Abstract

The organizations of horticultural producers and, particularly, those that deal with extremely perishable endogenous fruits, such as peaches and cherries, have a greater need to optimize production flows and processes. A particularity of the horticultural industry is the short shelf life of raw materials and the seasonality of products. In this paper, optimization techniques are used to improve the production flows and the management of cold storage and distribution in a fruit central. The application of Lean tools allowed reducing the cycle time by 4.37 min and the lead time by 7.10 min of the whole process, i.e., a reduction of 35.5% and 10.6% of the cycle time and lead time, respectively, excluding the cold conservation operation. The study shows that it is possible to reduce, or even eliminate, waste throughout the process, reduce unnecessary movement, adapt the layout, maximize workspace, and level stocks, as well as greater supplier involvement in a continuous improvement approach. This approach can be outlined as a good practice for the optimization of productive flows and management logistics that may benefit productivity, energy efficiency, human resources distribution, food quality, and reduce food waste.

1. Introduction

Over the past ten years, the approach to business management around the world has undergone a profound change. To combat the politico-economically unstable environment, organizations have sought to find new ways and means of responding based on knowledge, market research, and study, as well as creating and adapting to new work methodologies through metrics-driven management [1,2]. Organizational survival depends on the construction and integration of knowledge promoting adaptation and stimulation of the environment, as well as change through the firm’s knowledge and practices [3].

The management of a firm requires access to information and efficient data management to monitor activities and evaluate the performance of the business processes. This analysis can be present in financial operations, customers, and products to obtain an analytical view of problems and opportunities [4].

Organizations are constantly looking for new ways to improve their performance, product quality and competitiveness [5]. In the agricultural sector, many innovations occur in the production process through improved production techniques. However, these can happen at any stage of the product and/or in certain processes in the supply chain [6]. In the last two decades, the development is quite remarkable. Although there is uneven development between different countries, which is reflected in differences in productivity between farms, it remains an issue that is grounded through structural adjustment [7].

Innovation can be interpreted as an opportunity for agricultural producers to do more and better with fewer resources. Better management of available resources and anticipation of problems can be reflected in increased productivity and consequently reduced costs. It also ensures long-term viability and reduces the negative environmental impacts of production, such as pollutants and waste. The existence of healthy, ecological, and sustainable food systems are fundamental principles to achieving the development of the chains [8].

Supply chain analysis provides a single, broad view of the entire supply chain, reveals opportunities for cost savings, and stimulates revenue growth. As well as increasing production efficiency and optimizing delivery time [9]. The competitive marketplace requires organizations to design reliable products that can be produced efficiently and quickly. In this quest to maximize the value and quality of the product that is offered to the customer, as well as to reduce lead times and costs, the Lean philosophy is an efficient alternative for continuous improvement [10]. Lean helps convert business inputs, such as people, machines, and raw materials, through value-adding processes. It can achieve the right results most effectively and efficiently by creating value for customers with fewer resources [3]. This philosophy seeks to simplify processes, eliminate waste, and use resources more efficiently in accomplishing tasks, as well as involving employees throughout the process, by creating value for customers and therefore value for the company [11].

Time is a key component that organizations can neither discard nor devalue. The expression “time is money” has gained more prominence these days, and in the industry, it isn’t different. Time is precious and how organizations “spend” their time can determine their future success. It is up to top management to understand where time is spent and which activities may or may not add value, this way it will be possible to identify opportunities for improvement, saving time and consequently money [12].

Lean thinking can significantly improve many of the problems that agricultural organizations face daily such as long working hours, high staff turnover, repetition problems, breakdowns, waste, safety, and high costs are some of the factors usually identified.

This paper aims to learn how to identify waste, create employed and motivated teams, work more efficiently and productively, and solve problems quickly to save time and reduce costs, thus improving business performance and farm performance. The main objective is to support and boost the development of small organizations located in the interior of the country. These organizations are often conditioned and limited by agricultural policy issues, such as the lack of financial incentives (subsidies) from the State and European Funds, an aging population, and lack of unemployment, leading to very pronounced desertification [13]. This study will be carried out through the analysis of several studies carried out in the Agribusiness industry.

This article is organized into 5 chapters. Section 1 presents the contextualization of the work developed, the motivations for its realization, the defined objectives, the methodology used, and finally, the structure of this article is explained. In the Section 2, a theoretical framework of the Lean philosophy is presented, which includes its historical evolution, the definition of waste, its principles, and the main techniques, and tools. In the same chapter, examples of practical applications of Lean tools in Agribusiness are described. In Section 3, the company of the case study is presented and characterized, as well as the description of the entire production process and layout. The Section 4 aims to identify the Lean principles applied in the company, an initial survey is presented in which waste is identified and the respective proposals for improvement with the implementation of the 5S and Kaizen tools. In the final phase, the Value Stream Mapping tool is applied, which allowed the identification of the waste of resources along the production flow, a proposal for an adjustment to the current layout, as well as the definition of a new layout, and the reorganization of the cold rooms. In the Section 5, the conclusions and limitations of the study are presented, and proposals for future improvements that could be useful to the company in which the case study was carried out could be replicated in other companies in the same sector.

2. Literature Review

In this chapter a theoretical framework of the Lean philosophy is presented, including historical evolution, the definition of waste, principles, the main techniques, and tools.

In this paper, inductive and explanatory research is applied, focusing on the quantitative perspective. Inductive research aims to infer theoretical concepts and patterns from observed data, seeking to link ideas and identified factors to understand the causes and effects of phenomenon determination [14]. The literature review was conducted by searching and analyzing case studies published in scientific articles, books, scientific conference proceedings, and publications that fall within the scope of the research. At this stage, a thorough analysis was carried out to understand the results already produced and the type of instruments used to obtain them. The databases to be used to collect these documents were: Scopus, Web of Science, Science Direct, and IEEE Xplore. Based on the information collected and analyzed, a reflection was made on the optimization tools that can be applied to the case study.

2.1. The Origins and Evolution of Lean Management

The scientific organization of work led to the emergence of mass production. The standard times and the rationalization, standardization, and decomposition of work into tasks, in industrial terms, had Frederick Taylor as a great proponent of the scientific organization of work. Taylor emphasized the importance of the standardization of work, also known as Taylorism [15].

After the First World War large companies were created, mainly in the automobile industry, for example, the Ford Motor Company founded by Henry Ford. Ford chose to rationalize and control the assembly process and create a continuous flow throughout the whole process [16].

In parallel, Sakichi Toyoda, founder of Toyota Industries Corporation Ltd. developed the automatic loom, which was able to stop automatically when a thread breakage was detected. This led to the creation of the Jidoka concept, also defined as intelligent automation, which allowed the operator to control more machines during the manufacturing process [17].

In the 1980s Taiichi Ohno in collaboration with Shigeo Shingo developed the Toyota Production System (TPS). TPS is derived from the production process in the Japanese automobile industry, which aimed to improve and control production that was previously based on mass production. It was the result of innovative thinking forced to find a solution to resource scarcity and financial turbulence [18]. Lean began to gain greater prominence with the publication of the article “Triumph of the Lean Production System” in 1988 [19]. In 1990, the book “Machine That Changed the World” was published which revolutionized the perceptions of many scientists and professionals about the production process [20]. This book essentially introduced the term Lean to the world by describing Lean production [18]. Since then, the Lean philosophy has become a new management approach that has proven to be effective for the performance and management of organizations, both from a qualitative (e.g., employee satisfaction, commitment, safe and harmonious work environment) and quantitative point of view (e.g., improvements in processing, cycles and setup times, reduction of queues and defects) [21].

Despite the numerous definitions of Lean, it is important to understand that it is a business strategy and not a casual practice. Womack and Jones, in 1996, published a second book “Lean Thinking: Banish Waste and Create Wealth in your Corporation” [22], in which they presented the Lean philosophy based on five principles, seven wastes, and a set of extremely simple and powerful tools. The five fundamental principles of the Lean philosophy are [23]:

- Define value—Identify how much the customer is willing to pay;

- Identify and map the value stream—Identify the activities that create value and those that do not add value to the end customer;

- Create a flow that eliminates waste—Ensure that what is flowing from the next steps occurs without interruptions or delays;

- Pull System—Match customer demand and set up a downstream production system;

- Pursue perfection—The vision to be achieved by using the previously listed principles together.

However, the five principles presented above have some shortcomings: only the customer value chain is considered (in fact, in an organization there are several value chains: one for each stakeholder), so the challenge is not in the creation of value, but in the creation of value [24]. Another constraint is that these tend to lead organizations into endless cycles of waste reduction ignoring the crucial activity of creating value through product, service, and process innovation. In this sense, two more principles were created with the aim of guiding the organization on the right path to excellence and extraordinary performance, they are: “Know the stakeholder” and “Always innovate” [24].

For Ohno [25], the Lean philosophy consists in improving processes through the removal of Muda (waste, e.g., everything that does not add value is waste and as such should be eliminated), Muri (excess or insufficiency, the organization should only do what is necessary when requested, based on a Pull system) and Mura (irregularity, it is eliminated by the standardization of work) in production [26]. The main objective is to achieve high-quality standards at low cost (reducing variability), with short lead times, eliminating waste of time and activities (Muda and Muri) [27].

Thus, being the whole basis of the Lean philosophy the elimination of waste, or elimination of Muda, it is also important to know how to identify them in the processes under study to achieve total quality [28]. Ohno [25] defined seven sources of waste as follows [16]:

- Overproduction—More quantities are manufactured than are needed and ordered by customers. Unsold products may have to be discarded, which becomes expensive;

- Waiting time—Usually caused by material waiting or shortages, idle or insufficient equipment capacity, and inefficient production order instruction;

- Stocks—When stock is excessive, there is product degradation or damaged material, longer lead times in the production process, and high inventory holding costs can be associated;

- Movements—Include any unnecessary movement of people, tools, or machines;

- Transport—All unnecessary movements of resources that do not add value to the product are considered;

- Defective products—This happens when the product does not comply with the minimum quality requirements. The definition of waste includes defects or quality problems. It also includes inspection costs, response to customer complaints, and rework. Human errors create defects;

- Over-processing—This is related to excessive steps in manufacturing, e.g., doing more than is essential. Using more precision equipment than necessary or using components with capacity beyond what is needed can lead to exponential wear and tear of equipment and consequently a reduction in its useful life.

Initially, seven Muda were considered, e.g., seven possible sources of waste, but with the evolution of the Lean philosophy and knowledge of the production system, there are now eight, defined as the under-utilization of labor. This represents the existence of qualified labor that is not performing functions that correspond to their capacities, represents a waste of knowledge, but also a waste of capacity and creativity, since due to their qualifications, they could represent added value to the company, even with ideas for new methods of eliminating waste [27].

2.2. Lean Tools

This philosophy was not created overnight, nor was it developed by just Toyota. Lean has become internationally known and recognized, and has gradually developed, both conceptually and in fields of application other than production [28].

One of the ways to reduce the waste generated by organizations, and thus achieve greater competitiveness, productivity, and optimization of results is through the implementation of Lean philosophy and tools [29].

The diversity of Lean tools proves to have answers for the most diverse challenges, and companies are aware of this, adopting more and more methodologies and processes that aim to progressively reduce waste and adapt their production paradigm to what the market demands. It is up to each top management to survey the most important tools, and understand what they are, how they work, and how they can help the organization. Their evaluation and implementation can be key steps to success [29].

In this subchapter, some of the numerous Lean tools available are presented. Although there is a great variety and diversity of Lean tools, this article will focus on 5S methodology, Value Stream Mapping (VSM), and Kaizen.

