1. Introduction

Environmental contaminants are toxic and undesirable compounds that can endanger human health and the survivorship of life on Earth. Thus, their removal from the environment has become a hot topic of numerous research works [

1]. The application of advanced materials and new applied technologies gives very important results in various fields, such as in improving human life, eliminating environmental pollution, and environmental remediation. There is great interest in producing efficient photocatalytic compounds that can remove a wide spectrum of toxic pollutants to remediate the environment. Photocatalysis technology has undergone ultra-fast development during the past several decades and has been widely applied in many fields, such as photo-synthesis, pollutant treatment, and other chemical- or energy-related processes [

2,

3]. Photocatalysis is accepted as a beneficial and environmentally friendly solution for the removal of undesirable contaminants. This environmentally friendly technology uses non-hazardous reactants that do not lead to the problem of environmental contamination. The results of energy-saving, simplicity, and reproducibility are also important characteristics of this efficient technology [

4]. Its most substantial advantage is the capability to mineralize a wide variety of contaminants. In recent years, a remarkable number of scientific papers have been reported on the utilization of oxide nanostructures to eliminate environmental pollution [

5,

6,

7]. The energy gap for the nanophotocatalysts was determined, making the nanocomposites favorable for removing contaminants. With a completely environmentally friendly method in the photocatalytic process, utilizing sunlight in the presence of photocatalytic compounds, poisonous contaminants can be oxidized or even degraded [

8,

9]. Optimization studies for the photocatalytic decomposition of each contaminant demonstrated that the best performance could be achieved at a specific amount of contaminant and nanocatalyst [

10].

Two major problems related to population growth, urbanization, and economic growth, environmental and public health concerns, as well as the depletion of non-renewable resources, are caused by the problem of inadequate waste management. According to the available data, the total world production of natural and synthetic rubber amounted to over 25 million tons [

11], of which about 60% was used for the production of car tires. Preliminary estimates suggest that the total stock of waste tires is around 100 million tons, with only about 10% being recoverable [

12,

13].

Tires are a specific category of waste, as they are very durable and almost non-degradable [

14,

15], which is why they are a major environmental problem [

16,

17]. Waste tire management methods depend on various factors, such as country characteristics, industry development, and population. According to some projections, worldwide, waste raised from tires amounts to 1.5 billion tons/year and by the end of 2025, is expected to be more than 2.5 billion tons [

18].

Results of certain studies conclude that Europe, Asia, and North America generate 90% of the total amount of scrap tires [

19,

20]. Eastern Europe has traditionally had disposal fees at a lower level than Western Europe, and lower safety standards have enabled the intensification of the trade of used tires and their reuse. A necessary condition for putting things under control is to increase disposal fees and strengthen safety regulations [

21]. At the same time, some research suggests that the model of “manufacturer and importer responsibility” for tire recycling should be applied in other countries as well, as it has proven successful in most European countries [

22,

23].

Waste tire management includes a set of measures for the collection, takeover and transport, storage, and treatment of waste tires. After the end of the life cycle, numerous recycling alternatives (pyrolysis, retread, shredding, compacting rubberized concrete, crumbing, reclaiming, rubber modified asphalt) are carried out in the process of waste tire treatment, which creates conditions for using waste tires for energy purposes. European directives do not cover part of the management of waste tires, as is the case with electrical and electronic waste, waste batteries, and accumulators. Although the EU has banned the disposal of tires in landfills since 2009, most countries do not have specific legislation on waste tire collection. However, a number of countries are trying to find ways to extend their life cycle. Improperly collected and disposed waste tires can endanger the environment by polluting the air, soil, and water.

Additionally, due to mechanical abrasion, car tires release particles in the environment, and many studies point to the problem of car tires as a source of microplastics in the environment [

24,

25,

26]. As the release of this abrasive material is not possible in the near future [

27], the results of some recent research suggest that emission reduction of non-exhaust emission source [

28] and tire wear and tear [

29,

30] should be given more prominence on the political agenda [

31].

The problem of waste tires is rising from year to year, especially in countries in transition. The policy and mechanism of waste reuse and recycling is based on the rational use of resources, and not uncontrolled one-time use, or uncontrolled ignition and improper disposal in the case of tires. The combustion of tires produces many toxic substances [

32,

33,

34] and is extremely harmful to all three media in the environment, suggesting that the problems are not only environmental, but also health-related. They are very hazardous waste and drastically impair air quality through the emission of combustion products [

35], which requires an expensive air emission control system [

36]. Atmospheric toxic pollutants emitted from burning tires directly endanger public health and safety [

37,

38], and cause various types of mild to severe diseases [

39,

40,

41].

In order to alleviate the energy crisis and environmental degradation, it has become imperative to use technology to obtain energy from unconventional sources, such as municipal and/or industrial waste, in which used tires have a special place. Due to their high calorific value, tires are used as an energy source in some countries (controlled incineration) where incinerators contain the necessary systems for the purification and treatment of gases. As waste tires have a higher energy content than coal, scrap tire recycling can significantly contribute to reducing GHG emissions [

42]. However, this is not the primary option in tire treatment. The literature suggests several processes for used tires, analyzes the environmental and economic aspects of these processes, and investigates different management schemes for used tires [

43]. As the need for the recovery and recycling of waste is increasingly emphasized, efforts are being made for the development of new technologies for used tire treatment [

44,

45,

46,

47,

48].

