A Review on Pollution Treatment in Cement Industrial Areas: From Prevention Techniques to Python-Based Monitoring and Controlling Models

Abstract

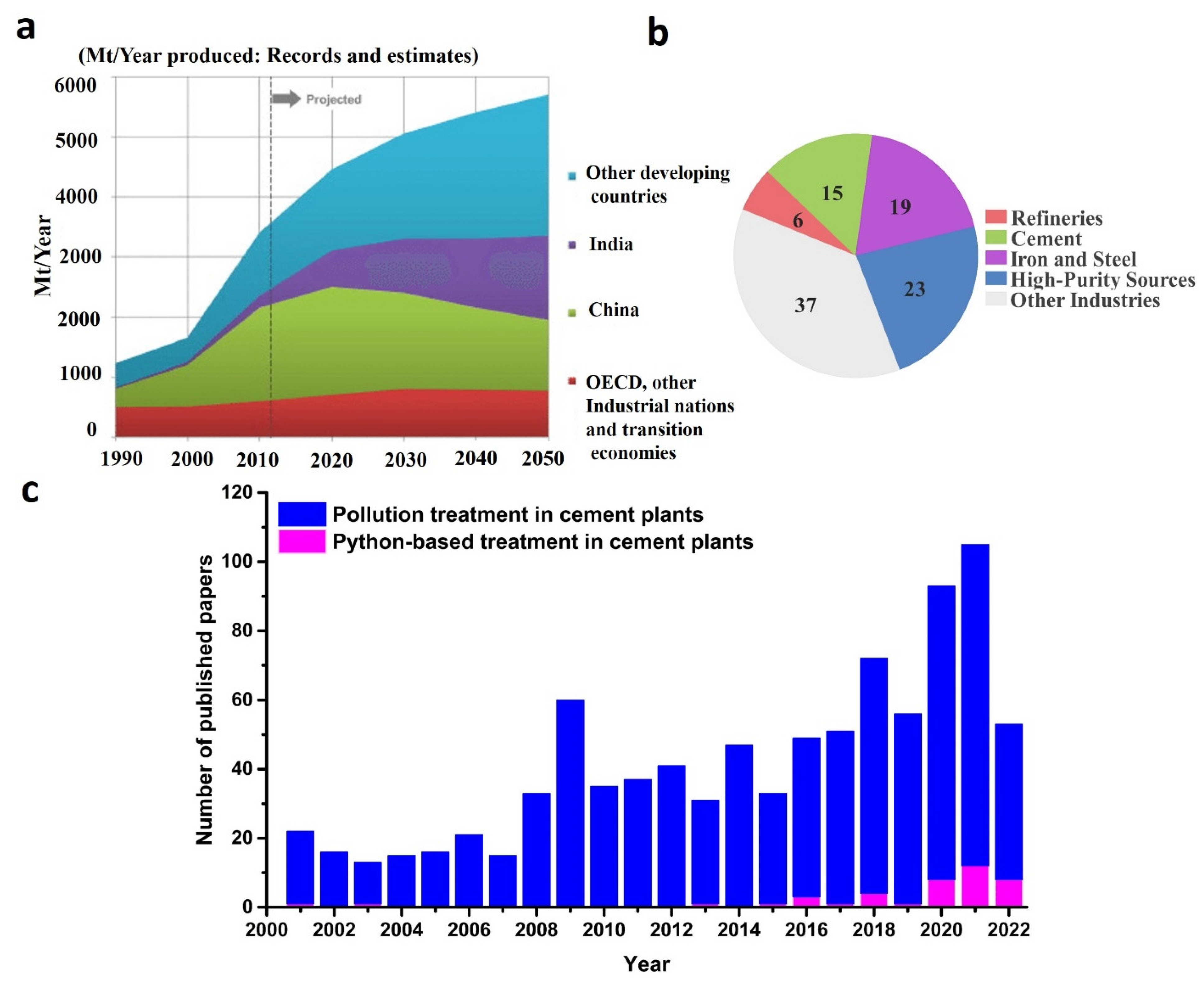

:1. Introduction

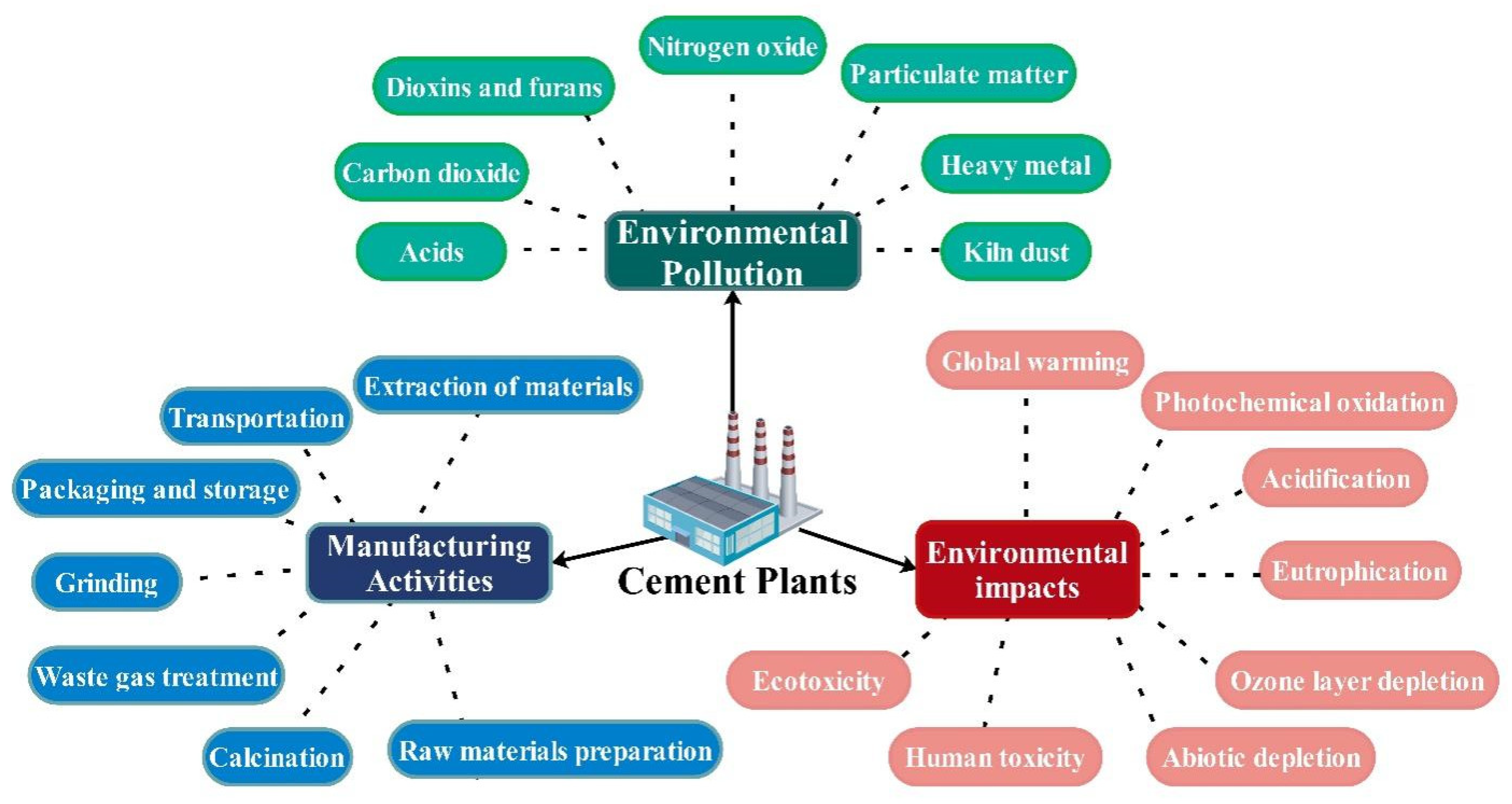

2. Overview of Pollution Emission from Cement Industries

2.1. Solid Waste

2.2. Wastewater

2.3. Air Pollutant Emission

2.4. Noise Pollution

2.5. Emissions from Fuel Consumption

3. Pollution Prevention Methods in the Cement Plant

4. Modeling Techniques for the Prediction and Control of Pollution Focusing on Python

4.1. Python Models for Pollution Treatment in Various Sectors

4.2. Application of Python Models in Cement Industries

5. Conclusions and Future Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Adeyanju, E.; Okeke, C.A. Exposure effect to cement dust pollution: A mini review. SN Appl. Sci. 2019, 1, 1572. [Google Scholar] [CrossRef] [Green Version]

- Farrag, F.A. The Role of SPOT Satellite Images in Mapping Air Pollution Caused by Cement Factories. Int. Arch. Photogramm. Remote Sens. 2000, 33, 46–53. [Google Scholar]

- Box, L. Determination of the elemental contents in soils around Diamond Cement Factory, Aflao. Res. J. Environ. Earth Sci. 2011, 3, 46–50. [Google Scholar]

- Zhang, L.; Su, M.; Wang, Y. Development of the use of sulfo- and ferroaluminate cements in China. Adv. Cem. Res. 1999, 11, 15–21. [Google Scholar] [CrossRef]

