Comprehensive Review of Hydrothermal Pretreatment Parameters Affecting Fermentation and Anaerobic Digestion of Municipal Sludge

Abstract

1. Introduction

2. Hydrothermal Pretreatment and Sludge Disintegration

3. Hydrothermal Pretreatment and Fermentation

4. Hydrothermal Pretreatment and Anaerobic Digestion

5. Full-Scale Hydrothermal Pretreatment Technologies

6. Conclusions

- HTP condition operated both in batch and semi-continuous reactors increased dissolution of organic matter and suspended-solid removal efficiency.

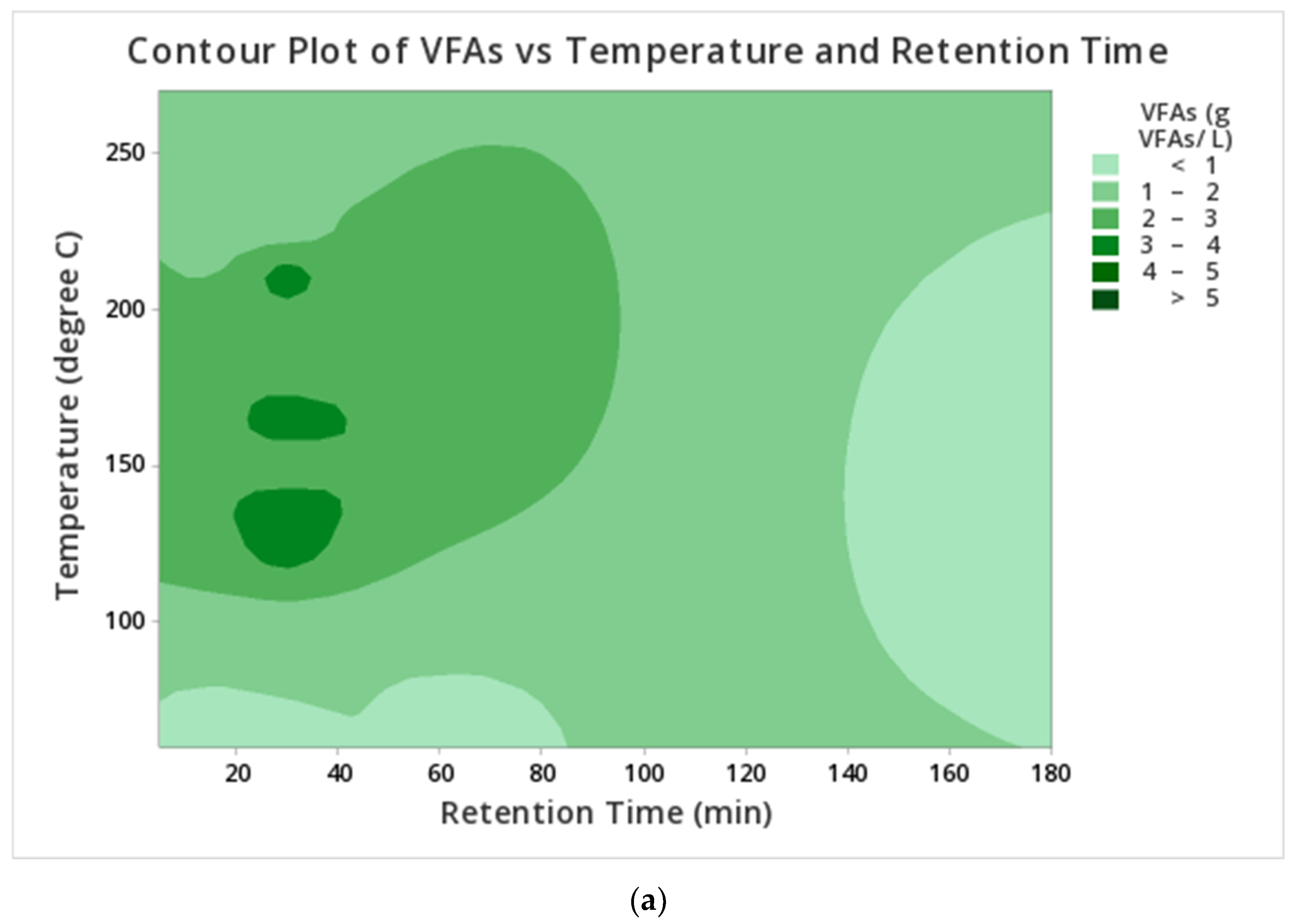

- Most of the reviewed articles on fermentation of TWAS revealed that higher VFA yields were observed at pretreatment temperature ranges from 160 °C to 180 °C. Waste-activated sludge treated with the hydrothermal pretreatment technique resulted in a 35 to 50% increase in VFA yields compared with the raw sample.

- Temperature, retention time, and solid content are considered the most important parameters affecting the hydrothermal pretreatment of TWAS, while the temperature is the dominant factor.

