A Metallic Fracture Estimation Method Using Digital Image Correlation

Abstract

:1. Introduction

2. Related Work

3. Fracture Estimation

3.1. DIC-Based Fracture Estimation

- In an SDG sequence of a number of load cycles, define L as the number of SDGs for a cycle. Let l = 1.

- Select L SDGs in a row: Gs = {gl, gl+1, gl+2, …, gl+L−1}, and extract the valid pixels of each SDG in Gs (some pixels in the AOI are invalid due to distortion by the crack or blocking by the fixtures), so we obtain a new sequence Gs′ = {g′l, g′l+1, g′l+2, …, g′l+L−1}.

- Compute the mean of each SDG in Gs′: {sl, sl+1, sl+2, …, sl+L−1}.

- Find sk that meets the following:

- 5.

- If sk can be found, then gk is the SDG of the cycle. Let l = l + L, and return to step 2 for the next cycle.

- 6.

- If sk cannot be found, let l = l + 1, and return to step 2.

3.2. Fracture Estimation by Deep Learning Regression

4. Fatigue Test and Data Acquisition

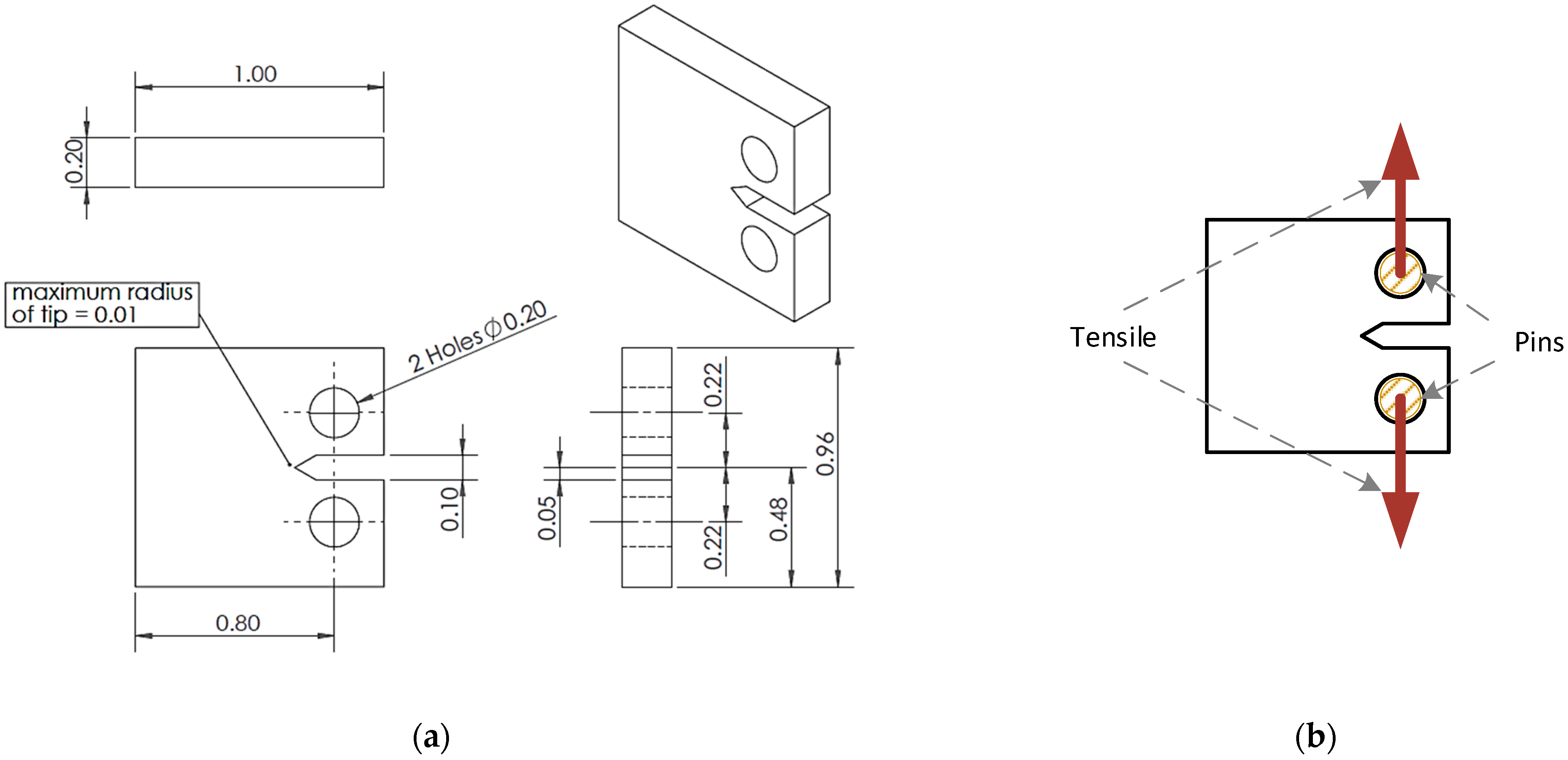

4.1. Specimens

4.2. Testing System

- The load frame measures the load value from its feedback sensor, and transmits the value to the DIC system;

- Once the load drops below a specified low-level threshold, the DIC system is triggered and keeps capturing n pictures. Assuming that the DIC frame rate is fDIC, to guarantee that all pictures are within a load cycle, the parameters should satisfy the following equation:

- 3.

- The DIC system stops to wait for the next trigger.

4.3. Testing Procedure

- Prepare a specimen as illustrated in Section 4.1, and fix it in the load frame;