- Lungu, I.; Taranu, G.; Hohan, R.; Plesu, G. Efficient use of green cements in structural elements for civil engineering applications. In Proceedings of the 3rd International Conference on Advanced Materials and Systems, ICAMS, Bucharest, Romania, 26–28 October 2010. [Google Scholar]

- Liska, M.; Wilson, A.; Bensted, J. Special Cements. In Lea’s Chemistry of Cement and Concrete, 5th ed.; Hewlett, P.C., Liska, M., Eds.; Butterworth-Heinemann: Oxford, UK, 2019; p. 618. [Google Scholar]

- Gots, V.; Gelevera, A.; Petropavlovsky, O.; Rogozina, N.; Smeshko, V. (Eds.) Influence of whitening additives on the properties of decorative slag-alkaline cements. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Kharkiv, Ukraine, 21–22 May 2020; IOP Publishing: Bristol, UK, 2020. [Google Scholar]

- Vorobchuk, V.; Matveeva, M.; Peshkov, A. (Eds.) Decorative concrete on white cement: Resource provision, technology, properties and cost-effectiveness. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2018. [Google Scholar]

- Smith, D.C. Medical and dental applications of cements. J. Biomed. Mater. Res. 1971, 5, 189–205. [Google Scholar] [CrossRef] [PubMed]

- Hatton, P.; Hurrell-Gillingham, K.; Brook, I. Biocompatibility of glass-ionomer bone cements. J. Dent. 2006, 34, 598–601. [Google Scholar] [CrossRef]

- Dorozhkin, S.V. Calcium orthophosphate cements for biomedical application. J. Mater. Sci. 2008, 43, 3028–3057. [Google Scholar] [CrossRef]

- Salman, D.M. An assessment to the oligopoly cement industry in Egypt: Is it a curse or a blessing? Int. J. Green Econ. 2017, 11, 41–61. [Google Scholar] [CrossRef]

