regime of Bele-Shira closed basin in Southern Siberia and its reflection in the radial growth of Larix sibirica. Reg. Environ. Change 2017, 17, 1725–1737. [Google Scholar] [CrossRef]

- Timilsena, Y.P.; Adhikari, R.; Barrow, C.J.; Adhikari, B. Microencapsulation of chia seed oil using chia seed protein isolate chia seed gum complex coacervates. Int. J. Biol. Macromol. 2016, 91, 347–357. [Google Scholar] [CrossRef]

- Simopoulos, A.P. The omega-6/omega-3 fatty acid ratio: Health implications. Oléagineux Corps Gras Lipides 2010, 17, 267–275. [Google Scholar] [CrossRef]

- Hernandez, E.; Hosokawa, M. Omega-3 Oils: Applications in Functional Foods; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Barrow, C.J.; Nolan, C.; Holub, B.J. Bioequivalence of encapsulated and microencapsulated fish-oil supplementation. J. Funct. Foods 2009, 1, 38–43. [Google Scholar] [CrossRef]

- Tanwar, B.; Goyal, A. Oilseeds: Health Attributes and Food Applications; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Hasler, C.M. Functional foods: Benefits, concerns and challenges—A position paper from the American Council on Science and Health. J. Nutr. 2002, 132, 3772–3781. [Google Scholar] [CrossRef]

- Calder, P.C.; Yaqoob, P. Marine omega-3 fatty acids and coronary heart disease. Curr. Opin. Cardiol. 2012, 27, 412–419. [Google Scholar] [CrossRef] [PubMed]

- Shi, M.; Ying, D.; Hlaing, M.M.; Ye, J.; Sanguansri, L.; Augustin, M.A. Oxidative stability of spray dried matcha-tuna oil powders. Food Res. Int. 2020, 132, 109050. [Google Scholar] [CrossRef] [PubMed]

- Takashige, S.; Iwamoto, S.; Shiga, H.; Kakizaki, Y.; Yamaya, Y.; Ushirosako, A.; Yoshii, H. Stability of Fish Oil Encapsulated in Spray-dried Powders Coated with Starch Particles. Food Sci. Technol. Res. 2019, 25, 363–371. [Google Scholar] [CrossRef]

- Kolanowski, W.; Ziolkowski, M.; Weißbrodt, J.; Kunz, B.; Laufenberg, G. Microencapsulation of fish oil by spray drying—Impact on oxidative stability Part 1. Eur. Food Res. Technol. 2006, 222, 336–342. [Google Scholar] [CrossRef]

- Hogan, S.A.; O’riordan, E.D.; O’sullivan, M. Microencapsulation and oxidative stability of spray-dried fish oil emulsions. J. Microencapsul. 2003, 20, 675–688. [Google Scholar] [CrossRef]

- Encina, C.; Vergara, C.; Márquez-Ruiz, G.; Holgado, F.; Robert, P.; Giménez, B. Influence of solvent and lecithin in microencapsulation of fish oil by spray-drying. RSC Adv. 2018, 8, 4172–4181. [Google Scholar] [CrossRef]

- Yue, H.; Qiu, B.; Jia, M.; Liu, J.; Wang, J.; Huang, F.; Xu, T. Development and optimization of spray-dried functional oil microcapsules: Oxidation stability and release kinetics. Food Sci. Nutr. 2020, 8, 4730–4738. [Google Scholar] [CrossRef]

