Quality Characteristics and Antioxidant Activity of Fresh Noodles Formulated with Flour-Bran Blends Varied by Particle Size and Blend Ratio of Purple-Colored Wheat Bran

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Size Reduction of Purple-Colored Wheat Bran and Measurement of Bran Particle Size

2.3. Analysis of Physicochemical Properties of Purple-Colored Wheat Bran

2.4. Preparation of Flour-Bran Blends with Different Blending Ratios

2.5. Solvent Retention Capacity of Flour-Bran Blends

2.6. Preparation of Fresh White-Salted Noodles Formulated with the Flour-Bran Blends

2.7. Color Measurements of Fresh Noodle Sheets and Cooked Noodles

2.8. Measurement of Turbidity of Cooking Water

2.9. Analysis of Textural Property of Fresh and Cooked Noodles

2.10. Measurement of Total Polyphenol Content of Fresh Noodles

2.11. Measurement of Total Anthocyanin Content of Fresh Noodles

2.12. Antioxidant Activity of Fresh Noodles—ABTS Radical Scavenging Capacity

2.13. Antioxidant Activity of Fresh Noodles—DPPH Radical-Scavenging Capacity

2.14. Statistical Analysis

3. Results and Discussion

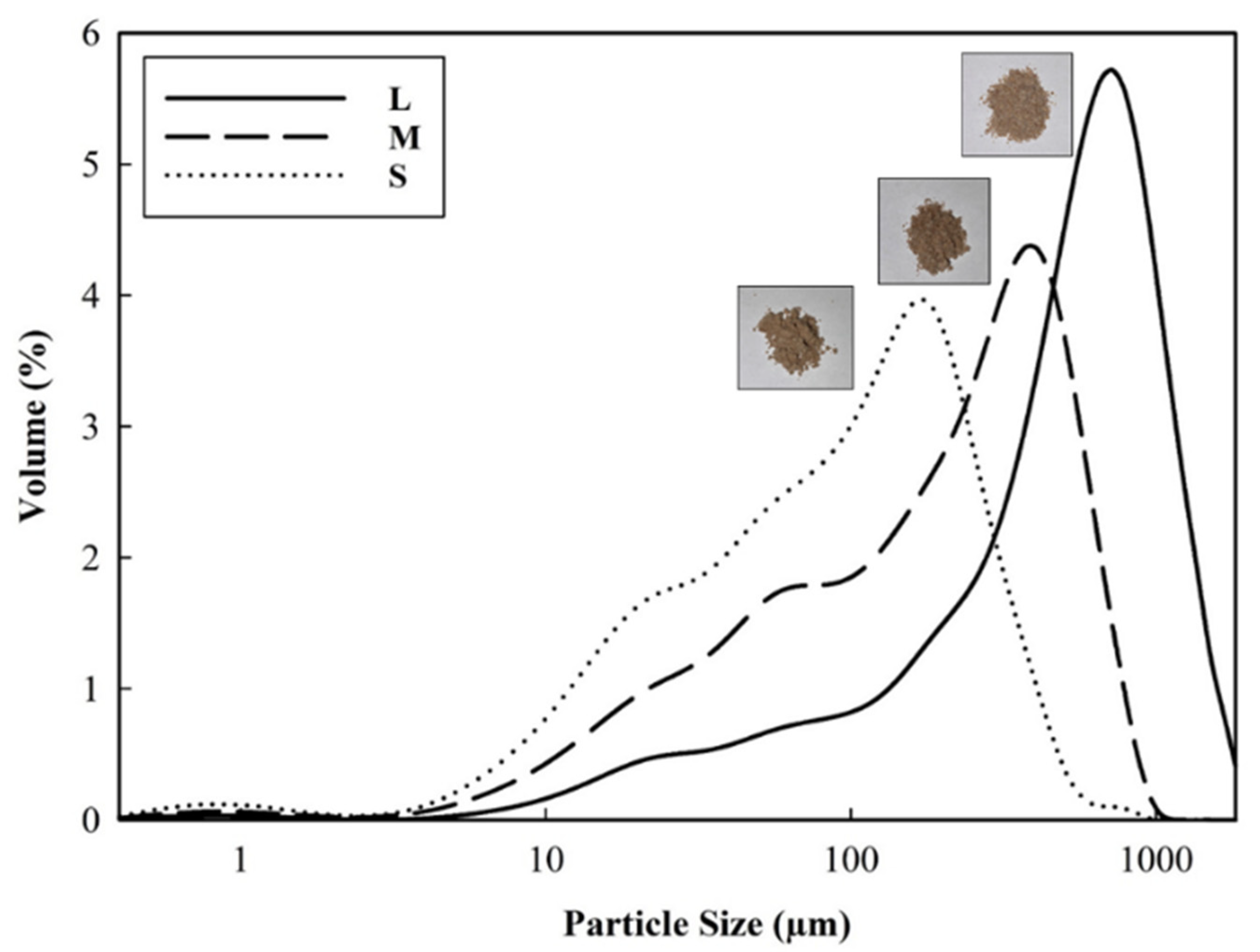

3.1. Particle Size of Purple-Colored Wheat Bran Milled with an Ultra-Centrifugal Mill

3.2. Physicochemical Properties of Purple-Colored Wheat Bran

3.3. Solvent Retention Capacity Values of Flour-Bran Blends

3.4. Appearance and Texture of Fresh Noodles

3.5. Turbidity of Cooking Water and Textural Characteristics of Cooked Noodles

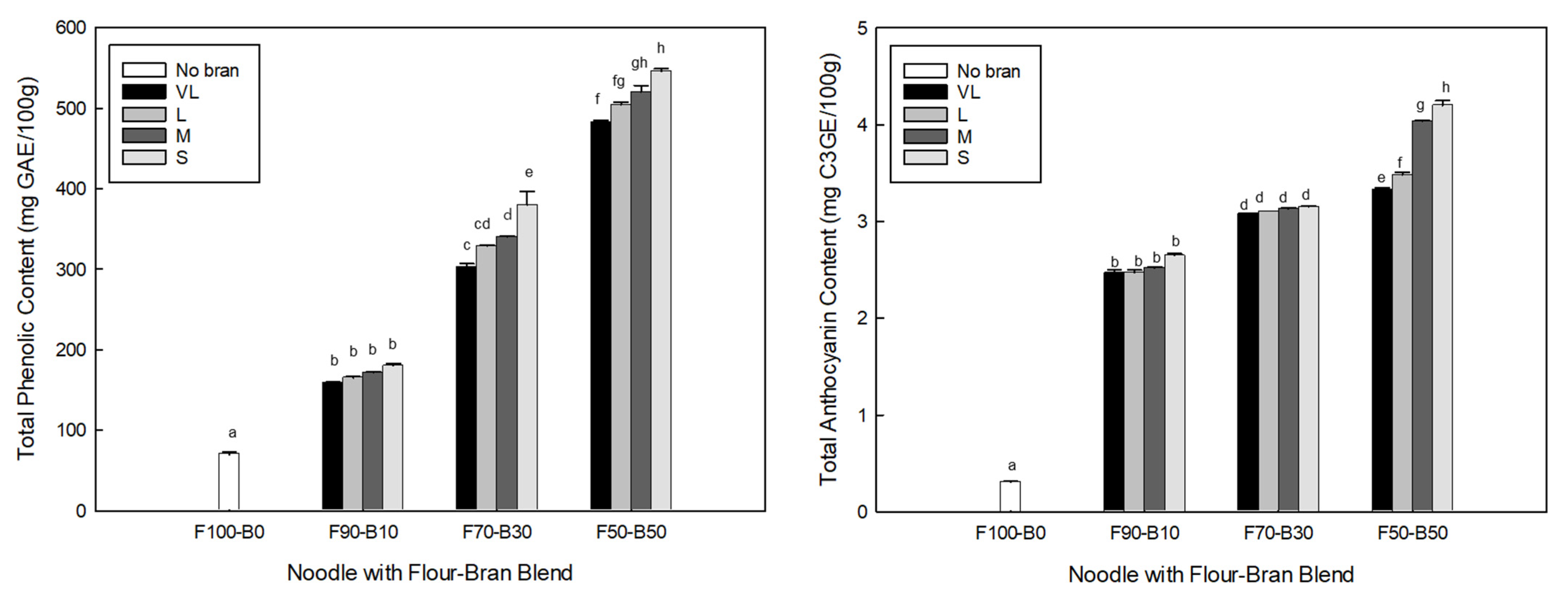

3.6. Total Phenolic Compound and Total Anthocyanin Contents of Fresh Noodles Prepared with Flour-Bran Blends

3.7. Antioxidant Activity of Fresh Noodles Prepared with Flour-Bran Blends

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Vitaglione, P.; Napolitano, A.; Fogliano, V. Cereal dietary fibre: A natural functional ingredient to deliver phenolic compounds into the gut. Trends Food Sci. Technol. 2008, 19, 451–463. [Google Scholar] [CrossRef]

