Heat Transfer Performance of Plate Fin and Pin Fin Heat Sinks Using Al2O3/H2O Nanofluid in Electronic Cooling

Abstract

:1. Introduction

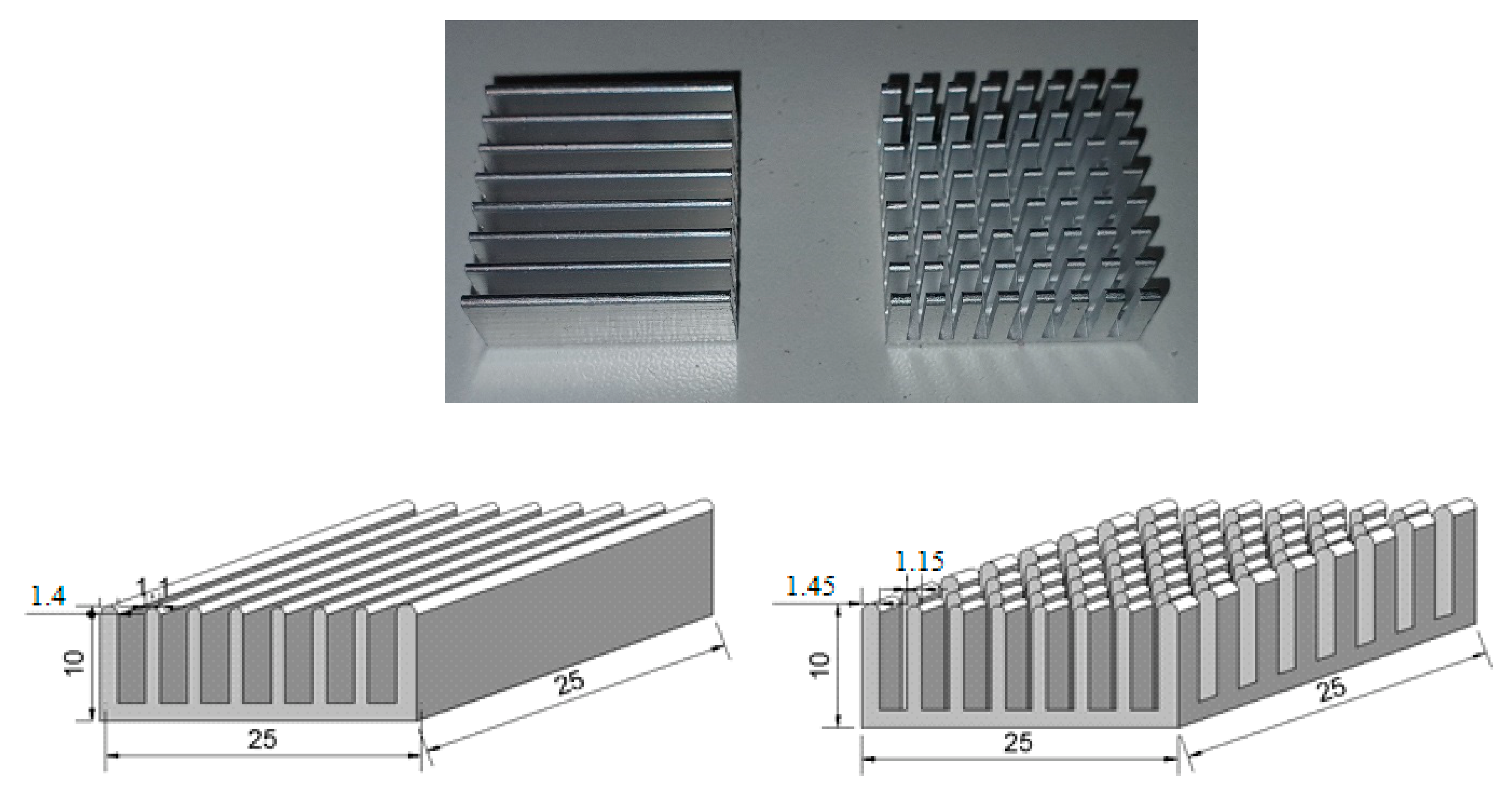

2. Materials and Methods

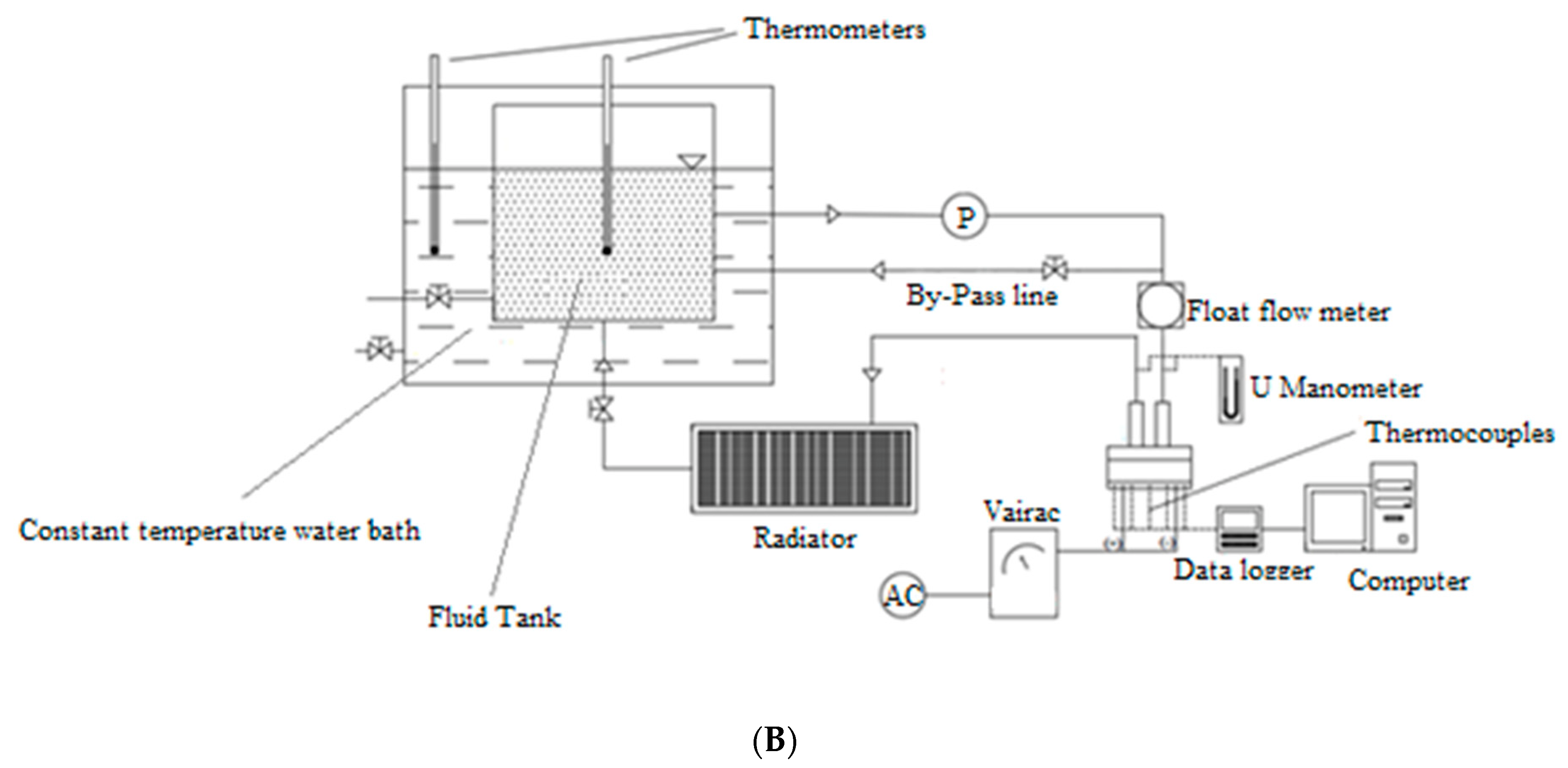