- Hägg, M.-B.; Lindbråthen, A.; He, X.; Nodeland, S.; Cantero, T. Pilot demonstration-reporting on CO2 capture from a cement plant using hollow fiber process. Energy Procedia 2017, 114, 6150–6165. [Google Scholar] [CrossRef]

- Al Biajawi, M.I.; Embong, R.; Muthusamy, K.; Ismail, N.; Obianyo, I.I. Recycled coal bottom ash as sustainable materials for cement replacement in cementitious Composites: A review. Constr. Build. Mater. 2022, 338, 127624. [Google Scholar] [CrossRef]

- Kuter, N. Reclamation of degraded landscapes due to opencast mining. In Advances in Landscape Architecture; IntechOpen: London, UK, 2013. [Google Scholar]

- Ciobanu, C.; Tudor, P.; Istrate, I.-A.; Voicu, G. Assessment of Environmental Pollution in Cement Plant Areas in Romania by Co-Processing Waste in Clinker Kilns. Energies 2022, 15, 2656. [Google Scholar] [CrossRef]

- Cai, C.; Devassy, R.P.; El-Sherbiny, M.M.; Agusti, S. Cement and oil refining industries as the predominant sources of trace metal pollution in the Red Sea: A systematic study of element concentrations in the Red Sea zooplankton. Mar. Pollut. Bull. 2021, 174, 113221. [Google Scholar] [CrossRef] [PubMed]

- Haneklaus, N.; Zheng, Y.; Allelein, H.-J. Stop Smoking—Tube-In-Tube Helical System for Flameless Calcination of Minerals. Processes 2017, 5, 67. [Google Scholar] [CrossRef] [Green Version]

- Caselles, L.D.; Roosz, C.; Hot, J.; Blotevogel, S.; Cyr, M. Immobilization of molybdenum by alternative cementitious binders and synthetic C-S-H: An experimental and numerical study. Sci. Total Environ. 2021, 789, 148069. [Google Scholar] [CrossRef] [PubMed]

- Subramanian, S.; Arumairaj, P.; Subramani, T. Experimental and modelling study of clay stabilized with bottom ash-eco sand slurry pile. Géoméch. Eng. 2017, 12, 523–539. [Google Scholar] [CrossRef]

- Ariyaratne, W.K.H.; Manjula, E.V.P.J.; Melaaen, M.C.; Tokheim, L.A. Kiln Process Impact of Alternative Solid Fuel Combustion in the Cement Kiln Main Burner—Mathematical Modelling and Full-Scale Experiment. In Advanced Materials Research; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2014. [Google Scholar]

- Sharipov, D.; Muradov, F.; Akhmedov, D. Numerical modeling method for short-term air quality forecast in industrial regions. Appl. Math. E-Notes 2019, 19, 575–584. [Google Scholar]

- Qi, C.; Wu, M.; Zheng, J.; Chen, Q.; Chai, L. Rapid identification of reactivity for the efficient recycling of coal fly ash: Hybrid machine learning modeling and interpretation. J. Clean. Prod. 2022, 343, 130958. [Google Scholar] [CrossRef]

- Shamsabadi, E.A.; Roshan, N.; Hadigheh, S.A.; Nehdi, M.L.; Khodabakhshian, A.; Ghalehnovi, M. Machine learning-based compressive strength modelling of concrete incorporating waste marble powder. Constr. Build. Mater. 2022, 324, 126592. [Google Scholar] [CrossRef]

- Amin, M.N.; Ahmad, W.; Khan, K.; Ahmad, A.; Nazar, S.; Alabdullah, A.A. Use of Artificial Intelligence for Predicting Parameters of Sustainable Concrete and Raw Ingredient Effects and Interactions. Materials 2022, 15, 5207. [Google Scholar] [CrossRef]

- Streeter, H.W. Studies of the pollution and natural purification of the Ohio River, Part III, Factors concerned in the phenomena of oxidation and reaeration. Public Health Bull. 1925, 146, 1–80. [Google Scholar]

- Chapra, S.C.; Camacho, L.A.; McBride, G.B. Impact of Global Warming on Dissolved Oxygen and BOD Assimilative Capacity of the World’s Rivers: Modeling Analysis. Water 2021, 13, 2408. [Google Scholar] [CrossRef]

- Kumar, K.; Pande, B.P. Air pollution prediction with machine learning: A case study of Indian cities. Int. J. Environ. Sci. Technol. 2022, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Schneider, M.; Romer, M.; Tschudin, M.; Bolio, H. Sustainable cement production—Present and future. Cem. Concr. Res. 2011, 41, 642–650. [Google Scholar] [CrossRef]

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A. Environmental impact of cement production: Detail of the different processes and cement plant variability evaluation. J. Clean. Prod. 2010, 18, 478–485. [Google Scholar] [CrossRef]

- Habert, G.; Billard, C.; Rossi, P.; Chen, C.; Roussel, N. Cement production technology improvement compared to factor 4 objectives. Cem. Concr. Res. 2010, 40, 820–826. [Google Scholar] [CrossRef]

- Mohamad, N.; Muthusamy, K.; Embong, R.; Kusbiantoro, A.; Hashim, M.H. Environmental impact of cement production and Solutions: A review. Mater. Today: Proc. 2021, 48, 741–746. [Google Scholar] [CrossRef]

- Fennell, P.S.; Davis, S.J.; Mohammed, A. Decarbonizing cement production. Joule 2021, 5, 1305–1311. [Google Scholar] [CrossRef]

