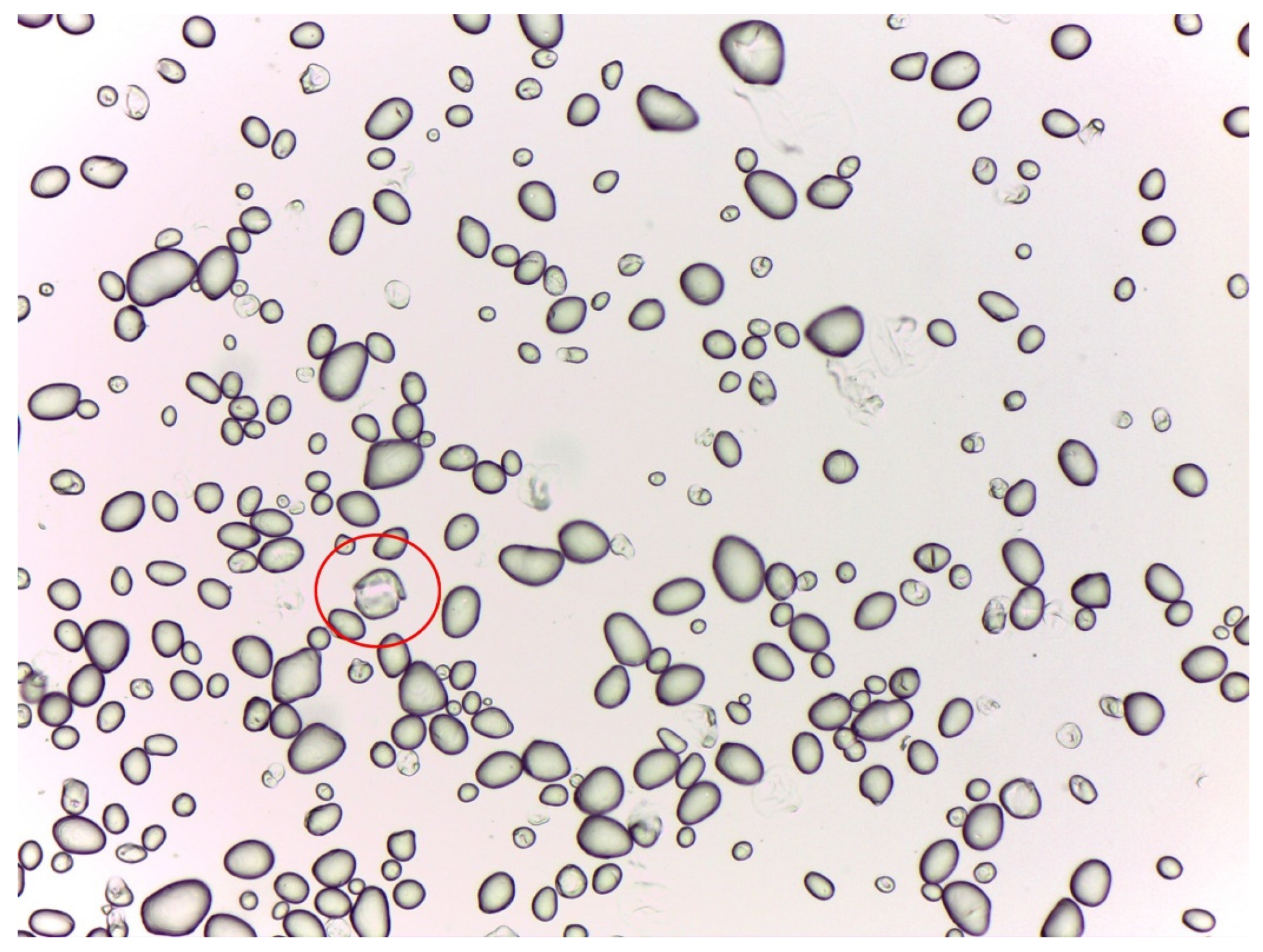

Use of ImageJ Software for Assessment of Mechanical Damage to Starch Granules

Abstract

:1. Introduction

2. Materials and Methods

- Potato starch, manufactured by the Potato Processing Company “Zetpezet” Ltd. in Pila, Poland

- Wheat starch, manufactured by Cargill Wroclaw, Poland

- Maize starch, manufactured by Chemical Works “Bochem” in Pionki, Poland

- Rice starch, manufactured in Belgium (BENEO—Remy, BE3018 Wijgmaol, Leven, Belgium),

- Tapioca starch, manufactured in Thailand.

