Study on Dust Suppression of Air Curtain Soft-Sealing System of Grab Ship Unloader

Abstract

:1. Introduction

2. Numerical Simulation and Law Study of Gas–Solid Two-Phase Flow Field in Grab Unloading

2.1. Simulation Method

2.1.1. CFD-DEM Governing Equations

2.1.2. Fluid–Particle Interaction Forces

2.2. Simulation Modeling

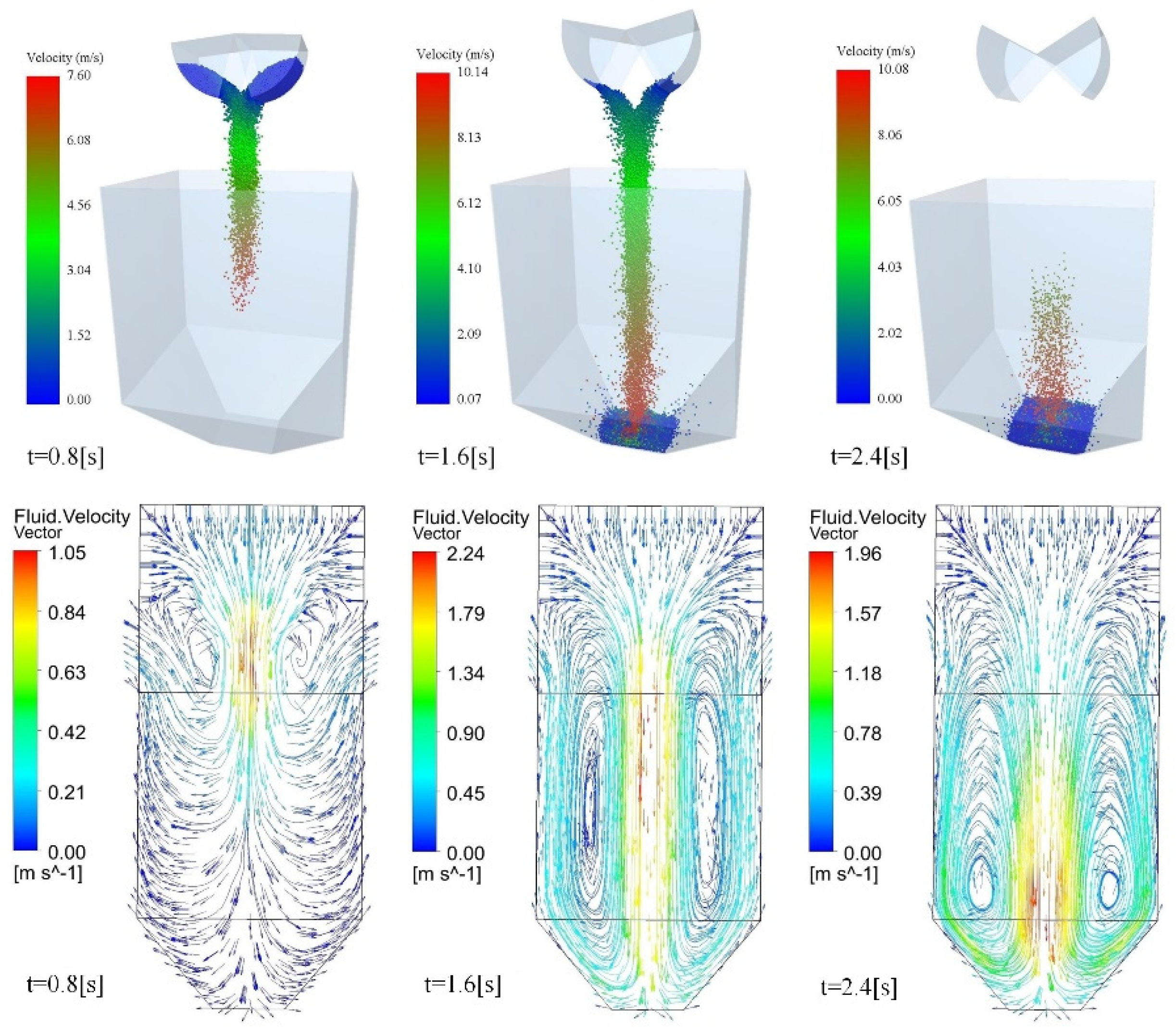

2.3. Motion Trajectory and Velocity Distribution of Particle Flow Field and Air Flow Field

2.4. Analysis of Air Flow Field in Five Planes above the Hopper

3. Numerical Simulation of Barrier Performance of Air Curtain

3.1. Simulation Modeling of Air Curtain and Air Flow Field

3.2. CFD Parameter Settings

3.3. Grid Independence Test

3.4. Design of Air Curtain Parameters

4. Experiment and Validation

5. Analysis and Discussion of Barrier Performance of Air Curtain

5.1. Distributions of Velocity Vectors and Diffusion Range of Pollutants

5.2. The Variation in the Mass Fraction of Pollutants in the Horizontal Direction

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Reed, W.R.; Zheng, Y.; Yekich, M. Laboratory testing of a shuttle car canopy air curtain for respirable coal mine dust control. Int. J. Coal Sci. Technol. 2018, 5, 10. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Sa, Z.; Cheng, W. Effects of forced-air volume and suction region on the migration and dust suppression of air curtain during fully mechanized tunneling process. Process. Saf. Environ. Prot. 2020, 145, 222–235. [Google Scholar] [CrossRef]

- Geng, F.; Gui, C.; Wang, Y.; Zhou, F.; Hu, S.; Luo, G. Dust distribution and control in a coal roadway driven by an air curtain system: A numerical study. Process. Saf. Environ. Prot. 2019, 121, 32–42. [Google Scholar] [CrossRef]

- Cai, P.; Nie, W.; Liu, Z. Study on the air curtain dust control technology with a dust purifying fan for fully mechanized mining face. Powder Technol. 2020, 374, 507–521. [Google Scholar] [CrossRef]