- Etim, M.-A.; Babaremu, K.; Lazarus, J.; Omole, D. Health Risk and Environmental Assessment of Cement Production in Nigeria. Atmosphere 2021, 12, 1111. [Google Scholar] [CrossRef]

- Rithuparna, R.; Jittin, V.; Bahurudeen, A. Influence of different processing methods on the recycling potential of agro-waste ashes for sustainable cement production: A review. J. Clean. Prod. 2021, 316, 128242. [Google Scholar] [CrossRef]

- Kleib, J.; Aouad, G.; Abriak, N.-E.; Benzerzour, M. Production of Portland cement clinker from French Municipal Solid Waste Incineration Bottom Ash. Case Stud. Constr. Mater. 2021, 15, e00629. [Google Scholar] [CrossRef]

- Usón, A.A.; López-Sabirón, A.M.; Ferreira, G.; Sastresa, E.L. Uses of alternative fuels and raw materials in the cement industry as sustainable waste management options. Renew. Sustain. Energy Rev. 2013, 23, 242–260. [Google Scholar] [CrossRef]

- Kosajan, V.; Wen, Z.; Zheng, K.; Fei, F.; Wang, Z.; Tian, H. Municipal solid waste (MSW) co-processing in cement kiln to relieve China’s Msw treatment capacity pressure. Resour. Conserv. Recycl. 2021, 167, 105384. [Google Scholar] [CrossRef]

- Nanda, S.; Berruti, F. Municipal solid waste management and landfilling technologies: A review. Environ. Chem. Lett. 2020, 19, 1433–1456. [Google Scholar] [CrossRef]

- Berner, U. Evolution of pore water chemistry during degradation of cement in a radioactive waste repository environment. Waste Manag. 1992, 12, 201–219. [Google Scholar] [CrossRef]

- Batchelor, B. Overview of waste stabilization with cement. Waste Manag. 2006, 26, 689–698. [Google Scholar] [CrossRef]

- Zamorani, E. Deeds and misdeeds of cement composites in waste management. Cem. Concr. Res. 1992, 22, 359–367. [Google Scholar] [CrossRef]

- Coppola, L.; Bellezze, T.; Belli, A.; Bignozzi, M.C.; Bolzoni, F.M.; Brenna, A.; Cabrini, M.; Candamano, S.; Cappai, M.; Caputo, D.; et al. Binders alternative to Portland cement and waste management for sustainable construction—Part 1. J. Appl. Biomater. Funct. Mater. 2018, 16, 186–202. [Google Scholar] [CrossRef] [Green Version]

- Faisal, G.H.; Jaeel, A.J.; Al-Gasham, T.S. BOD and COD reduction using porous concrete pavements. Case Stud. Constr. Mater. 2020, 13, e00396. [Google Scholar] [CrossRef]

- Hasaballah, A.F.; Hegazy, T.; Ibrahim, M.; El-Emam, D.A. Cement kiln dust as an alternative technique for wastewater treatment. Ain Shams Eng. J. 2021, 12, 4201–4209. [Google Scholar] [CrossRef]

- Perera, K.; Ranathunga, R.; Keshani, Y.; Asanka, K.; Prabhamini, T.; Piyathilaka, K.; Arachchige, U.S. Cement Industry in Sri Lanka. J. Res. Technol. Eng. 2020, 1, 16–27. [Google Scholar]

- Brown, D.; Sadiq, R.; Hewage, K. An overview of air emission intensities and environmental performance of grey cement manufacturing in Canada. Clean Technol. Environ. Policy 2014, 16, 1119–1131. [Google Scholar] [CrossRef]

- Zhang, Y.; Cao, S.-X.; Shao, S.; Chen, Y.; Liu, S.-L.; Zhang, S.-S. Aspen Plus-based simulation of a cement calciner and optimization analysis of air pollutants emission. Clean Technol. Environ. Policy 2010, 13, 459–468. [Google Scholar] [CrossRef]

- Calvo, V.L.V.; Giner-Santonja, G.; Alonso-Fariñas, B.; Aguado, J.M. The effect of the European Industrial Emissions Directive on the air emission limit values set by competent authorities in the permitting procedure: The case of the Spanish cement industry. Sci. Total Environ. 2021, 773, 145491. [Google Scholar] [CrossRef]

- Das, P.; Mandal, I.; Debanshi, S.; Mahato, S.; Talukdar, S.; Giri, B.; Pal, S. Short term unwinding lockdown effects on air pollution. J. Clean. Prod. 2021, 296, 126514. [Google Scholar] [CrossRef]

- Ciobanu, C.; Istrate, I.A.; Tudor, P.; Voicu, G. Dust Emission Monitoring in Cement Plant Mills: A Case Study in Romania. Int. J. Environ. Res. Public Health 2021, 18, 9096. [Google Scholar] [CrossRef]

- Karimi Ghoozlou, R.; Ahmadi, A.; Abbaspour, M.; Abbaszadeh, N. Assessment of Environmental Pollutant Particles PM10 and PM2. 5 with Air Quality Index Method (Case Study: Tehran Industrial Cement Complex). J. Environ. Sci. Technol. 2021, 23, 155–167. [Google Scholar]

- Thai, T.; Kučera, P.; Bernatik, A. Noise Pollution and Its Correlations with Occupational Noise-Induced Hearing Loss in Cement Plants in Vietnam. Int. J. Environ. Res. Public Health 2021, 18, 4229. [Google Scholar] [CrossRef]

- Guide, E.C.B. Cement Clinker Production; Natural Resources Canada–Office of Energy Efficiency: Ottawa, ON, Canada, 2001.

