Effect of Surface Roughness on the Performance of a Shallow Spiral Groove Liquid Mechanical Seal

Abstract

:1. Introduction

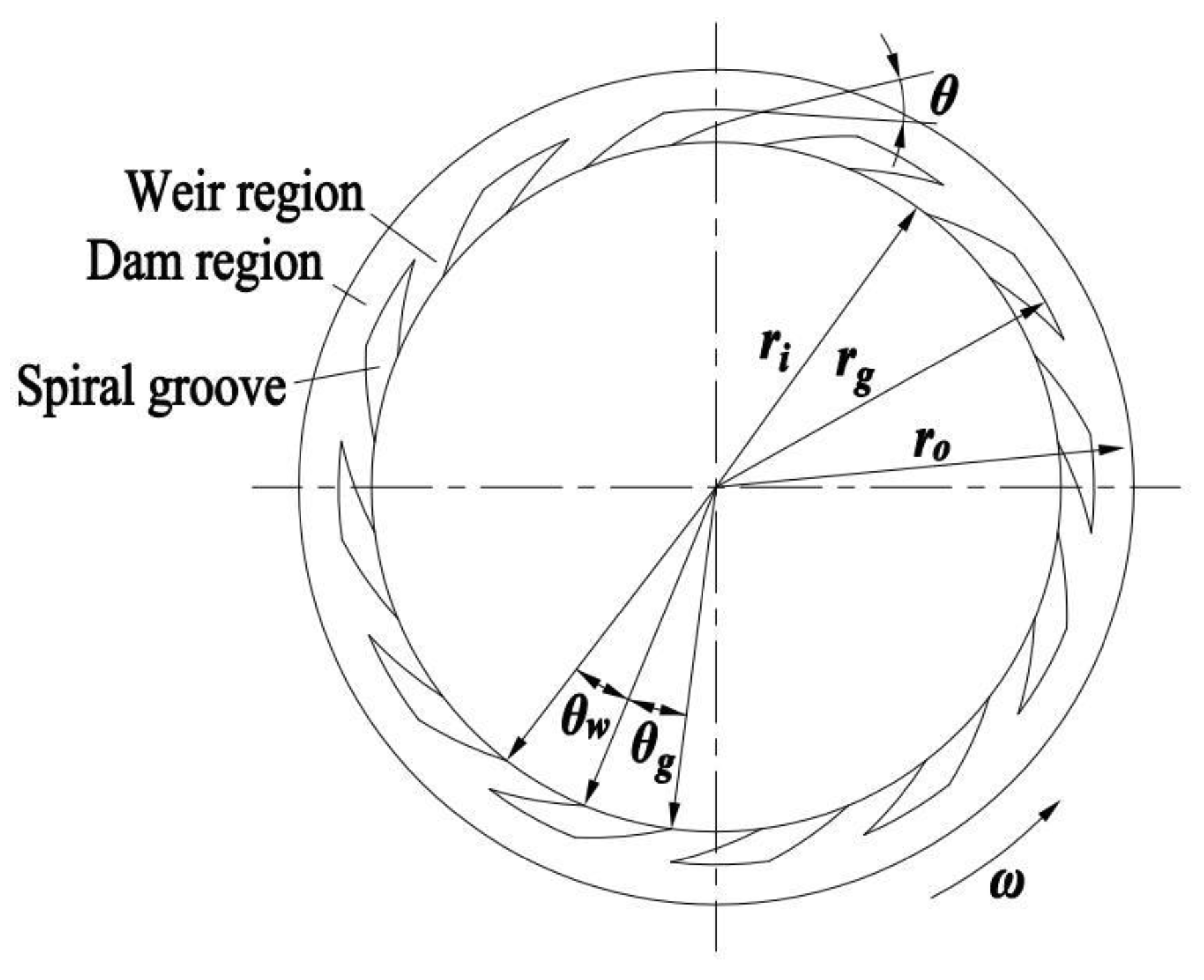

2. Geometric and Mathematic Models

2.1. Geometric Model

2.2. Mathematical Model

- The micro-gap lubrication film has a laminar flow pattern.

- The deformation of the seal ring and the gravity of the lubricating film medium are ignored.

- There is no relative slip between the lubricating medium and the seal surface.

- Changes of the viscosity and temperature of the medium in the lubrication film are ignored.

2.3. Number of Rough Micro-Elements and Validation of Grid Independence

3. Model Validation

- Design, process, and measure the slotted mechanical seal ring.