2.2.1. 5S Methodology

5S is a Japanese organization methodology developed by Kaoru Ishikawa in 1950 [30]. This tool is governed by five distinct steps to organize, keep the place clean, and in this way increase productivity and standardize how tasks are executed [31].

It can be considered a systematic process, or a set of practical tools, that allows the organization of work areas, to eliminate or reduce waste in operations, improve hygiene, safety, ergonomics, and environmental conditions of workstations or areas of common use [32,33]. The main objective is to change attitudes and behaviors, eliminate waste and ensure competitiveness [33]. The name 5S has as acronyms five words, in Japanese, listed below:

- Seiri (Sense of use)—Is it useful?Identify objects, materials, and equipment at the workplace; List and separate by type, what is useful from what is useless; Mark what is not necessary; Eliminate or remove objects that are not necessary;

- Seiton (Sense of organization)—Is it easy to find?Define a place for each tool; Verify that each tool is in its place; Place the most frequently used tools at hand; Place identification labels (visual aids) on the tools and the respective place where they should be kept;

- Seiso (Sense of cleanliness)—Is the work area clean?Divide the workstation and assign a zone to each team member; Clean each zone of the workstation, as well as the surrounding area;

- Seiketsu (Sense of standardization)—What is the standard?Define a general standard/rule of tidiness and cleanliness for the workstation; Identify the visual aids and procedures, tidiness and cleanliness standards that work; Standardize throughout the factory the same type of equipment and workstations to ensure that the previous three steps are fulfilled;

- Shitsuke (Sense of discipline)—Is the standard respected?Practice the principles of organization, systematization, and cleanliness; Eliminate variability, e.g., always do it right the first time; Establish procedures for visual control (tidiness and cleanliness); Verify that actions and inspections are being carried out correctly; Develop a system of checklists and visual aids (colors, lights, direction indicators or charts).

An increasing number of companies are adding a sixth “S”. The “S” of Safety is not independent, nor can it be dissociated from the previous ones, or any activity performed. For Jiménez et al. [34], this is a mandatory inclusion in the 5S method, not only because it will reduce and even eliminate the different risks that may exist in a workplace, but it also ensures that the work area complies with regulations, both regarding safety issues on the use of machinery and equipment and health. The main objective of 6S is to eliminate waste by controlling Muda, Muri, and Mura. This new methodology, 6S, forms the necessary and ideal basis for implementing a significant number of other Lean tools [34].

2.2.2. Value Stream Mapping (VSM)

Value Stream Management (VSM) is a simple, yet powerful and logical tool that allows an organization to identify wasted resources along the production stream [35]. It allows to analyze the current state and make a forecast for the future state. The goal of the current state is to map the existing state and find possible ways to implement Lean tools, reduce waste, align production, and demand, and develop action plans to arrive at a future state map [36].

The value stream is the set of value-added and non-value-added activities required to effectively transmit information since it allows the mapping of the processes involved, relates the processes, and allows the identification of which activities add value and which do not [30].

To simplify reading and interpretation, it presents a simple legend and basic icons (equipment, group work, departments or suppliers, and customers). In the definition and creation of these maps should be perceptible three sections [37].

In the first section, the process or production flow is represented, in which all tasks and sub-tasks are identified. The process flow is drawn from left to right and by reading it is possible to observe the main operations and secondary steps of the process, as well as tasks performed in parallel [38].

The communication section is included all kinds of information and communication, in-formal or formal, about the process and data transmission [38]. In this case, information can be read in both directions. In Lean, the information flow is as important as the material flow [30].

The time window section provides a visual representation of the timeline or timeline of the value stream. The upper part of the time scale represents the average time it takes for a component to move on to the next task (Production Lead Time). The lower part, on the other hand, represents the average time that each component takes to be worked on (Value Add Time) [38].

According to Dias et al. [39], the spaghetti diagram can be a complementary tool to the VSM. Similar to VSM, the spaghetti diagram allows the visualization of activities that do not generate value. This diagram is the visual representation that demonstrates the incidence of movements, number of movements, overlapping and crossing movements, and the features that happens due to the dispersion of all machines, which leads to the registration of movements that are often unnecessary [30].

2.2.3. Kaizen

Kaizen, meaning continuous improvement, is divided by the Japanese terms’ kai and zen meaning change and improvement, respectively. Kaizen uses critical and analytical thinking to find solutions [29]. According to Otsuka and Ben-Mazw [40], Kaizen can be defined as activities that bridge the gap between the current state and the ideal state by solving problems or accomplishing tasks at an operational level. Thus, to be successful, an organization practicing kaizen must understand the current state, identify the ideal state, and have the will to bridge the gap between the two states [40]. Kaizen itself is about making small improvements that, as a whole, represent a big change, in a Leaner sense [30].

2.3. Examples of Practical Applications

The agri-food industry is of particular interest since it tries to deal simultaneously with a set of peculiar characteristics, often unseen in other industries (for example, the short shelf life of raw materials or seasonality of products) [41]. According to Lopes et al. [42], despite numerous successful applications in various sectors, the particular characteristics of the food sector may have led to resistance to changing companies’ practices and the implementation of new management philosophies. For Pearce et al. [43], more recent studies highlight that rising food prices and increasingly limited agricultural production capacity are contributing to the renewal of processes in primary production, with an emphasis on sustainability. They also highlight the urgency in eliminating waste that is strongly aligned with the agricultural need to reduce operational waste, whether in the form of inefficient labor used, food waste, water, or energy [43]. Solano et al. [44], defend that the current conditions of agricultural production increasingly require an improvement of techniques and tools to improve the management quality and productivity in agriculture. This will allow for increased yields and work efficiency, and simultaneously minimize costs, waste, and balanced management of natural resources.

Studies such as Lehtinen and Torkko [45], Jiménez et al. [46], Dora et al. [47], Wesana et al. [48], Hmidach et al. [49], Rojas-Benites et al. [50], Somasundaram et al. [31], Farissi et al. [51], and Ali [52] proved that Lean practices are significantly beneficial through improvements such as: service and product value creation, production efficiency, increased employee involvement, team spirit, coordination between production and maintenance, and waste reduction, production cost reduction, optimization of storage area and stock control, and reduction of setup and lead time.

Ashraf et al. [53] through the implementation of 5S in a food and beverage industry (waters, juices, and lollipops) obtained a reduction in rejected products (19.4% to 13.3%) and an increase in productivity by 38.65%. Rojas-Benites et al. [50] tried to fight overproduction and immobilized products, and excess raw material. Using tools such as 5S and Kaizen, it was possible to reduce the 15.78% of immobilized stocks, which represented 8% of the annual turnover and to reduce waste by 9.56%. Jiménez et al. [46], through VSM, 5S, and Kaizen, achieved a reduction in stocks, a more adequate selection of relevant information, a 16% reduction in waste, and a decrease in lead time to 56%.

Considering the objective of this article, which consists of the implementation of Lean principles in an organization producing fruit to reduce waste, increase production efficiency, improve overall business performance, increase competitiveness and adaptability to demand, the following tools were selected: 5S, VSM and Kaizen. The selection criteria were the studies mentioned, the characteristics, limitations of the tools, and the respective constraints of the organization (size, human/financial resources).

3. Case Study

This study was conducted in a fruits distribution center. The organization was founded in 1982 by 25 producer members and markets fruit intending to promote Beira Interior and help small producers in the area to sell their products. Currently, 23 member producers and 18 non-member producers are still associated. It is a cooperative of certified producers that commercializes mostly peaches, apples, and pears of high quality from the Cova da Beira region, Portugal, an area of long tradition and great aptitude for fruit growing. It has a production area of about 160 hectares of orchards distributed by: 45 hectares of pear and apple and 110 hectares of stone fruits, of which peach. It also has cultivation areas located in the Cova da Beira region, in the counties of Fundão, Covilhã, Belmonte, Guarda and Sabugal. Other studies trying to improve productivity and sustainability, maintain the fruit quality, and characterize and reduce energy consumption were already developed in this distribution center [54,55,56].

Layout and Production Flow

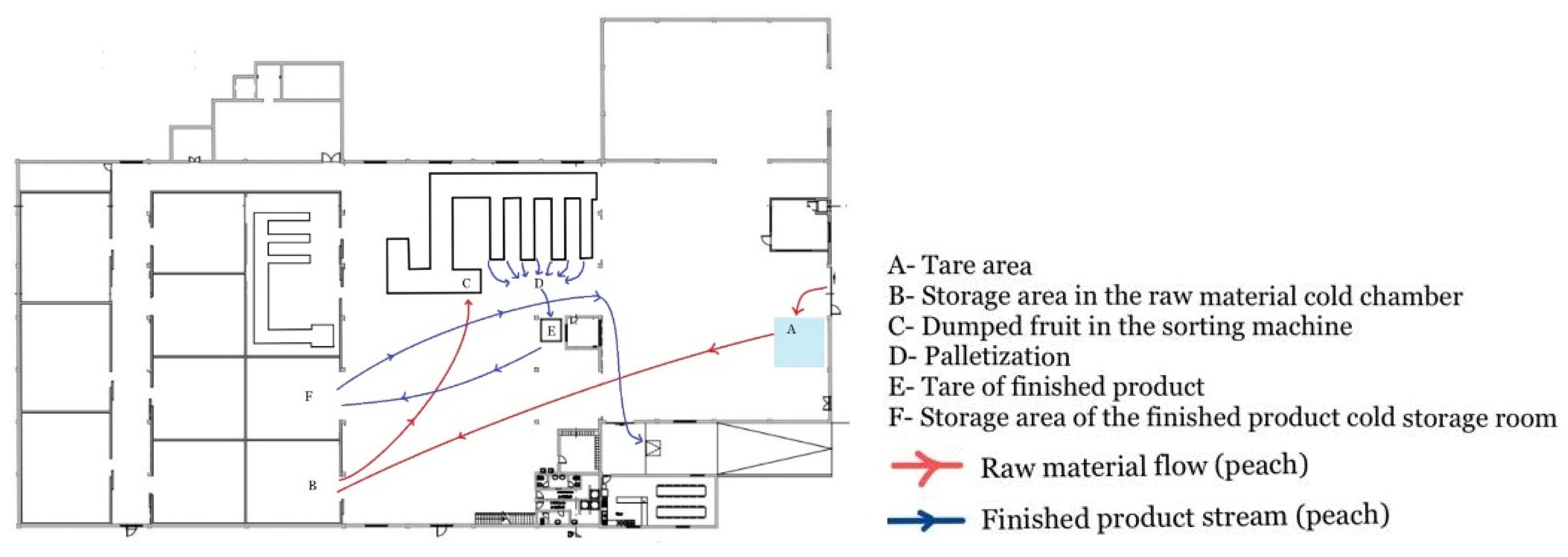

An analysis of the production system was performed by representing the movements on the floor plan of the company’s facilities. In the plant of the analyzed production lines were drawn that represent the movements during a certain period.