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Russ, J.C. Image Analysis of Foods. J. Food Sci. 2015, 80, E1974–E1987. [Google Scholar] [CrossRef] [PubMed]

- Kropatsch Walter, G. Digital Image Analysis; Springer: New York, NY, USA, 2013. [Google Scholar]

- Umbaugh Scott, E. Computer Imaging: Digital Image Analysis and Processing; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Abramoff, M.; Magalhaes, P.; Ram, S. Image processing with ImageJ. Biophotonics Int. 2004, 11, 36–42. [Google Scholar]

- Collins, T.J. ImageJ for microscopy. Biotechniques 2007, 43 (Suppl. S1), S25–S30. [Google Scholar] [CrossRef] [PubMed]

- Igathinathane, C.; Pordesimo, L.O.; Batchelor, W.D. Major orthogonal dimensions measurement of food grains by machine vision using ImageJ. Food Res. Int. 2009, 42, 76–84. [Google Scholar] [CrossRef]

- Igathinathane, C.; Pordesimo, L.O.; Columbus, E.P.; Batchelor, W.D.; Methuku, S.R. Shape identification and particles size distribution from basic shape parameters using ImageJ. Comput. Electron. Agric. 2008, 63, 168–182. [Google Scholar] [CrossRef]

- Tegge, G. Stärke und Stärkederivate; Behr’s Verlag DE: Hamburg, Germany, 2004. [Google Scholar]

- Wang, Q.; Li, L.; Zheng, X. A review of milling damaged starch: Generation, measurement, functionality and its effect on starch-based food systems. Food Chem. 2020, 315, 126267. [Google Scholar] [CrossRef] [PubMed]

- Asmeda, R.; Noorlaila, A.; Norziah, M.H. Relationships of damaged starch granules and particle size distribution with pasting and thermal profiles of milled MR263 rice flour. Food Chem. 2016, 191, 45–51. [Google Scholar] [CrossRef]

- Barrera, G.N.; Calderón-Domínguez, G.; Chanona-Pérez, J.; Gutiérrez-López, G.F.; León, A.E.; Ribotta, P.D. Evaluation of the mechanical damage on wheat starch granules by SEM, ESEM, AFM and texture image analysis. Carbohydr. Polym. 2013, 98, 1449–1457. [Google Scholar] [CrossRef] [PubMed]

- Bettge, A.; Giroux, M.; Morris, C. Susceptibility of Waxy Starch Granules to Mechanical Damage. Cereal Chem. 2000, 77, 750–753. [Google Scholar] [CrossRef] [Green Version]

- Kwaśniewska-Karolak, I.; Nebesny, E.; Krala, L. Effect of genotype and weather conditions on wheat grain harness and the degree of starch damage. Acta Sci. Pol. Agric. 2011, 10, 25–32. [Google Scholar]

- Tester, R.; Morrison, W.; Gidley, M.; Kirkland, M.; Karkalas, J. Properties of Damaged Starch Granules. III. Microscopy and Particle Size Analysis of Undamaged Granules and Remnants. J. Cereal Sci. 1994, 20, 59–67. [Google Scholar] [CrossRef]

- ImageJ. Available online: https://imagej.nih.gov/ij/ (accessed on 13 March 2022).

- Grishagin, I.V. Automatic cell counting with ImageJ. Anal. Biochem. 2015, 473, 63–65. [Google Scholar] [CrossRef] [PubMed]

- Lind, R. Open Source software for image processing and Analysis: Picture this with ImageJ. In Woodhead Publishing Series in Biomedicine; Open Source Software in Life Science Research; Woodhead Publishing: Sawston Cambridge, UK, 2012; pp. 131–149. [Google Scholar]

- Liu, C.; Song, M.; Liu, L.; Hong, J.; Guan, E.; Bian, K.; Zheng, X. Effect of heat-moisture treatment on the structure and physicochemical properties of ball mill damaged starches from different botanical sources. Int. J. Biol. Macromol. 2020, 156, 403–410. [Google Scholar] [CrossRef]