By reviewing the literature, we observed a significant number of life cycle assessment (LCA) studies of tire production, retreading, and recycling, with the LCA approach being necessary to allow a comprehensive and in-depth analysis of processes and products on the environment, throughout the life cycle [

49]. The latest research is dedicated to the development of effective waste tire management schemes, from the early stages of their production to the post-consumption step with the purpose of improving a circular economy model [

12]. Although the data, assumptions, and results of retreading-related studies differ [

50,

51], basically this process prolongs the life of tires. Also, it actively reduces the number of tires in use, saves natural resources, and reduces carbon dioxide emissions, as well as the size of car waste. However, many countries need to further regulate and improve legislation in this area and strengthen its implementation. An alternative to retreading tires, especially in the case of extremely worn tires, is the process of recycling tires. This process has long been the subject of analysis in many studies in the previous period, and was examined from different perspectives [

52,

53,

54]. Due to their high calorific value, waste tires can be used as an alternative fuel in some industries [

14,

55], but also for many other purposes [

56,

57,

58,

59,

60].

The way in which waste tires in Montenegro are collected, transported, sorted, stored, and processed is not satisfactory. This paper is the result of research conducted for a feasibility study for the collection, takeover and transport, sorting, and storage of waste pneumatic tires from the Capital city of Podgorica, with consideration of the possibility of the collection of waste tires from the Old Royal Capital of Cetinje and the municipality of Danilovgrad. This project was conducted for the Government of Montenegro, i.e., the Line Ministry. The paper is organized into several sections. The Introduction emphasizes certain issues of environmentally and economically sustainable waste management, with a focus on the problem of the adequate collection and disposal of waste pneumatic tires. In the second section, we present a review of reference sources from the literature in this scientific field, with an emphasis on sources that treat the environmental and economic aspects of waste tire management. The third section of the paper explains the current situation and articulates current problems in the field of waste tire management in Montenegro, specifically in three municipalities (Podgorica, Cetinje, and Danilovgrad). As the goal of our article is a financial and economic feasibility evaluation of the project of establishing the Center for Waste Tire Management (on the site within the existing sanitary landfill of non-hazardous municipal waste, “Livade”, in Podgorica), the fourth section presents a methodological framework for conducting these analyses. In this section, we applied the European Commission methodology for cost–benefit analysis (CBA). The fifth section offers the basic results of this project’s financial and economic feasibility analysis. At the end, we provide conclusions, the limitations of the research, and further opportunities for research improvement in this area.

2. Literature Review

Tire management waste projects, although with commercial potential, are undoubtedly typical environmental projects. Therefore, their evaluation can be completed only through the framework of supplemented and improved CBA, with a broader analytical framework and monetization of intangible items [

61], as well as any other category of financial costs and benefits during project implementation. The application of a holistic approach is imposed as a necessity due to the necessary integration of economic, social, and ecological aspects of sustainability. The necessity of the economic, social, and ecological perspective of evaluation of these projects [

62] requires overcoming the framework of the simplified and incomplete original version of the CBA, as well as eliminating the shortcomings of such a problematic project evaluation [

63,

64]. In this regard, we note efforts to develop and improve the CBA methodological framework and to evaluate the effectiveness of waste management systems [

65].

The literature suggests that CBA is used in the evaluation of circular economy projects, which includes projects of environmentally and economically sustainable waste tire management. The results of the conducted analyses, due to indisputable external effects on the environment and ecosystem, predominantly indicate the economic sustainability of these projects. The results also suggest that financial sustainability is not always guaranteed, especially if recycling is not undertaken. Although disposal is the most popular method, even earlier research has indicated that only the disposal of tires dissipates the potential in material and energy, which can otherwise be used by processing tires [

66]. Therefore, it is indisputable that the utilization rate of scrap tires has increased significantly, due to the economic and environmental benefits that were observed earlier [

67,

68], as well as the industry efforts to promote the circular economy [

12]. Hence, there are significantly more studies that assess the economic and environmental sustainability of waste rubber processing projects. A recent study, which tested the investment’s financial and economic feasibility in innovative textile fiber recycling technology (as a relevant part of end-of-life tire material) and its use as an additive for bituminous conglomerates, suggests medium- and long-term financial feasibility, but also a high economic sustainability [

69].

The latest research confirms that tire recycling is a desirable alternative to the process of landfilling or combusting tires. Recent research has assumed recycling is a necessity and took as a starting point the implementation of the tire redesign process. The redesign process is needed in order to achieve effects in reducing energy consumption and negative effects on the environment during the recycling process. By applying the CBA, the efficiency of the proposed technical redesign solution, from the technical, economic, social, and environmental point of view, was confirmed [

70]. In addition, the use of rubber bitumen in asphalt mixes is favorable compared to conventional bitumen, as production costs are higher, but maintenance costs are lower. The aforementioned indicates the generation of significant social and environmental benefits, such as reducing international regularity index variability over time and reducing GHG and noise [

71].

Due to the positive results of the research, waste tires are today treated as a resource and not as waste, and their uses are varied. The available statistics are encouraging; in 1992, material recycling amounted to only 5% in EU member states, while in 2017 it increased to 38% [

13]. This fact contributed to significant savings in materials and energy. Developed countries such as the US, Canada, and Japan are now recycling almost 90% of waste tires, predominantly in energy co-generation systems [

72,

73]. As modern economies become increasingly focused on renewable energy production, waste tires have proven to be a significant potential for sustainable energy [

59,

74,

75,

76]. At the same time, significant effects are achieved: a reduction of the impact on the environment, while achieving economic sustainability, i.e., economic, environmental, and social benefits. Although waste tires have the potential to be a key source of renewable energy, certain economic problems must be overcome in order to ensure the wider implementation of this technology and commercialization [

77].

Interested business entities will start reusing and recycling scrap tires only if the potential profit per tire is high enough. This applies if there is a good return on capital invested in the construction of the factory and if equipment purchases for tire processing can be provided [

78]. A recent study indicated an increase in profitability due to the addition of a tire retreading facility to the logistics network of a company, which initially dealt only with tire recycling [

79].

