THC and CO Emissions from Diesel Engines Using Biodiesel Produced from Residual Frying Oil by Non-Thermal Plasma Technology

Abstract

:1. Introduction

2. Materials and Methods

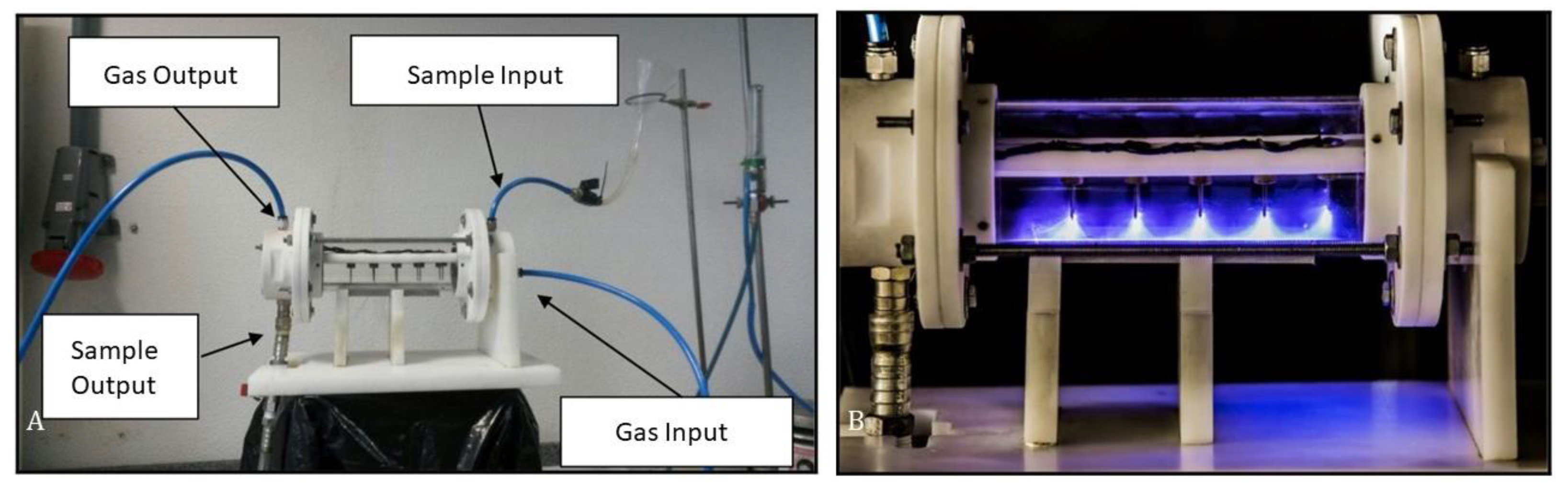

2.1. Biodiesel Production

- Biodiesel produced by CC (B100)—100% biodiesel

- Biodiesel produced through CC added to common diesel in the proportions (v/v): 2% (B2), 12% (B12), 20% (B20), and 50% (B50) of biodiesel.

- Biodiesel produced by NTP with 15 min of treatment (B100-NTP15) added to common diesel in the proportions (v/v): 2% (B2-NTP15), 12% (B12-NTP15), 20% (B20-NTP15), 50% (B50-NTP15), and 100% (B100-NTP15) of biodiesel.

- Biodiesel produced by NTP with 30 min of treatment (B100-NTP 30) added to common diesel in the proportions (v/v): 2% (B2-NTP30), 12% (B12NTP30), 20% (B20-NTP30), 50% (B50-NTP30), and 100% (B100-NTP30) of biodiesel.

- Common diesel—S-500 (100% petroleum derived diesel, with no additives and without the presence of biodiesel).

