The Design and Magnetic Field Analysis of a Double Rotor Permanent Magnet Braking Device

Abstract

:1. Introduction

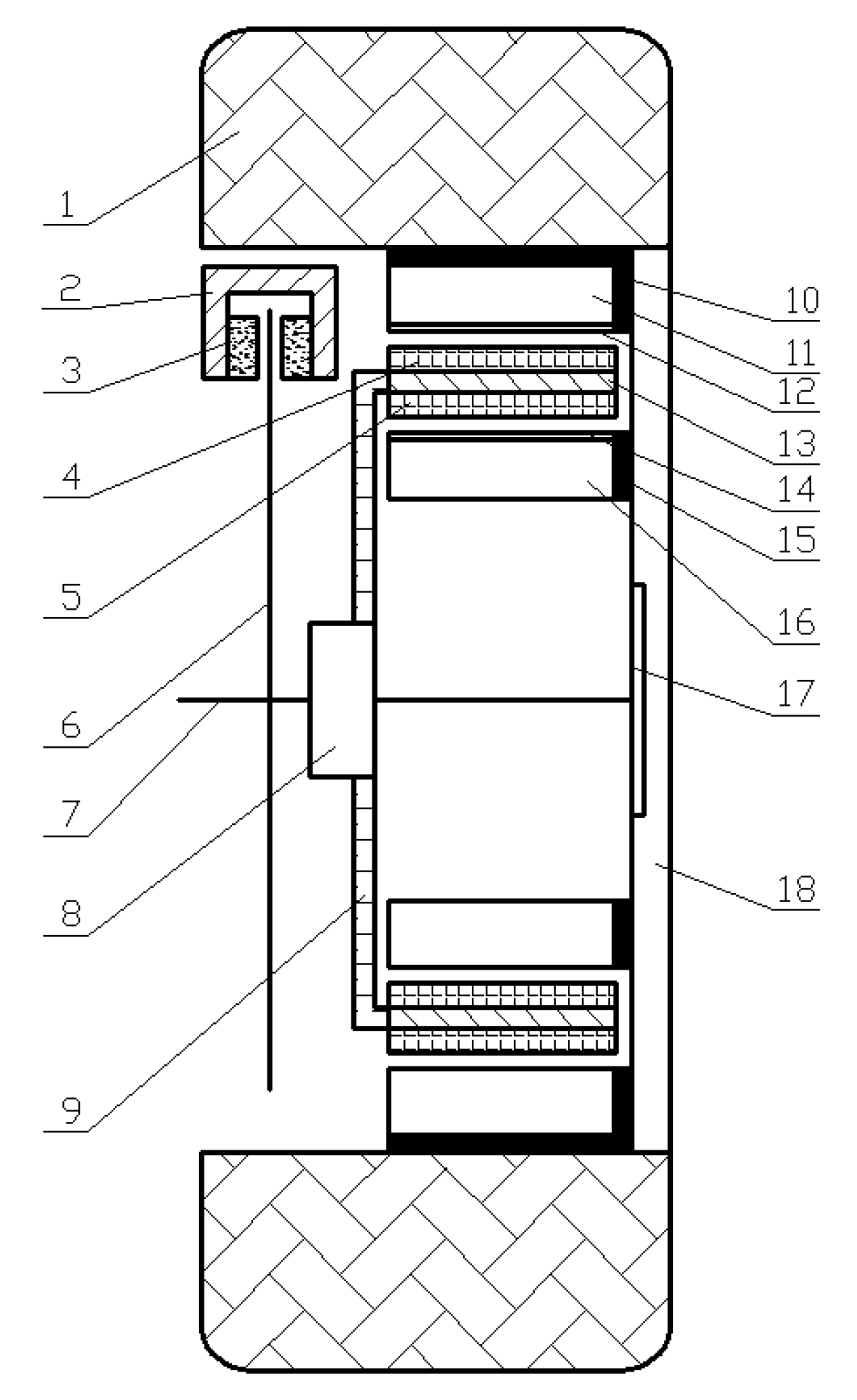

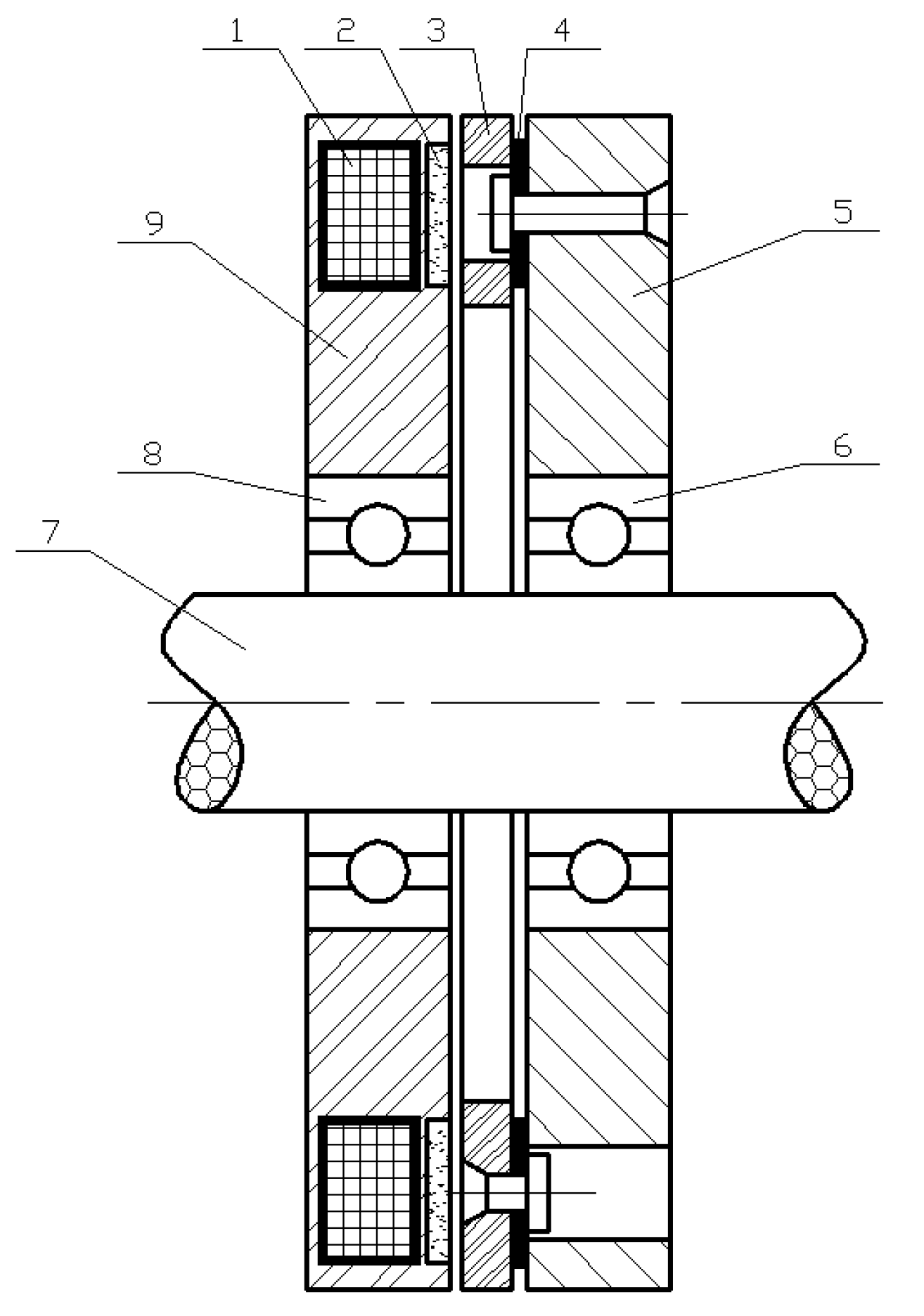

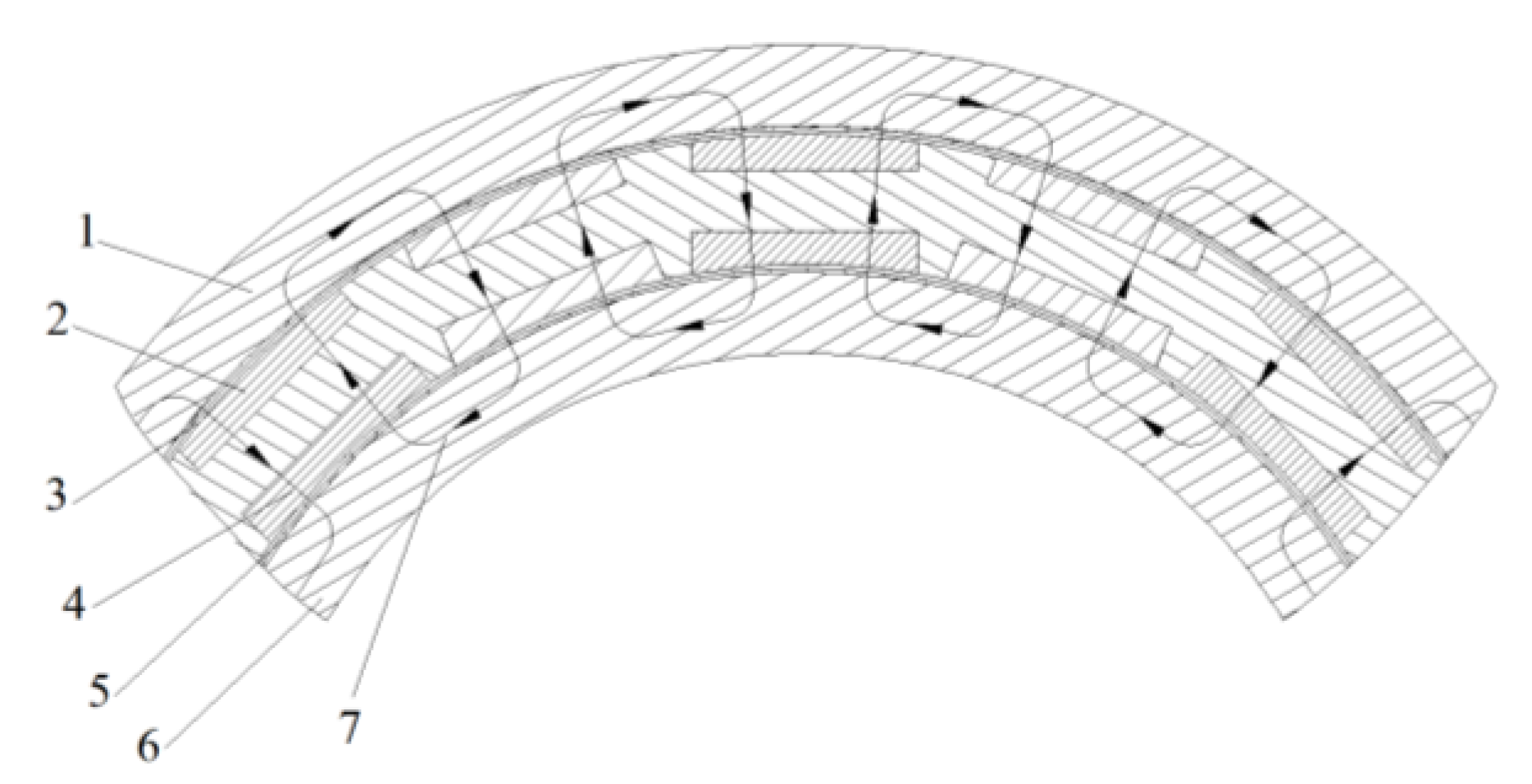

