Abstract

Oil and gas (O&G) supply chain management (SCM) is complex because it deals with different geographic locations to manage demand and supply, transportation, inventory, and distribution. Blockchain technology has created an interesting research gap in the SCM domain, and this study is designed to describe the relevancy of blockchain technology for O&G SCM. SCM is based on agile and lean supply chains (SCs). Agile SC focuses on increasing flexibility and responsiveness to gain competitive advantages, and lean SC is based on eliminating waste and processes to improve firm performance. This study is an initial effort to propose a framework that suggests the implication of blockchain for O&G by providing an overview of O&G SCM. Data were collected from SC managers of O&G companies, and we analyzed the impact of agile and lean SCs on firm performance. The results indicate that agile SC is highly important for O&G industries in comparison to lean SC. This study proposes the key requirements of agile SC and how blockchain can uplift agile SC technology with state-of-the-art properties such as data-driven management, information sharing, data privacy, cyber-security, transparency, smart contracts, visibility, traceability, and reliability, which boost SC agility as well as firm performance.

1. Introduction

Oil and gas (O&G) are considered the world’s most important sources of energy, and their products underpin modern society, fueling vehicles for the transportation and delivery of supplies. O&G-related products are critically important for almost every industry due to their usage in daily life [1]. The supply chain (SC) is one of the most effective tools for achieving business objectives, such as controlling manufacturing processes or providing a competitive edge by delivering a product more quickly, efficiently, and effectively to the right place, at the right time, and of the right quantity [2,3,4]. The transition from a traditional SC to smart SC comprises four stages. The first stage is a determination of where the SC stands now (using, e.g., enterprise resource planning (ERP)). The second stage comprises product innovation focused on the customer; SCs with stable structures already in the second stage must focus on process innovation, which is the third stage. The final stage is where the SCs are revamped for both product and process innovation. This process of innovation can be achieved through emerging technologies such as the Internet of Things (IoT), information and communication technologies (ICT), big data, artificial intelligence (AI), and blockchain [5,6]. Industry 4.0 combines these concepts, as they are interlinked [7,8,9,10]. For example, big data can be produced through IoT and needs to be processed through AI. Similarly, IoT may require strong ICT and blockchain. As one of the hurdles in IoT implementation is security, blockchain may play a vital role. Recently, many challenges have arisen in maintaining modernized SCs, as process innovation is abrupt. Innovations must align with the need for emerging technologies, as different vendors are participating globally in SC processes. In this context, a shared common database is essential, along with maintaining all transactions in a ledger [11].

O&G SCM is complex because it deals with different geographic locations at the same time to manage the demand and supply, transportation, and distribution of O&G products in more competitive environments. To cope with increasing competition, many SCs have started adopting lean SC practices in general, and just-in-time (JIT) approaches in particular [12,13]. These types of practices for managing and eliminating “waste” provide higher levels of productivity and efficiency, and potentially remarkably increase productivity and efficiency for small- and medium-sized SCs [14]. Furthermore, participating in agile practices provides flexibility and responsiveness to SC functions [15,16,17]. Blockchain technology has created an interesting research gap in the SC domain, as it replaced old technologies and reduced human interactions during service delivery while optimizing logistics via virtual agent techniques and providing secure and real-time information [18]. Lean and agile practices play a significant role in the O&G industry to boost SC performance. Agile SCs focus on increasing flexibility and responsiveness to gain competitive advantages. In this context, blockchain may increase firm responsiveness by reducing uncertainty and increasing the trust level of suppliers and customers through a real-time information-sharing platform, along with transparency, reliability, privacy, and visibility in all SC functions [19,20]. In contrast, a lean SC is based on eliminating waste, processes, poor information, and resources to improve firm performance and efficiency [21,22], and blockchain may provide immutable and irrevocable data-driven management and smart contracts, which increase the lean performance.

This study describes the relevancy of blockchain technology for O&G SCM and focuses on agile and lean supply chain practices. This study proposes a framework which suggests the importance of blockchain for O&G. This study analyzes the impact of agile and lean SC on firm performance, illustrating the relevancy of blockchain technology with agile and lean SCs in the context of the O&G industry. To this end, the Pakistan O&G sector was chosen because this sector is highly neglected by researchers, and the Pakistan O&G sector plays a vital role in the economy and it is necessary to uplift this sector. To fill the research gaps, this study represents an initial effort to examine the need for blockchain in SCs according to lean and agile SCs. We identified SC practices according to agile and lean SCs; then, we analyzed the impact of these practices on firms’ SC performance. Based on the literature, we developed an understanding of blockchain’s relevancy to agile and lean SCs. We gathered empirical evidence regarding which SC approaches (agile and lean) are highly implemented. Then, we identified which SC types are suitable for the adoption of blockchain. To support this study, the oil and gas industries were chosen to validate the results. This study highlights the following research questions.

RQ1: How does blockchain technology fit into the oil and gas supply chain?

RQ2: How do agile and lean supply chain practices improve oil and gas performance?

RQ3: How are agile supply chain optimized using blockchain?

The remainder of this paper is organized as follows. Section 2 focuses on the literature review, including SCM practices and blockchain technology. Section 3 discusses the methodology and results of the study, and Section 4 presents a discussion. Finally, conclusions, implications, and future work are presented in Section 5.

2. Literature Review

2.1. Oil and Gas Industry and Supply Chain Management

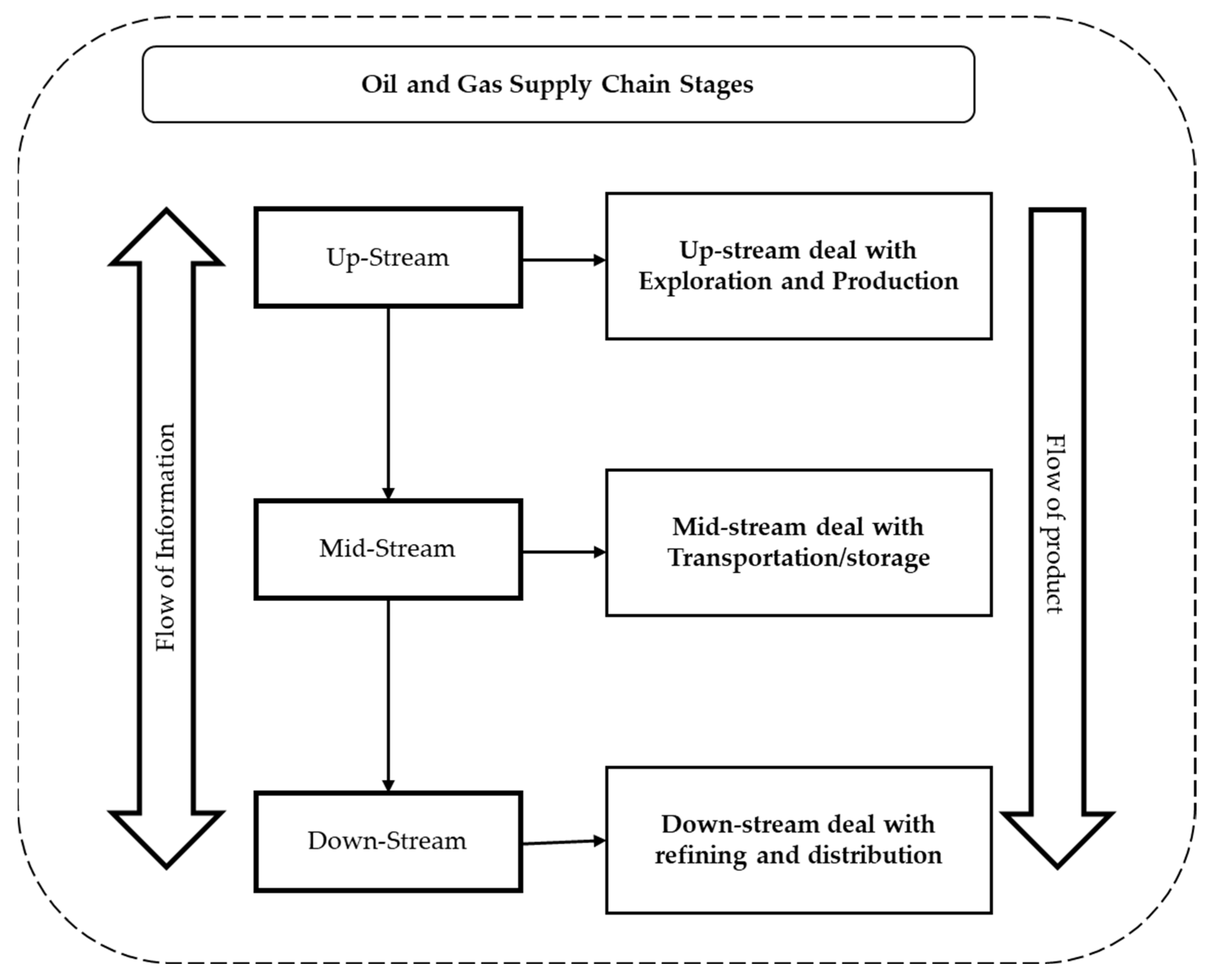

The O&G value chain is based on three stages: upstream, midstream, and downstream. Upstream involves multiple activities, such as exploration and production of O&G with the help of acquiring the land rights for digging to find O&G reserves. Midstream SC is involved with the transportation and storage of the raw products, and finally, downstream SC focuses on the refining and distribution of products (Figure 1). In the modern era, exploring O&G reserves uses the latest theological equipment, which is based on artificial intelligence (AI). After the exploration of reserves, production activities also consist of modern technology, such as mechanical digging and automated fracking. With the advancement of technology, O&G exploration and production methods developed rapidly in recent years using artificial intelligence, big data, and the Industrial Internet of Things (IIoT), such as marine digital platforms, intelligent O&G fields, and drilling, and predictive maintenance using machine learning algorithms [23]. Using these emerging technologies, the O&G industry is gradually developing in the direction of automation, digitalization, and intellectualization. Unfortunately, the operational activity, especially SCM, is relatively less developed because the use of emerging technologies is limited, and this causes poor SCM, high operational costs, higher lead time, and higher uncertainty.