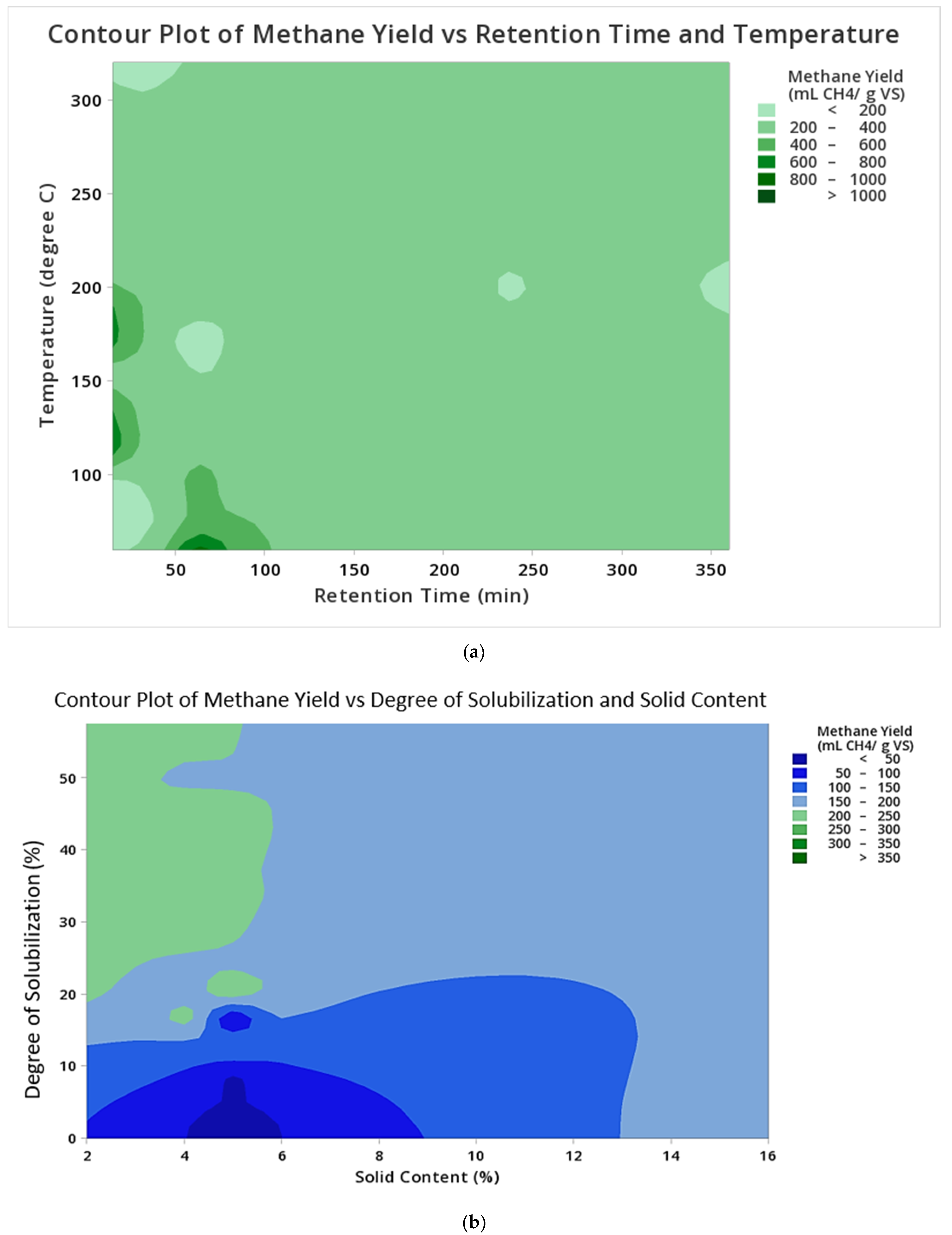

- HTP in the range of 175 °C to 200 °C with a 60 min retention time was the optimal condition for increased biogas production. At the optimum condition, a 30% increase in biodegradability of waste-activated sludge was generally observed, which resulted in higher biogas production.

- Most of the studies reported that HTP increases the hydrolysis of WAS up to a specific temperature range. The temperature range beyond 200 °C showed a significant reduction in VFA and biogas production. In addition, a lower temperature cannot efficiently decompose the complex organics in the AD process unless combined with other pretreatment techniques.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Razavi, A.S.; Hosseini Koupaie, E.; Azizi, A.; Hafez, H.; Elbeshbishy, E. Hydrothermal pretreatment of source separated organics for enhanced solubilization and biomethane recovery. Bioresour. Technol. 2019, 274, 502–511. [Google Scholar] [CrossRef] [PubMed]

- Azizi, A.; Hosseini Koupaie, E.; Hafez, H.; Elbeshbishy, E. Improving single-and two-stage anaerobic digestion of source separated organics by hydrothermal pretreatment. Biochem. Eng. J. 2019, 148, 77–86. [Google Scholar] [CrossRef]

- Ding, L.; Cheng, J.; Qiao, D.; Yue, L.; Li, Y.Y.; Zhou, J.; Cen, K. Investigating hydrothermal pretreatment of food waste for two-stage fermentative hydrogen and methane co-production. Bioresour. Technol. 2017, 241, 491–499. [Google Scholar] [CrossRef]

- Mancini, G. Different Approaches to Enhance the Biogas Production from the Anaerobic Digestion of Lignocellulosic Materials. Ph.D. Thesis, Universite Paris-EST, Champs-sur-Marne, France, 2019. [Google Scholar]