2. Structure and Principle of Double Rotor Permanent Magnet Braking Device

3. Parameter Design of Double Rotor Permanent Magnet Braking Device

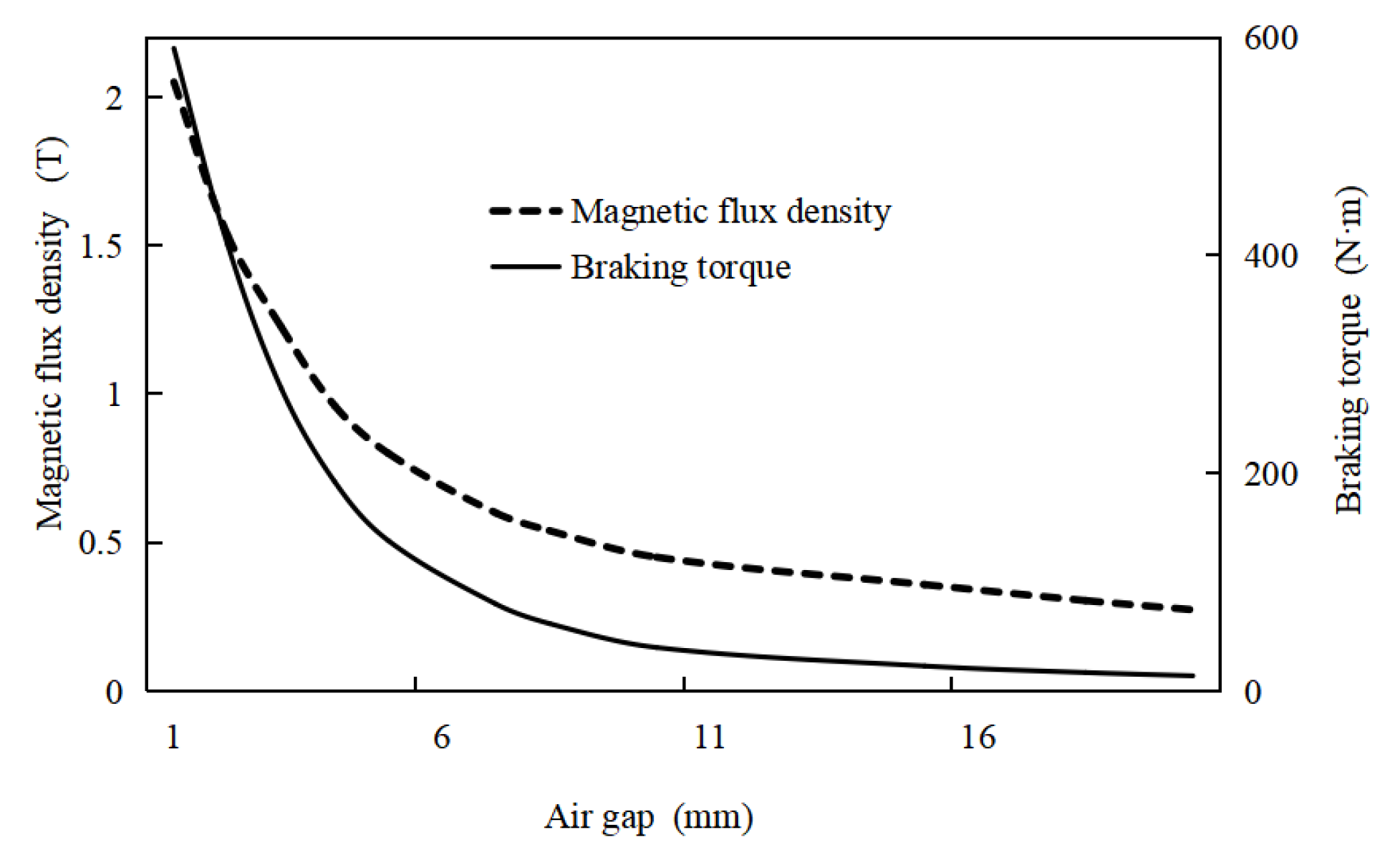

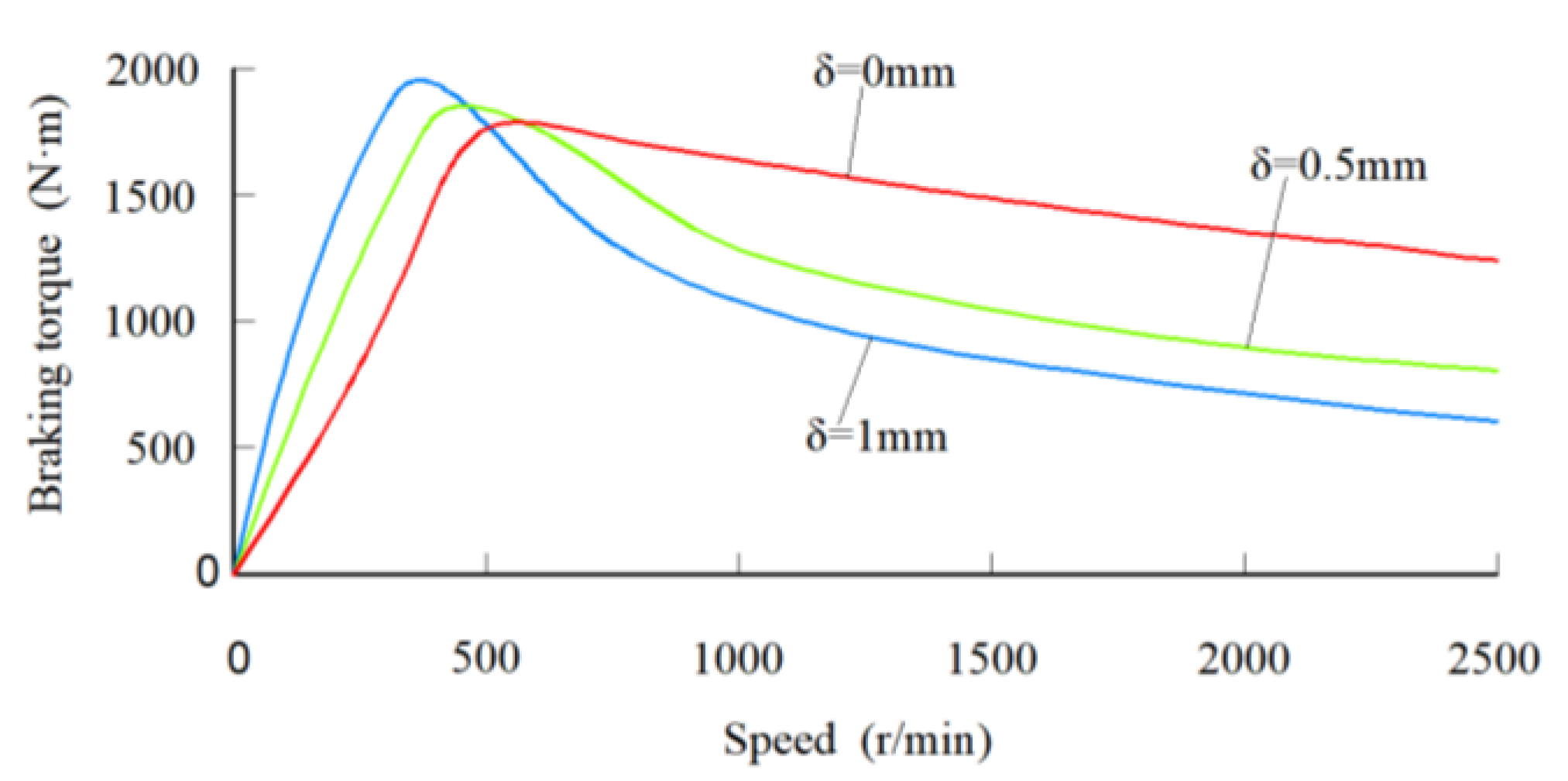