Figure 1.

Oil and gas supply chain stages.

According to the oil consumer index, Pakistan is the 33rd largest country to consume O&G products. In Pakistan, the consumption of petroleum products is mainly for transportation, energy production (power sector), and manufacturing. Among them, the transport industry’s consumption is 60%, the energy production sector consumes 32%, and the manufacturing sector uses 8%. Due to the higher dependency of major industries on O&G products, the smooth flow of supply is critically important for Pakistan’s O&G sector. Unfortunately, Pakistan O&G reserves meet just one-fifth of the total demand, and the remaining demand is fulfilled via high-price imports [24]. Therefore, Pakistan O&G is highly dependent on importing O&G products around the globe, and the entire SCM is more complex because it deals with different geographic locations. Due to the importance of O&G products in Pakistan, the SCM of this sector should be optimized, responsive, flexible, fully integrated, and with a highly secure payment platform, with end-to-end visibility to avoid any hurdles for the smooth flow of products to meet the demand and supply requirements on time. Consequently, blockchain technology is highly recommended for Pakistan’s O&G industry to manage supply chain operations more effectively using state-of-the-art technological properties such as transparency, cyber-security, real-time information sharing, reliability, traceability, and end-to-end visibility. O&G SCM deals with various organizations, suppliers, stakeholders, and customers; therefore, decision-making is difficult in this complex SC structure, and many uncertainties may exist. These can be overcome by using a strong integration system among all SC functions. Ideally, this integration is achieved through real-time information sharing; however, the idea of such real-time information sharing through web-based platforms has been challenging over time owing to security issues. Consequently, blockchain provides a better understanding of SC operations through real-time information sharing, visibility, and transparency to minimize uncertainties and improve SC performance [25,26]. In one study, blockchain technology was used in a digital distributed ledger for SCs to design a digital platform summarizing the information and documents of a shipment that could be managed [27]. An SC can be enhanced by using a digital infrastructure system such as blockchain, where all participants (such as vendors) can access and share product-related information such as the rate/price, payment (in a transparent manner), delivery status, lead time, and shipment details with delivery tracking. In this system, suppliers or customers can monitor product and payment issues in detail using digital control. Blockchain technology provides greater security than traditional information technology (IT) infrastructure [28,29]. Blockchain may enhance IT by providing different usable applications related to SC and operations management with the help of advanced computing and distributed software. The application of blockchain to the SC is based on a combination of different theories to allow for the implementation of the blockchain structure in the SC [30], such as network theory, resource-based view, transaction cost theory, transaction cost analysis, and principal–agent theory [31]. In the literature, the implementation of blockchain for SCM has been widely discussed, but most approaches are from a generic perspective. Therefore, it is important to understand the blockchain needs according to the SC type. This study is an initial effort toward providing a framework for understanding the implementation of blockchain as per SC type, based on the oil and gas sectors of Pakistan.

2.2. Agile and Lean Supply Chain, Supply Chain Management-Related Firm Performance, and Blockchain Technology

The supply chain network depends on a set of different activities called SC practices for completing the SCM process and delivering the final product to customers with an efficient integrated system. These practices include sourcing, managing supplier relationships, procuring raw materials, production planning, scheduling, warehousing and inventory management, ordering techniques, distribution management, providing transportation, and managing logistics [32,33,34,35]. In this study, 12 SC practices were derived from identified SC types, and their needs for blockchain were discussed according to the essential blockchain features of each type. An SC network can be classified as agile (responsiveness) or lean (eliminating waste) according to the operational needs of the SC [16,36,37,38,39]. Furthermore, SCM-related firm performance is generally based on five dimensions: increases in sales, more accurate costing, increases in coordination with vendors, increases in coordination between departments, and increases in coordination with customers [15,16]. An agile SC focuses on flexibility and the ability to handle changes in supply and demand under uncertain conditions. Agile SCs respond quickly and effectively to changes in customer preferences in unpredictable environments [40,41]. Consequently, an agile SC must develop strong partnerships and interactions among suppliers, partners, and customers to build flexibility and responsiveness. An agile-based SC avoids certain warehouse costs by using outsourcing and third-party logistics (3PL) techniques while minimizing inventory. The literature shows that agile SCs are based on different SC practices, such as close partnerships with suppliers, close partnerships with customers, outsourcing, e-procurement, 3PL, subcontracting, and using many suppliers; these help the SC maintain flexibility in managing the uncertainty in supply and demand [15,16,17]. Blockchain is a modern internet-based technology offering a high-tech technological architecture for SCs with various benefits including transparency, visibility, and security in transactions during procurement [42,43,44]. Blockchain can help agile-based SCs perform more responsibly and flexibly because it has an inherent capacity for integration among all SC networks. It can provide more accurate stock management and demand forecasting, improve the tracing and tracking of inventory, and remove payment problems by providing or facilitating digital trust in third parties, subcontractors, and suppliers [45,46]. Blockchain technology is useful for these types of SC practices because they require strong integration, effective flows of information, and transparency within the entire SC, and boost firm SC performance by developing effective coordination among vendors, customers, and departments [47,48].

In contrast, a lean SC focuses on maximizing savings through continuous improvement techniques and eliminating waste and processes from SC networks. The lean SC represents a traditional “factory” chain for producing high volumes at a low cost [49,50]. Lean SCs focus on reliability and predictability rather than flexibility and adaptability. This type of SC is widely used in production, as the primary purpose of lean SCs is to reduce costs and improve firm performance by more accurate costing and reduced inventory levels. There are numerous lean SC practices, e.g., JIT, strategic planning, benchmarking, holding safety stock, and using few suppliers [21,22,51,52]. Lean SC practices help firms reduce their lead times and optimize their performance by using JIT delivery/supply, providing effective planning for inventory (raw, in-process, and finished), and maintaining useful collaboration within the organization. Therefore, an effective lean SC firm can produce high-quality products with minimal waste. Lean practices also focus on eliminating unnecessary processing and/or providing process improvement techniques [53]. Lean SC is highly dependent on information-sharing systems, trust levels, and financial transactions with vendors [54]. Lean SCs face many challenges, such as those concerning the links between physical and information flows, accessibility, continuity of information, and trust. In this context, ERP and IoT have been used for resolving information-sharing and trust problems [55,56,57]. There is active adoption of ERP and IoT for lean practices [58,59], but the acceptance of emerging technologies such as big data, AI, and blockchain remains slow and questionable [60]. Blockchain has effective properties for lean SCs for improving lean firm performance, including immutable and irrevocable information sharing, data-driven management, trust, smart contracts, centralized data, and control [61,62,63]. Table 1 summarizes the blockchain properties and their implications in agile and lean SC environments.

Table 1.

Blockchain properties and implications for agile and lean supply chains.