- Select the seal installation mode.

- Select a seal ring; install and debug it; control the specific spring pressure; apply different internal pressures and different speed conditions; and measure the pressure, end temperature, friction torque, and leakage rate of the system.

- Adjust the specific pressure and repeat step 1 until the specified specific pressure series is completed.

- Remove the sealing ring, select another sealing ring, and repeat step 2 and step 3.

- Measure the friction torque of the system, except for that of the experimental mechanical seal.

4. Results and Discussion

4.1. Effect of the Roughness of the Grooved Zone of the Rotating Ring on the Opening Force

4.1.1. Effect of the Roughness of the Grooved Zone of the Rotating Ring on the Opening Force

4.1.2. Effect of the Roughness of the Non-Grooved Zone of the Rotating Ring on the Opening Force

4.1.3. Effect of end Face Roughness of Stationary Ring on Opening Force

4.2. Effect of Surface Roughness on Leakage

4.2.1. Effect of the Roughness of the Grooved Zone of Rotating Ring on Leakage

4.2.2. Effect of the Roughness of the Non-Grooved Zone of the Rotating Ring on the Leakage

4.2.3. Effect of the Roughness of the Stationary Ring Surface on the Leakage

4.3. Effect of Surface Roughness on Friction Torque

4.4. Performance Comparison between Full-Face Roughness and Partial Roughness

5. Conclusions

- The roughness of the sealing surface causes the lubrication film to produce a hydrodynamic effect. The effect increases as the rotating speed increases. The opening force of the lubrication film increases as the roughness increases, and the growth trend exhibits an increasing rate as the rotating speed increases. The roughness of the rotating ring’s grooved zone is primarily used to increase the film pressure in the grooved zone through the hydrodynamic effect. The effect on the opening force is weak. In terms of the roughness of the non-grooved zone of the rotating ring, the hydrodynamic effect and increased flow resistance of the dam region expand the range and increase the pressure in the high-pressure areas. The effect on the increase in the opening force is the greatest. The roughness of the stationary ring surface produces a hydrodynamic effect, increases the flow resistance of the dam region, and increases the flow resistance of the pumping flow. The effect on the increase in the opening force is second to the effect of the roughness of the non-grooved zone of the rotating ring. Considering the sensitivity of different parts to roughness, improving the roughness of the non-grooved area and the end face of the stationary ring can increase the opening force.

- Increasing the roughness of the grooved zone of the rotating ring only results in an increase in negative leakage when the speed is high. When the non-grooved zone of the rotating ring is rough, it can inhibit the negative leakage flow and cause the negative leakage to become positive. The positive leakage increases as the rotating speed increases. However, increasing the roughness has a weak effect on leakage. When the stationary ring surface is rough, both the positive and negative leakages decrease, and the leakage decreases as the roughness increases.

- The friction torque primarily increases when the rotating speed is high. It increases as the surface roughness of the stationary ring and the roughness of the grooved zone of the rotating ring increase, but the increase in the surface roughness of the non-grooved zone of the rotating ring has a slight effect on the friction torque.

- Compared to the other conditions, the opening force increases the most, the positive leakage is the largest, and the friction torque increases slightly when the whole face is rough, and all of them increase was the rotating speed increases. Compared to smooth surfaces, when the rotating speed is 1000 rpm~10,000 rpm and considering the median value of conventional roughness, the roughness of the non-grooved area and end face of rotating ring increase the opening force by 2.40~57.94% and 3.55~69.33%, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cao, W.; Mao, J. Study of the affinity law of energy and cavitation characteristics in emergency drainage pumps at different rotating speeds. Processes 2019, 7, 932. [Google Scholar] [CrossRef] [Green Version]

- Li, F.; Cui, B.; Zhai, L. Research on rotordynamic characteristics of pump annular seals based on a new transient CFD method. Processes 2020, 8, 227. [Google Scholar] [CrossRef] [Green Version]

- Lebeck, A.O. Experiments and modeling of zero leakage backward pumping mechanical face seals. Tribol. Trans. 2008, 51, 389–395. [Google Scholar] [CrossRef]

- Salant, R.T.; Homiller, S.T. Stiffness and leakage in spiral groove upstream pumping mechanical seals. Tribol. Trans. 1992, 36, 55–60. [Google Scholar] [CrossRef]