- Junejo, S.H.; Geng, H.; Wang, N.; Wang, H.; Ding, Y.; Zhou, Y.; Rashid, A. Effects of particle size on physicochemical and in vitro digestion properties of durum wheat bran. Int. J. Food Sci. Technol. 2019, 54, 221–230. [Google Scholar] [CrossRef] [Green Version]

- Coda, R.; Kärki, I.; Nordlund, E.; Heiniö, R.L.; Poutanen, K.; Katina, K. Influence of particle size on bioprocess induced changes on technological functionality of wheat bran. Food Microbiol. 2014, 37, 69–77. [Google Scholar] [CrossRef] [PubMed]

- Deroover, L.; Tie, Y.; Verspreet, J.; Verspreet, J.; Courtin, C.M.; Verbeke, K. Modifying wheat bran to improve its health benefits. Crit. Rev. Food Sci. Nutr. 2020, 60, 1104–1122. [Google Scholar] [CrossRef] [PubMed]

- Rico, D.; Villaverde, A.; Martinez-Villaluenga, C.; Gutierrez, A.L.; Caballero, P.A.; Ronda, F.; Penas, E.; Frias, J.; Diana Martin, A.B. Application of autoclave treatment for development of a natural wheat bran antioxidant ingredient. Foods 2020, 9, 781. [Google Scholar] [CrossRef] [PubMed]

- Abdel-Aal, E.-S.M.; Hucl, P. Composition and stability of anthocyanins in blue-grained wheat. J. Agric. Food Chem. 2003, 51, 2174–2180. [Google Scholar] [CrossRef] [PubMed]

- Hosseinian, F.S.; Li, W.; Beta, T. Measurement of anthocyanins and other physicochemicals in purple wheat. Food Chem. 2008, 109, 916–924. [Google Scholar] [CrossRef]

- Sanz Penella, J.M.; Collar, C.; Haros, M. Effect of wheat bran and enzyme addition on dough functional performance and phytic acid levels in bread. J. Cereal Sci. 2008, 48, 715–721. [Google Scholar] [CrossRef]

- Noort, M.W.J.; van Haaster, D.; Hemery, Y.; Schols, H.A.; Hamer, R.J. The effect of particle size of wheat bran fractions on bread quality—Evidence for fibre-protein interactions. J. Cereal Sci. 2010, 52, 59–64. [Google Scholar] [CrossRef]

- Zhang, J.; Li, M.; Li, C.; Liu, Y. Effect of wheat bran insoluble dietary fiber with different particle size on the textural properties, protein secondary structure, and microstructure of noodles. Grains Oil Sci. Technol. 2019, 2, 97–102. [Google Scholar] [CrossRef]

- Aravind, N.; Sissons, M.; Fellows, C.M. Effect of soluble fibre (guar gum and carboxymethylcellulose) addition on technological, sensory and structural properties of durum wheat spaghetti. Food Chem. 2012, 131, 893–900. [Google Scholar] [CrossRef]

- Lang, R.; Jebb, S.A. Who consumes whole grains, and how much? Proc. Nutr. Soc. 2003, 62, 123–127. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bressiani, J.; Oro, T.; Santetti, G.S.; Almeida, J.L.; Bertolin, T.E.; Gómez, M.; Gutkoski, L.C. Properties of whole grain flour and performance in bakery products as a function of particle size. J. Cereal Sci. 2017, 75, 269–277. [Google Scholar] [CrossRef]

- Fu, B.X. Asian noodles: History, classification, raw materials, and processing. Food Res. Int. 2008, 41, 888–902. [Google Scholar] [CrossRef]

- Kartina, K.; Juvonen, R.; Laitila, A.; Flander, L.; Nordlund, E.; Kariluoto, S.; Piironen, V.; Poutanen, K. Fermented wheat bran as a functional ingredient in baking. Cereal Chem. 2012, 89, 126–134. [Google Scholar] [CrossRef]

- Wu, T.; Li, Z.; Sui, W.; Zhang, M. Effect of extrusion, steam explosion and enzymatic hydrolysis on functional properties of wheat bran. Food Sci. Technol. Res. 2018, 24, 591–598. [Google Scholar] [CrossRef] [Green Version]

- Park, E.Y.; Fuerst, E.P.; Baik, B.K. Effect of bran hydration with enzymes on functional properties of flour-bran blends. Cereal Chem. 2019, 96, 273–282. [Google Scholar] [CrossRef]

- Seguchi, M.; Uozu, M.; Oneda, H.; Murayama, R.; Okusu, H. Effect of outer bran layers from germinated wheat grains on bread-making properties. Cereal Chem. 2010, 87, 231–236. [Google Scholar] [CrossRef]