- Selvamuthukumaran, M. Handbook on Spray Drying Applications for Food Industries; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Lakkis, J.M. Encapsulation and controlled release applications in confectionery and oral care products. Encapsulation Control. Release Technol. Food Syst. 2016, 2, 236. [Google Scholar]

| Independent Variables | Units | Coded Levels | ||||

|---|---|---|---|---|---|---|

| −2 | −1 | 0 | +1 | +2 | ||

| Inlet Air Temperature (IAT) | (°C) | 125 | 140 | 155 | 170 | 185 |

| Wall Material (WM) | (%) | 5 | 10 | 15 | 20 | 25 |

| Pump Speed (PS) | (mL/min) | 3 | 4 | 5 | 6 | 7 |

| Needle Speed (NS) | (S) | 3 | 5 | 7 | 9 | 11 |

| Fatty Acids | Fish Oil | Chia Seed Oil | Oil Blend |

|---|---|---|---|

| C18:3 (α-Linolenic acid, ALA) | - | 62.22 ± 0.45% | 31.3 ± 0.64% |

| C20:5 (Eicosapentaenoic acid, EPA) | 3.40 ± 0.18% | - | 2.34 ± 0.23% |

| C22:6 (Docosahexaenoic acid, DHA) | 18.33 ± 0.34% | - | 8.9 ± 0.38% |

| Free fatty acid (FFA) | 7.1 ± 0.22% | 1.7 ± 0.12% | 2.1 ± 0.21% |

| Peroxide value (PV) | 3.15 ± 0.14 meq O2/kg | 1.65 ± 0.10 meq O2/kg | 2.06 ± 0.18 meq O2/kg |

| Spray Drying Run | Independent Variables | Dependent Variables | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IAT (°C) | WM (%) | PS (mL/min) | NS (S) | Coded (IAT) | Coded (WM) | Coded (PS) | Coded (NS) | Retention Loss | FFA (%) | PV (meq O2/kg) | |||

| ALA (%) | EPA (%) | DHA (%) | |||||||||||

| 1 (C1) | 155 | 15 | 5 | 7 | 0 | 0 | 0 | 0 | 6.35 ± 0.27 i | 7.14 ± 0.26 ij | 3.70 ± 0.18 gh | 0.70 ± 0.13 b | 1.40 ± 0.17 e |

| 2 (C2) | 155 | 15 | 5 | 7 | 0 | 0 | 0 | 0 | 6.32 ± 0.30 ij | 7.12 ± 0.28 ij | 3.38 ± 0.20 h | 0.69 ± 0.13 b | 1.39 ± 0.17 e |

| 3 | 155 | 15 | 5 | 3 | 0 | 0 | 0 | −2 | 7.57 ± 0.32 ij | 7.71 ± 0.30 ij | 5.28 ± 0.23 hi | 0.70 ± 0.13 b | 1.40 ± 0.17 e |

| 4 | 155 | 15 | 7 | 7 | 0 | 0 | +2 | 0 | 7.79 ± 0.34 ij | 8.0 ± 0.32 j | 5.61 ± 0.25 hi | 0.69 ± 0.13 b | 1.38 ± 0.16 de |

| 5 | 140 | 20 | 4 | 9 | −1 | +1 | −1 | +1 | 5.39 ± 0.25 hi | 6.57 ± 0.23 i | 1.79 ± 0.16 fg | 0.71 ± 0.14 bc | 1.44 ± 0.18 f |

| 6 | 155 | 25 | 5 | 7 | 0 | +2 | 0 | 0 | 7.28 ± 0.31 ij | 7.42 ± 0.28 ij | 4.60 ± 0.21 h | 0.69 ± 0.13 b | 1.39 ± 0.17 e |

| 7 | 170 | 10 | 4 | 5 | +1 | −1 | −1 | −1 | 8.14 ± 0.35 j | 8.57 ± 0.34 j | 6.74 ± 0.29 i | 0.68 ± 0.12 ab | 1.37 ± 0.16 de |

| 8 (C3) | 155 | 15 | 5 | 7 | 0 | 0 | 0 | 0 | 6.42 ± 0.28 i | 7.14 ± 0.26 ij | 3.82 ± 0.18 gh | 0.70 ± 0.13 b | 1.40 ± 0.17 e |

