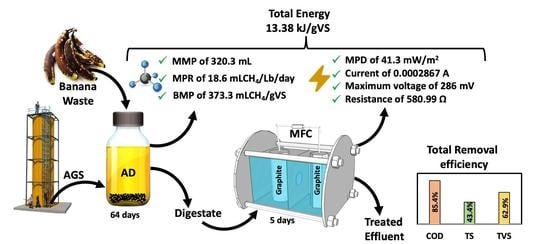

Banana Waste-to-Energy Valorization by Microbial Fuel Cell Coupled with Anaerobic Digestion

Abstract

:1. Introduction

2. Materials and Methods

2.1. Banana Waste (BW)

2.2. Anaerobic Granular Sludge (AGS)

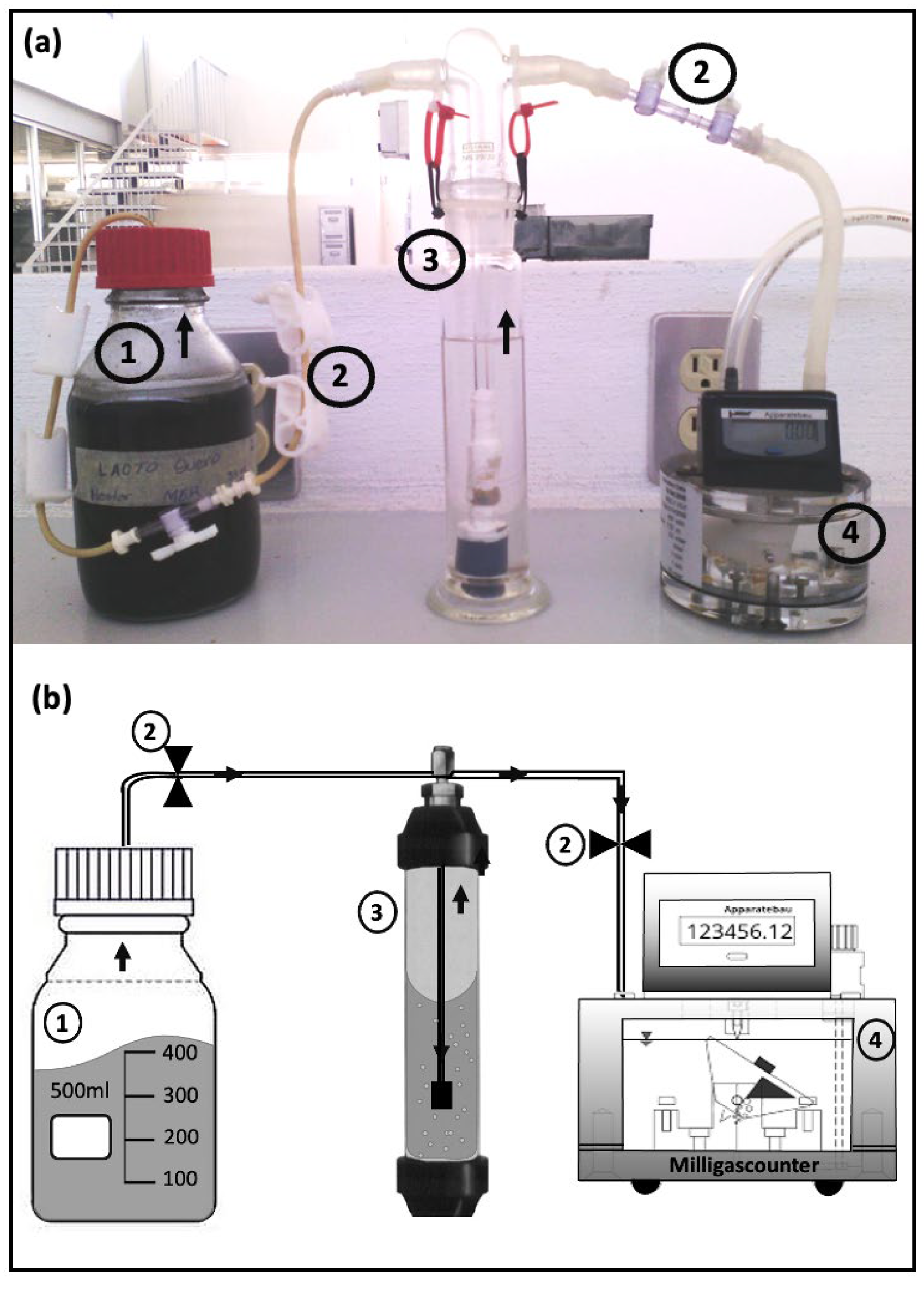

2.3. Anaerobic Digestion (AD) Process

2.4. Microbial Fuel Cell (MFC)

2.5. Analysis Methods

2.5.1. Characteristics Analysis

