Research on Mechanical–Structural and Oil Yield Properties during Xanthoceras sorbifolium Seed Oil Extraction

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

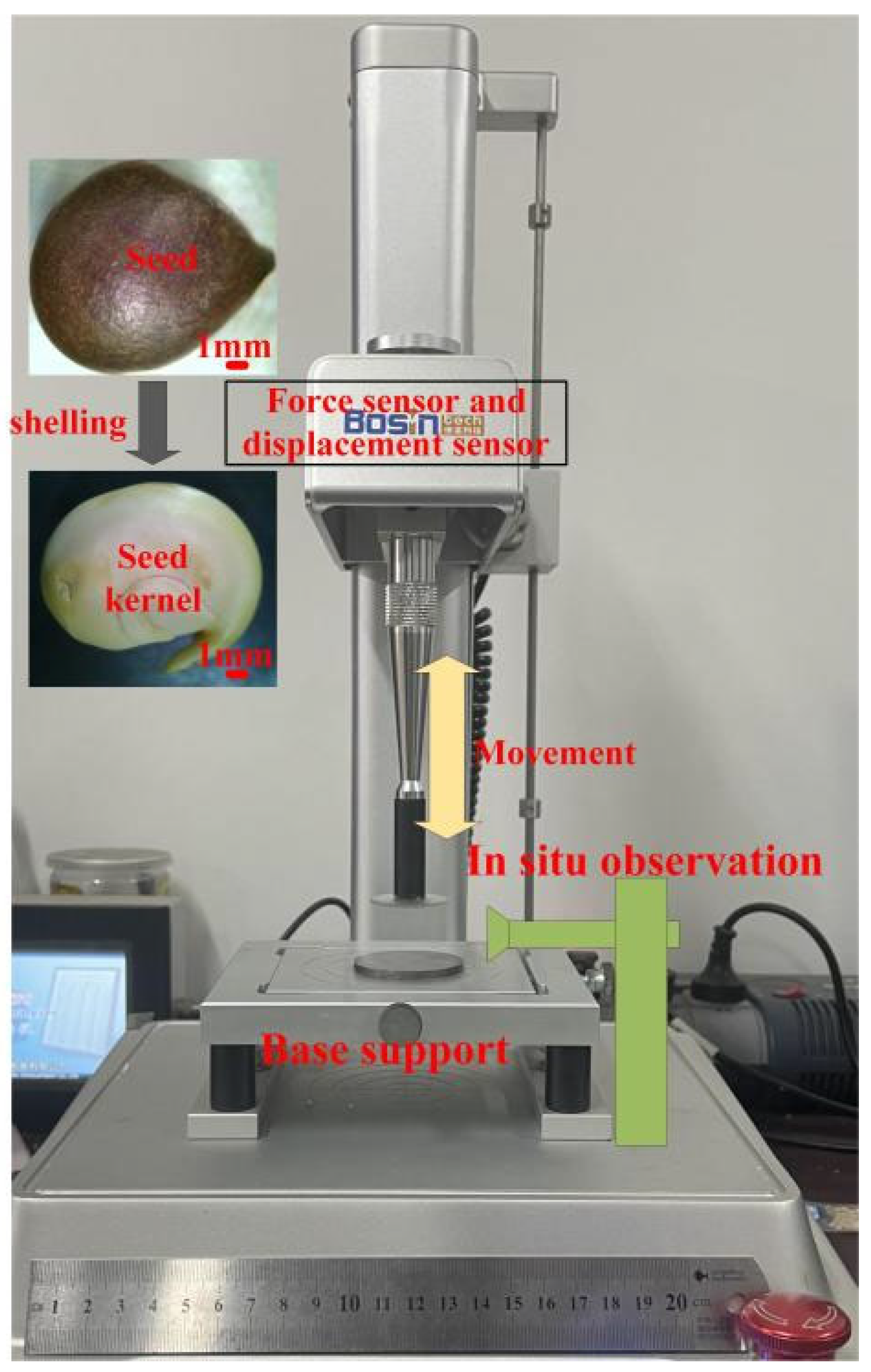

2.2. Experimental Procedure

2.2.1. Compression Test Design for X. sorbifolium Seed Kernel

2.2.2. Structural–Mechanical and Oil Output Characterization

3. Results and Discussion

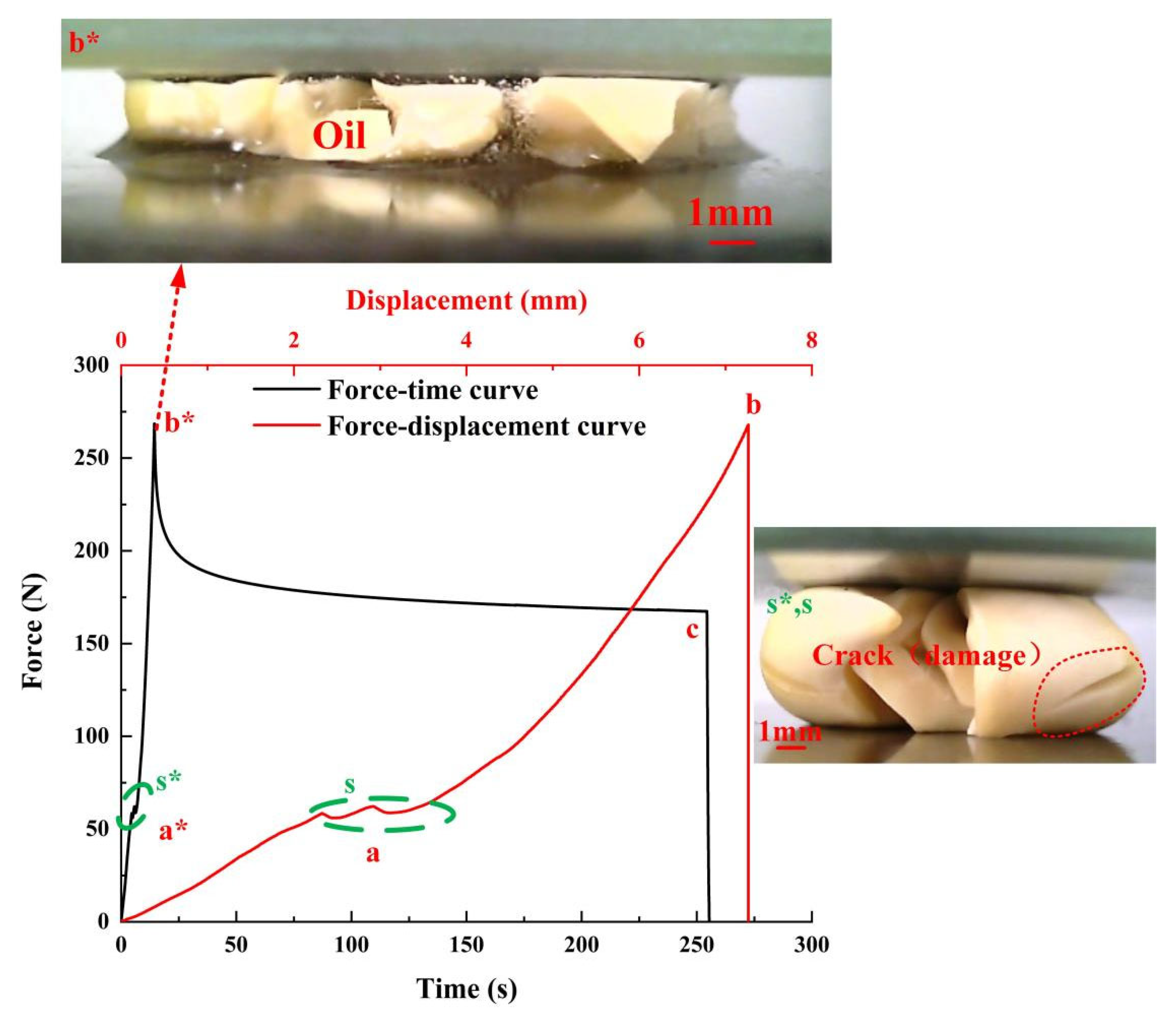

3.1. Compression Curve Analysis for X. sorbifolium Seed

Seed Kernel Structural–Mechanical Properties and Oil Output during Extrusion

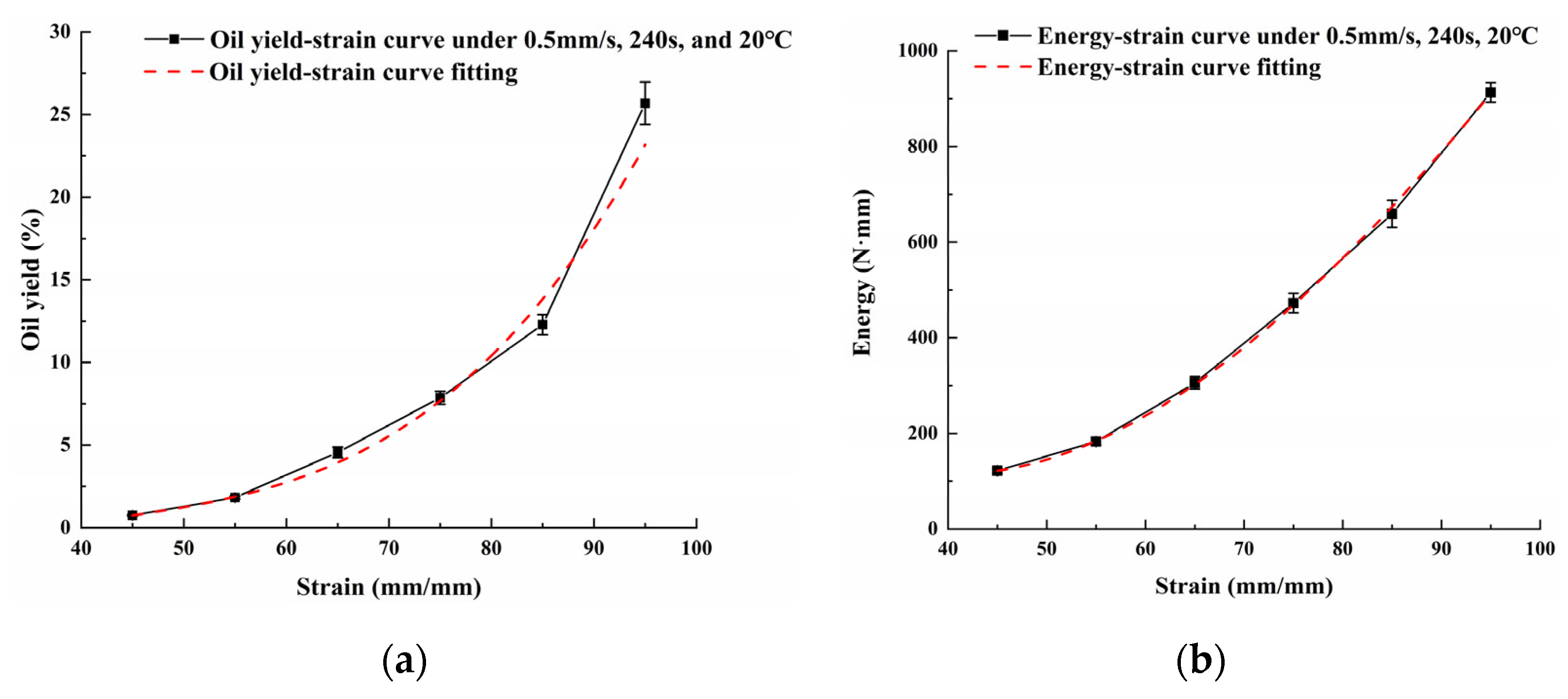

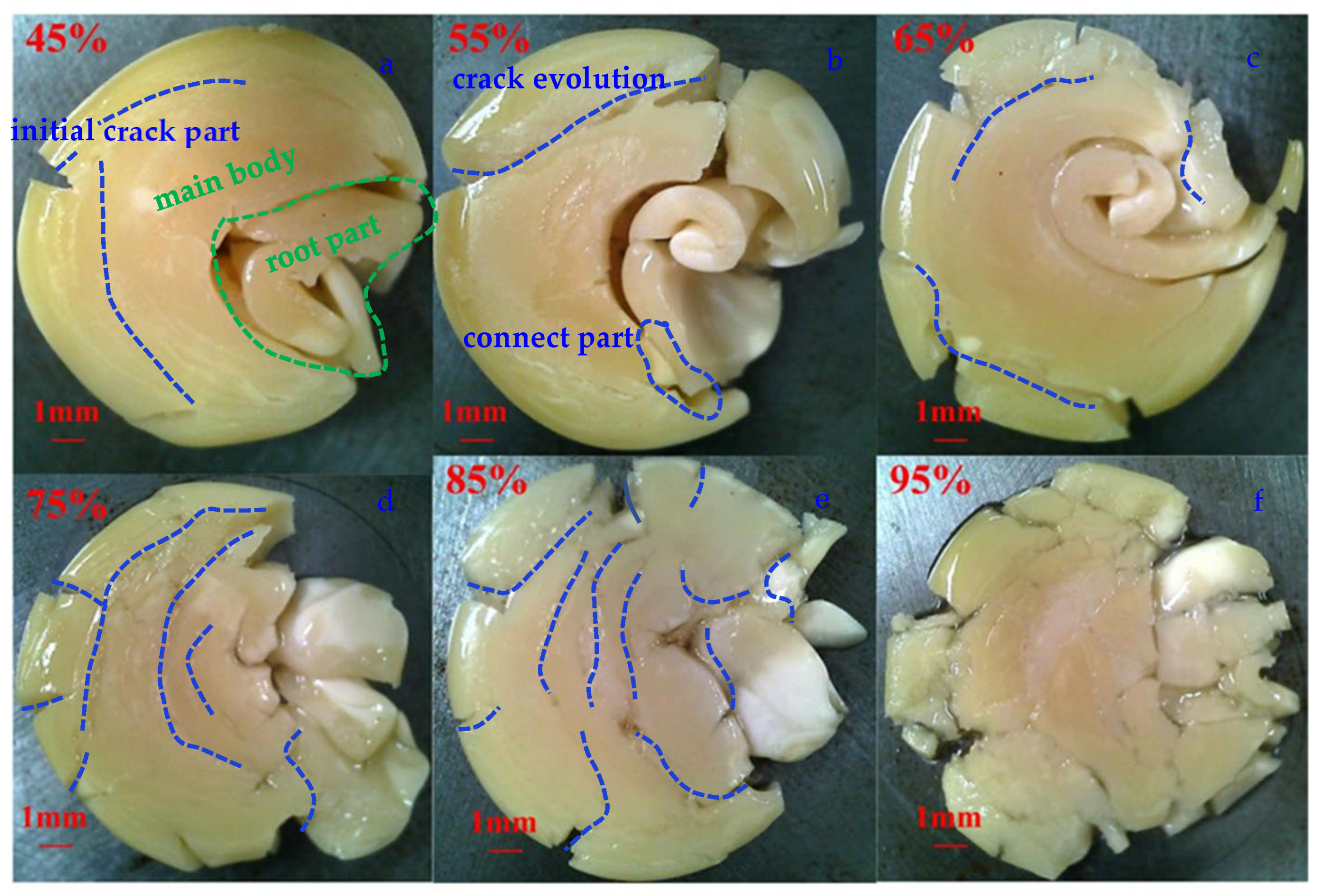