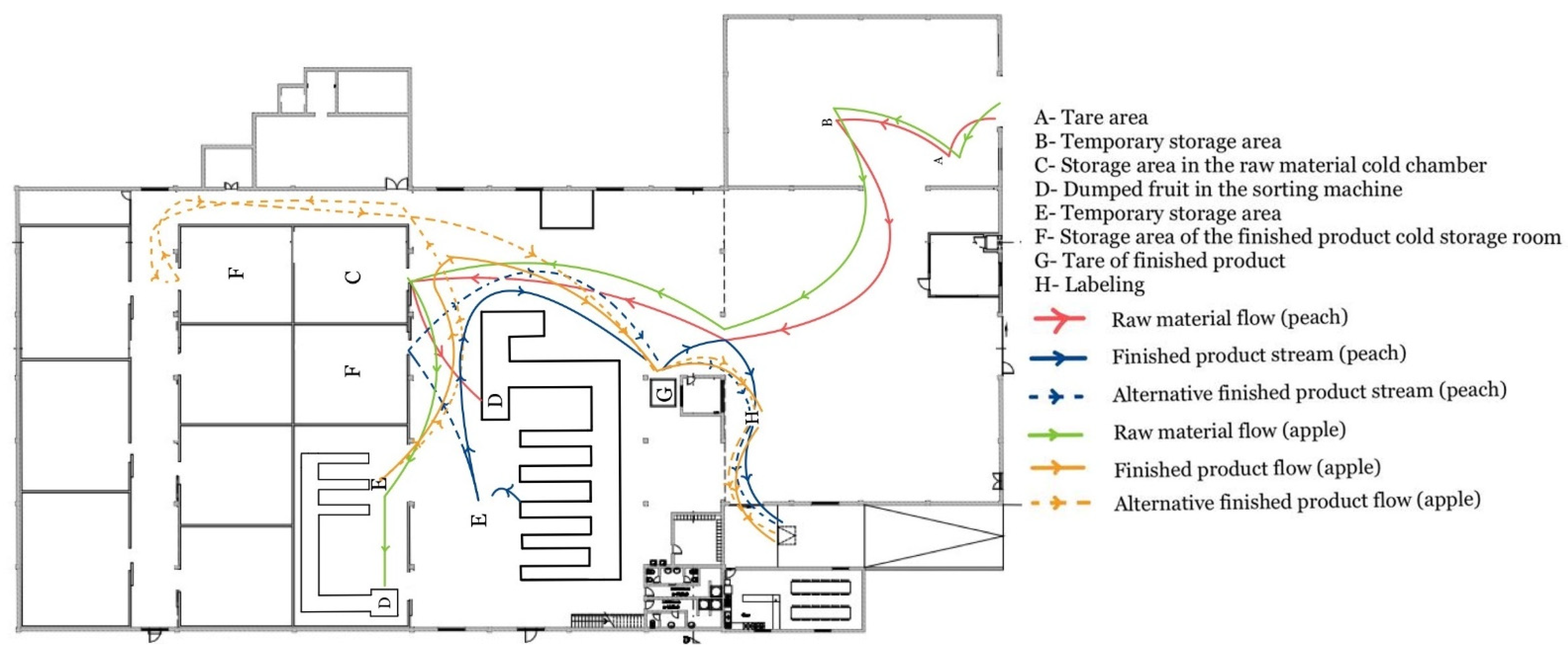

Figure 1 is represented the spaghetti diagram of the production flow from the moment of entry of the raw material in Warehouse 1 until the time of shipment.

Figure 1.

Spaghetti diagram of the production flow.

Unnecessary movements were identified, as well as overlaps of different products and the crossing of raw material with the finished product. As illustrated in the figure, it is possible to observe that when the organization works with more than one type of fruit (for example, peach and apple) there is an overlap of several movements.

The whole process starts in the production field. Each producer is responsible for picking, collecting, and delivering the fruit to the premises. As a first step, the producer makes the delivery to Warehouse 1. In the area indicated A, the reception and control of technical requirements (e.g., weight, quantity, quality, and lot) is performed. Meanwhile, six random fruit samples are taken for quality control (penetrometer, °Brix, rottenness, stalk or stone condition, and taste). Afterward, the pallet boxes are temporarily stored in zone B until the person in charge has the availability to transport them to the cooling chambers located in Warehouse 2.

In Warehouse 2, considered the core of the whole production section, the fruit is stored in a controlled atmosphere in the cold chamber for raw materials (C) where the temperature varies between 1.6 °C and 7 °C, and which tries to respect the FIFO criterion (First In, First Out).

The pallet boxes are then dumped into the sorting machine (D) where the fruit is brushed and classified according to the caliber. The fruit falls along the lines and is sorted for packing into boxes. The boxes are placed on pallets in zone E, according to size, and transported to D to be weighed. When only one type of caliber is ordered, the remaining pallets are directed to chamber F, for finished products.

Finally, the pallets are again sent to Warehouse 1 where they are labeled and shipped (H). The expedition is carried out upon the arrival of the transport vehicles in appropriate conditions.

Warehouse 3 is only used when there is a larger production flow or when the organization works with different types of fruit, which need different storage conditions. In this case, the cold rooms are switched on and when there is more than one quality of fruit to be packed, the smaller sorting machine, located in warehouse 2, is used. This situation is quite recurrent in times of peak production. However, when there is only a small quantity of the other fruit being worked on, it is stored together with the remaining fruit in the same chamber F.

4. Discussion

4.1. Application of the Lean Philosophy

Implementing the Lean Philosophy allows to introduce systems and routines, save time, and provide a calm environment among employees. Lean tools involve all employees positively, through change, and in creating value for the customer. At the same time, it means that there will be fewer errors and more efficient and methodical workflows [2].

As mentioned before, Lean is based on five basic principles that are considered key elements of the Lean philosophy. In this subchapter, some of the principles will be presented and explained with application in the practical case.

4.1.1. Define Value

This principle aims to identify how much the customer is willing to pay. It is important to prioritize and identify where value exists. In this case study, value is created for the customer, since the customer can order according to the desired caliber and the variety of fruit required. The company offers a wide range of products from different producers.

4.1.2. Identify and Create a Flow That Eliminates Waste

The activities that create value and those that do not add value for the end customer should be identified. What does not add value for the customer may be considered waste and should be reduced or eliminated. An alternative used by the company is to sell fruits that do not comply with the stipulated quality requirements. This fruit is sent to partners who are responsible for reusing the fruit by transforming it into jams and juices. The concept of adding value can also be defined as a strategy to reduce losses.

It is also important to define a continuous flow, without interruptions to speed up production and reduce the waiting time between activities. In this case, sometimes there are long waiting times in the transportation of the raw material from reception to storage, as well as when the trucks arrive to ship the product. This long period can influence and accelerate the deterioration process of the fruit since it is at room temperature.

4.1.3. Pull System

Efficient stock management must match customer demand and define a downstream production system, e.g., produce only what is required in order not to create stocks. A particularity of the agri-food industry is the short shelf life of raw materials and seasonality of products. In the organization, one of the biggest difficulties faced is the control of raw material delivery by the producers. The producers deliver the raw material according to the maturation of the fruit, there is never an order to the supplier according to the needs of the organization. Given this limitation, at times of increased production flow, there may be an increase in stocks and difficulties in the organization of the cold storage rooms.

4.2. Improvement Proposals

In this subsection, the improvement proposals are presented with the practical application of the selected tools, Value Stream Mapping (VSM), 5S, and Kaizen. The main objective is the application of improvement proposals according to 5S, allied to Kaizen, and the identification of waste of resources along with the production flow (VSM) to organize the workplace and thus maximize efficiency and productivity.

4.2.1. Implementation of 5S and Kaizen

The 5S methodology can be extended to most work situations in a short period due to its simplicity. From raw material input to the final stage of shipping, activities were recorded and photographed to evaluate all processes. Each activity was evaluated separately to identify anomalies in production, such as tool movements, pallet arrangement, movements and changes of workers, changeover times, time spent on each activity, and use of work areas.

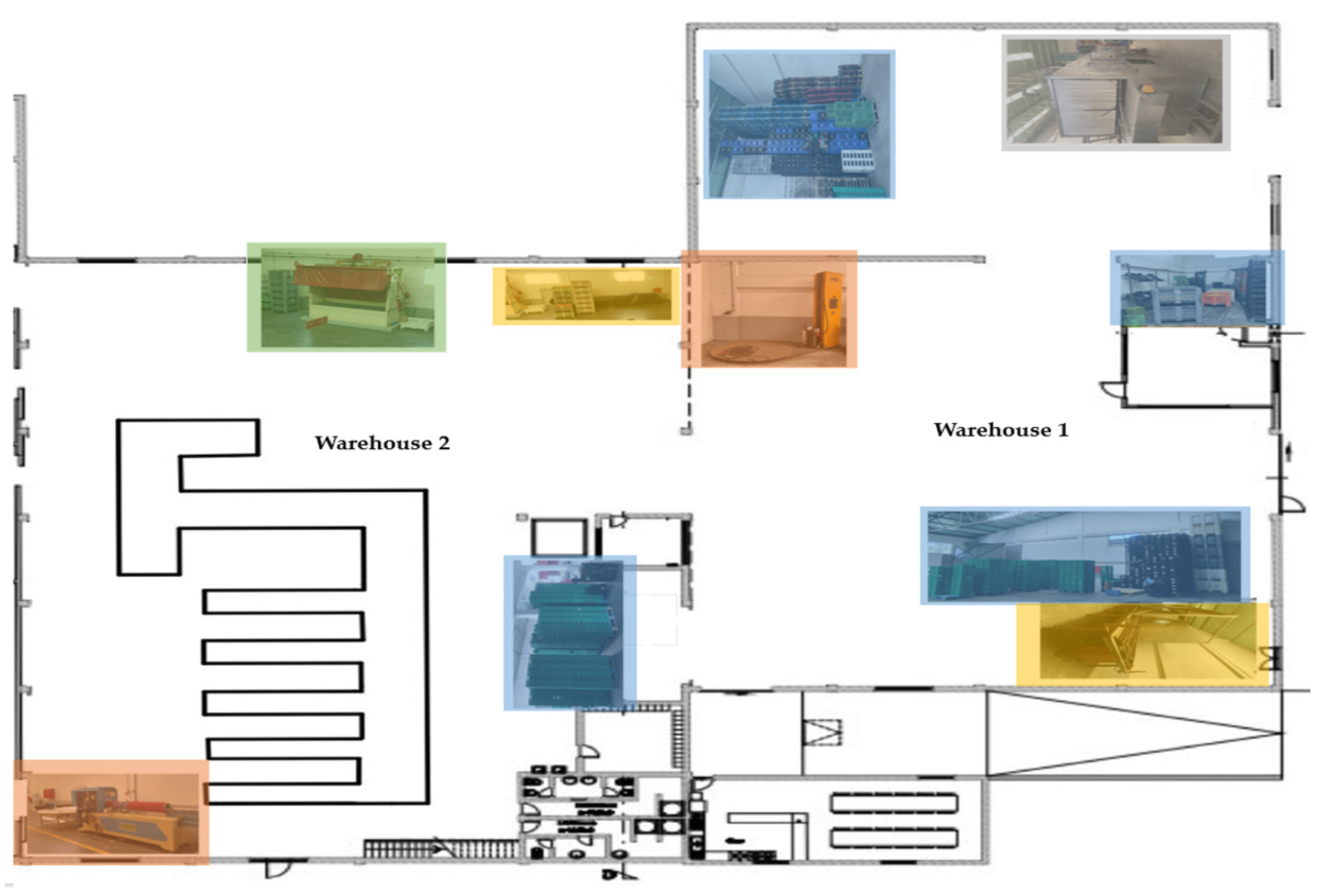

Figure 2 shows the layout of warehouses 1 and 2 with the respective constraints and bottlenecks identified. In summary, many of the problems mentioned are related to poor organization, layout not product-oriented, and unnecessary movements due to the dispersion of equipment.

Figure 2.

Distribution of machines in the facility.