3.1. Braking Torque Model of Permanent Magnet Braking Device

3.2. Parameter Calculation of Permanent Magnet Braking Device

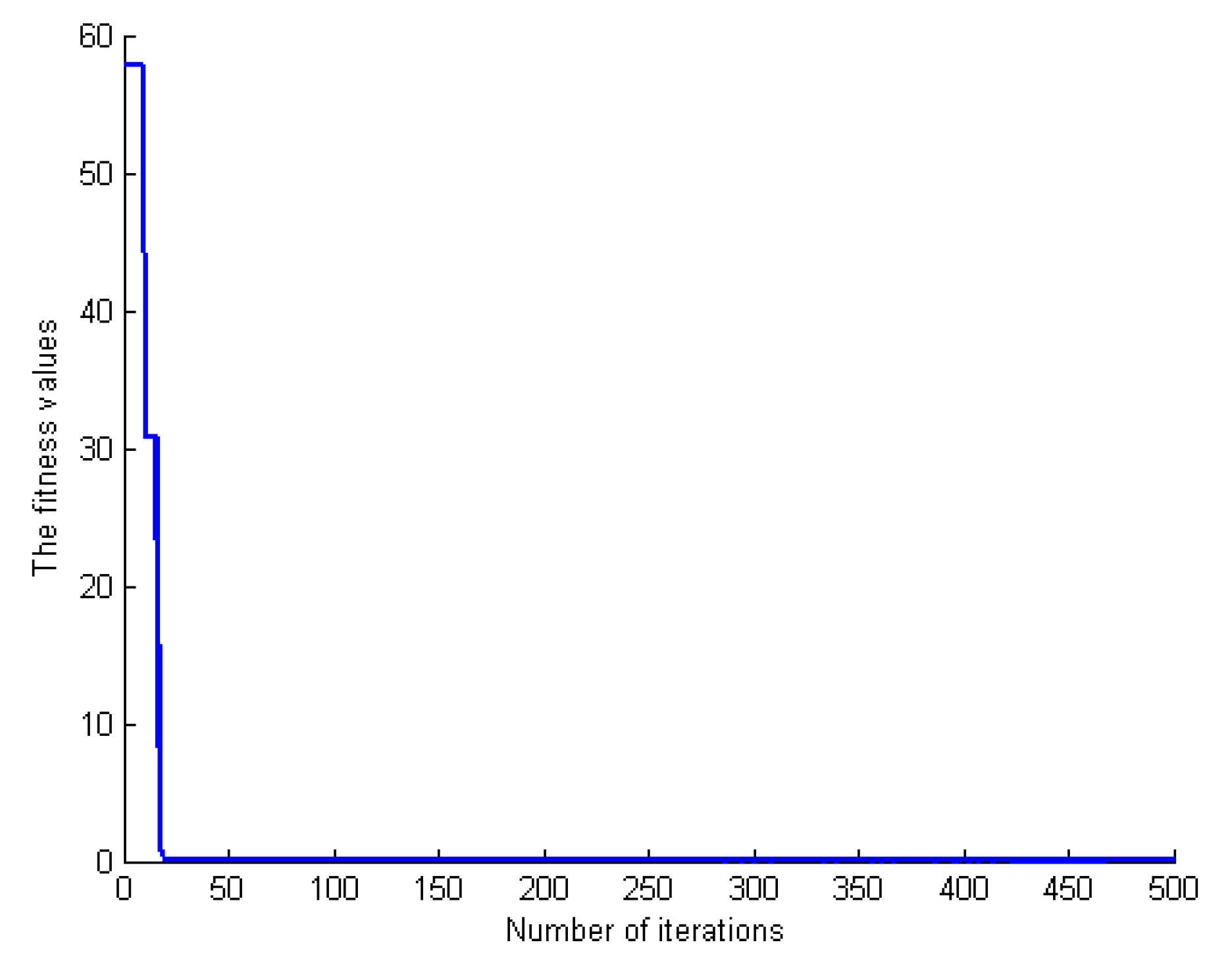

3.3. Parameter Optimization of Permanent Magnet Braking Device

- (1)

- The total number of particles in the population: N = 400.

- (2)

- Maximum number of iterations: kmax = 500.

- (3)

- Inertia weight ω can be expressed as:

- (4)

- The acceleration factors c1 and c2 are set as: c1 = c2 = 2.