Analysis of Biodiesel Produced

2.2. Test Bench and Instrumentation

2.2.1. Discovery G-4 Vehicle Analyzer

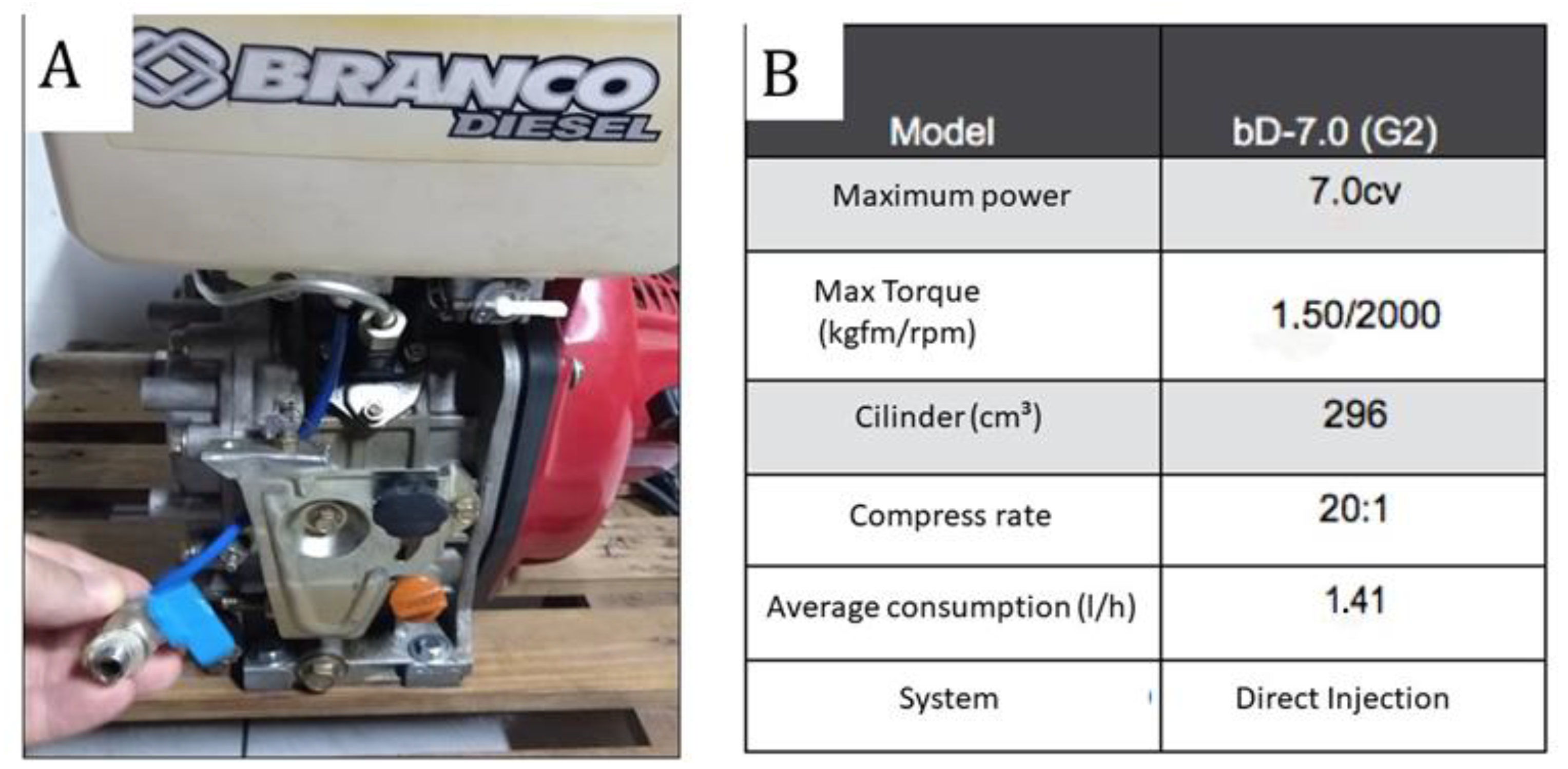

2.2.2. Diesel or Biodiesel Engine—WHITE BD-7.0 (G2)

2.2.3. Vehicle Gas Analyzer for THC Determination (% v/v)

2.2.4. Gas Alert MAX XT-II Gas Analyzer and Detector

2.2.5. Measurement of Engine Speed and Temperature

2.3. Emission Testing

2.4. Investigation of Stabilizing Action of NTP

3. Results and Discussion

3.1. Characterization of Biodiesel Produced Applying NTP and CC

3.2. GCC Pollutant Emission Analysis

3.2.1. Emission of CO in Exhaust

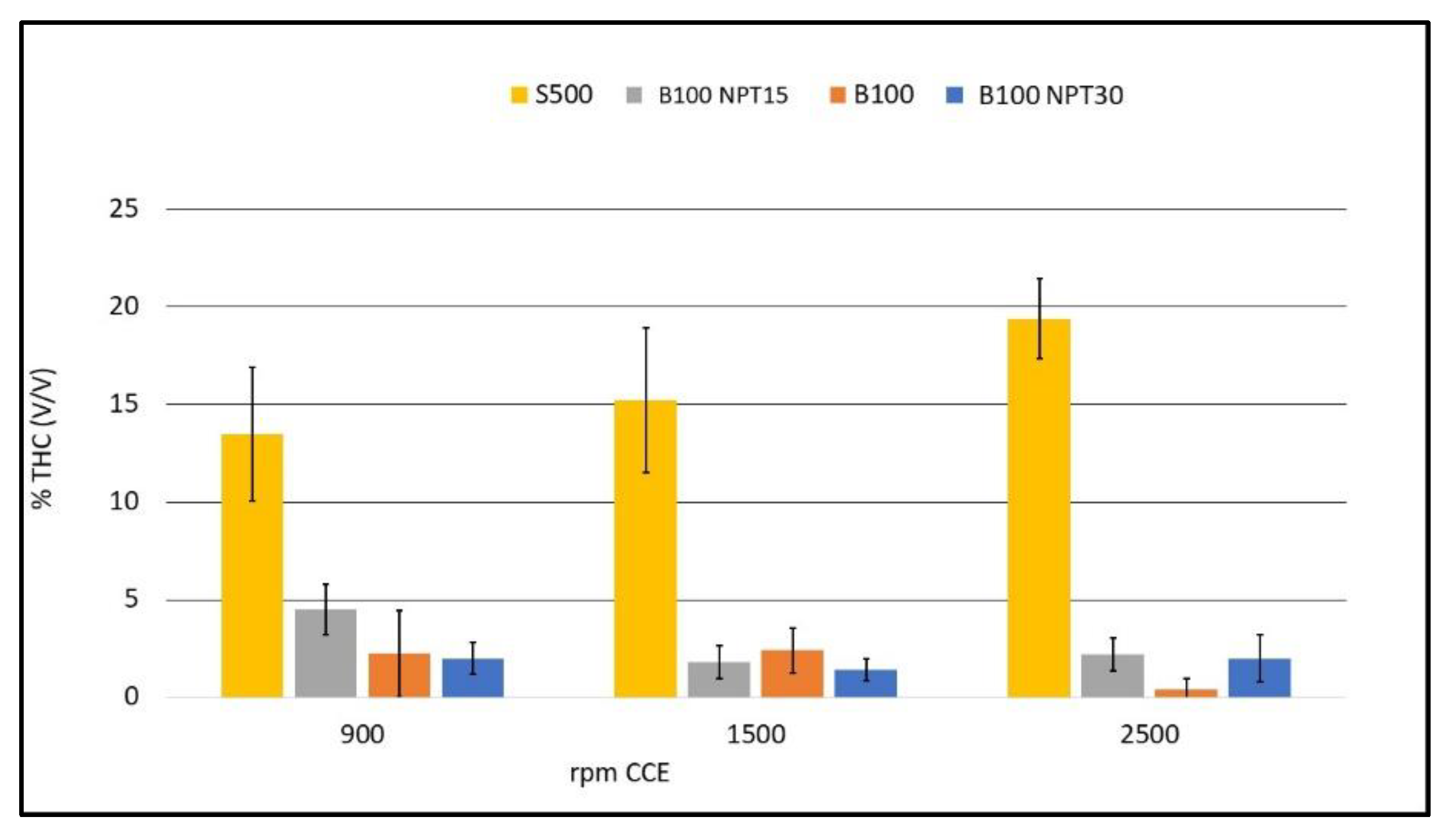

3.2.2. Total Hydrocarbons (THC) in the Exhaust Gas

3.2.3. Stability of Biodiesel Obtained from NTP

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- PNUD. Transformando Nosso Mundo: A Agenda 2030 Para o Desenvolvimento Sustentável. A/Res/70/. Available online: http://www.un.org/ga/search/view_doc.asp?symbol=A/RES/70/1&Lang=E20151-49 (accessed on 1 July 2022).