As mentioned above, upon receipt in Warehouse 1, the pallet boxes with fruit are stored for an indefinite time at room temperature until they are transported to the cold storage rooms. In this same area several pallets, pallet boxes, and empty boxes of different sizes are also stored represented blue in the figure. If this material were removed, it would free up space and allow for a better organization at the time of unloading.

A similar situation occurs in the place where the shelf-life verification procedure is performed next to the small store. As can be seen in the figure, represented in blue, there are boxes and pallet boxes with fruit accumulated. Throughout the warehouse, there are more dispersed boxes that are often obstructing the movement of raw material, people, and stackers.

In this same reception area is located industrial washing equipment for plastic boxes, represented in gray. The final procedure of sanitizing the boxes is performed after the boxes return from customers. A proposal for improvement would be to move this equipment to another area and thus free up even more space.

There is also a large industrial washing machine for boxes (yellow) that is inactively located in the warehouse 1. The same happens with a sorting machine located in warehouse 2 that is no longer used (yellow). In addition to the equipment already mentioned, two packaging machines are no longer used. In the pictures, there is an automatic pallet packaging equipment (warehouse 1, orange) and a tubular net bag packaging machine (warehouse 2, orange). One suggestion would be to sell these machines, to maximize the storage and circulation space, as well as recover part of the money spent on the purchase and maintenance of this equipment.

In the main warehouse (2) there is a Hydrocooler for the fruit (green). Although the hydro-refrigeration is one of the most effective means of refrigeration, not only because it allows to maximize the shelf life, but also to guarantee the freshness of the fruit, the equipment in question is not used. This is refrigeration equipment with a closed circuit of cold water that allows decreasing the temperature of the pulp, eliminating the biological load, as well as to remove dust or garbage. This equipment was poorly structured, as it damages the fruit when the water cascades down. One of the proposals for improvement is to sell this equipment and buy one that is adequate or adapted to the needs.

Another situation that can be improved is the maintenance of the cleanliness of the workplace since there was an accumulation of leaves, dust, and peach hair near the calibration machine, as well as some pieces of fruit scattered around the factory floor. A proposal for improvement would be the creation of a daily hygiene control checklist. In this list, one or more employees responsible for cleaning the grading machine at the end of the day would be defined. This would be a preventive measure that would allow preventing the development of pests and/or microbiological niches, as well as prevent product contamination. It would also make it easier to clean, sanitize and preserve hygienic conditions during and after the maintenance of the grading machine.

The organization has track marks on the floor, but some are already barely visible due to wear and tear. Since there is a constant circulation of forklifts, the safety signs for the circulation routes must be visible, as well as the warning signs for forklift circulation. Thus, allowing the circulation and movement of workers under safe conditions. It is important to carry out continuous maintenance of the road markings. A proposal for improvement is the biannual maintenance and placement of signage.

As mentioned before, the company has several cold rooms, however only two are used, one for raw material and the other for the finished product. One of the recurring situations is the accumulation of stock at the time of seasonal peaks in the cold storage chamber for the raw material, which can reach up to 25 pallet boxes per day. The organization has no control over which days and quantities will be made available by the suppliers. Currently, the only person responsible for the storage creates lines of pallet boxes according to the day of entry and the producer. On days when the amount of fruit received is high, the person in charge distributes the pallet boxes by the cold chamber without any criterion. Despite trying to respect the FIFO criterion, many times it becomes complicated to respect and manage the organization of the cold chamber due to the great affluence of raw material. In extreme situations, it is necessary to mix the pallet boxes with the finished product. This situation occurs not only in this sector. Incorrect logistics practices using cold chambers are transversal to all the agri-food sector [57,58].

Another recurring situation is when, for example, the customer orders only pallets of one type of caliber, the other calibers must be stored in the cold stores until they are ordered by a future customer. Due to the unpredictability of deliveries, one improvement proposal is to connect one more of the available chambers. This would allow maximizing the working space and easier control and respect of the FIFO criterion. Another improvement proposal can be applied in both chambers, through the creation of floor markings. In the raw material chambers, it is suggested the separation of a variety of fruit and the day of the reception. Regarding the cold storage of packaged products, the separation can be carried out by creating areas inside the chamber according to the size and day of packaging. It is suggested that marks be applied on the floor to identify and separate the size and fruit that has been packed the longest is placed closest to the door. This allows any employee to easily identify the fruit that has to be shipped first and its respective caliber. This new way of organizing the spaces makes it easier to find and locate the desired fruit and to prepare the fruit in the chamber when it needs to be shipped.

In addition to the problems previously identified, other problems were perceived:

- Weak involvement of workers. The workers are neither motivated nor informed about the daily and global objectives of the company. To combat this demotivation and misinformation, the organization can give productivity bonuses. The organization can motivate workers with extra monetary compensation, such as for punctuality, attendance (e.g., no absences for two months in a row), and completion of previously established goals. The company would be able to motivate employees to be more productive in their daily tasks and to improve communication with their bosses.

- Lack of training of seasonal employees. It is suggested to invest in training and cooperation with more experienced employees.

- Existence of only two employees able to drive forklifts, the one responsible for unloading the goods when they arrive from the producer and the one responsible for production. When an employee is absent there is no substitute who can operate the forklifts and the work piles up. To mitigate this situation, we suggest the training of at least one more worker with a forklift driver’s license, so that he can substitute whenever one of the employees is absent.

- Lack of employees, which can be overcome with a new distribution and attribution of tasks among the employees. On production lines, on the grading machine, it is suggested that more experienced employees be at the beginning of the line.

- Lack of monitoring after the initial implementation of the organization. The process was never reviewed and was rarely checked to ensure it was being followed. Whenever a new action plan is implemented, there should be periodic monitoring.

- Difficulty in performing equipment calibration and adjustments. It is suggested that a new product-oriented sorting machine be purchased, and that training be provided to the workers.

- Lack of a continuous improvement culture. The organization should promote the implementation of Lean tools with the full cooperation of all workers.

After the analysis of the current state of the factory floor, unused machines, pallet boxes, pallets, and boxes of different sizes stored in the warehouse were identified, which can be removed or reorganized in another suitable location, as well as the implementation of a cleaning routine of the workplace. One of the main problems identified was the inadequate planning of the layout and bad use of all the available areas. Thus, one proposal would be to improve the layout of the organization.