| 9 | 140 | 10 | 4 | 5 | −1 | −1 | −1 | −1 | 4.18 ± 0.20 h | 5.71 ± 0.20 hi | 0.44 ± 0.10 a | 0.72 ± 0.15 bc | 1.45 ± 0.19 f |

| 10 | 170 | 20 | 4 | 5 | +1 | +1 | −1 | −1 | 8.49 ± 0.36 j | 8.85 ± 0.35 j | 7.52 ± 0.31 ij | 0.68 ± 0.12 ab | 1.36 ± 0.16 d |

| 11 (C4) | 155 | 15 | 5 | 7 | 0 | 0 | 0 | 0 | 6.38 ± 0.27 i | 7.14 ± 0.26 ij | 3.70 ± 0.18 gh | 0.70 ± 0.13 b | 1.40 ± 0.17 e |

| 12 (C5) | 155 | 15 | 5 | 7 | 0 | 0 | 0 | 0 | 6.45 ± 0.29 i | 6.85 ± 0.25 i | 3.82 ± 0.18 gh | 0.70 ± 0.13 b | 1.40 ± 0.17 e |

| 13 | 155 | 5 | 5 | 7 | 0 | −2 | 0 | 0 | 7.73 ± 0.34 ij | 8.0 ± 0.32 j | 5.95 ± 0.26 hi | 0.70 ± 0.13 b | 1.39 ± 0.17 e |

| 14 | 140 | 10 | 6 | 9 | −1 | −1 | +1 | +1 | 5.81 ± 0.26 hi | 6.57 ± 0.24 i | 2.80 ± 0.17 g | 0.71 ± 0.14 bc | 1.43 ± 0.18 ef |

| 15 | 170 | 10 | 6 | 5 | +1 | −1 | +1 | −1 | 8.65 ± 0.36 j | 9.14 ± 0.36 jk | 7.97 ± 0.32 ij | 0.68 ± 0.12 ab | 1.36 ± 0.16 d |

| 16 | 170 | 10 | 6 | 9 | +1 | −1 | +1 | +1 | 9.32 ± 0.38 jk | 9.42 ± 0.38 jk | 8.87 ± 0.35 j | 0.67 ± 0.11 ab | 1.34 ± 0.16 cd |

| 17 | 170 | 10 | 4 | 9 | +1 | −1 | −1 | +1 | 8.97 ± 0.37 j | 9.42 ± 0.38 jk | 8.42 ± 0.33 j | 0.68 ± 0.12 ab | 1.35 ± 0.16 d |

| 18 | 140 | 20 | 4 | 5 | −1 | −1 | −1 | −1 | 4.63 ± 0.22 h | 6.0 ± 0.22 i | 1.01 ± 0.16 c | 0.72 ± 0.15 bc | 1.44 ± 0.18 f |

| 19 | 140 | 10 | 4 | 9 | −1 | −1 | −1 | +1 | 4.88 ± 0.23 h | 6.28 ± 0.23 i | 1.46 ± 0.16 f | 0.72 ± 0.15 bc | 1.43 ± 0.18 ef |

| 20 | 140 | 10 | 6 | 5 | −1 | −1 | +1 | −1 | 5.49 ± 0.26 hi | 6.57 ± 0.24 i | 2.35 ± 0.17 g | 0.71 ± 0.14 bc | 1.44 ± 0.18 f |

| 21 | 185 | 15 | 5 | 7 | +2 | 0 | 0 | 0 | 4.92 ± 0.24 h | 6.85 ± 0.25 i | 3.25 ± 0.18 gh | 0.71 ± 0.14 bc | 1.43 ± 0.18 ef |

| 22 | 140 | 20 | 6 | 9 | −1 | +1 | +1 | +1 | 6.35 ± 0.27 i | 6.85 ± 0.25 i | 3.48 ± 0.18 gh | 0.71 ± 0.14 bc | 1.42 ± 0.18 ef |

