Influence of Nonlinear Dynamics Behavior of the Roller Follower on the Contact Stress of Polydyne Cam Profile

Abstract

:1. Introduction

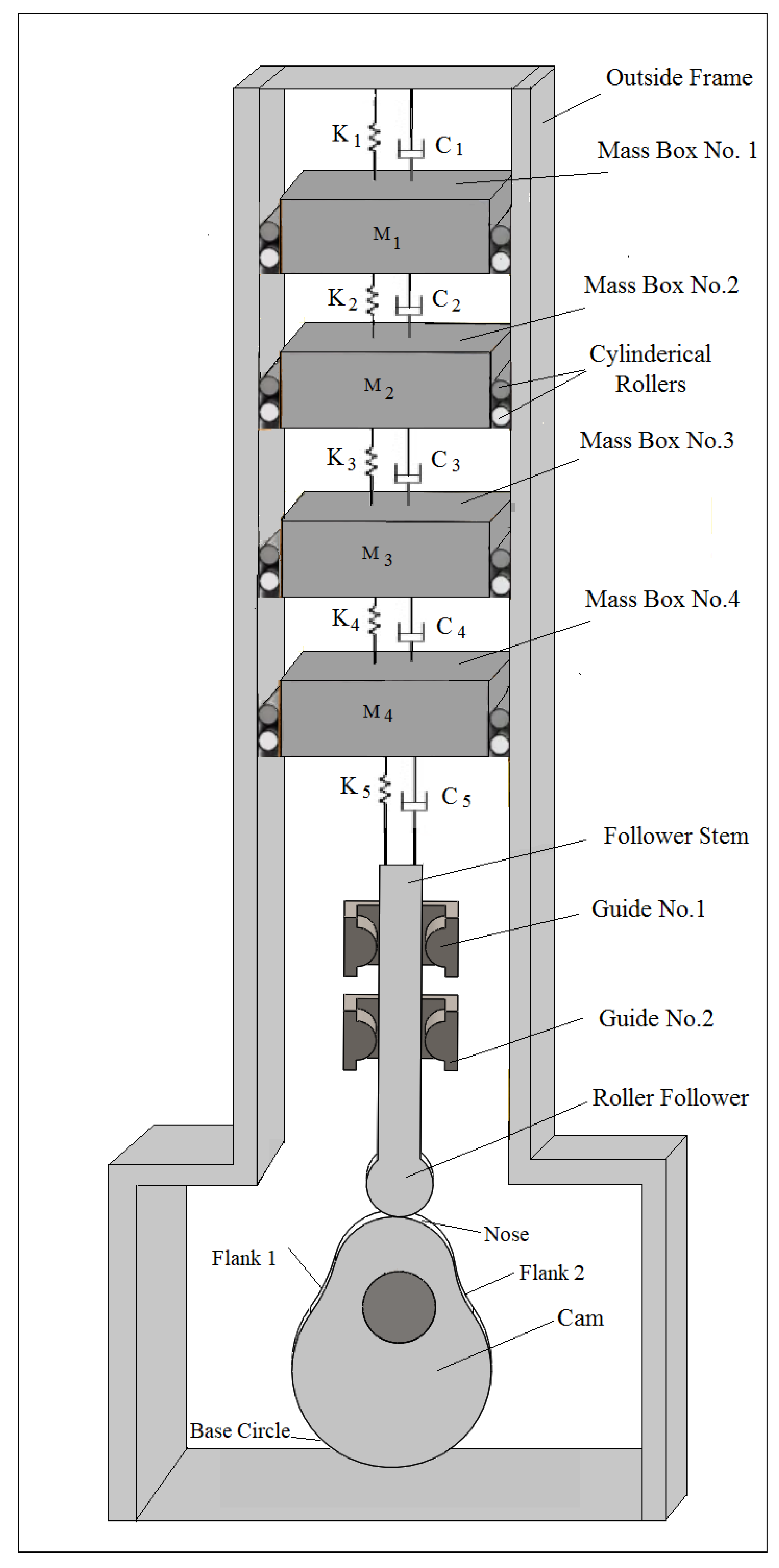

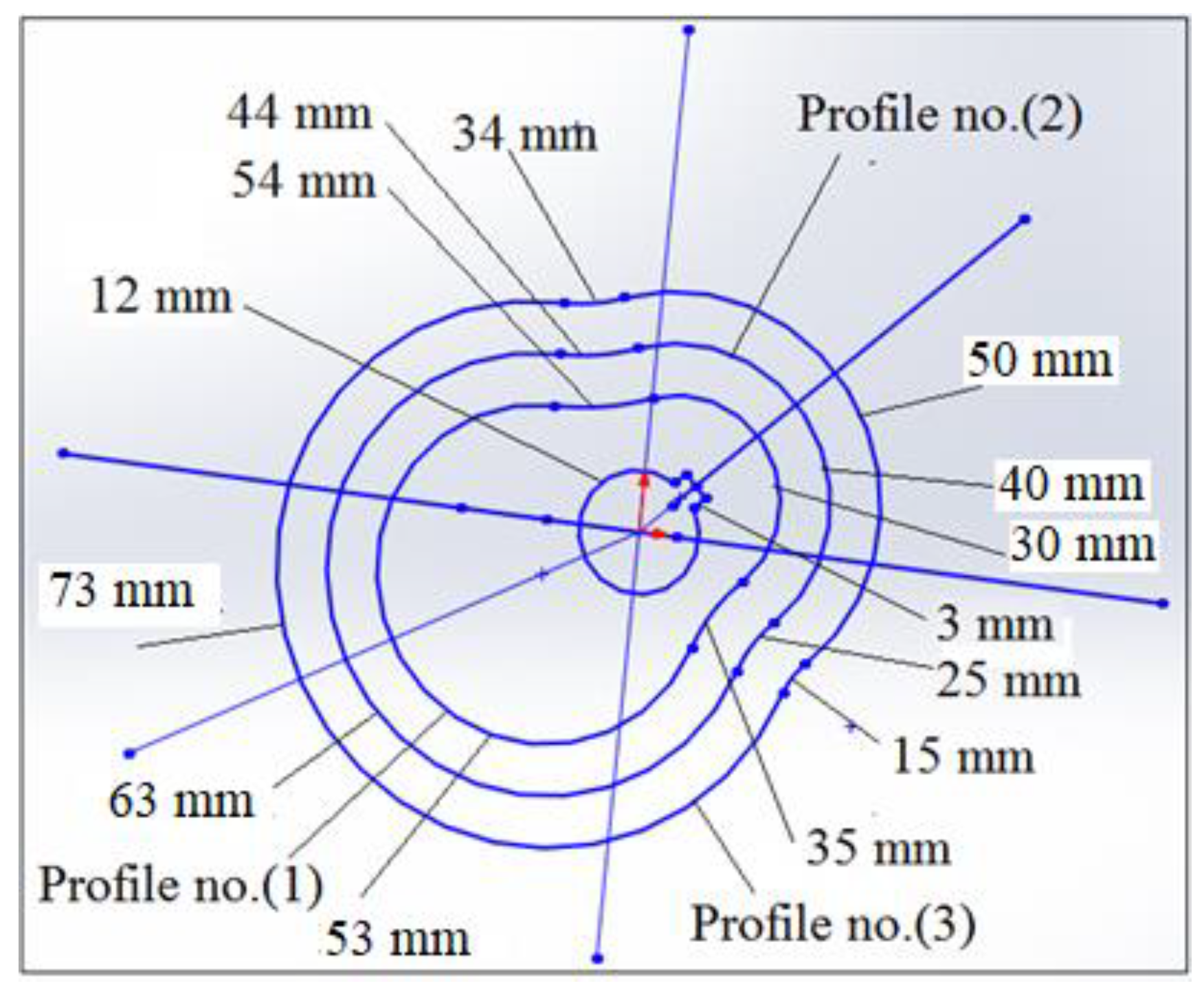

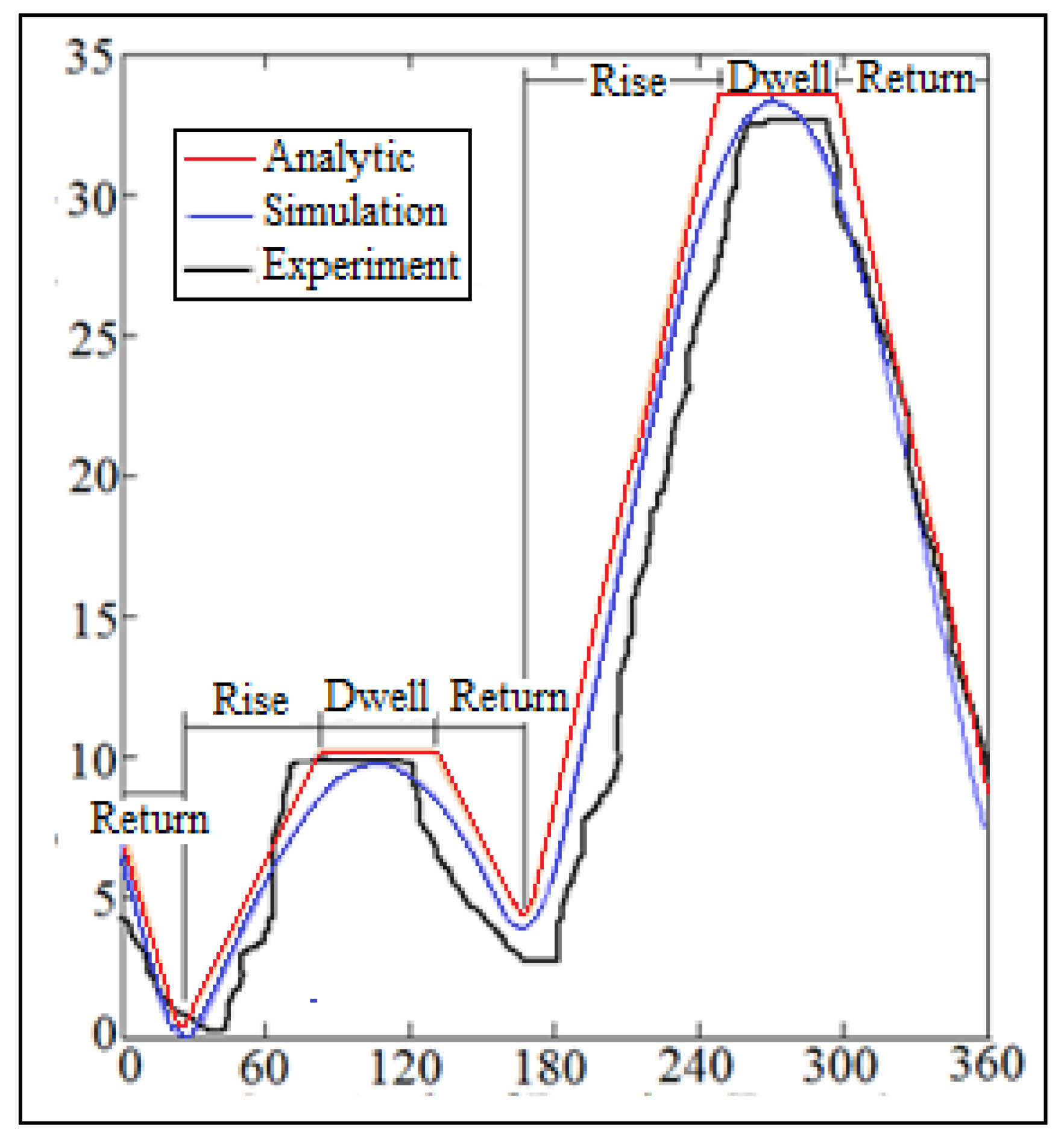