In favor of improving waste tire management practices, the results of some research offer the optimization of the model of the waste tire recycling network. The aim of optimization is to achieve the unity of several goals: environmental protection, short-term economic benefits, and strategic partnerships with suppliers [

80]. In addition, some research suggests the importance of economic and policy instruments to support waste tire management practices, and in particular scrap tire recycling programs [

81]. However, some research warns of a lack of recycling capacity in relation to the amount of waste tires generated annually [

82], but also of the shortcomings and limitations of different tire recycling methods [

83]. In this regard, continuous efforts are being made to develop new tire recycling methodologies [

84], with pyrolysis of scrap tires being considered an environmentally, economically, and health-sustainable alternative to recycling [

85,

86,

87,

88].

3. Current Status of Waste Tire Management: The Case of Montenegro

In 1996, the Collaborative Working Group on Solid Waste Management in low- and middle-income countries developed a framework system for integrated and sustainable waste management (ISWM), emphasizing public health, the environment, and resource recovery. In order to establish a satisfying and sustainable ISWM, in addition to technical elements, it is necessary to systematically include all stakeholders in the planning, implementing, and monitoring phases [

89]. In relation to the above, sustainable development is significantly based on the management of tire waste, including its environmental, economic, and social effects. The United Nations has emphasized the key elements of waste management systems: policies and regulations, supporting institutions, proper financial mechanisms, stakeholder participation, and supporting technologies [

90]. In many developing countries, waste tire management has not received the attention it deserves, and the processing, treatment, and disposal of waste tires are still in their initial phase. In some countries (e.g., Mexico and Russia), an integrated reverse logistics (RL) model has been proposed, which includes the processes of re-manufacturing and diversification, providing an economical and sustainable system of waste management. The same model has been successfully applied in some developed countries (Japan, Spain, and Germany), and contributes to the improvement of other strategies in the EU, Japan, Colombia, Italy, and Romania, [

91]. However, developed countries also need more efficient and innovative methods related to recovery and recycling in waste tire management, regardless of the progress made.

In some developing countries, until recently, waste tires were dumped in legal and illegal landfills and have posed a serious environmental problem. By harmonizing legislation with EU law, the practice of treating waste tires as an important resource for the production of various rubber products or energy in cement plants is introduced [

92]. Generally, in the second half of the previous decade, methods for managing waste tires have been adopted worldwide, with minimal threat to the environment and people. The main alternatives for end-of-life tire management have also been accepted, and this is viewed in the context of 4R: reduction, reuse, recovery, and recycling. Many developing and transition countries have faced knowledge inadequacies in order to implement integrated programs that include “environmental sustainability, stockpiling of whole tires at landfills, lack of consistent and systematic approaches to tire regulation, lack of methods and tools to update tire data and trends, limited application of technology to process and treat WTs, and lack of societal acceptance” [

93]. In the meantime, used tire recycling management schemes have been developed and identified in the literature, including extended producer responsibility (EPR), free market, and government [

43].

Montenegro has not yet resolved the issue of waste tire management and rubber technical products in an appropriate, environmentally and economically sustainable way. The problem is further complicated by the fact that the amount of waste tires generated annually in the capital of Podgorica and Montenegro is growing, primarily due to the growth of all types of motor vehicles.

Based on previous experiences, it can be stated that the management of waste tires—pneumatics in the Capital Podgorica, and in Montenegro in general—has not been adequately addressed. Namely, the Law on Waste Management [

94] prescribes the obligation of manufacturers and importers of pneumatics to ensure the functioning of the waste tire management system. Another way to solve the problem is to get involved in the organized system managed by a company listed in the register of organized systems for waste collection and treatment. So far, there have been authorized collectors of waste tires (verified by the Environment Protection Agency), as well as authorized freight forwarders, who have not transported waste tires to legal landfills. In the previous period, there were no authorized companies for receiving waste tires in Montenegro and Podgorica, nor legal warehouses for storing waste tires.

The recommendation of the competent bodies of the European Commission emphasizes the need to preserve the environment and to organize a space where waste tires can be collected, stored, and treated, as in highly developed EU countries. Acquiring the status of a candidate country and opening Chapter 27 for negotiations between the EU and Montenegro intensifies the obligations of Montenegro in the implementation of regulations that are in line with European legislation. This increases the possibilities for providing greater financial support from EU pre-accession funds in the form of grants or quality credit lines to address waste management issues.

In Podgorica, problems in the management of waste pneumatic tires are evident and more intense. A significant number of waste tires are disposed of in illegal and unregulated landfills in the capital, while some tires are disposed of in containers together with mixed municipal waste. These illegal landfills are becoming, especially in the summer, potential places for fires due to the intentional and uncontrolled combustion of tires (or accidental, due to electric discharge), which sometimes burn for months. Thus, gases are emitted in large quantities, which is dangerous for people and all living beings. This situation has imposed the need to urgently address the problem of waste tire management. After determining the location (within the sanitary landfill of non-hazardous municipal waste, “Livade”, in Podgorica), the next step in solving this problem is to analyze the justification of the first phase of waste tire management. This phase includes collection, transport, sorting, and storage in the Waste Tire Management Center in Podgorica.

The total area of the municipal waste landfill is 575,000 m2, while the selected location for waste tires within this landfill has an area of 9600 m2. The subject location is about 5 km away from the center of Podgorica. The distance of the existing watercourses, in the territory of Podgorica, from the subject location is from 0.5 to 4.5 km. On the southwest side of the selected location there is a suburban settlement, and the nearest buildings are at a distance of about 180 m. Northeast of the location is the recycling center building (as part of the landfill) at a distance of about 70 m, while on the south and southeast side there are no buildings, but the vineyards are at the closest distance of about 190 m. To the east of the selected location, there are sanitary baths for municipal waste disposal.