2.5.2. Methane Analysis

2.5.3. Bioelectricity Analysis

2.5.4. Organic Matter Removal Efficiency and Power Generation

2.6. Statistical Methods

3. Results and Discussion

3.1. Physicochemical Characterization

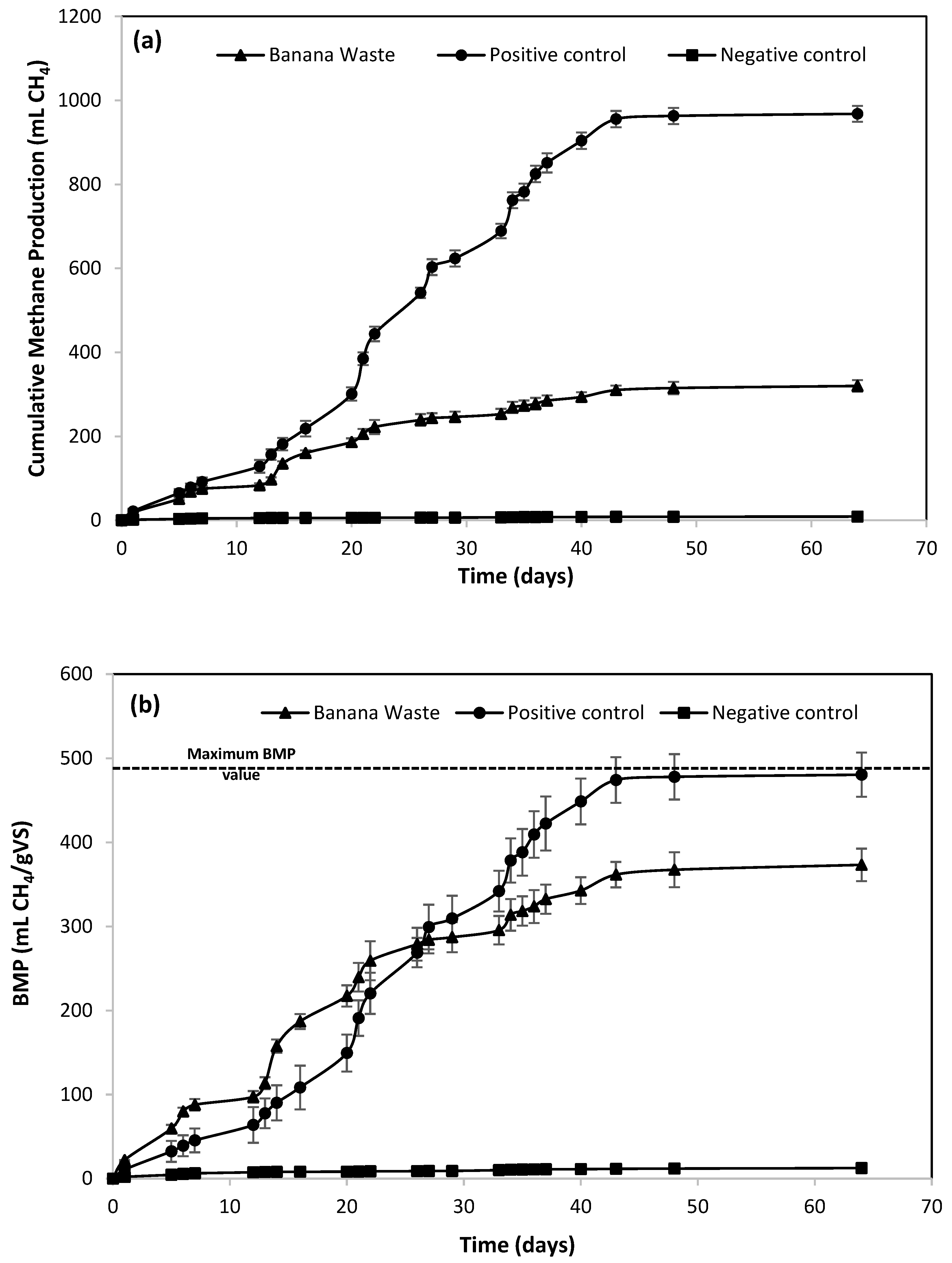

3.2. Anaerobic Digestion

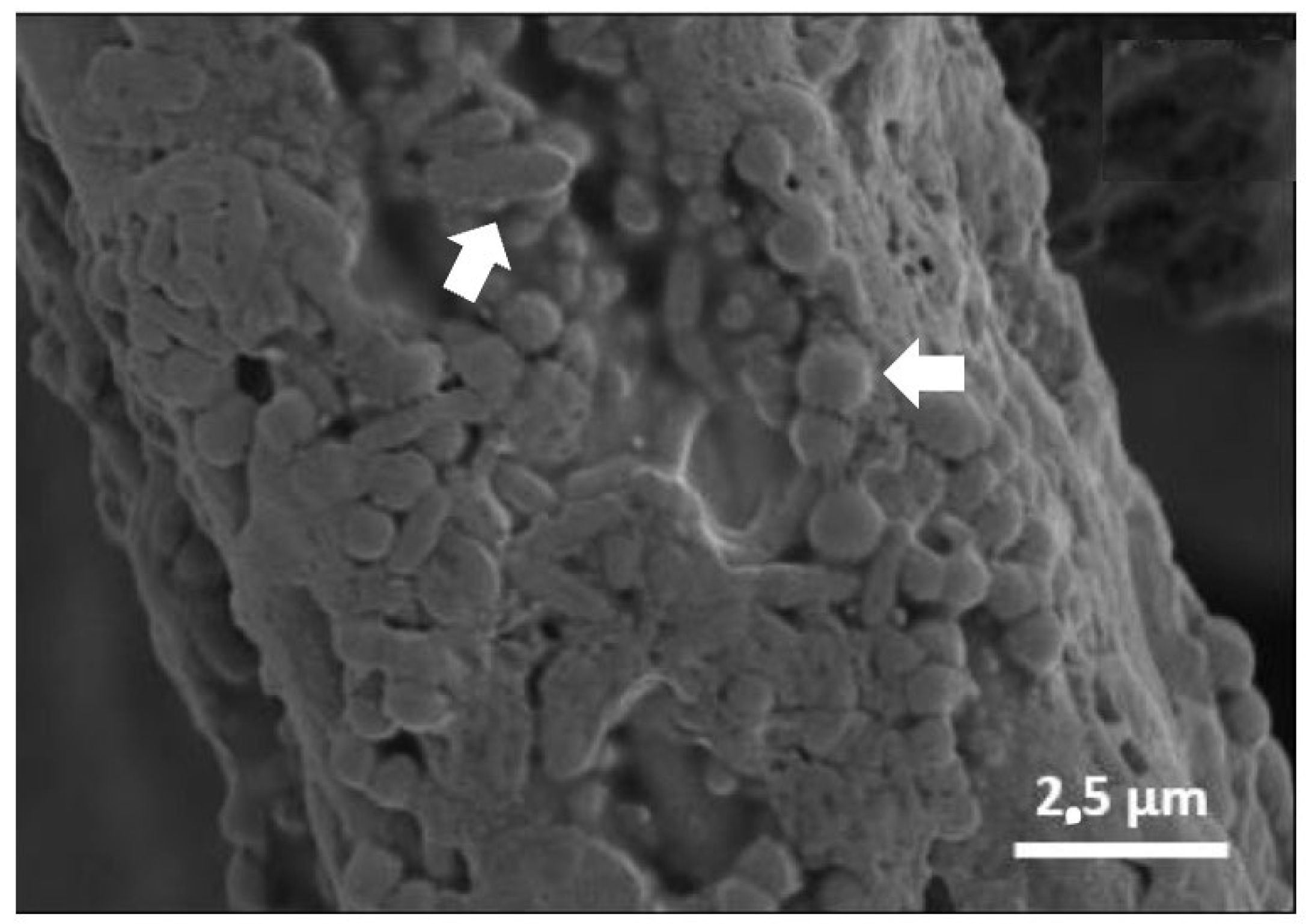

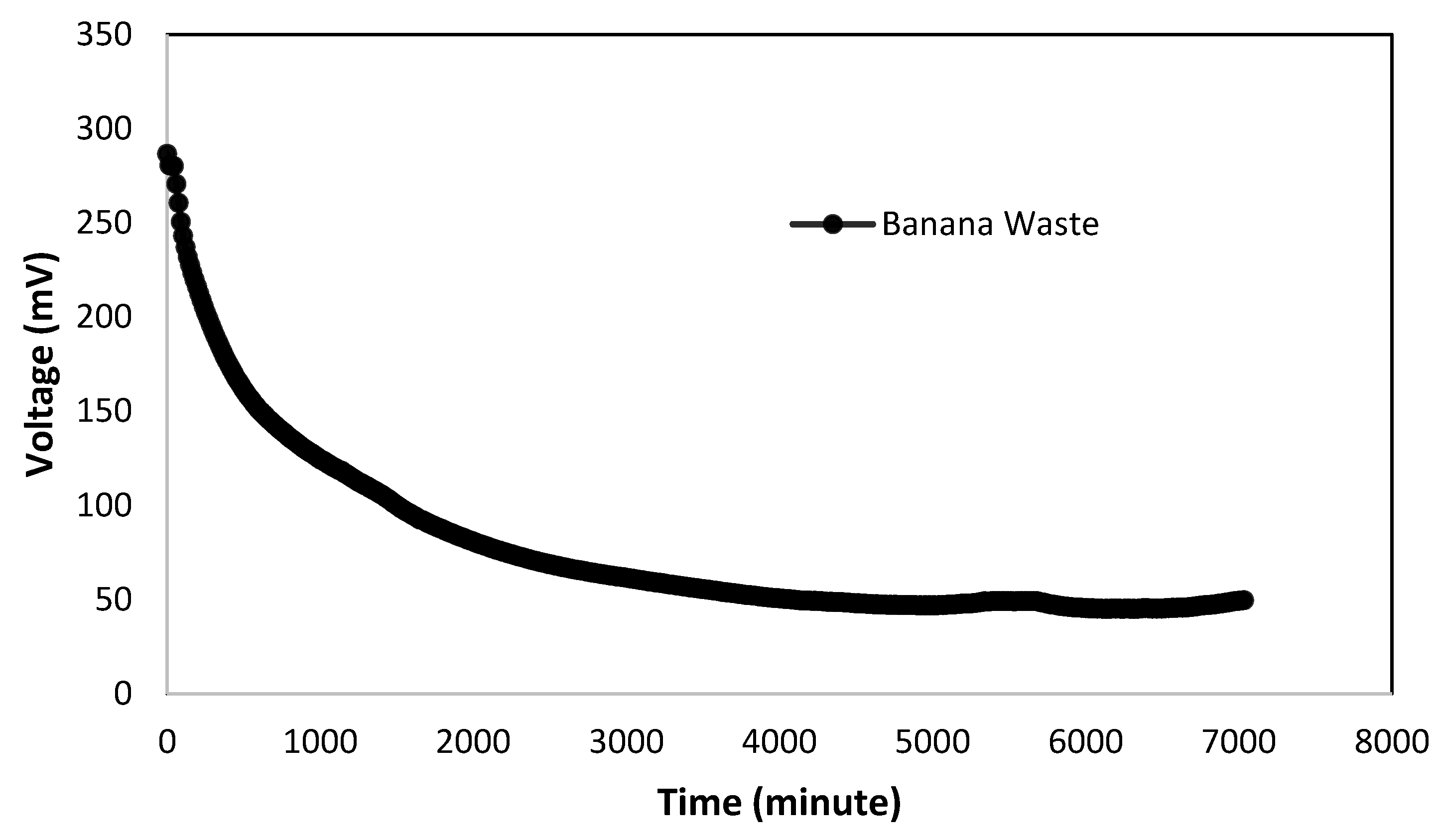

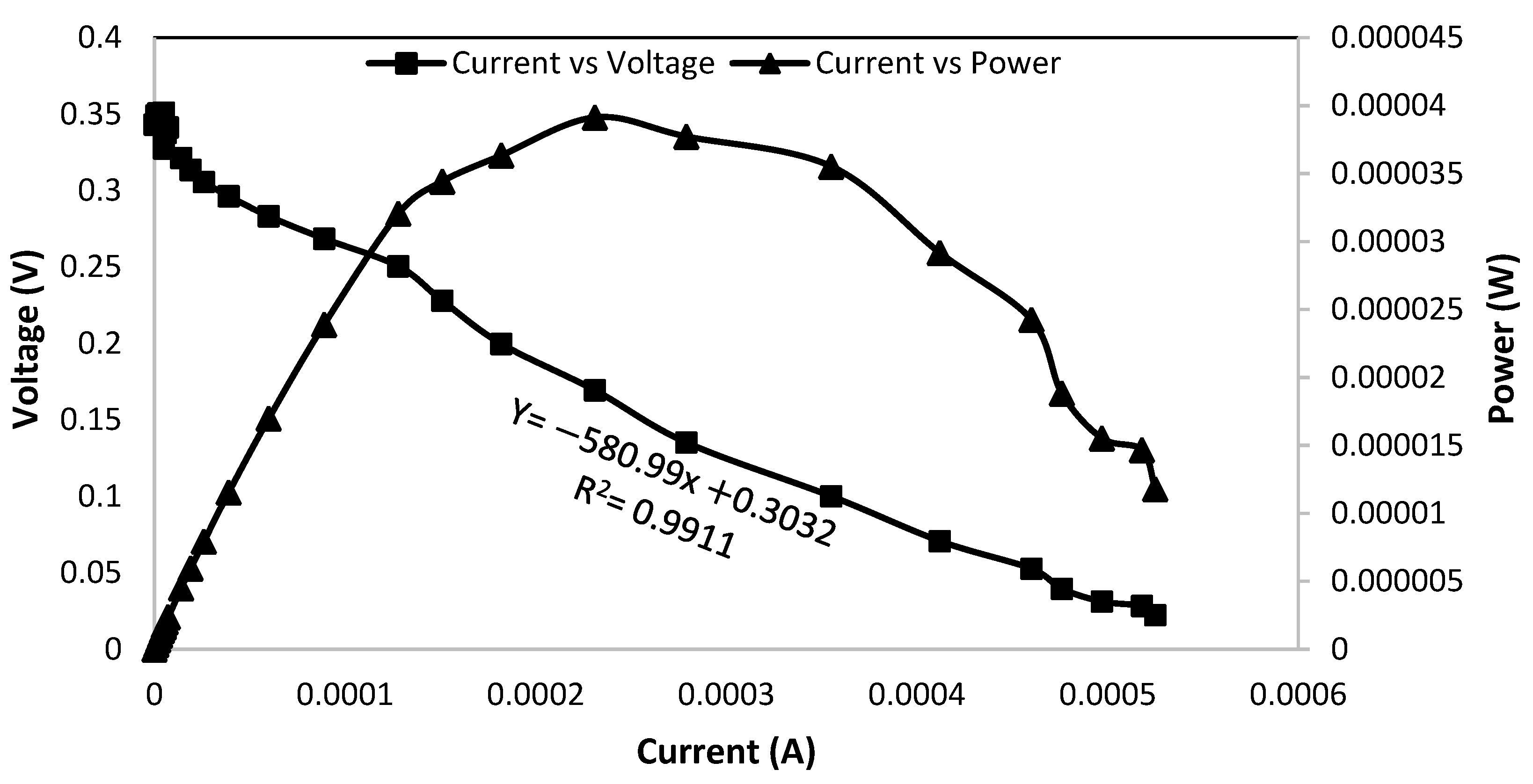

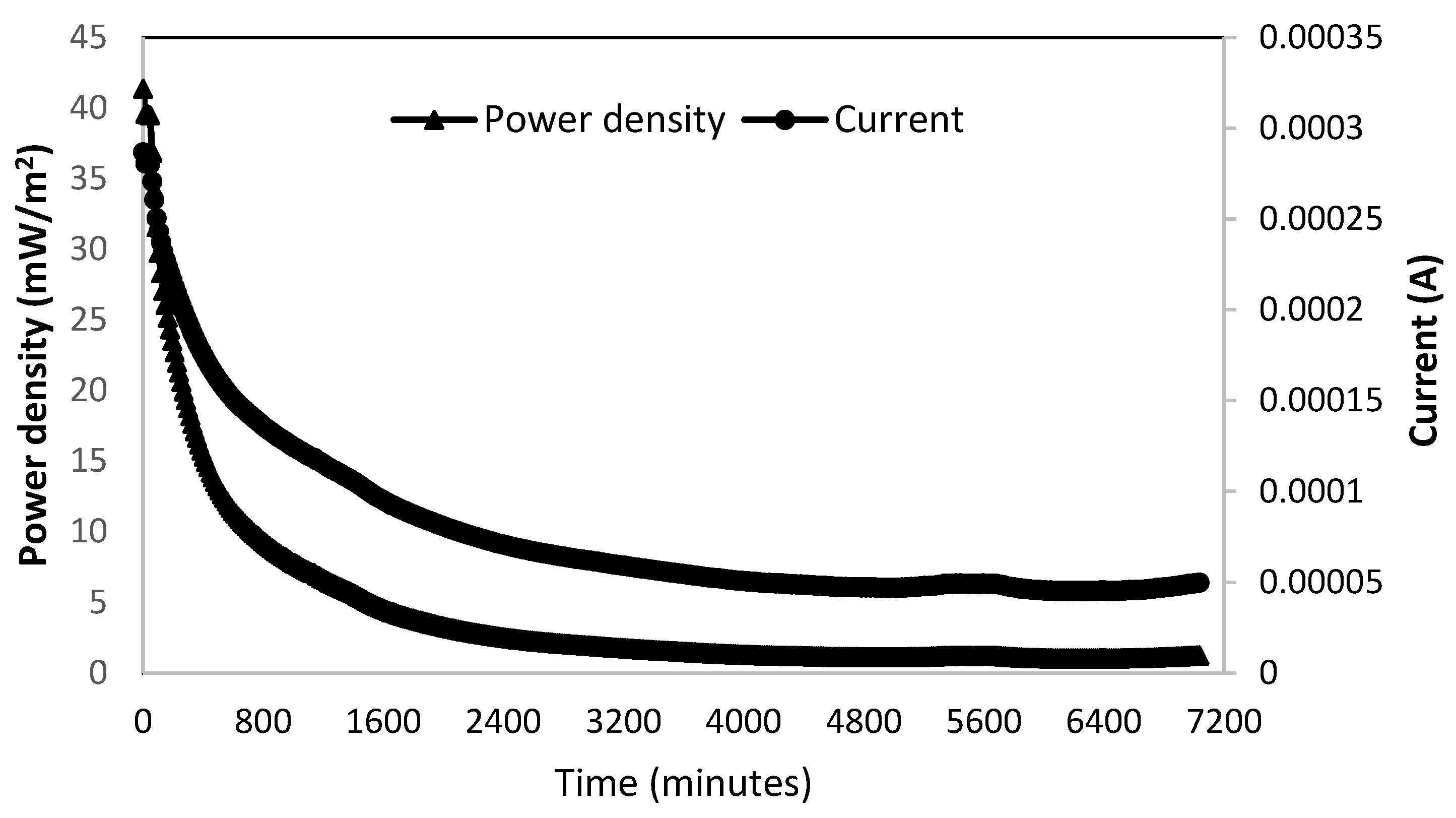

3.3. Microbial Fuel Cell

4. Conclusions

5. Statement of Novelty

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ΔH | Change in Enthalpy |

| % | Percentage sign |

| A | Area |

| AD | Anaerobic digestion |

| AGS | Anaerobic granular sludge |

| BMP | Biochemical methane potential |

| BW | Banana waste |

| Ceff | Effluent concentration |

| Cinf | Influent concentration |

| CH4 | Methane |

| CO2 | Carbon dioxide |

| COD | Chemical oxygen demand |

| E | Removal efficiency |

| E1 | Removal efficiency by AD |

| E2 | Removal efficiency by MFC |

| EDTA | Ethylenediaminetetraacetic acid |

| EET | Extracellular electron transfer |

| ET | Total removal efficiency |

| g/L | Grams per liter |

| gCOD | Grams of chemical oxygen demand |

| gCOD/gVSS | Grams of chemical oxygen demand per gram of volatile suspended solids |