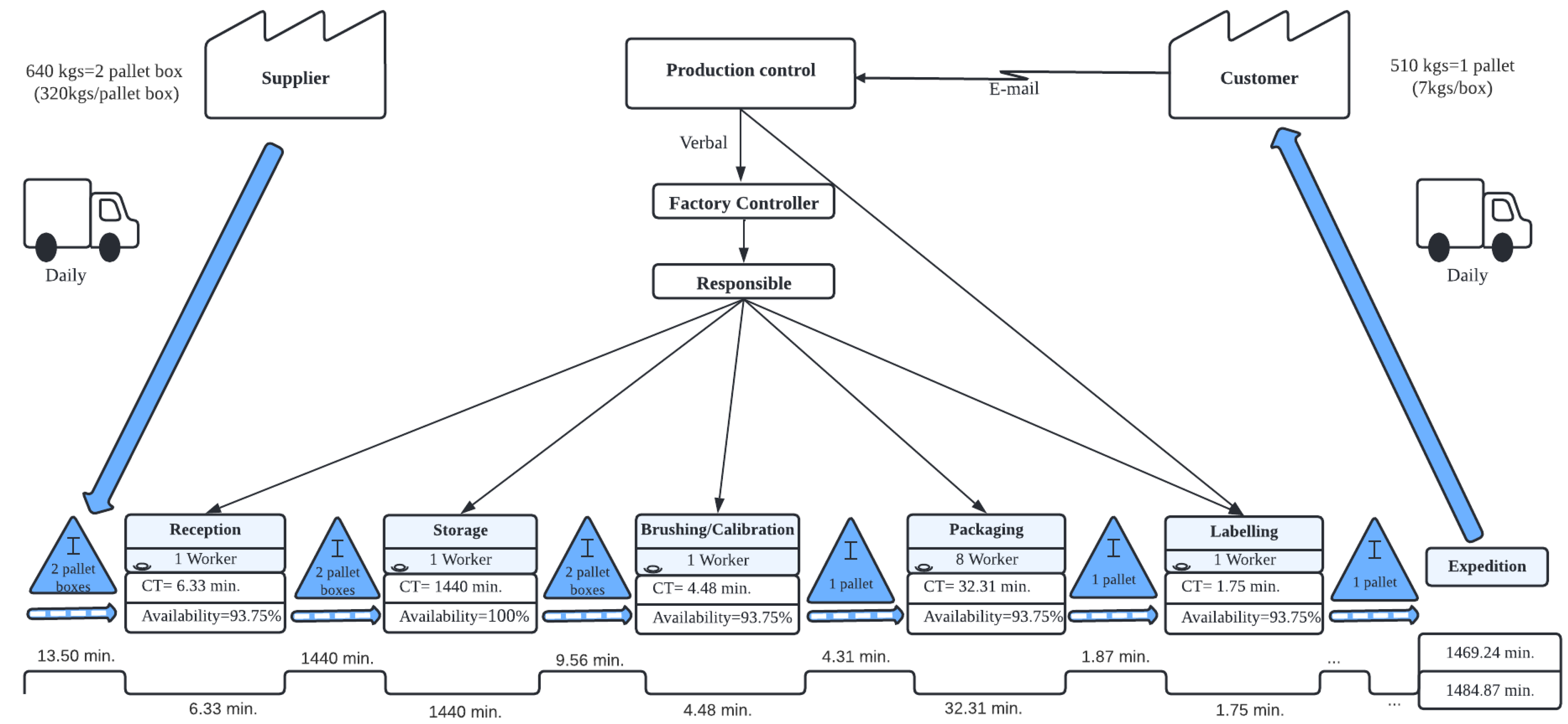

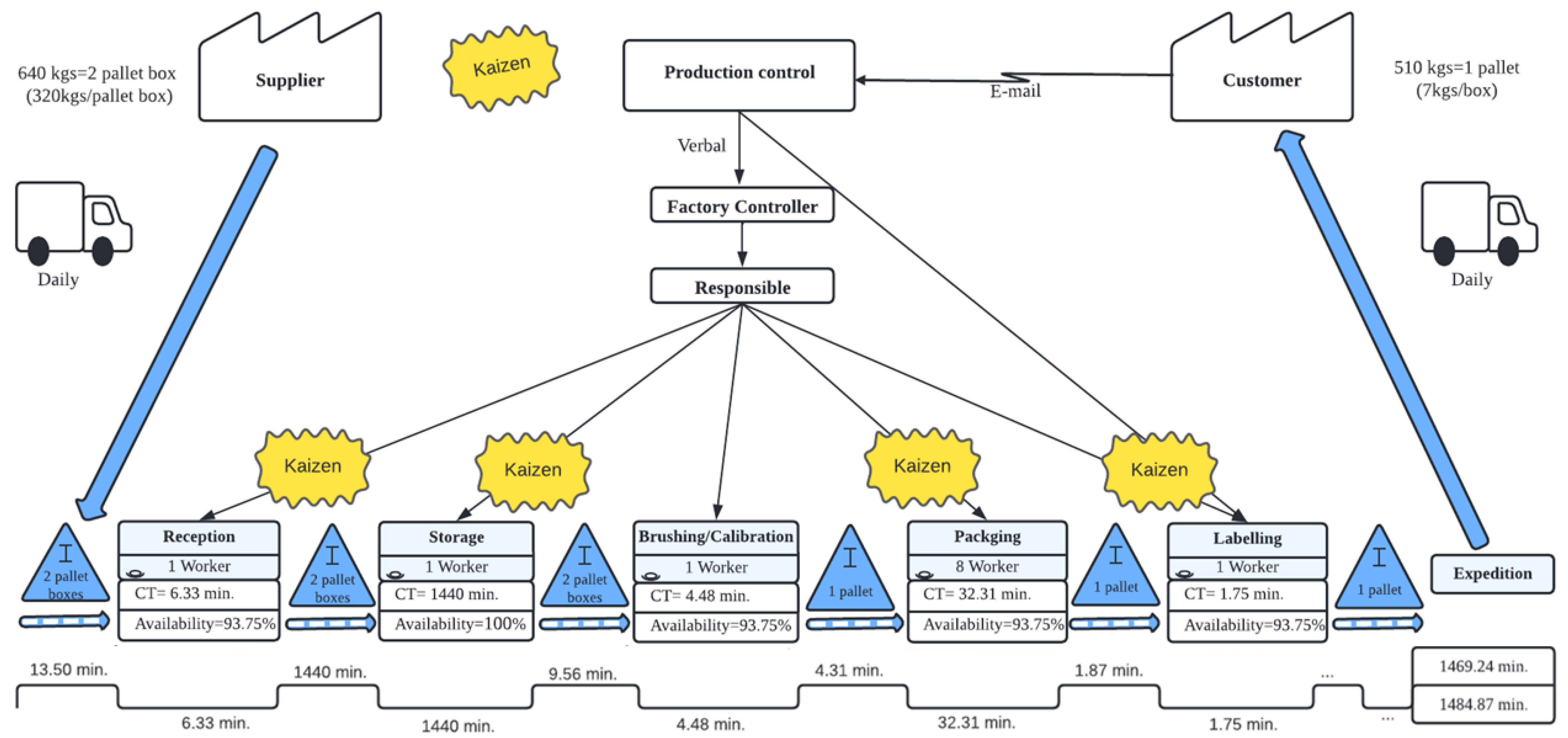

4.2.2. Implementation of Value Stream Mapping (VSM)

The VSM of the initial state was prepared to obtain a detailed view of the entire process. The collection of information for its elaboration was carried out through direct observation of all operations performed and dialogues with the workers who normally operate the machines and execute the tasks. The dialogue with the control and production manager was also fundamental for the collection and validation of data.

After defining the objectives and collecting all the necessary information and data for the preparation of the VSM of the current state, we processed an order of 516 kg of peach AA, which corresponds to a pallet with 72 boxes, over the phone. This is a frequent customer who orders weekly. The production control transmits the information verbally to the production manager, who transmits it to the person in charge. According to the customer’s request, the person in charge checks if the ordered variety of fruit is in stock.

In this case, there is no contact between production control and the suppliers since they only deliver the fruit when it is ripe. A pallet box of fruit averages 320 kg, and in this case, two pallet boxes had to be processed to satisfy the customer’s needs. Knowing that the utilization rate is on average 80%, e.g., two pallets (640 kg, 320 kg each one) will correspond to one pallet (516 kg). It is important to keep in mind that these are average values since when the peach is received all the calibers are mixed.

The employees work 8 h a day, 5 days a week with 15 min breaks both in the morning and the afternoon, which translates into an availability of 450 min per day.

The main activities, metrics, cycle time, lead time, availability, and a number of workers needed throughout the process were identified. Through observation, the activities were timed, the processing time for all operations was recorded, and the total average time for each operation and its standard deviation were calculated, as shown in Table 1.

Table 1.

Timing of sample processing.

At the moment of “Reception”, it was considered the unloading time, weight, and data entry into the system. At this stage, all receiving activities are performed by a single worker, who at peak times is overloaded due to the high number of suppliers waiting to unload the raw material.

In the “Storage” were considered 1440 min, because the pallet boxes are piled up, and it is difficult to respect the FIFO criterion, and the organization chooses to keep the peach stored for one day since the storage time is determined by its state of ripeness.

In the “Brushing/Calibration” phase, the time from the moment the pallet boxes were picked from the cold storage, the unloading in the sorting machine until the fruit falls along the lines was considered. Greater dispersion of values was registered, since the fruit becomes stuck in the sorting machine due to the large turnout, and only one worker is available for all the tasks.

In “Packing” a permanent employee was selected, and the time required to complete a box was recorded. Situations such as picking up the box and/or the cardboard base material from the box, as well as stopping duties to assist seasonal employees were some of the main constraints observed. Considering the constraints mentioned above, an average time of 3.59 min per box. Knowing that, on average, 8 employees operate, it is possible to make 8 boxes in 3.59 min. In this case, making a pallet with 72 boxes takes 32.31 min. Equation (1) is calculated the total average time to make a pallet. This value will be used in the cycle time of the actual production VSM since one pallet is processed instead of one box.

In the last phase, “Labeling”, an employee takes an average of 1.75 min to label each pallet.

According to Equation (2), the sum of cycle times or Value Add Time is given by:

After adding up the waiting times and the processing times for all operations, it is possible to calculate the total lead time. The lead time is calculated by summing the product of intermediate stocks and cycle time using Equation (3).

It is possible to conclude that the current state map has a lead time for the processing of an order of one pallet (516 kg) of 2954.11 min, which corresponds to 2.05 days. However, only 1484.87 min correspond to activities that add value, which represents 50.26% of the entire process. This means that the organization to meet the customer’s needs is delayed by 2.05 days, e.g., it has to have the necessary quantities in stock, and this only happens when the suppliers deliver the ripe fruit.

In this case, the customer orders weekly, every 5 days. Considering that the month has an average of 22 working days, 4 weeks, the organization has 5.5 days to prepare an order. Considering that it takes 2.05 days to process an order for a pallet, which leaves only 3.45 days to respond to any adversities that may arise.

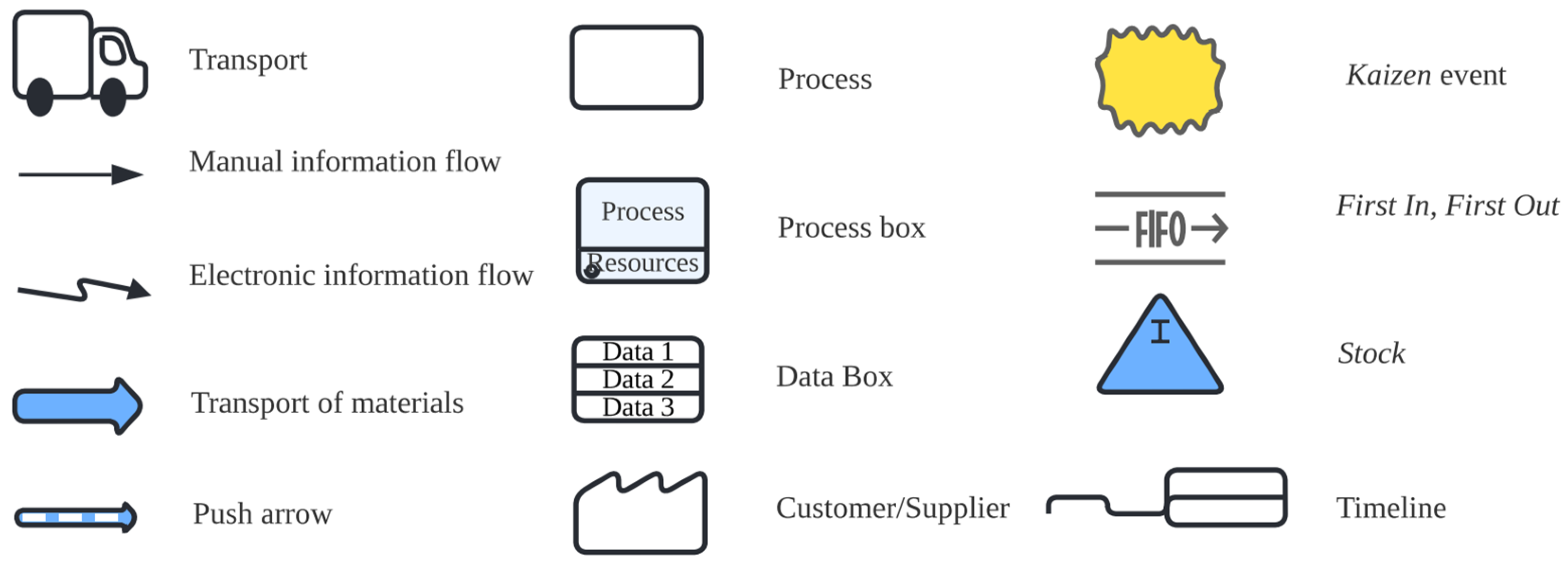

To aid the understanding of Value Stream Mapping, Figure 3 shows the symbology used in the VSM tool.

Figure 3.

Symbology used in the VSM tool (Lucidchart, 2022).

Figure 4 shows the current VSM in which the previously mentioned order was processed.

Figure 4.

Current VSM of production.

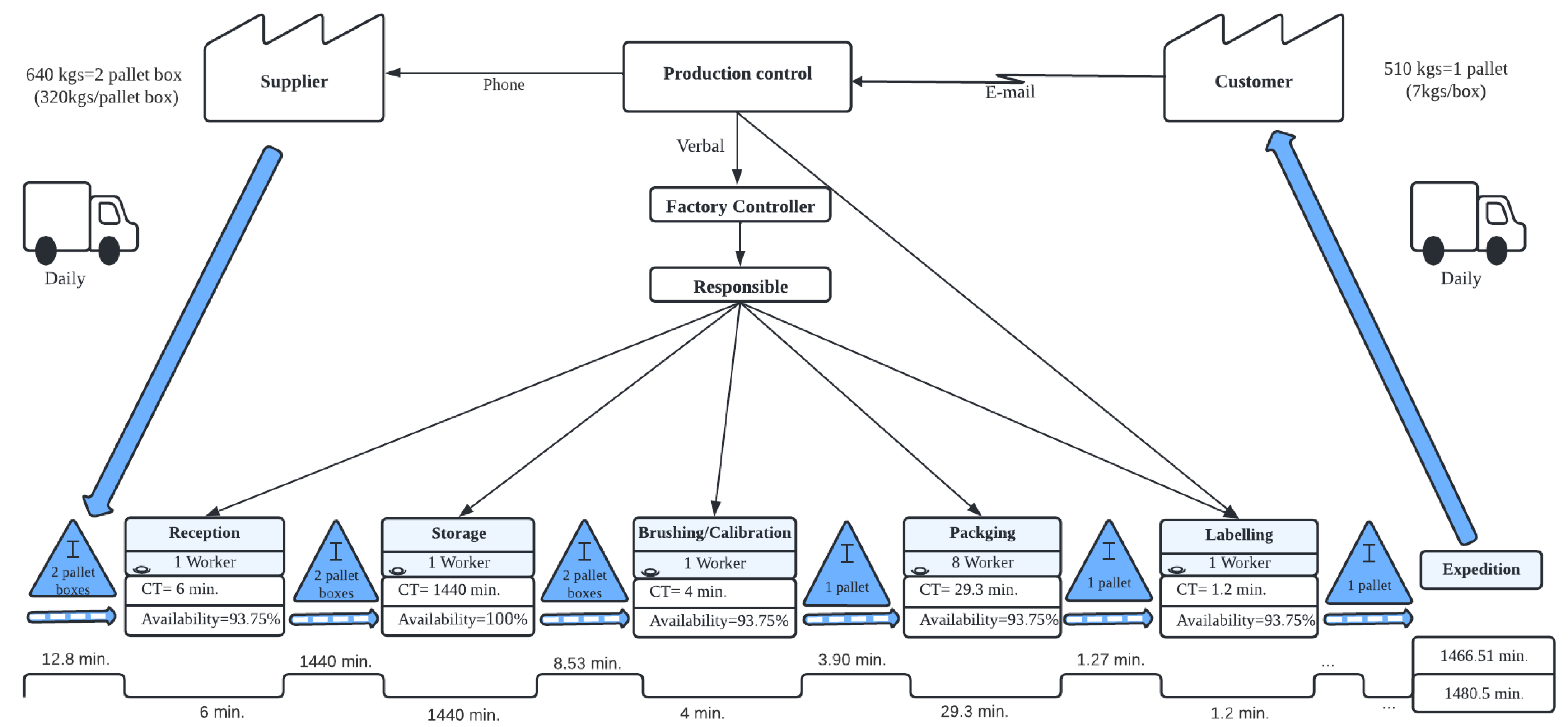

After synthesizing the flow through the current VSM, the previously identified problems and constraints, as well as opportunities for improvement, were considered. Figure 5 shows the VSM with the improvement proposals.