- Zlatko, S. Investigation of Co-Digestion of Food Waste and Primary Sludge at SNJ-Wastewater Treatment Plant. Master’s Thesis, University of Stavanger, Stavanger, Norway, 2020. [Google Scholar]

- Ehalt MacEdo, H.; Lehner, B.; Nicell, J.; Grill, G.; Li, J.; Limtong, A.; Shakya, R. Distribution and characteristics of wastewater treatment plants within the global river network. Earth Syst. Sci. Data 2022, 14, 559–577. [Google Scholar] [CrossRef]

- Qadir, M.; Drechsel, P.; Jiménez Cisneros, B.; Kim, Y.; Pramanik, A.; Mehta, P.; Olaniyan, O. Global and regional potential of wastewater as a water, nutrient and energy source. Nat. Resour. Forum 2020, 44, 40–51. [Google Scholar] [CrossRef]

- Zhang, Q.; Hu, J.; Lee, D.J.; Chang, Y.; Lee, Y.J. Sludge treatment: Current research trends. Bioresour. Technol. 2017, 243, 1159–1172. [Google Scholar] [CrossRef]

- Environment and Climate Change Canada. Canadian Environmental Sustainability Indicators: Greenhouse Gas Emissions; Environment and Climate Change Canada: Winnipeg, MB, Canada, 2020.

- EPA Basic Information about Biosolids. Available online: https://www.epa.gov/biosolids/basic-information-about-biosolids (accessed on 13 November 2022).

- Shanmugam, K.; Gadhamshetty, V.; Tysklind, M.; Bhattacharyya, D.; Upadhyayula, V.K.K. A sustainable performance assessment framework for circular management of municipal wastewater treatment plants. J. Clean. Prod. 2022, 339, 130657. [Google Scholar] [CrossRef]

- Norouzi, O.; Dutta, A. The Current Status and Future Potential of Biogas Production from Canada’s Organic Fraction Municipal Solid Waste. Energies 2022, 15, 475. [Google Scholar] [CrossRef]

- Papastergiadis, E.; Sklari, S.; Zouboulis, A.; Chasiotis, A.; Samaras, P. The use of steelmaking slag for sewage sludge stabilization. Desalin. Water Treat. 2015, 55, 1697–1702. [Google Scholar] [CrossRef]

- Kosowski, P.; Szostek, M.; Pieniazek, R.; Antos, P.; Skrobacz, K.; Piechowiak, T.; Zaczek, A.; Józefczyk, R.; Balawejder, M. New approach for sewage sludge stabilization with ozone. Sustainability 2020, 12, 886. [Google Scholar] [CrossRef]

- Kozak, J.; Wlodarczyk-Makula, M.; Popenda, A. Impact of Aerobic Stabilization of Sewage Sludge on PAHs Concentration in Reject Waters. J. Ecol. Eng. 2021, 22, 27–35. [Google Scholar]

- Hanum, F.; Yuan, L.C.; Kamahara, H.; Aziz, H.A.; Atsuta, Y.; Yamada, T.; Daimon, H. Treatment of sewage sludge using anaerobic digestion in Malaysia: Current state and challenges. Front. Energy Res. 2019, 7, 19. [Google Scholar] [CrossRef]

- Water Environment Federation. Design of Municipal Wastewater Treatment Plants; Water Environment Federation: Alexandria, VA, USA, 2009; Volume 30. [Google Scholar]

- Acharya, B.; Sule, I.; Dutta, A. A review on advances of torrefaction technologies for biomass processing. Biomass Convers. Biorefinery 2012, 2, 349–369. [Google Scholar] [CrossRef]

- Libra, J.A.; Ro, K.S.; Kammann, C.; Funke, A.; Berge, N.D.; Neubauer, Y.; Titirici, M.-M.; Fuhner, C.; Bens, O.; Kern, J.; et al. Hydrothermal carbonization of biomass residuals: A comparative review of the chemistry, processes and applications of wet and dry pyrolysis. Biofuels 2011, 2, 71–106. [Google Scholar] [CrossRef]

- Hu, M.; Ye, Z.; Zhang, H.; Chen, B.; Pan, Z.; Wang, J. Thermochemical conversion of sewage sludge for energy and resource recovery: Technical challenges and prospects. Environ. Pollut. Bioavailab. 2021, 33, 145–163. [Google Scholar] [CrossRef]

- Chen, Y.; Yi, L.; Li, S.; Yin, J.; Jin, H. Catalytic gasification of sewage sludge in near and supercritical water with different catalysts. Chem. Eng. J. 2020, 388, 124292. [Google Scholar] [CrossRef]

- Aragón-Briceño, C.; Ross, A.B.; Camargo-Valero, M.A. Evaluation and comparison of product yields and bio-methane potential in sewage digestate following hydrothermal treatment. Appl. Energy 2017, 208, 1357–1369. [Google Scholar] [CrossRef]

- Abdulazeez, M. Scholarship @ Western Co-Digestion of Food Waste and Thickened Waste Activated Sludge: Microbial Communities and Inhibition Control Using Biochar. Available online: http://ezproxy.lib.ryerson.ca/login?url=https://www.proquest.com/dissertations-theses/co-digestion-food-waste-thickened-activated/docview/2714864402/se-2 (accessed on 12 November 2022).

