The Product Customization Process in Relation to Industry 4.0 and Digitalization

Abstract

:1. Introduction

2. Theoretical Background

2.1. Definition of Terms

2.1.1. Industry 4.0 and Technology Readiness

2.1.2. Digitalization

2.1.3. Internal Integration

2.1.4. External Integration

2.1.5. Internal Value Chain

2.1.6. Customization

2.2. Practical Applications of the Customization Process

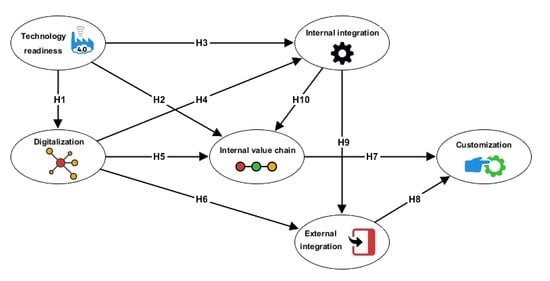

2.3. Conceptual Research Model and Hypotheses

3. Materials and Methods

3.1. Data Sample

3.2. Construct of Variables and Indicators

3.3. Methods

4. Results

4.1. Evaluation of Measurement Model

4.1.1. Reliability and Validity

4.1.2. Multicollinearity, Loadings, and Weights

4.1.3. Overall Fit of the Saturated Measurement Model

4.2. Evaluation of the Structural Model

4.2.1. Overall Fit of the Saturated Measurement Model

4.2.2. Evaluation of the Overall Fit of the Estimated Model

4.2.3. Results of the Structural Model Effects

4.2.4. Results of Hypotheses Evaluation

5. Discussion

5.1. Conceptual Model and Theoretical Implications

5.2. Barriers and Limitations

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Factor Description | F1 | F2 | F3 | F4 | Indicator Abbreviation |

|---|---|---|---|---|---|

| Digitalization | External Integration | Internal Value Chain | Internal Integration | ||

| Customers | 0.1610 | 0.8940 | 0.0991 | 0.2201 | EXI1 |

| Suppliers | 0.1434 | 0.9111 | 0.1252 | 0.1652 | EXI2 |

| Departments | 0.1785 | 0.4137 | 0.2613 | 0.7323 | ICO1 |

| Processes | 0.2570 | 0.2455 | 0.2076 | 0.8070 | ICO2 |

| Development | 0.1867 | 0.1613 | 0.8574 | 0.0146 | PLC1 |

| Planning | 0.2235 | 0.1054 | 0.7617 | 0.4189 | PLC2 |

| Manufacturing | 0.2862 | 0.1054 | 0.7018 | 0.4304 | PLC3 |

| Information systems | 0.7395 | 0.1640 | 0.3612 | 0.1767 | DIG1 |

| Communication | 0.7940 | 0.2003 | 0.2157 | 0.1880 | DIG2 |

| IoT and cloud | 0.7586 | 0.1604 | 0.1581 | 0.2094 | DIG3 |

| Integration | 0.7542 | 0.1335 | 0.1558 | 0.1592 | DIG4 |

| Eigenvalues | 2.6325 | 2.0196 | 2.1710 | 1.7599 | Total = 8.5830 |

| Explained variance | 0.2393 | 0.1836 | 0.1974 | 0.1600 | Total = 0.7803 |

Appendix B

| External Integration | Indicator | Mean | Std. Dev. |

| → EXI1 | We are connected to customers and processes are electronic | 3.6198 | 1.7236 |

| → EXI2 | We are connected with suppliers and processes are electronic | 3.5335 | 1.7817 |

| Internal integration | Indicator | Mean | Std. dev. |

| → ICO1 | Organizational departments are connected and processes are carried out electronically | 3.5240 | 1.7182 |

| → ICO2 | Computer technology (IT) supports the automatic execution of processes | 3.2492 | 1.9313 |

| Internal value chain | Indicator | Mean | Std. dev. |

| → PLC1 | New product design and the development process is digitized | 2.9361 | 2.2651 |

| → PLC2 | The production planning process is digitized | 3.2013 | 1.8920 |

| → PLC3 | The manufacturing and production control is digitized | 3.0064 | 1.7820 |

| Digitalization | Indicator | Mean | Std. dev. |

| → DIG1 | Machines, robots, and equipment are controlled and managed by information systems | 2.7444 | 2.1332 |

| → DIG2 | Machines and devices communicate with each other | 2.2716 | 1.8010 |

| → DIG3 | Machines and devices communicate via the Internet (using IoT, cloud) | 2.0735 | 1.6004 |

| → DIG4 | All systems, devices, machines are integrated into information systems across hierarchical levels | 2.0863 | 1.5342 |

| Customization | Indicator | Mean | Std. dev. |

| → CUST | To what extent can the customer flexibly customize the product? (5-point Likert scale with anchors: 1 totally disagree … 5 totally agree; where 1 means craft/tailored production and 5 is possibility of mass personification) | 2.7604 | 2.3495 |

| Index VPi4 | Indicator | Mean | Std. Dev. |

|---|---|---|---|

| → VPI | What is the level of the Industry 4.0 technology readiness in your company according to the second level of VPi4 index? * (based on the % rank, readiness is evaluated as five levels: 0–20%—1, 21–40%—2, 40–60%—3, 60–80%—4, 80–100%—5 | 3.1693 | 1.4488 |

References

- Jafari-Sadeghi, V.; Garcia-Perez, A.; Candelo, E.; Couturier, J. Exploring the Impact of Digital Transformation on Technology Entrepreneurship and Technological Market Expansion: The Role of Technology Readiness, Exploration and Exploitation. J. Bus. Res. 2021, 124, 100–111. [Google Scholar] [CrossRef]

- Nadkarni, S.; Prügl, R. Digital Transformation: A Review, Synthesis and Opportunities for Future Research. Manag. Rev. Q. 2021, 71, 233–341. [Google Scholar] [CrossRef] [Green Version]

- Mathradas, A. Council Post: COVID-19 Accelerated E-Commerce Adoption: What Does It Mean for the Future? Available online: https://www.forbes.com/sites/forbesbusinesscouncil/2021/12/29/covid-19-accelerated-e-commerce-adoption-what-does-it-mean-for-the-future/ (accessed on 21 January 2022).