4. Magnetic Field Analysis of a Double Rotor Permanent Magnet Braking Device

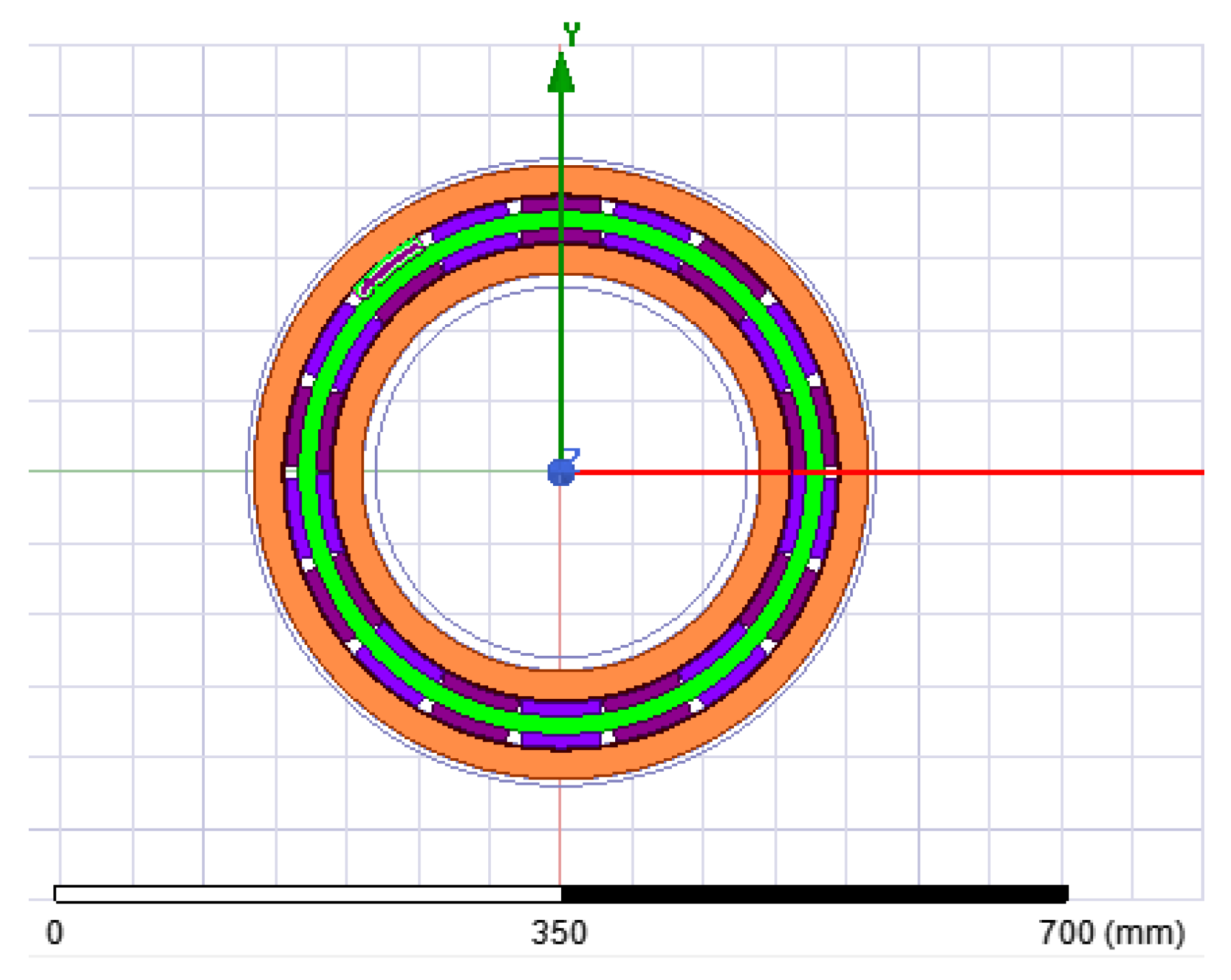

4.1. Modeling of Permanent Magnet Braking Device

4.2. Material Properties and Model Meshing

4.3. Excitation Source and Boundary Conditions