- Elbeshbishy, E.; Dhar, B.R.; Nakhla, G.; Lee, H.S. A critical review on inhibition of dark biohydrogen fermentation. Renew. Sustain. Energy Rev. 2017, 79, 656–668. [Google Scholar] [CrossRef]

- Yu, L.; Jiang, W.; Yu, Y.; Sun, C. Effects of dilution ratio and Fe° dosing on biohydrogen production from dewatered sludge by hydrothermal pretreatment. Environ. Technol. 2014, 35, 3092–3104. [Google Scholar] [CrossRef]

- Yuan, T.; Cheng, Y.; Zhang, Z.; Lei, Z.; Shimizu, K. Comparative study on hydrothermal treatment as pre- and post-treatment of anaerobic digestion of primary sludge: Focus on energy balance, resources transformation and sludge dewaterability. Appl. Energy 2019, 239, 171–180. [Google Scholar] [CrossRef]

- Carrère, H.; Dumas, C.; Battimelli, A.; Batstone, D.J.; Delgenès, J.P.; Steyer, J.P.; Ferrer, I. Pretreatment methods to improve sludge anaerobic degradability: A review. J. Hazard. Mater. 2010, 183, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Elbeshbishy, E.E. Enhancement of Biohydrogen and Biomethane Production from Wastes Using Ultrasonication. Ph.D. Thesis, University of Western Ontario, London, ON, Canada, 2011. [Google Scholar]

- Kakar, F.; Koupaie, E.; Hafez, H.; Elbeshbishy, E. Effect of Hydrothermal Pretreatment on Volatile Fatty Acids Production from Source-Separated Organics. Processes 2019, 7, 576. [Google Scholar] [CrossRef]

- Rajput, A.A.; Zeshan, S.; Visvanathan, C. Effect of thermal pretreatment on chemical composition, physical structure and biogas production kinetics of wheat straw. J. Environ. Manag. 2018, 221, 45–52. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Guo, J.; Cheng, H.; Wang, W.; Dong, R. Two-phase anaerobic digestion of municipal solid wastes enhanced by hydrothermal pretreatment: Viability, performance and microbial community evaluation. Appl. Energy 2017, 189, 613–622. [Google Scholar] [CrossRef]

- Yin, J.; Wang, K.; Yang, Y.; Shen, D.; Wang, M.; Mo, H. Improving production of volatile fatty acids from food waste fermentation by hydrothermal pretreatment. Bioresour. Technol. 2014, 171, 323–329. [Google Scholar] [CrossRef]

- Kim, D.; Lee, K.; Park, K. Enhancement of biogas production from anaerobic digestion of waste activated sludge by hydrothermal pre-treatment. Int. Biodeterior. Biodegrad. 2015, 101, 42–46. [Google Scholar] [CrossRef]

- Qiao, W.; Yan, X.; Ye, J.; Sun, Y.; Wang, W.; Zhang, Z. Evaluation of biogas production from different biomass wastes with/without hydrothermal pretreatment. Renew. Energy 2011, 36, 3313–3318. [Google Scholar] [CrossRef]

- Higgins, M.; Beightol, S.; Mandahar, U.; Suzuki, R.; Xiao, S.; Lu, H.; Le, T.; Mah, J.; Pathak, B.; DeClippeleir, H.; et al. Pretreatment of a primary and secondary sludge blend at different thermal hydrolysis temperatures: Impacts on anaerobic digestion, dewatering and filtrate characteristics. Water Res. 2017, 122, 557–569. [Google Scholar] [CrossRef]

- Donoso-Bravo, A.; Pérez-Elvira, S.; Aymerich, E.; Fdz-Polanco, F. Assessment of the influence of thermal pre-treatment time on the macromolecular composition and anaerobic biodegradability of sewage sludge. Bioresour. Technol. 2011, 102, 660–666. [Google Scholar] [CrossRef]

- Abe, N.; Tang, Y.; Iwamura, M.; Morimura, S.; Kida, K. Pretreatment followed by anaerobic digestion of secondary sludge for reduction of sewage sludge volume. Water Sci. Technol. 2013, 67, 2527–2533. [Google Scholar] [CrossRef]

- Xue, Y.; Liu, H.; Chen, S.; Dichtl, N.; Dai, X.; Li, N. Effects of thermal hydrolysis on organic matter solubilization and anaerobic digestion of high solid sludge. Chem. Eng. J. 2015, 264, 174–180. [Google Scholar] [CrossRef]

- Zhang, P.; Chen, Y.; Zhou, Q. Waste activated sludge hydrolysis and short-chain fatty acids accumulation under mesophilic and thermophilic conditions: Effect of pH. Water Res. 2009, 43, 3735–3742. [Google Scholar] [CrossRef] [PubMed]

- Kakar, F.I.; Koupaie, E.H.; Razavi, A.S.; Hafez, H.; Elbeshbishy, E. Effect of Hydrothermal Pretreatment on Volatile Fatty Acids Production from Thickened Waste Activated Sludge. Bioenergy Res. 2020, 13, 591–604. [Google Scholar] [CrossRef]

- Appels, L.; Degrève, J.; Van der Bruggen, B.; Van Impe, J.; Dewil, R. Influence of low temperature thermal pre-treatment on sludge solubilisation, heavy metal release and anaerobic digestion. Bioresour. Technol. 2010, 101, 5743–5748. [Google Scholar] [CrossRef] [PubMed]