Prior to the project implementation, it will be necessary to perform direct measurements of air quality at the selected location—the “zero state”. The obtained results will be the starting point for comparing possible future cumulative impacts in this area. Adequate resolution of this issue should result in the prevention of soil, water, and air pollution, as the interaction with these environments is minimal when preparing a quality substrate for waste disposal.

The defined location is sufficient for the realization of the first phase of the process (the collection, takeover and transport, sorting, and storage of waste pneumatic tires), but also for the realization of the second phase (the processing of waste car tires and other rubber technical products). All the necessary infrastructure (road, water, electricity, sewage) for the selected location of the Center for Waste Tire Management can be provided.

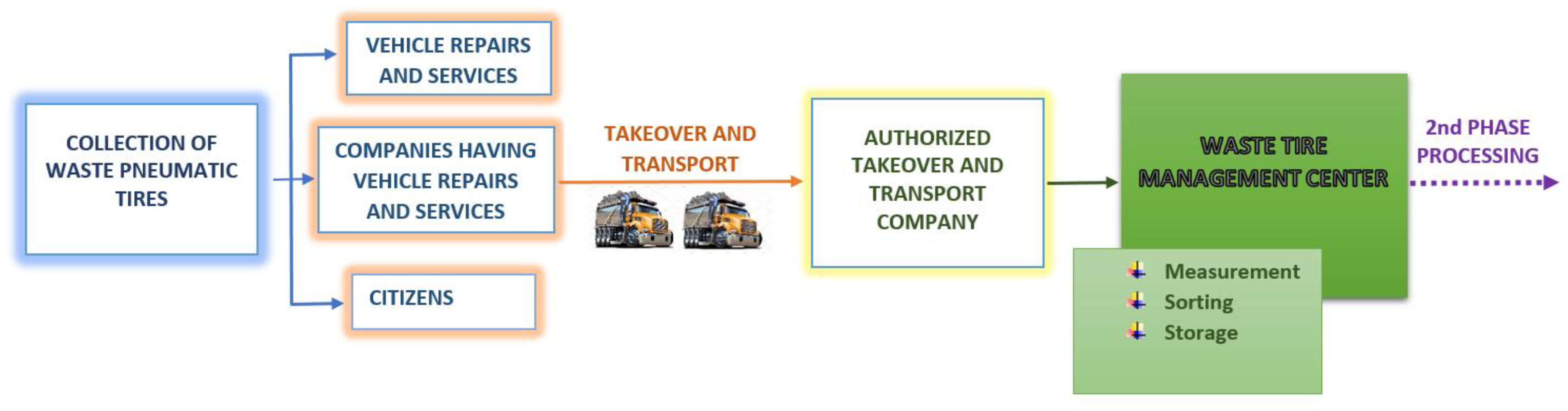

In providing the necessary inputs for the feasibility analysis of establishing a Center for Waste Tire Management, it was most difficult to define the process of collecting waste pneumatic tires. There are no accurate records of all sites with the replacement or repair of tires, nor accurate data on which companies produce waste pneumatic tires, based on existing fleets. With the legal framework (adoption of a special regulation), the obligation of all producers of waste tires (car repair shops, construction and other companies, physical persons, etc.) will be to deliver the waste tires to authorized companies, which will be in charge of their collection and transport to the established locations. The collection of waste pneumatic tires should be entrusted to authorized collectors and transporters of waste car tires, licensed by the Environment Protection Agency of Montenegro. The authorized collector will have a legal obligation to collect and transport automobile tire waste directly to the Waste Tire Management Center. The competent state administration body should decide on waste management fees, which will be paid by entities that generate waste tires. The establishment of such a Center requires the construction of a space for the collection, takeover and transport, storage, and sorting of waste pneumatic tires, the procurement of equipment, and all infrastructure construction for this type of waste.

Figure 1 shows the final technological scheme of waste tire management in Podgorica for the first phase of the project.

Waste tire management is a non-profit business, so the EU member states (the latest example is Croatia) have committed to subsidizing in order to solve this burning environmental problem. As this project, according to the Law, is under the jurisdiction of the Government of Montenegro, i.e., the Line Ministry, the proposal is to include in its financing the Capital Podgorica, the Environmental Protection Fund of Montenegro, and EU donations. By using modern, eco-friendly technology for the treatment of waste tires, useful products (rubber granulate, metal, biogas, diesel fuel, hot water) are obtained in EU countries, with a low degree of pollution. In this regard, the realization of the second phase of this project implies the implementation of a modern technological solution for the processing of waste tires in Podgorica, but this phase is not the subject of analysis in our paper.

Our paper aims to assess the financial and economic feasibility of the first phase of the project, which includes the collection, takeover and transport, sorting, and storage of waste tires from the territory of three municipalities in Montenegro. The goals of establishing the Center for Waste Tire Management, as a significant environmental project in Montenegro, are multiple. A necessary precondition for the successful implementation of this project is the need to develop the public awareness of the citizens of Podgorica, as well as Montenegro, with regard to the process of waste tire management. The main goal of the project is to prevent the disposal of waste tires in unauthorized and illegal places, in order to minimize or completely eliminate the negative impact of the inadequate disposal of waste tires on land and in surface and groundwater. This also includes air pollution reduction (PM particles, CO

2, dioxins, and other hazardous gases), due to the reckless burning of waste tires in illegal landfills and in the riverbeds of surrounding rivers. In this way, it contributes to the ecological functionality of the space, as the basic preconditions for the socio-economic development of the city and the entire country, in the coming period. The realization of the main goal achieves the final disposal of waste tires in accordance with national regulations [

94,

95] and EU directives. This creates the necessary preconditions for the recycling of waste tires in the next phase of the project and to enable the reuse of separated raw materials for the production of commercially usable and energy efficient products. The realization of this project, ultimately, should reduce the threat to the environment and improve the safety and health of the population of the capital and the surrounding area.