- Huang, X. Air Curtain Dust Removal Device Design and Dust Prevention Strategy in Heading Face. Adv. Civ. Eng. 2020, 2020, 8891599. [Google Scholar] [CrossRef]

- Wang, H.; Nie, W.; Cheng, W. Effects of air volume ratio parameters on air curtain dust suppression in a rock tunnel’s fully-mechanized working face. Adv. Powder Technol. 2017, 29, 230–244. [Google Scholar] [CrossRef]

- Li, X.; Jiang, Y.B.; Zhu, J.C. Air curtain dust-collecting technology: Investigation of industrial application in tobacco factory of the air curtain dust-collecting system. Process. Saf. Environ. Prot. 2021, 149, 676–683. [Google Scholar] [CrossRef]

- Xiao, D.; Li, X.; Yan, W.; Fang, Z. Experimental investigation and numerical simulation of small-volume transverse-flow air curtain performances. Powder Technol. 2019, 352, 262–272. [Google Scholar] [CrossRef]

- Yang, C.S.; An, S.Y.; Chang, W.L. Using air curtain to control pollutant spreading for emergency management in a cleanroom. Build. Environ. 2011, 46, 1104–1114. [Google Scholar]

- Zhao, F.Y.; Shen, G.; Liu, K.J. Room airborne pollutant separation by the use of air curtains in the large building enclosure: Infiltration efficiency and partial enclosure ventilation rate. J. Build. Eng. 2018, 18, 386–394. [Google Scholar] [CrossRef]

- Cao, Z.K.; Han, H.; Gu, B. A novel optimization strategy for the design of air curtains for open vertical refrigerated display cases. Appl. Therm. Eng. 2011, 31, 3098–3105. [Google Scholar] [CrossRef]

- Wang, H.; Qian, H.; Zhou, R. A novel circulated air curtain system to confine the transmission of exhaled contaminants: A numerical and experimental investigation. Build. Simul. 2020, 13, 1425–1437. [Google Scholar] [CrossRef] [PubMed]

- Shu, C.; Wang, L.L.; Zhang, C. Air curtain effectiveness rating based on aerodynamics. Build. Environ. 2020, 169, 106582. [Google Scholar] [CrossRef]