Figure 5.

VSM with improvement proposal.

The improvements identified were:

- Frequent communication between the company and the supplier, via telephone, to make a forecast every 2 weeks to know the state of ripeness of the fruit.

- Transport of the pallet boxes to the respective cold storage rooms immediately after receiving the raw material.

- Reorganization of the storage area inside the chambers, since sometimes they are accumulated without any criterion and consequently it becomes difficult to respect and comply with the FIFO criterion.

- Improvement of the labeling process, carried out manually, with the help of a label applicator.

- Reducing the cycle time of each of the activities and movements by changing the layout.

As mentioned earlier in the current VSM, about 49.74% is idle time, e.g., the product is waiting to be transported or is in steps that do not add value. If this time is reduced or even eliminated, several costs can be reduced.

The improvements identified will reduce the cycle times of each of the activities, except for “Storage”, since the fruit has to be stored for 1440 min, e.g., one day. The “Receiving” activity will be reduced from 6.33 min to 6.00 min, by reducing unnecessary movements; the “Brushing/Crushing” activity will be reduced from 4.48 min to 4.00 min, by reducing unnecessary movements and reorganizing the layout and cold rooms; the “Packing” process will be reduced from 32.31 min to 29.30 min, by reorganizing the distribution of workers along the lines and improving the arrangement of materials (boxes and bases); finally “Labeling” will be reduced from 1.75 min to 1.20 min, with the help of a label applicator. Equation (4) presents the sum of the cycle times for the new VSM:

Next, the lead time was calculated by summing the product of intermediate stocks with the cycle time, through the Equation (5).

With the improvements of the proposed new VSM, it will be possible to reduce 4.37 min in cycle time and the lead time of a pallet to 2947.01 min, 7.10 min less than the current VSM. In this case, it would take 2.04 days to process the 516 kg order. Although this is a negligible reduction, at the end of a month it will represent a total of 156.20 min and at the end of a year of operation, 1874.40 min, approximately 32 h, which is 8 h of work per day corresponds to 4 days, which in addition to the benefits inherent in better organization of space, incorporates a cost reduction.

It is suggested that the future VSM map be applied progressively in the short to medium term. Performance measurement and goal setting are important for the growth process, as it establishes a feasibility mindset in the team and leads to the successful implementation of the action plan. Next, a future vision of the most efficient value stream is presented through the representation of the future VSM illustrated in Figure 6.

Figure 6.

Future VSM.

4.3. Future Solution Proposals

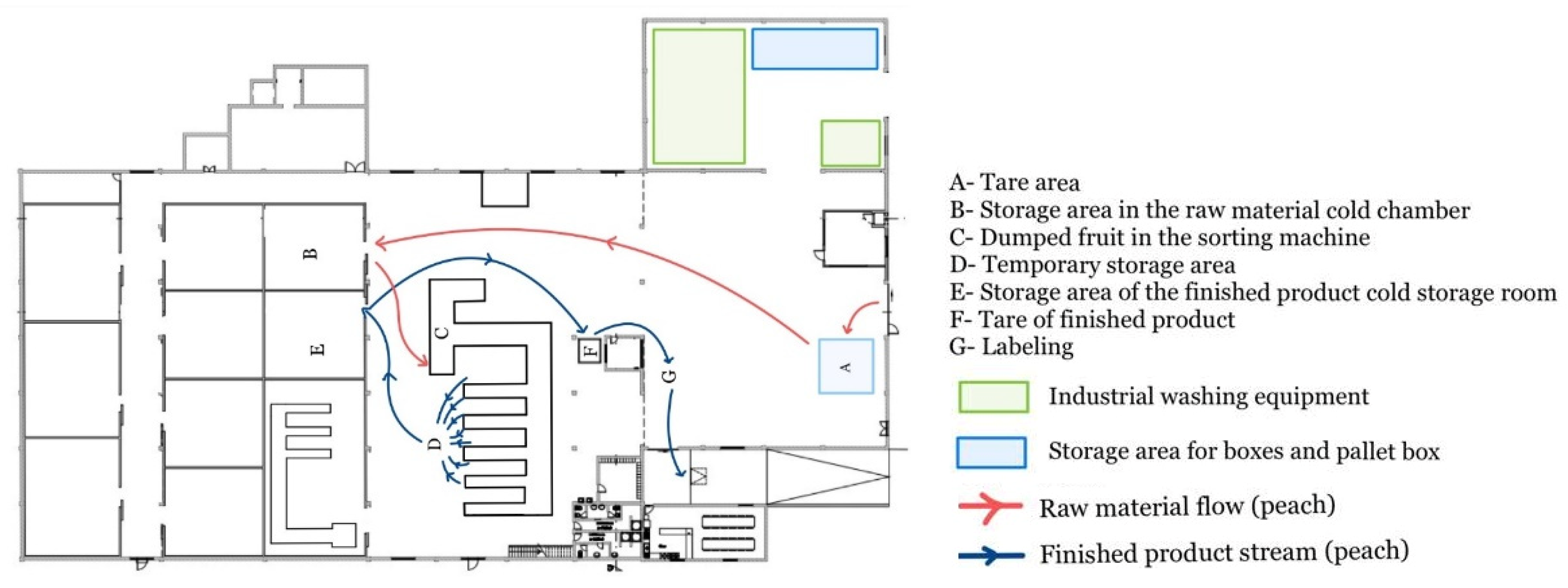

In this subchapter, through the spaghetti diagram and the VSM, the proposals for improving the production layout of the agricultural company are presented, as well as the reorganization of the cold storage rooms.

4.3.1. Layout

One of the main problems identified was the poor management of available space by the organization, which has a large area. Situations such as the dispersion of machines, the overlapping of product movements, and disorganization in storage, since there is no area indicated for the storage of accumulated boxes, result in inefficient use of space, a situation that worsens in periods of seasonal peaks.

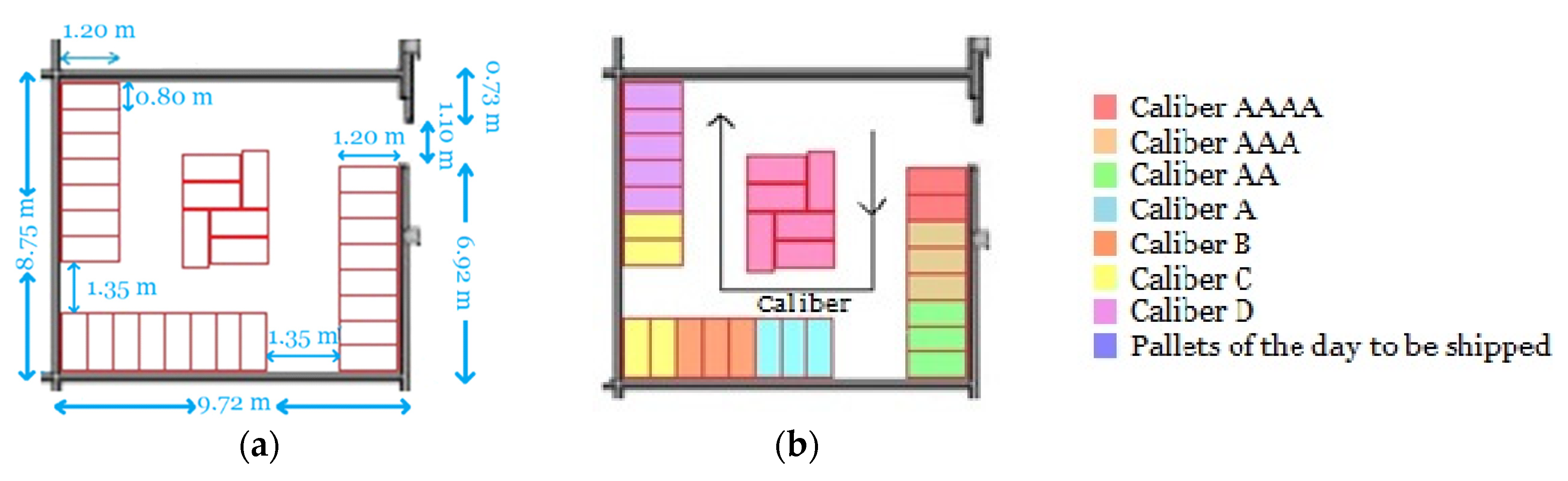

Figure 7 shows a proposal for a new layout. One of the main problems faced was to resize the largest sorting machine since it was only possible by eliminating production lines. The last line where the fruit considered “scrap” falls was removed. It is suggested that the warehouse where the smaller sorting machine is located be reused because previously this warehouse was cold storage and still has the same characteristics. This same space would be divided into two chambers of the same size, one for the raw material and the other for the finished product. The other two chambers would be adapted for the other classification machine as can be seen in Figure 7.

Figure 7.

New layout.

This new layout will allow the finished product to be transported already packed in D, so that it can be weighed, and the “Labeling” process can then be carried out. After this process, the pallets would be forwarded to the cold storage chamber where they would be stored up to 10 min before the arrival of the transport.

Figure 8 illustrates the current layout with the proposed improvements. If the organization chooses to keep the same layout, it is suggested that the reception of the raw material is performed in another area designated as A. Subsequently, after the reception, the pallet boxes should be immediately transported to the chamber indicated as B. In D, it is suggested that whenever a pallet is finished, it should be directed to the cold storage chamber (E), and only removed no more than 40 min before dispatch so that the “Labeling” process can be carried out.

Figure 8.

Current layout with proposals for improvement.

This new layout organization will maximize the use of space and organization indicated for the various boxes and pallet boxes spread throughout the warehouses.

4.3.2. Storage Area

Regardless of the layout chosen by the organization, another suggestion is the reorganization of the cold stores and the introduction of optical readers that allow not only to automate the process but also to control the entry and exit of stocks. By reading a bar-coded label, it would be possible to identify the pallet, which variety of fruit it contains, the lot number, the date of entry, and the producer. This data would be filled in at the reception of each pallet box.

In cold stores, by reading the barcodes, when it was necessary to load the pallet box into the sorting machine, it would be easily possible to identify the “latest” pallet box and thus respect the FIFO criterion.

A proposal for improvement would be to organize the cold rooms for the raw material and the finished product. It is known that the smallest chambers have an area of 85 m2 and the largest, located in Warehouse 3, has 190 m2.