4. Materials and Methods

CBA is the basic methodological framework used in this paper to assess the feasibility of the first phase of the waste tire management project from the territory of three municipalities in Montenegro. It begins with the project’s individual effects (financial analysis). The inclusion or exclusion of certain groups of benefits and costs leads to the overall effects of the project, for society as a whole (economic analysis). The financial and economic feasibility analyses of the waste tire management project in the three municipalities in Montenegro were conducted in accordance with the guidelines of the relevant European methodology [

96], using the available inputs and previous experience of authors in preparing similar analyses.

By applying CBA, all benefits and costs related to project implementation are quantified and monetized, on the basis of which the net profit of the project is calculated. As could be concluded from the literature review, this analysis is not used exclusively for projects that bring only direct market and commercial effects (which can be measured and quantified), but, above all, for projects that bring significant indirect and immeasurable effects. Typical of such projects are environment projects, in which indirect and immeasurable effects usually prevail over commercial effects, due to which, ultimately, these projects are predominantly implemented. In this regard, CBA, as a useful tool, is used by policy makers to make public decisions, whose exclusive focus is not on profit orientation, but on the realization of public interests, whose outputs are non-market (e.g., improving environmental quality). In this way, CBA contributes to the optimal allocation of limited resources, because the distribution of income is optimal when it is desirable from the point of view of the social community as a whole.

As is already known, a CBA considers multiple benefits and costs, regardless of who realizes them. Lost benefits should be considered as costs, and the reduction of certain costs should be taken as benefits. All benefits and costs should be determined, measured, and monetized. In the CBA application, in imperfect markets (especially in underdeveloped countries), corrected market prices (“shadow prices”) are used.

In the first part of the analysis, we assessed the financial feasibility of the waste tire management project within the Waste Tire Management Center in Podgorica. The following assumptions are included in the financial analysis:

The analysis was performed in euros;

The analysis was conducted using real/constant prices;

The analysis was conducted on the basis of available market data;

The defined projection period was 9 years (2022–2030), because the realization of the project is expected in the first half of 2022, and the defined period of project observation is until the end of 2030;

According to the recommendations [

96], the financial discount rate was set at 4%.

The financial feasibility analysis of this project, with full respect to the reference CBA methodology [

96], was performed in several steps:

Defining the amount of the investment. This is the initial step of a financial and economic analysis. Based on the appropriate technical documentation and budget, at this point, we defined the value of the investment (CAPEX), as well as the dynamics of the investment.

Determining the elements for project cost calculation and their projection. In this step, we identified the project costs, their value, and their projection. These project costs included maintenance costs and operating expenses (OPEX). Maintenance costs covered the maintenance of buildings (0.5–1% of investment value) and equipment maintenance (1–3% of investment value). OPEX comprises employee costs, electricity costs, costs of chemicals and office supplies, and water costs. Employee costs are calculated based on a defined number of employees and projected net wages, adjusted for total gross expenditures for the employer. Electricity costs are computed based on the assumed monthly energy consumption (per m2 of space) and on the official price of electricity in Montenegro. Water costs are calculated based on the estimated average water consumption and its price. Costs of chemicals and office supplies are determined as a lump sum on an annual basis.

Determining the elements for project revenue calculation and their projection. Project revenues were estimated based on the amount of tires collected, as well as unit fees by service categories.

Projection of the project’s economic flow. Based on the previously completed steps in the analysis, we performed the projection of the economic flow, i.e., the confrontation of all financial costs and revenues of the project and the calculation of net effects, in order to measure the justification of the project.

Calculation of the dynamic indicators of financial justification of the project. Given the constant negative amount of net effects of the project during the projection period, the financial performance of the project was considered by establishing two basic efficiency indicators–net present value (NPV) and benefit–cost ratio (B/C ratio). As the NPV is the difference between the present value of cash inflows and outflows of the project, the condition of project eligibility is that the NPV is greater than 0 and the B/C ratio is greater than 1. If the B/C ratio is greater than 1, the project is suitable, as the benefits, measured by the present value of total inflows, outweigh the costs, measured by the present value of total outflows.

In the second part of the analysis, following the financial analysis and the calculation of financial performance indicators, we conducted the economic feasibility study. The aim of the economic feasibility study is to determine the effects of the project from the perspective of the wider community and to assess the project’s contribution to the overall community well-being. Contrary to the financial feasibility analysis, which is performed from the point of view of the owner/investor, the economic feasibility analysis is performed from the point of view of the wider community. This analysis relies on the fact that the observed market prices of input and output values often do not reflect their social value (i.e., their social opportunity cost).

In addition, investment projects often have impacts that do not manifest as direct market values. In such situations, it is necessary to approach the monetization of these impacts using different evaluation techniques, depending on the nature of the observed effect. The key objective of the economic feasibility analysis is to prove that the present value of the economic benefits should exceed the present value of the economic costs, meaning that the project makes a positive net contribution to society. This is evidenced by the positive economic net present value of the project (ENPV > 0), the economic rate of return (ERR) being higher than the defined discount rate (opportunity cost of capital–OCC), and the benefit–cost ratio (B/C ratio) being higher than 1.

According to the guidelines of the relevant methodology [

96], the effects of this project were assessed by considering the impact on society, the environment, and economic development. In this regard, the following steps were carried out to evaluate the economic feasibility of the project:

Standard factor conversion (SCF) calculation. Determination of this factor is necessary in order to translate the financial values of costs into economic. The conversion factor is calculated based on the data collection of total imports, exports, and customs revenues and the appropriate mathematical formula for this calculation [

96].

Determining the amount of gas emissions during the combustion process of waste tires. For the purposes of this step, we reviewed the international literature, which provided reliable results that served as input for our analysis. We performed an analysis, which included the identification of certain types of gases that occur in the process of waste tires combustion, as well as their quantity assessment (in grams per kilogram of tires).