- Perform a sine cyclic tensile load to precrack the specimen until a crack occurs that reaches 1 mm;

- Perform a sine cyclic tensile load to fatigue the specimen until complete failure occurs;

- The DIC system is triggered and n pictures are captured in every cycle, and the crack length is measured;

- Keep the test until the specimen completely fails.

5. Experiments and Results

5.1. Cyclic Load Test for Fatigue

5.2. Training and Testing of the Fracture Estimation Model

6. Conclusions and Further Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ji, B.; Qu, W. The Research of Acoustic Emission Techniques for Non Destructive Testing and Health Monitoring on Civil Engineering Structures. In Proceedings of the 2008 International Conference on Condition Monitoring and Diagnosis (CMD), Beijing, China, 21–24 April 2008. [Google Scholar]

- Jin, L.; Yang, Q.; Liu, S.; Zhang, C.; Li, P. Electromagnetic Stimulation of the Acoustic Emission for Fatigue Crack Detection of the Sheet Metal. IEEE Trans. Appl. Supercond. 2010, 20, 1848–1851. [Google Scholar] [CrossRef]

- Albishi, A.M.; Boybay, M.S.; Ramahi, O.M. Complementary Split-Ring Resonator for Crack Detection in Metallic Surfaces. IEEE Microw. Wirel. Compon. Lett. 2012, 22, 330–332. [Google Scholar] [CrossRef]

- Perez, N. Fracture Mechanics, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2016; ISBN 3319249975. [Google Scholar]

- ASTM E399; Standard Test Method for Linear-Elastic Plane-Strain Fracture Toughness K1C of Metallic Material. ASTM International: West Conshohocken, PA, USA, 2013.