3.2. Effect of Pressing Strain on the Mechanical–Structural Properties and Oil Yield of Seed Kernels

3.3. Effect of Pressing Speed on Mechanical–Structural Properties and Oil Yield of Seed Kernels

3.4. Effect of Dwell Time on Oil Yield of Seed Kernels

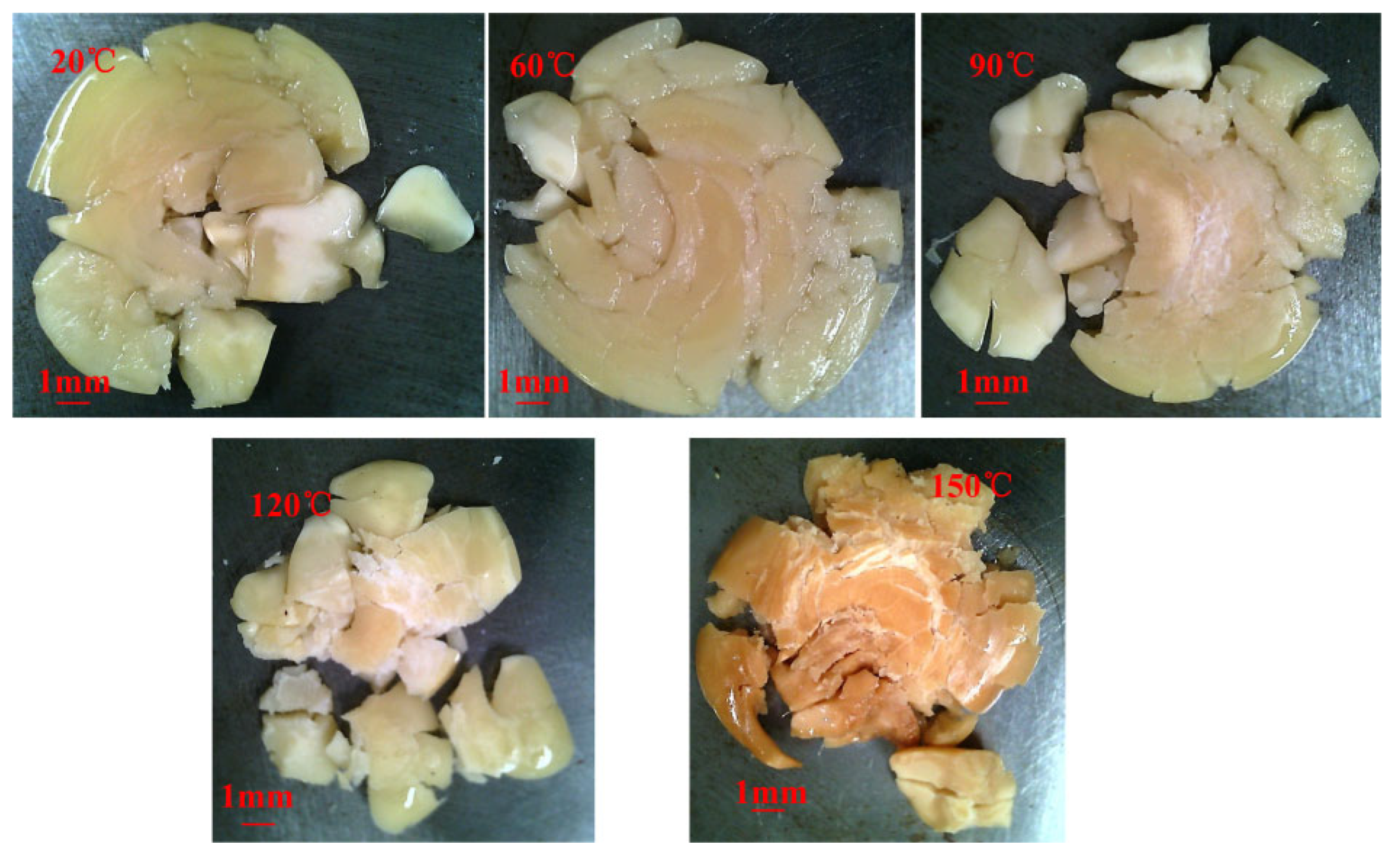

3.5. Effect of Drying Temperature on the Mechanical–Structural Properties and Oil Yield of Seed Kernels

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gu, L.B.; Zhang, G.J.; Du, L.; Du, J.; Qi, K.; Zhu, X.L.; Zhang, X.Y.; Jiang, Z.H. Comparative study on the extraction of Xanthoceras sorbifolia Bunge (yellow horn) seed