2. Analytic Calculations of the Nonlinear Response of Vibration

3. Numerical Simulation

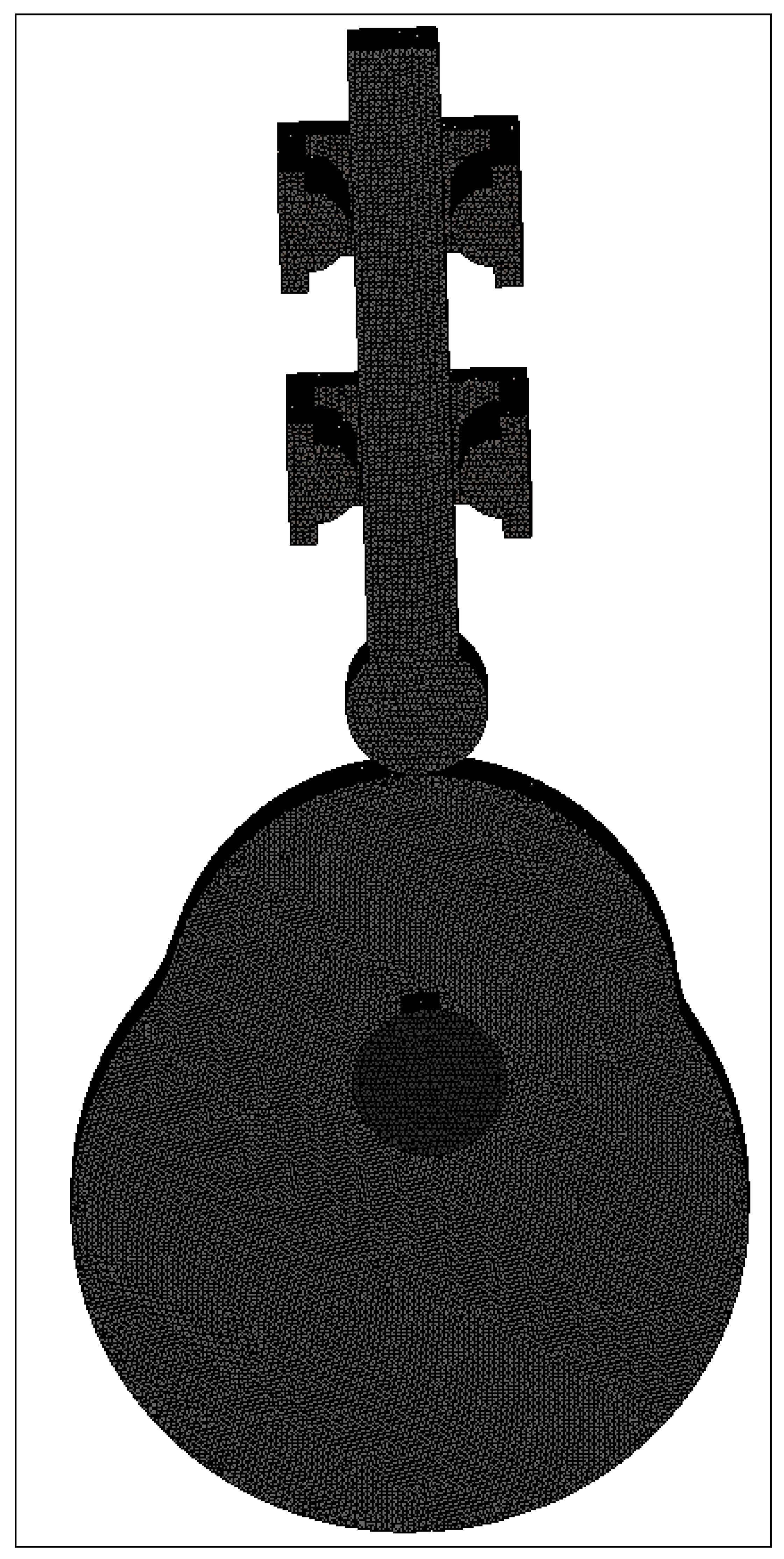

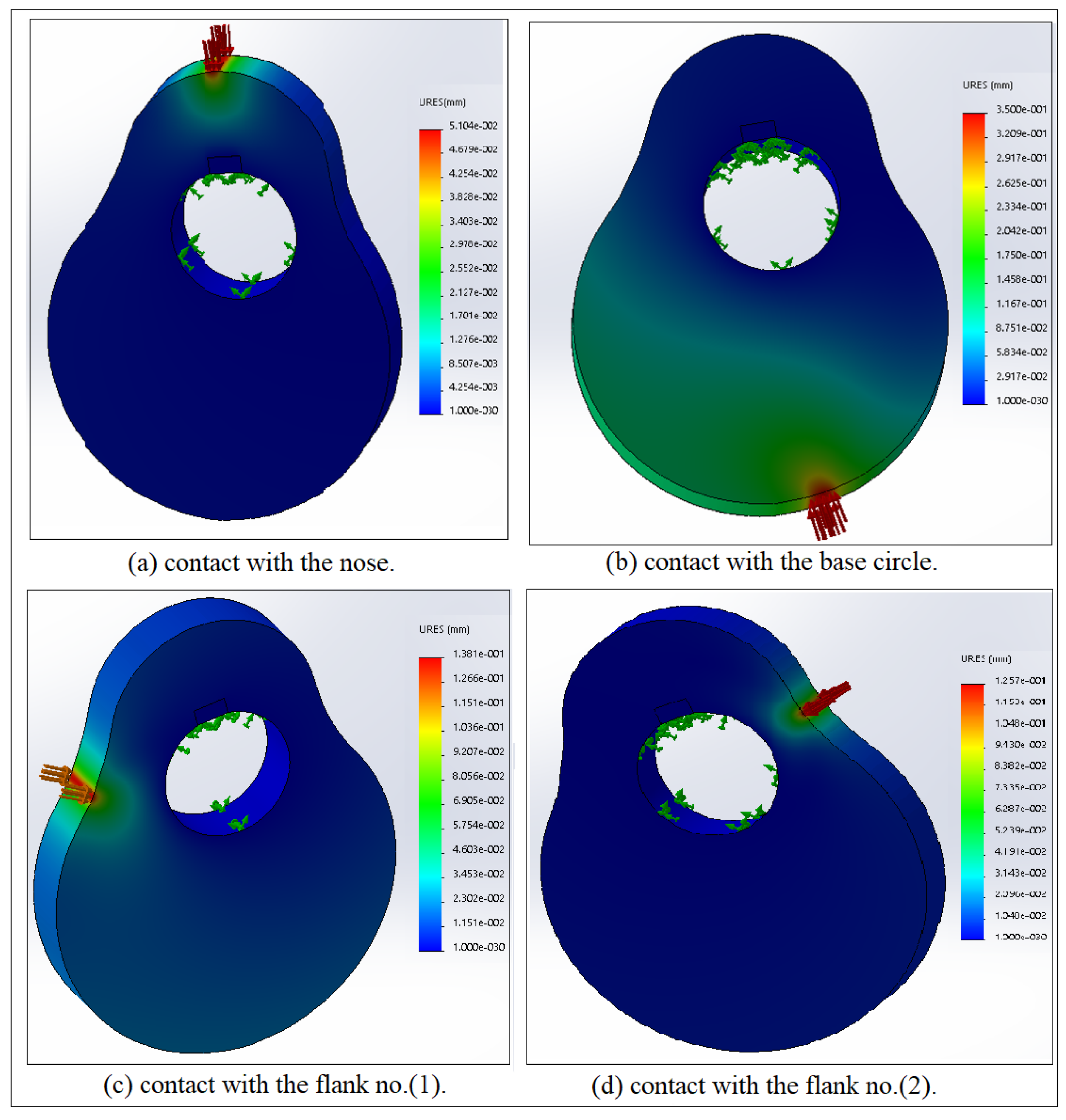

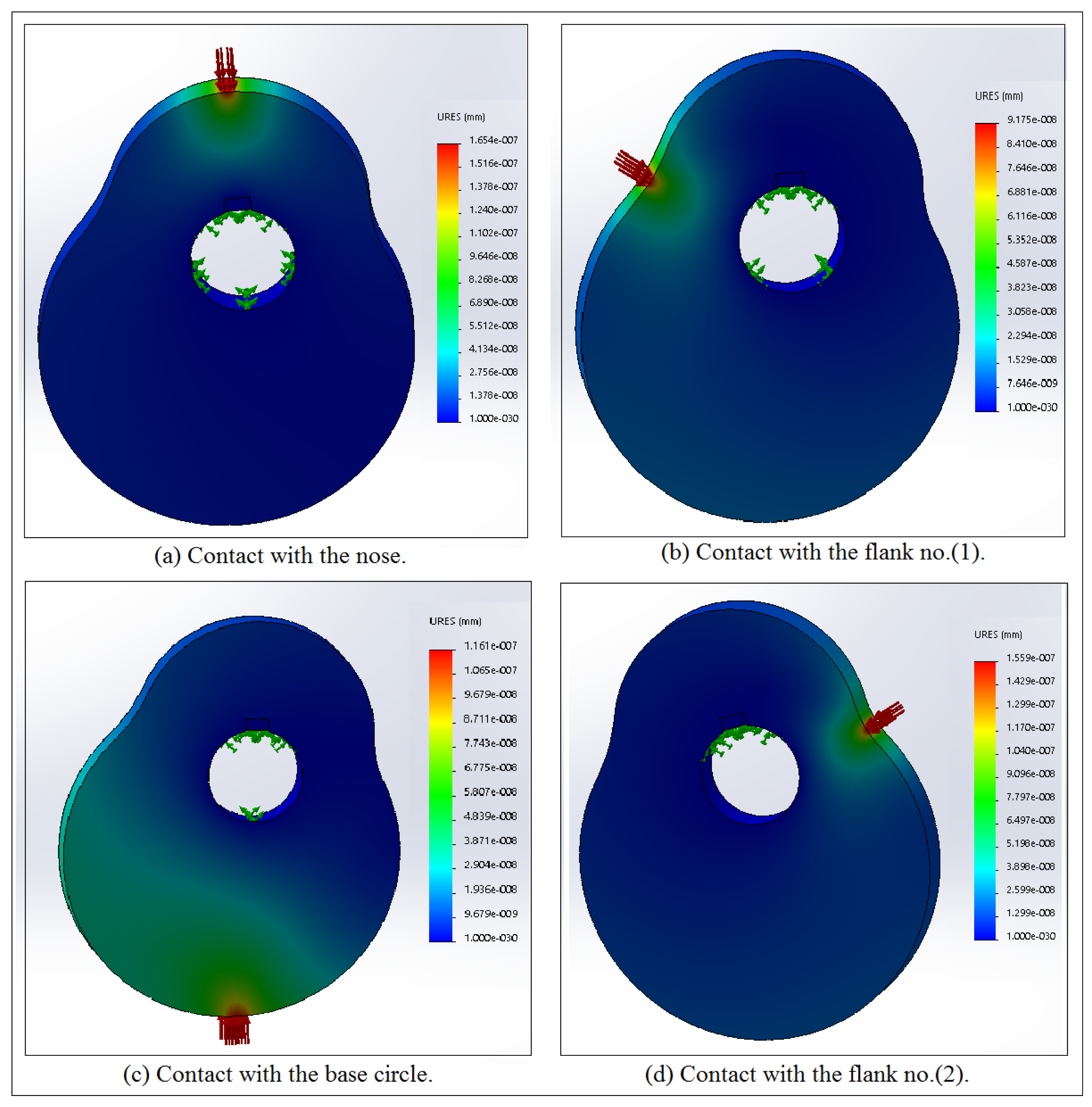

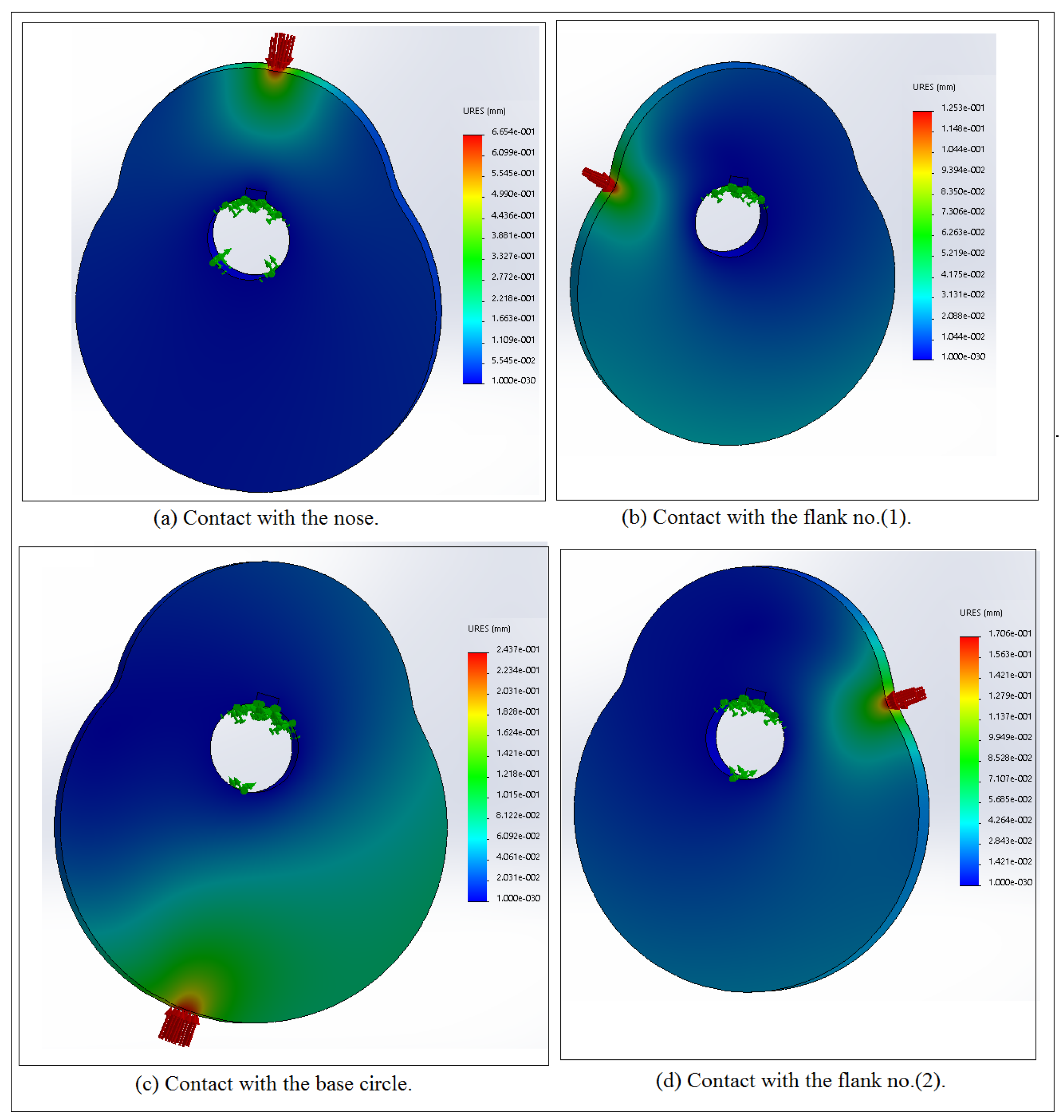