2.3. Proposed Framework and Hypotheses

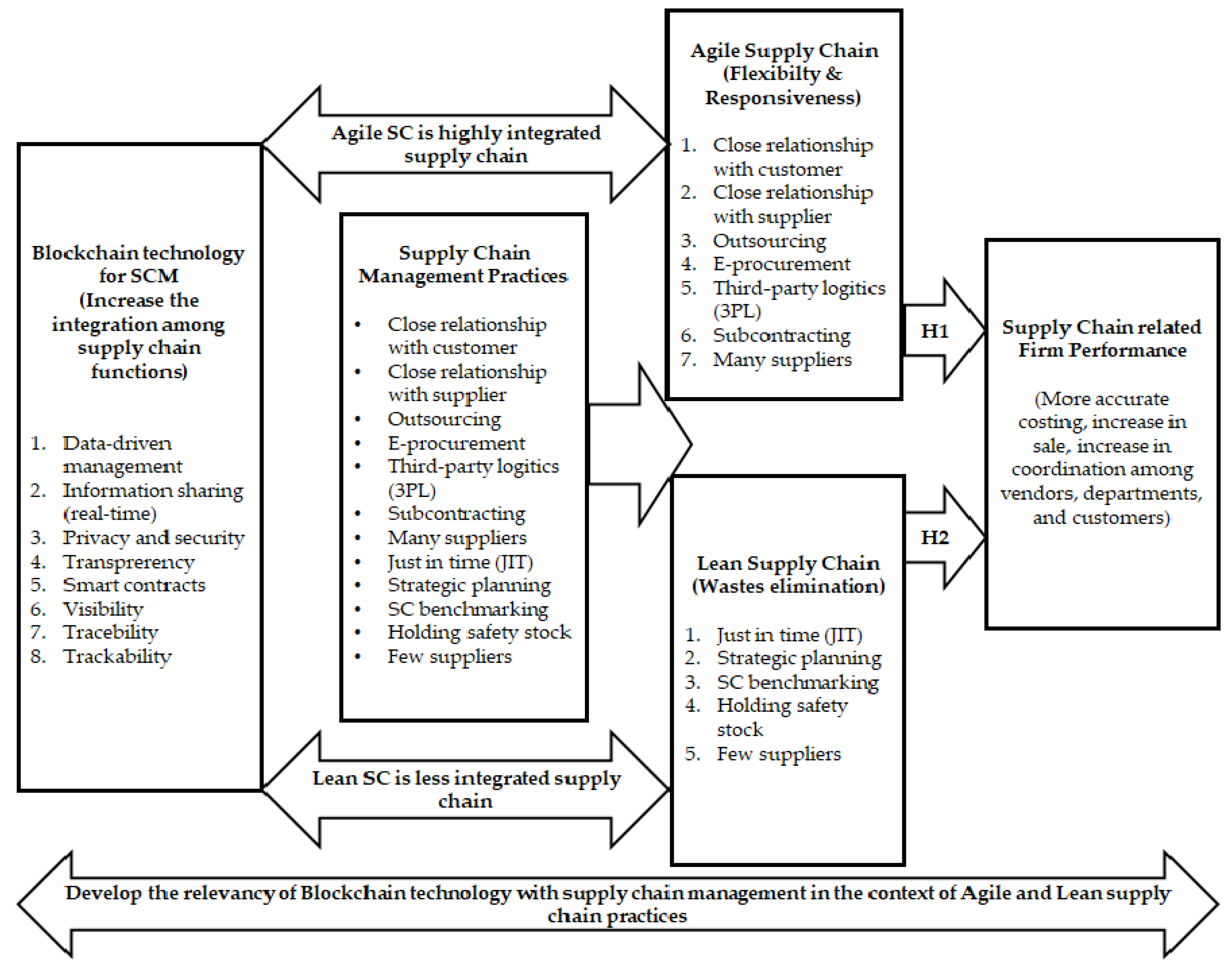

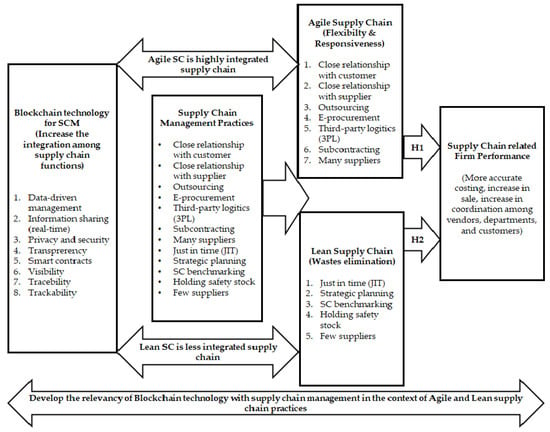

This study derived SC practices based on agile and lean approaches: seven practices are linked to agile SCs (close partnership with customers, close partnership with customers, outsourcing, e-procurement, 3PL, subcontracting, and many suppliers), and five practices belong to lean SCs (JIT, strategic planning, benchmarking, holding safety stock, and few suppliers). Agile and lean SCs improve a firm’s SC-related performance by providing more accurate costing, increasing sales, and increasing coordination among vendors, departments, and customers. Below, we analyze the impacts of agile and lean SCs on firm SC performance based on hypotheses H1 and H2, respectively. The proposed framework of this study is presented in Figure 2. This study identifies the relationships between the agile and lean SCs and firm SC performance and examines the relevancy of blockchain properties to agile and lean SCs (refer to Table 1).

Figure 2.

Proposed framework.

To understand the impacts of SC practices (agile and lean) on SCM-related firm performance in the O&G industry, this study examined the following hypotheses.

H1.

Agile SC practices have a positive and significant impact on SCM-related performance in the oil and gas industry.

H2.

Lean SC practices have a positive and significant impact on SCM-related performance in the oil and gas industry.

3. Methodology

The methodology of this study is as follows:

- i.

- Classify the SCM into two dimensions i.e., agile and lean.

- ii.

- Determine the SCM practices according to SC type (agile and lean).

- iii.

- Examine the impacts of these SC practices (based on agile and lean) on firms’ SCM-related performance.

- iv.

- Identify the relevancy of blockchain to agile and lean SCs.

- v.

- Recommend the implementation of blockchain according to the needs of each SC type.

Sampling and Measures

According to the literature, SC practices were identified in the context of these SC types (agile and lean). The agile SC was based on seven SCM practices: close partnerships with suppliers, close partnerships with customers, outsourcing, e-procurement, 3PL, subcontracting, and having many suppliers. The lean SC was based on five SCM practices: JIT, strategic planning, benchmarking, holding safety stock, and having a few suppliers. SC managers in the oil and manufacturing sectors were asked to what extent the identified SCM practices were implemented in their firms based on a five-point Likert scale ranging from 1 = not at all implemented to 5 = fully implemented [16]. The objectives of the SC management and practices were divided into two types. First, the short term was based on uplifting productivity, minimizing lead time, and reducing on-hand inventory. Second, the long term included the integration of the SC among all SC partners (vendors, stakeholders, distributors, logistics providers, and customers) and increasing the market share. In light of these objectives and the effective implementation of SCM, the firm performance was improved and measured according to five dimensions (increase in sales, more accurate costing, increase in coordination with vendors, increase in coordination between departments, and increase in coordination with the customers). The questions also asked how the firm performed in the past three years relative to their competitors under implemented SCM practices on a five-point scale ranging from 1 = definitely worse to 5 = definitely better. Seventeen questions were used to examine the impacts of the SC approaches (agile and lean) on SCM-related firm performance [15,16]. The Appendix A presented the survey questionnaires. The O&G industries of Pakistan were selected for analysis, and a non-probability convenient and judgmental (professional experience) sampling technique was used. The O&G industry has a complex SC environment owing to its flexibility and responsiveness, as numerous activities are involved in procurement, logistics, and scheduling [64,65]. In this context, focusing on agile SC approaches to fulfil customers’ needs requires a limited lead time. The data were collected from November 2021 to January 2022 from SC managers working in the O&G sectors (each manager represented one firm). A total of 200 SC managers were selected, 185 managers participated, and after data cleaning, 152 SC managers were considered suitable for this study. The overall response rate of this survey was 76%.

4. Results and Discussion

4.1. Demographic Analysis

In this study, 185 supply chain managers from oil and gas companies participated in the survey. For analyzing the profiles of respondents, they were asked four questions on their gender, age, qualifications, and experience with oil and gas SCM. Regarding gender, 85.4% were male and 14.6% were female, which shows that Pakistan’s oil and gas sector is predominantly male. Regarding age, 51% of respondents were 36–45, which indicates that the SC managers are experienced. In the context of qualifications, 54% of SC managers had a master’s degree and 19% had a post-graduate degree, which shows that SC managers are generally well educated. Lastly, in terms of respondent experience with oil and gas SCM, 29.72% of SC managers had more than 20 years of experience, and 21.6%, 24.3%, and 16.2% had 6–11, 11–15, and 16–20 years of experience, respectively, which demonstrates that the SC managers are overall experienced and professional. Table 2 presents the respondent profile in detail.

Table 2.

Respondent profile.

4.2. Factor Loading and Reliability Analysis

This study examines the relationship between SC practices (agile and lean) and SCM-related firm performance in the O&G sectors. To evaluate the measures, factor loading and reliability (α) were carried out using SPSS software (IBM, Armonk, NY, USA). The reliability values range from 0.756 to 0.768, i.e., greater than the acceptable value of 0.7. The factor loading ranges from 0.644 to 0.816, i.e., higher than 0.4. The results in Table 3 indicate that the measurement reliability and internal consistency are sufficient.

Table 3.

Factor loading and reliability analysis.

4.3. Descriptive and Correlation Analysis

To validate the relationships among SC practices (i.e., the agile and lean practices and improved SCM-related firm performance) in the context of the O&G sectors, a descriptive and correlation analysis is presented in Table 4. The correlation values of the agile and lean practices with the SCM-related firm performance are 0.236 (p < 0.01) and 0.179 * (p < 0.05), respectively, indicating that agile SCs have a higher impact on firm SCM performance (23.6%). Consequently, lean SC practices are relatively less important (17.9%) for O&G SCs.