| gTVS | Grams of total volatile solids |

| gVSS | Grams of volatile suspended solids |

| H2O | Water |

| I | Current |

| kg/year | Kilogram per year |

| kJ | Kilojoule |

| kJ/gCOD | Kilojoule per gram of chemical oxygen demand |

| kWh/year | Kilowatt-hour per year |

| Lb | Liters of bioreactor (bioreactor volume) |

| m2 | Square meter |

| MFC | Microbial fuel cell |

| mL | Milliliter |

| mLCH4/gCOD | Milliliters of methane per gram of chemical oxygen demand |

| mm | Millimeter |

| MMP | Maximum methane production |

| MPR | Methane production rate |

| mW | Milliwatts |

| mW/m2 | Milliwatts per square meter |

| OM | Organic matter |

| O2 | Molecular oxygen |

| °C | Degrees Celsius |

| P | Power |

| PD | Power density |

| pH | Potential of hydrogen |

| POSW | Putrescible organic solid waste |

| SMA | Specific methanogenic activity |

| ton | Tonne |

| ton/year | Tonne per year |

| TS | Total solids |

| TVS | Total volatile solids |

| TVS/TS ratio | Total volatile solids to total solids ratio |

| UASB | Upflow Anaerobic Sludge Blanket |

| USW | Urban solid waste |

| V | Voltage |

| VSS | Volatile suspended solids |

| W | Watts |

| W⋅s | Watts per second |

| WWTP | Wastewater treatment plant |

| Ω | Ohm |

References

- IEA—International Energy Agency. IEA. Available online: https://www.iea.org (accessed on 1 May 2022).

- Edenhofer, O.; Pichs-Madruga, R.; Sokona, Y. Fuentes de Energía Renovables y Mitigación del Cambio Climático. Informe Especial del Grupo Intergubernamental de Expertos Sobre el Cambio Climático. 242. 2011. Available online: https://archive.ipcc.ch/pdf/special-reports/srren/srren_report_es.pdf (accessed on 1 May 2022).

- Hegerl, G.C.; Brönnimann, S.; Schurer, A.; Cowan, T. The early 20th century warming: Anomalies, causes, and consequences. Wiley Interdiscip Rev. Clim. Change 2018, 9, e522. [Google Scholar] [CrossRef] [Green Version]

- World Bank Publications. Atlas of Global Development: A Visual Guide to the World’s Greatest Challenges, 4th ed.; World Bank Publications: Washington, DC, USA, 2013. [Google Scholar]

- Robles, C.; Rodriguez, O. Un panorama de las energías renovables en el Mundo, Latinoamérica y Colombia. Revista ESPACIOS 2018, 39, 10. Available online: https://www.revistaespacios.com/a18v39n34/18393410.html (accessed on 1 May 2022).

- Barba, F.J. An integrated approach for the valorization of cheese whey. Foods 2021, 10, 564. [Google Scholar] [CrossRef] [PubMed]

- Food and Agriculture Organization of the United Nations. World Food and Agriculture—Statistical Pocketbook; Food and Agriculture Organization, Ed.; Food & Agriculture Organization of the United Nations (FAO): Rome, Italy, 2021. [Google Scholar]

- Subagyo, A.; Chafidz, A. Banana Pseudo-Stem Fiber: Preparation, Characteristics, and Applications. In Banana Nutrition—Function and Processing Kinetics; IntechOpen: London, UK, 2020. [Google Scholar]

- López, R.; Quinto, P.; Aguilar, H.; Garibay, C. Evaluación de la Producción de Biogás a Partir de Residuos Orgánicos Putrescibles en la Ciudad de México. Revista de la Facultad de Ciencias Químicas (10). 2014. Available online: https://publicaciones.ucuenca.edu.ec/ojs/index.php/quimica/article/view/347/294 (accessed on 1 May 2022).

- SEMARNAT. Diagnóstico Básico para la Gestión Integral de los Residuos. 2020. Available online: https://www.gob.mx/cms/uploads/attachment/file/554385/DBGIR-15-mayo-2020.pdf (accessed on 2 May 2022).

- Achinas, S.; Krooneman, J.; Euverink, G.J.W. Enhanced biogas production from the anaerobic batch treatment of banana peels. Engineering 2020, 5, 970–978. [Google Scholar] [CrossRef]

- Martínez-Ruano, J.A.; Caballero-Galván, A.S.; Restrepo-Serna, D.L.; Cardona, C.A. Techno-economic and environmental assessment of biogas production from banana peel (Musa paradisiaca) in a biorefinery concept. Environ. Sci. Pollut. Res. Int. 2018, 25, 35971–35980. [Google Scholar] [CrossRef]

- Yang, Y.; Lin, E.; Sun, S.; Chen, H.; Chow, A.T. Direct electricity production from subaqueous wetland sediments and banana peels using membrane-less microbial fuel cells. Ind. Crops. Prod. 2019, 128, 70–79. [Google Scholar] [CrossRef]

- López Dávila, E.; Jiménez Hernández, J.; Romero Romero, O.; Dewulf, J. Aplicación de la Tecnología de Digestión Anaerobia para tratar Residuos Sólidos Agroindustriales Utilizando Inóculo de Estiércol Porcino, en Condiciones Mesofílicas. Tecnol. Quím 2022, 32, 274–281. Available online: http://scielo.sld.cu/scielo.php?script=sci_arttext&pid=S2224-61852012000300011 (accessed on 3 May 2022).