- Raina, A.K.; Soni, A.K.; Vajre, R.; Sangode, A.G. Impact of topography on attenuation of noise from a cement plant in a hilly terrain. Sci. Total Environ. 2022, 835, 155532. [Google Scholar] [CrossRef]

- Khan, M.H.; Havukainen, J.; Horttanainen, M. Impact of utilizing solid recovered fuel on the global warming potential of cement production and waste management system: A life cycle assessment approach. Waste Manag. Res. J. Sustain. Circ. Econ. 2020, 39, 561–572. [Google Scholar] [CrossRef]

- Ishak, S.A.; Hashim, H. Low carbon measures for cement plant–A review. J. Clean. Prod. 2015, 103, 260–274. [Google Scholar] [CrossRef]

- Majchrzycka, K.; Okrasa, M.; Jachowicz, A.; Szulc, J.; Gutarowska, B. Microbial Growth on Dust-Loaded Filtering Materials Used for the Protection of Respiratory Tract as a Factor Affecting Filtration Efficiency. Int. J. Environ. Res. Public Health 2018, 15, 1902. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guo, R.; Love, E. Fuzzy set-valued and grey filtering statistical inferences on a system operating data. J. Qual. Maint. Eng. 2005, 11, 267–278. [Google Scholar] [CrossRef]

- Gebert, R.; Rinschler, C.; Polizzi, C.; Harig, U.; Pranghofer, G.; Miller, S. A new filter system, combining a fabric filter and electrostatic precipitator for effective pollution control behind cement kilns. In Proceedings of the Cement Industry Technical Conference, 2003 Conference Record IEEE-IAS/PCA, Dallas, TX, USA, 4–9 May 2003; IEEE: Piscataway, NJ, USA, 2003. [Google Scholar]

- Lazik, P.-R.; University of Stuttgart; Garrecht, H. Wood ashes from electrostatic filter as a replacement for the fly ashes in concrete. J. Constr. Mater. 2021, 2, 2–6. [Google Scholar] [CrossRef]

- Miller, M.M.; Callaghan, R.M. Lime kiln dust as a potential raw material in Portland cement manufacturing. US Geol. Surv. Open-File Rep. 2004, 2004, 1336. [Google Scholar]

- Fantom, I.; Cottingham, C.; Should, I. Replace my Electrostatic Precipitator (ESP) with a Fabric Filter (FF)? Filtr. -Coalville 2005, 5, 277. [Google Scholar]

- Ando, H.; Shiromaru, N.; Mochizuki, Y. Recent technology of moving electrode electrostatic precipitator. Int. J. Plasma Environ. Sci. Technol. 2011, 5, 130–134. [Google Scholar]

- Kherbouche, F.; Benmimoun, Y.; Tilmatine, A.; Zouaghi, A.; Zouzou, N. Study of a new electrostatic precipitator with asymmetrical wire-to-cylinder configuration for cement particles collection. J. Electrost. 2016, 83, 7–15. [Google Scholar] [CrossRef]

- Bhargava, A. Design of bag filter for the control of dust emissions for a cement plant. Int. J. Sci. Dev. Res. IJSDR 2016, 1, 249–251. [Google Scholar]

- Purnomo, C.W.; Budhijanto, W.; Alfisyah, M. Improvement of cement plant dust emission by bag filter system. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018. [Google Scholar]

- Abishek, P.; Ramachandran, P. Design of pleated bag filter system for particulate emission control in cement industry. Int. Res. J. Eng. Technol. (IRJET) 2015, 2, 763–768. [Google Scholar]

- Ngala, G.; Tela, B.; Highina, B. Mercury Removal in Cement Industry Using Venturi Type Wet Scrubber. Int. J. Eng. Technol. Res. 2014, 2, 48–54. [Google Scholar]

- Tela, B.; Ngala, G.; Abubakar, A. Separation of Gas Particle Using Venturi-Type Wet Scrubber in Ashaka Cement Factory PLC. Int. J. Res. Mech. Eng. 2014, 2, 91–98. [Google Scholar]

- Sharma, K.; Jain, U.; Singhal, A. Treatment of Waste Generated from Cement Industry and Their Treatment—A Review. 2012. Available online: http://dl.lib.mrt.ac.lk/handle/123/8889 (accessed on 18 October 2022).

- Chatziaras, N.; Psomopoulos, C.S.; Themelis, N.J. Use of waste derived fuels in cement industry: A review. Manag. Environ. Qual. Int. J. 2016, 27, 178–193. [Google Scholar] [CrossRef]

- Tsiligiannis, A.; Tsiliyannis, C. Oil refinery sludge and renewable fuel blends as energy sources for the cement industry. Renew. Energy 2020, 157, 55–70. [Google Scholar] [CrossRef]

- Gomes, S.D.C.; Zhou, J.L.; Li, W.; Long, G. Progress in manufacture and properties of construction materials incorporating water treatment sludge: A review. Resour. Conserv. Recycl. 2019, 145, 148–159. [Google Scholar] [CrossRef]

- Kim, J.-H.; Kim, J.-H.; Kim, H.-S.; Kim, H.-J.; Kang, S.-H.; Ryu, J.-H.; Shim, S.-S. Reduction of NOx Emission from the Cement Industry in South Korea: A Review. Atmosphere 2022, 13, 121. [Google Scholar] [CrossRef]

- Rahman, A. Utilization of Waste Products as Alternative Fuels for Cement Industry. Ph.D. Thesis, CQUniversity, Rockhampton, Australia, 2016. [Google Scholar]

- Orkomi, A.A.; Tavakoli, B.; Noorpoor, A. Noise pollution analysis in Tehran cement plant. J. Occup. Health Epidemiol. 2013, 2, 44–53. [Google Scholar] [CrossRef]