oil using subcritical n -butane, supercritical CO2, and the Soxhlet method. LWT Food Sci. Technol. 2019, 111, 548–554. [Google Scholar] [CrossRef]

- Zhang, Z.S.; Zhang, Y.; Ao, Y.; Saunders, M.R.; Xu, W. Diversity of seed and seed oil physicochemical traits of Xanthoceras sorbifolium Bunge. J. Food Compos. Anal. 2020, 96, 103705–103710. [Google Scholar] [CrossRef]

- Ao, Y.; Duan, J.; Yu, H.; Jiang, C.; Ma, L. Research progress on Xanthoceras sorbifolia Bunge. J. China Agric. Univ. 2012, 17, 197–203. [Google Scholar]

- Li, J.; Zu, Y.G.; Luo, M.; Gu, C.B.; Zhao, C.J.; Efferth, T.; Fu, Y.J. Aqueous enzymatic process assisted by microwave extraction of oil from yellow horn (Xanthoceras sorbifolia Bunge.) seed kernels and its quality evaluation. Food Chem. 2013, 138, 2152–2158. [Google Scholar] [CrossRef]

- Liu, S.M.; Sun, B.Y.; He, A.Q.; Liu, D.L.; Zhang, G.; Wei, D.D. Geographical Change of Seed Characteristic and the Main Chemical Composition of Xanthoceras sorbifolia Population in the West of China. Entia Silvae Sin. 2012, 48, 43–48. [Google Scholar]

- Li, J.; Zu, Y.G.; Fu, Y.J.; Yang, Y.C.; Li, S.M.; Li, Z.N.; Wink, M. Optimization of microwave-assisted extraction of triterpene saponins from defatted residue of yellow horn (Xanthoceras sorbifolia Bunge.) kernel and evaluation of its antioxidant activity. Innov. Food Sci. Emerg. Technol. 2010, 11, 637–643. [Google Scholar] [CrossRef]

- Szentmihályi, K.; Vinkler, P.; Lakatos, B.; Illés, V.; Then, M. Rose hip (Rosa canina L.) oil obtained from waste hip seeds by different extraction methods. Bioresour. Technol. 2002, 82, 195–201. [Google Scholar] [CrossRef]

- Qu, X.J.; Fu, Y.J.; Luo, M.; Zhao, C.J.; Zu, Y.G.; Li, C.Y.; Wang, W.; Li, J.; Wei, Z.F. Acidic pH based microwave-assisted aqueous extraction of seed oil from yellow horn (Xanthoceras sorbifolia Bunge.). Ind. Crops Prod. 2013, 43, 420–426. [Google Scholar] [CrossRef]

