Effective Similarity Variables for the Computations of MHD Flow of Williamson Nanofluid over a Non-Linear Stretching Surface

Abstract

:1. Introduction

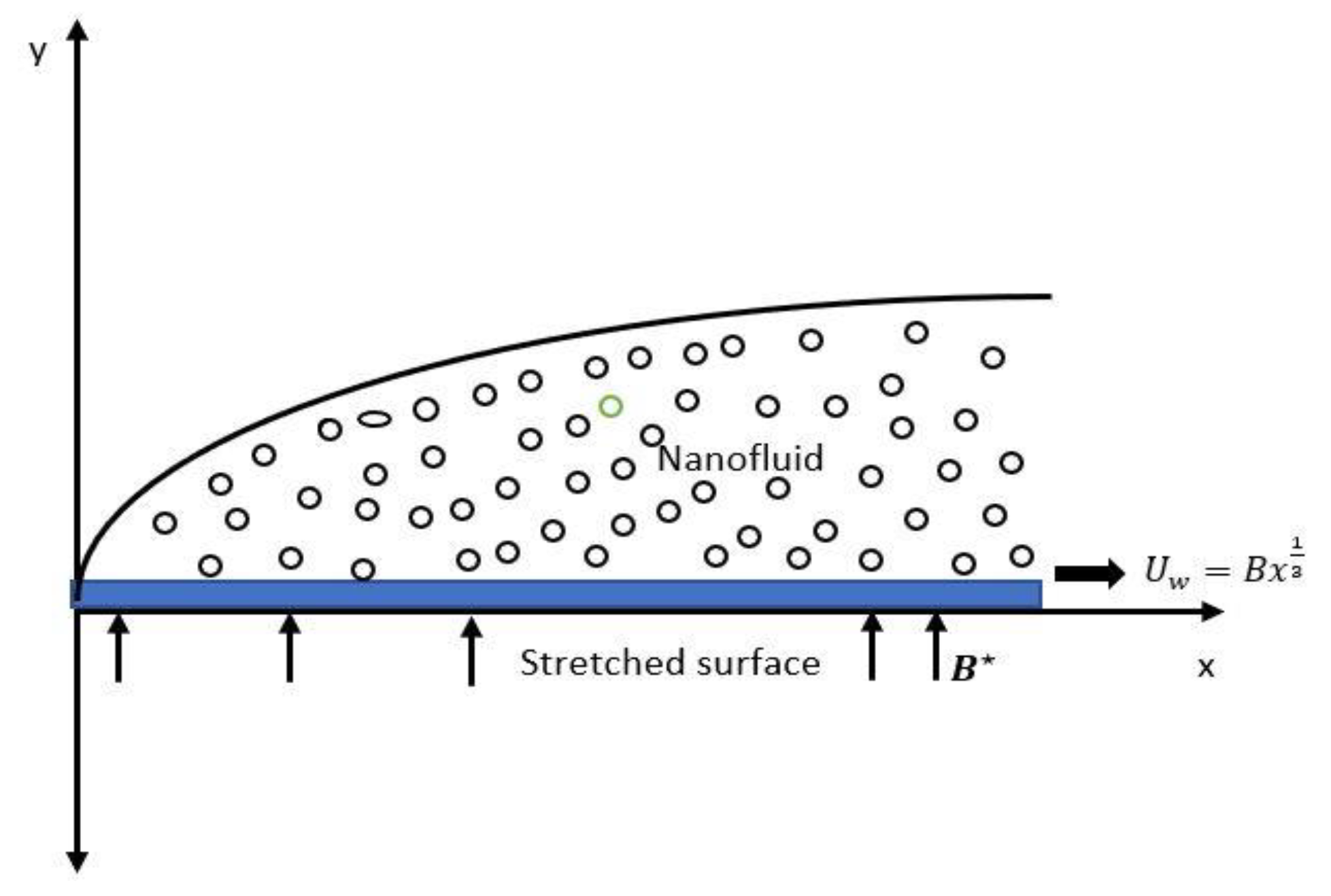

2. Problem Description

2.1. Friction and Heat Transport Quantities

2.2. Solution Procedure

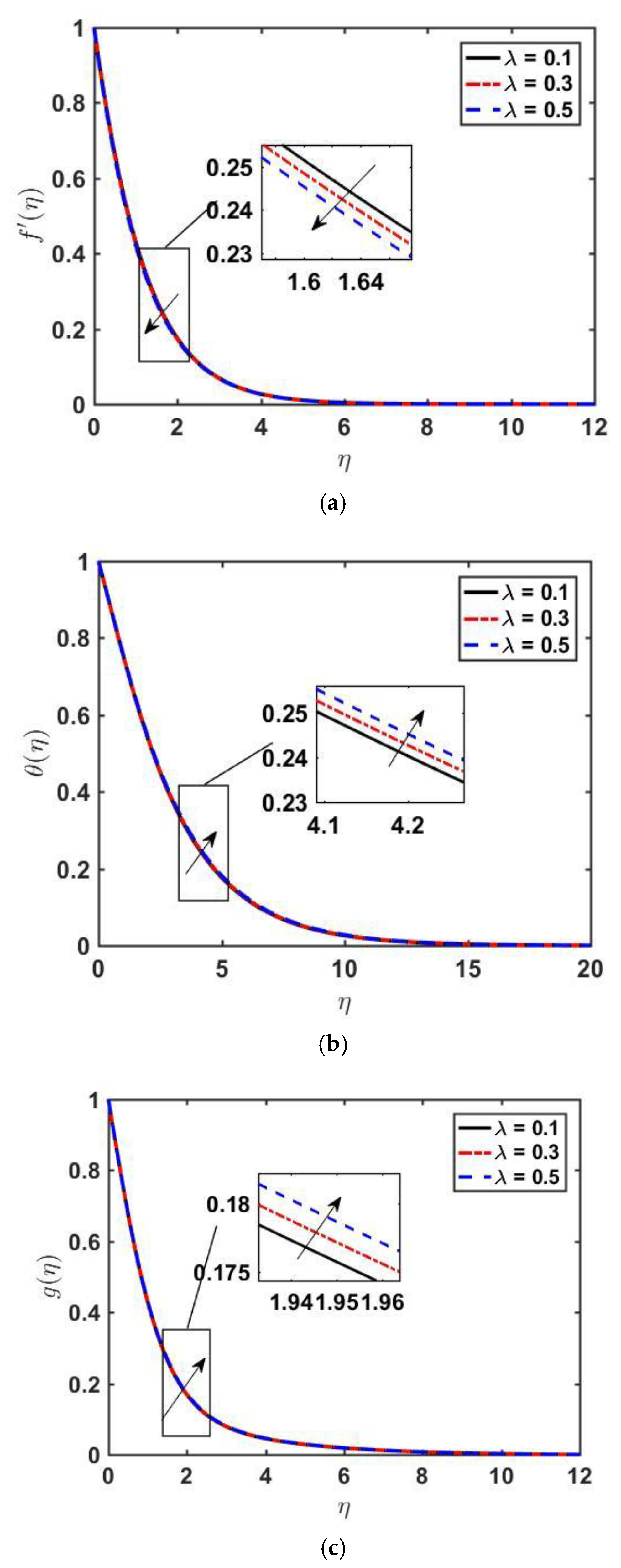

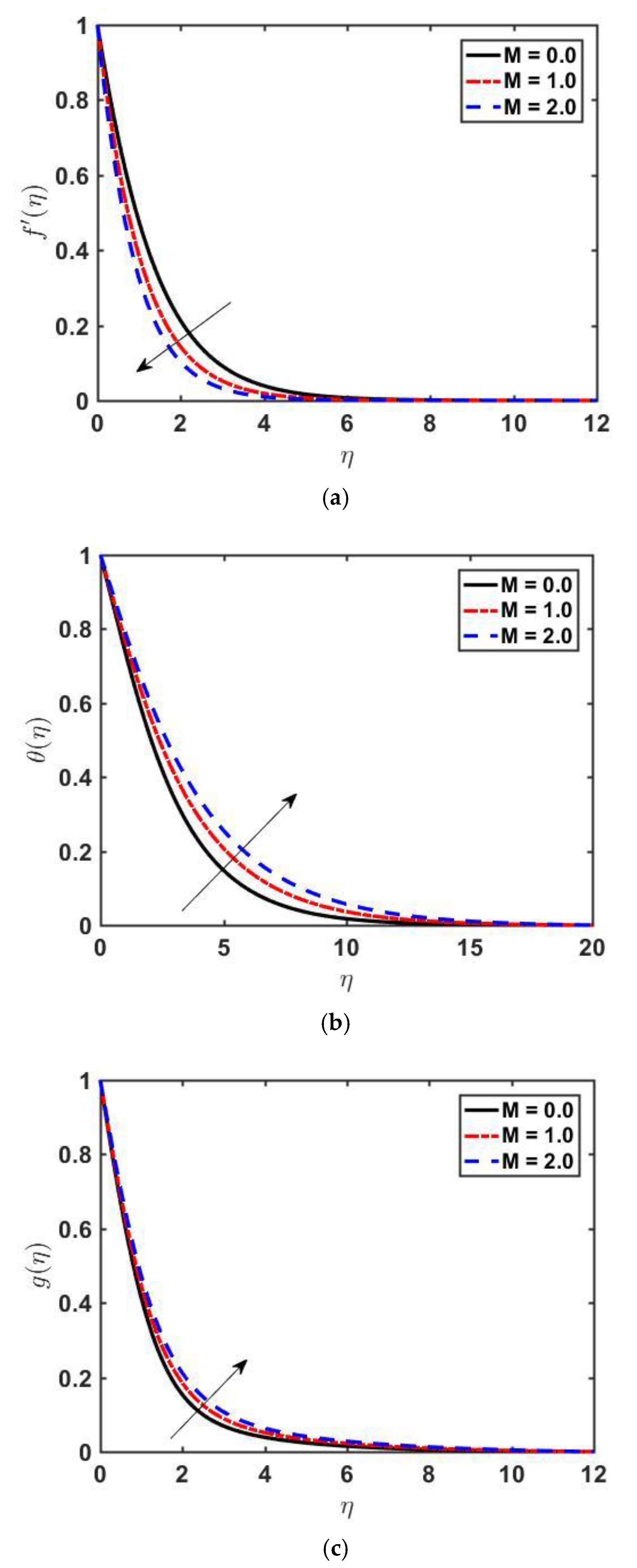

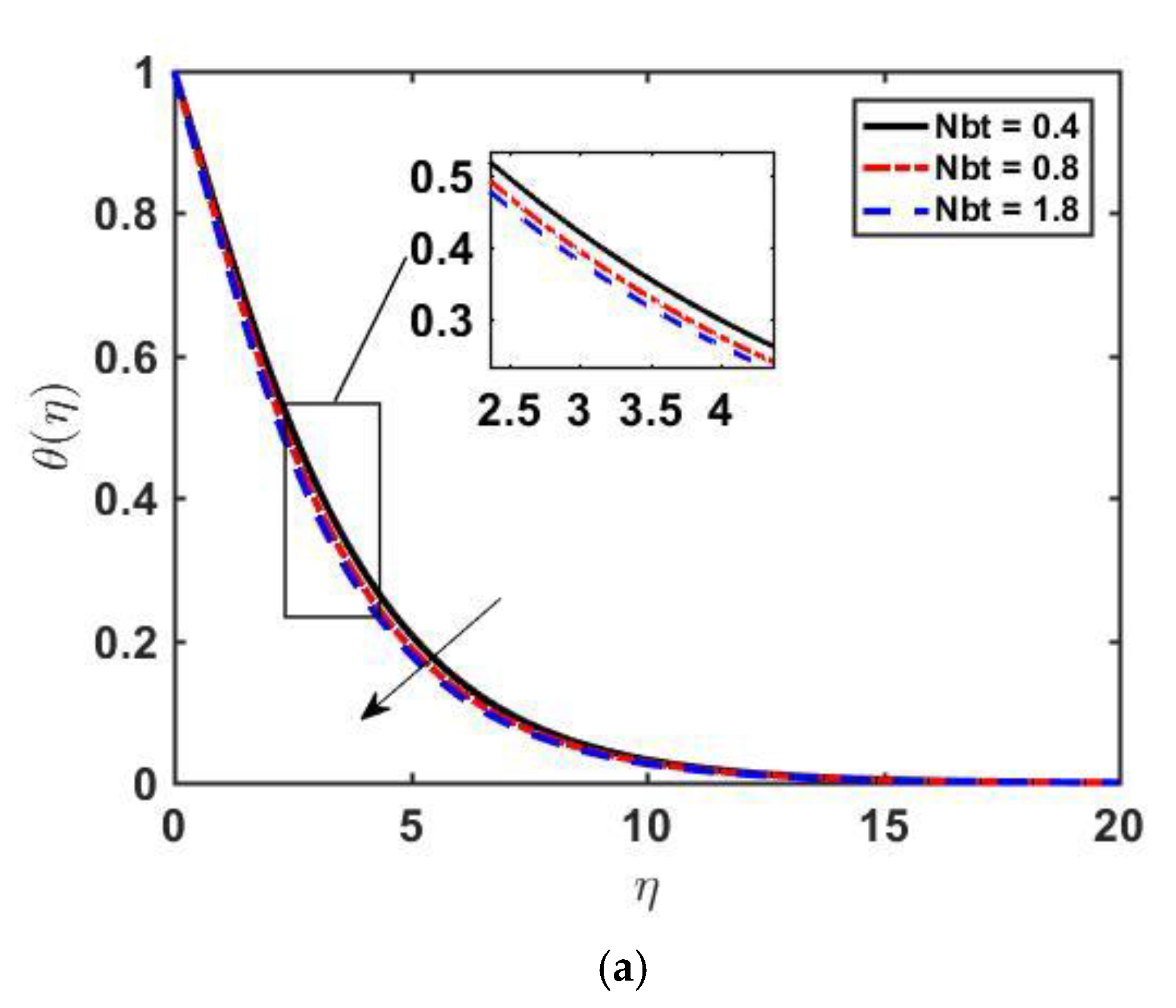

3. Results and Discussion

4. Conclusions

- The Williamson parameter and magnetic parameter have opposite impacts on skin friction coefficient.

- The wall temperature gradient decreases when increasing the value of Williamson parameter λ, and heat capacities ratio whereas it increases for Prandtl number and Lewis number . Moreover, the Lewis number reveals a strong effect on wall temperature gradient .

- The diffusivity ratio Nbt, heat capacities ratio Nc, and the Schmidt number Sc show direct relation with the Sherwood number −g′(0). An opposite relation is seen with Williamson parameter and Lewis number . It is worth mentioning that the most substantial outcome is seen for the Schmidt number , where there is a increment in the Sherwood number.

- When raising the values of Williamson parameter and magnetic parameter , the velocity profile settles at lower values, whereas the temperature and concentration profile settles at higher values. Moreover, the velocity boundary layer contracts, and the thermal boundary layer enlarges.

- The temperature profile settles at lower values when raising the Prandtl number and diffusivity ratio .