- Acosta, G. Wegmans, Trader Joe’s Master Pandemic Customer Service. Available online: https://progressivegrocer.com/wegmans-trader-joes-master-pandemic-customer-service (accessed on 21 January 2022).

- Zhang, X.; Ming, X.; Liu, Z.; Zheng, M.; Qu, Y. A New Customization Model for Enterprises Based on Improved Framework of Customer to Business: A Case Study in Automobile Industry. Adv. Mech. Eng. 2019, 11, 168781401983388. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Ma, H.-S.; Yang, J.-H.; Wang, K.-S. Industry 4.0: A Way from Mass Customization to Mass Personalization Production. Adv. Manuf. 2017, 5, 311–320. [Google Scholar] [CrossRef]

- Crowther, S.; Ford, H. My Life and Work; Project Gutenberg; Illinois Benedictine College: Champaign, IL, USA, 2005. [Google Scholar]

- Deloitte. The Deloitte Consumer Review—Made-to-Order: The Rise of Mass Personalisation. Available online: https://www2.deloitte.com/content/dam/Deloitte/ch/Documents/consumer-business/ch-en-consumer-business-made-to-order-consumer-review.pdf (accessed on 21 January 2022).

- Ernest-Jones, T. The Digital Company 2013: How Technology Will Empower the Customer. Available online: https://www.pwc.com/gx/en/technology/assets/digital_co_1.pdf (accessed on 5 January 2022).

- Oliver, K.; Moeller, H.L.; Lakenan, B. Smart Customization: Profitable Growth through Tailored Business Streams. Strategy+Business 2004, 34. Available online: https://www.strategy-business.com/article/04104 (accessed on 15 January 2022).

- Resca, A.; Za, S.; Spagnoletti, P. Digital Platforms as Sources for Organizational and Strategic Transformation: A Case Study of the Midblue Project. J. Theor. Appl. Electron. Commer. Res. 2013, 8, 11–12. [Google Scholar] [CrossRef] [Green Version]

- Baranauskas, G. Digitalization Impact on Transformations of Mass Customization Concept: Conceptual Modelling of Online Customization Frameworks. MMI 2020, 3, 120–132. [Google Scholar] [CrossRef]

- Wiedmann, K.-P.; Hennigs, N.; Varelmann, D.; Reeh, M.-O. Determinants of Consumers’ Perceived Trust in IT-Ecosystems. J. Theor. Appl. Electron. Commer. Res. 2010, 5, 137–154. [Google Scholar] [CrossRef] [Green Version]

- Koufteros, X.; Vonderembse, M.; Jayaram, J. Internal and External Integration for Product Development: The Contingency Effects of Uncertainty, Equivocality, and Platform Strategy. Decis. Sci. 2005, 36, 97–133. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, D.; Tao, F.; Liu, A. Data Driven Smart Customization. Procedia CIRP 2019, 81, 564–569. [Google Scholar] [CrossRef]

- Schöning, H.; Dorchain, M. Data Mining und Analyse. In Industrie 4.0 in Produktion, Automatisierung und Logistik; Bauernhansl, T., ten Hompel, M., Vogel-Heuser, B., Eds.; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2014; pp. 543–554. ISBN 978-3-658-04681-1. [Google Scholar]

- Pech, M.; Vrchota, J.; Bednář, J. Predictive Maintenance and Intelligent Sensors in Smart Factory: Review. Sensors 2021, 21, 1470. [Google Scholar] [CrossRef]

- Rymaszewska, A.; Helo, P.; Gunasekaran, A. IoT Powered Servitization of Manufacturing—An Exploratory Case Study. Int. J. Prod. Econ. 2017, 192, 92–105. [Google Scholar] [CrossRef]

- Cupek, R.; Drewniak, M.; Ziebinski, A.; Fojcik, M. “Digital Twins” for Highly Customized Electronic Devices—Case Study on a Rework Operation. IEEE Access 2019, 7, 164127–164143. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital Twin-Driven Product Design, Manufacturing and Service with Big Data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Nwaiwu, F. Review and Comparison of Conceptual Frameworks on Digital Business Transformation. JOC 2018, 10, 86–100. [Google Scholar] [CrossRef] [Green Version]

- Zhao, X.; Huo, B.; Selen, W.; Yeung, J.H.Y. The Impact of Internal Integration and Relationship Commitment on External Integration. J. Oper. Manag. 2011, 29, 17–32. [Google Scholar] [CrossRef]

- Bauer, W.; Schlund, S.; Hornung, T.; Schuler, S. Digitalization of Industrial Value Chains—A Review and Evaluation of Existing Use Cases of Industry 4.0 in Germany. Logforum 2018, 14, 331–340. [Google Scholar] [CrossRef]

- Schumacher, A.; Nemeth, T.; Sihn, W. Roadmapping towards Industrial Digitalization Based on an Industry 4.0 Maturity Model for Manufacturing Enterprises. Procedia CIRP 2019, 79, 409–414. [Google Scholar] [CrossRef]

- Schroeder, A.; Ziaee Bigdeli, A.; Galera Zarco, C.; Baines, T. Capturing the Benefits of Industry 4.0: A Business Network Perspective. Prod. Plan. Control 2019, 30, 1305–1321. [Google Scholar] [CrossRef]

- Ober, J. Innovation Adoption: Empirical Analysis on the Example of Selected Factors of Organizational Culture in the IT Industry in Poland. Sustainability 2020, 12, 8630. [Google Scholar] [CrossRef]

- Brodny, J.; Tutak, M. Assessing the Level of Digitalization and Robotization in the Enterprises of the European Union Member States. PLoS ONE 2021, 16, e0254993. [Google Scholar] [CrossRef] [PubMed]