- Zuo, Y.Y.J.; Hébraud, P.; Hemar, Y.; Ashokkumar, M. Quantification of high-power ultrasound induced damage on potato starch granules using light microscopy. Ultrason. Sonochem. 2012, 19, 421–426. [Google Scholar] [CrossRef] [PubMed]

- Loubes, M.A.; González, L.C.; Tolaba, M.P. Pasting behaviour of high impact ball milled rice flours and its correlation with the starch structure. J. Food Sci. Technol. 2018, 55, 2985–2993. [Google Scholar] [CrossRef] [PubMed]

- Palavecino, P.M.; Penci, M.C.; Ribotta, P.D. Effect of planetary ball milling on physicochemical and morphological properties of sorghum flour. J. Food Eng. 2019, 262, 22–28. [Google Scholar] [CrossRef]

- Wu, T.; Wang, L.; Li, Y.; Qian, H.; Liu, L.; Tong, L.; Zhou, X.; Wang, L.; Zhou, S. Effect of milling methods on the properties of rice flour and gluten-free rice bread. LWT—Food Sci. Technol. 2019, 108, 137–144. [Google Scholar] [CrossRef]

- Yu, D.; Chen, J.; Ma, J.; Sun, H.; Yuan, Y.; Ju, Q.; Teng, Y.; Yang, M.; Li, W.; Fujita, K.; et al. Effects of different milling methods on physicochemical properties of common buckwheat flour. LWT—Food Sci. Technol. 2018, 92, 220–226. [Google Scholar] [CrossRef]

- Ross, A.S.; Kongraksawech, T. Characterizing whole-wheat flours produced using a commercial stone mill, laboratory mills, and household single-stream flour mills. Cereal Chem. 2018, 95, 239–252. [Google Scholar] [CrossRef] [Green Version]

- Hasjim, J.; Li, E.; Dhital, S. Milling of rice grains: The roles of starch structures in the solubility and swelling properties of rice flour. Starch-Stärke 2012, 64, 631–645. [Google Scholar] [CrossRef]

- Drakos, A.; Kyriakakis, G.; Evageliou, V.; Protonotariou, S.; Mandala, I.; Ritzoulis, C. Influence of jet milling and particle size on the composition, physicochemical and mechanical properties of barley and rye flours. Food Chem. 2017, 215, 326–332. [Google Scholar] [CrossRef] [PubMed]

- Angelidis, G.; Protonotariou, S.; Mandala, I.; Rosell, C.M. Jet milling effect on wheat flour characteristics and starch hydrolysis. J. Food Sci. Technol. 2016, 53, 784–791. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hossen, S.; Sotome, I.; Nanayama, K.; Sasaki, T.; Okadome, H. Functional Properties of Submicron-Scale Rice Flour Produced by Wet Media Grinding. Cereal Chem. 2016, 93, 53–57. [Google Scholar] [CrossRef]

| Moisture [%] | Ash Content [%/Dry Weight] | |

|---|---|---|

| Corn starch | 13.1 | 0.1 |

| Wheat starch | 13.2 | 0.2 |

| Rice starch | 3.6 | 0.2 |

| Tapioka starch | 12.2 | 0.2 |

| Potato starch | 18.3 | 0.4 |

| Starch Type | Area [µm2] | Perimeter [µm] | Feret [µm] | Min Feret [µm] | Circularity | Roundness |

|---|---|---|---|---|---|---|

| Corn | 77.1 a ± 21.4 | 32.7 a ± 10.3 | 11.3 a ± 1.6 | 8.8 a ± 1.4 | 0.85 c ± 0.01 | 0.82 c ± 0.01 |

| Wheat | 96.4 b ± 51.2 | 37.3 b ± 9.8 | 12.8 b ± 2.2 | 9.7 b ± 1.6 | 0.81 b ± 0.01 | 0.79 b ± 0.01 |

| Rice | 58.8 c ± 39.5 | 30.1 c ± 10.4 | 9.9 c ± 3.1 | 6.9 c ± 2.1 | 0.63 a ± 0.01 | 0.72 a ± 0.01 |

| Tapioca | 118.0 d ± 82.3 | 40.7 d ± 17.3 | 13.9 d ± 4.2 | 10.5 d ± 2.6 | 0.81 b ± 0.01 | 0.79 b ± 0.01 |