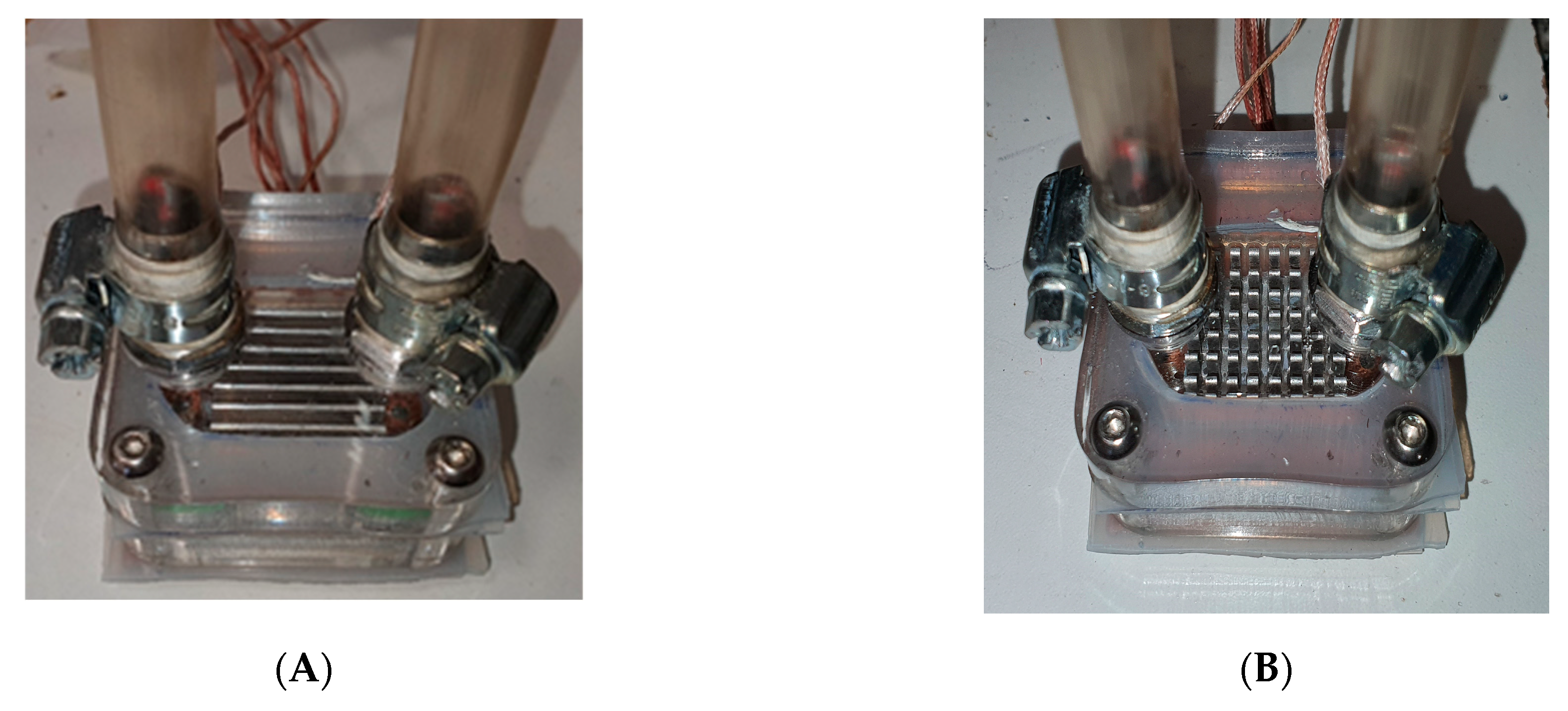

2.1. Experimental Set-Up

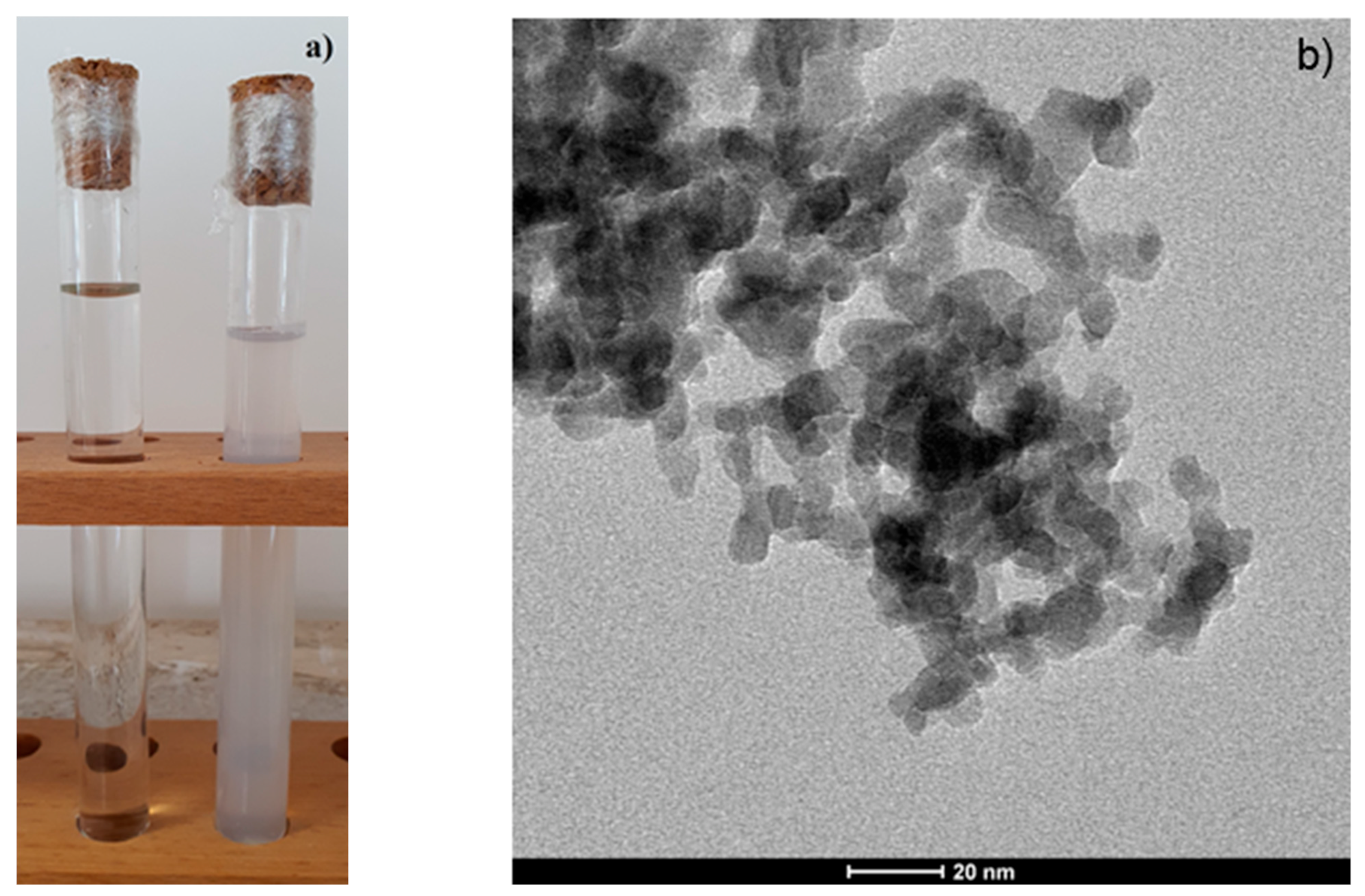

2.2. Nanofluid Preparation

2.3. Analysis of Experimental Data

2.4. Uncertainty Analysis

3. Results and Discussion

4. Conclusions

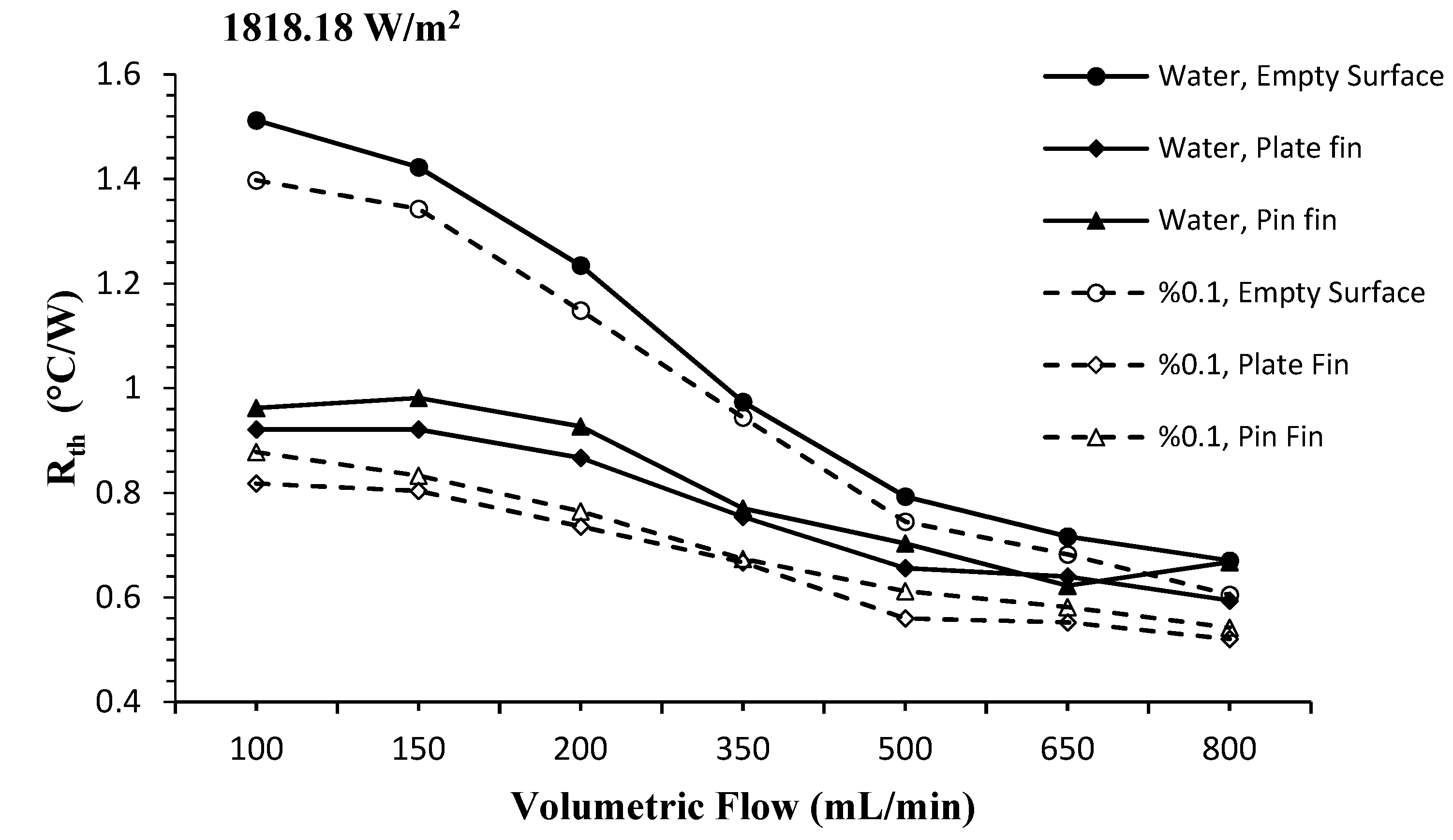

- For all cases, it was observed that the mean surface temperatures decreased rapidly with increasing volumetric flow rate. However, after a certain flow rate (650 mL/min), it was observed that the amount of decrease in the mean average surface temperature decreased.