| 23 (C6) | 155 | 15 | 5 | 7 | 0 | 0 | 0 | 0 | 6.32 ± 0.27 i | 7.14 ± 0.26 ij | 3.70 ± 0.18 gh | 0.70 ± 0.13 b | 1.40 ± 0.17 e |

| 24 | 155 | 15 | 5 | 11 | 0 | 0 | 0 | +2 | 7.98 ± 0.33 ij | 8.28 ± 0.33 j | 6.51 ± 0.27 i | 0.69 ± 0.13 b | 1.38 ± 0.17 de |

| 25 | 155 | 15 | 3 | 7 | 0 | 0 | −2 | 0 | 7.73 ± 0.31 ij | 8.0 ± 0.31 j | 5.05 ± 0.22 hi | 0.70 ± 0.13 b | 1.39 ± 0.17 e |

| 26 | 170 | 20 | 6 | 9 | +1 | +1 | +1 | +1 | 9.90 ± 0.40 jk | 9.71 ± 0.39 jk | 9.77 ± 0.39 jk | 0.67 ± 0.11 ab | 1.33 ± 0.16 cd |

| 27 | 170 | 20 | 4 | 9 | +1 | +1 | −1 | +1 | 9.55 ± 0.38 jk | 9.42 ± 0.37 jk | 9.21 ± 0.37 jk | 0.67 ± 0.11 ab | 1.34 ± 0.16 cd |

| 28 | 170 | 20 | 6 | 5 | +1 | +1 | +1 | −1 | 8.81 ± 0.37 j | 9.14 ± 0.36 jk | 8.20 ± 0.33 j | 0.67 ± 0.11 ab | 1.35 ± 0.16 d |

| 29 | 125 | 15 | 5 | 7 | −2 | 0 | 0 | 0 | 9.23 ± 0.39 jk | 9.14 ± 0.36 jk | 8.76 ± 0.34 j | 0.69 ± 0.13 b | 1.36 ± 0.16 d |

| 30 | 140 | 20 | 6 | 5 | −1 | +1 | +1 | −1 | 5.97 ± 0.26 hi | 6.85 ± 0.25 i | 3.25 ± 0.17 gh | 0.71 ± 0.14 bc | 1.43 ± 0.18 ef |

| Source of Variation | * DF | ALA Loss (%) | EPA Loss (%) | DHA Loss (%) | FFA (%) | PV (meq O2/kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ** MS | p-Value | ** MS | p-Value | ** MS | p-Value | ** MS | p-Value | ** MS | p-Value | |||

| Model | 14 | 1.84 * | 0.84 | 1.24 * | 0.60 | 4.30 ** | 0.65 | 1.40 * | 0.21 | 1.01 * | 0.67 | |

| Linear Effects | A-IAT | 1 | 0.38 NS | 0.73 | 0.02 NS | 0.89 | 0.76 * | 0.71 | 0.001 NS | 0.72 | 0.001 NS | 0.92 |

| B-PS | 1 | 0.002 | 0.99 | 00.1 NS | 0.99 | 0.03 NS | 0.93 | 0.007 NS | 0.99 | 0.002 NS | 0.88 | |

| C-MD | 1 | 1.87 * | 0.45 | 1.10 * | 0.39 | 4.77 ** | 0.36 | 0.004 NS | 0.51 | 0.002 NS | 0.66 | |

| D-NS | 1 | 0.03 NS | 0.92 | 0.16 NS | 0.74 | 0.49 NS | 0.76 | 0.004 NS | 0.49 | 0.001 NS | 0.97 | |

| Interaction Effects | AB | 1 | 0.006 NS | 0.96 | 0.02 NS | 0.90 | 0.65 * | 0.73 | 0.004 NS | 0.52 | 0.002 NS | 0.89 |