- Brito, F.D.O. Desenvolvimento de Usina de Produção de Biodiesel a Partir de Òleo de Fritura Usando Simuladores de Processo: Aspectos Operacionais. Master’s Thesis, Postgraduation in Civil Engineering. Centro de Tecnologia da Universidade Federal do Ceará, Fortaleza, Brazil, 2013. [Google Scholar]

- Ministério de Minas e Energia; Empresa de Pesquisa Energética. MME-EPE Balanço Energético Nacional 2019; MME: Brasilia, Brazil; EPE: Rio de Janeiro, Brazil, 2019; p. 303.

- Agência Nacional do Petróleo Gás Natural e Biocombustíveis. ANP Ranp 45-2014. Available online: https://www.gov.br/anp/pt-br/assuntos/producao-e-fornecimento-de-biocombustiveis/biodiesel/especificacao-do-biodiesel (accessed on 1 July 2022).

- Puhan, S.; Vedaraman, N.; Sankaranarayanan, G.; Ram, B.V.B. Desempenho e estudo de emissão de óleo de Mahua (óleo madhuca indica) éster etílico em um motor diesel de injeção direta aspirado natural de 4 tempos. Renov. Energ. 2005, 30, 1269–1278. [Google Scholar] [CrossRef]

- Yuan, X.; Liu, J.; Zeng, G.; Shi, J.; Tong, J.; Huang, G. Otimização da conversão de resíduos de óleo de colza com alta FFA para biodiesel usando metodologia de superfície de resposta. Renov. Energ. 2005, 33, 1678–1684. [Google Scholar] [CrossRef]

- Ulusoy, Y. Alibaßs, K. Investigação tecnológica e econômica do uso de biodiesel como combustível alternativo. R. Fac. Agric. Uludag Univ. 2002, 16, 37–50. [Google Scholar]

- Van Gerpen, J.H. Biodiesel processing and production. Fuel Process. Technol. 2005, 86, 1097–1107. [Google Scholar] [CrossRef]

- Abdul-Majeed, W.S.; Aal-Thani, G.S.; Al-Sabahi, J.N. Aplicação de Plasma a jato voador para produção de combustível de biodiesel a partir de óleo vegetal desperdiçado. Plasma Chem. Processo Plasma 2016, 36, 1517–1531. [Google Scholar] [CrossRef]

- Moecke, E.H.S.; Feller, R.; Santos, H.A.D.; Machado, M.D.M.; Cubas, A.L.V.; Dutra, A.R.D.A.; Santos, L.L.V.; Soares, S.R. Produção de biodiesel a partir de resíduos de óleo de cozinha para uso como combustível em barcos de pesca artesanais: Integração de aspectos ambientais, econômicos e sociais. J. Clean. Prod. 2016, 135, 679–688. [Google Scholar] [CrossRef]