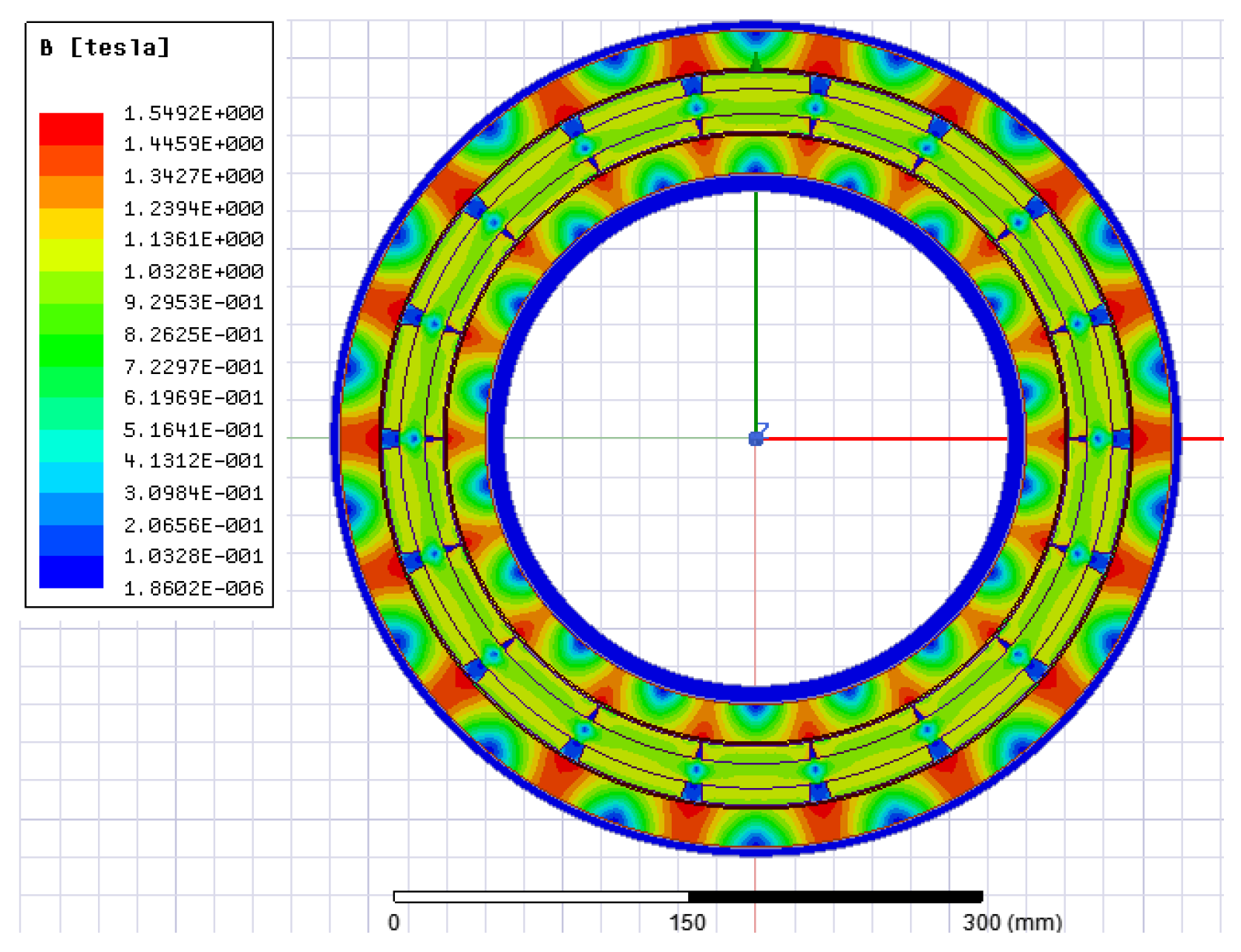

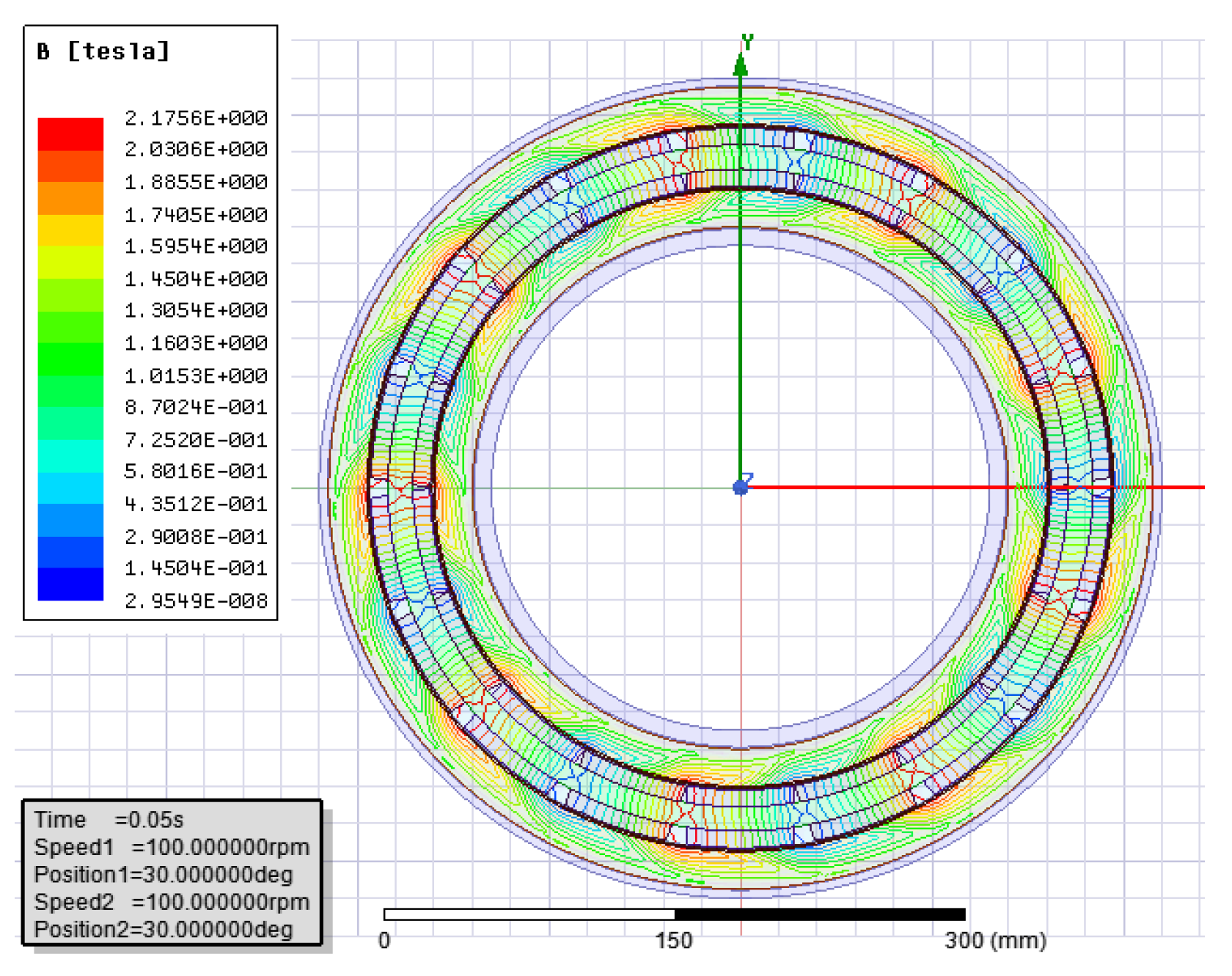

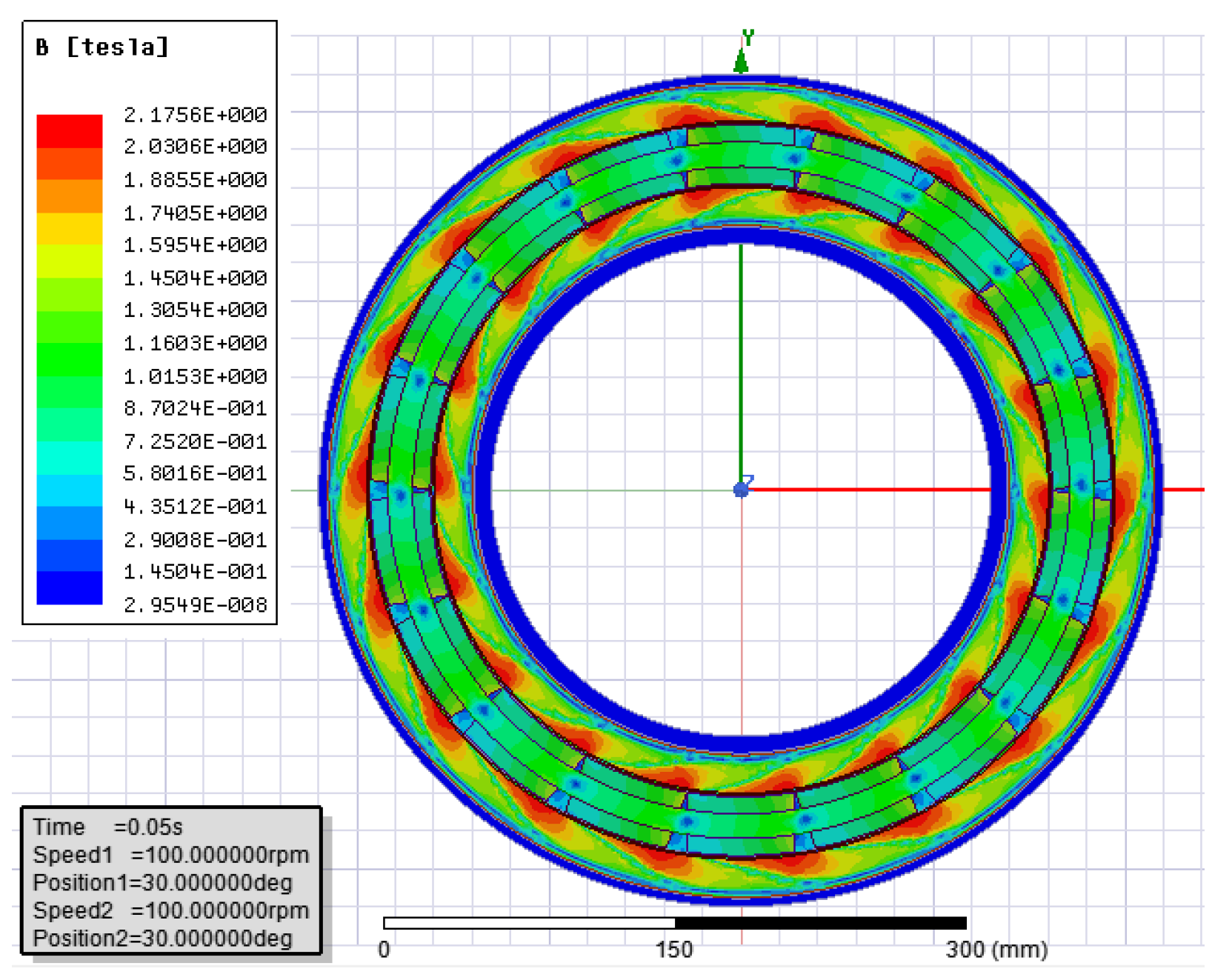

4.4. Analysis Results of Static Magnetic Field

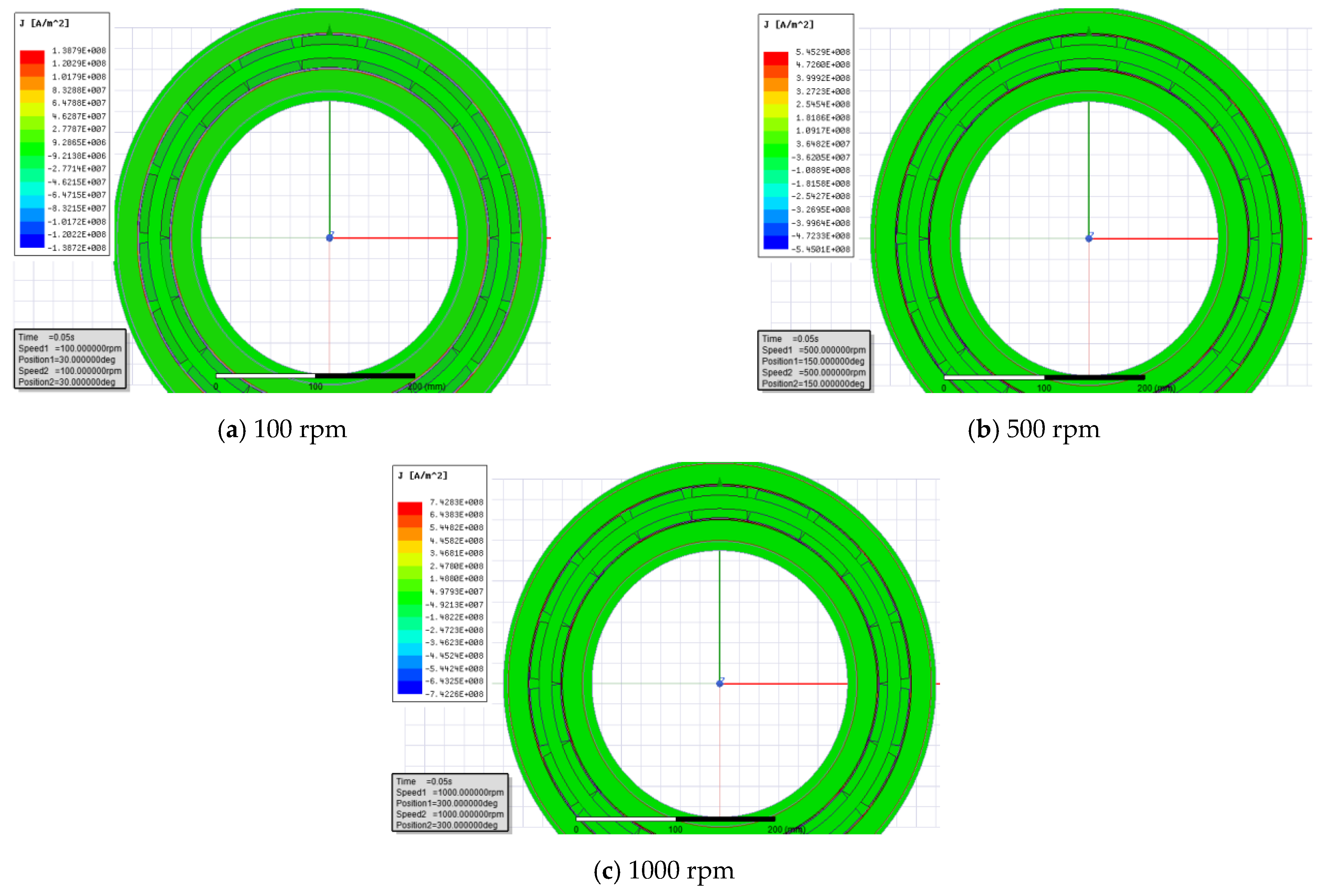