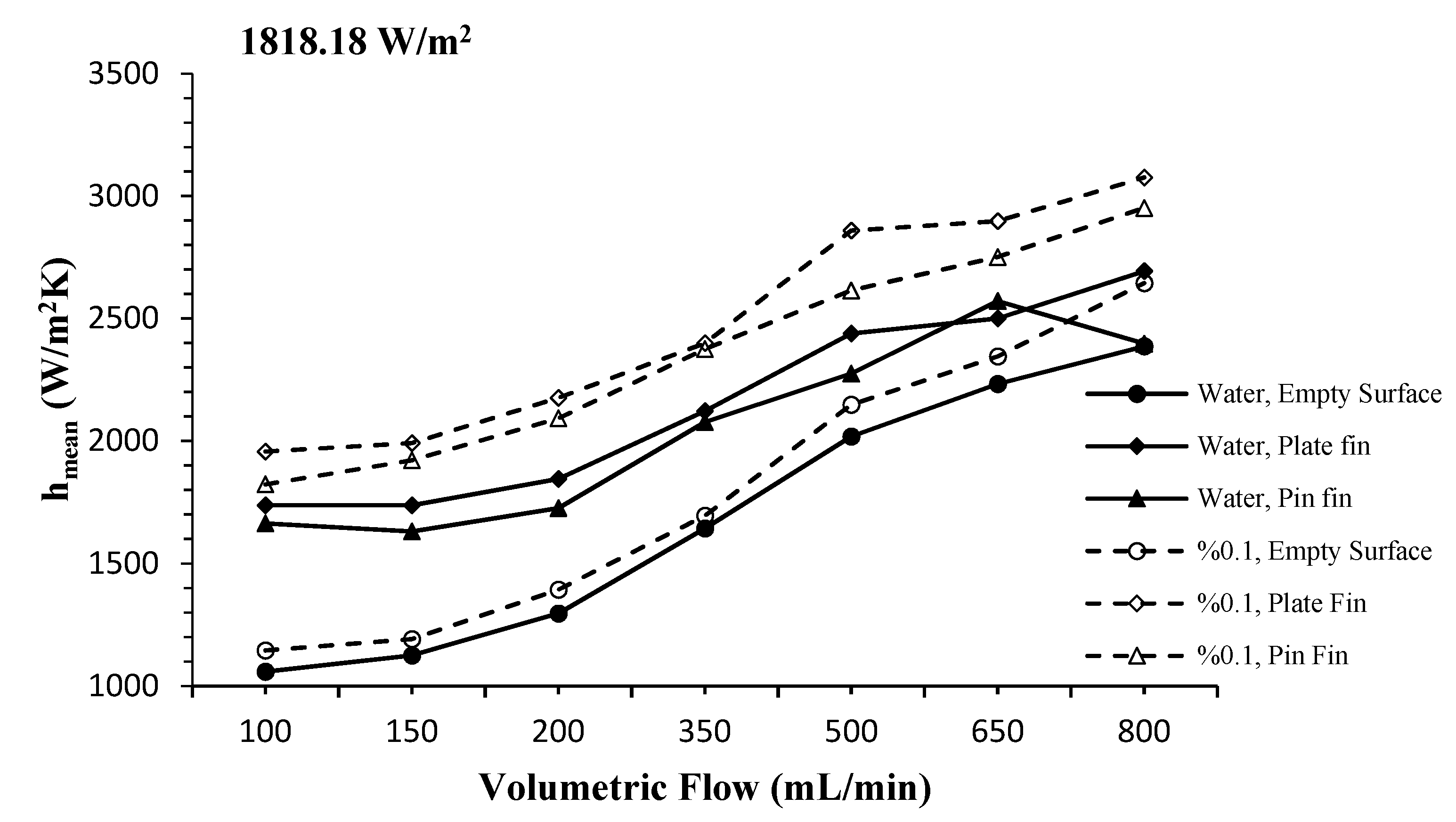

- With the use of nanofluid on the empty surface, a greater decrease in the mean surface temperatures was observed compared to the base fluid. Accordingly, the maximum improvement amount that was obtained by using nanofluids at the mean surface temperatures was determined as 10.5%.

- By using plate fin and pin fin heat sinks with a base fluid, an improvement of 27.48% and 24.57% was observed in the surface temperatures compared to the empty surface, respectively. In the use of nanofluid with the plate and pin-finned heat sink instead of the base fluid, 35.73% and 29.49% improvements in the surface temperatures were obtained.

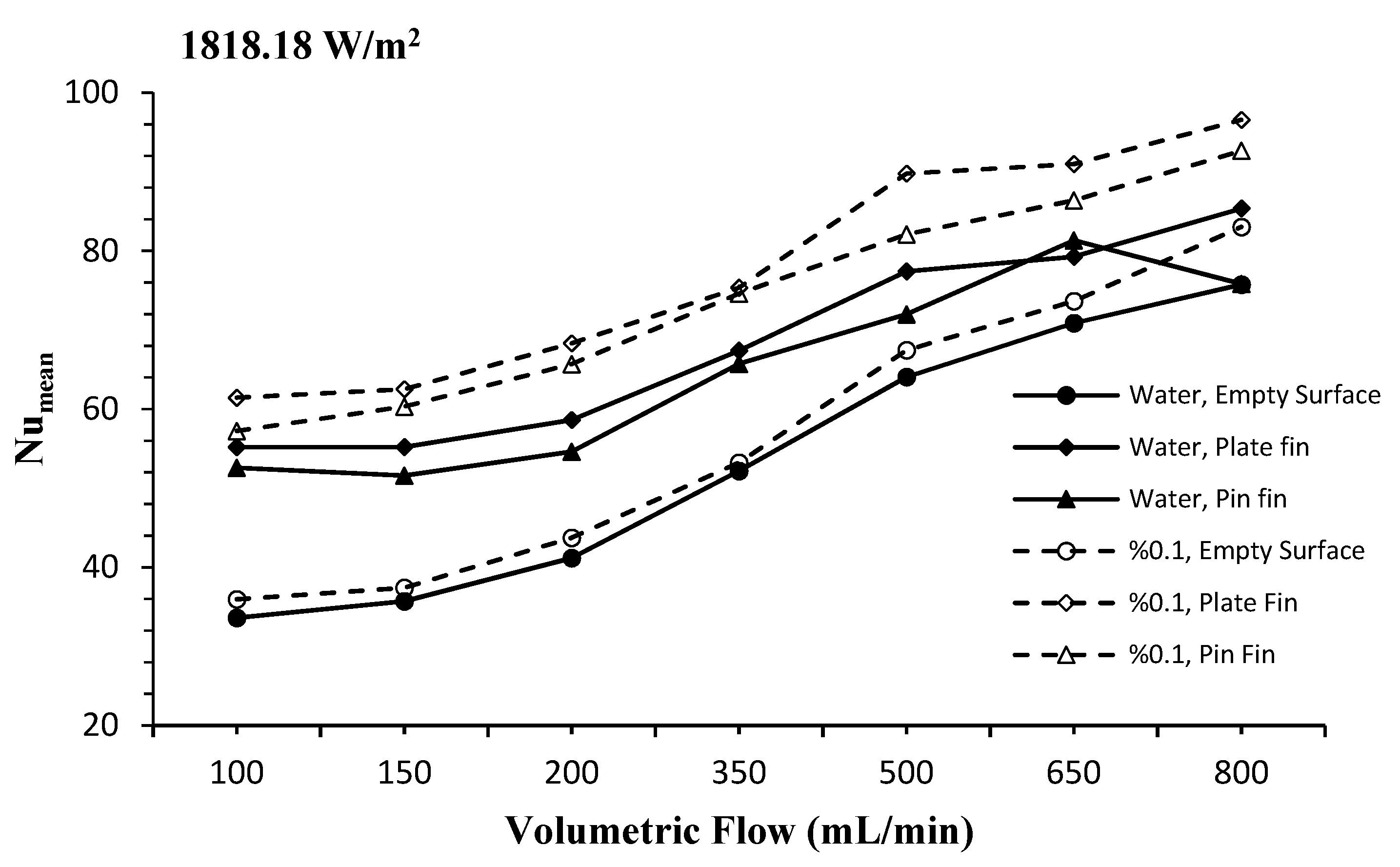

- With the use of nanofluid on the empty surface, a 22.15% improvement was observed in the mean Nusselt number compared to the base fluid.

- In the use of pin fin and plate fin heat sinks with the base fluid, 56.4% and 64.2% improvements in the mean Nusselt number were obtained, respectively. The maximum improvement in the mean Nusselt number that was obtained using nanofluid with pin fin and plate fin heat sinks was determined as 70.2% and 82.8%, respectively.