- Celent, L.; Mladineo, M.; Gjeldum, N.; Zizic, M.C. Multi-Criteria Decision Support System for Smart and Sustainable Machining Process. Energies 2022, 15, 772. [Google Scholar] [CrossRef]

- Enyoghasi, C.; Badurdeen, F. Industry 4.0 for Sustainable Manufacturing: Opportunities at the Product, Process, and System Levels. Resour. Conserv. Recycl. 2021, 166, 105362. [Google Scholar] [CrossRef]

- Raptis, T.P.; Passarella, A.; Conti, M. Data Management in Industry 4.0: State of the Art and Open Challenges. IEEE Access 2019, 7, 97052–97093. [Google Scholar] [CrossRef]

- Tutak, M.; Brodny, J. Business Digital Maturity in Europe and Its Implication for Open Innovation. J. Open Innov. Technol. Mark. Complex. 2022, 8, 27. [Google Scholar] [CrossRef]

- Pivoto, D.G.; de Almeida, L.F.; da Rosa Righi, R.; Rodrigues, J.J.; Lugli, A.B.; Alberti, A.M. Cyber-Physical Systems Architectures for Industrial Internet of Things Applications in Industry 4.0: A Literature Review. J. Manuf. Syst. 2021, 58, 176–192. [Google Scholar] [CrossRef]

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0: The Future of Productivity and Growth in Manufacturing Industries; Boston Consulting Group: Boston, MA, USA, 2015; Volume 9, pp. 54–89. [Google Scholar]

- Sony, M.; Naik, S. Key Ingredients for Evaluating Industry 4.0 Readiness for Organizations: A Literature Review. Benchmarking Int. J. 2019, 27, 2213–2232. [Google Scholar] [CrossRef]

- Mavropoulos, A.; Nilsen, W.A. Industry 4.0 and Circular Economy: Towards a Wasteless Future or a Wasteful Planet? John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0—A Glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing Smart Factory of Industrie 4.0: An Outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 3159805. [Google Scholar] [CrossRef] [Green Version]

- Cozmiuc, D.C.; Pettinger, R. Consultants’ Tools to Manage Digital Transformation: The Case of PWC, Siemens, and Oracle. J. Cases Inf. Technol. 2021, 23, 1–29. [Google Scholar] [CrossRef]

- Waite, M. Oxford English Dictionary; Oxford University Press: Oxford, UK, 2013. [Google Scholar]

- Brennen, S.J.; Kreiss, D. Digitalization. In The International Encyclopedia of Communication Theory and Philosophy; Jensen, K.B., Rothenbuhler, E.W., Pooley, J.D., Craig, R.T., Eds.; Wiley: Hoboken, NJ, USA, 2016. [Google Scholar]

- Geisberger, E.; Broy, M. AgendaCPS—Integrierte Forschungsagenda Cyber-Physical Systems; Springer: Berlin, Germany, 2012. [Google Scholar]

- Matt, C.; Hess, T.; Benlian, A. Digital Transformation Strategies. Bus. Inf. Syst. Eng. 2015, 57, 339–343. [Google Scholar] [CrossRef]

- Entschew, E.M. Acceleration through Digital Communication: Theorizing on a Perceived Lack of Time. Humanist. Manag. J. 2021, 6, 273–287. [Google Scholar] [CrossRef]

- Hess, T.; Matt, C.; Benlian, A.; Wiesböck, F. Options for Formulating a Digital Transformation Strategy. MIS Q. Exec. 2016, 15, 123–139. [Google Scholar] [CrossRef]

- Yeh, T.-M.; Pai, F.-Y.; Wu, L.-C. Relationship Stability and Supply Chain Performance for SMEs: From Internal, Supplier, and Customer Integration Perspectives. Mathematics 2020, 8, 1902. [Google Scholar] [CrossRef]

- Basnet, C. The Measurement of Internal Supply Chain Integration. Manag. Res. Rev. 2013, 36, 153–172. [Google Scholar] [CrossRef]

- Kaynak, H. The Relationship between Just-in-Time Purchasing Techniques and Firm Performance. IEEE Trans. Eng. Manag. 2002, 49, 205–217. [Google Scholar] [CrossRef]

- Basnet, C.; Wisner, J. Nurturing Internal Supply Chain Integration. OSCM Int. J. 2014, 5, 27–41. [Google Scholar] [CrossRef]

- Javalgi, R.G.; Hall, K.D.; Cavusgil, S.T. Corporate Entrepreneurship, Customer-Oriented Selling, Absorptive Capacity, and International Sales Performance in the International B2B Setting: Conceptual Framework and Research Propositions. Int. Bus. Rev. 2014, 23, 1193–1202. [Google Scholar] [CrossRef] [Green Version]

- Hillebrand, B.; Biemans, W.G. The Relationship between Internal and External Cooperation. J. Bus. Res. 2003, 56, 735–743. [Google Scholar] [CrossRef]

- Kouvelis, P.; Lariviere, M.A. Decentralizing Cross-Functional Decisions: Coordination Through Internal Markets. Manag. Sci. 2000, 46, 1049–1058. [Google Scholar] [CrossRef]

- Shen, N.; Au, K.; Li, W. Strategic Alignment of Intangible Assets: The Role of Corporate Social Responsibility. Asia Pac. J. Manag. 2020, 37, 1119–1139. [Google Scholar] [CrossRef]

- Wynstra, F.; Weggeman, M.; van Weele, A. Exploring Purchasing Integration in Product Development. Ind. Mark. Manag. 2003, 32, 69–83. [Google Scholar] [CrossRef]

- Narasimhan, R.; Swink, M.; Kim, S.W. Disentangling Leanness and Agility: An Empirical Investigation. J. Oper. Manag. 2006, 24, 440–457. [Google Scholar] [CrossRef]

- Frohlich, M.T.; Westbrook, R. Arcs of Integration: An International Study of Supply Chain Strategies. J. Oper. Manag. 2001, 19, 185–200. [Google Scholar] [CrossRef]