| Potato | 322.2 e ± 293.2 | 62.5 e ± 21.5 | 21.4 e ± 7.7 | 16.4 e ± 6.3 | 0.85 c ± 0.01 | 0.81 c ± 0.01 |

| LSD | 8.98 | 1.16 | 0.37 | 0.26 | 0.008 | 0.007 |

| Corn Starch | Area [µm2] | Perimeter [µm] | Feret [µm] | Min Feret [µm] | Circularity | Roundness |

|---|---|---|---|---|---|---|

| Control | 77.1 a ± 21.4 | 32.7 a ± 10.3 | 11.3 a ± 1.6 | 8.8 a ± 1.4 | 0.85 a ± 0.01 | 0.82 a ± 0.01 |

| Mill for 30 min | 67.0 b ± 19.4 | 30.3 b ± 9.8 | 10.5 b ± 1.5 | 8.3 b ± 1.3 | 0.87 b ± 0.01 | 0.83 b ± 0.01 |

| LSD | 2.48 | 0.56 | 0.18 | 0.13 | 0.005 | 0.006 |

| Thermomix for 30 min | 81.0 b ± 22.5 | 33.8 b ± 10.4 | 11.6 b ± 1.7 | 9.2 b ± 1.5 | 0.85 a ± 0.01 | 0.83 b ± 0.01 |

| LSD | 2.75 | 0.61 | 0.20 | 0.14 | 0.005 | 0.006 |

| Drying for 30 min | 72.0 b ± 20.1 | 32.7 a ± 10.2 | 11.3 a ± 1.6 | 8.6 b ± 1.3 | 0.81 b ± 0.01 | 0.79 b ± 0.01 |

| LSD | 2.57 | 0.59 | 0.19 | 0.14 | 0.006 | 0.006 |

| Wheat Starch | Area [µm2] | Perimeter [µm] | Feret [µm] | Min Feret [µm] | Circularity | Roundness |

|---|---|---|---|---|---|---|

| Control | 96.5 a ± 51.2 | 37.3 a ± 9.8 | 12.8 a ± 2.2 | 9.7 a ± 1.6 | 0.81 a ± 0.01 | 0.79 a ± 0.01 |

| Mill for 30 min | 67.4 b ± 39.4 | 30.4 b ± 8.5 | 10.5 b ± 1.5 | 8.4 b ± 1.4 | 0.87 b ± 0.01 | 0.83 b ± 0.01 |

| LSD | 3.33 | 0.63 | 0.20 | 0.14 | 0.006 | 0.005 |

| Thermomix for 30 min | 78.6 b ± 41.1 | 33.5 b ± 8.7 | 11.5 b ± 1.8 | 9.1 b ± 1.6 | 0.84 b ± 0.01 | 0.82 b ± 0.01 |

| LSD | 3.99 | 0.74 | 0.23 | 0.17 | 0.007 | 0.006 |

| Drying for 30 min | 79.2 b ± 43.5 | 33.8 b ± 8.8 | 11.7 b ± 1.7 | 9.0 b ± 1.5 | 0.83 b ± 0.01 | 0.80 b ± 0.01 |

| LSD | 3.94 | 0.74 | 0.23 | 0.17 | 0.007 | 0.006 |

| Rice Starch | Area [µm2] | Perimeter [µm] | Feret [µm] | Min Feret [µm] | Circularity | Roundness |

|---|---|---|---|---|---|---|

| Control | 58.8 a ± 39.5 | 30.1 a ± 10.4 | 9.9 a ± 3.1 | 6.9 a ± 2.1 | 0.64 a ± 0.01 | 0.72 a ± 0.01 |

| Mill for 30 min | 15.5 b ± 8.6 | 15.2 b ± 6.7 | 5.4 b ± 2.2 | 4.1 b ± 1.7 | 0.85 b ± 0.01 | 0.80 b ± 0.01 |

| LSD | 3.45 | 0.71 | 0.21 | 0.15 | 0.009 | 0.007 |

| Thermomix for 30 min | 30.9 b ± 21.2 | 21.1 b ± 9.8 | 7.1 b ± 2.6 | 5.1 b ± 1.9 | 0.72 b ± 0.01 | 0.75 b ± 0.01 |

| LSD | 4.90 | 0.94 | 0.28 | 0.20 | 0.011 | 0.007 |

| Drying for 30 min | 41.8 b ± 26.4 | 23.9 b ± 10.3 | 8.2 b ± 2.8 | 5.8 b ± 2.1 | 0.72 b ± 0.01 | 0.73 b ± 0.01 |