- Canakci, M. O potencial dos lipídios de resíduos de restaurantes como matérias-primas de biodiesel. Bioresour. Technol. 2007, 98, 183–190. [Google Scholar] [CrossRef]

- Çetinkaya, M.; Ulusoy, Y.; Tekìn, Y.; Karaosmanoǧlu, F. Engine and winter road test performances of used cooking oil originated biodiesel. Energy Convers. Manag. 2005, 46, 1279–1291. [Google Scholar] [CrossRef]

- Cancelli, D.M.; Dias, N.L. BRevê: Uma metodologia objetiva de cálculo de emissões para a frota brasileira de veículos. Eng. Sanit. Ambient. 2014, 19, 13–20. [Google Scholar] [CrossRef] [Green Version]

- Kumar, M.V.; Babu, A.V.; Kumar, P.R. Os impactos na combustão, desempenho e emissões de biodiesel usando aditivos em motor diesel de injeção direta. Alex. Eng. J. 2018, 57, 509–516. [Google Scholar]

- Reis, E.F.; Cunha, J.P.B.; Mateus, D.L.S.; Delmond, J.G.; Couto, R.F. Desempenho e emissões de um motor-gerador ciclo diesel sob diferentes concentrações de biodiesel de soja. Rev. Bras. Eng. Agrícola Ambient. 2013, 2013, 565–571. [Google Scholar] [CrossRef] [Green Version]

- Alam, S. Imece2015-51900 Runner of a Diesel Engine Run on Biodiesel to Improve the Air-Fuel. In Proceedings of the International Mechanical Engineering Congress and Exposition (IMECE2015), Houston, TX, USA, 13–19 November 2015; pp. 1–7. [Google Scholar]

- Aydin, S.; Dizendo, C.; Aydin, H. Investigação da usabilidade do biodiesel obtido a partir de óleo de fritura residual em um motor diesel com revestimento de barreira térmica. Appl. Therm. Eng. 2015, 80, 212–219. [Google Scholar] [CrossRef]

- Cubas, A.L.V.; Machado, M.M.; Pinto, C.R.S.C.; Moecke, E.H.S.; Dutra, A.R.A. Biodiesel production using fatty acids from food industry waste using corona discharge plasma technology. Waste Manag. 2016, 47, 149–154. [Google Scholar] [CrossRef]

- Fridman, A.; Gutsol, A.; Gangoli, S.; Ju, Y.; Ombrello, T. Características do arco de deslizamento e sua aplicação em aprimoramento de combustão. J. Propuls. Power 2008, 24, 1216–1228. [Google Scholar] [CrossRef]

- Buchori, L.; Istadi, eu.; Purwanto, P. Tecnologias avançadas de reator químico para produção de biodiesel a partir de óleos vegetais — uma revisão. Bull. Chem. React. Eng. Catal. 2016, 11, 406–430. [Google Scholar] [CrossRef] [Green Version]

- Buchori, L.; Istadi, I.; Purwanto, P. Síntese de Biodiesel em um Reator Catalítico-Plasma híbrido sobre K2O/CaO-ZnO Catalyst. Sci. Study Res. Chem. Chem. Eng. Biotechnol. Food Ind. 2017, 18, 303–318. [Google Scholar]

- Istadi, I.; Yudhistira, A.D.; Anggoro, D.D.; Buchori, L. Sistema de eletro-catálise para síntese de biodiesel a partir de óleo de palma sobre reator de plasma de descarga de barreira dielelétrica. Bull. Chem. React. Eng. O Catal. 2014, 9, 111–120. [Google Scholar]

- Hyun, Y.; Mok, Y.; Jang, D. Transesterificação de Óleos Vegetais no Processo de Descarga de Plasma Pulsed-Corona. J. Korean Oil Chem. Soc. 2012, 29, 81–87. [Google Scholar]