- Jiang, J.; Peng, X.; Li, J.; Chen, Y. Leakage and stiffness characteristics of bionic cluster spiral groove dry gas seal. Chin. J. Mech. Eng. 2018, 31, 148–158. [Google Scholar] [CrossRef] [Green Version]

- Sun, J.; Ma, C.; Yu, Q.; Lu, J.; Zhou, M.; Zhou, P. Numerical analysis on a new pump-out hydrodynamics mechanical seal. Tribol. Int. 2017, 106, 62–70. [Google Scholar]

- Rouillon, M.; Brunetière, N. Spiral groove face seal behavior and performance in liquid lubricated applications. Tribol. Trans. 2018, 61, 1048–1056. [Google Scholar] [CrossRef]

- Du, Q.; Zhang, D. Research on the performance of supercritical CO2 dry gas seal with different deep spiral groove. J. Therm. Sci. 2019, 28, 547–558. [Google Scholar] [CrossRef]

- Matsuzaki, Y.; Kazamaki, T. Effect of surface roughness on compressive stress of static seals. JSME Int. J. Ser. 3 Vib. Control. Eng. Eng. Ind. 1988, 31, 99–106. [Google Scholar] [CrossRef]

- Matsuzaki, Y.; Hosokawa, K.; Funabashi, K. Effect of surface roughness on contact pressure of static seals: Sealing characteristics of knife-edge seals. JSME Int. J. Ser. 3 Vib. Control. Eng. Eng. Ind. 1992, 35, 470–476. [Google Scholar] [CrossRef] [Green Version]

- Arghavani, J.; Derenne, M.; Marchand, L. Effect of surface characteristics on compressive stress and leakage rate in gasketed flanged joints. Int. J. Adv. Manuf. Technol. 2003, 21, 713732. [Google Scholar] [CrossRef]

- Minet, C.; Brunetière, N.; Tournerie, B. A deterministic mixed lubrication model for mechanical seals. J. Tribol. 2011, 133, 042203. [Google Scholar] [CrossRef]

- Minet, C.; Brunetière, N.; Tournerie, B. On the lubrication of mechanical seals with rough surfaces: A parametric study. IMechE Part J J. Eng. Tribol. 2012, 226, 1109–1126. [Google Scholar] [CrossRef]

- Hu, S.; Huang, W.; Brunetière, N.; Song, Z.; Liu, X.; Wang, Y. Stratified effect of continuous bi-Gaussian rough surface on lubrication and asperity contact. Tribol. Int. 2016, 104, 328–341. [Google Scholar] [CrossRef]

- Chen, W.; Meng, X.; Wang, Y.; Liang, Y.; Peng, X. Finite element model and tribological properties analysis of textured mechanical seals considering roughness effect. Tribology 2019, 39, 523–531. [Google Scholar]

- Chen, H.; Zhang, P.; Sun, D. Effect of surface roughness on properties of liquid film lubricated hydrodynamic mechanical seal. J. Drain. Irrig. Mach. Eng. 2020, 38, 176–182. [Google Scholar]

- Majumdar, A.; Bhushan, B. Fractal model of elastic-plastic contact between rough surfaces. ASME. J. Tribol. 1991, 113, 1–11. [Google Scholar] [CrossRef]

- Yan, W.; Komvopoulos, K. Contact analysis of elastic-plastic fractal surfaces. J. Appl. Phys. 1998, 84, 3617–3624. [Google Scholar] [CrossRef]

- Morag, Y.; Etsion, I. Resolving the contradiction of asperities plastic to elastic mode transition in current contact models of fractal rough surfaces. Wear 2007, 262, 624–629. [Google Scholar] [CrossRef]

- Wen, Q.; Liu, Y.; Huang, W.; Suo, S.; Wang, Y. The effect of surface roughness on thermal-elasto-hydrodynamic model of contact mechanical seals. Sci. China (Phys. Mech. Astron.) 2013, 56, 1920–1929. [Google Scholar] [CrossRef]

- Miao, X.; Huang, X. A complete contact model of a fractal rough surface. Wear 2014, 309, 145–151. [Google Scholar] [CrossRef]

- Yu, R.; Chen, W. Fractal modeling of elastic-plastic contact between three-dimensional rough surfaces. Ind. Lubr. Tribol. 2018, 70, 290–300. [Google Scholar] [CrossRef]