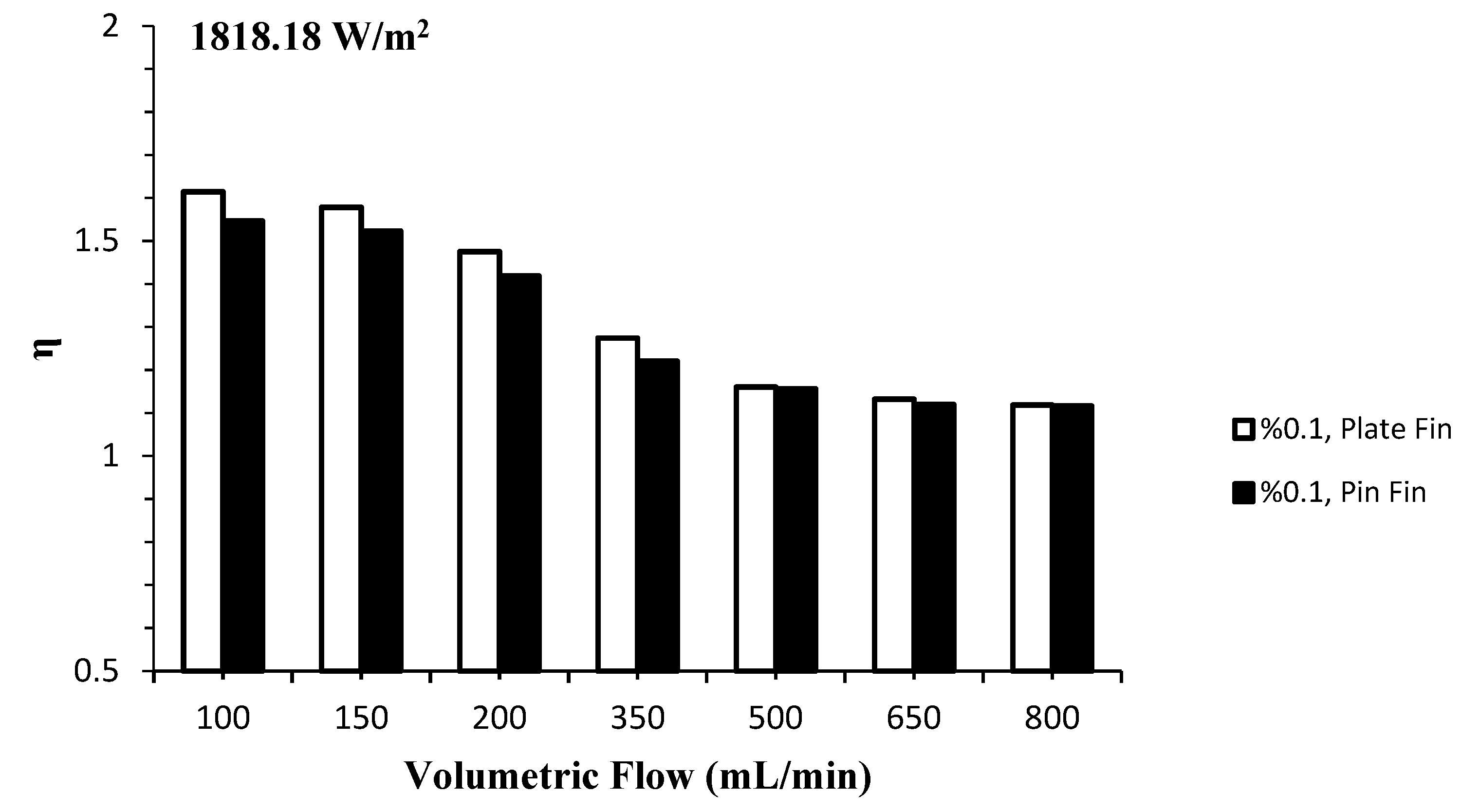

- When the performance index was examined, it was seen that the use of a plate fin heat sink was more suitable than the pin fin heat sink in the cooling of electronic systems. Although the performance index that was obtained for the two fin types approached each other with increasing volumetric flow rate, the best result was obtained in the plate fin heat sink.