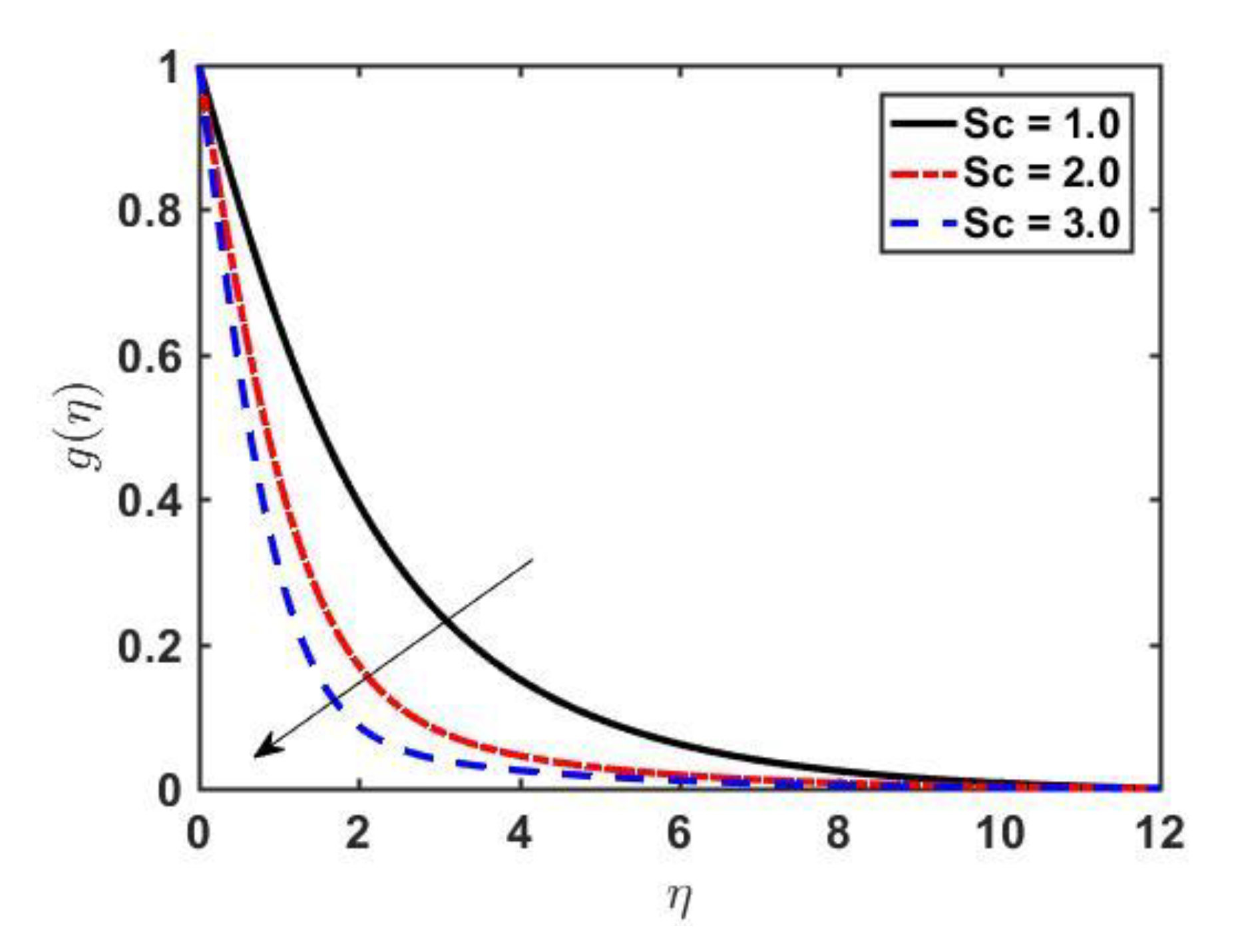

- The concentration profile shows direct relation to the Lewis number and an inverse relation to diffusivity and Schmidt number whereas Prandtl number shows dual behavior.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Rate of stretching surface | First Rivilin-Erickson tensor | ||

| Magnetic field strength | local Nusselt number | ||

| Skin friction coefficient | local Sherwood number | ||

| Prandtl number | Shear stress at the wall | ||

| Magnetic parameter | heat flux at the wall | ||

| Fluid temperature | wall mass flux | ||

| Diffusivity parameter | Surface temperature | ||

| Lewis number | Ambient temperature | ||

| Heat capacity ratio | Wall velocity | ||

| Schmidt number | Dimensionless stream function | ||

| Velocity components | Cartesian coordinates | ||

| local Reynolds number | Nanoparticle volume fraction | ||

| Concentration of nanoparticle | Concentration of nanoparticle at the surface | ||

| Ambient concentration of nanoparticle | Coefficient of Brownian diffusion | ||

| Coefficient of thermophoresis diffusion | |||

| Greek Letters | |||

| Dimensionless similarity variable | Kinematic viscosity | ||

| Electrical conductivity | Density | ||

| Positive time constant | Williamson fluid parameter | ||

| Thermal diffusivity | Dynamic viscosity | ||

| Dimensionless temperature | Heat capacity of the fluid | ||