- Yang, S.; Alrawashdehm, H.; Zhang, C. Wind effects on air curtain performance at building entrances. Build. Environ. 2019, 151, 75–87. [Google Scholar] [CrossRef]

- Zhang, H.Z.; Meng, W.J.; Wang, B.B. Research on Gas-solid Two-phase Flow Field Based on CFD-DEM Coupling Simulation in Grab Unloading. Min. Res. Dev. 2022, 42, 166–172. [Google Scholar]

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| Particle diameter (mm) | 5, 10, 30 | Geometric shear modulus (Pa) | 7.9 × 1010 |

| Total mass of particles (kg) | 220 | Particle–particle restitution coefficient | 0.5 |

| Particle Poisson ratio | 0.4 | Particle–particle static friction coefficient | 0.6 |

| Particle density (kg/m3) | 1023 | Particle–particle rolling friction coefficient | 0.04 |

| Particle shear modulus (Pa) | 1.1 × 107 | Particle–geometry restitution coefficient | 0.5 |

| Geometric Poisson ratio | 0.3 | Particle–geometry static friction coefficient | 0.4 |

| Geometric density (kg/m3) | 7850 | Particle–geometry rolling friction coefficient | 0.05 |

| Description | Model |

|---|---|

| Solver | Pressure-based |

| Viscous model | Standard k-epsilon |

| Inlet | Pressure inlet (gauge pressure = 0) |

| Outlet | Pressure outlet (gauge pressure = 0) |

| Wall | Stationary wall (no slip) |

| Scenario | Case | Air curtain Jet Mode | Jet Width (mm) | Jet Velocity(m/s) | Induced Wind Velocity(m/s) |

|---|---|---|---|---|---|

| 1 | blow and suction | 20 | 5 | 0.8 | |

| 1 | 2 | blow and suction | 10 | 5 | 0.8 |

| 3 | blow and suction | 40 | 5 | 0.8 | |

| 1 | blow and suction | 20 | 5 | 0.8 | |

| 2 | 4 | unilateral blowing | 20 | 5 | 0.8 |

| 5 | bilateral blowing | 20 | 2.5 | 0.8 | |

| 1 | blow and suction | 20 | 5 | 0.8 | |

| 3 | 6 | blow and suction | 20 | 3.5 | 0.8 |

| 7 | blow and suction | 20 | 6.5 | 0.8 | |

| 1 | blow and suction | 20 | 5 | 0.8 | |

| 4 | 8 | blow and suction | 20 | 5 | 1.1 |

| 9 | blow and suction | 20 | 5 | 0.5 |

| Case | The Average Mass Fraction of Pollutants outside the Air Curtain | Compared with the Non-Air Curtain Jet, the Average Mass Fraction of Pollutants outside the Air Curtain Decreased (%) |

|---|---|---|

| 1 | 0.006604 | 70.02 |

| 2 | 0.019007 | 13.71 |

| 3 | 0.016662 | 24.36 |

| 4 | 0.009459 | 57.06 |

| 5 | 0.014355 | 34.83 |

| 6 | 0.018330 | 16.78 |

| 7 | 0.014507 | 34.14 |

| 8 | 0.005719 | 74.03 |

| 9 | 0.012605 | 42.78 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Meng, W. Study on Dust Suppression of Air Curtain Soft-Sealing System of Grab Ship Unloader. Processes 2022, 10, 1505. https://doi.org/10.3390/pr10081505

Zhang H, Meng W. Study on Dust Suppression of Air Curtain Soft-Sealing System of Grab Ship Unloader. Processes. 2022; 10(8):1505. https://doi.org/10.3390/pr10081505

Chicago/Turabian StyleZhang, Hanzhong, and Wenjun Meng. 2022. "Study on Dust Suppression of Air Curtain Soft-Sealing System of Grab Ship Unloader" Processes 10, no. 8: 1505. https://doi.org/10.3390/pr10081505

APA StyleZhang, H., & Meng, W. (2022). Study on Dust Suppression of Air Curtain Soft-Sealing System of Grab Ship Unloader. Processes, 10(8), 1505. https://doi.org/10.3390/pr10081505