- Zermane, H.; Mouss, H.; Oulmi, T.; Hemal, S. Fuzzy-based process control system of a bagfilter in cement manufacturing plant. In Proceedings of the 2017 6th International Conference on Systems and Control (ICSC), Batna, Algeria, 7–9 May 2017. [Google Scholar]

- Adeniran, J.A.; Yusuf, R.O.; Fakinle, B.S.; Sonibare, J.A. Air quality assessment and modelling of pollutants emission from a major cement plant complex in Nigeria. Atmos. Pollut. Res. 2019, 10, 257–266. [Google Scholar] [CrossRef] [Green Version]

- Yazdi, N.; Arhami, M.; Ketabchy, M.; Delavarrafeei, M. Modeling of cement factory air pollution dispersion by AERMOD. In Proceedings of the A&WMA’s 109th Annual Conference & Exhibition Paper, New Orleans, LA, USA, 20–23 June 2016. [Google Scholar]

- Lutz, M. Programming Python; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2001. [Google Scholar]

- Hao, J.; Ho, T.K. Machine Learning Made Easy: A Review of Scikit-learn Package in Python Programming Language. J. Educ. Behav. Stat. 2019, 44, 348–361. [Google Scholar] [CrossRef]

- Hussain, Z.; Khan, M.S. Introducing Python programming for engineering scholars. Int. J. Comput. Sci. Netw. Secur. 2018, 18, 26–33. [Google Scholar]

- Ding, L.; Ahmed, S.; Shapiro, A. A Python package for multi-stage stochastic programming. Optim. Online 2019, 1–42. Available online: https://optimization-online.org/?p=15797 (accessed on 18 October 2022).

- Kumar, R.; Carroll, C.; Hartikainen, A.; Martin, O. ArviZ a unified library for exploratory analysis of Bayesian models in Python. J. Open Source Softw. 2019, 4, 1143–1147. [Google Scholar] [CrossRef]

- Lemenkova, P. Testing Linear Regressions by StatsModel Library of Python for Oceanological Data Interpretation. Aquat. Sci. Eng. 2019, 34, 51–60. [Google Scholar] [CrossRef]

- Eaton, D.A.R. Toytree: A minimalist tree visualization and manipulation library for Python. Methods Ecol. Evol. 2019, 11, 187–191. [Google Scholar] [CrossRef] [Green Version]

- Fredericks, S.; Parrish, K.; Sayre, D.; Zhu, Q. PyXtal: A Python library for crystal structure generation and symmetry analysis. Comput. Phys. Commun. 2020, 261, 107810. [Google Scholar] [CrossRef]

- Kadiyala, A.; Kumar, A. Applications of Python to evaluate environmental data science problems. Environ. Prog. Sustain. Energy 2017, 36, 1580–1586. [Google Scholar] [CrossRef]

- Ma, X.; Longley, I.; Salmond, J.; Gao, J. PyLUR: Efficient software for land use regression modeling the spatial distribution of air pollutants using GDAL/OGR library in Python. Front. Environ. Sci. Eng. 2020, 14, 1–14. [Google Scholar] [CrossRef]

- Lella, D.B.; Jogu, V.; Ballu, H. Analysing Air Pollution Through Maps & Tools and Predicting Aqi Using Python. Int. Res. J. Mod. Eng. Technol. Sci. 2022, 4, 1996–2004. [Google Scholar]

- Amarpuri, L.; Yadav, N.; Kumar, G.; Agrawal, S. Prediction of CO2 emissions using deep learning hybrid approach: A Case Study in Indian Context. In Proceedings of the 2019 Twelfth International Conference on Contemporary Computing (IC3), Noida, India, 8–9 August 2019. [Google Scholar]

- Resch, E.; Andresen, I.; Cherubini, F.; Brattebø, H. Estimating dynamic climate change effects of material use in buildings—Timing, uncertainty, and emission sources. Build. Environ. 2021, 187, 107399. [Google Scholar] [CrossRef]

- Haji, S.H.; Sallow, A.B. IoT for smart environment monitoring based on Python: A review. Asian J. Res. Comput. Sci. 2021, 9, 57–70. [Google Scholar] [CrossRef]

- Pătrășcoiu, N.; Rus, C.; Roșulescu, C.; Negru, N. System for Monitoring the Parameters of Pollution Factors in Industrial Areas with Application in the Jiu Valley Area. Ann. Univ. Petrosani Electr. Eng. 2020, 21, 30–43. [Google Scholar]

- Khoi, D.N.; Quan, N.T.; Linh, D.Q.; Nhi, P.T.T.; Thuy, N.T.D. Using Machine Learning Models for Predicting the Water Quality Index in the La Buong River, Vietnam. Water 2022, 14, 1552. [Google Scholar] [CrossRef]

- Cascone, C.; Murphy, K.R.; Markensten, H.; Kern, J.S.; Schleich, C.; Keucken, A.; Köhler, S.J. AbspectroscoPY, a Python toolbox for absorbance-based sensor data in water quality monitoring. Environ. Sci. Water Res. Technol. 2022, 8, 836–848. [Google Scholar] [CrossRef]

- Shah, S.k.; Tariq, Z.; Lee, J.; Lee, Y. Real-time machine learning for air quality and environmental noise detection. In IEEE International Conference on Big Data; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar]

- Yao, Y. Internet of Things in the Quality Control of Cement Mixing Pile Construction. J. Cases Inf. Technol. (JCIT) 2022, 24, 1–22. [Google Scholar] [CrossRef]