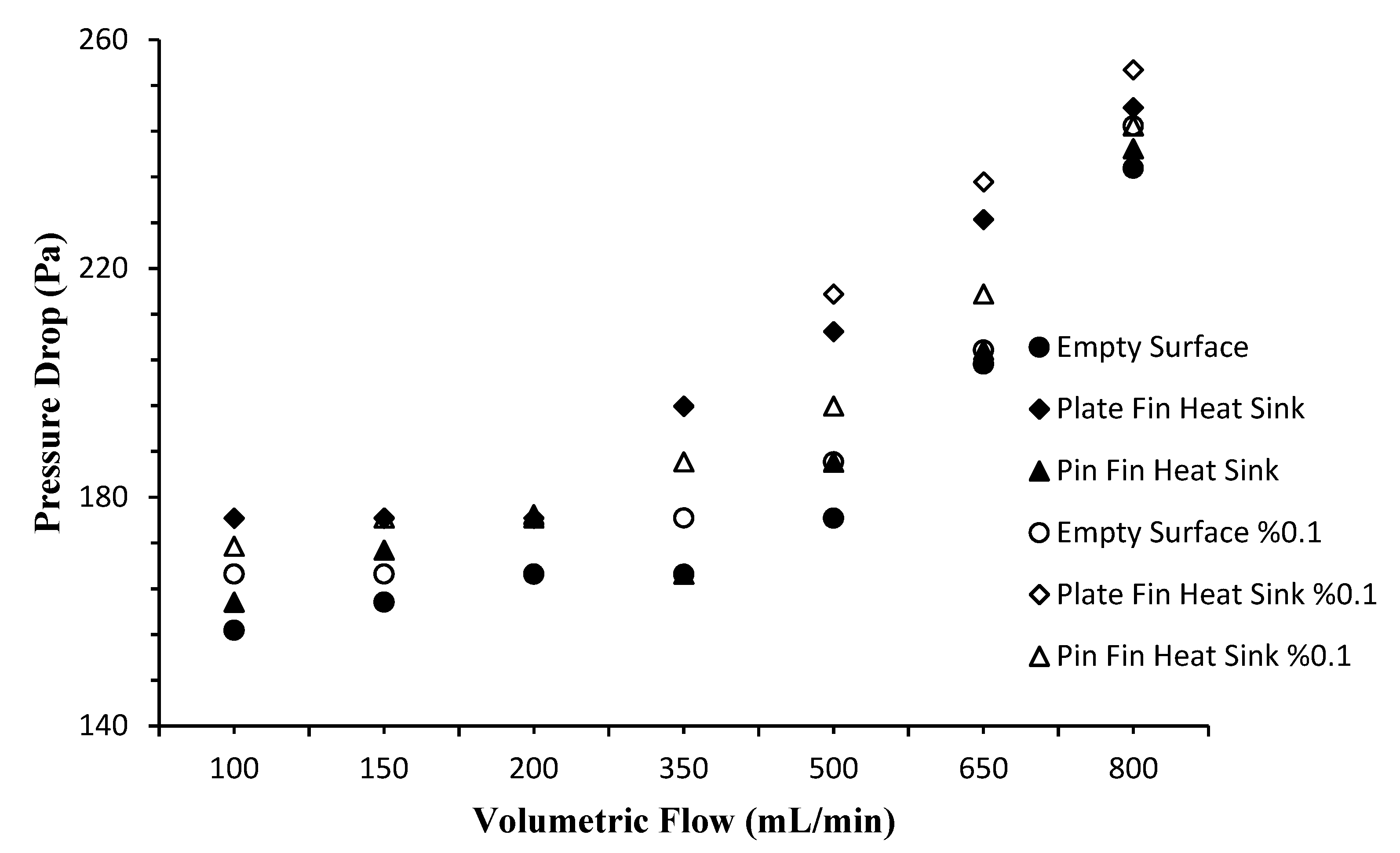

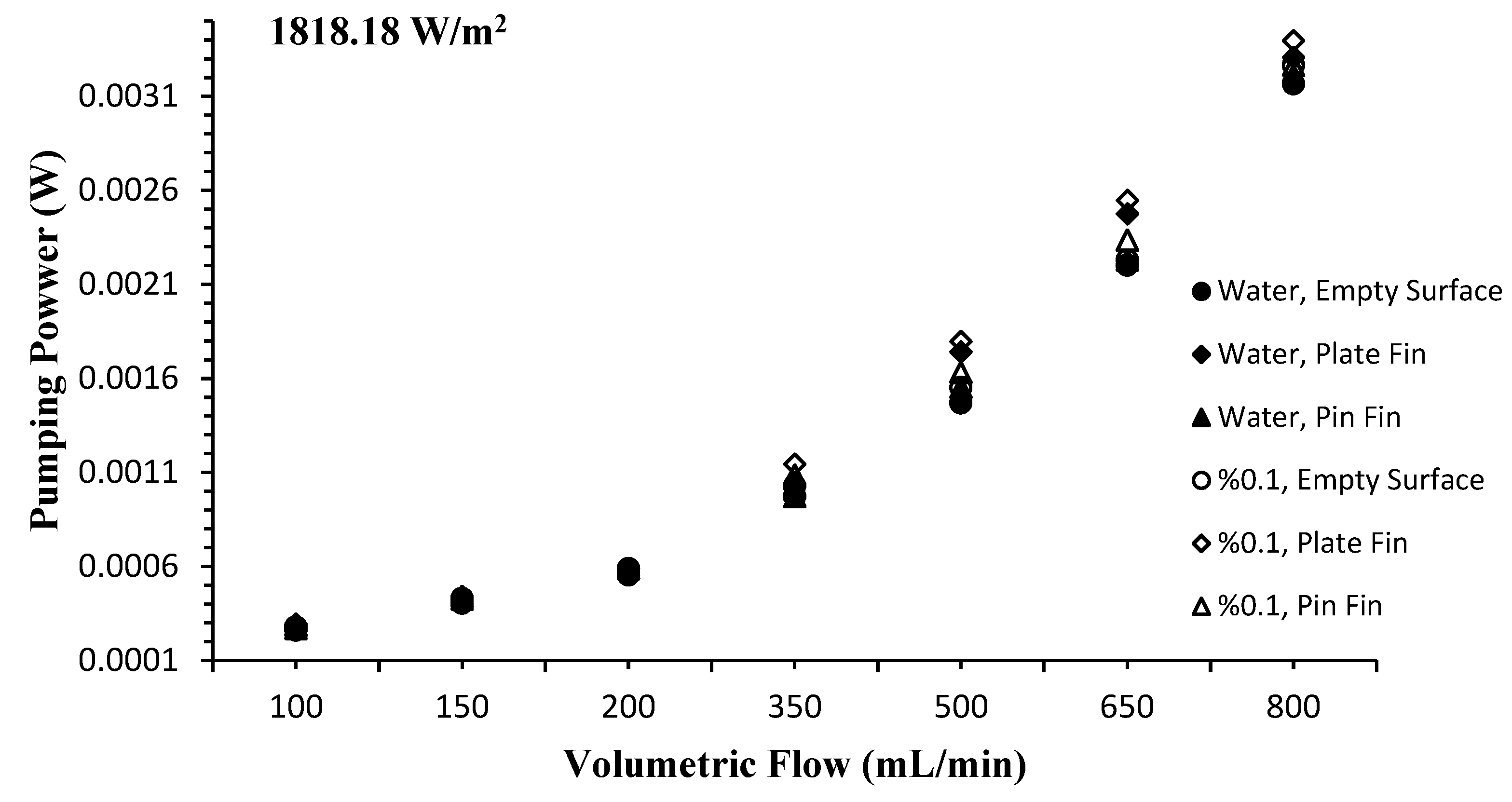

- With the use of nanofluid on the empty surface, no significant increase in pressure drop and pumping power was observed compared to the base fluid. However, with the use of finned heat sinks, the pressure drop and the increase in pumping power for both fluids became more pronounced. When the performance index was examined, it was determined that this increase in the use of finned heat sinks and nanofluids could be ignored according to the amount of improvement in heat transfer.

- Commercial Al2O3 nanoparticles (Alu 130) which were used in this study promise hope for both nanofluid research and the production of commercial nanofluids for electronic cooling.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Symbols | |

| As | Water block surface area [m2] |

| Cp | Specific heat [J/kgK] |

| Hydraulic diameter [m] | |

| hmean | Mean convective heat transfer coefficient [W/m2K] |

| k | Thermal conductivity [W/mK] |

| kf | Fluid conductive heat transfer coefficient [W/mK] |

| Numean | Mean Nusselt number [-] |

| Pp | Pumping power [W] |

| Conduction heat transfer rate [W] | |

| Convection heat transfer rate [W] | |

| Heat transfer rate from heater [W] | |

| qconv. | Convection heat flux [W/m2] |

| R | Electrical resistance [Ohm] |

| Thermal resistance [°C/W] | |

| Ti | Fluid inlet temperature [°C] |

| T*Smean | Mean Surface temperature [°C] |

| V | Voltage [V] |

| Volumetric flow rate [mL/min] | |

| ΔT | Temperature difference [K] |

| Δx | Thickness [m] |

| Uncertainty [-] | |

| ε | Thermal performance of nanofluid [-] |

| η | Performance index [-] |

| ρ | Density (g/cm3) |

| ν | Viscosity [m2/s] |

| Volumetric concentration [-] | |

| Mass fraction [-] | |

| Subscripts | |

| bf | Base fluid |

| nf | Nanofluid |

| p | Nanoparticle |

| s | Surface |

| f | Fluid |

| Abbreviations | |

| PPI | Pores Per Inch |

References

- Choi, S.U.S.; Eastman, J.A. Enhancing Thermal Conductivities of Fluids with Nanoparticles; No. ANL/MSD/CP-84938; CONF-951135-29; Argonne National Lab. (ANL): Argonne, IL, USA, 1995. [Google Scholar]

- Nazari, M.; Karami, M.; Ashouri, M. Comparing the thermal performance of water, ethylene glycol, alumina and CNT nanofluids in CPU cooling: Experimental study. Exp. Therm. Fluid Sci. 2014, 57, 371–377. [Google Scholar] [CrossRef]

- Rafati, M.; Hamidi, A.A.; Niaser, M.S. Application of nanofluids in computer cooling systems (heat transfer performance of nanofluids). Appl. Therm. Eng. 2012, 45–46, 9–14. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Arya, A.; Hormozi, F.; Nikkhah, V. On the convective thermal performance of a CPU cooler working with liquid gallium and CuO/water nanofluid: A comparative study. Appl. Therm. Eng. 2017, 112, 1373–1381. [Google Scholar] [CrossRef]

- Alfaryjat, A.A.; Miron, L.; Pop, H.; Apostol, V.; Stefanescu, M.F.; Dobrovicescu, A. Experimental investigation of thermal and pressure performance in computer cooling systems using different types of nanofluids. Nanomaterials 2019, 9, 1231. [Google Scholar] [CrossRef] [PubMed]

- Selvakumar, P.; Suresh, S. Convective performance of CuO/water nanofluid in an electronic heat sink. Exp. Therm. Fluid Sci. 2012, 40, 57–63. [Google Scholar] [CrossRef]