Defining pollution unit costs. At this step, we determined pollution unit costs due to the emission of certain types of gases, which were defined in the previous part of the analysis. For the purposes of our analysis, we examined relevant research in order to determine the correlation between the emission of certain types of gases and their harmful effects on health. These unit costs have been reduced to the recommended value for Montenegro by a comparative analysis of GDP with the EU countries.

Projection of the project’s economic flow. After the previously performed steps, in the continuation of the analysis, we performed a projection of the economic flow, i.e., a comparison of all economic costs and project revenues and a calculation of the net effect, in order to measure the profitability of the project. In this step, the financial values of the costs are reduced to their economic value by applying a standard conversion factor.

Calculation of the dynamic indicators of economic justification of the project. This calculation was done using standard dynamic indicators: ERR, ENPV, and B/C ratio. The precondition for this was to define the adequate economic discount rate.

The third part of the analysis in our paper is project sensitivity analysis. This part refers to the threshold of project profitability which is determined by varying the selected key parameters of the analysis, namely the scope of work, size of capital investment, and discount rate. The analysis ends with a review of the results of the performed sensitivity tests.

After the completion of the presented analyses, and according to the obtained results, the authors offer appropriate conclusions regarding the implementation of this project.

In order to better monitor and understand the steps during the financial and economic feasibility analyses of the waste tire management project’s first phase in the three municipalities in Montenegro (Podgorica, Danilovgrad, and Cetinje),

Figure 2 presents the methodological flowchart.

5. Results and Discussion

In the first part of this section, the obtained results of the financial feasibility analysis of the first phase of the project will be presented and discussed. As mentioned above, the condition for organizing the first phase of the project is the foundation of the Waste Tire Management Center, within the sanitary landfill for non-hazardous municipal waste, “Livade”, in Podgorica. The project’s non-market benefits (environmental, health, social) are assessed in the second part of the section by applying the economic analysis, followed by a discussion of the obtained results. At the end of the section, we conduct a sensitivity analysis in order to check the sensitivity of the project to oscillations of some of the key parameters.

5.1. Financial Analysis

When conducting the financial feasibility analysis, from the point of view of the investor, the analysis included the direct revenues and expenditures of the project, which can be monitored and quantified and have an impact on the results. The basic preconditions for performing the assessment of the financial feasibility of this project are:

Based on the defined input data, we made a forecast of the project’s economic flow, which served as the basis for the calculation of the dynamic indicators of project feasibility.

The investment costs of a specific project include the cost of construction works and the cost of purchasing equipment. The structure of the estimated capital expenses (CAPEX), by individual items, is shown in

Table 1.

In addition to the costs that are a condition for initiating the investment, in the period of project exploitation (2023–2030), there are certain cost categories as a condition for performing the business activity. In this regard, an assessment of two basic groups of costs was made: maintenance costs and operating expenses (OPEX). Maintenance costs are defined as a certain percentage (%) of the value of investment in buildings and land and the value of investment in equipment, as shown in

Table 2.

The projection of maintenance costs is shown in

Table 3, which follows below.

The following cost categories are included in the calculation of project operating expenses (OPEX): staff costs, electricity costs, costs of chemicals and office supplies, and water costs. Employee costs are calculated based on the defined number of employees and projected net wages, adjusted for total gross expenditures for the employer. Electricity costs are calculated based on the assumed monthly consumption of 5 kWh per square meter of office space, or 2 kWh per square meter of tire storage space, considering the official electricity prices in Montenegro. The cost of chemicals for the maintenance of the premises and the cost of office supplies are estimated at EUR 200.00 per month, while the cost of water is estimated based on the estimated average water consumption of 30 L per worker and a price of 1.2 EUR/m3.

Based on the previously defined inputs, a projection of the operational expenses of the project for the period of 2022–2030 was made, as shown in

Table 4.

Operating revenues from the collection, transport, sorting, and storage of tires at a defined location are projected based on the estimated amount of collected tires (in accordance with the projected dynamics), as well as the unit fees for this service, defined as in countries in the region.

Table 5 presents the defined fees by service categories.

Based on previously defined inputs—the amount of unit fees and the estimated amount of waste tire generation—a projection of the Center’s business revenues was made, including the collection, transport, sorting, and storage of tires in the period of 2022–2030, with the start of operations of the Center planned in the second half of 2022.

In order to estimate the generation of waste tires for three municipalities (Podgorica, Cetinje, Danilovgrad) in the period of 2022–2030, we considered a number of criteria: the assessment of the population in the current and future period, the number of registered motor vehicles, the assessment of waste tire generation in the previous and in the following period, the number of vehicle repairs and services, and those services in companies engaged in transport, construction, etc. The estimated amount of waste tires was taken as the basis for the projection of the revenues of the project’s first phase (2022–2030), as shown in

Table 6.

In order to increase the visibility of the level of financial efficiency of the project’s first phase,

Figure 3 shows the relationship between the total costs and operating revenues of the project during the total observation period.

Considering previously determined projections, we prepared the projection of the economic flow, which is the basis for assessing the financial feasibility of this project. The forecast of the economic flow of the project is shown in

Table 7.

Following the economic flow forecast, the assessment of the project’s financial feasibility was performed using dynamic indicators of investment justification. The profitability analysis of this project, given the constant negative number of net effects, was conducted by identifying two basic indicators of project efficiency: NPV and B/C ratio. The effects of this project implementation—costs and benefits, by year in the economic life of 9 years, discounted using the selected rate of 4%—are reduced to a common denominator, i.e., they are expressed in the current values of monetary units. An overview of the established basic dynamic indicators of the financial feasibility of the project is given in

Table 8.