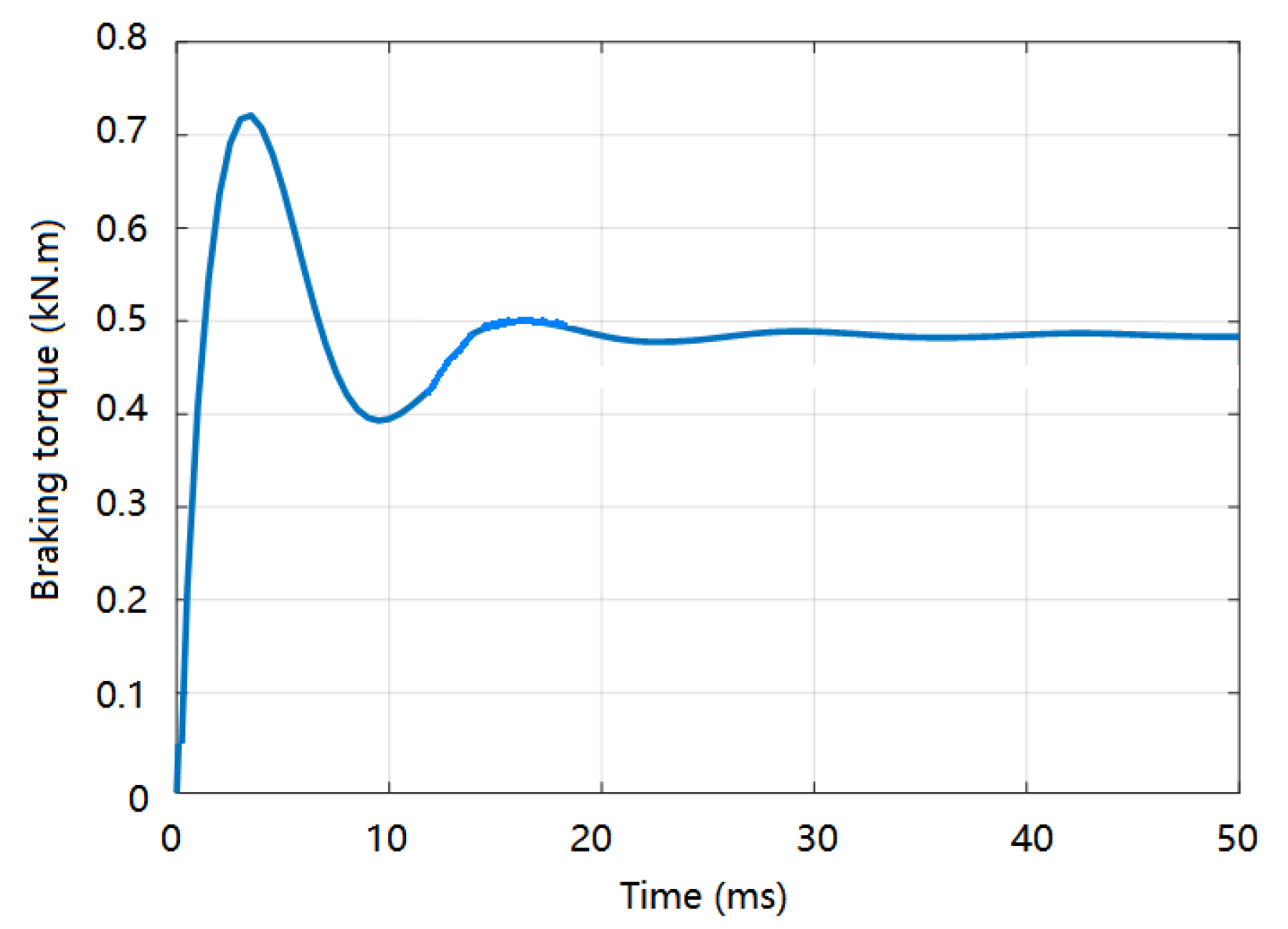

4.5. Analysis Results of Transient Magnetic Field

5. Conclusions

- (1)

- A design scheme of a double rotor permanent magnet braking device was proposed, and its main structural parameters were designed and calculated.