| Heat capacity of nanoparticles | Extra stress tensor | ||

| Subscripts | |||

| Condition at the wall | Condition at the free stream | ||

| Superscripts | |||

| ‘ | Derivative w.r.t | ||

| Abbreviations | |||

| ODEs | ordinary differential equations | PDEs | partial differential equations |

| MHD | Magnetohydrodynamics | ||

References

- Williamson, R.V. The flow of pseudoplastic materials. Ind. Eng. Chem. 1929, 21, 1108–1111. [Google Scholar] [CrossRef]

- Felder, E.; Levrau, C. Analysis of the lubrication by a pseudoplastic fluid: Application to wire drawing. Tribol. Int. 2011, 44, 845–849. [Google Scholar] [CrossRef]

- Cramer, S.D.; Marchello, J.M. Numerical Evaluation of Models Describing Non-Newtonian Behavior. AIChE J. 1968, 14, 980–983. [Google Scholar] [CrossRef]

- Lyubimov, D.V.; Perminov, A.V. Motion of a Thin Oblique Layer of a Pseudoplastic Fluid. J. Eng. Phys. Thermophys. 2002, 75, 920–924. [Google Scholar] [CrossRef]

- Nadeem, S.; Akbar, N.S. Numerical solutions of peristaltic flow of Williamson fluid with radially varying MHD in an endoscope. Int. J. Numer. Methods Fluids 2011, 66, 212–220. [Google Scholar] [CrossRef]

- Akbar, N.S.; Nadeem, S. Carreau fluid model for blood flow through a tapered artery with a stenosis. Ain. Shams Eng. J. 2014, 5, 1307–1316. [Google Scholar] [CrossRef] [Green Version]