Table 4.

Descriptive and correlation analysis.

4.4. Regression Analysis

A regression analysis was conducted to investigate the proposed hypotheses (H1 and H2) and present the impacts of both agile and lean SC practices on SCM-related firm performance. The results (Table 5) indicate that the effects of agile and lean SC practices are positive and significant for SCM-related O&G performance. The agile SC practice has a relatively higher impact (with a beta (β) value of 0.331 and p < 0.05), suggesting that H1 is supported by empirical evidence, i.e., that the Pakistan O&G industry is more focused on agile SC activities.

Table 5.

Hypotheses testing.

The results reveal that in the O&G sector, agile SC practices are highly implemented, and the impact of these agile SC practices is significant for SCM-related firm performance. Lean SC practices have a positive and significant impact on SCM-related firm performance, but a comparatively lower impact than agile SCs. Accordingly, this study concludes that the implementation of agile SCs is common in the O&G sector. The next question is how to improve the agile SC performance. The literature suggests that agile SCs are highly reliant on integration [66,67,68,69] and that integration can be achieved using blockchain technology [44,70]. Additionally, agile SC practices provide flexibility and responsiveness through strong integration among SCM functions, real-time information sharing, cybersecurity, visibility, traceability, reliability, and transparency [71,72,73,74]. Blockchain has the capabilities to provide a technologically oriented platform for supporting the agile SC, uplifting agile integration, and boosting firm performance. However, the literature indicates that the primary function of the lean SC is to increase the firm productivity while minimizing waste. In this context, lean SC practices are recommended for handling the continuous elimination of waste from the production processes, resulting in shorter lead times, lower production costs, and increased output [75,76,77]. Waste is something that customers are not willing to pay for and must be eliminated. To eliminate waste, firms already use effective tools such as total quality control, Kanban (JIY), and Kaizen (continuous improvement) [78,79,80]. Regarding information system support, ERP, industrial IoT, and management information systems (MIS) already provide effective platforms for managing information-sharing systems, transparency, coordination, and the facilitation of information flows among all departments [81,82,83]. To obtain greater benefits from technology, blockchain provides state-of-the-art technology for providing effective information flows, traceability, cyber-security, data management, privacy, and transparency [84]. However, the need for blockchain for lean SCs remains unclear because previously adopted technologies such as ERP, IoT, and MIS are still sufficient to fulfill the information and coordination needs [85,86].

This study observed that an agile SC based on flexibility and responsiveness can be achieved through integration to develop close relationships between suppliers and customers, third-party logistics, and e-procurement practices for managing financial transactions and information sharing. Therefore, secure and transparent information is important for this type of SC network. The blockchain can provide the best solution and enhance integration through real-time information sharing with security and transparency, resulting in increased efficiency by reducing the uncertainty and variation in the information [87,88,89]. The implementation of blockchain technology for confidential information sharing and financial transactions becomes more necessary with an agile supply chain in which many supply chain activities and members are participating, and trust is low. In contrast, the primary objective of lean SC practices is to eliminate waste and improve productivity by using SC practices such as JIT, strategic planning, SC benchmarking, holding safety stock, and having a few suppliers. However, the concepts of reducing waste and timely production also require a strong information-sharing system among all departments [78,79,80,81,82,83]. This can be achieved without blockchain using IoT and ERP [78,79,80,90]. Alternatively, the flow of quality information is also one of the success factors for boosting the internal function of an organization; therefore, implementing blockchain may reduce wasted time and safety threats for information sharing and financial transactions, respectively.

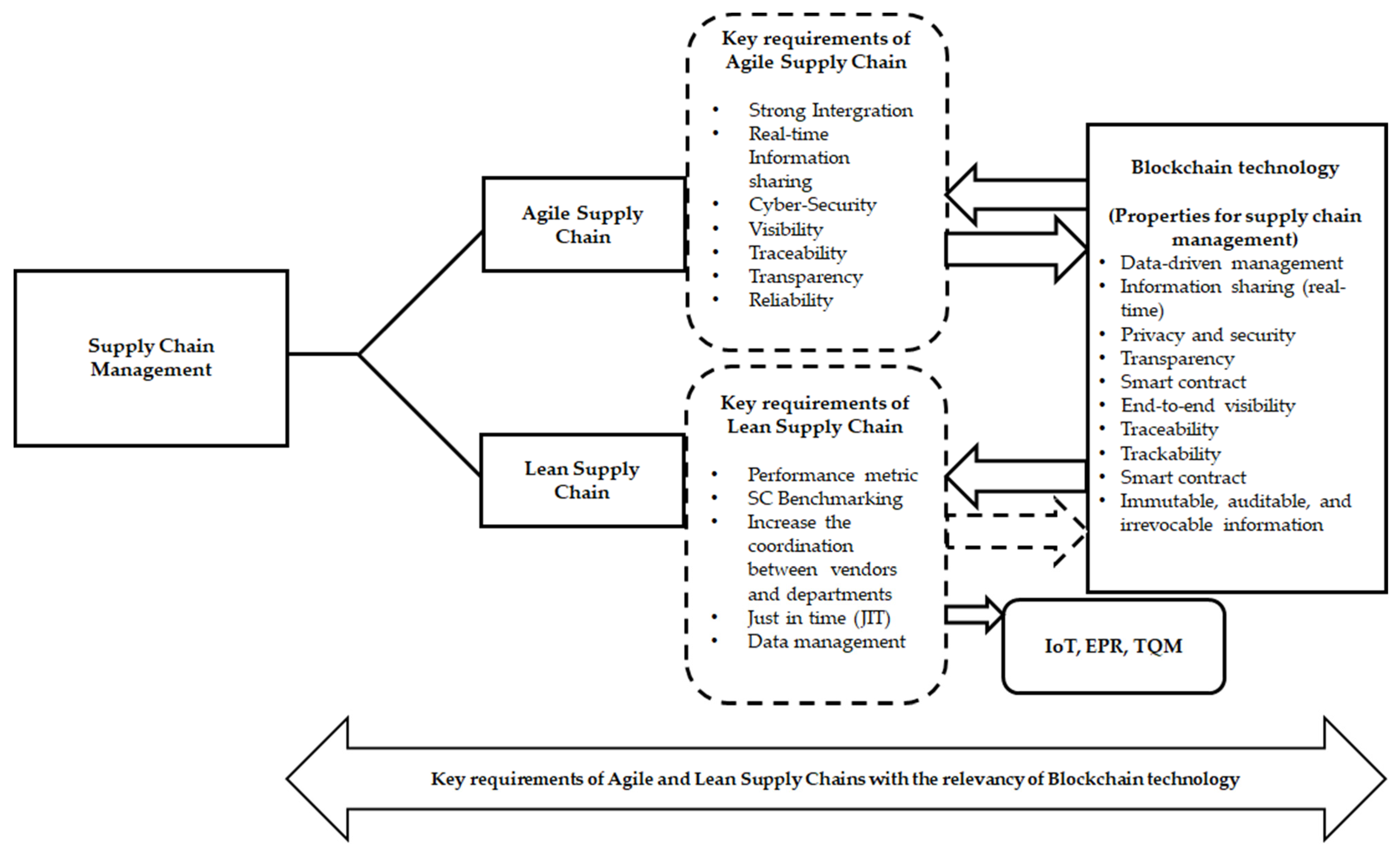

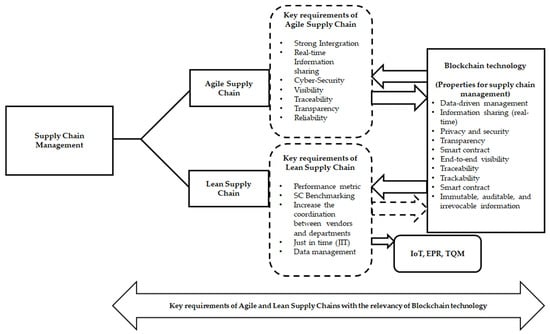

The respective needs for blockchain for agile and lean SCs are illustrated in Figure 3. The literature shows that blockchain has numerous and highly significant properties for SC management. The relevance of blockchain to agile and lean SCs is shown in Table 1. The key requirements of an agile SC are strong integration, real-time information sharing, data privacy, security, visibility, traceability, transparency, and reliability. These requirements are closely related to the blockchain properties for SC management [71,72,73,74]. The key requirements for lean SCs are performance metrics, benchmarking practices, and effective coordination among SC partners, stakeholders, and departments [91,92,93,94]. Blockchain technology is the best solution for fulfilling these requirements, but the literature suggests that these requirements can be fulfilled using less expensive technology-based solutions, such as IoT, ERP, and TQM practices [78,79,80,90]. Therefore, this study concludes that a lean SC is less integrated and has low trust issues because the adoption of blockchain requires a significant amount of capital. The adoption of blockchain according to its properties under the agile and lean SC key requirements described in Table 1 is shown in Figure 3.

Figure 3.