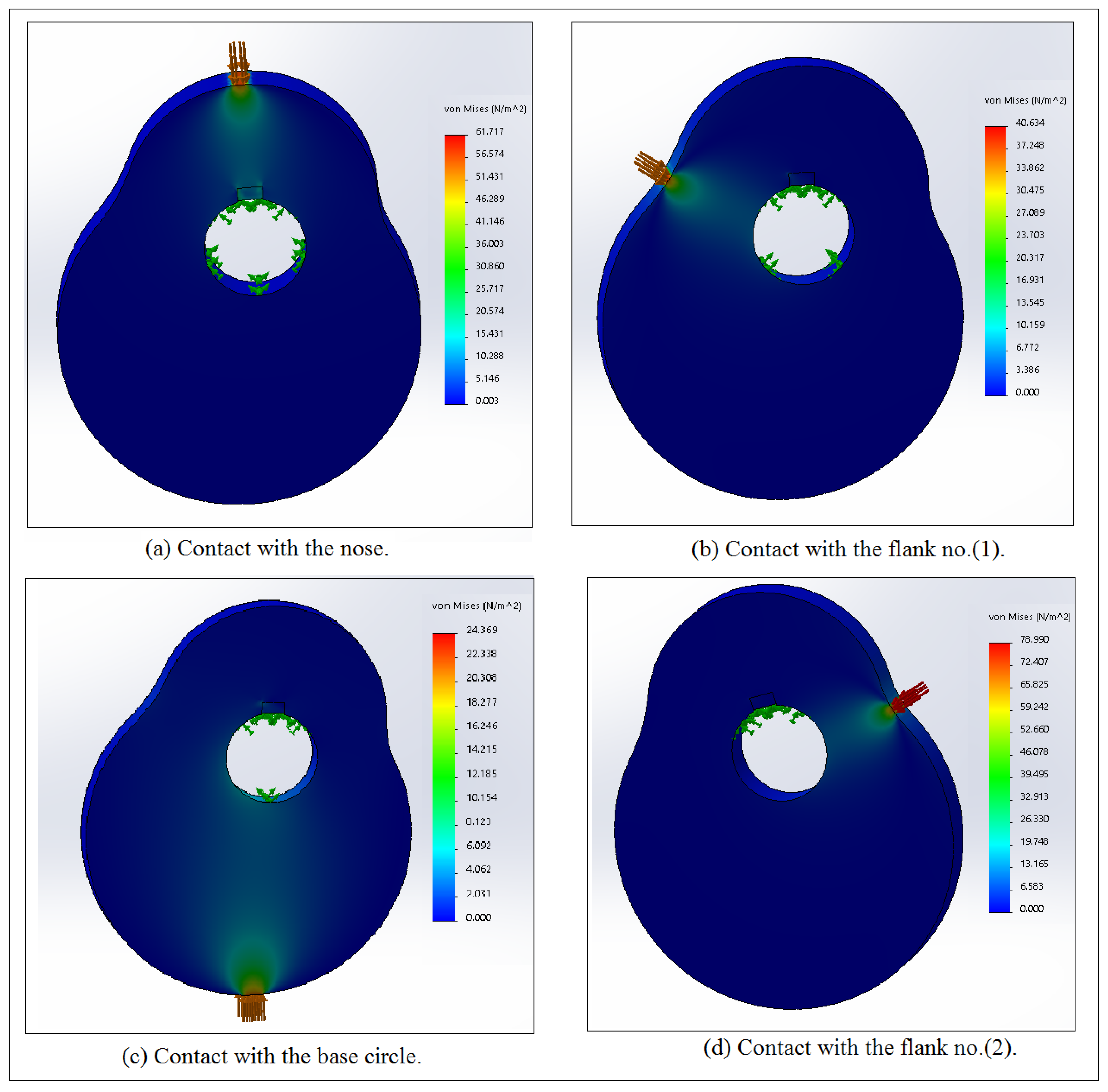

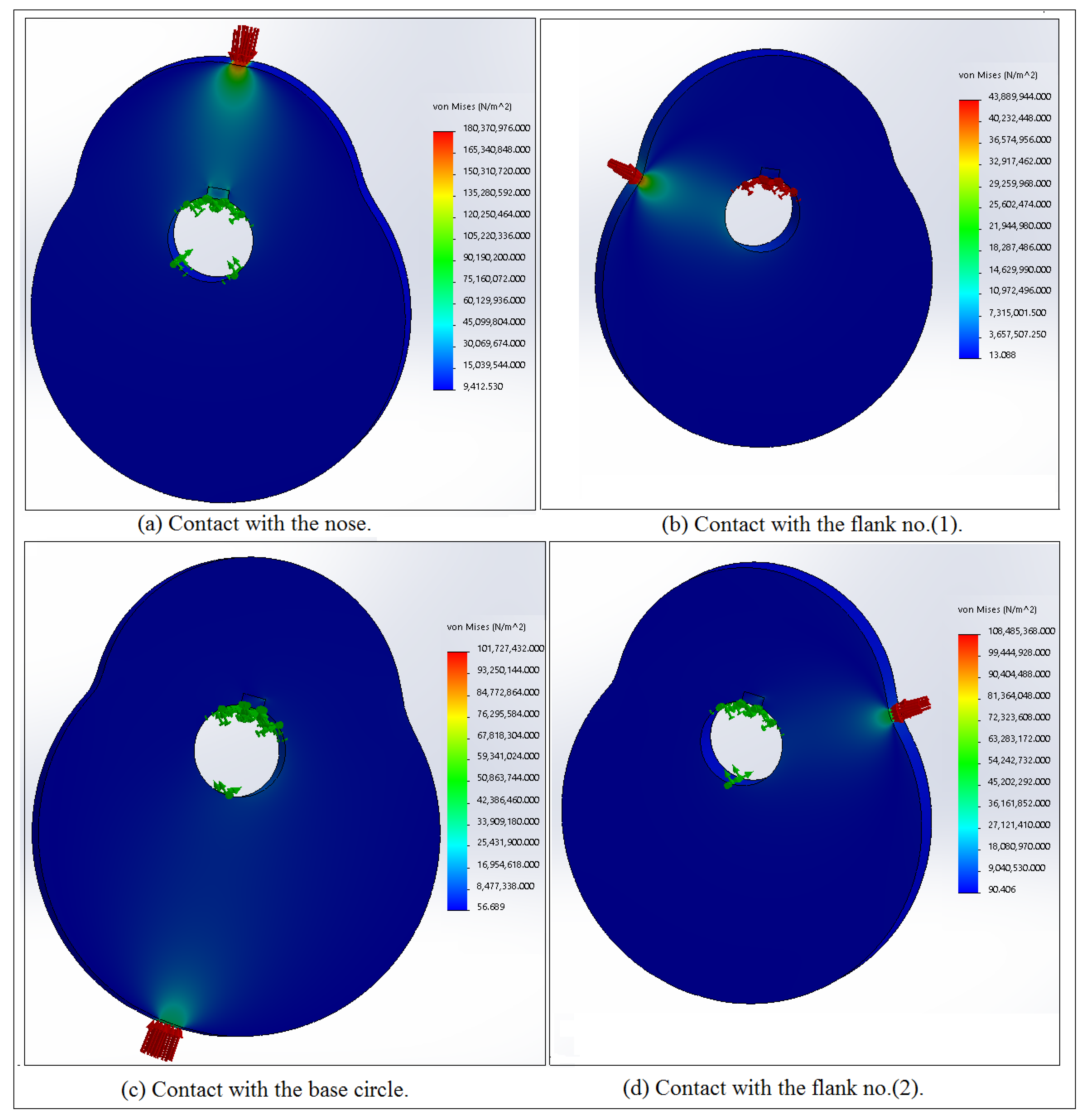

4. Finite Element Analysis Steps Using SolidWorks Program

- (a)

- Import the (pearcam.SLDPRT and squaregroovingkey.SLDPRT) parts for the cam and square grooving key geometries, respectively.