- Istadi, I.; Anggoro, D.D.; Marwoto, P.; Suherman, S.; Nugroho, B.T. Biodiesel Produção de Óleo Vegetal sobre Reator de Plasma: Otimização do Rendimento do Biodiesel utilizando a Metodologia de Superfície de Resposta. Bull. Chem. React. Eng. Catal. 2009, 4, 23–31. [Google Scholar] [CrossRef]

- Machado, M.M. Conversão de Óleo Vegetal Residual em Biodiesel Através da Tecnologia de Plasma: Avaliação do Potencial de Sustentabilidade do Processo. Ph.D. Thesis, Postgraduation Program in Environmental Engineering. Universidade Federal de Santa Catarina, Florianópolis, Brazil, 2018. [Google Scholar]

- Meng, X.; Chen, G.; Wang, Y. Biodiesel production from waste cooking oil via alkali catalyst and its engine test. Fuel Process. Technol. 2008, 89, 851–857. [Google Scholar] [CrossRef]

- AOAC—Associação de Químicos Analíticos Oficiais. Métodos Oficiais de Análise da AOAC International, 18th ed.; AOAC: Washington, DC, ESA, 2005. [Google Scholar]

- Diwakar, B.T.; Dutta, P.K.; Lokesh, B.R.; Naidu, K.A. Propriedades Físico-Químicas de Garden Cress (Lepidium sativum L.) Óleo de Sementes. J. Am. Oil. Chem. Soc. 2010, 87, 539–548. [Google Scholar] [CrossRef]

- Corsini, M.S.; Jorge, N. Estabilidade oxidativa de óleos vegetais utilizados em frituras de mandioca palito congelada. Ciência Tecnol. Aliment. 2006, 26, 27–32. [Google Scholar] [CrossRef] [Green Version]

- Amaral, B.; Rezende, D.B.; Pasa, V.M.D. Avaliação de envelhecimento e estabilidade de misturas diesel/biodiesel armazenadas em garrafas de polietileno âmbar em diferentes condições de umidade. Combustível 2020, 279, 118289. [Google Scholar] [CrossRef]

- Miranda, G.R.D.; Lisboa, H.D.M.; Meier, H.F.; Vieira, M.V.; Hartmann, E.M. Avaliação das emissões de CO, NO, NOX e SO2 provenientes da combustão, em motor monocilíndrico, de misturas de diesel e biodiesel de óleo de fritura. Rev. Ciências Ambient. 2013, 7, 33–43. [Google Scholar]

- Völz, M.; Pozzebon, A.; Oliveira, G.; D’oca, M.G.M.; Villararreyes, J. Comportamento da esterificação de ácidos graxos livres óleo de soja. In Proceedings of the Congresso Latinoamericano de Óleos e Gorduras, Florianópolis, Brazil, 12–14 November 2000. [Google Scholar]

- Elhalwagy, M.; Zhang, C. Uma Cinética de Combustão de Biodiesel Proposta com base na dinâmica do fluido computacional resulta em um testador de qualidade de ignição. J. Energy Resour. Technol. Trans. ASME 2019, 141, 082204. [Google Scholar] [CrossRef]

- Mahalingam, A.; Deverajan, Y. Radhakrishnan, S.; Vellaiyan, S.; Nagappan, B. Análise de emissões em biodiesel de óleo de mahua e misturas mais altas de álcool no motor diesel. Alex. Univ.-Alex. Eng. J. 2018, 57, 2627–2631. [Google Scholar] [CrossRef]