Implication of blockchain for agile and lean supply chains.

Blockchain is considered a game-changing technological innovation for supply chain management because SC professionals and managers believe that the adoption of blockchain boosts SC operation and increases firm capability and capacity [95,96]. Despite the interesting benefits of blockchain described in serval studies, it is also important to discuss the adoption barriers and challenges. This will help the firm to understand the possible barriers to the adoption of novel technology such as blockchain. The possible challenges for adoption are categorized into four types: (i) intra-organizational, (ii) inter-organizational, (iii) system-related, and (iv) external [73,97,98,99,100]. Intra-organizational challenges are related to the problems which arise from internal departments or within the organization. Blockchain technology is a novel technology for supply chain management and requires high investment, and firms face some financial constraints in spending huge amounts of capital on adoption. Thus, financial problems are fundamental challenges for the implementation of blockchain [101,102]. Furthermore, for the adoption of new technology, top managers should provide resources to their employees such as training, new personal computers, and software support and also acquire finance. The oil and gas sector focuses on the procurement, storage, and distribution of oil- and gas-related products. The top management is highly interested in investing the maximum resources to buy the products rather than spending to implement new technologies such as blockchain because it is capital-intensive technology [103]. Inter-organizational challenges refer to external stakeholders such as SC members (customers, suppliers, investors, third-party logistics contractors). Oil and gas SCs deal with different geographic locations, and the SCM culture can also be affected, e.g., because a partner did not understand the importance of blockchain and they were not willing to use it. If the customer is not aware of blockchain’s benefits for shipment and delivery tracking, then the firm should not invest in implementing blockchain. System-related barriers are related to new information technology (IT) tools because blockchain is IT-based software, and it requires new IT tools. Thus, firms need to replace previous technology structures with the latest ones. For example, blockchain provides real-time information and records high-volume data as well as gives access to all SC participants. Therefore, high data storage and advanced cloud computing systems will be demanded [104,105]. The external barriers refer to external institutions such as governments and industries which are not directly related to firm SC functions. The lack of involvement from the government to support the firms in adopting the new technology [106,107]. On the other hand, the lack of pressure from competitors is another barrier to adopting blockchain because still, few oil and gas companies are using blockchain.

5. Conclusions

This paper provides an understanding of the adoption of blockchain in supply chains in the context of the agile and lean SC types that have been described in the literature [16,36,37,38,39]. For this purpose, we chose O&G industries to validate the implications of agile and lean SCs and the impact on firm SCM-related performance. With reference to the literature, SC practices were identified and divided into two SC types: agile and lean. The results revealed that both SC types positively and significantly impact a firm’s performance in the O&G industries. Additionally, agile SC is more important for O&G industries in comparison to lean SC. With the help of an extensive literature review, this study contributes to developing the need for blockchain technology for supply chain management in the context of agile and lean SCs [108,109,110]. Agile supply chains deal with complex supply chain networks and focus on increasing flexibility and responsiveness in the competitive environment and can be boosted with the adoption of blockchain. However, lean supply chains focus on eliminating waste and increasing the firm’s productivity and can be achieved using less expensive technology such as ERP and IoT. Therefore, agile SC is better suited for the adoption of blockchain because this technology has state-of-the-art properties such as data-driven management, information sharing, data privacy, cyber-security, transparency, smart contracts, visibility, traceability, and reliability, which are highly aligned with the key requirements of agile SC, such as strong integration and real-time information sharing.

5.1. Implications

This study has managerial and practical implications. From a managerial point of view, this study provides a distinction between lean and agile SC along with blockchain properties. This study highlights the implementation of blockchain according to supply chain types. Furthermore, this study develops the relevancy of blockchain technology for SCM, as well as how blockchain is suitable for an agile supply chain. From a practical point of view, this study gives examples of the adaptation of blockchain for the supply chain and suggests that supply chain managers or decision makers evaluate their supply chain types according to agile and lean, and then focus on the implementation of blockchain technology because the adoption of blockchain is costly and requires significant capital. Finally, we conclude that blockchain technology is recommended for agile-based supply chain firms.

5.2. Limitations and Future Work

The main limitation of this study is that developing the relevancy of blockchain properties with agile and lean supply chains is based on the literature and could not be expressed empirically. This study considered only the oil and gas sectors for analysis; other sectors such as manufacturing and services were not included. Due to the high capital investments required for blockchain adoption, we propose future work on a new concept of “blockchain as services”. This technique will provide customized blockchain services for supply chains according to their requirements, but it needs to be explored in further studies. Moreover, the adoption of blockchain is not easy, and we suggest that future studies consider the potential barriers and challenges to the adoption and implication of blockchain.

Author Contributions

Conceptualization, J.A. and Y.B.K.; methodology, N.T.K. and A.S.; software, J.A.; validation, J.A., A.S. and Y.B.K.; formal analysis, N.T.K.; investigation, J.A.; resources, Y.B.K.; data curation, J.A.; writing—original draft preparation, J.A. and A.S.; writing—review and editing, N.T.K. and Y.B.K.; visualization, J.A.; supervision, Y.B.K.; project administration, Y.B.K.; funding acquisition, Y.B.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Research Foundation of Korea (NRF), a grant funded by the Korea Government (MSIT) (NRF-2022R1A2C1013147).

Data Availability Statement

Data will be provided upon request to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Survey Questions

Appendix A.1. Respondent Profile

| Sr. No. | Variable | Options |

| 1 | Gender | Male |

| Female | ||

| 2 | Age (in years) | 20–25 |

| 26–30 | ||

| 31–45 | ||

| 46–50 | ||

| Above 50 | ||

| 3 | Qualification | Diploma |

| Under-graduation | ||

| Master | ||

| Post-graduation | ||

| 4 | Total experience in oil and gas supply chain management (in years) | <5 |

| 6–10 | ||

| 11–15 | ||

| 16–20 | ||

| >20 |

Appendix A.2. Model-Related Questions

Table A1.

Agile supply chain practices. Q1. To what extent were the following agile SC practices implemented in your organization? [1 = not at all implemented; 2 = not implemented; 3 = partially implemented; 4 = implemented; 5 = fully implemented].

Table A1.

Agile supply chain practices. Q1. To what extent were the following agile SC practices implemented in your organization? [1 = not at all implemented; 2 = not implemented; 3 = partially implemented; 4 = implemented; 5 = fully implemented].

| Sr | Questions | (Five-Point Likert Scale Ranging from 1 = “Not at all Implemented” to 5 = ”Fully Implemented”) | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| 1 | Close relationship with customers | |||||

| 2 | Close relationship with suppliers | |||||

| 3 | Outsourcing | |||||

| 4 | E-procurement | |||||

| 5 | Third-party logistics (3PL) | |||||

| 6 | Subcontracting | |||||

| 7 | Many suppliers | |||||

Table A2.

Lean supply chain practices. Q2. To what extent were the following lean SC practices implemented in your organizations? [1 = not at all implemented; 2 = not implemented; 3 = partially implemented; 4 = implemented; 5 = fully implemented].

Table A2.

Lean supply chain practices. Q2. To what extent were the following lean SC practices implemented in your organizations? [1 = not at all implemented; 2 = not implemented; 3 = partially implemented; 4 = implemented; 5 = fully implemented].

| Sr | Questions | (Five-Point Likert Scale Ranging from 1 = “Not at all Implemented” to 5 = ” Fully Implemented”) | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| 1 | Just in time (JIT) | |||||

| 2 | Strategic planning | |||||

| 3 | Supply chain benchmarking | |||||

| 4 | Holding safety stock | |||||

| 5 | Few suppliers | |||||

Table A3.

Supply chain-related firm performance. Q3. How did your business perform over the past five years relative to major competitors on each of the firm’s performance criteria using SCM practices? [1 = definitely worse; 2 = worse; 3 = somewhat worse/better; 4 = better; 5 = definitely better].

Table A3.