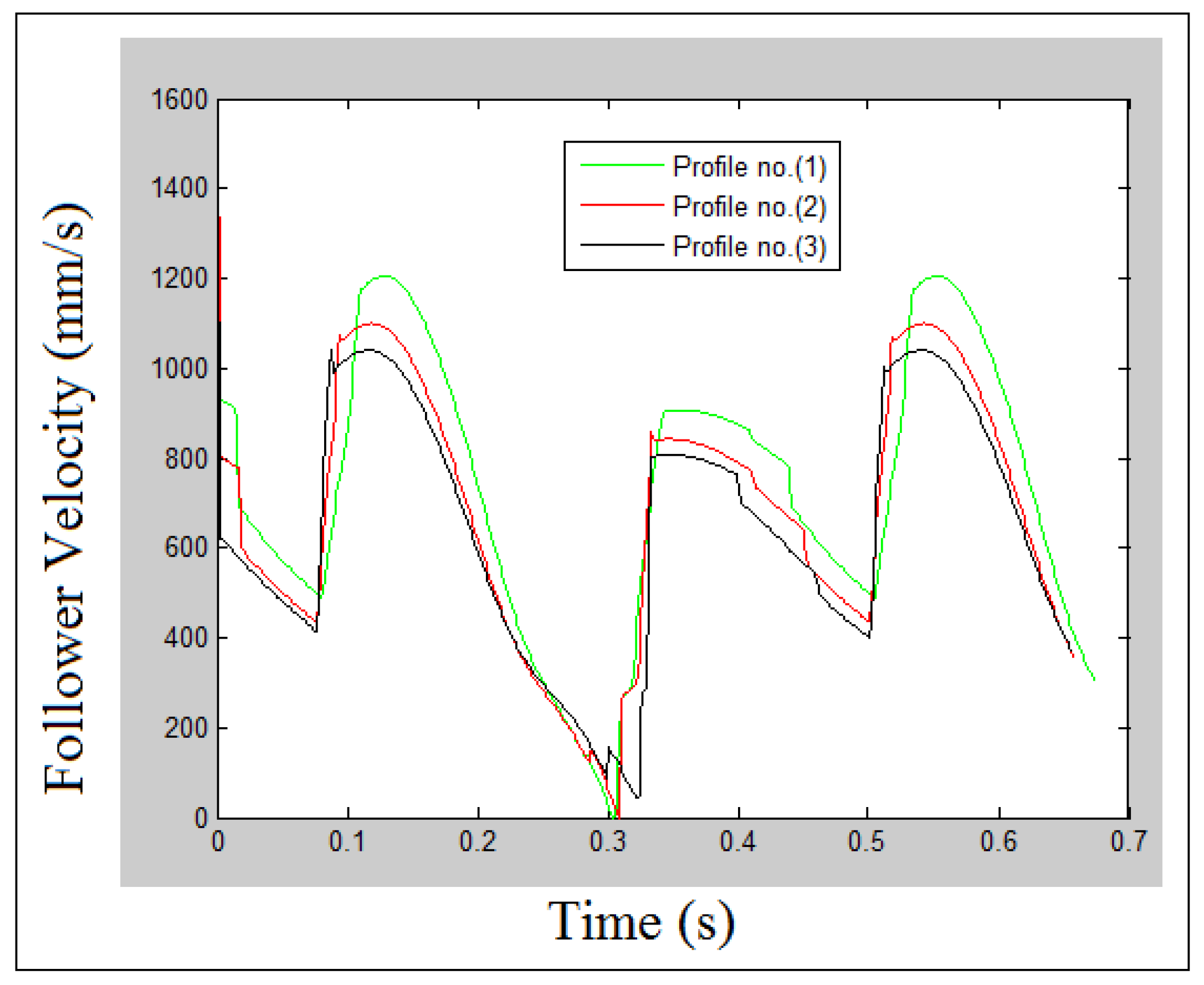

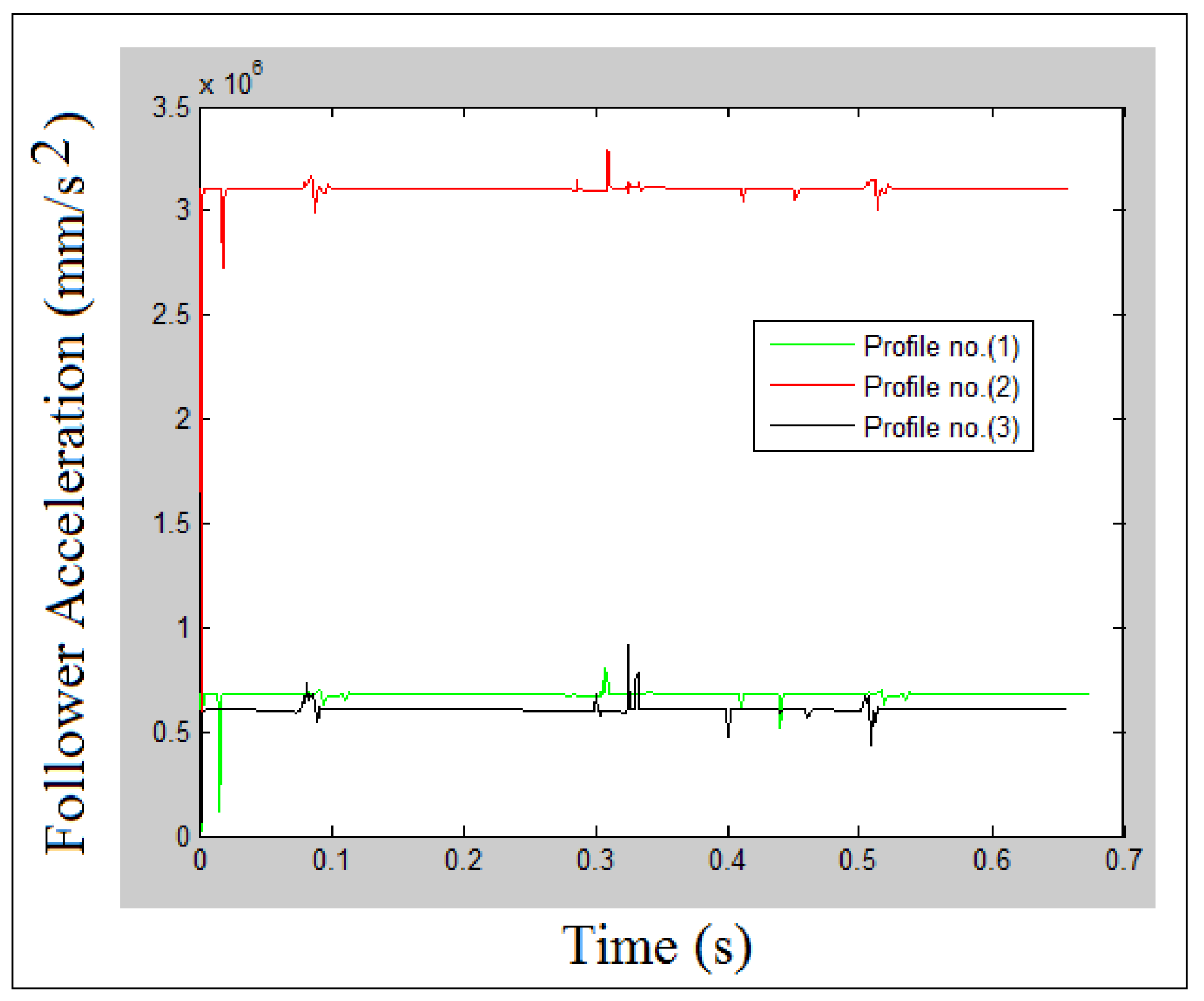

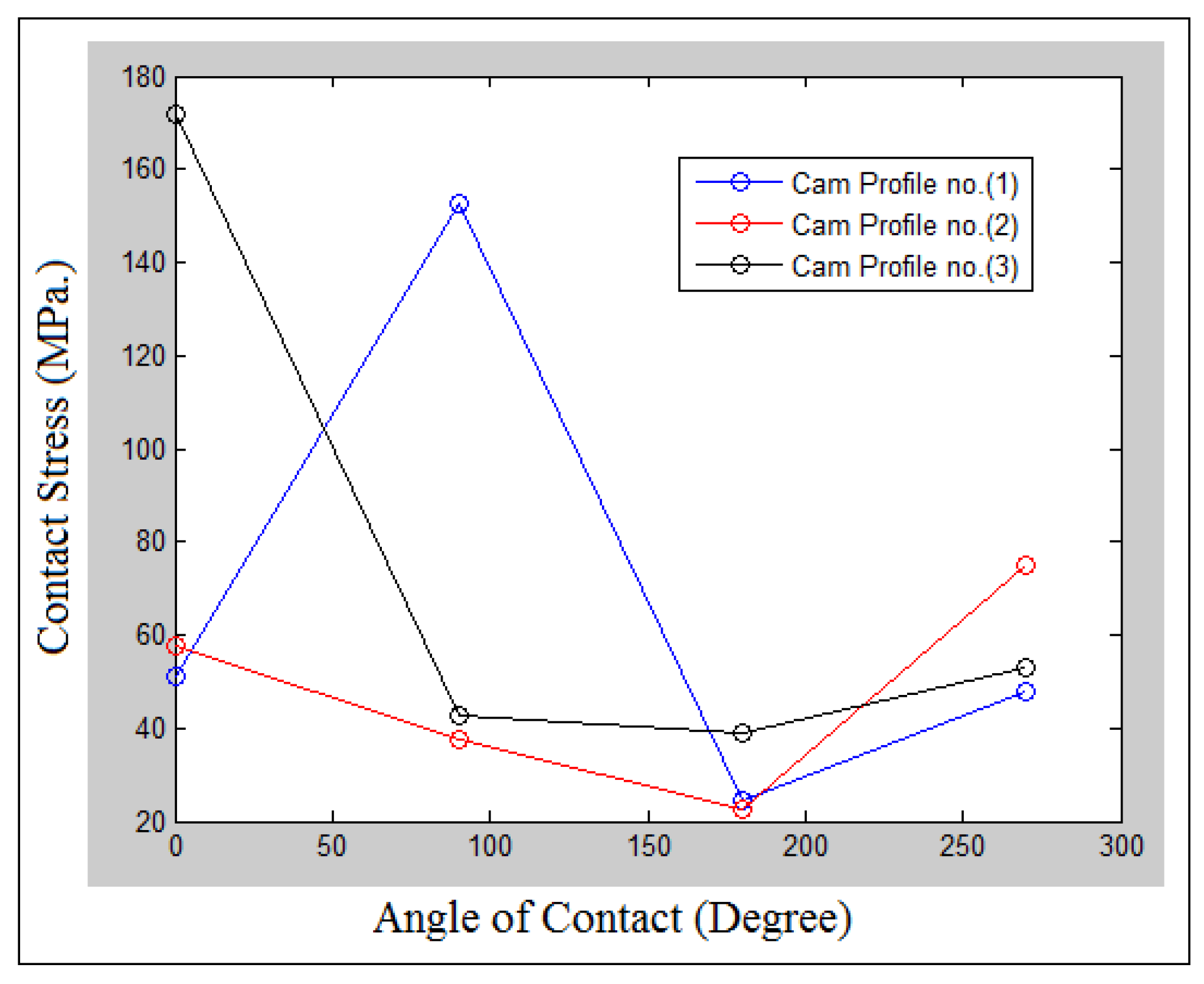

- (b)

- Select the Mate button to make the mates between the three sides of the pear cam and the three sides of the square grooving key.

- (c)

- Select the Connections button and choose Contact Sets to create contact between the three surfaces of the pear cam from inside and the three surfaces of the square grooving key from outside.

- (d)

- Select the Fixtures button and select Fixed Geometry to set the clamped boundary conditions at the hub radius (r = 12 mm) and the last surface of the square grooving key.

- (e)

- Select the External Loads button and choose Pressure since the value of the contact pressure is varied based on the contact with the nose, base circle, flank no.(1), and flank no.(2).