- Ali, A.; Keerio, H.A.; Panhwar, S.; Ahad, M.Z. Experimental Investigation of Methane Generation in the Presence of Surface and Un-Surface Nanoparticles of Iron Oxide. AgriEngineering 2022, 4, 134–140. [Google Scholar] [CrossRef]

- Cruz-Salomón, A.; Cruz-Salomón, E.; Pola-Albores, F.; Lagunas-Rivera, S.; Cruz-Rodríguez, R.I.; Cruz-Salomón, K.D.C.; Hernández-Méndez, J.M.E.; Domínguez-Espinosa, M.E.; Rios, E. Treatment of Cheese Whey Wastewater Using an Expanded Granular Sludge Bed (EGSB) Bioreactor with Biomethane Production. Processes 2020, 8, 931. [Google Scholar] [CrossRef]

- Chanakya, H.; Sharma, I.; Ramachandra, T. Micro-scale anaerobic digestion of point source components of organic fraction of municipal solid waste. Waste Manag. 2009, 29, 1306–1312. [Google Scholar] [CrossRef]

- Zhang, C.; Li, J.; Liu, C.; Liu, X.; Wang, J.; Li, S.; Fan, G.; Zhang, L. Alkaline pretreatment for enhancement of biogas production from banana stem and swine manure by anaerobic codigestion. Bioresour. Technol. 2013, 149, 353–358. [Google Scholar] [CrossRef] [PubMed]

- Zheng, W.; Phoungthong, K.; Lü, F.; Shao, L.-M.; He, P.-J. Evaluation of a classification method for biodegradable solid wastes using anaerobic degradation parameters. Waste Manag. 2013, 33, 2632–2640. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kamdem, I.; Hiligsmann, S.; Vanderghem, C.; Bilik, I.; Paquot, M.; Thonart, P. Comparative biochemical analysis during the anaerobic digestion of lignocellulosic biomass from six morphological parts of Williams Cavendish banana (Triploid Musa AAA group) plants. World J. Microbiol. Biotechnol. 2013, 29, 2259–2270. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nathoa, C.; Sirisukpoca, U.; Pisutpaisal, N. Production of Hydrogen and Methane from Banana Peel by Two Phase Anaerobic Fermentation. Energy Procedia 2014, 50, 702–710. [Google Scholar] [CrossRef] [Green Version]

- Wobiwo, F.A.; Emaga, T.H.; Fokou, E.; Boda, M.; Gillet, S.; Deleu, M.; Richel, A.; Gerin, P.A. Comparative biochemical methane potential of some varieties of residual banana biomass and renewable energy potential. Biomass Convers. Biorefinery 2017, 7, 167–177. [Google Scholar] [CrossRef]

- Joute, Y. Semi-continuous anaerobic co-digestion of cow manure and banana waste: Effects of mixture ratio. Appl. Ecol. Environ. Res. 2016, 14, 337–349. [Google Scholar] [CrossRef]

- Wobiwo, F.A.; Alleluya, V.K.; Emaga, T.H.; Boda, M.; Fokou, E.; Gillet, S.; Deleu, M.; Gerin, P.A. Recovery of fibers and biomethane from banana peduncles biomass through anaerobic digestion. Energy Sustain. Dev. 2017, 37, 60–65. [Google Scholar] [CrossRef]

- Jena, S.P.; Mohanty, U.K.; Mahapatra, S. Anaerobic digestion of semi-dried banana leaves in sewage water under the influence of certain additives. Mater. Today: Proc. 2020, 33, 4988–4992. [Google Scholar] [CrossRef]

- Revelo, D.M.; Hurtado, N.H.; Ruiz, J.O. Celdas de Combustible Microbianas (CCMs): Un Reto para la Remoción de Materia Orgánica y la Generación de Energía Eléctrica. CIT Inform. Tecnol. 2013, 24, 7–8. Available online: https://www.scielo.cl/scielo.php?script=sci_arttext&pid=S0718-07642013000600004&lng=en&nrm=iso&tlng=en (accessed on 3 May 2022). [CrossRef]

- Lopez-Alejo, J.E.; Elizalde-Martínez, I. Variables affecting the performance of microbial cell for energy production coupled to an anaerobic digester: An overview. Int. J. Technol. Res. Innov. 2021, 8, 48. [Google Scholar]

- Rabaey, K. Bioelectrochemical systems: A New Approach towards Environmental and Industrial Biotechnology. In Bioelectrochemical Systems: From Extracellular Electron Transfer to Biotechnological Application; IWA Publishing: London, UK, 2009; pp. 1–16. [Google Scholar]

- Aguilar-González, M.; Buitrón, G.; Shimada-Miyasaka, A.; Mora-Izaguirre, O. Estado actual de los sistemas bioelectroquímicos: Factibilidad de su uso para aumentar la producción ruminal de propionato. Agrociencia 1996, 50, 149–166. Available online: http://www.scielo.org.mx/scielo.php?pid=S1405-31952016000200149&script=sci_abstract&tlng=es (accessed on 7 May 2022).

- Makhtar, M.M.Z.; Tajarudin, H.A. Electricity generation using membrane-less microbial fuel cell powered by sludge supplemented with lignocellulosic waste. Int. J. Energy Res. 2020, 44, 3260–3265. [Google Scholar] [CrossRef]

- Abdallah, Y.K.; Estevez, A.T.; Tantawy, D.E.D.M.; Ibraheem, A.M.; Khalil, N.M. Employing Laccase-Producing Aspergillus sydowii NYKA 510 as a Cathodic Biocatalyst in Self-Sufficient Lighting Microbial Fuel Cell. J. Microbiol. Biotechnol. 2019, 29, 1861–1872. [Google Scholar] [CrossRef] [PubMed]

- Rincón-Catalán, N.I.; Pérez-Fabiel, S.; Mejía-González, G.; Herrera-López, D.; Castro-Chan, R.; Cruz-Salomón, A.; Sebastian, P.J. Power Generation from Cheese Whey Treatment by Anaerobic Digestion and Microbial Fuel Cell. Waste Biomass Valorization 2022, 13, 3221–3231. [Google Scholar] [CrossRef]