Supply chain-related firm performance. Q3. How did your business perform over the past five years relative to major competitors on each of the firm’s performance criteria using SCM practices? [1 = definitely worse; 2 = worse; 3 = somewhat worse/better; 4 = better; 5 = definitely better].

| Sr | Questions | (Five-Point Likert Scale Ranging from 1 = “Definitely Worse” to 5 = ”Definitely Better”) | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| 1 | More accurate costing | |||||

| 2 | Increase in sales | |||||

| 3 | Increase the coordination among suppliers | |||||

| 4 | Increase the coordination among customers | |||||

| 5 | Increase the coordination among departments | |||||

References

- Ahmad, W.N.K.W.; Rezaei, J.; de Brito, M.P.; Tavasszy, L.A. The influence of external factors on supply chain sustainability goals of the oil and gas industry. Resour. Policy 2016, 49, 302–314. [Google Scholar] [CrossRef]

- Bastas, A.; Liyanage, K. Integrated quality and supply chain management business diagnostics for organizational sustainability improvement. Sustain. Prod. Consum. 2019, 17, 11–30. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhao, J.; Bush, A.A. The effects of e-business processes in supply chain operations: Process component and value creation mechanisms. Int. J. Inf. Manage. 2020, 50, 273–285. [Google Scholar] [CrossRef]

- Kumar, V.; Bak, O.; Guo, R.; Shaw, S.L.; Colicchia, C.; Garza-Reyes, J.A.; Kumari, A. An empirical analysis of supply and manufacturing risk and business performance: A Chinese manufacturing supply chain perspective. Supply Chain Manag. Int. J. 2018, 23, 461–479. [Google Scholar] [CrossRef]

- Muheidat, F.; Patel, D.; Tammisetty, S.; Tawalbeh, L.A.; Tawalbeh, M. Emerging Concepts Using Blockchain and Big Data. Procedia Comput. Sci. 2022, 198, 15–22. [Google Scholar] [CrossRef]

- Haroon, A.; Basharat, M.; Khattak, A.M.; Ejaz, W. Internet of Things Platform for Transparency and Traceability of Food Supply Chain. In Proceedings of the 2019 IEEE 10th Annual Information Technology, Electronics and Mobile Communication Conference (IEMCON), Columbia, VA, Canada, 17–19 October 2019; pp. 13–19. [Google Scholar]

- Özdağoğlu, A.; Bahar, S. Logistics 4.0 and Smart Supply Chain Management. In Industry 4.0 and Global Businesses; Yakut, E., Ed.; Emerald Publishing Limited: Bingley, UK, 2022; pp. 163–183. ISBN1 978-1-80117-326-1. ISBN2 978-1-80117-327-8. [Google Scholar]

- Yousefi, S.; Tosarkani, B.M. An analytical approach for evaluating the impact of blockchain technology on sustainable supply chain performance. Int. J. Prod. Econ. 2022, 246, 108429. [Google Scholar] [CrossRef]

- Caiado, R.G.; Scavarda, L.F.; Azevedo, B.D.; de Mattos Nascimento, D.L.; Quelhas, O.L. Challenges and Benefits of Sustainable Industry 4.0 for Operations and Supply Chain Management—A Framework Headed toward the 2030 Agenda. Sustainability 2022, 14, 830. [Google Scholar]

- Raji, I.O.; Shevtshenko, E.; Rossi, T.; Strozzi, F. Industry 4.0 technologies as enablers of lean and agile supply chain strategies: An exploratory investigation. Int. J. Logist. Manag. 2021, 32, 1150–1189. [Google Scholar] [CrossRef]

- Santhi, A.R.; Muthuswamy, P. Influence of Blockchain Technology in Manufacturing Supply Chain and Logistics. Logist 2022, 6, 15. [Google Scholar] [CrossRef]

- Hussein, M.; Zayed, T. Critical factors for successful implementation of just-in-time concept in modular integrated construction: A systematic review and meta-analysis. J. Clean. Prod. 2021, 284, 124716. [Google Scholar] [CrossRef]

- Raut, R.D.; Mangla, S.K.; Narwane, V.S.; Dora, M.; Liu, M. Big Data Analytics as a mediator in Lean, Agile, Resilient, and Green (LARG) practices effects on sustainable supply chains. Transp. Res. Part E Logist. Transp. Rev. 2021, 145, 102170. [Google Scholar] [CrossRef]

- Garcia-Buendia, N.; Moyano-Fuentes, J.; Maqueira-Marín, J.M. Lean supply chain management and performance relationships: What has been done and what is left to do. CIRP J. Manuf. Sci. Technol. 2021, 32, 405–423. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Patel, C.; McGaughey, R.E. A framework for supply chain performance measurement. Int. J. Prod. Econ. 2004, 87, 333–347. [Google Scholar] [CrossRef]

- Koh, S.C.L.; Demirbag, M.; Bayraktar, E.; Tatoglu, E.; Zaim, S. The impact of supply chain management practices on performance of SMEs. Ind. Manag. Data Syst. 2007, 107, 103–124. [Google Scholar] [CrossRef]

- Gandhi, A.V.; Shaikh, A.; Sheorey, P.A. Impact of supply chain management practices on firm performance: Empirical evidence from a developing country. Int. J. Retail Distrib. Manag. 2017, 45, 366–384. [Google Scholar] [CrossRef]

- Verhoef, P.C.; Broekhuizen, T.; Bart, Y.; Bhattacharya, A.; Dong, J.Q.; Fabian, N.; Haenlein, M. Digital transformation: A multidisciplinary reflection and research agenda. J. Bus. Res. 2019, 122, 890–901. [Google Scholar] [CrossRef]

- Zhu, X.N.; Peko, G.; Sundaram, D.; Piramuthu, S. Blockchain-Based Agile Supply Chain Framework with IoT. Inf. Syst. Front. 2021, 24, 563–578. [Google Scholar] [CrossRef]

- Oliveira-Dias, D.; Maqueira-Marín, J.M.; Moyano-Fuentes, J. The link between information and digital technologies of industry 4.0 and agile supply chain: Mapping current research and establishing new research avenues. Comput. Ind. Eng. 2022, 167, 108000. [Google Scholar] [CrossRef]

- Takeda-Berger, S.L.; Tortorella, G.L.; Rodriguez, C.M.T.; Frazzon, E.M.; Yokoyama, T.T.; Oliveira, M.A. de Analysis of the relationship between barriers and practices in the lean supply chain management. Int. J. Lean Six Sigma 2021, 12, 607–626. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Miorando, R.; Marodin, G. Lean supply chain management: Empirical research on practices, contexts and performance. Int. J. Prod. Econ. 2017, 193, 98–112. [Google Scholar] [CrossRef]

- Koroteev, D.; Tekic, Z. Artificial intelligence in oil and gas upstream: Trends, challenges, and scenarios for the future. Energy AI 2021, 3, 100041. [Google Scholar] [CrossRef]

- Petroleum Sector of Pakistan and its Trade Dynamics. Available online: https://tdap.gov.pk/wp-content/uploads/2022/03/13-Petroleum-Sector-of-Pakistan-and-its-Trade-Dynamics-1.pdf (accessed on 28 November 2022).

- Ghode, D.; Yadav, V.; Jain, R.; Soni, G. Adoption of blockchain in supply chain: An analysis of influencing factors. J. Enterp. Inf. Manag. 2020, 33, 437–456. [Google Scholar] [CrossRef]

- Gohil, D.; Thakker, S.V. Blockchain-integrated technologies for solving supply chain challenges. Mod. Supply Chain Res. Appl. 2021, 3, 78–97. [Google Scholar] [CrossRef]

- Francisco, K.; Swanson, D. The Supply Chain Has No Clothes: Technology Adoption of Blockchain for Supply Chain Transparency. Logistics 2018, 2, 2. [Google Scholar] [CrossRef]

- Madhwal, Y.; Panfilov, P.B. Blockchain and supply chain management: Aircrafts’ parts’ business case. Ann. DAAAM Proc. Int. DAAAM Symp. 2017, 28, 1051–1056. [Google Scholar] [CrossRef]

- Helo, P.; Hao, Y. Blockchains in operations and supply chains: A model and reference implementation. Comput. Ind. Eng. 2019, 136, 242–251. [Google Scholar] [CrossRef]

- Treiblmaier, H. The impact of the blockchain on the supply chain: A theory-based research framework and a call for action. Supply Chain. Manag. 2018, 23, 545–559. [Google Scholar] [CrossRef]

- Halldórsson, Á.; Hsuan, J.; Kotzab, H. Complementary theories to supply chain management revisited—from borrowing theories to theorizing. Supply Chain. Manag. 2015, 20, 574–586. [Google Scholar] [CrossRef]

- Somjai, S.; Jermsittiparsert, K. Mediating impact of information sharing in the relationship of supply chain capabilities and business performance among the firms of Thailand. Int. J. Supply Chain Manag. 2019, 8, 357–368. [Google Scholar]

- Lummus, R.R.; Vokurka, R.J. Defining supply chain management: A historical perspective and practical guidelines Introduction to supply chain concepts Definition of supply chain. Ind. Manag. Data Syst. 1997, 99, 11–17. [Google Scholar] [CrossRef]

- Min, S.; Zacharia, Z.G.; Smith, C.D. Defining Supply Chain Management: In the Past, Present, and Future. J. Bus. Logist. 2019, 40, 44–55. [Google Scholar] [CrossRef]

- Pettit, T.J.; Croxton, K.L.; Fiksel, J. The Evolution of Resilience in Supply Chain Management: A Retrospective on Ensuring Supply Chain Resilience. J. Bus. Logist. 2019, 40, 56–65. [Google Scholar] [CrossRef]

- Towill, D.; Christopher, M. The Supply Chain Strategy Conundrum: To be Lean Or Agile or To be Lean And Agile? Int. J. Logist. Res. Appl. 2002, 5, 299–309. [Google Scholar] [CrossRef]

- Qrunfleh, S.; Tarafdar, M. Lean and agile supply chain strategies and supply chain responsiveness: The role of strategic supplier partnership and postponement. Supply Chain Manag. Int. J. 2013, 18, 571–582. [Google Scholar] [CrossRef]