Each pallet box has a dimension of 1200 × 1000 × 760 mm (0.912 m3), that is, it occupies an area of 1.2 m2 and in the chambers it is possible to overlap up to 13 pallet boxes. In the chambers, it will be necessary to take into consideration the circulation routes and the distance between pallet boxes. This distance is calculated by adding the external turning radius of the forklift, the distance between the forks and the front axle, the length of the forks with load, and the clearance, according to Equation (6):

Width between pallet boxes = 1.20 + 0.04 + 1.55 + 0.50 = 3.29 m

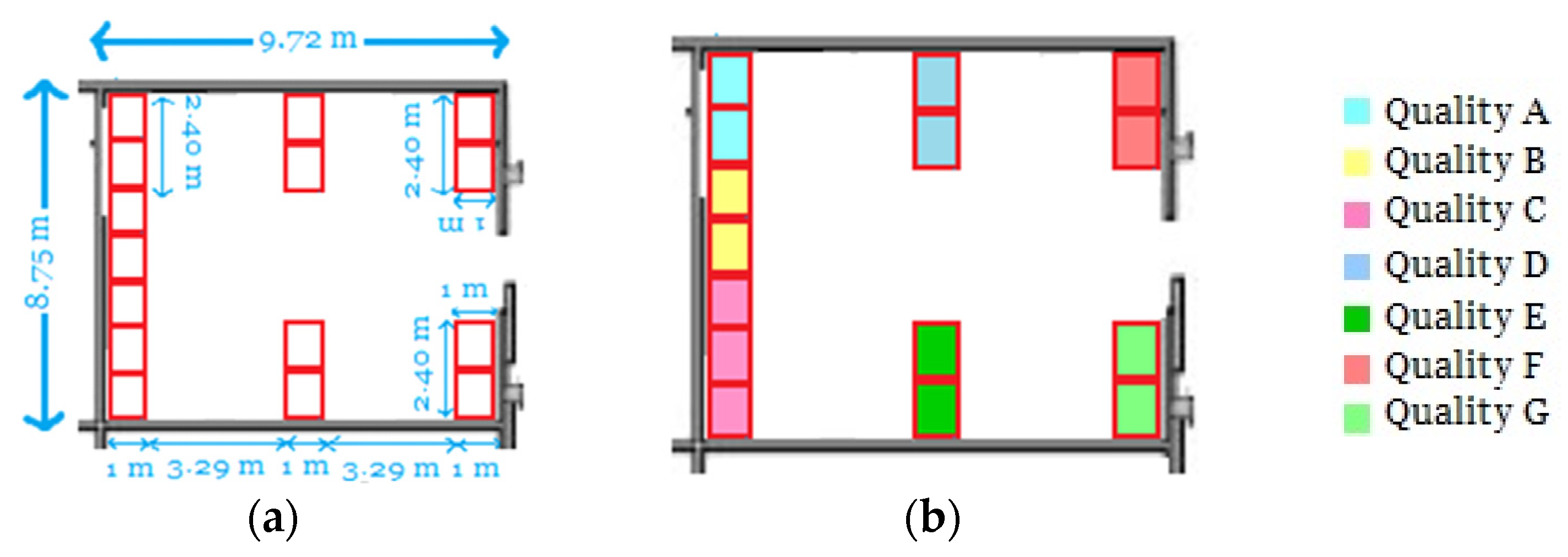

The distance between the pallet boxes so that the forklift can be safely maneuvered is 3.29 m. In this sense, a new layout of the raw material chamber is proposed, as shown in Figure 9, which would allow the storage space to be optimized without endangering the safety of the workers.

Figure 9.

(a,b) New layout of the cold room for the raw material.

Knowing that the organization works with 7 varieties of peaches, one of the solutions would be to create parallel rows of 2 pallet boxes according to variety and day of entry into storage, represented in (b). This new arrangement would not only allow 182 pallet boxes to be placed in the chamber, organized according to quality and day of reception, but also allow any employee to easily identify which pallet should be loaded into the sorting machine. This process would be made easier with the help of the optical readers suggested above, and the FIFO criterion would be respected.

In relation to the empty pallets, each has a dimension of 1200 × 800 × 144 mm (1382 m3). In this case, it is suggested that the storage be organized depending on the caliber, as illustrated in Figure 10.

Figure 10.

(a,b) New layout of the cold room for the finished product.

Since it is not possible to overlap the pallets, to facilitate circulation, it is suggested that the hand pallet truck be used with a distance of 1.35 m between pallets, as shown in (a). This would allow a larger maneuvering area and more storage. In (b) is also illustrated the distribution of the fruit size according to the new layout. To identify the caliber more easily, it is proposed that the pallets are placed from biggest to smallest size along the walls of the cold store. In the center can be placed the pallets that will be shipped on the day.

5. Conclusions

In recent decades, Lean has been an important catalyst for process organization and innovation in various industrial sectors. Despite successful applications in various industrial sectors, when it comes to the food and beverage industry, the application is more limited because it is a peculiar sector. The characteristics of this sector, such as the short shelf life of raw materials or seasonality of products, may have led to resistance to changing company practices and implementing new management philosophies such as LM [42]. LM implementation does not happen overnight. It needs time, stamina, focus on improving communication, and support from top management to make the change a reality. Continually increasing business competitiveness is vital to motivate change and sustain behaviors and attitudes, as well as by understanding and implementing Lean Thinking culture.

According to the authors, Pearce et al. [59], there is a dearth of studies investigating the application of Lean tools in the primary production segment of the agri-food supply chain. The application of Lean tools in the food processing industry has not received the same level of attention compared to traditional manufacturing industries. However, in 2021, the same authors Pearce et al. [43], point out that rising food prices and increasingly limited agricultural production capacity are contributing to process renewal in primary production with an emphasis on sustainability. They also highlight the urgency in eliminating waste that is strongly aligned with the agricultural need to reduce operational waste, whether in the form of inefficient labor used, food waste, water, or energy [43]. This idea was reinforced by the previously mentioned studies (Lehtinen and Torkko [45], Jiménez et al. [46], Dora et al. [47], Wesana et al. [48], Hmidach et al. [49], Rojas-Benites et al. [50], Somasundaram et al. [31], Farissi et al. [51], and Ali [52]) in which they proved that despite being a peculiar sector, the application of the Lean philosophy has grown exponentially. The excellent and promising results of the pioneering initiatives applied in Agribusiness demonstrate that this management philosophy can contribute to several fields of application, as well as allow the creation of synergies to enhance results and improve the management of available resources (financial and human).

It was concluded that the organization has a lead time of 2954.11 min, which corresponds to approximately 2.05 days. With the new VSM it would be possible to reduce the lead time to 2947.01 min, that is, 2.04 days. As well as reducing the cycle time from 1484.87 min to 1480.50 min. Although this is a slight reduction, it is quite significant after one year of operation, since it will allow the FIFO criterion to be respected and will allow the product to be sold in the order it was received, thus avoiding loss of product quality. If the cold conservation operation is excluded, the VSM application considers a reduction of 35.5% and 10.6% of the cycle time and lead time, respectively.

The application of Lean tools allows to reduce, or even eliminate waste throughout the process. Through the implementation of 5S, it is possible to reduce unnecessary movement, improve the layout and maximize workspace, level stocks, and motivate greater supplier involvement with a view to continuous improvement (Kaizen).

One of the main limitations was the seasonality and short shelf life of the product, which limited access to periodic data. As suggestions for future proposals regarding the subject under study, it is proposed:

- Installation of a pre-cooling area (Hydrocooler).

- Analysis of the feasibility of implementing Lean tools.

- Analysis of the feasibility of investing in a new sorting machine and defining a new product-oriented layout.

- Investing in Benchmarking allied to Industry 4.0 in the use of active and intelligent packing that allows the prolongation of the product’s useful life.

- Marketing plans, with the creation of a website with essential information, increased presence in social networks, and presence in cultural events.

- Evaluation and study of ergonomic issues since it is repetitive work.

This study can be used as a reference for future work since Lean tools can be implemented individually, which facilitates the implementation process. This implementation can also be replicated especially in other companies in the same industry, due to the seasonal peculiarity of the products and short shelf life, which are often constrained and limited by a lack of financial and human resources.

Author Contributions

Conceptualization, P.D.G.; methodology, P.D.G. and T.M.L.; software, A.P.P.; validation, P.D.G. and T.M.L.; formal analysis, A.P.P. and P.D.G.; investigation, A.P.P.; resources, P.D.G. and T.M.L.; data curation, A.P.P.; writing—original draft preparation, A.P.P.; writing—review and editing, P.D.G. and T.M.L.; supervision, P.D.G. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported in part by the Fundação para a Ciência e Tecnologia (FCT) and C-MAST (Centre for Mechanical and Aerospace Science and Technologies), under project UIDB/00151/2020.

Data Availability Statement

The authors confirm that the data supporting the findings of this study are available within the article.

Acknowledgments

This work was supported in part by the Fundação para a Ciência e Tecnologia (FCT) and C-MAST (Centre for Mechanical and Aerospace Science and Technologies.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hu, H.; Yin, M. Evolution of Business Intelligence: An Analysis from the Perspective of Social Network. Teh. Vjesn. 2022, 29, 497–503. [Google Scholar] [CrossRef]

- Marques, P.A.; Carvalho, A.M.; Santos, J.O. Improving Operational and Sustainability Performance in a Retail Fresh Food Market Using Lean: A Portuguese Case Study. Sustainability 2022, 14, 403. [Google Scholar] [CrossRef]

- Hartman, B.; Gerigscott, E. The Lean Farm: How to Minimize Waste, Increase Efficiency, and Maximize Value and Profits with Less Work; Chelsea Green Publishing: White River Junction, VT, USA, 2015. [Google Scholar]

- Hocken, J. The Lean Dairy Farm: Eliminate Waste, Save Time, Cut Costs-Creating a More Productive, Profitable and Higher Quality Farm; John Wiley & Sons: Milton, Australia, 2019. [Google Scholar]

- Hendriks, S.; Soussana, J.F.; Cole, M.; Kambugu, A.; Zilberman, D. Ensuring Access to Safe and Nutritious Food for All through Transformation of Food Systems: A Paper on Action Track 1; Center for Development Research (ZEF) in cooperation with the Scientific Group for the UN Food System Summit: Bonn, Germany, 2021. [Google Scholar] [CrossRef]

- EC and DG for Agriculture and Rural Development. EU Agricultural Outlook for Markets and Income 2020–2030; Publications Office of the European Union: Luxembourg, 2020; Available online: https://data.europa.eu/doi/10.2762/252413 (accessed on 23 February 2022).

- OCDE. Agricultural Productivity and Innovation. 2011. Available online: https://www.oecd.org/agriculture/topics/agricultural-productivity-and-innovation/ (accessed on 23 February 2022).

- FAO. The Future of Food and Agriculture. 2017. Available online: https://www.fao.org/3/i6583e/I6583E.pdf (accessed on 23 February 2022).