- Droge, C.; Jayaram, J.; Vickery, S.K. The Effects of Internal versus External Integration Practices on Time-Based Performance and Overall Firm Performance. J. Oper. Manag. 2004, 22, 557–573. [Google Scholar] [CrossRef]

- Abbas, A.E.; Agahari, W.; van de Ven, M.; Zuiderwijk, A.; de Reuver, M. Business Data Sharing through Data Marketplaces: A Systematic Literature Review. J. Theor. Appl. Electron. Commer. Res. 2021, 16, 3321–3339. [Google Scholar] [CrossRef]

- Zhao, X.; Huo, B.; Flynn, B.B.; Yeung, J.H.Y. The Impact of Power and Relationship Commitment on the Integration between Manufacturers and Customers in a Supply Chain. J. Oper. Manag. 2008, 26, 368–388. [Google Scholar] [CrossRef]

- Ross, F. Introduction to Supply Chain Management Technologies (Resource Management); CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Vanpoucke, E.; Vereecke, A.; Boyer, K.K. Triggers and Patterns of Integration Initiatives in Successful Buyer-Supplier Relationships. J. Oper. Manag. 2014, 32, 15–33. [Google Scholar] [CrossRef]

- Schuh, C.; Strohmer, F.M.; Easton, S.; Hales, M.; Triplat, A. Supplier Relationship Management. How to Maximize Supplier Value and Opportunit; Springer; Apress: New York, NY, USA, 2014. [Google Scholar]

- Forslund, H.; Jonsson, P. Dyadic Integration of the Performance Management Process: A Delivery Service Case Study. Int. J. Phys. Distrib. Logist. Manag. 2007, 37, 546–567. [Google Scholar] [CrossRef] [Green Version]

- O’Brien, J. Supplier Relationship Management: Unlocking the Hidden Value in Your Supply Base; Kogan Page Publishers: London, UK, 2014. [Google Scholar]

- Ragatz, G.L.; Handfield, R.B.; Petersen, K.J. Benefits Associated with Supplier Integration into New Product Development under Conditions of Technology Uncertainty. J. Bus. Res. 2002, 55, 389–400. [Google Scholar] [CrossRef]

- Vargo, S.L.; Lusch, R.F. Service-Dominant Logic: Continuing the Evolution. J. Acad. Mark. Sci. 2008, 36, 1–10. [Google Scholar] [CrossRef]

- Christopher, M.; Ryals, L.J. The Supply Chain Becomes the Demand Chain. J. Bus. Logist. 2014, 35, 29–35. [Google Scholar] [CrossRef]

- Syam, B.N.; Pazgal, A. Co-Creation with Production Externalities. Mark. Sci. 2013, 32, 805–820. [Google Scholar] [CrossRef]

- Martinelli, E.M.; Tunisini, A. Customer Integration into Supply Chains: Literature Review and Research Propositions. JBIM 2019, 34, 24–38. [Google Scholar] [CrossRef]

- Füller, K.; Weking, J.; Böhm, M.; Krcmar, H. Leveraging Customer-Integration Experience: A Review of Influencing Factors and Implications. CAIS 2019, 44, 81–128. [Google Scholar] [CrossRef]

- Füller, J.; Hutter, K.; Faullant, R. Why Co-Creation Experience Matters? Creative Experience and Its Impact on the Quantity and Quality of Creative Contributions: Why Co-Creation Experience Matters? R&D Manag. 2011, 41, 259–273. [Google Scholar] [CrossRef]

- Anshari, M.; Almunawar, M.N.; Lim, S.A.; Al-Mudimigh, A. Customer Relationship Management and Big Data Enabled: Personalization & Customization of Services. Appl. Comput. Inform. 2019, 15, 94–101. [Google Scholar] [CrossRef]

- Dean, J. Pricing Policies for New Products. Harv. Bus. Rev. 1950, 28, 45–53. [Google Scholar]

- Cao, H.; Folan, P. Product Life Cycle: The Evolution of a Paradigm and Literature Review from 1950–2009. Prod. Plan. Control 2012, 23, 641–662. [Google Scholar] [CrossRef]

- Porter, M.E. The Competitive Advantage: Creating and Sustaining Superior Performance; Free Press: New York City, NY, USA, 1998. [Google Scholar]

- Roucoules, L.; Anwer, N. Coevolution of Digitalisation, Organisations and Product Development Cycle. CIRP Ann. 2021, 70, 519–542. [Google Scholar] [CrossRef]

- Ralph, B.J.; Woschank, M.; Miklautsch, P.; Kaiblinger, A.; Pacher, C.; Sorger, M.; Zsifkovits, H.; Stockinger, M. MUL 4.0: Systematic Digitalization of a Value Chain from Raw Material to Recycling. Procedia Manuf. 2021, 55, 335–342. [Google Scholar] [CrossRef]

- Acharyulu, S.G.; Subbaiah, K.V.; Rao, K.N. Value Chain Model for Steel Manufacturing Sector: A Case Study. IJMVSC 2015, 6, 45–53. [Google Scholar] [CrossRef]

- Jiao, J.; Ma, Q.; Tseng, M.M. Towards High Value-Added Products and Services: Mass Customization and Beyond. Technovation 2003, 23, 809–821. [Google Scholar] [CrossRef]

- Murdiana, R.; Hajaoui, Z. E-Commerce Marketing Strategies in Industry 4.0. Int. J. Bus. Ecosyst. Strat. 2020, 2, 32–43. [Google Scholar] [CrossRef] [Green Version]

- Blecker, T.; Friedrich, G. Mass Customization Information Systems in Business; Information Science Reference: New York, NY, USA, 2007. [Google Scholar]

- Jiang, P. Segment-based Mass Customization: An Exploration of a New Conceptual Marketing Framework. Internet Res. 2000, 10, 215–226. [Google Scholar] [CrossRef]

- Zine, P.U.; Kulkarni, M.S.; Chawla, R.; Ray, A.K. A Framework for Value Co-Creation through Customization and Personalization in the Context of Machine Tool PSS. Procedia CIRP 2014, 16, 32–37. [Google Scholar] [CrossRef] [Green Version]