- Korpys, M.; Al-Rashed, M.; Dzido, G.; Wojcik, J. CPU heat sink cooled by nanofluids and water: Experimental and numerical study. In Proceedings of the 23rd European Symposium on Computer Aided Process Engineering—ESCAPE 23, Lappeenranta, Finland, 9–12 June 2013; pp. 409–414. [Google Scholar]

- Nguyen, C.T.; Roy, G.; Gauthier, C.; Galanis, N. Heat transfer enhancement by using Al2O3-water nanofluid for an electronic liquid cooling system. Appl. Therm. Eng. 2007, 27, 1501–1506. [Google Scholar] [CrossRef]

- Turgut, A.; Elbasan, E. Nanofluids for electronics cooling. In Proceedings of the 2014 IEEE 20th International Symposium for Design and Technology in Electronic Packaging (SIITME), Bucharest, Romania, 23–26 October 2014; pp. 35–37. [Google Scholar]

- Qi, C.; Hu, J.; Liu, M.; Guo, L.; Rao, Z. Experimental study on thermo-hydraulic performances of CPU cooled by nanofluids. Energy Convers. Manag. 2017, 153, 557–565. [Google Scholar] [CrossRef]

- Khaleduzzaman, S.S.; Mahbubul, I.M.; Sohel, M.R.; Saidur, R.; Selvaraj, J.; Ward, T.A.; Niza, M.E. Experimental analysis of energy and friction factor for titanium dioxide nanofluid in a water block heat sink. Int. J. Heat Mass Transf. 2017, 115, 77–85. [Google Scholar] [CrossRef]

- Arya, A.; Shahmiri, S.; Nikkhah, V.; Sarafraz, M.M. Cooling of high heat flux flat surface with nanofluid assisted convective loop: Experimental assessment. Arch. Mech. Eng. 2017, 4, 519–531. [Google Scholar] [CrossRef]

- Ho, C.J.; Chen, W.C. An experimental study on thermal performance of Al2O3/water nanofluid in a minichannel heat sink. Appl. Therm. Eng. 2013, 50, 516–522. [Google Scholar] [CrossRef]

- Sukhor, N.B.; Tijani, A.S.; Kubenthiran, J.; Muritala, I.K. Computational modeling of thermal characteristics of hybrid nanofluid in micro-pin fin heat sink for electronic cooling. Int. J. Green Energy 2021, 18, 1027–1045. [Google Scholar] [CrossRef]

- Hasan, M.I. Investigation of flow and heat transfer characteristics in micro pin fin heat sink with nanofluid. Appl. Therm. Eng. 2014, 63, 598–607. [Google Scholar] [CrossRef]

- Sajid, M.U.; Ali, H.M.; Sufyan, A.; Rashid, D.; Zahid, S.U.; Rehman, W.U. Experimental investigation of TiO2–water nanofluid flow and heat transfer inside wavy mini-channel heat sinks. J. Therm. Anal. Calorim. 2019, 137, 1279–1294. [Google Scholar] [CrossRef]

- Sajid, M.U.; Ali, H.M.; Bicer, Y. Exergetic performance assessment of magnesium oxide–water nanofluid in corrugated minichannel heat sinks: An experimental study. Int. J. Energy Res. 2020, 46, 9985–10001. [Google Scholar] [CrossRef]

- Miry, S.Z.; Roshani, M.; Hanafizadeh, P.; Ashjaee, M.; Amini, F. Heat Transfer and Hydrodynamic Performance Analysis of a Miniature Tangential Heat Sınk Using Al2O3–H2O and TiO2–H2O Nanofluids. Exp. Heat Transf. 2016, 29, 535–560. [Google Scholar] [CrossRef]

- Sehgal, S.S.; Krishnan, M.; Mohapatra, S.K. Experimental investigation of the effect of flow arrangements on the performance of a micro-channel heat sink. Exp. Heat Transf. 2011, 24, 215–233. [Google Scholar] [CrossRef]

- Sarbazi, Z.; Hormozi, F. Optimization of thermal and hydraulic performance of nanofluid in a rectangular miniature-channel with various fins using response surface methodology. J. Therm. Anal. Calorim. 2019, 137, 711–733. [Google Scholar] [CrossRef]

- Khoshvaght-Aliabadi, M.; Hormozi, F. Heat transfer enhancement by using copper–water nanofluid flow inside a pin channel. Exp. Heat Transf. 2015, 28, 446–463. [Google Scholar] [CrossRef]

- Khoshvaght-Aliabadi, M.; Hassani, S.M.; Mazloumi, S.H. Comparison of hydrothermal performance between plate fins and plate-pin fins subject to nanofluid-cooled corrugated miniature heat sinks. Microelectron. Reliab. 2017, 70, 84–96. [Google Scholar] [CrossRef]

- Khoshvaght-Aliabadi, M.; Mortazavi, S. Combined effects of holes and winglets on chevron plate-fins to enhance the performance of a plate-fin heat exchanger working with nanofluid. Exp. Heat Transf. 2019, 32, 84–599. [Google Scholar] [CrossRef]

- Abdollahi, A.; Mohammed, H.A.; Vanaki, S.M.; Sharma, R.N. Numerical investigation of fluid flow and heat transfer of nanofluids in microchannel with longitudinal fins. Ain Shams Eng. J. 2018, 9, 3411–3418. [Google Scholar] [CrossRef]

- Kumar, V.; Sarkar, J. Particle ratio optimization of Al2O3-MWCNT hybrid nanofluid in minichannel heat sink for best hydrothermal performance. Appl. Therm. Eng. 2020, 165, 114546. [Google Scholar] [CrossRef]

- Fazeli, H.; Pourrajabian, A.; Nikooei, E. Simultaneous optimization of geometric and nanofluid parameters in a rectangular microchannel heat sink. Heat Transf. Eng. 2021, 43, 1–18. [Google Scholar] [CrossRef]

- Khetib, Y.; Alahmadi, A.; Alzaed, A.; Saleem, H.A.; Sharifpur, M.; Kalbasi, R. The effect of pin-fin shapes on heat sink effectiveness in the presence of a turbulent nanofluid regime. Chem. Eng. Commun. 2021, 208, 1–16. [Google Scholar] [CrossRef]

- Ali, H.M.; Arshad, W. Thermal performance investigation of staggered and inline pin fin heat sinks using water based rutile and anatase TiO2 nanofluids. Energy Convers. Manag. 2015, 106, 793–803. [Google Scholar] [CrossRef]

- Ali, H.M.; Arshad, W. Effect of channel angle of pin-fin heat sink on heat transfer performance using water based graphene nanoplatelets nanofluids. Int. J. Heat Mass Transf. 2017, 106, 465–472. [Google Scholar] [CrossRef]

- Hwang, K.S.; Jang, S.P.; Choi, S.U.S. Flow and convective heat transfer characteristics of water-based Al2O3 nanofluids in fully developed laminar flow regime. Int. J. Heat Mass Transf. 2009, 52, 193–199. [Google Scholar] [CrossRef]

- Kim, S.; Tserengombo, B.; Choi, S.H.; Noh, J.; Huh, S.; Choi, B.; Chung, H.; Kim, J.; Jeong, H. Experimental investigation of heat transfer coefficient with Al2O3 nanofluid in small diameter tubes. Appl. Therm. Eng. 2019, 146, 346–355. [Google Scholar] [CrossRef]