- (f)

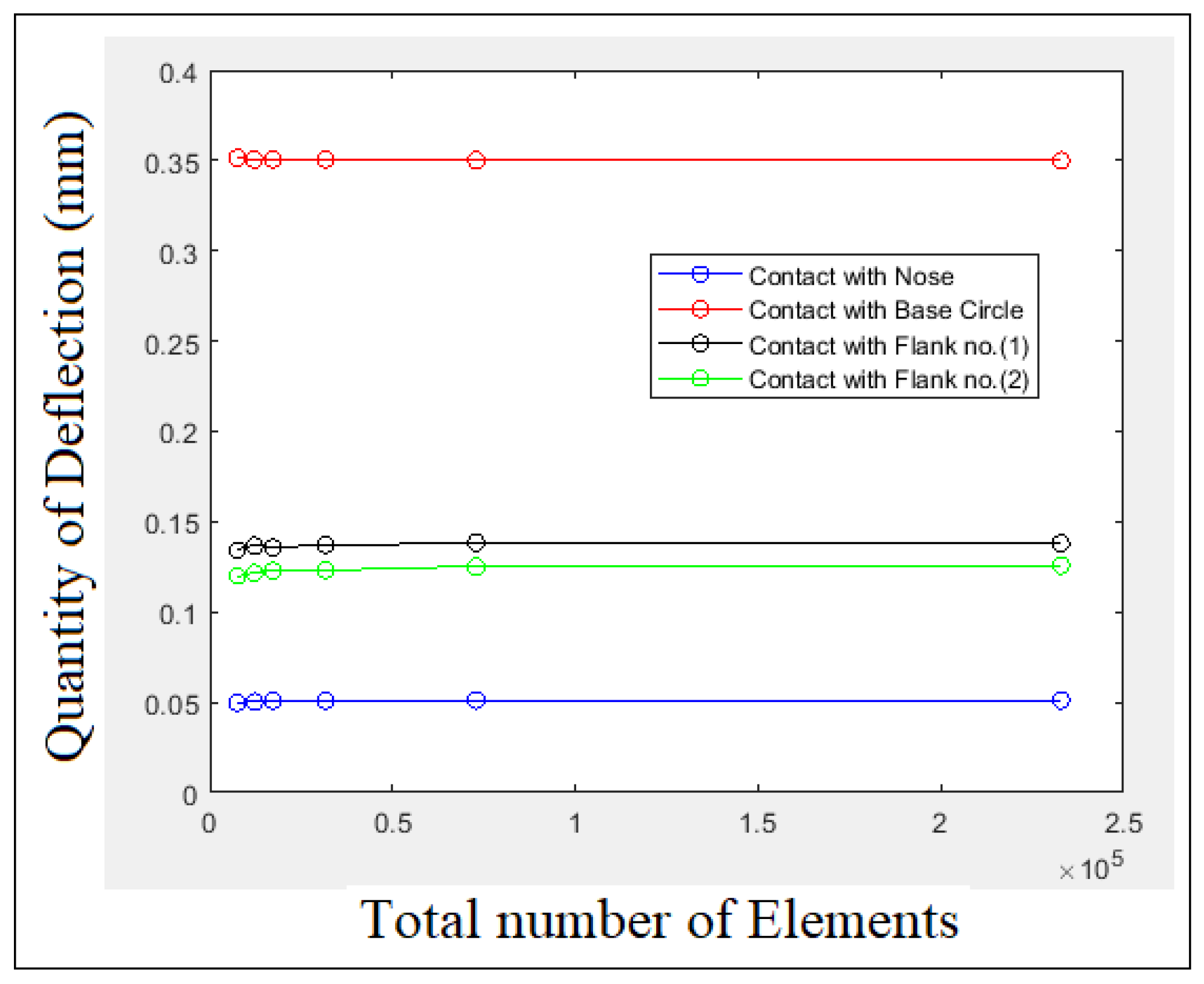

- Select the Mesh button and choose Create Mesh to carry out the mesh generation between the cam and square grooving key. Choose Details and Total Elements to describe the total number of elements. Keep changing the element size and the total number of elements to accomplish the convergence test of the bending deflection and the contact stress quantities.

- (g)

- Select the Simulation button to run the finite element model.

- (h)

- Select the Results button to see the contour of the bending deflection and the contact stress distributions.

- (1)

- Bonded: The two parts act as one part and the two parts behave as if they are welded.

- (2)

- No Penetration: This type of contact prevents interface between the two parts, but allows gaps to form. This is the most time-consuming option to solve.

- (3)

- Allow Penetration: This option treats the two parts as disjointed and the loads are allowed to cause interference between parts.