- Cai, L.; Choi, L.; Hyun, J.N.; Jeong, Y.K.; Baik, B.K. Influence of bran particle size on bread-baking quality of whole grain wheat flour and starch retrogradation. Cereal Chem. 2014, 91, 65–71. [Google Scholar] [CrossRef]

- Jacobs, P.J.; Hemdane, S.; Dornez, E.; Delcour, J.A.; Courtin, C.M. Study of hydration properties of wheat brans as a function of particle size. Food Chem. 2015, 179, 296–304. [Google Scholar] [CrossRef]

- Cai, L.; Choi, L.; Park, C.S.; Jeong, Y.K.; Baik, B.K. Bran hydration and physical treatment improve the bread-baking quality of whole grain wheat flour. Cereal Chem. 2015, 92, 557–564. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, F.; He, Z. Effects of bran hydration and autoclaving on processing quality of Chinese steamed bread and noodles produced from whole grain wheat flour. Cereal Chem. 2019, 96, 104–114. [Google Scholar] [CrossRef] [Green Version]

- Hemdane, S.; Leys, S.; Jacobs, P.J.; Dornez, E.; Delcour, J.A.; Courtin, C.M. Wheat milling by-products and their impact on bread making. Food Chem. 2015, 187, 280–289. [Google Scholar] [CrossRef] [PubMed]

- De Bondt, Y.; Liberloo, I.; Roye, C.; Windhab, E.J.; Lamothe, L.; King, R.; Courtin, C.M. The effect of wet milling and cryogenic milling on the structure and physicochemical properties of wheat bran. Foods 2020, 9, 1755. [Google Scholar] [CrossRef]

- Alzuwaid, N.T.; Pleming, D.; Fellows, C.M.; Laddomada, B.; Sissons, M. Influence of duram wheat bran particle size on phytochemical content and on leavened bread baking quality. Foods 2021, 10, 489. [Google Scholar] [CrossRef]

- Niu, M.; Hou, G.G.; Wang, L.; Chen, Z. Effects of superfine grinding on the quality characteristics of whole-wheat flour and its raw noodle product. J. Cereal Sci. 2014, 60, 382–388. [Google Scholar] [CrossRef]

- Chen, J.S.; Fei, M.J.; Shi, C.L.; Tian, J.C.; Sun, C.L.; Zhang, H.; Ma, Z.; Dong, H.X. Effect of particle size and addition level of wheat bran on quality of dry white Chinese noodles. J. Cereal Sci. 2011, 53, 217–224. [Google Scholar] [CrossRef]

- Memon, A.A.; Mahar, I.; Memon, R.; Soomro, S.; Harnly, J.; Memon, M.; Bhangar, M.I.; Luthria, D.L. Impact of flour particle size on nutrient and phenolic acid composition of commercial wheat varieties. J. Food Compost. Anal. 2020, 86, 103358. [Google Scholar] [CrossRef]

- Avarzed, E.; Wang, X.; Moon, Y.; Kim, K.H.; Kweon, M. Quality characteristics and antioxidant activities of cookies formulated with the blend of Korean domestic wheat flour and purple wheat bran. Korean J. Food Cook Sci. 2020, 36, 152–162. [Google Scholar] [CrossRef]

- AACC. Method 44-15.02, 56-11.02, 76-31.01. In Approved Methods of Analysis, 11th ed.; AACC International: St. Paul, MN, USA, 2010. [Google Scholar]

- Kweon, M.; Slade, L.; Levine, H. Solvent retention capacity (SRC) testing of wheat flour: Principles and value in predicting flour functionality in different wheat-based food processes and in wheat breeding–A review. Cereal Chem. 2011, 88, 537–552. [Google Scholar] [CrossRef]

- Moon, Y.; Kim, K.H.; Kweon, M. Effects of flour quality and drying rates controlled by temperature, air circulation, and relative humidity on the quality of dried white-salted noodles. Cereal Chem. 2019, 96, 1011–1021. [Google Scholar] [CrossRef]

- Wang, X.; Kweon, M. Quality of US soft red wheat flours and their suitability for making fresh noodles. Korean J. Food Cook Sci. 2021, 37, 134–143. [Google Scholar]

- Yu, L.; Beta, T. Identification and antioxidant properties of phenolic compounds during production of bread from purple wheat grains. Molecules 2015, 20, 15525–15549. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hatcher, D.W.; Anderson, M.J.; Desjardins, R.G.; Edwards, N.M.; Dexter, J.E. Effects of flour particle size and starch damage on processing and quality of white salted noodles. Cereal Chem. 2002, 79, 64–71. [Google Scholar] [CrossRef]