- Verano, T.D.C.; Medina, G.D.S.; Oliveira, J.R.D. Can Family Farmers Thrive in Commodity Markets? Quantitative Evidence on the Heterogeneity in Long Agribusiness Supply Chains. Logistics 2022, 6, 17. [Google Scholar] [CrossRef]

- Kanchan, B.; Chandan, G.; Aslam, M. Implication of lean philosophies in signing supplier quality agreement: An empirical study. Mater. Today 2022, 60, 335–340. [Google Scholar] [CrossRef]

- Hao, Z.; Liu, C.; Goh, M. Determining the effects of lean production and servitization of manufacturing on sustainable performance. Sustain. Prod. Consum. 2021, 25, 374–389. [Google Scholar] [CrossRef]

- Verreydt, M.; Dewaelheyns, N.; Van, C. Time is money: An analysis of the time-to-failure in a flexible reorganization system. Financ. Res. Lett. 2022, 46, 102262. [Google Scholar] [CrossRef]

- Oliveira, C.P.S.D. Agricultura familiar e desertificação: Estudos de casos nos distritos de Braga e da Guarda. Master’s Thesis, University Institute of Lisbon, Lisbon, Portugal, September 2015. [Google Scholar]

- Woiceshyn, J.; Daellenbach, U. Evaluating inductive vs. deductive research in management studies: Implications for authors, editors, reviewers. Qual. Res. Organ. Manag. Int. J. 2018, 13, 183–195. [Google Scholar] [CrossRef]

- Liu, H. Digital Taylorism in China’s e-commerce industry: A case study of internet professionals. Econ. Ind. Democr. 2022, 0143831X211068887. [Google Scholar] [CrossRef]

- Liker, J. Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer; McGraw-Hill: New York, NY, USA, 2020. [Google Scholar]

- Glass, R.; Seifermann, S.; Metternich, J. The Spread of Lean Production in the Assembly, Process and Machining Industry. Procedia CIRP 2016, 55, 278–283. [Google Scholar] [CrossRef][Green Version]

- Tasdemir, C.; Gazo, R. A systematic literature review for better understanding of lean driven sustainability. Sustainability 2018, 10, 2544. [Google Scholar] [CrossRef]

- Krafcik, J.F. Triumph of the Lean Production. Sloan Manag. Rev. 1988, 30, 41–52. [Google Scholar]

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine That Changed the World: The Story of Lean Production-Toyota’s Secret Weapon in the Global Car Wars That is Now Revolutionizing World Industry; Rawson Associates: New York, NY, USA, 1990; pp. 17–70. [Google Scholar]

- Danese, P.; Manfè, V.; Romano, P. A systematic literature review on recent lean research: State-of-the-art and future directions. Int. J. Manag. Rev. 2018, 20, 579–605. [Google Scholar] [CrossRef]

- Womack, J.P.; Jones, D.T. Lean Thinking: Banish Waste and Create Wealth in Your Corporation; Simon and Schuster: London, UK, 1996. [Google Scholar]

- Fowler, C.; Steffen, E.; Mentz, C. Using Lean Principles as an Implementation Strategy within the EBP Process. J. PeriAnesthesia Nurs. 2022, 37, 137–142. [Google Scholar] [CrossRef] [PubMed]

- Pinto, P. Pensamento Lean—A Filosofia Das Organizações Vencedoras; Lidel Edições Técnicas: Lisbon, Portugal, 2009. [Google Scholar]

- Ohno, T. Toyota Production System: Beyond Large Scale Production; Productivity Press: New York, NY, USA, 1988; pp. 1–44. [Google Scholar]

- Cifone, F.D.; Hoberg, K.; Holweg, M.; Staudacher, A.P. Lean 4.0: How can digital technologies support lean practices? Int. J. Prod. Econ. 2021, 241, 108258. [Google Scholar] [CrossRef]

- Alieva, J.; Haartman, R. Digital Muda—The New Form of Waste by Industry 4.0. OSCM 2020, 13, 269–278. [Google Scholar] [CrossRef]

- Paladugu, B.; Grau, D. Toyota Production System-Monitoring Construction Work Progress with Lean Principles. Encycl. Renew. Sustain. Mater. 2020, 5, 560–565. [Google Scholar] [CrossRef]

- Pinto, C.M.; Mendonça, J.; Babo, L.; Silva, F.J.; Fernandes, J.L. Analyzing the Implementation of Lean Methodologies and Practices in the Portuguese Industry: A Survey. Sustainability 2022, 14, 1929. [Google Scholar] [CrossRef]

- Guzel, D.; Asiabi, A.S. Increasing Productivity of Furniture Factory with Lean Manufacturing Techniques (Case Study). Teh. Glas. 2022, 16, 82–92. [Google Scholar] [CrossRef]

- Somasundaram, R.; Sundharesalingam, P.; Priya, P.V.; Renuka, P. Effectiveness of implementation of 5S tool in food industry during COVID-19. In Proceedings of the 2021 4th National Conference on Current and Emerging Process Technologies, Erode, India, 20 February 2021. [Google Scholar]

- Willis, D. Process Implementation through 5S: Laying the Foundations for Lean; Productivity Press: New York, NY, USA, 2016. [Google Scholar]

- Visco, D. 5S Made Easy: A Step-by-Step Guide to Implementing and Sustaining Your 5S Program; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Jiménez, M.; Romero, L.; Fernández, J.; Espinosa, M.M.; Domínguez, M. Extension of the Lean 5S Methodology to 6S with An Additional Layer to Ensure Occupational Safety and Health Levels. Sustainability 2019, 11, 3827. [Google Scholar] [CrossRef]

- Castillo, C. The workers’ perspective: Emotional consequences during a lean manufacturing change based on VSM analysis. J. Manuf. Technol. Manag. 2022, 33, 19–39. [Google Scholar] [CrossRef]

- Zahoor, S.; Abdul-Kader, W.; Ijaz, H.; Khan, A.Q.; Saeed, Z.; Muzaffar, S. A Combined VSM and Kaizen Approach for Sustainable Continuous Process Improvement. Int. J. Ind. Eng. Oper. Manag. 2019, 1, 125–137. [Google Scholar] [CrossRef]

- Waldron, K. Handbook of Waste Management and Co-Product Recovery in Food Processing; Woodhead Publishing: Sawston, UK, 2009. [Google Scholar]

- Ikatrinasari, Z.F.; Kosasih, K.; Vizano, N.A. Value Stream Mapping (VSM) basic training to increase industrial productivity. In Proceedings of the 2019 International Conference on Community Development, Bandar Seri Begawan, Indonesia, 24–25 July 2019. [Google Scholar]

- Dias, A.C.; Reis, A.C.; Oliveira, R.P.; Maruyama, Ú.; Martinez, P. Lean Manufacturing in healthcare: A systematic review of literature. Rev. Prod. Desenvolv. 2018, 4, 111–122. [Google Scholar] [CrossRef]

- Otsuka, K.; Ben-Mazw, N. The impact of Kaizen: Assessing the intensive Kaizen training of auto-parts suppliers in South Africa. S. Afr. J. Econ. Manag. Sci. 2022, 25, 9. [Google Scholar] [CrossRef]

- Muñoz-Villamizar, A.; Santos, J.; Grau, P.; Viles, E. Trends and gaps for integrating lean and green management in the agri-food sector. Br. Food J. 2019, 121, 1140–1153. [Google Scholar] [CrossRef]

- Lopes, R.; Freitas, F.; Sousa, I. Application of Lean Manufacturing Tools in the Food and Beverage Industries. J. Technol. Manag. Innov. 2015, 10, 120–130. [Google Scholar] [CrossRef]

- Pearce, D.; Dora, M.; Wesana, J.; Gellynck, X. Toward sustainable primary production through the application of lean management in South African fruit horticulture. J. Clean. Prod. 2021, 313, 127815. [Google Scholar] [CrossRef]

- Solano, N.; Llinás, G.; Montoya-Torres, J. Towards the integration of lean principles and optimization for agricultural production systems: A conceptual review proposition. J. Sci. Food Agric. 2020, 100, 453–464. [Google Scholar] [CrossRef]

- Lehtinen, U.; Torkko, M. The Lean Concept in the Food Industry: A Case Study of Contract a Manufacturer. J. Food Distrib. Res. 2005, 36, 57–67. [Google Scholar] [CrossRef]

- Jiménez, E.; Tejeda, A.; Pérez, M.; Blanco, J.; Martínez, E. Applicability of lean production with VSM to the Rioja wine sector. Int. J. Prod. Res. 2012, 50, 1890–1904. [Google Scholar] [CrossRef]

- Dora, M.; Van Goubergen, D.; Kumar, M.; Molnar, A.; Gellynck, X. Application of lean practices in small and medium-sized food enterprises. Br. Food J. 2014, 116, 125–141. [Google Scholar] [CrossRef]

- Wesana, J.; Gellynck, X.; Dora, M.K.; Pearce, D.; De Steur, H. Measuring food losses in the supply chain through value stream mapping: A case study in the dairy sector. In Saving Food; Academic Press: Cambridge, MA, USA, 2019; pp. 249–277. [Google Scholar] [CrossRef]

- Hmidach, S.; El Kihel, Y.; Amegouz, D.; El Kihel, B.; Regad, Y. Optimizing warehouse logistics flows by integrating new technologies: Case study of an agri-food industry. In Proceedings of the IEEE 2nd International Conference on Electronics, Control, Optimization and Computer Science (ICECOCS), Kenitra, Morocco, 2–3 December 2020. [Google Scholar]

- Rojas-Benites, S.; Castro-Arroyo, A.; Viacava, G.; Aparicio, V.; del Carpio, C. Reduction of Waste in an SME in the Meat Sector in Peru through a Lean Manufacturing Approach Using a Model Based on 5S, Standardization, Demand Forecasting and Kanban. In Proceedings of the 7th International Conference on Industrial and Business Engineering, Macau, China, 27–29 September 2021. [Google Scholar]

- Farissi, A.; Oumami, M.; Beidouri, Z. Assessing Lean Adoption in Food Companies: The Case of Morocco. Int. J. Technol. 2021, 12, 5–14. [Google Scholar] [CrossRef]

- Ali, F.A. The role of lean manufacturing in adopting new products application study of a sample of employees of Alittihad Food Industries Co. Ltd. in babil governorate. World Bull. Manag. Law 2022, 8, 78–87. Available online: https://scholarexpress.net/index.php/wbml/article/view/679 (accessed on 22 May 2022).

- Ashraf, S.R.B.; Rashid, M.M.; Rashid, A.H. Implementation of 5S methodology in a food & beverage industry: A case study. Int. Res. J. Eng. Technol. 2017, 4, 1791–1796. Available online: https://www.researchgate.net/publication/315697643_Implementation_of_5S_Methodology_in_a_Food_Beverage_Industry_A_Case_Study (accessed on 19 May 2022).

- Rodrigues, C.; Gaspar, P.D.; Simões, M.P.; Silva, P.D.; Andrade, L.P. Review on techniques and treatments toward the mitigation of the chilling injury of peaches. J. Food Process. Preserv. 2020, e14358. [Google Scholar] [CrossRef]

- Gaspar, J.P.; Gaspar, P.D.; da Silva, P.D.; Simões, M.P.; Santo, C.E. Energy life-cycle assessment of fruit products-case study of Beira Interior’s Peach (Portugal). Sustainability 2018, 10, 3530. [Google Scholar] [CrossRef]

- Gaspar, P.D.; Silva, P.D.; Nunes, J.; Andrade, L.P. Characterization of the specific electrical energy consumption of agrifood industries in the central region of Portugal. Appl. Mech. Mater. 2014, 590, 878–882. [Google Scholar] [CrossRef]

- Gaspar, P.D.; Carrilho Gonçalves, L.C.; Pitarma, R.A. CFD parametric studies for global performance improvement of open refrigerated display cabinets. Model. Simul. Eng. 2012, 2012, 867820. [Google Scholar] [CrossRef]

- Nunes, J.; Silva, P.D.; Andrade, L.P.; Gaspar, P.D. Characterization of the specific energy consumption of electricity in the Portuguese sausage industry. WIT Trans. Ecol. Environ. 2014, 186, 763–774. [Google Scholar] [CrossRef]

- Pearce, D.; Dora, M.; Wesana, J.; Gellynck, X. Determining factors driving sustainable performance through the application of lean management practices in horticultural primary production. J. Clean. Prod. 2018, 203, 400–417. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).