- Frank, A.G.; Mendes, G.H.S.; Ayala, N.F.; Ghezzi, A. Servitization and Industry 4.0 Convergence in the Digital Transformation of Product Firms: A Business Model Innovation Perspective. Technol. Forecast. Soc. Chang. 2019, 141, 341–351. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, Y.; Wu, C.; Ran, B. Understanding Individualization Driving States via Latent Dirichlet Allocation Model. IEEE Intell. Transp. Syst. Mag. 2019, 11, 41–53. [Google Scholar] [CrossRef]

- Pine, J.B. Mass Customization: The New Frontier in Business Competition; Harvard Business School Press: New York, NY, USA, 1993. [Google Scholar]

- Berry, L.L. Relationship Marketing of Services-Growing Interest, Emerging Perspectives. J. Acad. Mark. Sci. 1995, 23, 236–245. [Google Scholar] [CrossRef]

- Egaña, F.; Pezoa-Fuentes, C.; Roco, L. The Use of Digital Social Networks and Engagement in Chilean Wine Industry. JTAER 2021, 16, 1248–1265. [Google Scholar] [CrossRef]

- Benade, M. Essays on Smart Customization: Towards a Better Understanding of the Customer’s Perspective on Smart Customization Offers; RWTH University: Aachen, Germany, 2018. [Google Scholar]

- Piller, F.; Ihl, C.; Steiner, F. Embedded Toolkits for User Co-Design: A Technology Acceptance Study of Product Adaptability in the Usage Stage. In Proceedings of the 2010 43rd Hawaii International Conference on System Sciences, Honolulu, HI, USA, 5–8 January 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 1–10. [Google Scholar]

- Kim, J.W.; Sul, S.H.; Choi, J.B. Development of User Customized Smart Keyboard Using Smart Product Design-Finite Element Analysis Process in the Internet of Things. ISA Trans. 2018, 81, 231–243. [Google Scholar] [CrossRef] [PubMed]

- Lehmhus, D.; Aumund-Kopp, C.; Petzoldt, F.; Godlinski, D.; Haberkorn, A.; Zöllmer, V.; Busse, M. Customized Smartness: A Survey on Links between Additive Manufacturing and Sensor Integration. Procedia Technol. 2016, 26, 284–301. [Google Scholar] [CrossRef]

- CITO Research. How the IoT Is Shaping the Future of Customer Experience and Product Development. Available online: https://theinternetofthings.report/whitepapers/how-the-iot-is-shaping-the-future-of-customer-experience-and-product-development (accessed on 2 January 2021).

- Wang, Y.; Zio, E.; Wei, X.; Zhang, D.; Wu, B. A Resilience Perspective on Water Transport Systems: The Case of Eastern Star. Int. J. Disaster Risk Reduct. 2019, 33, 343–354. [Google Scholar] [CrossRef]

- Prabhu, K. 7 Best Product Customization Examples. Available online: https://productimize.com/blog/best-product-customization-examples/ (accessed on 20 January 2022).

- Gilmore, H.J.; Pine, B.J., II. The Four Faces of Mass Customization. Harv. Bus. Rev. 1997, 75, 91–101. [Google Scholar]

- Lima, G. Harnessing the Potential of Industry 4.0 Tech to Improve e-Commerce|UNIDO. Available online: https://www.unido.org/news/harnessing-potential-industry-40-tech-improve-e-commerce (accessed on 21 January 2022).

- PSFK. One-Man Manufacturer Explains Why Personalization Is Key to Small Business. Available online: https://www.psfk.com/2015/06/independent-retail-sol-local-heroes-campaign-kennedy-city-bicycles.html?utm_source=PSFK+Newsletter&utm_campaign=7bb290e8ee-Retail%3A+%2A%7CRSSITEM%3ADATE%7C%2A&utm_medium=email&utm_term=0_16a14e1b11-7bb290e8ee-426430369 (accessed on 20 January 2022).

- Mandell, D.J.; McIlraith, S.A. A Bottom-Up Approach to Automating Web Service Discovery, Customization, and Semantic Translation. In Proceedings of the Twelfth International World Wide Web Conference Workshop on E-Services and the Semantic Web, Budapest, Hungary, 20–24 May 2003; p. 6. [Google Scholar]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The Expected Contribution of Industry 4.0 Technologies for Industrial Performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- van Veldhoven, Z.; Vanthienen, J. Digital Transformation as an Interaction-Driven Perspective between Business, Society, and Technology. Electron. Mark. 2021. [Google Scholar] [CrossRef]

- Nagy, J.; Oláh, J.; Erdei, E.; Máté, D.; Popp, J. The Role and Impact of Industry 4.0 and the Internet of Things on the Business Strategy of the Value Chain—The Case of Hungary. Sustainability 2018, 10, 3491. [Google Scholar] [CrossRef] [Green Version]

- Pfohl, H.-C.; Yahsi, B.; Kurnaz, T. Concept and Diffusion-Factors of Industry 4.0 in the Supply Chain. In Dynamics in Logistics; Freitag, M., Kotzab, H., Pannek, J., Eds.; Lecture Notes in Logistics; Springer International Publishing: Cham, Switzerland, 2017; pp. 381–390. ISBN 978-3-319-45116-9. [Google Scholar]

- Wang, W.Y.C.; Heng, M.S.H.; Chau, P.Y.K. Supply Chain Management: Issues in the New Era of Collaboration and Competition; IGP Global: Hershey, PA, USA, 2007. [Google Scholar] [CrossRef]

- Zhang, J.; Gao, L.; Qin, W.; Lyu, Y.; Li, X. Big-Data-Driven Operational Analysis and Decision-Making Methodology in Intelligent Workshop. Comput. Integr. Manuf. Syst. 2016, 22, 1221–1229. [Google Scholar] [CrossRef]

- Angelov, P. Autonomous Learning Systems: From Data Streams to Knowledge in Real-Time; Wiley: New York, NY, USA, 2012. [Google Scholar]