- Gauthier, C.; Legault, J.; Girard-Lalancette, K.; Mshvildadze, V.; Pichette, A. Haemolytic activity, cytotoxicity and membrane cell permeabilization of semi-synthetic and natural lupane- and oleanane-type saponins. Bioorganic Med. Chem. 2009, 17, 2002–2008. [Google Scholar] [CrossRef]

- Lin, D. The development and prospective of bioenergy technology in China. Biomass Bioenergy 1998, 15, 181–186. [Google Scholar] [CrossRef]

- Chapuis, A.; Blin, J.; Carré, P.; Lecomte, D. Separation efficiency and energy consumption of oil expression using a screw-press: The case of Jatropha curcas L. seeds. Ind. Crops Prod. 2014, 52, 752–761. [Google Scholar] [CrossRef]

- Arrutia, F.; Bienner, E.; Williams, P.; Waldron, K.W. Oilseeds beyond oil: Press cakes and meals supplying global protein requirements. Trends Food Sci. Tech. 2020, 100, 88–102. [Google Scholar] [CrossRef]

- Evelien, U.; Philippe, E. Twin-screw extrusion technology for vegetable oil extraction: A review. J. Food Eng. 2017, 212, 190–200. [Google Scholar]

- Kabutey, A.; Herák, D.; Ambarita, H.; Sigalingging, R. Modeling of Linear and Non-linear Compression Processes of Sunflower Bulk Oilseeds. Energies 2019, 12, 2999. [Google Scholar] [CrossRef] [Green Version]

- Singh, K.K.; Wiesenborn, D.P.; Tostenson, K.; Kangas, N. Influence of moisture content and cooking on screw pressing of crambe seed. J. Am. Oil Chem. Soc. 2002, 79, 165–170. [Google Scholar] [CrossRef]

- Adeeko, K.A.; Ajibola, O.O. Processing factors affecting yield and quality of mechanically expressed groundnut oil. J. Agric. Eng. Res. 1990, 45, 31–43. [Google Scholar] [CrossRef]

- Patil, R.T.; Ali, N. Effect of Pre-Treatments on Mechanical Oil Expression of Soybean Using a Commercial Oil Expeller. Int. J. Food Prop. 2006, 9, 227–236. [Google Scholar] [CrossRef]

- Bargale, P.C.; Singh, J. Oil Expression Characteristics of Rapeseed for a Small Capacity Screw Press. J. Food Sci. Technol. Mysore 2000, 37, 130–134. [Google Scholar]

- Evon, P.; Amalia Kartika, I.; Cerny, M.; Rigal, L. Extraction of oil from jatropha seeds using a twin-screw extruder: Feasibility study. Ind. Crops Prod. 2013, 47, 33–42. [Google Scholar] [CrossRef] [Green Version]

- Tambunan, A.H.; Situmorang, J.P.; Silip, J.J.; Joelianingsih, A.; Araki, T. Yield and physicochemical properties of mechanically extracted crude Jatropha curcas L oil. Biomass Bioenergy 2012, 43, 12–17. [Google Scholar] [CrossRef]

- Fadhlullah, M.; Widiyanto, S.N.B.; Restiawaty, E. The Potential of Nyamplung (Calophyllum inophyllum L.) Seed Oil as Biodiesel Feedstock: Effect of Seed Moisture Content and Particle Size on Oil Yield. Energy Procedia 2015, 68, 177–185. [Google Scholar] [CrossRef] [Green Version]

- Martinez, M.L.; Penci, M.C.; Marin, M.A.; Ribotta, P.D. Screw press extraction of almond (Prunus dulcis (Miller) D.A. Webb): Oil recovery and oxidative stability. J. Food Eng. 2013, 119, 40–45. [Google Scholar] [CrossRef]

- Bogaert, L.; Mathieu, H.; Mhemdi, H.; Vorobiev, E. Characterization of oilseeds mechanical expression in an instrumented pilot screw press. Ind. Crops Prod. 2018, 121, 106–113. [Google Scholar] [CrossRef]

- Chouaibia, M.; Rezig, L.; Hamdi, S.; Ferrari, G. Chemical characteristics and compositions of red pepper seed oils extracted by different methods-Science Direct. Ind. Crops Prod. 2019, 128, 363–370. [Google Scholar] [CrossRef]

- Petropoulos, S.A.; Ângela, F.; Calhelha, R.C.; Danalatos, N.; Barros, L.; Ferreira, I.C.F.R. How extraction method affects yield, fatty acids composition and bioactive properties of cardoon seed oil? Ind. Crops Prod. 2018, 124, 459–465. [Google Scholar] [CrossRef] [Green Version]