- Ennouri, H.; Miladi, B.; Diaz, S.; Güelfo, L.; Solera, R.; Hamdi, M.; Bouallagui, H. Effect of thermal pretreatment on the biogas production and microbial communities balance during anaerobic digestion of urban and industrial waste activated sludge. Bioresour. Technol. 2016, 214, 184–191. [Google Scholar] [CrossRef] [PubMed]

- Morgan-Sagastume, F.; Pratt, S.; Karlsson, A.; Cirne, D.; Lant, P.; Werker, A. Production of volatile fatty acids by fermentation of waste activated sludge pre-treated in full-scale thermal hydrolysis plants. Bioresour. Technol. 2011, 102, 3089–3097. [Google Scholar] [CrossRef]

- Zhang, D.; Jiang, H.; Chang, J.; Sun, J.; Tu, W.; Wang, H. Effect of thermal hydrolysis pretreatment on volatile fatty acids production in sludge acidification and subsequent polyhydroxyalkanoates production. Bioresour. Technol. 2019, 279, 92–100. [Google Scholar] [CrossRef]

- Gavala, H.N.; Yenal, U.; Skiadas, I.V.; Westermann, P.; Ahring, B.K. Mesophilic and thermophilic anaerobic digestion of primary and secondary sludge. Effect of pre-treatment at elevated temperature. Water Res. 2003, 37, 4561–4572. [Google Scholar] [CrossRef]

- Abelleira-Pereira, J.M.; Pérez-Elvira, S.I.; Sánchez-Oneto, J.; de la Cruz, R.; Portela, J.R.; Nebot, E. Enhancement of methane production in mesophilic anaerobic digestion of secondary sewage sludge by advanced thermal hydrolysis pretreatment. Water Res. 2015, 71, 330–340. [Google Scholar] [CrossRef]

- Tran, K.C. Anaerobic digestion of microalgal biomass: Effects of solid concentration and pre-treatment. Ph.D. Thesis, University of Southampton, Southhampton, UK, 2017; p. 182. Available online: https://eprints.soton.ac.uk/415791/1/Final_e_thesis_for_e_prints_Khanh_Tran_24542342.pdf (accessed on 20 October 2022).

- Nazari, L.; Yuan, Z.; Santoro, D.; Sarathy, S.; Ho, D.; Batstone, D.; Xu, C.; Ray, M. Low-temperature thermal pre-treatment of municipal wastewater sludge: Process optimization and effects on solubilization and anaerobic degradation. Water Res. 2017, 113, 111–123. [Google Scholar] [CrossRef]

- Choi, J.; Han, S.; Lee, C. Enhancement of methane production in anaerobic digestion of sewage sludge by thermal hydrolysis pretreatment. Bioresour. Technol. 2018, 25, 207–213. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Rao, Y.; Cao, L.; Shi, Y.; Hao, S.; Luo, G.; Zhang, S. Hydrothermal conversion of sewage sludge: Focusing on the characterization of liquid products and their methane yields Huihui. Chem. Eng. J. 2019, 357, 367–375. [Google Scholar] [CrossRef]

- Bougrier, C.; Delgenès, J.; Carrère, H. Impacts of thermal pre-treatments on the semi-continuous anaerobic digestion of waste activated sludge. Biochem. Eng. J. 2007, 34, 20–27. [Google Scholar] [CrossRef]

- Ferrentino, R.; Merzari, F.; Fiori, L.; Andreottola, G. Biochemical Methane Potential Tests to Evaluate Anaerobic Digestion Enhancement by Thermal Hydrolysis Pretreatment. Bioenergy Res. 2019, 12, 722–732. [Google Scholar] [CrossRef]

- Kim, J.; Park, C.; Kim, T.H.; Lee, M.; Kim, S.; Kim, S.W.; Lee, J. Effects of various pretreatments for enhanced anaerobic digestion with waste activated sludge. J. Biosci. Bioeng. 2003, 95, 271–275. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Wang, W.; Gao, X.; Zhou, Y.; Shen, R. Effect of thermal pretreatment on the physical and chemical properties of municipal biomass waste. Waste Manag. 2012, 32, 249–255. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.J.; Li, X.X.; Liu, Y.X.; Yang, F.; Zhou, Q.; Ren, R.P. Optimization of hydrothermal pretreatment conditions for mesophilic and thermophilic anaerobic digestion of high-solid sludge. Bioresour. Technol. 2021, 321, 124454. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.; Gao, J.; Shi, Z.; Li, X.; Ma, W.; Yuan, H. Effect of hydrothermal pretreatment on two-stage anaerobic digestion of food waste and Enteromorpha: Digestion performance, bioenergy efficiency, and microbial community dynamics. Fuel 2022, 318, 123639. [Google Scholar] [CrossRef]

- Cheng, J.; Yue, L.; Hua, J.; Dong, H.; Zhou, J.; Li, Y.-Y. Hydrothermal alkali pretreatment contributes to fermentative methane production of a typical lipid from food waste through co-production of hydrogen with methane. Bioresour. Technol. 2020, 306, 123164. [Google Scholar] [CrossRef]