- Ismail, Z.; Abdullah, I.; Mustapha, N.; Amin, N. A power-law model of blood flow through a tapered overlapping stenosed artery. Appl. Math. Comput. 2008, 195, 669–680. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, K.; Akbar, T. Numerical investigation of magnetohydrodynamics Williamson nanofluid flow over an exponentially stretching surface. Adv. Mech. Eng. 2021, 13, 168781402110198. [Google Scholar] [CrossRef]

- Ramzan, M.; Liaquet, A.; Kadry, S.; Yu, S.; Nam, Y.; Lu, D. Impact of second-order slip and double stratification coatings on 3D MHD Williamson Nanofluid flow with cattaneo-christov heat flux. Coatings 2019, 9, 849. [Google Scholar] [CrossRef] [Green Version]

- Nasrin, R.; Hasanuzzaman, M.; Rahim, N.A. Effect of nano-fluids on heat transfer and cooling system of the photovoltaic/thermal performance. Int. J. Numer. Methods Heat Fluid Flow. 2019, 29, 1920–1946. [Google Scholar] [CrossRef]

- Vajravelu, K. Viscous flow over a nonlinearly stretching sheet. Appl. Math. Comput. 2001, 124, 281–288. [Google Scholar] [CrossRef]

- Cortell, R. Viscous flow and heat transfer over a nonlinearly stretching sheet. Appl. Math. Comput. 2007, 184, 864–873. [Google Scholar] [CrossRef]

- Khan, W.A.; Pop, I. Boundary-layer flow of a nanofluid past a stretching sheet. Int. J. Heat Mass Transf. 2010, 53, 2477–2483. [Google Scholar] [CrossRef]

- Van Gorder, R.A.; Sweet, E.; Vajravelu, K. Nano boundary layers over stretching surfaces. Commun. Nonlinear Sci. Numer. Simul. 2010, 15, 1494–1500. [Google Scholar] [CrossRef]

- ASHRAE Handbook—Fundamentals SI Edition Atlanta: American Society of Heating; Refrigerating and Air Conditioning Engineers, Inc.: Boca Raton, FL, USA, 2009.

- Kole, M.; Dey, T.K. Viscosity of alumina nanoparticles dispersed in car engine coolant. Exp. Therm. Fluid Sci. 2010, 34, 677–683. [Google Scholar] [CrossRef]

- Dittus, F.W.; Boelter, L.M.K. Heat transfer in automobile radiators of the tubular type. Int. Commun. Heat Mass Transf. 1985, 12, 3–22. [Google Scholar] [CrossRef]

- Wensel, J.; Wright, B.; Thomas, D.; Douglas, W.; Mannhalter, B.; Cross, W.; Hong, H.; Kellar, J.; Smith, P.; Roy, W. Enhanced thermal conductivity by aggregation in heat transfer nanofluids containing metal oxide nanoparticles and carbon nanotubes. Appl. Phys. Lett. 2008, 92, 9–12. [Google Scholar] [CrossRef]

- Kulkarni, D.P.; Namburu, P.K.; Ed Bargar, H.; Das, D.K. Convective heat transfer and fluid dynamic characteristics of SiO2—Ethylene glycol/water nanofluid. Heat Transf. Eng. 2008, 29, 1027–1035. [Google Scholar] [CrossRef]

- Abdul Hamid, K.; Azmi, W.H.; Mamat, R.; Usri, N.A. Heat transfer performance of titanium oxide in ethylene glycol based nanofluids under transition flow. Appl. Mech. Mater. 2014, 660, 684–688. [Google Scholar] [CrossRef]

- Li, H.; Xiao, H.G.; Yuan, J.; Ou, J.P. Microstructure of cement mortar with nano-particles. Compos. Part B Eng. 2004, 35, 185–189. [Google Scholar] [CrossRef]

- Vajjha, R.S.; Das, D.K.; Kulkarni, D.P. Development of new correlations for convective heat transfer and friction factor in turbulent regime for nanofluids. Int. J. Heat Mass Transf. 2010, 53, 4607–4618. [Google Scholar] [CrossRef]

- Berra, M.; Carassiti, F.; Mangialardi, T. Effects of nanosilica addition on workability and compressive strength of Portland cement pastes Constr. Build Mater 2012, 35, 666–675. [Google Scholar] [CrossRef]

- Syam Sundar, L.; Venkata Ramana, E.; Singh, M.K.; De Sousa, A.C.M. Viscosity of low volume concentrations of magnetic Fe3O4 nanoparticles dispersed in ethylene glycol and water mixture. Chem. Phys. Lett. 2012, 554, 236–242. [Google Scholar] [CrossRef]

