Experimental Study on the Acoustic Emission Characteristics of Fractured Granite after Repeated High Temperature-Water Cooling

Abstract

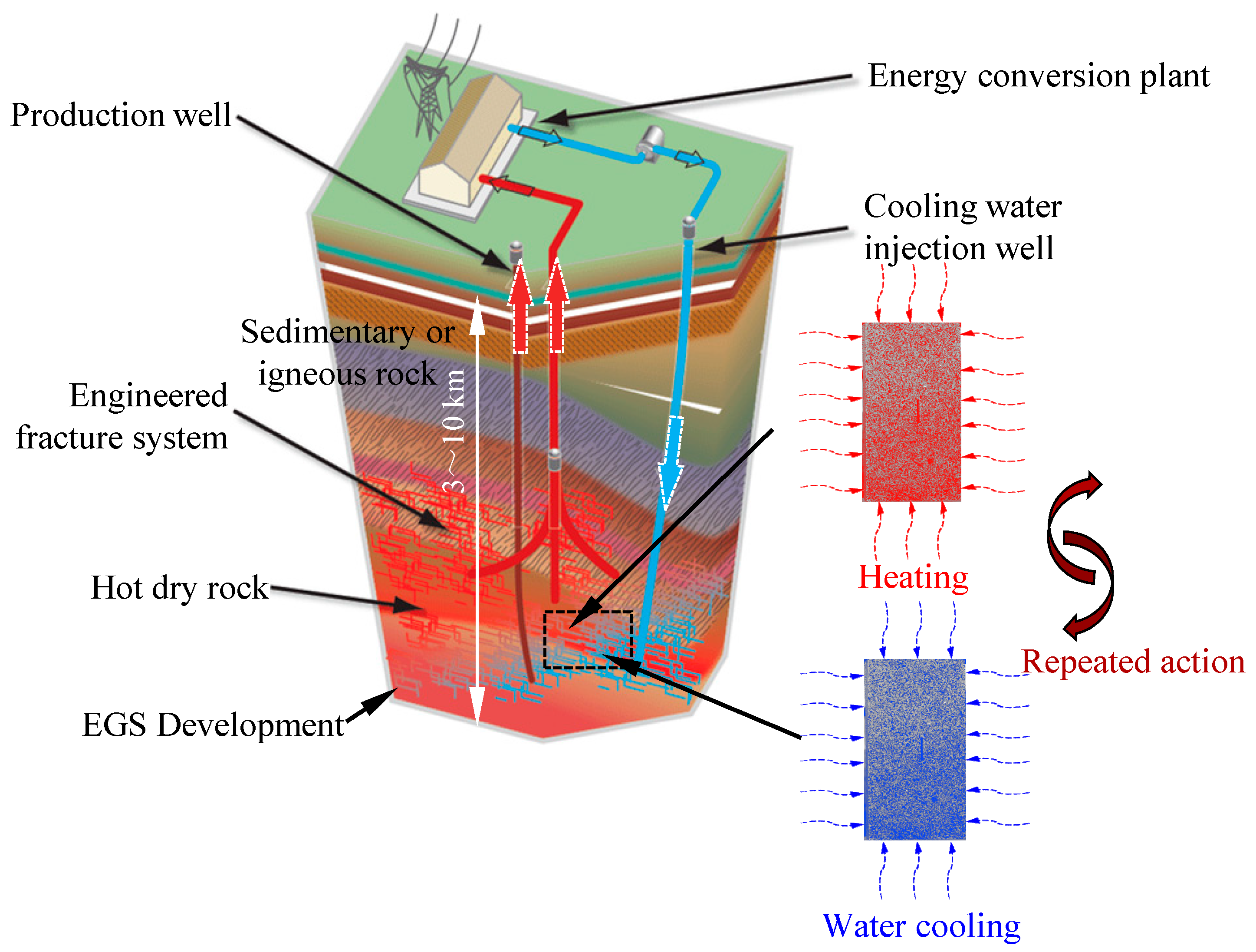

1. Introduction

2. Experimental Protocol Design