- Wang, F.; Hu, Y.-G.; Liu, L.; Deng, Y.; Gu, S. Interphase Effect on the Macro Nonlinear Mechanical Behavior of Cement-Based Solidified Sand Mixture. Materials 2022, 15, 1972. [Google Scholar] [CrossRef] [PubMed]

- Kumar, N.; Naranje, V.; Salunkhe, S. Cement strength prediction using cloud-based machine learning techniques. J. Struct. Integr. Maint. 2020, 5, 244–251. [Google Scholar] [CrossRef]

- Danila, A.; Tamas, F.L. The thermal field analysis of the rotary kiln for the cement plants by means of the image processing techniques. IOP Conf. Series: Mater. Sci. Eng. 2020, 789, 012016. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Omiotek, Z.; Szafraniec, M.; Dzierżak, R. An integrated texture analysis and machine learning approach for durability assessment of lightweight cement composites with hydrophobic coatings modified by nanocellulose. Measurement 2021, 179, 109538. [Google Scholar] [CrossRef]

- Nayak, S.; Krishnan, N.A.; Das, S. Fracture response of metallic particulate-reinforced cementitious composites: Insights from experiments and multiscale numerical simulations. Cem. Concr. Compos. 2019, 97, 154–165. [Google Scholar] [CrossRef] [Green Version]

- Plattenberger, D.A.; Opila, E.J.; Shahsavari, R.; Clarens, A.F. Feasibility of Using Calcium Silicate Carbonation to Synthesize High-Performance and Low-Carbon Cements. ACS Sustain. Chem. Eng. 2020, 8, 5431–5436. [Google Scholar] [CrossRef]

- Kurnaz, G.; Demir, A.S. Prediction of SO2 and PM10 air pollutants using a deep learning-based recurrent neural network: Case of industrial city Sakarya. Urban Clim. 2021, 41, 101051. [Google Scholar] [CrossRef]

- Ceylan, Z.; Bulkan, S. Forecasting PM10 levels using ANN and MLR: A case study for Sakarya City. Glob. Nest J. 2018, 20, 281–290. [Google Scholar]

- Zamani Joharestani, M.; Cao, C.; Ni, X.; Bashir, B.; Talebiesfandarani, S. PM2. 5 prediction based on random forest, XGBoost, and deep learning using multisource remote sensing data. Atmosphere 2019, 10, 373. [Google Scholar] [CrossRef] [Green Version]

- Atamaleki, A.; Zarandi, S.M.; Fakhri, Y.; Mehrizi, E.A.; Hesam, G.; Faramarzi, M.; Darbandi, M. Estimation of air pollutants emission (PM10, CO, SO2 and NOx) during development of the industry using AUSTAL 2000 model: A new method for sustainable development. MethodsX 2019, 6, 1581–1590. [Google Scholar] [CrossRef] [PubMed]

- Yaha, A.S.; Ahmad, A.N.; Othman, F.B.; Ibrahim, R.K.; Afan, H.A.; El-shafie, A.; Fai, C.M.; Hossain, M.S.; Ehteram, M.; Elshafie, A. Water Quality Prediction Model Based Support Vector Machine Model for Ungauged River Catchment under Dual Scenarios. Water 2019, 11, 1231. [Google Scholar] [CrossRef] [Green Version]

- Aceves-Fernández, M.A.; Domínguez-Guevara, R.; Pedraza-Ortega, J.C.; Vargas-Soto, J.E. Evaluation of Key Parameters Using Deep Convolutional Neural Networks for Airborne Pollution (PM10) Prediction. Discret. Dyn. Nat. Soc. 2020, 2020, 2792481. [Google Scholar] [CrossRef] [Green Version]

- Chatzilenas, C.; Gentimis, T.; Dalamagas, T.; Kokossis, A.C.; Katsiaboulas, A.; Marinos, I. Machine learning applications and process intelligence for cement industries. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2021; Volume 50, pp. 711–716. [Google Scholar] [CrossRef]

- Wang, Y.; Xue, S.; Ding, J. Research on water pollution prediction of township enterprises based on support vector regression machine. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2021; Volume 228, p. 02014. [Google Scholar]

- Sharma, P.; Rao, M.V.R.; Mohapatra, B.N.; Saxena, A. Development of suitable machine learning model for a cement plant calciner. Int. J. Eng. Appl. Sci. Technol. 2021, 6, 194–198. [Google Scholar] [CrossRef]

- Nasir, A.H.; Nawaz, R.; Haider, R.; Irshad, M.A. Modeling Air Pollution Health Risk for Environmental Management of an Internationally Important Site: The Salt Range (Kallar Kahar), Pakistan. Atmosphere 2022, 13, 100. [Google Scholar] [CrossRef]

- Carreño, G.; López-Cortés, X.A.; Marchant, C. Machine Learning Models to Predict Critical Episodes of Environmental Pollution for PM2.5 and PM10 in Talca, Chile. Mathematics 2022, 10, 373. [Google Scholar] [CrossRef]

- Ding, W.; Qie, X. Prediction of Air Pollutant Concentrations via RANDOM Forest Regressor Coupled with Uncertainty Analysis—A Case Study in Ningxia. Atmosphere 2022, 13, 960. [Google Scholar] [CrossRef]

- Fatahi, R.; Nasiri, H.; Dadfar, E.; Chelgani, S.C. Modeling of energy consumption factors for an industrial cement vertical roller mill by SHAP-XGBoost: A “conscious lab” approach. Sci. Rep. 2022, 12, 7543. [Google Scholar] [CrossRef]