- Azmi, W.H.; Sharma, K.V.; Sarma, P.K.; Mamat, R.; Anuar, S.; Rao, V. Experimental determination of turbulent forced convection heat transfer and friction factor with SiO2 nano-fluid Exp. Therm. Fluid Sci. 2013, 51, 103–111. [Google Scholar] [CrossRef] [Green Version]

- Azmi, W.H.; Sharma, K.V.; Sarma, P.K.; Mamat, R.; Anuar, S. Comparison of convective heat transfer coefficient and friction factor of TiO2 nanofluid flow in a tube with twisted tape inserts. Int. J. Therm. Sci. 2014, 81, 84–93. [Google Scholar] [CrossRef] [Green Version]

- Namburu, P.K.; Kulkarni, D.P.; Misra, D.; Das, D.K. Viscosity of copper oxide nanoparticles dispersed in ethylene glycol and water mixture. Exp. Therm. Fluid Sci. 2007, 32, 397–402. [Google Scholar] [CrossRef]

- Nguyen, C.T.; Desgranges, F.; Roy, G.; Galanis, N.; Maré, T.; Boucher, S.; Angue Mintsa, H. Temperature and particle-size dependent viscosity data for water-based nanofluids—Hysteresis phenomenon. Int. J. Heat Fluid Flow. 2007, 28, 1492–1506. [Google Scholar] [CrossRef]

- Jang, S.; Choi, S.U.S. Effects of Various Parameters on Nanofluid Thermal Conductivity. J. Heat Transf. 2007, 129, 617–623. [Google Scholar] [CrossRef]

- Prasher, R.; Bhattacharya, P.; Phelan, P.E. Thermal conductivity of nanoscale colloidal solutions (nanofluids). Phys. Rev. Lett. 2005, 94, 3–6. [Google Scholar] [CrossRef]

- Awan, A.U.; Abid, S.; Ullah, N.; Nadeem, S. Magnetohydrodynamic oblique stagnation point flow of second grade fluid over an oscillatory stretching surface. Results Phys. 2020, 18, 103233. [Google Scholar] [CrossRef]

- Abel, M.S.; Mahesha, N. Heat transfer in MHD viscoelastic fluid flow over a stretching sheet with variable thermal conductivity, non-uniform heat source and radiation. Appl. Math. Model. 2008, 32, 1965–1983. [Google Scholar] [CrossRef]

- Sreedevi, P.; Sudarsana Reddy, P.; Chamkha, A.J. Heat and mass transfer analysis of nanofluid over linear and non-linear stretching surfaces with thermal radiation and chemical reaction. Powder Technol. 2017, 315, 194–204. [Google Scholar] [CrossRef]

- Jahan, S.; Sakidin, H.; Nazar, R.; Pop, I. Flow and heat transfer past a permeable nonlinearly stretching/shrinking sheet in a nano-fluid: A revised model with stability analysis. J. Mol. Liq. 2017, 233, 211–221. [Google Scholar] [CrossRef]

- Sakiadis, B.C. Boundary—Layer behavior on continuous solid surfaces: III. The boundary layer on a continuous cylindrical surface. AIChE J. 1961, 7, 467–472. [Google Scholar] [CrossRef]

- Sakiadis, B.C. Boundary—Layer behavior on continuous solid surfaces: II. The boundary layer on a continuous flat surface. AIChE J. 1961, 7, 221–225. [Google Scholar] [CrossRef]

- Sakiadis, B.C. Boundary—Layer behavior on continuous solid surfaces: I. Boundary—layer equations for two—dimensional and axisymmetric flow. AIChE J. 1961, 7, 26–28. [Google Scholar] [CrossRef]

- Crane, L.J. Flow past a stretching plate. Z. Angew. Math. Phys. ZAMP 1970, 21, 645–647. [Google Scholar] [CrossRef]

- Gupta, P.S.; Gupta, A.S. Heat and Mass Transfer on a Stretching Sheet. Can. J. Chem. Eng. 1977, 55, 744–746. [Google Scholar] [CrossRef]

- Kameswaran, P.K.; Narayana, M.; Sibanda, P.; Murthy, P.V.S.N. Hydromagnetic nanofluid flow due to a stretching or shrinking sheet with viscous dissipation and chemical reaction effects. Int. J. Heat Mass Transf. 2012, 55, 7587–7595. [Google Scholar] [CrossRef]