- (2)

- The two-dimensional finite element model of the double rotor permanent magnet braking device was established, and its static magnetic field and transient magnetic field were analyzed. The analysis results show that the eddy current density increases with the increase in rotating speed, which is consistent with the theoretical calculation value.

- (3)

- The braking performance of the double rotor permanent magnet braking device was analyzed. The analysis results show that the maximum braking torque is close to the theoretical calculation value, the braking torque changes with the change of speed, and the maximum braking torque occurs in the low-speed region.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, R.; Zhang, R.J. A Brake and Braking Method Combining Permanent Magnet Braking and Friction Braking. Chinese Patent CN102155508b, 13 March 2013. [Google Scholar]

- Wang, K.Y.; He, R.; Tang, J.H.; Liu, R. Design and thermal analysis of a novel permanent magnet-friction integrated brake for vehicle. Therm. Sci. 2020, 24, 1827–1834. [Google Scholar] [CrossRef]

- Liu, C.; Zhao, Y.; Wang, Y.; Zhang, T.; Jia, H. Hybrid dynamic modeling and analysis of high-speed thin-rimmed gears. J. Mech. Des. 2021, 143, 123401. [Google Scholar] [CrossRef]

- Wang, K.Y.; He, R.; Tang, J.H.; Liu, R. Performances Analysis of a novel electromagnetic-frictional integrated brake based on multi-physical fields coupling. World Electr. Veh. J. 2019, 10, 9. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Liu, C.; Huang, Y.; Xiao, Y. Direct modulation pattern control for dual three-phase pmsm drive system. IEEE Trans. Ind. Electron. 2022, 69, 110–120. [Google Scholar] [CrossRef]

- Yang, W.; Lin, Y.; Chen, X.; Xu, Y.; Song, X. Wave mixing and high-harmonic generation enhancement by a two-color field driven dielectric metasurface. Chin. Opt. Lett. 2021, 19, 123202. [Google Scholar] [CrossRef]

- Shi, M.; Zhu, H.; Yang, C.; Xu, J.; Yan, C. Chemical reduction-induced fabrication of graphene hybrid fibers for energy-dense wire-shaped supercapacitors. Chin. J. Chem. Eng. 2021, 5, 45. [Google Scholar] [CrossRef]

- Dong, H.; Zhao, B.; Deng, Y. Instability phenomenon associated with two typical high speed railway vehicles. Int. J. Non-Linear Mech. 2018, 105, 130–145. [Google Scholar] [CrossRef]

- Tu, K. Research on the Electromagnetic and Friction Integrated Brake with Variable Air Gap Width in Passenger Car; Jiangsu University: Zhenjiang, China, 2017. [Google Scholar]

- Zhao, X.B.; Ji, C.Y.; Huang, Y.Q.; Zhou, J. Eddy current analysis and braking moment calculation of permanent magnet typed eddy current retarder. J. Mach. Des. 2008, 25, 62–65. [Google Scholar]

- Zuo, J.Y.; Tian, X.Y. Calculation of effective parameters of inductor eddy current dynamometer. Large Electr. Mach. Hydraul. Turbine. 1972, 2, 31–42. [Google Scholar]

- Wouterse, J.H. Critical torque and speed of eddy current brake with widely separated soft iron poles. IEE Proc.-B 1991, 138, 153–158. [Google Scholar] [CrossRef]

- Wang, J. Research on Structure Design Method of Braking Torque Graded Permanent Magnet Retarder; Jiangsu University: Zhenjiang, China, 2017. [Google Scholar]

- He, R.; Wang, J.; Wang, L. Design of graded permanent magnet retarder. J. Chongqing Jiaotong Univ. (Nat. Sci.) 2015, 34, 155–159. [Google Scholar]

- Ye, L.Z.; Liu, Y.P.; Cao, M.G.; Li, D.S. Braking characteristics and experiment of a permanent magnet eddy-current retarder. J. Beijing Univ. Technol. 2018, 44, 837–842. [Google Scholar]

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| Curb weight m (Kg) | 5770 | Wheelbase L (m) | 4.2 |

| Minimum ground clearance h (m) | 0.26 | Overall dimension (m) | 7.015 × 2.470 × 2.510 |

| Front axle load Gf (Kg) | 2410 | Rear-axle load Gr (Kg) | 3360 |

| Parameters | Np | w (mm) | h (mm) | a (mm) |

|---|---|---|---|---|

| Outer permanent magnet | 8 | 50 | 15 | 31 |

| Inner permanent magnet | 8 | 50 | 15 | 26 |

| Parameters | Values |

|---|---|

| Outer radius of outer rotor drum (mm) | 203 |

| Outer radius of inner rotor drum (mm) | 143 |

| Thickness of rotor drum (mm) | 10 |

| Thickness of copper clad layer (mm) | 1 |

| Air gap between copper clad layer and permanent magnet (mm) | 1 |

| Outer diameter of outer permanent magnet (mm) | 191 |

| Outer diameter of inner permanent magnet (mm) | 160 |

| Thickness of magnet bracket (mm) | 46 |

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| Density ρ (kg/m3) | 7870 | Thermal conductivity k (W/(m·K)) | 54.7 |

| Conductivity σ (S/m) | 6 × 106 | Thermal diffusivity α (m2/s) | 2.31 × 10−5 |

| Relative permeability μr | 200 | Specific heat capacity Cd (J/(kg·K)) | 574 |

| Components | Permanent Magnet | Bracket | Copper Clad Layer |

|---|---|---|---|

| Materials | NF38 | Mild steel | Copper |

| Coercivity Hc (A/m) | 9.07 × 105 | — | — |

| Relative permeability μr | 1.099 | 3000 | 0.999 |

| Conductivity σ (S/m) | — | 0.2 × 107 | 5.8 × 107 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, J.; Zuo, Y. The Design and Magnetic Field Analysis of a Double Rotor Permanent Magnet Braking Device. Processes 2022, 10, 346. https://doi.org/10.3390/pr10020346

Tang J, Zuo Y. The Design and Magnetic Field Analysis of a Double Rotor Permanent Magnet Braking Device. Processes. 2022; 10(2):346. https://doi.org/10.3390/pr10020346

Chicago/Turabian StyleTang, Jinhua, and Yanyan Zuo. 2022. "The Design and Magnetic Field Analysis of a Double Rotor Permanent Magnet Braking Device" Processes 10, no. 2: 346. https://doi.org/10.3390/pr10020346

APA StyleTang, J., & Zuo, Y. (2022). The Design and Magnetic Field Analysis of a Double Rotor Permanent Magnet Braking Device. Processes, 10(2), 346. https://doi.org/10.3390/pr10020346