- Albishi, A.M.; Ramahi, O.M. Microwaves-Based High Sensitivity Sensors for Crack Detection in Metallic Materials. IEEE Trans. Microw. Theory Tech. 2017, 65, 1864–1872. [Google Scholar] [CrossRef]

- Wang, Q.; Bi, K.; Hao, Y.; Guo, L.; Dong, G.; Wu, H.; Lei, M. High-Sensitivity Dielectric Resonator-Based Waveguide Sensor for Crack Detection on Metallic Surfaces. IEEE Sens. J. 2019, 19, 5470–5474. [Google Scholar] [CrossRef]

- Kralovec, C.; Schagerl, M. Review of Structural Health Monitoring Methods Regarding a Multi-Sensor Approach for Damage Assessment of Metal and Composite Structures. Sensors 2020, 20, 826. [Google Scholar] [CrossRef]

- Zhang, J.; Tian, G.Y.; Zhao, A.B. Passive RFID Sensor Systems for Crack Detection & Characterization. NDT E Int. 2017, 86, 89–99. [Google Scholar] [CrossRef]

- Sutton, M.A.; Orteu, J.J.; Schreier, H.W. Image Correlation for Shape, Motion and Deformation Measurements: Basic Concepts, Theory and Applications; Springer: Berlin/Heidelberg, Germany, 2009; ISBN 9788578110796. [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep Residual Learning for Image Recognition. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NV, USA, 27–30 June 2016; pp. 770–778. [Google Scholar]

- LeCun, Y.; Bottou, L.; Bengio, Y.; Haffner, P. Gradient-Based Learning Applied to Document Recognition. Proc. IEEE 1998, 86, 2278–2323. [Google Scholar] [CrossRef]

- Chady, T.; Enokizono, M.; Sikora, R. Crack Detection and Recognition Using an Eddy Current Differential Probe. IEEE Trans. Magn. 1999, 35, 1849–1852. [Google Scholar] [CrossRef]

- Shan, Q.; Dewhurst, R.J. Surface-Breaking Fatigue Crack Detection Using Laser Ultrasound. Appl. Phys. Lett. 1993, 62, 2649–2651. [Google Scholar] [CrossRef]

- Reber, K.; Beller, M.; Willems, H.; Barbian, O.A. A New Generation of Ultrasonic In-Line Inspection Tools for Detecting, Sizing and Locating Metal Loss and Cracks in Transmission Pipelines. In Proceedings of the 2002 IEEE Ultrasonics Symposium, Munich, Germany, 8–11 October 2002; Volume 1, pp. 665–671. [Google Scholar]

- Liu, P.; Jang, J.; Yang, S.; Sohn, H. Fatigue Crack Detection Using Dual Laser Induced Nonlinear Ultrasonic Modulation. Opt. Lasers Eng. 2018, 110, 420–430. [Google Scholar] [CrossRef]

- Zima, B.; Kędra, R. Detection and Size Estimation of Crack in Plate Based on Guided Wave Propagation. Mech. Syst. Signal Process. 2020, 142, 106788. [Google Scholar] [CrossRef]

- Kim, S.B.; Sohn, H. Instantaneous Reference-Free Crack Detection Based on Polarization Characteristics of Piezoelectric Materials. Smart Mater. Struct. 2007, 16, 2375–2387. [Google Scholar] [CrossRef]

- Broberg, P. Surface Crack Detection in Welds Using Thermography. NDT E Int. 2013, 57, 69–73. [Google Scholar] [CrossRef]

- Cao, J.; Li, F.; Ma, X.; Sun, Z. Study of Anisotropic Crack Growth Behavior for Aluminum Alloy 7050-T7451. Eng. Fract. Mech. 2018, 196, 98–112. [Google Scholar] [CrossRef]

- Farahani, B.; Belinha, J.; Amaral, R.; Tavares, P.J.; Moreira, P. A Digital Image Correlation Analysis on a Sheet AA6061-T6 Bi-Failure Specimen to Predict Static Failure. Eng. Fail. Anal. 2018, 90, 179–196. [Google Scholar] [CrossRef]

- Shrestha, S.; Kannan, M.; Morscher, G.N.; Presby, M.J.; Mostafa Razavi, S. In-Situ Fatigue Life Analysis by Modal Acoustic Emission, Direct Current Potential Drop and Digital Image Correlation for Steel. Int. J. Fatigue 2021, 142, 105924. [Google Scholar] [CrossRef]