- Guzman, M.P.; Rubia, B.N.; Peris, P.M.; Alfallaluque, R. Methodoligac development for the optimization of electricity cost in cement factories: The use of artificial intelligence in process variables. Electr. Eng. 2022, 104, 1681–1696. [Google Scholar] [CrossRef]

- Jadoon, U.K.; Ahmad, I.; Noor, T.; Kano, M.; Caliskan, H.; Ahsan, M. An intelligent sensing system for estimation of efficiency of carbon-capturing unit in a cement plant. J. Clean. Prod. 2022, 377, 134359. [Google Scholar] [CrossRef]

| Emission Type | Specific Pollutant | Resource of the Pollution Material |

|---|---|---|

| Air Emission | SO2 | Raw mill and kiln stack exit |

| NOx | ||

| CO | ||

| Water Pollution | Iron particles | Material washing, thermal pipes, and finishing |

| Suspended solids | ||

| Oxygen demand | ||

| Solid Waste | TSP | Clinker cooler, cement mill stacks exit, and outlets of dust control devices |

| PM2.5 | ||

| PM10 | ||

| Noise | Gas dynamic | Compressors and blower devices, |

| Mechanic | Milling and crusher equipment | |

| Electromagnetic | Electric motors | |

| Fuel Waste | Greenhouse gases | Energy supplying sections |

| Model | Description | Accuracy | Interpretation |

|---|---|---|---|

| Artificial intelligence | It developes problem solving ability, allows continuous learning, promotes creativity, and encourages social intelligence. | 0.95 [0.85, 0.99] | 0.88 [0.63, 0.99] |

| Support Vector Machine | This model can evaluate data for classification and data analysis via classification algorithms for two-category problems. | 0.92 [0.77, 0.99] | 0.85 [0.53, 0.99] |

| Linear regression | It describes the relationship between an independent variable and a dependent one. | 0.85 [0.69, 0.96] | 0.72 [0.51, 0.94] |

| Random forest regressor | Its potential is to integrate the accuracy and control overfitting through fitting and averaging a number of decision trees. | 0.88 [0.69, 0.99] | 0.73 [0.33, 0.99] |

| K-Nearest Neighbors Regression | This method approximates the relationship between independent variables via averaging in the same neibourhoods. | 0.78 [0.51, 0.94] | 0.69 [0.38, 0.91] |

| Gradient Boosted Regression | It is derived from the idea of decision tree model and can predict both continuous and categorical target variables. | 0.85 [0.75, 0.96] | 0.45 [0.11, 0.88] |

| Purpose of the Study | Zone | Model and Software | References |

|---|---|---|---|

| Predicting PM10 | Sakarya city, Turkey | Multi-linear regression and multilayer perception neural network models and MATLAB software | 2018 [107] |

| Modeling of PM2.5 | Tehran, Iran | Random forest model and Python software (XGBoost library) | 2019 [108] |

| Estimation of CO, SO2, NOx, and PM10 | Bojnourd Cement plants, Iran | AUSTAL 2000 model and Arc GIS software | 2019 [109] |

| Water pollution | Langat River, Malaysia | Support vector regression model | 2019 [110] |

| Forecasting PM10 | Mexicocity, USA | Multilayer perception model enhanced with Bagging ensemble model | 2020 [111] |

| Assessing the emitted NO2 | Auckland, Newzealand | Land use regression model and Python software | 2020 [90] |

| Fuel consumption | Cement plant, Greece | Machine learning-based model | 2021 [112] |

| Water pollution | Guangxi, China | Support vector regression model and MATLAB software | 2021 [113] |

| CO2 emission | Cement plant, India | Artificial neural network-based models | 2021 [114] |

| Assessing the health effects of PM2.5, PM10, NOx, and O3 | Cement plant, Pakistan | Air Q+ software | 2022 [115] |

| Prediction of SO2 and PM10 | Sakarya city, Turkey | Python software | 2022 [106] |

| Estimation of PM2.5 and PM10 | Talca, Chile | Support vector regression model and Python software | 2022 [116] |

| Evaluating the relationship between the air pollutants and the meteorological variables | Ningxia, China | Decision tree regression model | 2022 [117] |

| Fuel consumption | Cement plant, Iran | Support vector regression, random forest, and XGBoost models | 2022 [118] |

| Fuel consumption | Cement plant, Spain | Neural network and genetic algorithm models | 2022 [119] |

| Assessing the emitted CO2, SO2, and NO | Cement plant | Machine learning-based model and MATLAB software | 2022 [120] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, X.; Yang, J.; Huang, Q.; Liu, T. A Review on Pollution Treatment in Cement Industrial Areas: From Prevention Techniques to Python-Based Monitoring and Controlling Models. Processes 2022, 10, 2682. https://doi.org/10.3390/pr10122682

Zhu X, Yang J, Huang Q, Liu T. A Review on Pollution Treatment in Cement Industrial Areas: From Prevention Techniques to Python-Based Monitoring and Controlling Models. Processes. 2022; 10(12):2682. https://doi.org/10.3390/pr10122682

Chicago/Turabian StyleZhu, Xinghan, Jinzhong Yang, Qifei Huang, and Tao Liu. 2022. "A Review on Pollution Treatment in Cement Industrial Areas: From Prevention Techniques to Python-Based Monitoring and Controlling Models" Processes 10, no. 12: 2682. https://doi.org/10.3390/pr10122682

APA StyleZhu, X., Yang, J., Huang, Q., & Liu, T. (2022). A Review on Pollution Treatment in Cement Industrial Areas: From Prevention Techniques to Python-Based Monitoring and Controlling Models. Processes, 10(12), 2682. https://doi.org/10.3390/pr10122682