| LSD | 4.98 | 0.98 | 0.30 | 0.21 | 0.010 | 0.007 |

| Tapioca Starch | Area [µm2] | Perimeter [µm] | Feret [µm] | Min Feret [µm] | Circularity | Roundness |

|---|---|---|---|---|---|---|

| Control | 118.0 a ± 82.3 | 40.7 a ± 17.3 | 13.9 a ± 4.2 | 10.5 a ± 2.6 | 0.81 a ± 0.01 | 0.79 a ± 0.01 |

| Mill for 30 min | 93.6 b ± 68.4 | 36.3 b ± 16.2 | 12.1 b ± 3.7 | 10.0 b ± 2.4 | 0.85 b ± 0.01 | 0.86 b ± 0.01 |

| LSD | 6.62 | 1.08 | 0.34 | 0.25 | 0.008 | 0.007 |

| Thermomix for 30 min | 89.6 b ± 61.3 | 35.6 b ± 15.9 | 12.0 b ± 3.3 | 9.8 b ± 2.2 | 0.85 b ± 0.01 | 0.85 b ± 0.01 |

| LSD | 5.98 | 0.97 | 0.31 | 0.22 | 0.007 | 0.007 |

| Drying for 30 min | 93.4 b ± 62.7 | 36.9 b ± 16.1 | 12.6 b ± 3.6 | 9.8 b ± 2.1 | 0.82 b ± 0.01 | 0.81 b ± 0.01 |

| LSD | 6.40 | 1.04 | 0.33 | 0.24 | 0.008 | 0.008 |

| Potato Starch | Area [µm2] | Perimeter [µm] | Feret [µm] | Min Feret [µm] | Circularity | Roundness |

|---|---|---|---|---|---|---|

| Control | 322.2 a ± 293.2 | 62.5 a ± 21.5 | 21.4 a ± 7.7 | 16.4 a ± 6.3 | 0.85 a ± 0.01 | 0.81 a ± 0.01 |

| Mill for 30 min | 452.3 b ± 302.3 | 78.0 b ± 24.3 | 26.9 b ± 9.6 | 20.0 b ± 7.3 | 0.82 b ± 0.01 | 0.76 b ± 0.01 |

| LSD | 41.7 | 3.55 | 1.21 | 0.85 | 0.013 | 0.013 |

| Thermomix for 30 min | 317.7 a ± 287.2 | 65.3 a ± 23.8 | 22.4 b ± 7.9 | 16.7 a ± 6.4 | 0.80 b ± 0.01 | 0.78 b ± 0.01 |

| LSD | 32.0 | 2.80 | 0.95 | 0.67 | 0.011 | 0.011 |

| Drying for 30 min | 240.7 b ± 173.3 | 57.1 b ± 23.4 | 19.6 b ± 7.1 | 15.1 b ± 5.6 | 0.84 a ± 0.01 | 0.81 a ± 0.01 |

| LSD | 27.9 | 2.53 | 0.87 | 0.60 | 0.009 | 0.010 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boruczkowski, T.; Boruczkowska, H.; Drożdż, W.; Miszczak, M.; Leszczyński, W. Use of ImageJ Software for Assessment of Mechanical Damage to Starch Granules. Processes 2022, 10, 630. https://doi.org/10.3390/pr10040630

Boruczkowski T, Boruczkowska H, Drożdż W, Miszczak M, Leszczyński W. Use of ImageJ Software for Assessment of Mechanical Damage to Starch Granules. Processes. 2022; 10(4):630. https://doi.org/10.3390/pr10040630

Chicago/Turabian StyleBoruczkowski, Tomasz, Hanna Boruczkowska, Wioletta Drożdż, Marta Miszczak, and Wacław Leszczyński. 2022. "Use of ImageJ Software for Assessment of Mechanical Damage to Starch Granules" Processes 10, no. 4: 630. https://doi.org/10.3390/pr10040630

APA StyleBoruczkowski, T., Boruczkowska, H., Drożdż, W., Miszczak, M., & Leszczyński, W. (2022). Use of ImageJ Software for Assessment of Mechanical Damage to Starch Granules. Processes, 10(4), 630. https://doi.org/10.3390/pr10040630