- Subroto, E.; Manurung, R.; Heeres, H.J.; Broekhuis, A.A. Mechanical extraction of oil from Jatropha curcas L. kernel: Effect of processing parameters. Ind. Crops Prod. 2015, 63, 303–310. [Google Scholar] [CrossRef]

- Herák, D.; Gurdil, G.; Sedlacek, A.; Dajbych, O.; Simanjuntak, S. Energy demands for pressing Jatropha curcas L. seeds. Biosyst. Eng. 2010, 106, 527–534. [Google Scholar] [CrossRef]

- Kabutey, A.; Herák, D.; Chotěborský, R.; Sigalingging, R.; Mizera, Č. Effect of compression speed on energy requirement and oil yield of Jatropha curcas L. bulk seeds under linear compression. Biosyst. Eng. 2015, 136, 8–13. [Google Scholar] [CrossRef]

- Yang, L.; Chen, H.; Xiao, J.Y.; Fan, Y.C.; Song, S.Y.; Zhang, Y.L.; Liu, X.P. Research on Structural–Mechanical Properties during the Castor Episperm Breaking Process. Processes 2021, 9, 1777. [Google Scholar] [CrossRef]

- Noraphaiphipaksa, N.; Sochu, W.; Manonukul, A.; Kanchanomai, C. Experimental and numerical investigations to determine the modulus and fracture mechanics of tamarind seed (Tamarindus indica L.). Biosyst. Eng. 2016, 151, 17–27. [Google Scholar] [CrossRef]

- Toktam, M.M.; Ali, F.; Somayeh, H. The effect of different spices on the moisture content, texture characterizations and consumer preferences of roasted sunflower seeds. Food Chem. X 2021, 12, 100130. [Google Scholar]

- Ewunie, G.A.; Lekang, O.I.; Morken, J. Characterizing the potential and suitability of Ethiopian variety Jatropha curcas for biodiesel production: Variation in yield and physicochemical properties of oil across different growing areas. Energy Rep. 2021, 7, 439–452. [Google Scholar] [CrossRef]

- Jonas, M.; Ketlogetswe, C.; Gandure, J. Variation of Jatropha curcas seed oil content and fatty acid composition with fruit maturity stage. Heliyon 2020, 6, e03285. [Google Scholar] [CrossRef]

- Rubab, S.; Rizwani, G.H.; Bahadur, S.; Shah, M.; Alsamadany, H.; Alzahrani, Y.; Shuaib, M.; Hershan, A.; Hobani, Y.H.; Shah, A.A. Determination of the GC–MS analysis of seed oil and assessment of pharmacokinetics of leaf extract of Camellia sinensis L. J. King Saud Univ. Sci. 2020, 32, 3138–3144. [Google Scholar] [CrossRef]

- Saiedirad, M.H.; Tabatabaeefar, A.; Borghei, A.; Mirsalehi, M.; Badii, F.; Ghasemi Varnamkhasti, M. Effects of moisture content, seed size, loading rate and seed orientation on force and energy required for fracturing cumin seed (Cuminum cyminum Linn.) under quasi-static loading. J. Food Eng. 2008, 86, 565–572. [Google Scholar] [CrossRef]

- Braga, G.C.; Couto, S.M.; Hara, T.; Neto, J.T.P.A. Mechanical Behaviour of Macadamia Nut under Compression Loading. J. Agric. Eng. Res. 1999, 72, 239–245. [Google Scholar] [CrossRef]

- Cárcel, L.M.; Bon, J.; Acuña, L.; Nevares, I.; del Álamo, M.; Crespo, R. Moisture dependence on mechanical properties of pine nuts from Pinus pinea L. J. Food Eng. 2012, 110, 294–297. [Google Scholar] [CrossRef]

- Yu, C.Q.; Yu, Y.R.; Zhao, Y.M.; He, P.G.; Xu, C.S.; Fu, S.; Yang, Z.H. Mechanical properties and in situ fracture behavior of SiO 2f/phosphate geopolymer composites. Rare Met. 2019, 39, 1–8. [Google Scholar]

- Willems, P.; Kuipers, N.; Haan, A. Hydraulic pressing of oilseeds: Experimental determination and modeling of yield and pressing rates. J. Food Eng. 2008, 89, 8–16. [Google Scholar] [CrossRef]

- Petrů, M.; Novák, O.; Herák, D.; Simanjuntak, S. Finite element method model of the mechanical behaviour of Jatropha curcas L. seed under compression loading. Biosyst. Eng. 2012, 111, 412–421. [Google Scholar] [CrossRef]