- Chen, Y.; Ji, C.; Zhang, C.; Wang, F.; Song, X. Analysis for Post-Impact Tensile-Tensile Fatigue Damage of 2024-T3 Sheets Based on Tests, Digital Image Correlation (DIC) Technique and Finite Element Simulation. Int. J. Fatigue 2019, 122, 125–140. [Google Scholar] [CrossRef]

- Mohan, A.; Poobal, S. Crack Detection Using Image Processing: A Critical Review and Analysis. Alex. Eng. J. 2018, 57, 787–798. [Google Scholar] [CrossRef]

- Stewart, C.M.; Garcia, E. Fatigue Crack Growth of a Hot Mix Asphalt Using Digital Image Correlation. Int. J. Fatigue 2019, 120, 254–266. [Google Scholar] [CrossRef]

- Gao, Z.; Cecati, C.; Ding, S.X. A Survey of Fault Diagnosis and Fault-Tolerant Techniques-Part II: Fault Diagnosis with Knowledge-Based and Hybrid/Active Approaches. IEEE Trans. Ind. Electron. 2015, 62, 3768–3774. [Google Scholar] [CrossRef]

- Gao, Z.; Cecati, C.; Ding, S.X. A Survey of Fault Diagnosis and Fault-Tolerant Techniques-Part I: Fault Diagnosis with Model-Based and Signal-Based Approaches. IEEE Trans. Ind. Electron. 2015, 62, 3757–3767. [Google Scholar] [CrossRef]

- Zhang, Y.; Bingham, C.M.; Gallimore, M. Fault Detection and Diagnosis Based on Extensions of PCA. Adv. Mil. Technol. 2013, 8, 27–41. [Google Scholar]

- Kamble, R.G.; Raykar, N.R.; Jadhav, D.N. Machine Learning Approach to Predict Fatigue Crack Growth. Mater. Today Proc. 2021, 38, 2506–2511. [Google Scholar] [CrossRef]

- Ye, F.; Zhang, Z.; Chakrabarty, K.; Gu, X. Board-Level Functional Fault Diagnosis Using Multikernel Support Vector Machines and Incremental Learning. IEEE Trans. Comput. Aided Des. Integr. Circuits Syst. 2014, 33, 279–290. [Google Scholar] [CrossRef]

- Wu, Z.; Wu, G.; Chen, C.; Fang, Y.; Pan, L.; Huang, H. A Novel Breaking Strategy for Electrical Endurance Extension of Electromagnetic Alternating Current Contactors. IEEE Trans. Compon. Packag. Manuf. Technol. 2016, 6, 749–756. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Y. The Detection and Recognition of Bridges’ Cracks Based on Deep Belief Network. In Proceedings of the 2017 IEEE International Conference on Computational Science and Engineering (CSE) and IEEE International Conference on Embedded and Ubiquitous Computing (EUC), Guangzhou, China, 21–24 July 2017; pp. 768–771. [Google Scholar] [CrossRef]

- Zeng, X.; Liao, Y.; Li, W. Gearbox Fault Classification Using S-Transform and Convolutional Neural Network. In Proceedings of the International Conference on Sensing Technology (ICST), Nanjing, China, 11–13 November 2016; pp. 615–619. [Google Scholar]

- Wen, L.; Li, X.; Gao, L.; Zhang, Y. A New Convolutional Neural Network Based Data-Driven Fault Diagnosis Method. IEEE Trans. Ind. Electron. 2017, 65, 5990–5998. [Google Scholar] [CrossRef]

- Chen, F.-C.; Jahanshahi, M.R.; Wu, R.-T.; Joffe, C. A Texture-Based Video Processing Methodology Using Bayesian Data Fusion for Autonomous Crack Detection on Metallic Surfaces. Comput. Aided Civ. Infrastruct. Eng. 2017, 32, 271–287. [Google Scholar] [CrossRef]