- Oliveira, K.G.D. Obtenção de Antioxidantes Naturais e Aplicação em Misturas de Diesel e Biodiesel Sintetizado a Partir das Oleaginosas de Soja e Algodão. Master’s Thesis, Postgraduate Program in Chemistry. Universidade Federal do rio Grande do Norte Instituto de Química, Natal, Brazil, 2017. [Google Scholar]

| References | Objective | Experimental Conditions | Results |

|---|---|---|---|

| Istadi et al., 2009[24] Biodiesel production from vegetable oil over plasma reactor: optimization of biodiesel yield using response surface methodology | The purpose of this paper is to study the optimization of process parameters in biodiesel pro-duction over plasma reactor which maximizes the biodiesel product yield and minimizes the acid number of biodiesel. | DC high voltage source (400–1200 kV) and the plasma reactor in times to 2.9 to 17.1 min | Biodiesel obtaining is possible by replacing chemical catalysis with plasma technology, bringing out a maximum conversion rate 36%. |

| Hyun, Mok, and Jang (2012) [23] Transesterification of Vegetable Oils in Pulsed-Corona Plasma Discharge Process | They applied plasma technology with the addition of basic catalyst (KOH) | Molar ratio of 3:1, 5:1, and 8:1, content of catalyst KOH of 0.4, 0.6, and 0.8 wt% and applied voltage of 18, 23, and 28 kV | Conversion rate of 95% with 5 min reaction using camelina oil, and 98% conversion rate in 15 min using rapeseed oil. |

| Istadi et al. (2014)[22] Electro-catalysis system for biodiesel synthesis from palm oil over Dielectric-Barrier Discharge plasma reactor. Bulletin of Chemical Reaction Engineering and Catalysis | They studied the synthesis of biodiesel from palm oil using electrocatalysis through plasma technology in a dielectric barrier discharge reactor. | The reactor used had a continuous electric current of 15 kV; a 6:1 molar ratio was performed, varying some parameters: (a) 6 kV, 8 kV, and 10 kV, with an electrode gap of 1.5 cm and reaction time of 120 s; (b) Increasing gap between the electrodes to 1.5, 2.5, and 3.5 cm, and maintained the molar ratio of 6:1, 10 kV, and a reaction time of 120 s. | The best result reached by the authors was a conversion rate of 75.65% in 120 s, and it is recommended by authors that a shorter exposure time of the samples be established to the plasma, but using a high voltage and low current. They noted that the biodiesel produced by plasma can emit 10 times less particulate material than the biodiesel obtained by CC |

| Buchori, Istadi, and Purwanto, 2016 [20] Advanced chemical reactor technologies for biodiesel production from vegetable oils—A review. Bulletin of Chemical Reaction Engineering and Catalysis | This paper reviews briefly the technologies on transesterification reaction for biodiesel production using homogeneous, heterogeneous, and enzyme catalysts, as well as advanced methods (supercritical, microwave, ultrasonic, and plasma technology). Advantages and disadvantages of each method were described comprehensively. | Review article | The plasma technology is promising for biodiesel synthesis from vegetable oils due to very short reaction time, no soap formation, and no glycerol as a by-product |

| Abdul-Majeed, AAl-Thani, and Al-Sabahi (2016) [9] Application of Flying Jet Plasma for Production of Biodiesel Fuel from Wasted Vegetable Oil | They examined for the first time a special design flying jet atmospheric non-thermal plasma generator to treat wasted cooking oil samples before transesterification | Argon plasma generation with a power rating between 1.5 and 2.5 kW at approximately 30 kHz and an argon flow rate at 100 mL.min-1 in reactions durations about 40, 60, 80 min and 100 min | It was observed a yield improvement of 41% in terms of reaction time: 60 min for the reaction; also with 100 min reaction time the yield reached 72%. |

| Cubas et al. (2016)[18] Biodiesel production using fatty acids from food industry waste using corona discharge plasma technology | They described an alternative and innovative methodology to transform waste, frying oil in biodiesel through a technology called corona discharge plasma technology | Oil/methanol molar ratio of 6:1, ambient temperature (25 °C) and reaction time of 110 min and 30 mL of sample | Authors could conclude that corona discharge plasma may be promising technology, since it does not require a catalyst and the formation of a co-product does not occur. |