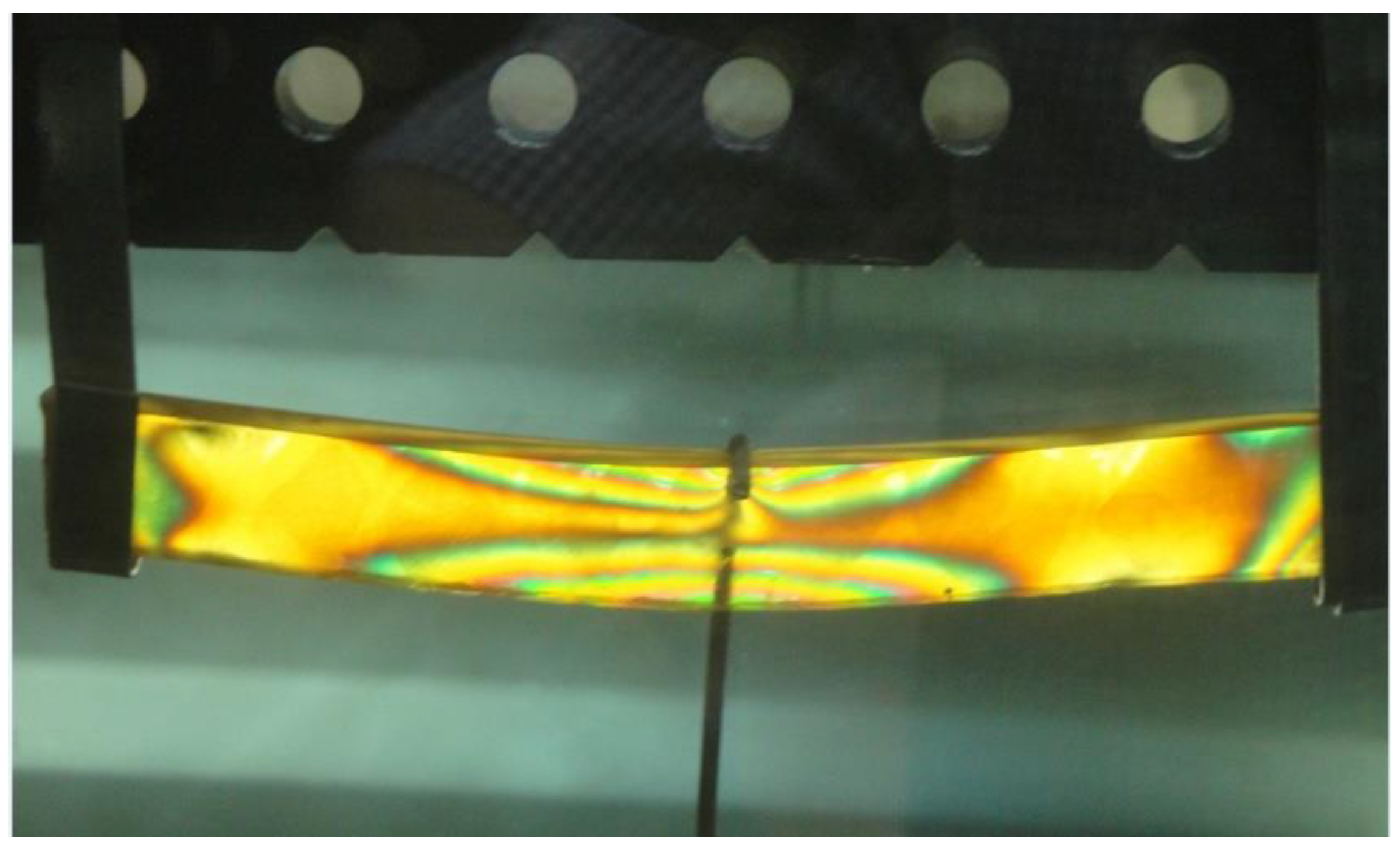

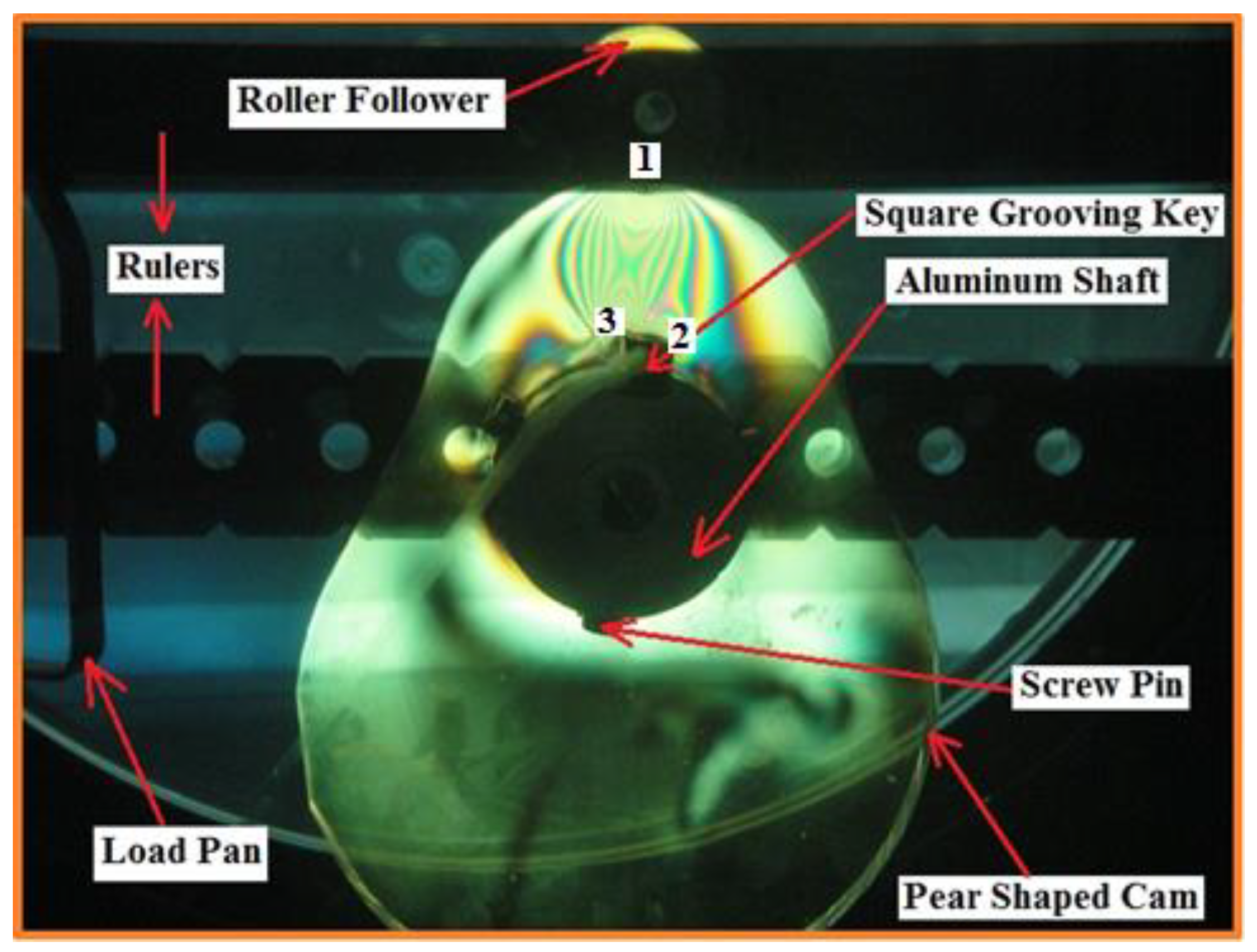

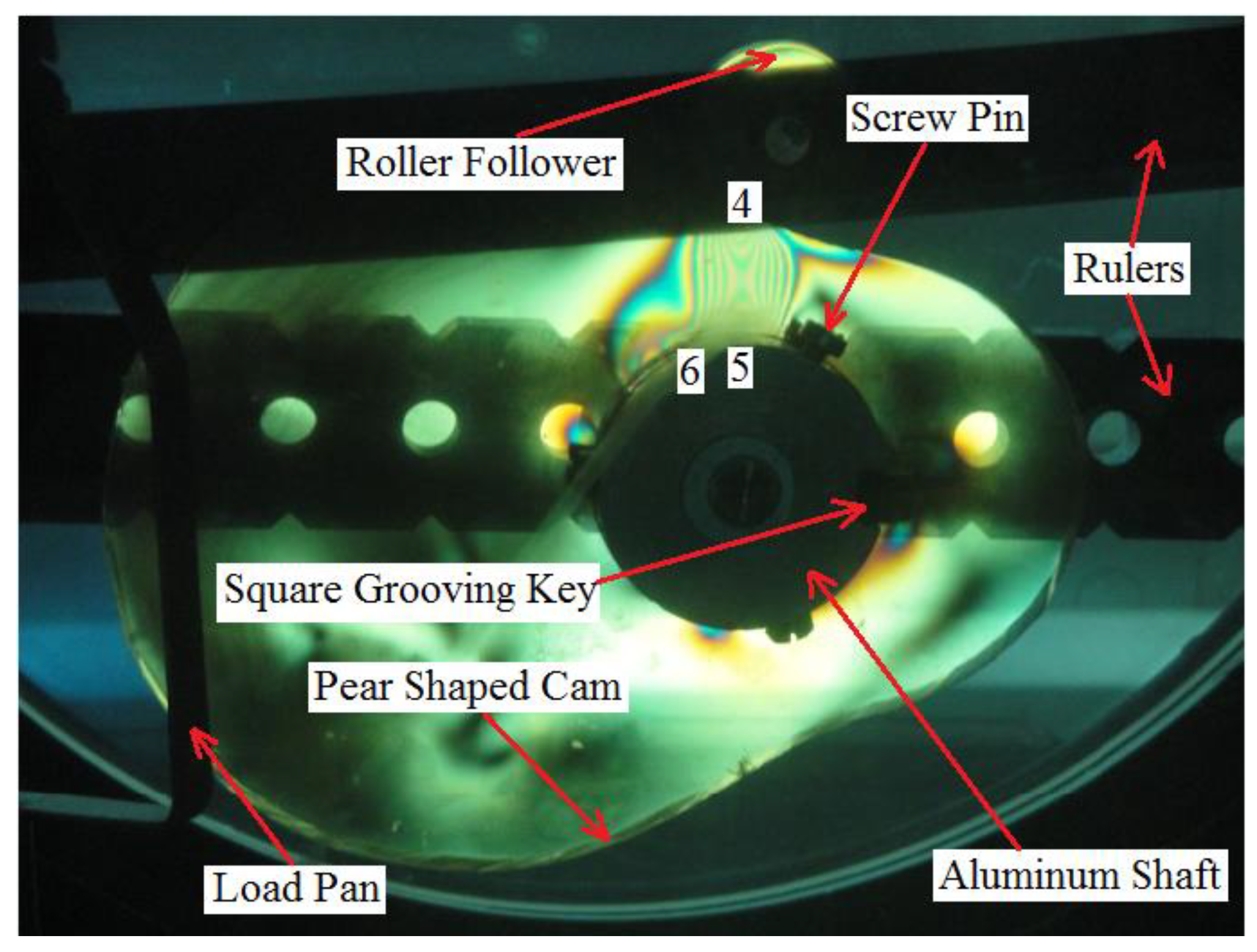

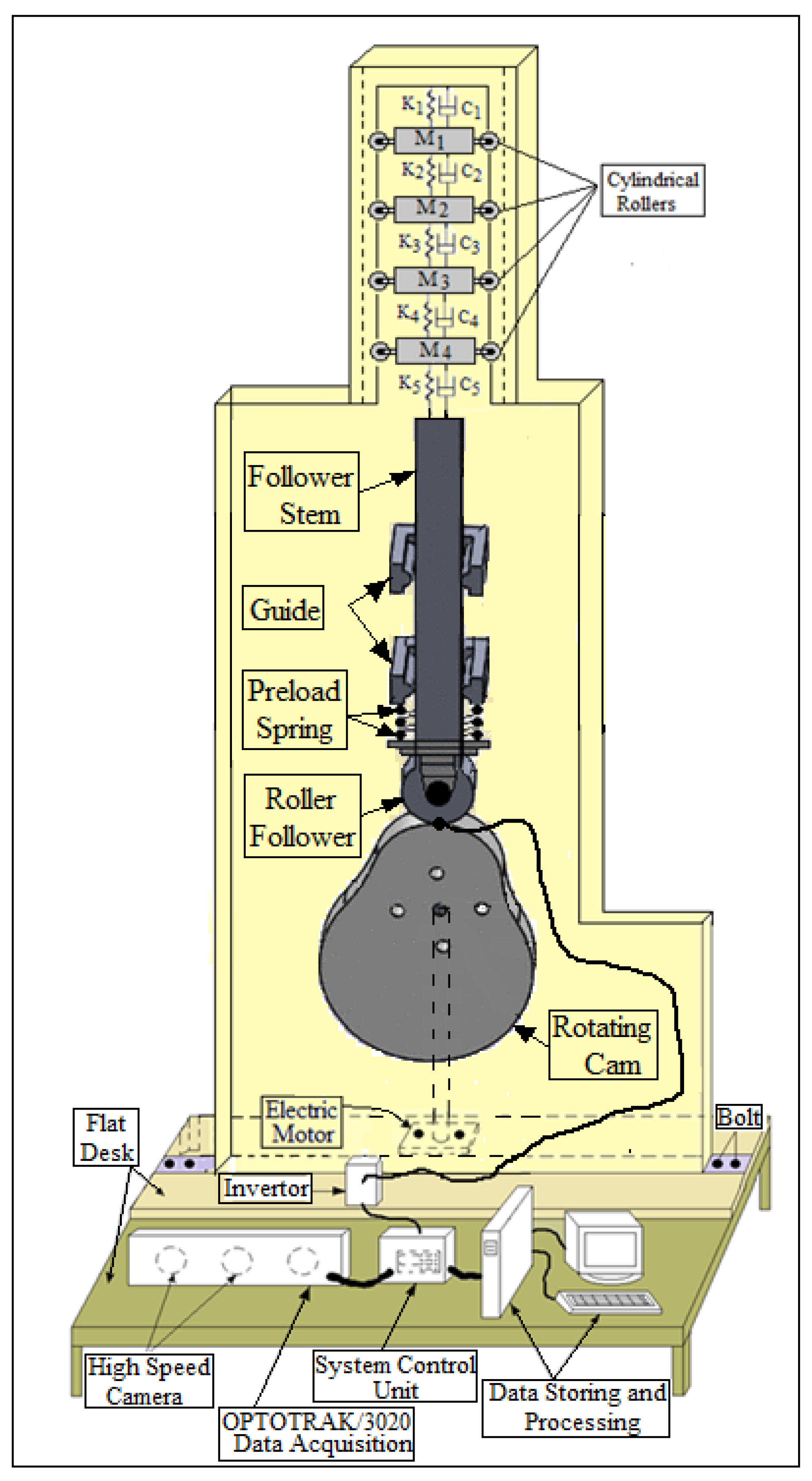

5. Methods of Experiment Setup

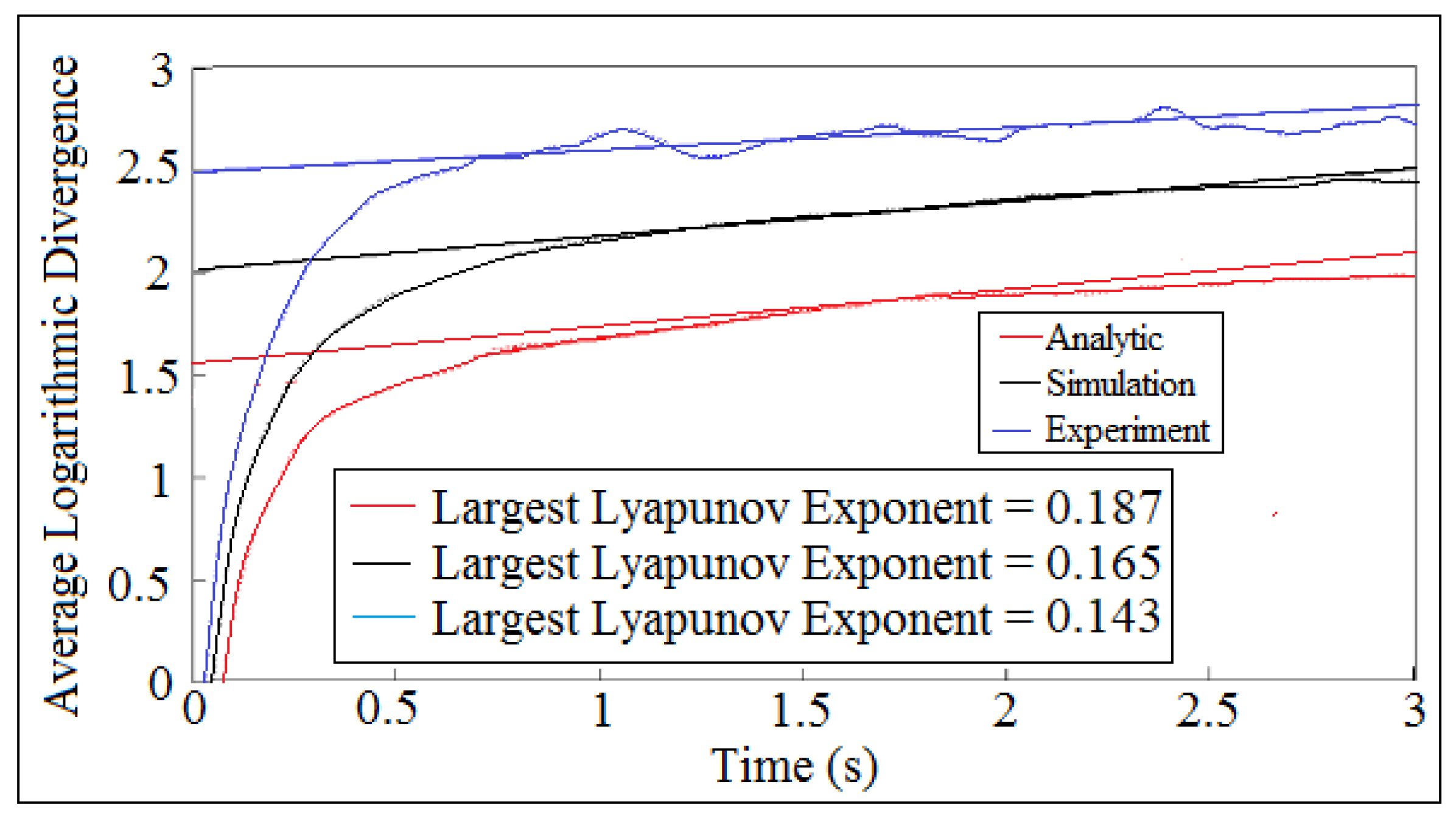

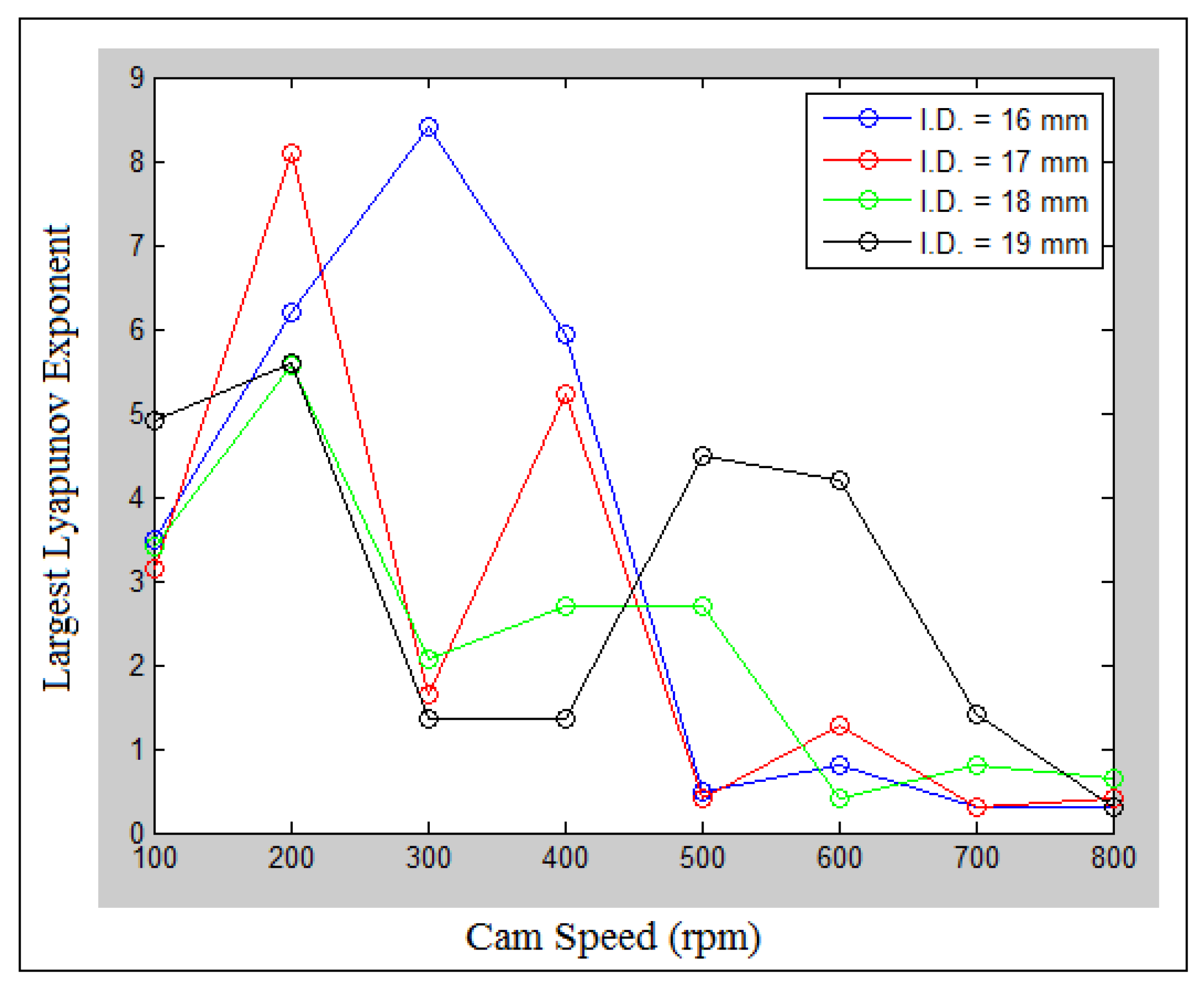

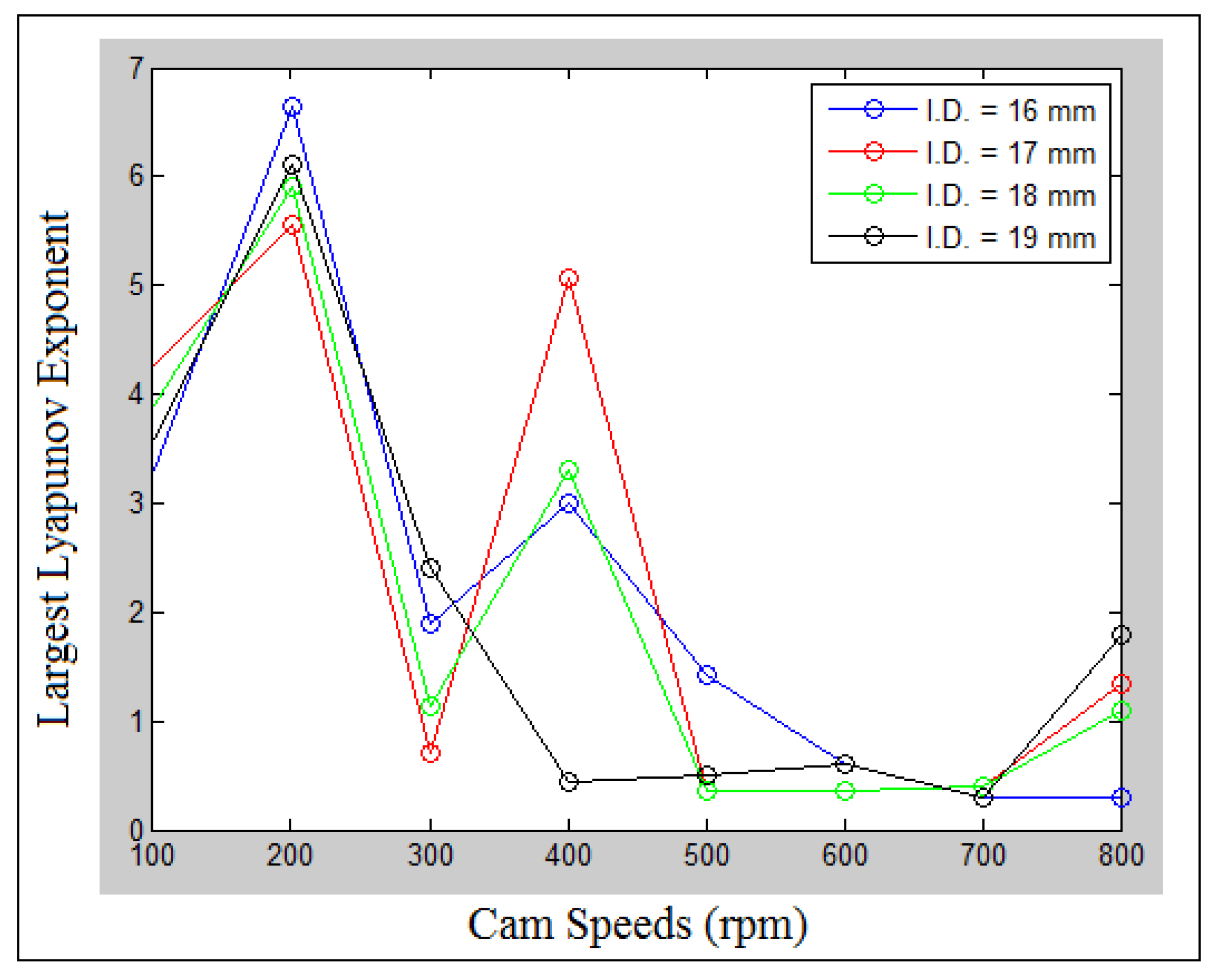

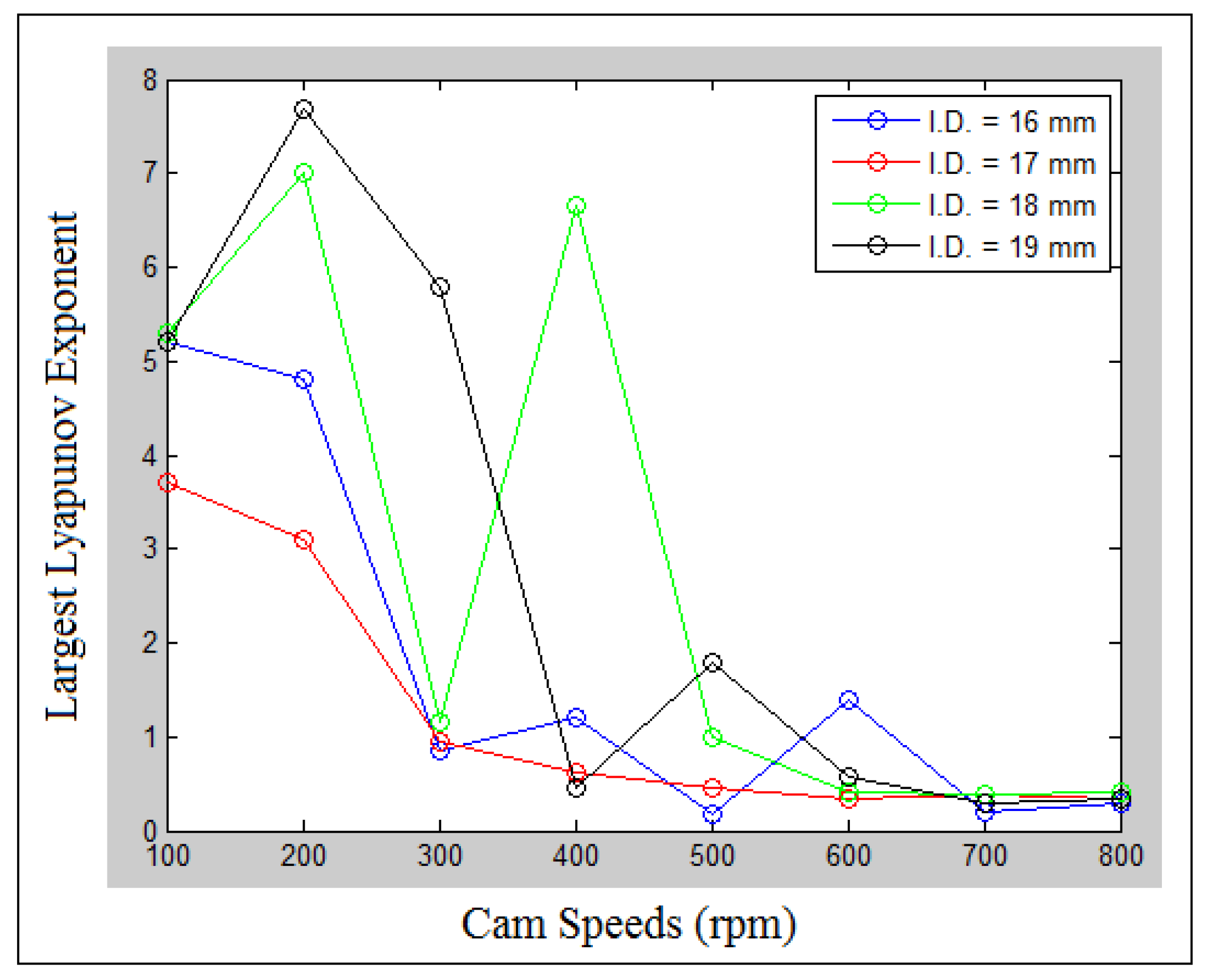

6. Largest Lyapunov Exponent Parameter

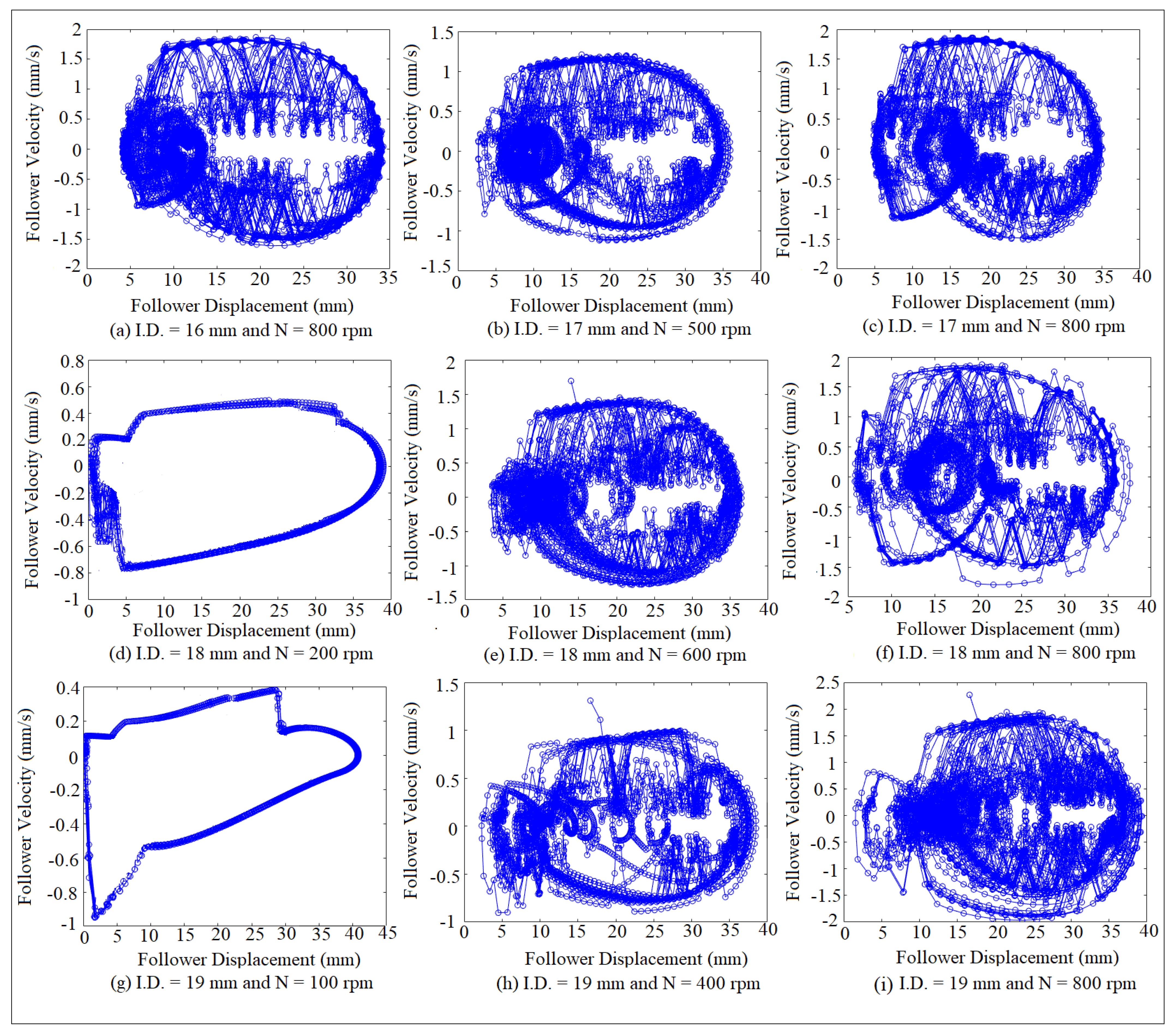

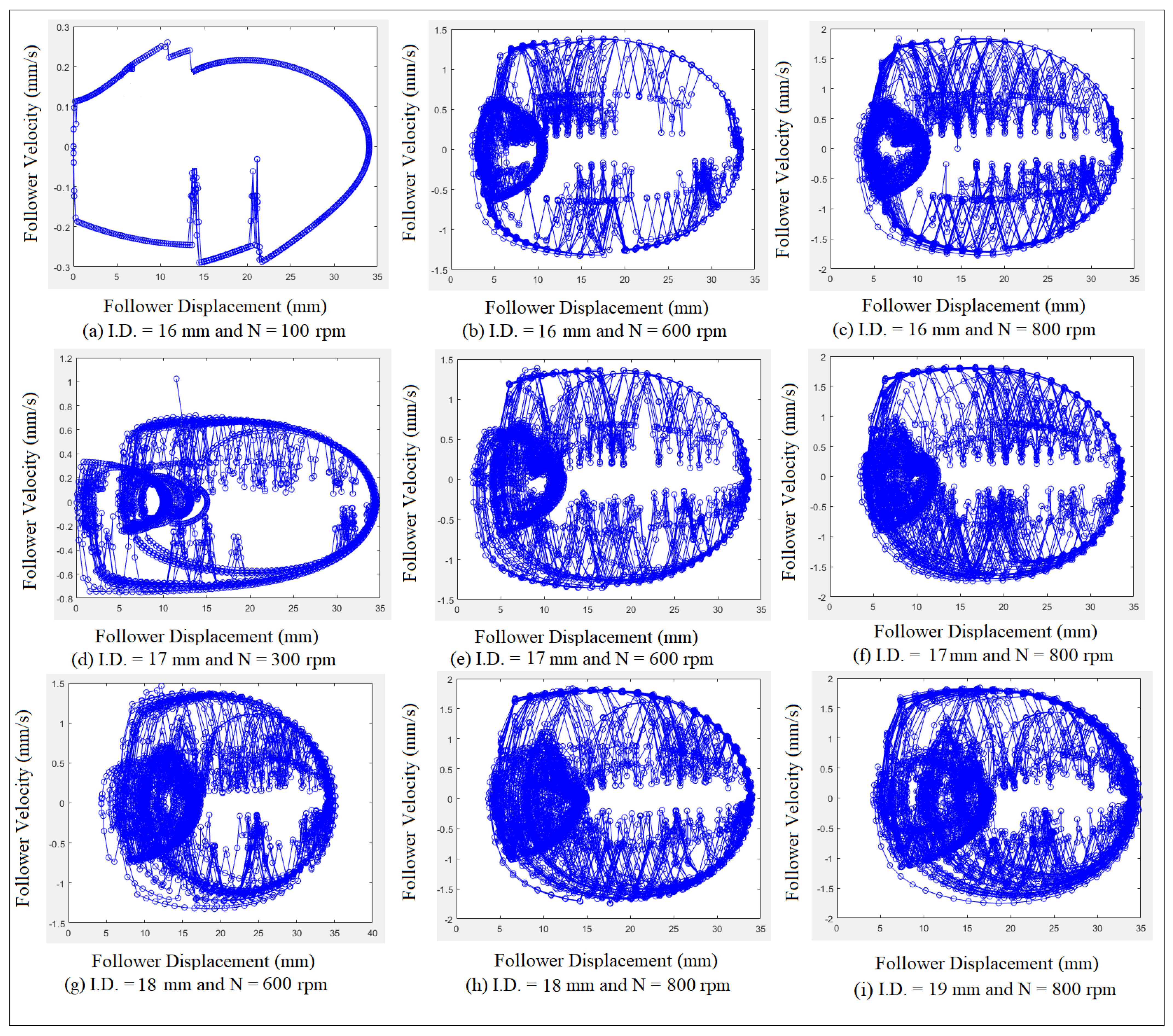

7. Phase-Plane Diagram

8. Results and Discussions

9. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| I.D. | Internal distance of the follower guide from inside, mm |

| N | Cam speed, rpm |

| I | Polar moment of inertia, |

| Dimensions of the follower stem, mm | |

| Spring stiffness, mm | |

| Damping coefficient, N·s/mm | |

| Radius of the base circle of the cam, mm | |

| m | Mass of the follower, kg |

| PC | Contact force between the cam and the follower, N |

| Preload spring extension, mm | |

| Contact stress between the cam and the follower, N/mm2 | |

| Thickness of the cam and the follower, mm | |

| Radius of curvature for the cam and the follower respectively, mm | |

| d(t) | Rate of change in the distance between nearest neighbors |

| dj(i) | Distance between the jth pair at (i) nearest neighbors, mm |

| t | Single time series, s |

| y(i) | Curve fitting of least square method for the follower displacement data |

| Ø | Phase shift angle of the vibration mode shape, Degree |

| Pressure angle, degree | |

| λ | Lyapunov exponent |

| Eigenvalue problem, rpm | |

| Discrete time steps, s | |

| D | Average displacement between trajectories at (t = 0) |

| N | Fringe order |

| Fs | Shear Force, N |

| h | Thickness of PMMA material, mm |

| I1 | Second moment of inertia, mm4 |

| y | Distance from neutral axis, mm |

| M | Bending moment of three bending point test, N.mm |

| Lo | Distance of PMMA specimen of three bending point test, mm |

| Principal stress in the direction 1, and 2 respectively |

References

- Yousuf, L.S.; Marghitu, D.B. Nonlinear dynamics behavior of cam-follower system using concave curvatures profile. Adv. Mech. Eng. 2020, 12, 1687814020945920. [Google Scholar] [CrossRef]

- Flores, P.; Machado, G.J.B.Q.A.; Pereira, R.M.S.; Claro, J.C.P. Kinematics of the Roller Motion and CAM Size Optimization of Disc CAM-Follower Mechanisms with Translating Roller Followers. In Proceedings of the 33rd Mechanisms and Robotics Conference, Parts A and B ASME, San Diego, CA, USA, 30 August–2 September 2009; Volume 7, pp. 421–432. [Google Scholar]