- Ruiz-Alba, J.L.; Guesalaga, R.; Ayestarán, R.; Morales Mediano, J. Interfunctional Coordination: The Role of Digitalization. JBIM 2019, 35, 404–419. [Google Scholar] [CrossRef]

- Boute, R.N.; van Mieghem, J.A. Digital Operations: Framework and Future Directions. Manag. Bus. Rev. 2019, 1, 177–186. [Google Scholar] [CrossRef]

- Ng, I.C.L.; Wakenshaw, S.Y.L. The Internet-of-Things: Review and Research Directions. Int. J. Res. Mark. 2017, 34, 3–21. [Google Scholar] [CrossRef] [Green Version]

- Bharadwaj, A.; el Sawy, O.A.; Pavlou, P.A.; Venkatraman, N. Digital Business Strategy: Toward a Next Generation of Insights. MIS Q. 2013, 37, 471–482. [Google Scholar] [CrossRef]

- Erol, S.; Jäger, A.; Hold, P.; Ott, K.; Sihn, W. Tangible Industry 4.0: A Scenario-Based Approach to Learning for the Future of Production. Procedia CIRP 2016, 54, 13–18. [Google Scholar] [CrossRef]

- Kozlenkova, I.V.; Samaha, S.A.; Palmatier, R.W. Resource-Based Theory in Marketing. J. Acad. Mark. Sci. 2014, 42, 1–21. [Google Scholar] [CrossRef]

- Burger, M.; Arlinghaus, J. Digital supplier integration—Transaction 4.0 in buyer-supplier relationships. In Supply Management Research; Bode, C., Bogaschewsky, R., Eßig, M., Lasch, R., Stölzle, W., Eds.; Advanced Studies in Supply Management; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2021; pp. 211–232. [Google Scholar]

- Birch-Jensen, A.; Gremyr, I.; Halldórsson, Á. Digitally Connected Services: Improvements through Customer-Initiated Feedback. Eur. Manag. J. 2020, 38, 814–825. [Google Scholar] [CrossRef]

- Granados, N.; Gupta, A. Transparency Strategy: Competing with Information in a Digital World. MIS Q. 2013, 37, 637–641. [Google Scholar] [CrossRef]

- Hansen, L.D.; Shneiderman, B.; Smith, A.M.; Himelboim, I. Analyzing Social Media Networks with NodeXL. Insights from a Connected World; Elsevier: Burlington, MA, USA, 2020. [Google Scholar]

- Pagani, M. Digital Business Strategy and Value Creation: Framing the Dynamic Cycle of Control Points. MIS Q. 2013, 37, 617–632. [Google Scholar] [CrossRef]

- Chan, F.T.S.; Bhagwat, R.; Wadhwa, S. Study on Suppliers’ Flexibility in Supply Chains: Is Real-Time Control Necessary? Int. J. Prod. Res. 2009, 47, 965–987. [Google Scholar] [CrossRef]

- Berger, R. Die Digitale Transformation der Industrie; Bundesverband der Deutschen Industrie e.V. (BDI): Berlin, Germany, 2015. [Google Scholar]

- Ward, P.; Zhou, H. Impact of Information Technology Integration and Lean/Just-In-Time Practices on Lead-Time Performance. Decis. Sci. 2006, 37, 177–203. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 Technologies: Implementation Patterns in Manufacturing Companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Park, S.R.; Pandey, S.; Rhee, S. Co-Creation of Customers’ Extrinsic Value through C2C and e-Store Interaction in an e-Commerce Setting. IJSSCI 2015, 5, 255. [Google Scholar] [CrossRef]

- Stank, T.P.; Keller, S.B.; Daugherty, P.J. Supply Chain Collaboration and Logistical Service Performance. J. Bus. Logist. 2001, 22, 29–48. [Google Scholar] [CrossRef]

- Pagell, M. Understanding the Factors That Enable and Inhibit the Integration of Operations, Purchasing and Logistics. J. Oper. Manag. 2004, 22, 459–487. [Google Scholar] [CrossRef]

- Viale, L. Intra-Functional Coordination: The Case of Purchasing during Innovation in the Agri-Food Sector. Supply Chain Forum Int. J. 2019, 20, 104–115. [Google Scholar] [CrossRef]

- Henard, D.H.; Szymanski, D.M. Why Some New Products Are More Successful than Others. J. Mark. Res. 2001, 38, 362–375. [Google Scholar] [CrossRef]

- Tatikonda, M.V.; Montoya-Weiss, M.M. Integrating Operations and Marketing Perspectives of Product Innovation: The Influence of Organizational Process Factors and Capabilities on Development Performance. Manag. Sci. 2001, 47, 151–172. [Google Scholar] [CrossRef]

- Baker, W.E.; Sinkula, J.M. Market Orientation and the New Product Paradox. J. Prod. Innov. Manag. 2005, 22, 483–502. [Google Scholar] [CrossRef]

- Knott, P.; Thnarudee, C. Strategic Planning as Inter-Unit Coordination: An in Depth Case Study in Thailand. Asia Pac. J. Manag. 2020. [Google Scholar] [CrossRef]

- Czech Statistical Office. Podniky Pod Tuzemskou a Zahraniční Kontrolou v Členění Podle Převažující Ekonomické Činnosti [Enterprises under Domestic and Foreign Control Broken down by Predominant Economic Activity]. Available online: https://vdb.czso.cz/vdbvo2/faces/index.jsf?page=vystup-objekt-vyhledavani&vyhltext=ifats&bkvt=aWZhdHM.&katalog=all&pvo=IFATSD001 (accessed on 1 October 2021).

- Czech Statistical Office. High-Tech Sector. Available online: https://www.czso.cz/csu/czso/high_tech_sektor (accessed on 25 November 2019).

- Vrchota, J.; Pech, M. Readiness of Enterprises in Czech Republic to Implement Industry 4.0: Index of Industry 4.0. Appl. Sci. 2019, 9, 5405. [Google Scholar] [CrossRef] [Green Version]

- Yáñez, F. The 20 Key Technologies of Industry 4.0 and Smart Factories: The Road to the Digital Factory of the Future: The Road to the Digital Factory of the Future; Independently Published; 2017; Available online: https://www.amazon.com/Technologies-Industry-Factories-Digital-Factory/dp/1973402106 (accessed on 20 January 2022).