- Perendeci, N.A.; Ciggin, A.S.; Kökdemir Ünşar, E.; Orhon, D. Optimization of alkaline hydrothermal pretreatment of biological sludge for enhanced methane generation under anaerobic conditions. Waste Manag. 2020, 107, 9–19. [Google Scholar] [CrossRef]

- Bayr, S.; Kaparaju, P.; Rintala, J. Screening pretreatment methods to enhance thermophilic anaerobic. Chem. Eng. J. 2013, 223, 479–486. [Google Scholar] [CrossRef]

- Mustafa, A.H.; Radwan, A.; Sheng, K.; Chen, X. Effect of hydrothermal and Ca(OH)2 pretreatments on anaerobic digestion of sugarcane bagasse for biogas production. Bioresour. Technol. 2018, 259, 54–60. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.; Yue, L.; Ding, L.; Li, Y.; Ye, Q.; Zhou, J.; Cen, K.; Lin, R. Improving fermentative hydrogen and methane production from an algal bloom through hydrothermal/steam acid pretreatment. Int. J. Hydrog. Energy 2019, 44, 5812–5820. [Google Scholar] [CrossRef]

- Wang, J.; Yin, Y. Principle and application of different pretreatment methods for enriching hydrogen-producing bacteria from mixed cultures. Int. J. Hydrog. Energy 2017, 42, 4804–4823. [Google Scholar] [CrossRef]

- Kakar, F.I.; Purohit, N.; Okoye, F.; Liss, S.N.; Elbeshbishy, E. Combined hydrothermal and free nitrous acid, alkali and acid pretreatment for biomethane recovery from municipal sludge. Waste Manag. 2021, 131, 376–385. [Google Scholar] [CrossRef] [PubMed]

| Substrate Characteristics (for the Raw Sample Only) | HTP Condition | System Configuration | Significant Results | Reference | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Substrate | TCOD | TS | VSS | pH | Solid Content | Temperature | Retention Time | Reactor Mode | Temperature | Solubilization | VFAs Production | |

| g/L | g/L | g/L | - | % | °C | min | B/S | M/T | % | g VFAs/L | ||

| TWAS | 49.6 | 34 | 22.7 | 6.3 | 3.4 | 150–240 | 5–30 | Batch | Mesophilic | 49.0 | 2.52 | [29] |

| TWAS | 62 | 44.19 | 33.38 | ND | 4.4193 | 150–270 | ND | Batch | Mesophilic | 46 | 3.31 | [33] |

| TWAS (Lab scale) | 108 | 99.8 | 75.7 | ND | 9.98 | 170 | 5–30 | Batch | Mesophilic | 48.1 | 0.52 | [36] |

| TWAS (Pilot scale) | 90.17 | 76.8 | 54 | 7.68 | 170 | 5–30 | Batch | Mesophilic | ND | 0.37 | ||

| TWAS | ND | 40.59 | 31.86 | 6 | 4.05 | 120–200 | 60 | Batch | Mesophilic | ND | 2.94 | [37] |

| WAS | 166 | 167 | ND | ND | 16.7 | 60–180 | 15–180 | Batch | Mesophilic | 85 | 2.5 | [38] |

| TWAS | 68.68 | 60.15 | 45.26 | 6.41 | 15.67 | 35–55 | 30 | Semi-continuous | Mesophilic | 15.5 | 5.15 | [39] |

| Thermophilic | 9.2 | 5.90 | ||||||||||

| TWAS | 88.8 | ND | ND | 7.6 | ND | 170–320 | 30 | Batch | Mesophilic | ND | 0.58 | [40] |

| WAS | 55.3 | ND | ND | ND | ND | 70–90 | 15–60 | Batch | Mesophilic | 17.8 | 2.74 | [41] |

| Urban WAS | ND | 12.91 | 8.58 | 7.15 | 1.29 | 60–120 | ND | Batch | Mesophilic | 43 | ND | [42] |

| Industrial WAS | ND | 13.44 | 7.92 | 8.07 | 1.34 | 60–120 | ND | Batch | Mesophilic | 67 | ND | |

| WAS | 134 | ND | ND | 6.4 | 130–180 | ND | Semi-continuous | Mesophilic | 22.3 | 4.54 | [43] | |

| Substrate Characteristics (for the Raw Sample Only) | HTP Condition | System Configuration | Significant Results | Reference | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Substrate | TCOD | TS | VS | pH | Solid Content | Temperature | Retention Time | Reactor Mode | Temp | Degree of Solubilization | Methane Production Yield | |

| g/L | g/L | g/L | - | % | °C | min | B/S | °C | % | mL CH4/g VS | ||

| WAS | 62 | 44.19 | 33.38 | ND | 4.4 | 150–270 | 30 | Batch | Mesophilic | 47.4 | 240 | [33] |

| WAS | 7.15 | 14.6 | 170 | 60 | Batch | Mesophilic | ND | 155.5 | [34] | |||

| WAS | 166 | 167 | 150.3 | ND | 16.7 | 60–180 | 15–180 | Batch | Mesophilic | ND | 1070 | [38] |

| WAS | ND | 12.91 | 8.58 | 7.15 | 1.3 | 60–120 | 30 | Batch | Mesophilic | ND | 420 | [39] |

| ND | 13.44 | 7.92 | 8.07 | 370 | ||||||||

| WAS | 55.3 | ND | ND | ND | ND | 70–90 | 15–60 | Batch | Mesophilic | 17.8 | 378 | [41] |