- Li, X.; Yang, Z.; Xu, J.; Chen, R.; Yang, H. The fractal leakage model of contact mechanical seals considering wear and thermal deformation. J. Braz. Soc. Mech. Sci. 2019, 41, 521. [Google Scholar] [CrossRef]

- Meng, X.; Bai, S.; Peng, X. Lubrication film flow control by oriented dimples for liquid lubricated mechanical seals. Tribol. Int. 2014, 77, 132–141. [Google Scholar] [CrossRef]

- Xie, Y.; Li, Y.; Suo, S.; Liu, X.; Li, J.; Wang, Y. A mass-conservative average flow model based on finite element method for complex textured surfaces. Sci. China Phys. Mech. 2013, 56, 1909–1919. [Google Scholar] [CrossRef]

- Ayadi, K.; Brunetière, N.; Tournerie, B.; Maoui, A. Experimental and numerical study of the lubrication regimes of a liquid mechanical seal. Tribol. Int. 2015, 92, 96–108. [Google Scholar] [CrossRef]

- Blasiak, S.; Zahorulko, A.V. A parametric and dynamic analysis of non-contacting gas face seals with modified surfaces. Tribol. Int. 2016, 94, 126–137. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, J.; Hu, Q.; Wang, D.; Zhang, X. Orientation effect of orderly roughness microstructure on spiral groove dry gas seal. Tribol. Int. 2018, 126, 97–105. [Google Scholar]

- Liao, B.; Sun, B.; Li, Y.; Yan, M.; Ren, Y.; Feng, Q.; Yang, D.; Zhou, K. Sealing reliability modeling of aviation seal based on interval uncertainty method and multidimensional response surface. Chin. J. Aeronaut. 2019, 32, 2188–2198. [Google Scholar] [CrossRef]

- Han, Y.; Meng, Q.; de Boer, G. Two-scale homogenization of hydrodynamic lubrication in a mechanical seal with isotropic roughness based on the Elrod cavitation algorithm. Proc. Inst. Mech. Eng. J-J. Eng. 2022, 236, 359–385. [Google Scholar] [CrossRef]

- Peng, X.; Li, J.; Sheng, S.; Yin, X.; Bai, S. Effects of surface roughness on performance prediction and geometric optimization of a spiral groove face seal. Tribology 2007, 6, 567–572. [Google Scholar]

- Chen, H.; Wu, Q.; Xu, C.; Zuo, M. Research on cavitation regions of upstream pumping mechanical seal based on dynamic mesh technique. Adv. Mech. Eng. 2014, 6, 821058. [Google Scholar] [CrossRef] [Green Version]

- Song, P. Study on the Characteristics of Liquid Film between Faces of Spiral Groove Hydrodynamic Mechanical Seal; Sichuan University: Chengdu, China, 1999. [Google Scholar]

| Geometrical Parameters | Value |

|---|---|

| Inner radius of lubrication film, ri (mm) | 25.5 |

| Outer radius of lubrication film, ro (mm) | 30.5 |

| Spiral groove outer root radius, rg (mm) | 28.5 |

| Spiral angle, θ (°) | 20 |

| Groove width ratio, γ | 0.5 |

| Groove diameter ratio, β | 0.6 |

| Depth of groove, hc (μm) | 4 |

| Lubrication film thickness, h (μm) | 3 |

| Groove number, Ng | 12 |

| Inlet pressure, Pi (MPa) | 0.6 |

| Outlet pressure, P0 (MPa) | 0 |

| Rotating speed, n (rpm) | 1000~10,000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Chen, Y.; Han, T.; Fu, Y.; Cheng, Q.; Wei, Z.; Zhao, B. Effect of Surface Roughness on the Performance of a Shallow Spiral Groove Liquid Mechanical Seal. Processes 2022, 10, 651. https://doi.org/10.3390/pr10040651

Chen H, Chen Y, Han T, Fu Y, Cheng Q, Wei Z, Zhao B. Effect of Surface Roughness on the Performance of a Shallow Spiral Groove Liquid Mechanical Seal. Processes. 2022; 10(4):651. https://doi.org/10.3390/pr10040651

Chicago/Turabian StyleChen, Huilong, Yingjian Chen, Ting Han, Yanxia Fu, Qian Cheng, Zepeng Wei, and Bingjuan Zhao. 2022. "Effect of Surface Roughness on the Performance of a Shallow Spiral Groove Liquid Mechanical Seal" Processes 10, no. 4: 651. https://doi.org/10.3390/pr10040651