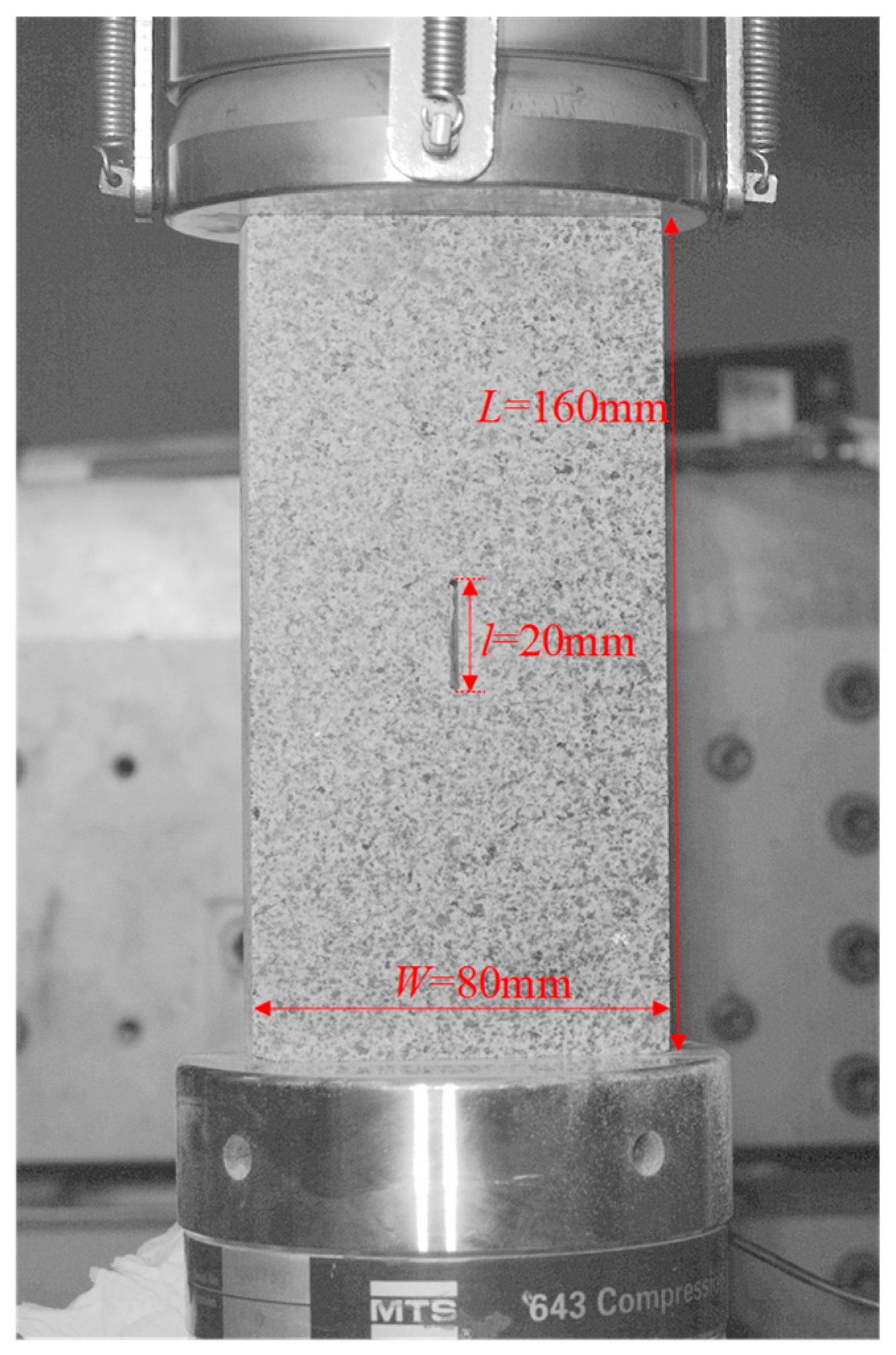

2.1. Specimen Processing and Handling

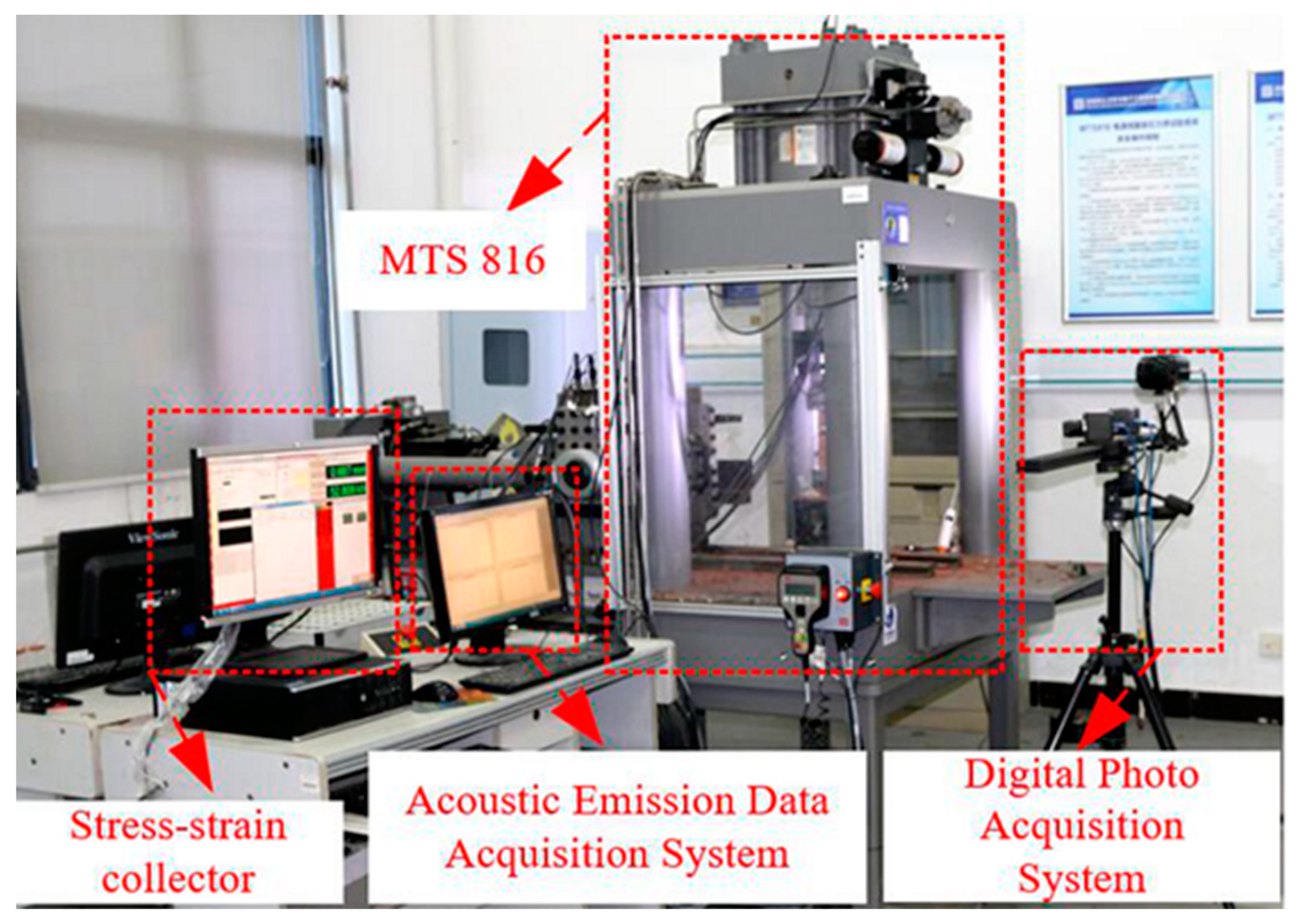

2.2. Loading and Data