| WAS | 52.4 | 39.1 | 28.5 | 7.76 | 3.9 | 40–80 | 60–300 | ND | ND | 20.3 | ND | [48] |

| WAS | 169 | ND | ND | ND | 14 | 75–200 | 15–90 | Batch and continuous | Mesophilic | ND | 230 | [49] |

| WAS | 169 | ND | ND | ND | 14 | 75–200 | 15–90 | Batch and continuous | Mesophilic | ND | 230 | |

| TWAS | 0.75 | ND | ND | ND | ND | 140–370 | 30–360 | Batch | Mesophilic | ND | 286 | [50] |

| WAS1 | 17.4 | 17.2 | 12.1 | ND | 1.7 | 130–170 | 30 | Semi-continuous | Mesophilic | ND | 228 | [51] |

| WAS2 | 17.7 | 16.9 | 12.5 | ND | 1.7 | 130–170 | 30 | Semi-continuous | Mesophilic | ND | 330 | |

| TWAS | 51.6 | 49.8 | 36.8 | 4.9 | 150–170 | 30–60 | Batch | Mesophilic | 15.7 | 28 | [52] | |

| WAS | 27.7 | 38 | 26 | 6.7 | 3.8 | 121 | 30 | Batch | Mesophilic | 17.6 | 135 | [53] |

| WAS | ND | 157.4 | 108.2 | ND | 15.7 | 175 | 60 | Batch | Mesophilic | 0.5 | 200 | [54] |

| TWAS | 54.6 | 110 | 40 | 7.5 | 10–11 | 160–180 | 30–240 | Batch and continuous | Mesophilic | 41 | 250 | [55] |

| Thermophilic | 37 | 200 | ||||||||||

| Substrate | Pretreatment Condition | Process | Impact on Solubilization | Impact on BMP | Reference | |

|---|---|---|---|---|---|---|

| 1 | WAS | Alkaline HTP—pH 12 using 10 M NaOH + 134 °C for 30 min | continuous, 15-day SRT | 37% disintegration degree, 28% improvement in VS reduction | 130% improvement in daily methane production | [54] |

| 2 | WAS | Alkaline HTP—0.2 mg NaOH/mg VS + 190 °C, 10 min | BMP | 36% solubilization of VS | 113% increase in methane production | [58] |

| 3 | pulp and papermill sludge | HTP and enzyme—150 °C for 10 min + Accelerate 1500, 0.07 g/g VS at 50 °C for 72 h | thermophilic BMP | COD solubilization increased by 9 times | methane yield increased by 19% | [59] |

| 4 | pulp and papermill sludge | ultrasonic and HTP—45 kHz, 30 min, 150 °C for 10 min | thermophilic BMP | COD solubilization increased by 9 times | methane yield increased by 31% | |

| 5 | pulp and papermill sludge | ultrasonic, HTP and enzyme—45 kHz, 30 min, 150 °C for 10 min, accelerate 1500, 0.07 g/g VS at 50 °C for 72 h | thermophilic BMP | COD solubilization increased by 10 times | methane yield increased by 21% | |

| 6 | sugarcane bagasse | HTP and alkaline, 180 °C for 20 min and 8.5% Ca (OH)2 | BMP | 83 and 46% degradation of hemicellulose and lignin | 47% increase in methane production | [60] |

| 7 | algal bloom | HTP and acid, 2% H2SO4, 135 °C for 15 min | 2 stage fermentation | Increased sugar yield by 94.5% | 33% increase in methane production | [61] |

| 8 | WAS | FNA and heat—0.7 mgHNO2-N/L, 55 °C, 24 h, pH 5.5 | BMP | - | 26% methane improvement compared to control and 16% improvement in FNA only | [62] |

| 9 | TWAS | FNA, acid and alkaline combined with HTP—170 °C, 30 min | BMP | COD solubilization increased by almost 50% with thermochemical pretreatment | 45–55% improvement in methane production compared to the raw sample | [63] |