- Benitez, J.; Henseler, J.; Castillo, A.; Schuberth, F. How to Perform and Report an Impactful Analysis Using Partial Least Squares: Guidelines for Confirmatory and Explanatory IS Research. Inf. Manag. 2020, 57, 103168. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D.F. Evaluating Structural Equation Models with Unobservable Variables and Measurement Error. J. Mark. Res. 1981, 18, 39. [Google Scholar] [CrossRef]

- Voorhees, C.M.; Brady, M.K.; Calantone, R.; Ramirez, E. Discriminant Validity Testing in Marketing: An Analysis, Causes for Concern, and Proposed Remedies. J. Acad. Mark. Sci. 2016, 44, 119–134. [Google Scholar] [CrossRef]

- Hair, J.F.; Ringle, C.M.; Sarstedt, M. PLS-SEM: Indeed a Silver Bullet. J. Mark. Theory Pract. 2011, 19, 139–152. [Google Scholar] [CrossRef]

- Henseler, J.; Hubona, G.; Ray, P.A. Using PLS Path Modeling in New Technology Research: Updated Guidelines. Ind. Manag. Data Syst. 2016, 116, 2–20. [Google Scholar] [CrossRef]

- Rigdon, E.E. Rethinking Partial Least Squares Path Modeling: In Praise of Simple Methods. Long Range Plan. 2012, 45, 341–358. [Google Scholar] [CrossRef]

- Henseler, J. ADANCO 2.0.1 User Manual; Composite Modeling: Kleve, Germany, 2017. [Google Scholar]

- Vinzi, V.; Chin, W.; Helseler, J.; Wang, H. Handbook of Computational Statistics—PLS and Marketing; Springer: New York, NY, USA, 2008. [Google Scholar]

- Dijkstra, T.K.; Henseler, J. Consistent and Asymptotically Normal PLS Estimators for Linear Structural Equations. Comput. Stat. Data Anal. 2015, 81, 10–23. [Google Scholar] [CrossRef] [Green Version]

- Henseler, J.; Sarstedt, M. Goodness-of-Fit Indices for Partial Least Squares Path Modeling. Comput. Stat. 2013, 28, 565–580. [Google Scholar] [CrossRef] [Green Version]

- Cohen, J. Statistical Power Analysis for the Behavioral Sciences, 2nd ed.; L. Erlbaum Associates: Hillsdale, NJ, USA, 1988; ISBN 978-0-8058-0283-2. [Google Scholar]

- Henseler, J.; Dijkstra, T.K.; Sarstedt, M.; Ringle, C.M.; Diamantopoulos, A.; Straub, D.W.; Ketchen, D.J.; Hair, J.F.; Hult, G.T.M.; Calantone, R.J. Common Beliefs and Reality About PLS: Comments on Rönkkö and Evermann (2013). Organ. Res. Methods 2014, 17, 182–209. [Google Scholar] [CrossRef] [Green Version]

- Veile, J.W.; Kiel, D.; Müller, J.M.; Voigt, K.-I. Lessons Learned from Industry 4.0 Implementation in the German Manufacturing Industry. JMTM 2019, 31, 977–997. [Google Scholar] [CrossRef] [Green Version]

- Murphy, C. Walmart to End Contract with Company Providing Robots to Scan Shelves. Available online: https://www.usatoday.com/story/money/2020/11/03/walmart-robots-retailer-reportedly-ends-contract-robots-stores/6136684002/ (accessed on 21 January 2022).

- Wang, Y.; Li, D. Testing the Moderating Effects of Toolkits and User Communities in Personalization: The Case of Social Networking Service. Decis. Support Syst. 2013, 55, 31–42. [Google Scholar] [CrossRef]

- Jäger, J.; Schöllhammer, O.; Lickefett, M.; Bauernhansl, T. Advanced Complexity Management Strategic Recommendations of Handling the “Industrie 4.0” Complexity for Small and Medium Enterprises. Procedia CIRP 2016, 57, 116–121. [Google Scholar] [CrossRef]

- Marsh, H.W.; Hau, K.-T.; Balla, J.R.; Grayson, D. Is More Ever Too Much? The Number of Indicators per Factor in Confirmatory Factor Analysis. Multivar. Behav. Res. 1998, 33, 181–220. [Google Scholar] [CrossRef] [PubMed]

- Rossiter, J.R. The C-OAR-SE Procedure for Scale Development in Marketing. Int. J. Res. Mark. 2002, 19, 305–335. [Google Scholar] [CrossRef] [Green Version]

- Sackett, P.R.; Larson, J.R. Research Strategies and Tactics in I/O Psychology. In Handbook of Industrial and Organizational Psychology; Dunnette, D.M., Ackerman, L.P., Hough, M.L., Triandis, C.H., Eds.; Consulting Psychologist Press: Palo Alto, CA, USA, 1990; Volume 1, pp. 419–489. [Google Scholar]

- Reilly, T. A Necessary and Sufficient Condition for Identification of Confirmatory Factor Analysis Models of Factor Complexity One. Sociol. Methods Res. 1995, 23, 421–441. [Google Scholar] [CrossRef]

- Nachtigall, C.; Kroehne, U.; Funke, F.; Steyer, R. (Why) Should We Use SEM? Pros and Cons of Structural Equation Modeling. Methods Psychol. Res. Online 2003, 8, 1–22. [Google Scholar]

- Zhang, S. Sinopec Europa GmbH. Available online: https://www.unido.org/news/harnessing-potential-industry-40-tech-improve-e-commerce (accessed on 21 January 2022).