- Piotrowicz, W.D.; Ryciuk, U.; Szymczak, M. Lean and agile metrics. Literature review and framework for measuring leagile supply chain. Int. J. Product. Perform. Manag. 2021. ahead-of-print. [Google Scholar] [CrossRef]

- Ali, S.; Shin, W.S.; Song, H. Blockchain-Enabled Open Quality System for Smart Manufacturing: Applications and Challenges. Sustainability 2022, 14, 11677. [Google Scholar] [CrossRef]

- Christopher, M.; Lowson, R.; Peck, H. Creating agile supply chains in the fashion industry. Int. J. Retail Distrib. Manag. 2004, 32, 367–376. [Google Scholar] [CrossRef]

- Swafford, P.M.; Ghosh, S.; Murthy, N. Achieving supply chain agility through IT integration and flexibility. Int. J. Prod. Econ. 2008, 116, 288–297. [Google Scholar] [CrossRef]

- Kshetri, N. Blockchain and Supply Chain Management; Elsevier Science: Amsterdam, The Netherlands, 2021; ISBN 9780323899352. [Google Scholar]

- Queiroz, M.M.; Telles, R.; Bonilla, S.H. Blockchain and supply chain management integration: A systematic review of the literature. Supply Chain Manag. Int. J. 2020, 25, 241–254. [Google Scholar] [CrossRef]

- Aslam, J.; Saleem, A.; Khan, N.T.; Kim, Y.B. Factors influencing blockchain adoption in supply chain management practices: A study based on the oil industry. J. Innov. Knowl. 2021, 6, 124–134. [Google Scholar] [CrossRef]

- Sheel, A.; Nath, V. Effect of blockchain technology adoption on supply chain adaptability, agility, alignment and performance. Manag. Res. Rev. 2019, 42, 1353–1374. [Google Scholar] [CrossRef]

- Kurpjuweit, S.; Schmidt, C.G.; Klöckner, M.; Wagner, S.M. Blockchain in Additive Manufacturing and its Impact on Supply Chains. J. Bus. Logist. 2021, 42, 46–70. [Google Scholar] [CrossRef]

- Ahram, T.; Sargolzaei, A.; Sargolzaei, S.; Daniels, J.; Amaba, B. Blockchain technology innovations. In Proceedings of the 2017 IEEE Technology Engineering Management Conference (TEMSCON), Santa Clara, CA, USA, 8–10 June 2017; pp. 137–141. [Google Scholar]

- Cole, R.; Stevenson, M.; Aitken, J. Blockchain technology: Implications for operations and supply chain management. Supply Chain Manag. Int. J. 2019, 24, 469–483. [Google Scholar] [CrossRef]

- Myerson, P. Lean Supply Chain and Logistics Management, 1st ed.; McGraw-Hill Education: New York, NY, USA, 2012; ISBN 9780071766265. [Google Scholar]

- Arif-Uz-Zaman, K.; Nazmul Ahsan, A.M.M. Lean supply chain performance measurement. Int. J. Product. Perform. Manag. 2014, 63, 588–612. [Google Scholar] [CrossRef]

- Hearnshaw, E.J.S.; Wilson, M.M.J. A complex network approach to supply chain network theory. Int. J. Oper. Prod. Manag. 2013, 33, 442–469. [Google Scholar] [CrossRef]

- Li, S.; Rao, S.S.; Ragu-Nathan, T.S.; Ragu-Nathan, B. Development and validation of a measurement instrument for studying supply chain management practices. J. Oper. Manag. 2005, 23, 618–641. [Google Scholar] [CrossRef]

- Agus, A.; Hajinoor, M.S. Lean production supply chain management as driver towards enhancing product quality and business performance: Case study of manufacturing companies in Malaysia. Int. J. Qual. Reliab. Manag. 2012, 29, 92–121. [Google Scholar] [CrossRef]

- Juan Ding, M.; Jie, F.; Parton, K.A.; Matanda, M.J. Relationships between quality of information sharing and supply chain food quality in the Australian beef processing industry. Int. J. Logist. Manag. 2014, 25, 85–108. [Google Scholar] [CrossRef]

- Nimeh, H.A.; Abdallah, A.B.; Sweis, R. Lean supply chain management practices and performance: Empirical evidence from manufacturing companies. Int. J. Supply Chain Manag. 2018, 7, 1–15. [Google Scholar]

- Kwon, I.G.; Suh, T. Trust, commitment and relationships in supply chain management: A path analysis. Supply Chain Manag. Int. J. 2005, 10, 26–33. [Google Scholar] [CrossRef]

- Ibrahim, S.E.; Ogunyemi, O. The effect of linkages and information sharing on supply chain and export performance. J. Manuf. Technol. Manag. 2012, 23, 441–463. [Google Scholar] [CrossRef]

- Powell, D. ERP systems in lean production: New insights from a review of lean and ERP literature. Int. J. Oper. Prod. Manag. 2013, 33, 1490–1510. [Google Scholar] [CrossRef]

- Powell, D.; Alfnes, E.; Strandhagen, J.O.; Dreyer, H. ERP Support for Lean Production BT—Advances in Production Management Systems. Value Networks: Innovation, Technologies, and Management; Frick, J., Laugen, B.T., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 115–122. [Google Scholar]

- Ghode, D.J.; Yadav, V.; Jain, R.; Soni, G. Blockchain adoption in the supply chain: An appraisal on challenges. J. Manuf. Technol. Manag. 2021, 32, 42–62. [Google Scholar] [CrossRef]

- Suhail, S.; Hussain, R.; Jurdak, R.; Oracevic, A.; Salah, K.; Hong, C.S.; Matulevičius, R. Blockchain-Based Digital Twins: Research Trends, Issues, and Future Challenges. ACM Comput. Surv. 2022, 54, 1–34. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Vecchio, P.D.; Oropallo, E.; Secundo, G. Blockchain technology for bridging trust, traceability and transparency in circular supply chain. Inf. Manag. 2021, 59, 103508. [Google Scholar] [CrossRef]

- Yang, W.; Garg, S.; Huang, Z.; Kang, B. A decision model for blockchain applicability into knowledge-based conversation system. Knowl.-Based Syst. 2021, 220, 106791. [Google Scholar] [CrossRef]

- Ahmad, N.K.W.; de Brito, M.P.; Rezaei, J.; Tavasszy, L.A. An integrative framework for sustainable supply chain management practices in the oil and gas industry. J. Environ. Plan. Manag. 2017, 60, 577–601. [Google Scholar] [CrossRef]

- Saad, S.M.; Elsaghier, E.H.; Ezaga, D. Planning and optimising petroleum supply chain. Procedia Manuf. 2018, 17, 803–810. [Google Scholar] [CrossRef]

- Ariadi, G.; Surachman; Sumiati; Rohman, F. The effect of lean and agile supply chain strategy on financial performance with mediating of strategic supplier integration & strategic customer integration: Evidence from bottled drinking-water industry in Indonesia. Cogent Bus. Manag. 2021, 8, 1930500. [Google Scholar] [CrossRef]

- Oliveira-Dias, D.; Moyano-Fuentes, J.; Maqueira-Marín, J.M. Understanding the relationships between information technology and lean and agile supply chain strategies: A systematic literature review. Ann. Oper. Res. 2022, 312, 973–1005. [Google Scholar] [CrossRef]

- Christopher, M.; Towill, D. An integrated model for the design of agile supply chains. Int. J. Phys. Distrib. Logist. Manag. 2001, 31, 235–246. [Google Scholar] [CrossRef]

- Alzoubi, H.M.; Elrehail, H.; Hanaysha, J.R.; Al-Gasaymeh, A.; Al-Adaileh, R. The Role of Supply Chain Integration and Agile Practices in Improving Lead Time During the COVID-19 Crisis. Int. J. Serv. Sci. Manag. Eng. Technol. 2021, 13, 1–11. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Subramanian, N.; Ghadge, A.; Belhadi, A.; Venkatesh, M. Blockchain technology’s impact on supply chain integration and sustainable supply chain performance: Evidence from the automotive industry. Ann. Oper. Res. 2021, 1–26. [Google Scholar] [CrossRef]

- Jafari, H.; Ghaderi, H.; Malik, M.; Bernardes, E. The effects of supply chain flexibility on customer responsiveness: The moderating role of innovation orientation. Prod. Plan. Control 2022, 1–19. [Google Scholar] [CrossRef]

- Nandi, S.; Sarkis, J.; Hervani, A.A.; Helms, M.M. Redesigning Supply Chains using Blockchain-Enabled Circular Economy and COVID-19 Experiences. Sustain. Prod. Consum. 2021, 27, 10–22. [Google Scholar] [CrossRef]

- Saleem, A.; Aslam, J.; Kim, Y.B.; Nauman, S.; Khan, N.T. Motives towards e-Shopping Adoption among Pakistani Consumers: An Application of the Technology Acceptance Model and Theory of Reasoned Action. Sustainability 2022, 14, 4180. [Google Scholar] [CrossRef]