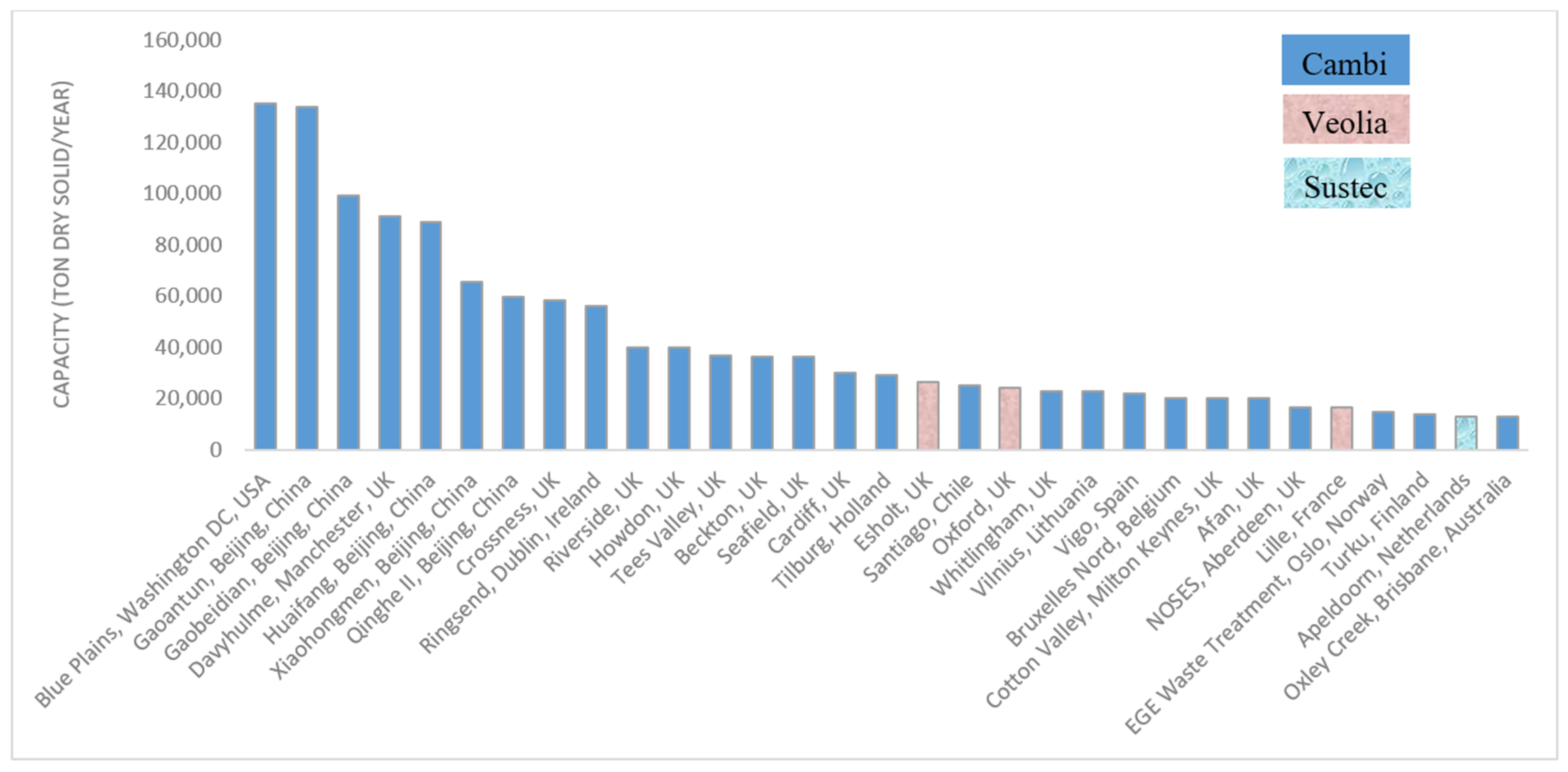

| Technology | Mechanisms | Reactor Mode | Waste | Heat Transfer | Sludge Flow | Number of Installations in WWTPs by 2021 | Footprint | |||

|---|---|---|---|---|---|---|---|---|---|---|

| HTP Conditions | Steam Injection | |||||||||

| Retention Time | Temperature | Solid Content | ||||||||

| Cambi | 30 min | 165 °C | 12–15% | Yes | Series of batch tanks | Primary and secondary sludge | Intermittent Steam Injection Based on Timers and Number of Reactors | Pumps | 41 | No |

| Exelys | 30 min | 165 °C | No | Continuous plug flow reactor | Primary and secondary sludge | Continuous Steam Injection | Pumps | 3 | No | |

| Haarslev | 20 min | 165 °C | Yes | Continuous plug flow reactor | Biosolids | Continuous steam injection | Pressurization | ND | Yes | |

| Lystek | 75 °C | 13–16% | ND | Continuous plug flow reactor | Biosolids | Low pressure steam injection | Pumps | ND | No | |

| Sustec | 30 min | 165 °C | 10–12% | No | Continuous plug flow reactor | Biomass | Continuous steam injection | Pumps | 1 | No |

| Lysotherm | 30 min | 165 °C | 3–5% | No | Continuous plug flow reactor | WAS | Continuous steam injection | Pumps | 3 | No |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kakar, F.L.; Tadesse, F.; Elbeshbishy, E. Comprehensive Review of Hydrothermal Pretreatment Parameters Affecting Fermentation and Anaerobic Digestion of Municipal Sludge. Processes 2022, 10, 2518. https://doi.org/10.3390/pr10122518

Kakar FL, Tadesse F, Elbeshbishy E. Comprehensive Review of Hydrothermal Pretreatment Parameters Affecting Fermentation and Anaerobic Digestion of Municipal Sludge. Processes. 2022; 10(12):2518. https://doi.org/10.3390/pr10122518

Chicago/Turabian StyleKakar, Farokh Laqa, Frew Tadesse, and Elsayed Elbeshbishy. 2022. "Comprehensive Review of Hydrothermal Pretreatment Parameters Affecting Fermentation and Anaerobic Digestion of Municipal Sludge" Processes 10, no. 12: 2518. https://doi.org/10.3390/pr10122518

APA StyleKakar, F. L., Tadesse, F., & Elbeshbishy, E. (2022). Comprehensive Review of Hydrothermal Pretreatment Parameters Affecting Fermentation and Anaerobic Digestion of Municipal Sludge. Processes, 10(12), 2518. https://doi.org/10.3390/pr10122518