- Domínguez-Espinosa, M.E.; Fuentes-Ruíz, A.; Arreola-González, A.; Jaime-Ornelas, T.D.J.; Morales-Ovando, M.A.; Hernández-Méndez, J.M.E.; Hernández-Cruz, M.D.C.; Cruz-Rodríguez, R.I.; Romero-Cortés, T.; Tirado-Gallegos, J.M.; et al. Edible coating based on banana starch and chitosan for postharvest conservation of guava. J. Food Process. Preserv. 2022, 46, e16154. [Google Scholar] [CrossRef]

- Rincón-Catalán, N.I. Power Generation from the Treatment of Banana Waste and Cheese Whey, Using Anaerobic Digestion and Microbial Fuel Cells. Master’s Thesis, Universidad Politécnica de Chiapas, Chiapas, Mexico, 2017. [Google Scholar]

- APHA. Standard Methods for the Examination of Water & Wastewater: Contennial Edition, 21st ed.; American Public Health Association: Washington, DC, USA, 2005. [Google Scholar]

- Association of Official Analytical Chemists (AOAC). Official Methods of Analysis, 21st ed.; International: Rockville, MD, USA, 2019; Available online: https://www.aoac.org/official-methods-of-analysis-21st-edition-2019/ (accessed on 5 May 2022).

- Salomón, A.C.; Meza-Gordillo, R.; Rosales-Quintero, A.; Ventura-Canseco, C.; Lagunas-Rivera, S.; Carrasco-Cervantes, J. Biogas production from a native beverage vinasse using a modified UASB bioreactor. Fuel 2017, 198, 170–174. [Google Scholar] [CrossRef]

- Vaquerizo, F.R.; Cruz-Salomon, A.; Valdovinos, E.R.; Albores, F.P.; Rivera, S.L.; Gordillo, R.M.; Valdiviezo, V.M.R.; Champo, R.S.; Acosta, J.M. Anaerobic Treatment of Vinasse from Sugarcane Ethanol Production in Expanded Granular Sludge Bed Bioreactor. J. Chem. Eng. Process. Technol. 2017, 9, 375. [Google Scholar] [CrossRef]

- Cruz-Salomón, A.; Ríos-Valdovinos, E.; Pola-Albores, F.; Lagunas-Rivera, S.; Meza-Gordillo, R.; Ruíz-Valdiviezo, V.M. Evaluation of Hydraulic Retention Time on Treatment of Coffee Processing Wastewater (CPWW) in EGSB Bioreactor. Sustainability 2018, 10, 83. [Google Scholar] [CrossRef] [Green Version]

- Bermúdez-Caraballoso, I.; Orellana, P.; García, L.; Veitía, N.; Padrón, Y.; Romero, C. Physic-Chemical characterization of mature fruit of three mutants of FHIA-21 (Musa AAAB). Biotecnol. Veg. 2009, 9, 4. Available online: https://revista.ibp.co.cu/index.php/BV/article/view/328 (accessed on 7 May 2022).

- Etienne, A.; Génard, M.; Bancel, D.; Benoit, S.; Bugaud, C. A model approach revealed the relationship between banana pulp acidity and composition during growth and post harvest ripening. Sci. Hortic. 2013, 162, 125–134. [Google Scholar] [CrossRef]

- Balat, M.; Balat, H. Biogas as a Renewable Energy Source—A Review. Energy Sources Part A Recover. Util. Environ. Eff. 2009, 31, 1280–1293. [Google Scholar] [CrossRef]

- Kalia, V.; Sonakya, V.; Raizada, N. Anaerobic digestion of banana stem waste. Bioresour. Technol. 2000, 73, 191–193. [Google Scholar] [CrossRef]

- González-Sánchez, M.E.; Pérez-Fabiel, S.; Wong-Villarreal, A.; Bello-Mendoza, R.; Yañez-Ocampo, G. Residuos agroindustriales con potencial para la producción de metano mediante la digestión anaerobia. Rev. Argent. De Microbiol. 2015, 47, 229–235. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Angelidaki, I.; Alves, M.M.; Bolzonella, D.; Borzacconi, L.; Campos, J.L.; Guwy, A.J.; Kalyuzhnyi, S.; Jenicek, P.; Van Lier, J.B. Defining the biomethane potential (BMP) of solid organic wastes and energy crops: A proposed protocol for batch assays. Water Sci. Technol. 2009, 59, 927–934. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cazier, E.A.; Trably, E.; Steyer, J.P.; Escudie, R. Biomass hydrolysis inhibition at high hydrogen partial pressure in solid-state anaerobic digestion. Bioresour Technol. 2015, 190, 106–113. [Google Scholar] [CrossRef] [Green Version]

- Prabhudessai, V.; Ganguly, A.; Mutnuri, S. Biochemical Methane Potential of Agro Wastes. J. Energy 2013, 2013, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Odedina, M.J.; Charnnok, B.; Saritpongteeraka, K.; Chaiprapat, S. Effects of size and thermophilic pre-hydrolysis of banana peel during anaerobic digestion, and biomethanation potential of key tropical fruit wastes. Waste Manag. 2017, 68, 128–138. [Google Scholar] [CrossRef]

- Tock, J.Y.; Lai, C.L.; Lee, K.T.; Tan, K.T.; Bhatia, S. Banana biomass as potential renewable energy resource: A Malaysian case study. Renew. Sustain. Energy Rev. 2010, 14, 798–805. [Google Scholar] [CrossRef]

- Moqsud, M.; Yoshitake, J.; Bushra, Q.; Hyodo, M.; Omine, K.; Strik, D. Compost in plant microbial fuel cell for bioelectricity generation. Waste Manag. 2015, 36, 63–69. [Google Scholar] [CrossRef]

- Logan, B.E.; Hamelers, B.; Rozendal, R.; Schröder, U.; Keller, J.; Freguia, S.; Aelterman, P.; Verstraete, W.; Rabaey, K. Microbial Fuel Cells: Methodology and Technology. Environ. Sci. Technol. 2006, 40, 5181–5192. [Google Scholar] [CrossRef]