- Doblado-Maldonado, A.F.; Pike, O.A.; Sweley, J.C.; Rose, D.J. Key issues and challenges in whole wheat flour milling and storage. J. Cereal Sci. 2012, 56, 119–126. [Google Scholar] [CrossRef]

- Okusu, H.; Otsubo, S.; Dexter, J. Wheat milling and flour quality analysis for noodles in Japan. In Asian Noodles; Hou, G.G., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010; pp. 57–73. [Google Scholar]

- Zhu, K.; Huang, S.; Peng, W.; Qian, H.; Zhou, H. Effect of ultrafine grinding on hydration and antioxidant properties of wheat bran dietary fiber. Food Res. Int. 2010, 43, 943–948. [Google Scholar] [CrossRef]

- Habuš, M.; Novotni, D.; Gregov, M.; Štifter, S.; Mistač, N.Č.; Voucko, B.; Ćuric, D. Influence of particle size reduction and high-intensity ultrasound on polyphenol oxidase, phenolics, and technological properties of wheat bran. J. Food Process. Preserv. 2021, 45, 15204. [Google Scholar] [CrossRef]

- Hossain, K.; Ulven, C.; Glover, K.; Ghavami, F.; Simsek, S.; Alamri, M.; Kumar, A.; Mergoum, M. Interdependence of Cultivar and Environment on Fiber Composition in Wheat Bran. Aust. J. Crop. Sci. 2013, 7, 525–531. [Google Scholar]

- Hemdane, S.; Jacobs, P.J.; Dornez, E.; Verspreet, J.; Delcour, J.A.; Courtin, C.M. Wheat (Triticum aestivum L.) bran in bread making: A critical review. Compr. Rev. Food Sci. Food Saf. 2016, 15, 28–42. [Google Scholar] [CrossRef] [Green Version]

- Hemdane, S.; Langenaeken, N.A.; Jacobs, P.J.; Verspreet, J.; Delcour, J.A.; Courtin, C.M. Study of the intrinsic properties of wheat bran and pearlings obtained by sequential debranning and their role in bran-enriched bread making. J. Cereal Sci. 2016, 71, 78–85. [Google Scholar] [CrossRef]

- Barak, S.; Mudgil, D.; Khatkar, B.S. Effect of flour particle size and damaged starch on the quality of cookies. J. Food Sci. Technol. 2012, 51, 1342–1348. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lu, L.; Cao, X.; Zhou, S.; Li, Y.; Wang, L.; Qian, H.; Zhang, H.; Qi, X. Effect of wheat bran particle size on the quality of whole wheat based instant fried noodles. J. Food Nutr. Res. 2018, 6, 295–301. [Google Scholar] [CrossRef]

- Dhaka, V.; Khatkar, B.S. Effects of gliadin/glutenin and HMW-GS/LMW-GS ratio on dough rheological properties and bread-making potential of wheat varieties. J. Food Qual. 2015, 38, 71–82. [Google Scholar] [CrossRef]

- Goesaert, H.; Brijs, K.; Veraverbeke, W.S.; Courtin, C.M.; Gebruers, K.; Delcour, J.A. Wheat flour constituents: How they impact bread quality, and how to impact their functionality. Trends Food Sci. Technol. 2005, 16, 12–30. [Google Scholar] [CrossRef]

- Xiong, L.; Zhang, B.; Niu, M.; Zhao, S. Protein polymerization and water mobility in whole-wheat dough influenced by bran particle size distribution. LWT-Food Sci. Technol. 2017, 82, 396–403. [Google Scholar] [CrossRef]

- Wang, N.; Hou, G.G.; Dubat, A. Effects of flour particle size on the quality attributes of reconstituted whole-wheat flour and Chinese southern-type steamed bread. LWT-Food Sci. Technol. 2017, 82, 147–153. [Google Scholar] [CrossRef]

- Lin, S.; Jin, X.; Gao, Z.; Ying, J.; Wang, Y.; Dong, Z.; Zhou, W. Impact of wheat bran micronization on dough properties and bread quality: Part I–Bran functionality and dough properties. Food Chem. 2021, 353, 129407. [Google Scholar] [CrossRef]

- Zhang, D.; Moore, W.R. Effect of wheat bran particle size on dough rheological properties. J. Sci. Food Agric. 1997, 74, 490–496. [Google Scholar] [CrossRef]