- Flores, P. Cam Size Optimization of Disc Cam-Follower Mechanisms with Translating Roller Followers. In New Trends in Mechanism Science; Springer: Berlin/Heidelberg, Germany, 2010; pp. 225–233. [Google Scholar] [CrossRef]

- Yousyf, L.S. Chaos investigation in a polydyne cam with flat-faced follower mechanism. J. King Saud Univ. Eng. 2020, 37, 507–516. [Google Scholar] [CrossRef]

- Ouyang, T.; Wang, P.; Huang, H. Cam profile optimization for the delivery system of an offset press. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2016, 231, 4287–4297. [Google Scholar] [CrossRef]

- Djeddou, F.; Smata, L.; Ferhat, H. Optimization and a reliability analysis of a cam-roller follower mechanism. J. Adv. Mech. Des. Syst. Manuf. 2018, 12, JAMDSM0121. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, T.T.N.; Duong, T.X.; Nguyen, V.S. Design general cam profiles based on finite element method. J. Appl. Sci. 2021, 11, 6052. [Google Scholar] [CrossRef]

- Lassaad, W.; Mohamed, T.; Yassine, D.; Fakher, C.; Taher, F.; Mohamed, H. Nonlinear dynamic behaviour of a cam mechanism with oscillating roller follower in presence of profile error. Front. Mech. Eng. 2013, 8, 127–136. [Google Scholar] [CrossRef]

- Yang, Y.-F.; Lu, Y.; Jiang, T.-D.; Lu, N. Modeling and Nonlinear Response of the Cam-Follower Oblique-Impact System. Discret. Dyn. Nat. Soc. 2016, 2016, 6142501. [Google Scholar] [CrossRef] [Green Version]

- Sinha, A.; Bharti, S.K.; Samantaray, A.K.; Bhattacharyya, R. Sommerfeld effect in a single-DOF system with base excitation from motor driven mechanism. Mech. Mach. Theory 2020, 148, 103808. [Google Scholar] [CrossRef]

- Norton, R.L. Cam Design and Manufacturing Handbook. J. Mech. Des. 2004, 126, 375. [Google Scholar] [CrossRef]

- Sinha, A. Vibration of Mechanical Systems, 1st ed.; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Shakoor, M.M. Fatigue Life Investigation for Cams with Translating Roller-Follower and Translating Flat-Face Follower Systems. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2006. [Google Scholar]

- Hamza, F.; Abderazek, H.; Lakhdar, S.; Ferhat, D.; Yildiz, A.R. Optimum design of cam-roller follower mechanism using a new evolutionary algorithm. Int. J. Adv. Manuf. Technol. 2018, 99, 1267–1282. [Google Scholar] [CrossRef]