- Cozmiuc, D.; Petrisor, I. Industrie 4.0 by Siemens: Steps Made Next. J. Cases Inf. Technol. 2018, 20, 31–45. [Google Scholar] [CrossRef] [Green Version]

| Construct/Indicator | ρA | α | AVE | VIF | Weights | Loadings |

|---|---|---|---|---|---|---|

| External integration | 0.8822 | 0.8892 | 0.7892 | |||

| → EXI1 (customers) | 2.6513 | 0.5300 | 0.8906 | |||

| → EXI2 (suppliers) | 2.6513 | 0.5273 | 0.8861 | |||

| Internal integration | 0.8091 | 0.8066 | 0.6774 | |||

| → ICO1 (department) | 1.8410 | 0.5642 | 0.8498 | |||

| → ICO2 (processes) | 1.8410 | 0.5281 | 0.7954 | |||

| Internal value chain | 0.8569 | 0.8398 | 0.6497 | |||

| → PLC1 (development) | 1.5591 | 0.3260 | 0.6864 | |||

| → PLC2 (planning) | 2.8848 | 0.4034 | 0.8493 | |||

| → PLC3 (manufacturing) | 2.6685 | 0.4131 | 0.8698 | |||

| Digitalization | 0.8579 | 0.8507 | 0.5921 | |||

| → DIG1 (IS) | 2.2181 | 0.3346 | 0.8556 | |||

| → DIG (connection) | 2.3323 | 0.3102 | 0.7932 | |||

| → DIG3 (IoT) | 1.8052 | 0.2778 | 0.7103 | |||

| → DIG4 (systems) | 1.6441 | 0.2772 | 0.7090 |

| Discrepancy | Value | HI95 | HI99 | Conclusion |

|---|---|---|---|---|

| SRMR | 0.0278 | 0.0286 | 0.0314 | Supported |

| dULS | 0.0701 | 0.0745 | 0.0895 | Supported |

| dG | 0.0578 | 0.0611 | 0.0700 | Supported |

| Construct | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Digitalization | 1.0000 | |||||

| Technology readiness | 0.7055 | 1.0000 | ||||

| Internal value chain | 0.6859 | 0.6139 | 1.0000 | |||

| Customization | 0.3343 | 0.2079 | 0.3885 | 1.0000 | ||

| External integration | 0.4739 | 0.3703 | 0.4142 | 0.2819 | 1.0000 | |

| Internal integration | 0.6557 | 0.6218 | 0.7332 | 0.2229 | 0.6741 | 1.0000 |

| Discrepancy | Value | HI95 | HI99 | Conclusion |

|---|---|---|---|---|

| SRMR | 0.0378 | 0.0342 | 0.0382 | Supported |

| dULS | 0.1297 | 0.1066 | 0.1325 | Supported |

| dG | 0.0690 | 0.0658 | 0.0751 | Supported |

| Path Direction | Direct Effect | Indirect Effect | Total Effect | Cohen’s f2 |

|---|---|---|---|---|

| Technology readiness → Digitalization | 0.7055 *** | 0.7055 *** | 0.9911 | |

| Technology readiness → Internal integration | 0.3169 *** | 0.3048 *** | 0.6218 *** | 0.0971 |

| Technology readiness → External integration | 0.4358 *** | 0.4358 *** | ||

| Technology readiness → Internal value chain | 0.1109 | 0.5030 *** | 0.6139 *** | 0.0147 |

| Technology readiness → Customization | 0.2650 *** | 0.2650 *** | ||

| Digitalization → Internal integration | 0.4321 *** | 0.4321 *** | 0.1804 | |

| Digitalization → External integration | 0.0560 | 0.2754 *** | 0.3314 *** | 0.0033 |

| Digitalization → Internal value chain | 0.3020 *** | 0.2014 *** | 0.5035 *** | 0.1014 |

| Digitalization → Customization | 0.2135 *** | 0.2135 *** | ||

| External integration → Customization | 0.1460 * | 0.1460 * | 0.0212 | |

| Internal integration → External integration | 0.6373 *** | 0.6373 *** | 0.4258 | |

| Internal integration → Internal value chain | 0.4662 *** | 0.4662 *** | 0.2949 | |

| Internal integration → Customization | 0.2460 *** | 0.2460 *** | ||

| Internal value chain → Customization | 0.3280 *** | 0.3280 *** | 0.1072 |

| Direct Effects | Path Coef. (β) | t-Value | p-Value |

|---|---|---|---|

| Technology readiness → Digitalization (H1) | 0.7055 | 21.9613 | 0.0000 *** |

| Technology readiness → Internal value chain (H2) | 0.1109 | 1.4416 | 0.0747 |

| Technology readiness → Internal integration (H3) | 0.3169 | 4.2819 | 0.0000 *** |

| Digitalization → Internal integration (H4) | 0.4321 | 5.6126 | 0.0000 *** |

| Digitalization → Internal value chain (H5) | 0.3020 | 3.2075 | 0.0007 *** |

| Digitalization → External integration (H6) | 0.0560 | 0.6531 | 0.2568 |

| Internal value chain → Customization (H7) | 0.3280 | 4.9757 | 0.0000 *** |

| External integration → Customization (H8) | 0.1460 | 2.1832 | 0.0145 * |

| Internal integration → External integration (H9) | 0.6373 | 7.3406 | 0.0000 *** |

| Internal integration → Internal value chain (H10) | 0.4662 | 5.0435 | 0.0000 *** |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pech, M.; Vrchota, J. The Product Customization Process in Relation to Industry 4.0 and Digitalization. Processes 2022, 10, 539. https://doi.org/10.3390/pr10030539

Pech M, Vrchota J. The Product Customization Process in Relation to Industry 4.0 and Digitalization. Processes. 2022; 10(3):539. https://doi.org/10.3390/pr10030539

Chicago/Turabian StylePech, Martin, and Jaroslav Vrchota. 2022. "The Product Customization Process in Relation to Industry 4.0 and Digitalization" Processes 10, no. 3: 539. https://doi.org/10.3390/pr10030539

APA StylePech, M., & Vrchota, J. (2022). The Product Customization Process in Relation to Industry 4.0 and Digitalization. Processes, 10(3), 539. https://doi.org/10.3390/pr10030539