- Sudha, M.L.; Vetrimani, R.; Leelavathi, K. Influence of fibre from different cereals on the rheological characteristics of wheat flour dough and on biscuit quality. Food Chem. 2007, 100, 1365–1370. [Google Scholar] [CrossRef]

- Özboy, Ö.; Köksel, H. Unexpected strengthening effects of a coarse wheat bran on dough rheological properties and baking quality. J. Cereal Sci. 1997, 25, 77–82. [Google Scholar] [CrossRef]

- Niu, M.; Hou, G.G.; Kindelspire, J.; Krishnan, P.; Zhao, S. Microstructural. Textural, and sensory properties of whole wheat noodle modified by enzymes and emulsifiers. Food Chem. 2017, 223, 16–24. [Google Scholar] [CrossRef] [PubMed]

- Sozer, N.; Cicerelli, L.; Heiniö, R.L.; Poutanen, K. Effect of wheat bran addition on in vitro starch digestibility, physico-mechanical and sensory properties of biscuits. J. Cereal Sci. 2014, 60, 105–113. [Google Scholar] [CrossRef]

- Ma, S.; Wang, C.; Li, L.; Wang, X. Effects of particle size on the quality attributes of wheat flour made by the milling process. Cereal Chem. 2020, 97, 172–182. [Google Scholar] [CrossRef]

- Brewer, L.R.; Kubola, J.; Siriamornpun, S.; Herald, T.J.; Shi, Y.C. Wheat bran particle size influence on phytochemical extractability and antioxidant properties. Food Chem. 2014, 152, 483–490. [Google Scholar] [CrossRef]

- Li, W.D.; Shan, F.; Sun, S.C.; Corke, H.; Beta, T. Free radical scavenging properties and phenolic content of Chinese black-grained wheat. J. Agric. Food Chem. 2005, 53, 8533–8536. [Google Scholar] [CrossRef] [PubMed]

- Zhou, K.; Su, L.; Yu, L. Phytochemicals and antioxidant properties in wheat bran. J. Agric. Food Chem. 2004, 52, 6108–6114. [Google Scholar] [CrossRef] [PubMed]

| Ingredients | Formula (g) | |||

|---|---|---|---|---|

| F100-B0 (1) | F90-B10 | F70-B30 | F50-B50 | |

| Flour | 100.0 | 90.0 | 70.0 | 50.0 |

| Wheat bran | 0.0 | 10.0 | 30.0 | 50.0 |

| Water | 30.0 | 32.0 | 37.4 | 43.3 |

| Salt | 2.0 | 2.0 | 2.0 | 2.0 |

| Bran Size | Moisture Content (%) | Damaged Starch Content (%) | Swelling Capacity (%) |