- Wang, Y.; Han, J.H.; Beynon-Davies, P. Understanding blockchain technology for future supply chains: A systematic literature review and research agenda. Supply Chain Manag. Int. J. 2019, 24, 62–84. [Google Scholar] [CrossRef]

- Iranmanesh, M.; Zailani, S.; Hyun, S.S.; Ali, M.H.; Kim, K. Impact of lean manufacturing practices on firms’ sustainable performance: Lean culture as a moderator. Sustain 2019, 11, 1112. [Google Scholar] [CrossRef]

- Afonso, H.; Cabrita, M.D.R. Developing a Lean Supply Chain Performance Framework in a SME: A Perspective Based on the Balanced Scorecard. Procedia Eng. 2015, 131, 270–279. [Google Scholar] [CrossRef]

- Hajmohammad, S.; Vachon, S.; Klassen, R.D.; Gavronski, I. Lean management and supply management: Their role in green practices and performance. J. Clean. Prod. 2013, 39, 312–320. [Google Scholar] [CrossRef]

- Rahman, N.A.A.; Sharif, S.M.; Esa, M.M. Lean Manufacturing Case Study with Kanban System Implementation. Procedia Econ. Financ. 2013, 7, 174–180. [Google Scholar] [CrossRef]

- Anvari, A.; Ismail, Y. A Study on Total Quality Management and Lean Manufacturing: Through Lean Thinking Approach Personnel Selection View project A method for calculating average run length by the use of markov chain View project. World Appl. Sci. J. 2011, 12, 1585–1596. [Google Scholar]

- Chiarini, A.; Baccarani, C.; Mascherpa, V. Lean production, Toyota Production System and Kaizen philosophy. TQM J. 2018, 30, 425–438. [Google Scholar] [CrossRef]

- Beheshti, H.M.; Beheshti, C.M. Improving productivity and firm performance with enterprise resource planning. Enterp. Inf. Syst. 2010, 4, 445–472. [Google Scholar] [CrossRef]

- Jasperneite, J.; Sauter, T.; Wollschlaeger, M. Why We Need Automation Models: Handling Complexity in Industry 4.0 and the Internet of Things. IEEE Ind. Electron. Mag. 2020, 14, 29–40. [Google Scholar] [CrossRef]

- Valentinetti, D.; Muñoz, F.F. Internet of things: Emerging impacts on digital reporting. J. Bus. Res. 2021, 131, 549–562. [Google Scholar] [CrossRef]

- Agi, M.A.N.; Jha, A.K. Blockchain technology in the supply chain: An integrated theoretical perspective of organizational adoption. Int. J. Prod. Econ. 2022, 247, 108458. [Google Scholar] [CrossRef]

- Kumar, R.L.; Khan, F.; Kadry, S.; Rho, S. A Survey on blockchain for industrial Internet of Things. Alexandria Eng. J. 2022, 61, 6001–6022. [Google Scholar] [CrossRef]

- Pérez, A.T.E.; Rossit, D.A.; Tohmé, F.; Vásquez, Ó.C. Mass customized/personalized manufacturing in Industry 4.0 and blockchain: Research challenges, main problems, and the design of an information architecture. Inf. Fusion 2022, 79, 44–57. [Google Scholar] [CrossRef]

- Kim, J.S.; Shin, N. The impact of blockchain technology application on supply chain partnership and performance. Sustainability 2019, 11, 6181. [Google Scholar] [CrossRef]

- Koçoǧlu, I.; Imamoǧlu, S.Z.; Ince, H.; Keskin, H. The effect of supply chain integration on information sharing: Enhancing the supply chain performance. Procedia Soc. Behav. Sci. 2011, 24, 1630–1649. [Google Scholar] [CrossRef]

- Jayaram, J.; Tan, K.C.; Nachiappan, S.P. Examining the interrelationships between supply chain integration scope and supply chain management efforts. Int. J. Prod. Res. 2010, 48, 6837–6857. [Google Scholar] [CrossRef]

- Tavana, M.; Hajipour, V.; Oveisi, S. IoT-based enterprise resource planning: Challenges, open issues, applications, architecture, and future research directions. Internet Things 2020, 11, 100262. [Google Scholar] [CrossRef]

- Fu, Q.; Rahman, A.A.A.; Jiang, H.; Abbas, J.; Comite, U. Sustainable Supply Chain and Business Performance: The Impact of Strategy, Network Design, Information Systems, and Organizational Structure. Sustainability 2022, 14, 1080. [Google Scholar] [CrossRef]

- Van Der Vorst, J. Supply Chain Management: Theory and practices. Emerg. Sci. Chain. Networks Bridg. Theory Pract. 2004, 1–19. [Google Scholar]

- Singh, H.; Garg, R.K.; Sachdeva, A. Supply chain collaboration: A state-of-the-art literature review. Uncertain Supply Chain. Manag. 2018, 6, 149–180. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Oropallo, E.; El-Garaihy, W.H.; Farag, T.; Al Shehri, K.H. Towards a sustainable development assessment framework to bridge supply chain practices and technologies. Sustain. Dev. 2021, 30, 647–663. [Google Scholar] [CrossRef]

- Nandi, S.; Sarkis, J.; Hervani, A.; Helms, M. Do blockchain and circular economy practices improve post COVID-19 supply chains? A resource-based and resource dependence perspective. Ind. Manag. Data Syst. 2021, 121, 333–363. [Google Scholar] [CrossRef]

- Rejeb, A.; Keogh, J.G.; Simske, S.J.; Stafford, T.; Treiblmaier, H. Potentials of blockchain technologies for supply chain collaboration: A conceptual framework. Int. J. Logist. Manag. 2021, 32, 973–994. [Google Scholar] [CrossRef]

- Sadouskaya, K. Adoption of Blockchain Technology in Supply Chain and Logistics. South-Eastern Finl. Univ. Appl. Sci. Finl. 2017, 20–25. [Google Scholar]

- Jardim, L.; Pranto, S.; Ruivo, P.; Oliveira, T. What are the main drivers of Blockchain Adoption within Supply Chain?—An exploratory research. Procedia Comput. Sci. 2021, 181, 495–502. [Google Scholar] [CrossRef]

- Chen, S.; Liu, X.; Yan, J.; Hu, G.; Shi, Y. Processes, benefits, and challenges for adoption of blockchain technologies in food supply chains: A thematic analysis. Inf. Syst. E-bus. Manag. 2021, 19, 909–935. [Google Scholar] [CrossRef]

- Katsikouli, P.; Wilde, A.S.; Dragoni, N.; Høgh-Jensen, H. On the benefits and challenges of blockchains for managing food supply chains. J. Sci. Food Agric. 2021, 101, 2175–2181. [Google Scholar] [CrossRef] [PubMed]

- Astarita, V.; Giofrè, V.P.; Mirabelli, G.; Solina, V. A Review of Blockchain-Based Systems in Transportation. Information 2020, 11, 21. [Google Scholar] [CrossRef]

- Choi, T.M. Supply chain financing using blockchain: Impacts on supply chains selling fashionable products. Ann. Oper. Res. 2020, 1–23. [Google Scholar] [CrossRef]

- Kim, H.; Laskowski, M. A Perspective on Blockchain Smart Contracts: Reducing Uncertainty and Complexity in Value Exchange. In Proceedings of the 2017 26th International Conference on Computer Communication and Networks (ICCCN), Vancouver, BC, Canada, 31 July–3 August 2017; pp. 1–6. [Google Scholar]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef]

- Vu, N.; Ghadge, A.; Bourlakis, M. Blockchain adoption in food supply chains: A review and implementation framework. Prod. Plan. Control 2021, 1–18. [Google Scholar] [CrossRef]

- Zhou, Y.; Soh, Y.S.; Loh, H.S.; Yuen, K.F. The key challenges and critical success factors of blockchain implementation: Policy implications for Singapore’s maritime industry. Mar. Policy 2020, 122, 104265. [Google Scholar] [CrossRef]

- Toufaily, E.; Zalan, T.; Dhaou, S. Ben A framework of blockchain technology adoption: An investigation of challenges and expected value. Inf. Manag. 2021, 58, 103444. [Google Scholar] [CrossRef]

- Zehir, C.; Zehir, M.; Borodin, A.; Mamedov, Z.F.; Qurbanov, S. Tailored Blockchain Applications for the Natural Gas Industry: The Case Study of SOCAR. Energies 2022, 15, 6010. [Google Scholar] [CrossRef]

- Ara, R.A.; Paardenkooper, K.; van Duin, R. A new blockchain system design to improve the supply chain of engineering, procurement and construction (EPC) companies—a case study in the oil and gas sector. J. Eng. Des. Technol. 2022, 20, 887–913. [Google Scholar] [CrossRef]

- Ahmad, R.W.; Salah, K.; Jayaraman, R.; Yaqoob, I.; Omar, M. Blockchain in oil and gas industry: Applications, challenges, and future trends. Technol. Soc. 2022, 68, 101941. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).