| AC | 1 | 0.57 * | 0.67 | 0.08 NS | 0.81 | 0.47 NS | 0.77 | 0.002 NS | 0.63 | 0.003 NS | 1.00 | |

| AD | 1 | 0.14 NS | 0.83 | 0.08 NS | 0.81 | 2.53 * | 0.50 | 0.003 NS | 1.00 | 0.001 NS | 0.78 | |

| BC | 1 | 0.001 NS | 0.98 | 0.006 NS | 0.99 | 0.036 NS | 0.93 | 0.003 NS | 1.00 | 0.002 NS | 0.89 | |

| BD | 1 | 0.03 NS | 0.91 | 0.006 NS | 0.99 | 0.65 * | 0.73 | 0.002 NS | 0.87 | 0.002 NS | 0.89 | |

| CD | 1 | 0.05 NS | 0.90 | 0.18 NS | 0.72 | 0.57 * | 0.74 | 0.004 NS | 0.52 | 0.006 NS | 1.00 | |

| Quadratic Effects | A² | 1 | 0.20 NS | 0.80 | 1.06 * | 0.40 | 9.30 ** | 0.20 | 0.001 NS | 0.67 | 0.004 NS | 0.95 |

| B² | 1 | 1.01 * | 0.58 | 0.43 NS | 0.59 | 4.38 ** | 0.38 | 0.001 NS | 0.30 | 0.007 NS | 0.81 | |

| C² | 1 | 1.79 * | 0.46 | 1.07 * | 0.40 | 4.69 ** | 0.36 | 0.003 NS | 0.53 | 0.002 NS | 0.67 | |

| D² | 1 | 1.85 * | 0.45 | 1.06 * | 0.40 | 8.44 ** | 0.22 | 0.003 NS | 0.53 | 0.007 NS | 0.81 | |

| Residual | 15 | 3.17 * | - | 1.43 * | - | 5.36 ** | - | 0.009 NS | - | 0.001 NS | - | |

| Lack of Fit | 10 | 4.73 ** | 0.001 | 2.13 * | 0.001 | 8.00 ** | <0.0001 | 0.001 NS | 0.002 | 0.001 NS | <0.0001 | |

| Pure Error | 5 | 0.07 NS | - | 0.03 NS | - | 0.070 NS | - | 0.008 NS | - | 0.001 NS | - | |

| Cor. Total | 29 | - | - | - | - | - | - | - | - | - | - | |

| Response Parameter | Regression Form | Regression Equations |

|---|---|---|

| ALA loss (%) | Coded | R1 = +172.77 − 3.85A − 0.089B +130.44C −1.11D − 0.019AB − 1.88AC + 0.093AD − 0.081BC + 0.048BD − 0.56CD + 0.084A2 + 0.19B2 + 25.57C2 + 0.26D2 |

| Actual | R1 = +7.83686 − 0.014567IAT − 0.19298WM − 0.13635PS − 1.18432NS − 2.0004IAT × WM − 0.012542IAT × PS + 3.10417E-003IAT × NS − 1.62500E-003WM × PS + 4.0003WM × NS − 0.027812PS × NS + 3.75463E-004IAT2 + 7.0003WM2 + 0.25573PS2 + 0.064870NS2 | |

| EPA loss (%) | Coded | R2 = +134.08 − 1.03A + 7.0003B +100.13C − 2.48D − 0.036AB − 0.71AC + 0.071AD − 6.0003BC + 6.0004BD − 1.07CD + 0.20A2 + 0.12B2 + 19.74C2 + 0.20D2 |

| Actual | R2 = +23.4085 − 0.20692IAT − 0.071479WM − 0.72531PS − 0.69036NS − 4.0004IAT × WM − 4.0003IAT × PS + 2.0003IAT × NS − 1.0004WM × PS + 6.0005WM × NS − 0.053437PS × NS + 8.0004IAT2 + 4.0003WM2 + 0.19740PS2 + 0.049036NS2 | |

| DHA loss (%) | Coded | R3 = +266.71 + 5.45A − 1.21B + 208.53C − 4.39D + 0.20AB + 1.71AC + 0.40AD − 0.47BC + 0.20BD − 1.89CD + 0.58A2 + 0.40B2 + 41.35C2 + 0.55D2 |