| Istadi et al. (2014) [22] Electro-Catalysis System for Biodiesel Synthesis from palm Oil over Dielectric-Barrier Discharge Plasma Reactor | They studied the reaction of synthesis of biodiesel from palm oil, using the Dielectric-Barrier Discharge (DBD) plasma reactor | Palm oil and methanol with 6:1 molar ratio were inserted into the reactor and heated to 65 °C, at a high voltage of 10 kV DC (direct current) and reaction time ranging from 30, 120, and 300 s | The authors obtained a yield of 75.65% fatty acid methyl ester in 120 s, without generating glycerol and soap. |

| Buchori, Istadi, and Purwanto, 2017 [21] Synthesis of Biodiesel on a Hybrid Catalytic-Plasma Reactor Over K2O/CaO-ZnO Catalyst | This paper aimed to study the synergistic effects of dielectric barrier discharge plasma and 5% K2O/CaO-ZnO catalyst on biodiesel synthesis. | Reactants (methanol and soybean oil) with the molar ratio of methanol/oil of 15:1 were flowed into the mixing tank and vigorously stirred. Thus, the reactant mixture was fed into the catalytic-plasma reactor packed with the 15.15 g of 5KCZ catalyst. | The results demonstrated that synergistic effects of the plasma system and the catalyst basicity has a significant role on the performance of catalytic-plasma reactor for biodiesel production. |

| Properties | B100-CC | B100-NTP15 | B100-NTP30 | Unit |

|---|---|---|---|---|

| Acidity | 0.378 | 0.298 | 0.300 | mg KOH g−1 |

| Saponification | 172.10 | 199.05 | 199.87 | mg KOH g−1 |

| Biodiesel content | 96.40 | 64.88 | 56.69 | % (v/v) |

| Acids | B100 (10−3) | B100-NTP15 (10−3) | B100-NTP30 (10−3) | Unit |

|---|---|---|---|---|

| Palmitic acid-C16:0 (n-hexadecanoic acid) | 1.76 ± 0.19 | 1.64 ± 0.26 | 1.53 ± 0.20 | Mg |

| Linoleic acid-C18:2 (9,12-octadienoic acid) | 3.53 ± 0.06 | 4.11 ± 0.51 | 3.83 ± 0.06 | Mg |

| Oleic acid-C18:1 (9-octadecenoic acid) | 3.48 ± 0.16 | 4.69 ± 0.52 | 3.35 ± 0.48 | Mg |

| Stearic acid-C18:0 (octadecanoic acid) | 0.02 ± 0.68 | 0.57 ± 0.12 | 0.56 ± 0.02 | Mg |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cubas, A.L.V.; Moecke, E.H.S.; Ferreira, F.M.; Osório, F.d.S. THC and CO Emissions from Diesel Engines Using Biodiesel Produced from Residual Frying Oil by Non-Thermal Plasma Technology. Processes 2022, 10, 1663. https://doi.org/10.3390/pr10081663

Cubas ALV, Moecke EHS, Ferreira FM, Osório FdS. THC and CO Emissions from Diesel Engines Using Biodiesel Produced from Residual Frying Oil by Non-Thermal Plasma Technology. Processes. 2022; 10(8):1663. https://doi.org/10.3390/pr10081663

Chicago/Turabian StyleCubas, Anelise Leal Vieira, Elisa Helena Siegel Moecke, Franciele Mendonça Ferreira, and Fernando da Silva Osório. 2022. "THC and CO Emissions from Diesel Engines Using Biodiesel Produced from Residual Frying Oil by Non-Thermal Plasma Technology" Processes 10, no. 8: 1663. https://doi.org/10.3390/pr10081663

APA StyleCubas, A. L. V., Moecke, E. H. S., Ferreira, F. M., & Osório, F. d. S. (2022). THC and CO Emissions from Diesel Engines Using Biodiesel Produced from Residual Frying Oil by Non-Thermal Plasma Technology. Processes, 10(8), 1663. https://doi.org/10.3390/pr10081663