|---|---|---|---|

| VL (1) | 12.2 ± 0.0 d(2) | 1.9 ± 0.0 a | 58.7 ± 0.0 a |

| L | 11.9 ± 0.2 c | 2.7 ± 0.0 b | 74.2 ± 2.0 b |

| M | 10.2 ± 0.1 b | 3.0 ± 0.1 c | 80.4 ± 0.8 bc |

| S | 9.0 ± 0.1 a | 4.0 ± 0.1 d | 85.3 ± 3.5 d |

| Flour-Bran Blend | Bran Size | SRC (%) | |

|---|---|---|---|

| Water | Sodium Carbonate | ||

| F100-B0 (1) | - | 60.9 ± 0.2 a(2) | 78.7 ± 0.1 a |

| F90-B10 | VL (3) | 65.0 ± 0.3 b | 82.7 ± 0.0 b |

| L | 65.4 ± 0.1 bc | 83.2 ± 0.4 bc | |

| M | 65.8 ± 0.1 bc | 84.1 ± 0.3 bc | |

| S | 66.5 ± 0.1 c | 84.7 ± 0.0 c | |

| F70-B30 | VL | 76.0 ± 0.4 d | 94.6 ± 0.4 d |

| L | 76.6 ± 0.1 d | 95.8 ± 0.1 d | |

| M | 76.9 ± 0.2 d | 97.5 ± 0.4 e | |

| S | 78.8 ± 0.3 e | 99.3 ± 0.1 f | |

| F50-B50 | VL | 88.6 ± 0.1 f | 106.0 ± 0.2 g |

| L | 89.5 ± 0.1 fg | 110.8 ± 0.3 h | |

| M | 89.8 ± 0.0 fg | 113.2 ± 0.4 i | |

| S | 90.3 ± 0.4 g | 113.8 ± 0.3 i | |

| Flour-Bran Blend | Bran Size | Resistance (N) | Extensibility (mm) | R/E |

|---|---|---|---|---|

| F100-B0 (1) | - | 1.37 ± 0.04 e(2) | 14.76 ± 0.07 f | 0.093 ± 0.003 cd |

| F90-B10 | VL (3) | 1.18 ± 0.05 de | 11.20 ± 0.03 e | 0.106 ± 0.006 de |

| L | 1.20 ± 0.03 de | 10.08 ± 0.15 bc | 0.119 ± 0.002 ef | |

| M | 1.32 ± 0.03 e | 9.81 ± 0.07 ab | 0.134 ± 0.003 fg | |

| S | 1.42 ± 0.03 e | 9.78 ± 0.06 ab | 0.145 ± 0.003 g | |

| F70-B30 | VL | 0.83 ± 0.03 bc | 10.84 ± 0.09 de | 0.077 ± 0.003 bc |

| L | 1.00 ± 0.05 cd | 9.67 ± 0.09 ab | 0.103 ± 0.006 de | |

| M | 1.16 ± 0.10 de | 9.64 ± 0.09 a | 0.120 ± 0.013 ef | |

| S | 1.18 ± 0.08 de | 9.58 ± 0.05 a | 0.123 ± 0.011 efg | |

| F50-B50 | VL | 0.51 ± 0.01 a | 10.49 ± 0.01 cd | 0.048 ± 0.001 a |

| L | 0.55 ± 0.02 a | 9.50 ± 0.07 a | 0.058 ± 0.002 ab | |

| M | 0.71 ± 0.04 ab | 9.53 ± 0.01 a | 0.074 ± 0.006 bc | |

| S | 0.74 ± 0.03 abc | 9.52 ± 0.03 a | 0.078 ± 0.004 bc |

| Flour-Bran Blend | Bran Size | Uncooked | Cooked | ||||

|---|---|---|---|---|---|---|---|

| L* | a* | b* | L* | a* | b* | ||

| F100-B0 (1) | - | 86.2 ± 0.5 f(2) | 2.7 ± 0.1 a | 15.3 ± 0.8 d | 74.4 ± 0.3 h | (−0.8 ± 0.1) a | 12.0 ± 0.2 bcde |

| F90-B10 | VL (3) | 73.5 ± 1.8 e | 3.8 ± 0.3 ab | 9.6 ± 0.4 a | 56.5 ± 1.1 g | 4.6 ± 0.6 b | 7.3 ± 1.1 a |

| L | 72.0 ± 1.2 de | 4.8 ± 0.4 bc | 10.7 ± 0.6 ab | 54.8 ± 0.7 fg | 5.8 ± 0.2 bc | 8.9 ± 0.3 ab | |

| M | 67.2 ± 1.9 de | 6.0 ± 0.5 cd | 11.6 ± 0.5 abc | 52.2 ± 0.4 f | 6.5 ± 0.3 bcd | 10.4 ± 0.4 abcd | |

| S | 65.9 ± 0.5 d | 6.8 ± 0.2 de | 12.8 ± 0.4 bcd | 51.1 ± 0.7 f | 7.2 ± 0.3 cde | 10.9 ± 0.2 abcd | |

| F70-B30 | VL | 57.8 ± 1.3 c | 6.4 ± 0.4 cde | 11.6 ± 0.7 abc | 45.4 ± 1.4 e | 6.7 ± 0.6 cd | 9.3 ± 1.4 abc |

| L | 54.0 ± 1.7 c | 8.0 ± 0.5 ef | 13.2 ± 0.6 bcd | 44.2 ± 0.4 de | 7.4 ± 0.4 cde | 10.1 ± 0.6 abc | |

| M | 51.4 ± 1.0 bc | 8.5 ± 0.1 fg | 13.8 ± 0.3 cd | 41.3 ± 0.4 cd | 8.4 ± 0.4 defg | 12.3 ± 1.1 bcde | |

| S | 53.9 ± 0.6 c | 9.1 ± 0.1 fg | 14.7 ± 0.3 cd | 40.4 ± 0.5 bcd | 9.4 ± 0.3 fg | 14.0 ± 0.6 de | |

| F50-B50 | VL | 46.0 ± 2.1 a | 8.9 ± 0.2 g | 13.6 ± 0.2 cd | 38.1 ± 1.0 abc | 7.7 ± 0.2 cdef | 9.7 ± 0.5 ab |

| L | 41.7 ± 0.6 a | 9.7 ± 0.1 g | 13.9 ± 0.2 cd | 37.2 ± 0.3 ab | 8.8 ± 0.3 efg | 12.0 ± 0.4 bcde | |