Based on the final results of the conducted financial analysis (

Table 8), we concluded that the first phase, independently, is not sufficient to ensure financially feasibility. The NPV of this project is negative, which means that the investor, if expecting a return at the rate of 4%, will be at a loss for the NPV amount. The B/C ratio of this project is 0.21, meaning that the value of total discounted revenues is less than the value of total discounted costs. In relation with the above, we conclude that in order for the project to meet the dynamic criteria of financial justification, it is necessary to organize the second phase. This phase should include the implementation of a modern technological solution for the waste tire processing and the production of commercially usable and energy efficient products and necessary commercial effects which can be expected.

It is obvious that the results of our financial feasibility analysis of the first phase raised the issue of the reuse of waste tires. Some previous research has identified the problem of low fees for the collection and disposal of waste tires as one of the key barriers to the growth of the waste tire industry in the near future [

98]. Therefore, this research suggests a change in these fees, with the active participation of governments and tax systems that should be selective in such a way as to support only technologies that are environmentally friendly.

Furthermore, it is known that the issue of tire waste processing is very relevant, as the world production of tire products is over 31 million tons annually [

99]. In this regard, we state that some recent research has assessed the financial performance (measured with NPV and IRR) and financial sustainability (through sensitivity analysis) of improved waste tire recycling technology [

100]. The results of this study confirmed the high efficiency of these technologies, from a technical, economic, and environmental point of view. It was concluded that any change in the recycling process, which leads to a faster and easier separation of the three basic components of rubber (rubber, textile inserts, and metal inserts) improves process performance (reduces energy consumption and increases productivity). Furthermore, there are numerous examples of research that indicates the positive financial effects that occur when using different components of generated waste tires, such as textile fibers [

101], and similar financial effects have been confirmed for regenerated rubber in the paving industry [

102].

5.2. Economic Analysis

In an economic feasibility analysis of a project, financial prices are converted to economic prices, usually by using conversion factors, if there are any. In the case of there being no sector-specific conversion factors, the standard conversion factor (SCF) is determined on the basis of average differences between domestic and international prices. It can be determined on the basis of foreign trade statistics using the following equation [

96]:

where M is the total import, X is the total export, and T

m is the total value of duties on import.

Based on the available data, the calculation of the SCF was performed, which is shown in

Table 9.

As pointed out in the Introduction, certain gases and chemicals that are released by combusting waste tires are extremely toxic and harmful to human health, but also very harmful to the environment. When tires are combusted, a whole range of pollutants is released, which can be divided into two groups. The first group includes pollutants for which there are legally prescribed upper exposure limits, such as particulate matter (PM), carbon monoxide (CO), sulfur oxides (SOX), nitrogen oxides (NOX), and volatile organic compounds (VOC). The second group comprises pollutants for which there are no upper exposure limits, i.e., they have a detrimental effect on health even when emitted in very small quantities. This group includes polycyclic aromatic hydrocarbons (PCBs), dioxins, furans, hydrochloride, benzene, polychlorinated biphenyls, and metals (such as cadmium, nickel, zinc, mercury, chromium, and vanadium). All of these pollutants can cause significant short-term and long-term health effects.

Studies has shown that, on average, a car tire combusts in 50 min, which highlights the degree of pollution that is released by their combustion. It has been proven that the uncontrolled combustion of tires can have significantly more harmful effects, compared to wood or coal in controlled conditions. We emphasize that during the analysis for the purposes of this paper, only gases from the first group were considered. For these gases, we performed appropriate research from which certain useful data were taken for our analysis, related to the amount of gas emissions during tire combustion and their unit value. For the purposes of our analysis, the results of one of the recent studies refer to the determined amounts of emissions from the first group of pollutants (PM, SO

X, NO

X, VOC, and CO) which are released during tire combustion [

105], as shown in

Table 10.

Air pollution, as a result of the destruction/combustion of waste tires, poses enormous risks to human health and life. Evident harmful effects cause significant spending for health services, but above all, large negative effects due to prematurely lost lives (based on the principle of the value of statistical life—VSL). Therefore, investments in the reduction of environmental pollution result in savings in these costs, which can be quantified as economic savings of these investments. Given that investments in environmental protection directly cause a reduction in emissions of certain types of gases, the most acceptable method for an economic analysis of these investments is to determine the “damage” caused by certain gases, per unit of emission, usually in tons. This is not an easy task, because it is necessary to establish a clear correlation between the emission of individual gases, the harmful effects on health that these gases cause, and the values of health services for these purposes and VSL.

In Montenegro, but also in most EU countries, no individual research of these values has been done, but certain analyses and studies have been done at the EU level [

106,

107,

108], which adequately investigated this issue and determined the values of gas emissions. Within these studies, the effects of air pollution on human health were examined in detail. A correlation was established between the costs of health services and the VSL, on the one hand, and the amount of emissions of certain gases, on the other. The results of these studies are given as an overview of the unit values of pollution costs by gas type in

Table 11.

The presented values of pollution costs are calculated based on the average exposure by EU countries, but they do not reflect the difference in the amount of GDP by country, as they are calculated based on the average values of certain services for the EU. For this reason, these values need to be adjusted to the GDP of Montenegro and its relationship with the average GDP of EU member states. According to the Eurostat data, the average GDP of EU member states in 2020 amounted to EUR 26,380, while in the same year the GDP in Montenegro amounted to EUR 6,844. Considering the stated relative ratio in GDP, the unit values of pollution costs have been corrected and are shown in

Table 12.

According to the estimated investment costs, we carried out projected reductions in gas emissions and the previously presented unit values of pollution costs (by gas type), a projection of socio-economic costs and effects of this project, and net effects determined as their difference. As can be concluded from

Table 13, the effects of investments are considered by years in the project’s economic life of 9 years, i.e., in the period from 2022 to 2030. By discounting and using the recommended discount rate of 5% [

96], the effects of investments are reduced to a common denominator in the present values of monetary units.