- Ringeisen, B.R.; Henderson, E.; Wu, P.K.; Pietron, J.; Ray, R.; Little, B.; Biffinger, J.C.; Jones-Meehan, J.M. High Power Density from a Miniature Microbial Fuel Cell Using Shewanella oneidensis DSP10. Environ. Sci. Technol. 2006, 40, 2629–2634. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Min, B.; Cheng, S.; Logan, B.E. Electricity generation using membrane and salt bridge microbial fuel cells. Water Res. 2005, 39, 1675–1686. [Google Scholar] [CrossRef] [PubMed]

- Oh, S.; Min, B.; Logan, B.E. Cathode Performance as a Factor in Electricity Generation in Microbial Fuel Cells. Environ. Sci. Technol. 2004, 38, 4900–4904. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.; Feng, Y.; Teng, Q.; Li, H. Effect of Inorganic Salt in the Culture on Microbial Fuel Cells Performance. Int. J. Electrochem. Sci. 2015, 10, 1316–1325. Available online: http://www.electrochemsci.org/papers/vol10/100201316.pdf (accessed on 7 May 2022).

| Parameter | BW |

|---|---|

| Density (g/mL) | 0.997 ± 0.09 |

| pH | 4.5 ± 0.10 |

| COD (g/L) | 147.7 ± 0.50 |

| TS (g/L) | 102.5 ± 2 |

| TVS (g/L) | 95.3 ± 3 |

| TVS/TS ratio | 0.93 ± 0.03 |

| Moisture (%) | 89.75 ± 0.2 |

| Inorganic matter (%) | 6.9 ± 2.9 |

| Organic matter (%) | 93 ± 2.9 |

| BW | Time | BMP | Biodegradability | Ref. |

|---|---|---|---|---|

| (Days) | (mLCH4/gVS) | (%) | ||

| Peels | 45 | 203-352 | 41.4–71.8 | [11] |

| Stem | 40 | 232 | 47.3 | [18] |

| Leaf blades | 188 | 98 | 20 | [20] |

| Petioles-midribs | 127 | 25.9 | ||

| Leaf sheaths | 141 | 28.7 | ||

| Floral stalks | 144 | 29.3 | ||

| Bulbs | 150 | 30.6 | ||

| Rachis stems | 162 | 33 | ||

| Peels | 12 | 251–284 | 51.2–57.9 | [21] |

| Peduncles | 132 | 162–257 | 33–52.4 | [22] |

| Green peels | 208–303 | 42.4–61.8 | ||

| Bulbs | 228–304 | 46.5–62 | ||

| BW | n.d. | 316 | 64.5 | [23] |

| Peduncles | 100 | 210–260 * | 60–74.2 | [24] |

| Peels | 30 | 268–331 | 54.6–67.5 | [48] |

| Pulp | 64 | 373.3 ± 9.4 | 76.2 ± 1.6 | This work |

| BW | Max Voltage (mV) | MPD (mW/m2) | Internal Resistance (Ω) | Ref. |

|---|---|---|---|---|

| Peels | 125–146 | 11.3–13.1 | 3500–4200 | [32] |

| Peels | 237.1 | 23.74 | n.d. | [33] |

| Peels | 760 | 160 | 32 | [34] |

| Pulp | 286 | 41.3 | 580.99 | This work |

| Parameter | AD | MFC | ET (%) | ||||

|---|---|---|---|---|---|---|---|

| Influent (g/L) | Digestate (g/L) | E1 (%) | Digestate (g/L) | Effluent (g/L) | E2 (%) | ||

| COD | 3.337 ± 0.2 | 0.544 ± 0.05 | 83 ± 1.7 | 0.544 ± 0.05 | 0.485 ± 0.03 | 10 ± 1.7 | 85.4 ± 1.0 |

| TS | 27.81 ± 1.7 | 20.3 ± 0.8 | 27 ± 2.2 | 20.3 ± 0.8 | 15.7 ± 0.2 | 22 ± 1.7 | 43.5 ± 1.9 |

| TVS | 6.2 ± 0.4 | 2.5 ± 0.1 | 59 ± 1.8 | 2.5 ± 0.1 | 2.3 ± 0.07 | 8 ± 0.8 | 62.9 ± 1.8 |

| pH * | 7.8 ± 0.1 | 7.2 ± 0.3 | - | 7.2 ± 0.3 | 6.9 ± 0.2 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rincón-Catalán, N.I.; Cruz-Salomón, A.; Sebastian, P.J.; Pérez-Fabiel, S.; Hernández-Cruz, M.d.C.; Sánchez-Albores, R.M.; Hernández-Méndez, J.M.E.; Domínguez-Espinosa, M.E.; Esquinca-Avilés, H.A.; Ríos-Valdovinos, E.I.; et al. Banana Waste-to-Energy Valorization by Microbial Fuel Cell Coupled with Anaerobic Digestion. Processes 2022, 10, 1552. https://doi.org/10.3390/pr10081552

Rincón-Catalán NI, Cruz-Salomón A, Sebastian PJ, Pérez-Fabiel S, Hernández-Cruz MdC, Sánchez-Albores RM, Hernández-Méndez JME, Domínguez-Espinosa ME, Esquinca-Avilés HA, Ríos-Valdovinos EI, et al. Banana Waste-to-Energy Valorization by Microbial Fuel Cell Coupled with Anaerobic Digestion. Processes. 2022; 10(8):1552. https://doi.org/10.3390/pr10081552

Chicago/Turabian StyleRincón-Catalán, Néstor Isidro, Abumalé Cruz-Salomón, P.J. Sebastian, Sergio Pérez-Fabiel, Maritza del Carmen Hernández-Cruz, Rocío Magdalena Sánchez-Albores, Jesús Mauricio Ernesto Hernández-Méndez, María Emperatriz Domínguez-Espinosa, Héctor Armando Esquinca-Avilés, Edna Iris Ríos-Valdovinos, and et al. 2022. "Banana Waste-to-Energy Valorization by Microbial Fuel Cell Coupled with Anaerobic Digestion" Processes 10, no. 8: 1552. https://doi.org/10.3390/pr10081552