- Hearn, E.J. Mechanics of Materials 2: An Introduction to the Mechanics of Elastic and Plastic Deformation of Solids and Structural Materials, 3rd ed.; Butterworth-Heinemann: Oxford, UK, 2001. [Google Scholar]

- Planchard, D. SolidWorks 2016 Reference Guide: A Comprehensive Reference Guide with over 250 Standalone Tutorials; SDC Publishing: Mission, KS, USA, 2015. [Google Scholar]

- King, R.H. Finite Element Analysis with SOLIDWORKS Simulation, 1st ed.; Cengage Learning: Boston, MA, USA, 2019. [Google Scholar]

- Parlitz, U. Estimating lyapunov exponents from time series. In Chaos Detection and Predictability; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1–34. [Google Scholar]

- Terrier, P.; Fabienne, R. Maximum Lyapunov exponent revisited: Long-term attractor divergence of gait dynamics is highly sensitive to the noise structure of stride intervals. J. Gait Posture 2018, 66, 236–241. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Contact Points | Experiment (MPa) | Numerical (MPa) | Error (%) | |

|---|---|---|---|---|

| Contact with the Nose | 1 | 23.944 | 26.708 | 10.348 |

| 2 | 8.089 | 8.903 | 9.143 | |

| 3 | 14.079 | 15.58 | 9.634 | |

| Contact with Flank no.(1) | 4 | 78.44 | 84.972 | 7.687 |

| 5 | 16.145 | 17.702 | 8.795 | |

| 6 | 12.445 | 14.162 | 12.123 | |

| Contact with the Base Circle | 7 | 76.88 | 85.999 | 10.603 |

| 8 | 26.5 | 28.66 | 7.536 | |

| 9 | 19.33 | 21.502 | 10.101 | |

| Contact with Flank no.(2) | 10 | 92.243 | 110.652 | 16.636 |

| 11 | 16.07 | 18.46 | 12.946 | |

| 12 | 19.242 | 21.614 | 10.974 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yousuf, L.S. Influence of Nonlinear Dynamics Behavior of the Roller Follower on the Contact Stress of Polydyne Cam Profile. Processes 2022, 10, 585. https://doi.org/10.3390/pr10030585

Yousuf LS. Influence of Nonlinear Dynamics Behavior of the Roller Follower on the Contact Stress of Polydyne Cam Profile. Processes. 2022; 10(3):585. https://doi.org/10.3390/pr10030585

Chicago/Turabian StyleYousuf, Louay S. 2022. "Influence of Nonlinear Dynamics Behavior of the Roller Follower on the Contact Stress of Polydyne Cam Profile" Processes 10, no. 3: 585. https://doi.org/10.3390/pr10030585

APA StyleYousuf, L. S. (2022). Influence of Nonlinear Dynamics Behavior of the Roller Follower on the Contact Stress of Polydyne Cam Profile. Processes, 10(3), 585. https://doi.org/10.3390/pr10030585