In order for readers to better understand the relationships between the estimated categories,

Figure 4 shows the relationship between the total costs and economic effects of the project.

Based on the previously calculated inputs, a calculation of the basic dynamic indicators of the economic viability of the project was made, as given in

Table 14.

The results of the conducted economic feasibility analysis indicate that all three indicators of economic feasibility are positive and that, from the perspective of the wider community, this project should be implemented. Our analysis showed that the direct benefits of this investment are savings in the cost of environmental pollution. Therefore, we conclude that the investment in the implementation of the first phase of this project within the Waste Tire Management Center in Podgorica has a satisfactory economic justification. The ERR is higher than the OCC (ERR = 15.82%), the ENPV is greater than 0 (ENPV = 371,100.00 EUR), and the B/C ratio is greater than 1 (B/C ratio = 1.23).

Compared to the results of other research, the results of our analysis are not surprising. Properly disposed of tires reduce environmental and health costs. The lack of appropriate facilities for storing waste tires, as well as their illegal incineration, are stressors for environmental health, which consequently affects health disparities, health morbidity, disease incidence, premature mortality, etc. A large number of small fires significantly increases the level of social costs. Much earlier research indicates potential social costs due to the inadequate disposal of scrap tires, such as health costs, environmental costs, and the lost value of natural resources and energy, [

109] as well as a high mutagenic emission factor which the open burning of scrap rubber tires produces [

110].

A number of studies indicate a direct relationship between higher levels of air pollutants (PM10, NO

2, CO, etc.) and hospital admission due to cardiovascular diseases [

111]. It should be borne in mind that some studies specify the potential for environmental pollution by heavy metals (due to the unregulated storage, decomposition, and disposal of waste tires); a set of appropriate taxes on tire consumers is proposed, in order to internalize negative externalities [

112].

Some of the previous research warns about rising social cost as a result of the unregulated storing, decomposition, and disposal processes of waste tires [

112]. In order to reduce the social costs of inadequate waste management, it is suggested to establish a regime for financing environmental policy by introducing a tire consumer fee, in order to reduce potential negative externalities (such as air pollution).

On the other hand, research indicates factors that may determine the relative level of the social costs of waste tires in the future. Some of these factors are the cost of disposing of tires in landfills, controlling tire ignition, the economic attractiveness of using waste tires for energy production, and the retreading of tires [

109]. Recent research has focused on environmentally friendly and cost-effective tire recycling methods, which is one of the largest environmental challenges of this century [

84].

5.3. Project Sensitivity Analysis

As future values are used during the evaluation of project efficiency, which causes a certain greater or lesser degree of uncertainty of the obtained results, we performed a project sensitivity analysis in order to determine the project profitability threshold by varying key analysis parameters, as follows:

Scope of work: ±10% and ±20%;

Size of capital investment: ±10%, ±20%;

Discount rate: 6%, 8%, and 10%.

Following the sensitivity analysis forecasts of economic flows, in

Table 15, we present the results of the analysis, with the predefined assumptions.

The sensitivity analysis showed that the project is resistant to all possible and real changes in input parameters and that all indicators remain in the cost-effectiveness zone, which further strengthens the belief in the necessity and justification of this project.

6. Conclusions

In general, Montenegro faces serious challenges in the future when it comes to waste tire management. This paper presents the results of the financial and economic evaluation of the feasibility of the project of establishing a Waste Tire Management Center, in the location within the existing sanitary landfill for non-hazardous municipal waste, “Livade”, in Podgorica, Montenegro. The financial analysis showed that in order to achieve project justification, it is necessary to organize the second phase. By organizing the second phase—the process of the modern processing of waste car tires—it should ensure commercial effects and secure the project’s financial sustainability.

Within the economic feasibility analysis, we assessed savings in the cost of environmental pollution as direct benefits from the project. In this regard, from the wider community perspective, this project is economically justified. As presented in the previous section, the indicators of the socio-economic justification of the project are positive, and a recommendation for this project to be implemented. The calculated ERR is higher than the defined discount rate and the ENPV is higher than 0, while the B/C ratio is higher than 1. The total present value of discounted costs in the observed period of 2022–2030 is EUR 1,620,080, while the total present value of positive economic effects amounts to EUR 1,991,180. Observing the net effects of the economic flow of the project, we concluded that the deadline for the return of this investment is in the seventh year of project implementation, when the cumulative number of positive economic effects exceeds the total value of investment and current costs.

The research presented in our paper includes the theoretical and practical dimension of the contribution. The quantifying and monetizing of environmental benefits from this project implementation is a theoretical contribution to overcoming the incomplete evaluation of such projects, as benefits not directly recognized by the market must be included in the feasibility analysis of such projects. In addition to the financial benefits, which should not be the only consideration in the decision-making process, the socio-economic benefits of the project must be examined. We believe that this analysis can serve as a methodological framework for the financial and socio-economic assessment of the feasibility of other projects, of this or a similar type. Furthermore, the results of our research can and should have practical implications in the field of waste tire management in Montenegro and beyond. The results of our analysis should provide strong support to decision makers in the decision-making process on the implementation of projects with a positive impact on the environment (such as this project), which indicates the practical contributions of this paper. Extended producer responsibility is certainly needed, and so is the infrastructure that enables a responsible and environmentally and economically sustainable waste tire management system.

One of the limitations in the paper concerns the economic feasibility analysis of the project, which included only an assessment of the effects of reducing emissions of the first group of pollutants. Improvement of the analysis can be achieved by including other groups of atmospheric toxic pollutants (having a detrimental effect on health, even in very small quantities), as well as other socio-economic effects, which would further enhance the results of the economic analysis and could be expanded in future research.