- Hinton, M.J.; Kaddour, A.S.; Soden, P.D. The world-wide failure exercise: Its origin, concept and content. In Failure Criteria in Fibre-Reinforced-Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2004; pp. 2–28. [Google Scholar]

- Yang, L.; Chen, H.; Yin, C.; Song, S.; Zhang, Y.; Liu, X.; Hu, Z. Research on mechanicalstructure properties during sunflower seed extrusion-oil extraction. J. Food Process. Preserv. 2021, 46, 16158–16163. [Google Scholar]

- Yate, A.V.; Narváez, P.C.; Orjuela, A.; Hernández, A.; Acevedo, H. A systematic Evaluation of the Mechanical Extraction of Jatropha Curcas L. Oil for biofuels production. Food Bioprod. Process. 2020, 122, 72–81. [Google Scholar] [CrossRef]

- Savoire, R.; Lanoisellé, J.L.; Vorobiev, E. Mechanical Continuous Oil Expression from Oilseeds: A Review. Food Bioprocess Technol. 2013, 6, 1–16. [Google Scholar] [CrossRef]

- Bargale, P.C.; Ford, R.J.; Wulfsohn, D.; Irudayaraj, J.; Sosulski, F.W. Measurement of consolidation and permeability properties of extruded soy under mechanical pressing. J. Agric. Eng. Res. 1999, 74, 155–165. [Google Scholar] [CrossRef]

- Bargale, P.C.; Wulfsohn, D.; Irudayaraj, J.; Ford, R.J.; Sosulski, F.W. PH-Postharvest Technology Prediction of Oil Expression by Uniaxial Compression using Time-varying Oilseed Properties. J. Agric. Eng. Res. 2000, 77, 171–181. [Google Scholar] [CrossRef]

- Rodrigues, J.; Miranda, I.; Gominho, J.; Vasconcelos, M.; Barradas, G.; Pereira, H.; Bianchi-de-Aguiar, F.; Ferreira-Dias, S. Modeling and optimization of laboratory-scale conditioning of Jatropha curcas L. seeds for oil expression. Ind. Crops Prod. 2016, 83, 614–619. [Google Scholar] [CrossRef]

- Williamson, L.; Lucas, P. The effect of moisture content on the mechanical properties of a seed shell. J. Mater. Sci. 1995, 30, 162–166. [Google Scholar] [CrossRef]

| No. | Item | Relative Content (%) |

|---|---|---|

| 1 | Seed oil content | 30~40 |

| 2 | Seed kernel oil content | 55~65 |

| 3 | Seed kernel moisture | ≈4 |

| 4 | Seed kernel weight/seed weight | 40~50 |

| 5 | Unsaturated fatty acids | 85~93 |

| 6 | Saturated fatty acids | ≤10 |

| 7 | Moisture and volatile content in oil | ≈0.4 |

| 8 | Ash | ≈2.3 |

| Levels | Factors | |||

|---|---|---|---|---|

| Strain (Deformation Degree) during Test (%) | Pressing Speed (mm/s) | Dwell Time (s) | Temperature (°C) | |

| 1 | 45 | 0.1 | 120 | 20 |

| 2 | 55 | 0.5 | 240 | 60 |

| 3 | 65 | 1.0 | 360 | 90 |

| 4 | 75 | 1.5 | 480 | 120 |

| 5 | 85 | 2.0 | 600 | 150 |

| 6 | 95 | — | 720 | — |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Chen, H.; Yang, L.; Zhang, Y. Research on Mechanical–Structural and Oil Yield Properties during Xanthoceras sorbifolium Seed Oil Extraction. Processes 2022, 10, 564. https://doi.org/10.3390/pr10030564

Liu X, Chen H, Yang L, Zhang Y. Research on Mechanical–Structural and Oil Yield Properties during Xanthoceras sorbifolium Seed Oil Extraction. Processes. 2022; 10(3):564. https://doi.org/10.3390/pr10030564

Chicago/Turabian StyleLiu, Xiaopeng, Huan Chen, Liu Yang, and Yonglin Zhang. 2022. "Research on Mechanical–Structural and Oil Yield Properties during Xanthoceras sorbifolium Seed Oil Extraction" Processes 10, no. 3: 564. https://doi.org/10.3390/pr10030564

APA StyleLiu, X., Chen, H., Yang, L., & Zhang, Y. (2022). Research on Mechanical–Structural and Oil Yield Properties during Xanthoceras sorbifolium Seed Oil Extraction. Processes, 10(3), 564. https://doi.org/10.3390/pr10030564