| M | 41.4 ± 0.6 a | 9.5 ± 0.2 fg | 13.9 ± 0.3 cd | 35.3 ± 0.3 a | 9.4 ± 0.2 fg | 13.8 ± 0.4 cde | |

| S | 43.6 ± 0.5 ab | 9.9 ± 0.1 g | 14.6 ± 0.2 cd | 34.8 ± 0.2 a | 10.2 ± 0.2 g | 15.1 ± 0.3 e | |

| Flour-Bran Blend | Bran Size | Textural Parameter | Turbidity of Cooked Water (ΔA hr−1 g flour−1) | |||

|---|---|---|---|---|---|---|

| Firmness (N) | Cohesiveness | Springiness | Chewiness (mJ) | |||

| F100-B0 (1) | - | 18.1 ± 0.9 def(2) | 0.62 ± 0.00 c | 0.91 ± 0.00 c | 19.8 ± 1.2 e | 0.78 ± 0.06 e |

| F90-B10 | VL (3) | 13.9 ± 0.2 bcd | 0.56 ± 0.02 c | 0.84 ± 0.01 bc | 15.5 ± 0.9 de | 1.09 ± 0.01 f |

| L | 14.6 ± 0.7 cde | 0.57 ± 0.02 c | 0.86 ± 0.03 bc | 16.0 ± 1.5 de | 0.65 ± 0.01 bcd | |

| M | 16.2 ± 1.1 de | 0.57 ± 0.02 c | 0.90 ± 0.01 c | 16.6 ± 1.6 de | 0.46 ± 0.02 a | |

| S | 16.4 ± 0.9 de | 0.59 ± 0.02 c | 0.91 ± 0.02 c | 17.1 ± 1.0 de | 0.56 ± 0.00 ab | |

| F70-B30 | VL | 9.5 ± 0.6 abc | 0.43 ± 0.03 abc | 0.74 ± 0.01 abc | 7.7 ± 0.5 abc | 1.30 ± 0.01 g |

| L | 14.7 ± 0.7 cde | 0.49 ± 0.12 bc | 0.83 ± 0.05 bc | 13.1 ± 4.3 cde | 0.69 ± 0.02 cde | |

| M | 17.8 ± 0.5 def | 0.46 ± 0.02 abc | 0.85 ± 0.04 bc | 13.7 ± 0.8 cde | 0.59 ± 0.00 bc | |

| S | 19.3 ± 1.1 ef | 0.48 ± 0.02 abc | 0.86 ± 0.02 bc | 15.8 ± 0.6 de | 0.62 ± 0.00 bc | |

| F50-B50 | VL | 4.4 ± 0.5 a | 0.24 ± 0.01 a | 0.57 ± 0.02 a | 2.0 ± 0.4 a | 1.35 ± 0.01 g |

| L | 8.8 ± 0.7 ab | 0.29 ± 0.06 ab | 0.57 ± 0.09 a | 3.8 ± 0.9 ab | 0.74 ± 0.01 de | |

| M | 14.5 ± 1.3 cde | 0.31 ± 0.02 ab | 0.67 ± 0.03 ab | 7.0 ± 1.7 abc | 0.65 ± 0.01 bcd | |

| S | 22.0 ± 1.8 f | 0.31 ± 0.06 ab | 0.80 ± 0.02 bc | 10.5 ± 1.9 bcd | 0.63 ± 0.00 bc | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, G.; Cho, H.; Kim, K.; Kweon, M. Quality Characteristics and Antioxidant Activity of Fresh Noodles Formulated with Flour-Bran Blends Varied by Particle Size and Blend Ratio of Purple-Colored Wheat Bran. Processes 2022, 10, 584. https://doi.org/10.3390/pr10030584

Park G, Cho H, Kim K, Kweon M. Quality Characteristics and Antioxidant Activity of Fresh Noodles Formulated with Flour-Bran Blends Varied by Particle Size and Blend Ratio of Purple-Colored Wheat Bran. Processes. 2022; 10(3):584. https://doi.org/10.3390/pr10030584

Chicago/Turabian StylePark, Gyuna, Hyejin Cho, Kyeonghoon Kim, and Meera Kweon. 2022. "Quality Characteristics and Antioxidant Activity of Fresh Noodles Formulated with Flour-Bran Blends Varied by Particle Size and Blend Ratio of Purple-Colored Wheat Bran" Processes 10, no. 3: 584. https://doi.org/10.3390/pr10030584