- Khan, U.; Ahmad, S.; Hayyat, A.; Khan, I.; Nisar, K.S.; Baleanu, D. On the Cattaneo-Christov heat flux model and OHAM analysis for three different types of nanofluids. Appl. Sci. 2020, 10, 886. [Google Scholar] [CrossRef] [Green Version]

- Rashidi, M.M.; Keimanesh, M.; Hung, T.K. Magnetohydrodynamic Biorheological transport phenomena in a porous medium: A simulation of magnetic blood flow control and filtration. Int. J. Numer. Method Biomed. Eng. 2011, 27, 805–821. [Google Scholar] [CrossRef]

- Oughton, S.; Matthaeus, W.H.; Dmitruk, P. Reduced MHD in Astrophysical Applications: Two-dimensional or Three-dimensional. Astrophys. J. 2017, 839, 2. [Google Scholar] [CrossRef] [Green Version]

- Carle, F.; Bai, K.; Casara, J.; Vanderlick, K.; Brown, E. Development of magnetic liquid metal suspensions for magnetohydrodynamics. Phys. Rev. Fluids 2017, 2, 1–20. [Google Scholar] [CrossRef]

- Pedchenko, A.; Gelfgat, Y. Study of the influence of current frequency and non-magnetic gap value on the efficiency of al-alloys stirring in metallurgical furnaces. Magnetohydrodynamics 2007, 43, 363–375. [Google Scholar] [CrossRef]

- Hainke, M.; Friedrich, J.; Vizman, D.; Müller, G. MHD effects in semiconductor crystal growth and alloy solidification. In Proceedings of the International Scientific Colloquium, Modelling for Electromagnetic Processing, Hannover, Germany, 24–26 March 2003; pp. 73–78. [Google Scholar]

- Hussain, Z.; Hayat, T.; Alsaedi, A.; Ullah, I. On MHD convective flow of Williamson fluid with homogeneous-heterogeneous reactions: A comparative study of sheet and cylinder. Int. Commun. Heat Mass Transf. 2021, 120, 105060. [Google Scholar] [CrossRef]

- Nadeem, S.; Hussain, S.T. Flow and heat transfer analysis of williamson nanofluid. Appl. Nanosci. 2014, 4, 1005–1012. [Google Scholar] [CrossRef] [Green Version]

- Nadeem, S.; Hussain, S.T.; Lee, C. Flow of a williamson fluid over a stretching sheet. Braz. J. Chem. Eng. 2013, 30, 619–625. [Google Scholar] [CrossRef] [Green Version]

| Shooting Method | bvp4c | |||||||

|---|---|---|---|---|---|---|---|---|

| 0.1 | ||||||||

| 0.2 | ||||||||

| Shooting Method | bvp4c | |||||||

|---|---|---|---|---|---|---|---|---|

| Linear Stretching—Nadeem et al. [48] | Nonlinear Stretching—Present Study | ||

|---|---|---|---|

| 0.0 | 0.314 | 0.319 | |

| 0.2 | 0.309 | 0.318 | |

| 0.4 | 0.302 | 0.317 | |

| 0.2 | 0.144 | 0.231 | |

| 0.6 | 0.355 | 0.347 | |

| 1.2 | 0.588 | 0.521 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, K.; McCash, L.B.; Akbar, T.; Nadeem, S. Effective Similarity Variables for the Computations of MHD Flow of Williamson Nanofluid over a Non-Linear Stretching Surface. Processes 2022, 10, 1119. https://doi.org/10.3390/pr10061119

Ahmed K, McCash LB, Akbar T, Nadeem S. Effective Similarity Variables for the Computations of MHD Flow of Williamson Nanofluid over a Non-Linear Stretching Surface. Processes. 2022; 10(6):1119. https://doi.org/10.3390/pr10061119

Chicago/Turabian StyleAhmed, Kamran, Luthais B. McCash, Tanvir Akbar, and Sohail Nadeem. 2022. "Effective Similarity Variables for the Computations of MHD Flow of Williamson Nanofluid over a Non-Linear Stretching Surface" Processes 10, no. 6: 1119. https://doi.org/10.3390/pr10061119

APA StyleAhmed, K., McCash, L. B., Akbar, T., & Nadeem, S. (2022). Effective Similarity Variables for the Computations of MHD Flow of Williamson Nanofluid over a Non-Linear Stretching Surface. Processes, 10(6), 1119. https://doi.org/10.3390/pr10061119