| Actual | R3 = +100.27506 − 0.91430IAT − 0.99338WM − 4.92604PS − 3.66344NS + 2.0003IAT × WM + 0.011417IAT × PS + 0.013250IAT × NS − 9.0003WM × PS + 0.020125WM × NS − 0.094375PS × NS + 2.0003IAT2 + 0.015992WM2 + 0.41354PS2 + 0.13870NS2 | |

| FFA (%) | Coded | R4 = −1.91 + 0.070A − 1.0003B − 1.98C − 0.13D + 5.000E-003AB + 0.037AC + 0.000AD + 0.0001BC − 1.0003BD − 0.050CD − 2.0003A2 − 6.250E-003B2 − 0.38C2 − 3.0003D2 |

| Actual | R4 = +0.81469 − 3.0004IAT − 2.0003WM + 5.0003PS + 0.023333NS + 6.0005IAT × WM + 2.0004IAT × PS + 3.0018IAT × NS +1.0017WM × PS − 1.0004WM × NS − 2.0003PS × NS − 1.0005IAT2 − 2.0004WM2 − 3.0003PS2 − 9.0004NS2 | |

| PV (meq O2/kg) | Coded | R5 = −0.53 − 0.022A − 0.034B − 1.50C − 6.0003D − 1.0003AB + 0.0001AC − 2.0003AD − 0.012BC + 1.0003BD + 0.0001CD − 4.0004A2 − 1.0003B2 − 0.29C2 − 1.0003D2 |

| Actual | R5 = +1.39488 − 9.0005IAT + 4.0003WM + 0.028750PS + 0.013542NS − 1.0005IAT × WM + 8.0018IAT × PS − 8.0005IAT × NS − 2.0004WM × PS + 1.0004WM × NS + 7.0017PS × NS − 1.0006IAT2 − 6.0005WM2 − 2.0003PS2 − 4.0004NS2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahim, M.A.; Imran, M.; Khan, M.K.; Haseeb Ahmad, M.; Nadeem, M.; Khalid, W.; Lorenzo, J.M.; Afifi, M.M.; AL-Farga, A.; Aljobair, M.O. Omega-3 Fatty Acid Retention and Oxidative Stability of Spray-Dried Chia–Fish-Oil-Prepared Microcapsules. Processes 2022, 10, 2184. https://doi.org/10.3390/pr10112184

Rahim MA, Imran M, Khan MK, Haseeb Ahmad M, Nadeem M, Khalid W, Lorenzo JM, Afifi MM, AL-Farga A, Aljobair MO. Omega-3 Fatty Acid Retention and Oxidative Stability of Spray-Dried Chia–Fish-Oil-Prepared Microcapsules. Processes. 2022; 10(11):2184. https://doi.org/10.3390/pr10112184

Chicago/Turabian StyleRahim, Muhammad Abdul, Muhammad Imran, Muhammad Kamran Khan, Muhammad Haseeb Ahmad, Muhammad Nadeem, Waseem Khalid, Jose Manuel Lorenzo, Mohamed M. Afifi, Ammar AL-Farga, and Moneera O. Aljobair. 2022. "Omega-3 Fatty Acid Retention and Oxidative Stability of Spray-Dried Chia–Fish-Oil-Prepared Microcapsules" Processes 10, no. 11: 2184. https://doi.org/10.3390/pr10112184

APA StyleRahim, M. A., Imran, M., Khan, M. K., Haseeb Ahmad, M., Nadeem, M., Khalid, W., Lorenzo, J. M., Afifi, M. M., AL-Farga, A., & Aljobair, M. O. (2022). Omega-3 Fatty Acid Retention and Oxidative Stability of Spray-Dried Chia–Fish-Oil-Prepared Microcapsules. Processes, 10(11), 2184. https://doi.org/10.3390/pr10112184