- Chen, F.-C.; Jahanshahi, M.R. NB-CNN: Deep Learning-Based Crack Detection Using Convolutional Neural Network and Naïve Bayes Data Fusion. IEEE Trans. Ind. Electron. 2018, 65, 4392–4400. [Google Scholar] [CrossRef]

- Hu, J.; Xu, W.; Gao, B.; Tian, G.Y.; Wang, Y.; Wu, Y.; Yin, Y.; Chen, J. Pattern Deep Region Learning for Crack Detection in Thermography Diagnosis System. Metals 2018, 8, 612. [Google Scholar] [CrossRef]

- Yuan, Y.; Ge, Z.; Su, X.; Guo, X.; Suo, T.; Liu, Y.; Yu, Q. Crack Length Measurement Using Convolutional Neural Networks and Image Processing. Sensors 2021, 21, 5894. [Google Scholar] [CrossRef]

- ASTM E647-15e1; Standard Test Method for Measurement of Fatigue Crack Growth Rates. ASTM International: West Conshohocken, PA, USA, 2015.

- Griffith, A.A. The Phenomena of Rupture and Flow in Solids. Philos. Trans. R. Soc. Math. Phys. Eng. Sci. 1921, 221, 163–198. [Google Scholar] [CrossRef]

- Shou, Z.; Wang, D.; Chang, S.-F. Temporal Action Localization in Untrimmed Videos via Multi-Stage CNNs. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016. [Google Scholar]

- Ji, S.; Xu, W.; Yang, M.; Yu, K. 3D Convolutional Neural Networks for Human Action Recognition. IEEE Trans. Pattern Anal. Mach. Intell. 2013, 35, 221–231. [Google Scholar] [CrossRef] [PubMed]

- Abadi, M.; Agarwal, A.; Barham, P.; Brevdo, E.; Chen, Z.; Citro, C.; Corrado, G.S.; Davis, A.; Dean, J.; Devin, M.; et al. TensorFlow: Large-Scale Machine Learning on Heterogeneous Systems. arXiv 2015, arXiv:1603.04467. [Google Scholar]

- Vingelmann, P.; Fitzek, F.H.P. CUDA, Release: 10.2.89; NVIDIA: Santa Clara, CA, USA, 2020; Available online: https://developer.nvidia.com/cuda-toolkit (accessed on 17 July 2022).

| Specimen | Precracking Cycle Count | Fatiguing Cycle Count | Crack Length before Failure |

|---|---|---|---|

| 1 | 1930 | 11,821 | 6.7 |

| 2 | 1750 | 7580 | 6.4 |

| 3 | 1820 | 7567 | 6.5 |

| 4 | 1940 | 6497 | 6.2 |

| 5 | 1410 | 5520 | 6.0 |

| Network | Test MAE (mm) | Estimation Time per Example (μs) | ||

|---|---|---|---|---|

| Strategy 1 | Strategy 2 | Strategy 1 | Strategy 2 | |

| ResNet-18 | 0.0089 | 0.0077 | 93 | 187 |

| LeNet-5 | 0.0154 | 0.0195 | 70 | 178 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Z.; Han, Y.; Liang, B.; Wu, G.; Bao, Z.; Qian, W. A Metallic Fracture Estimation Method Using Digital Image Correlation. Processes 2022, 10, 1599. https://doi.org/10.3390/pr10081599

Wu Z, Han Y, Liang B, Wu G, Bao Z, Qian W. A Metallic Fracture Estimation Method Using Digital Image Correlation. Processes. 2022; 10(8):1599. https://doi.org/10.3390/pr10081599

Chicago/Turabian StyleWu, Ziran, Yan Han, Bumeng Liang, Guichu Wu, Zhizhou Bao, and Weifei Qian. 2022. "A Metallic Fracture Estimation Method Using Digital Image Correlation" Processes 10, no. 8: 1599. https://doi.org/10.3390/pr10081599