- Zhao, N.; Guo, L.; Qi, C.; Chen, T.; Cui, X. Experimental study on thermo-hydraulic performance of nanofluids in CPU heat sink with rectangular grooves and cylindrical bugles based on exergy efficiency. Energy Convers. Manag. 2019, 181, 235–246. [Google Scholar] [CrossRef]

- Bahiraei, M.; Mazaheri, N.; Daneshyar, M.R. Employing elliptical pin-fins and nanofluid within a heat sink for cooling of electronic chips regarding energy efficiency perspective. Appl. Therm. Eng. 2021, 183, 116159. [Google Scholar] [CrossRef]

- Ambreen, T.; Kim, M.H. Comparative assessment of numerical models for nanofluids’ laminar forced convection in micro and mini channels. Int. J. Heat Mass Transf. 2017, 115, 513–523. [Google Scholar] [CrossRef]

- Ambreen, T.; Kim, M.H. Effects of variable particle sizes on hydrothermal characteristics of nanofluids in a microchannel. Int. J. Heat Mass Transf. 2018, 120, 490–498. [Google Scholar] [CrossRef]

- Ambreen, T.; Kim, M.H. Effect of fin shape on the thermal performance of nanofluid-cooled micro pin-fin heat sinks. Int. J. Heat Mass Transf. 2018, 126, 245–256. [Google Scholar] [CrossRef]

- Ambreen, T.; Saleem, A.; Park, C.W. Numerical analysis of the heat transfer and fluid flow characteristics of a nanofluid-cooled micropin-fin heat sink using the Eulerian-Lagrangian approach. Powder Technol. 2019, 345, 509–520. [Google Scholar] [CrossRef]

- Ambreen, T.; Saleem, A.; Ali, H.M.; Shehzad, S.A.; Park, C.W. Performance analysis of hybrid nanofluid in a heat sink equipped with sharp and streamlined micro pin-fins. Powder Technol. 2019, 355, 552–563. [Google Scholar] [CrossRef]

- Ambreen, T.; Saleem, A.; Tanveer, M.; Anirudh, K.; Shehzad, S.A.; Park, C.W. Irreversibility and hydrothermal analysis of the MWCNTs/GNPs-based nanofluids for electronics cooling applications of the pin-fin heat sinks: Multiphase Eulerian-Lagrangian modeling. Case Stud. Therm. Eng. 2022, 31, 101806. [Google Scholar] [CrossRef]

- Ambreen, T.; Saleem, A.; Park, C.W. Homogeneous and Multiphase Analysis of Nanofluids Containing Nonspherical MWCNT and GNP Nanoparticles Considering the Influence of Interfacial Layering. Nanomaterials 2021, 11, 277. [Google Scholar] [CrossRef]

- Shehzad, S.A.; Alshuraiaan, B.; Kamel, M.S.; Izadi, M.; Ambreen, T. Influence of fin orientation on the natural convection of aqueous-based nano-encapsulated PCMs in a heat exchanger equipped with wing-like fins. Chem. Eng. Process. Process Intensif. 2021, 160, 108287. [Google Scholar] [CrossRef]

- Ambreen, T.; Saleem, A.; Park, C.W. Thermal efficiency of eco-friendly MXene based nanofluid for performance enhancement of a pin-fin heat sink: Experimental and numerical analyses. Int. J. Heat Mass Transf. 2022, 186, 122451. [Google Scholar] [CrossRef]

- AEROXIDE. Production Information AEROXIDE Alu 130. Available online: https://glenncorp.com/wp-content/uploads/2013/12/AEROXIDE-Alu-130.pdf (accessed on 6 July 2022).

- Calvin, J.J.; Asplund, M.; Zhang, Y.; Huang, B.; Woodfield, B.F. Heat capacity and thermodynamic functions of γ-Al2O3. J. Chem. Thermodyn. 2017, 112, 77–85. [Google Scholar] [CrossRef]

- Prakash, A.; Satsangi, S.; Mittal, S.; Nigam, B.; Mahto, P.K.; Swain, B.P. Investigation on Al2O3 nanoparticles for nanofluid applications—A Review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 377, 012175. [Google Scholar] [CrossRef]

- Pourfarzad, E.; Ghadiri, K.; Behrangzade, A.; Ashjaee, M. Experimental investigation of heat transfer and pressure drop of alumina–water nano-fluid in a porous miniature heat sink. Exp. Heat Transf. 2018, 31, 495–512. [Google Scholar] [CrossRef]

- Holman, J.P. Analysis of experimental data. In Experimental Methods for Engineers, 6th ed.; McGraw-Hill, Inc.: New York, NY, USA, 1994; pp. 49–56. [Google Scholar]

| Density (ρ) | 2700 kg/m3 |

| Thermal Conductivity (k) | 209.5 W/mK |

| Melting Point | 615 °C |

| Dimensions | 2.5 × 2.5 × 1 cm |

| Specific Surface Area | 130 ± 20 m2/g |

| Tamped Density | 50 g/L |

| PH (in %4 dispersion) | 4.4–5.4 |

| Density | 3.27 g/cm3 |

| Fluids | Density (ρ) (g/cm3) | Viscosity (μ) (kg/ms) | Thermal Conductivity (k) (W/mK) | Specific Heat (Cp) (kJ/kgK) |

|---|---|---|---|---|

| Water | 0.9984 | 0.00098 | 0.5962 | 4182.8 |

| (w/w) 0.1% Al2O3-H2O | 0.9986 | 0.00134 | 0.5973 | 4181.8 |

| Measurement Tools | Sensibility | Uncertainties |

|---|---|---|

| 30-gauge T-type Thermocouples | ±1 °C | 0.015% |

| TT Technic VC-9808+ | ±0.8% + 5 (AC) | 0.14% |

| TT Technic VC-9808+ | ±0.8% + 3 (Ohm) | 0.042% |

| Float Flowmeter | ±3% | 0.03% |

| U manometer | ±0.5 (Pa) | 0.029% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ozbalci, O.; Dogan, A.; Asilturk, M. Heat Transfer Performance of Plate Fin and Pin Fin Heat Sinks Using Al2O3/H2O Nanofluid in Electronic Cooling. Processes 2022, 10, 1644. https://doi.org/10.3390/pr10081644

Ozbalci O, Dogan A, Asilturk M. Heat Transfer Performance of Plate Fin and Pin Fin Heat Sinks Using Al2O3/H2O Nanofluid in Electronic Cooling. Processes. 2022; 10(8):1644. https://doi.org/10.3390/pr10081644

Chicago/Turabian StyleOzbalci, Oguzhan, Ayla Dogan, and Meltem Asilturk. 2022. "Heat Transfer Performance of Plate Fin and Pin Fin Heat Sinks Using Al2O3/H2O Nanofluid in Electronic Cooling" Processes 10, no. 8: 1644. https://doi.org/10.3390/pr10081644

APA StyleOzbalci, O., Dogan, A., & Asilturk, M. (2022). Heat Transfer Performance of Plate Fin and Pin Fin Heat Sinks Using Al2O3/H2O Nanofluid in Electronic Cooling. Processes, 10(8), 1644. https://doi.org/10.3390/pr10081644