Acquisition Systems

3. Test Results

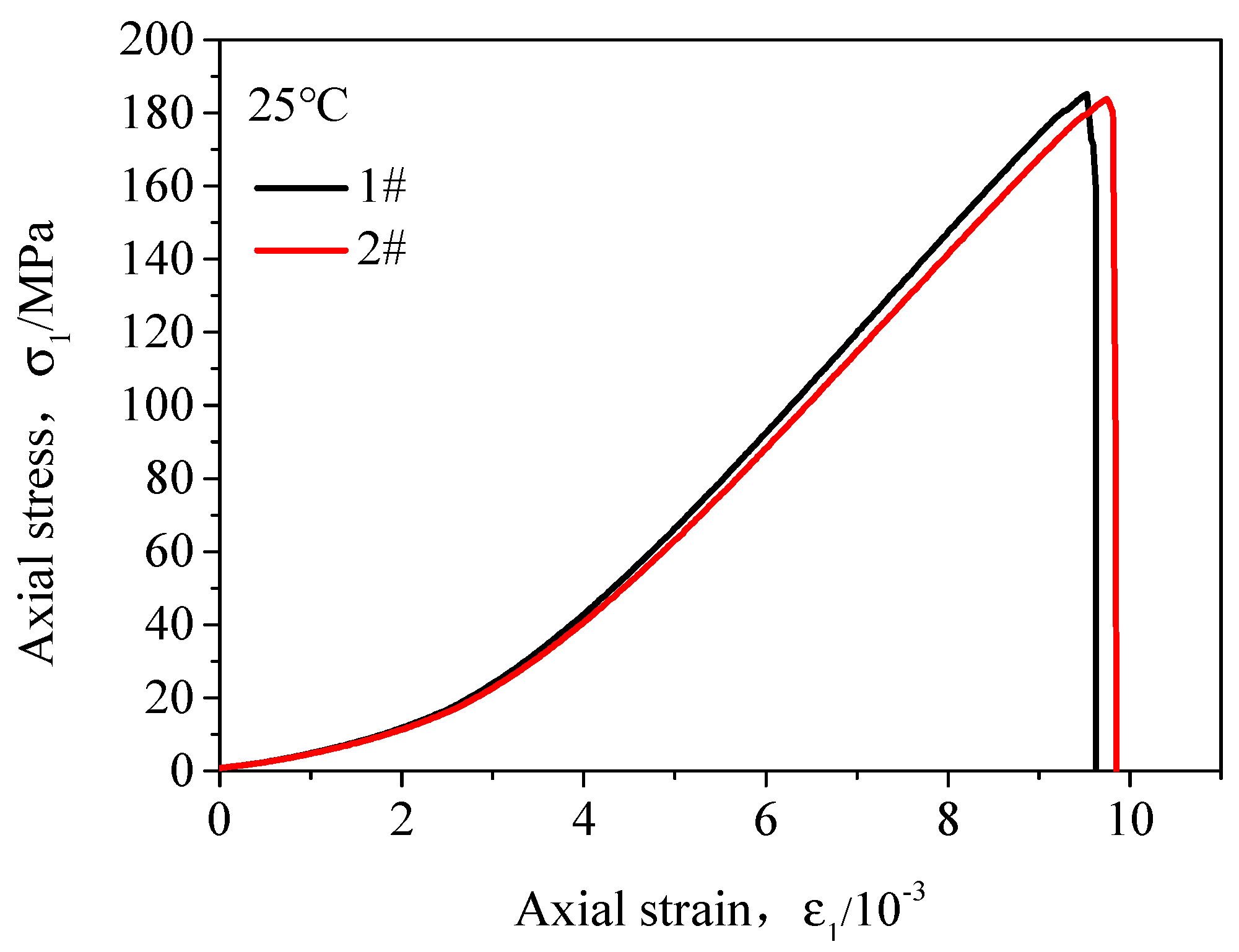

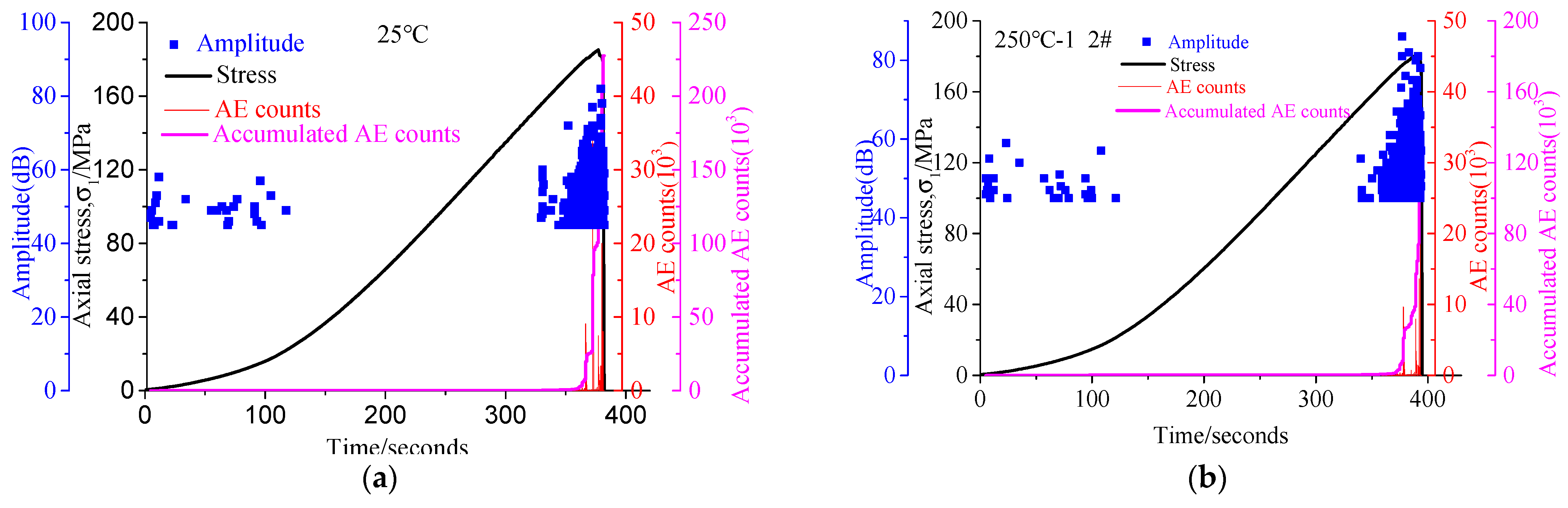

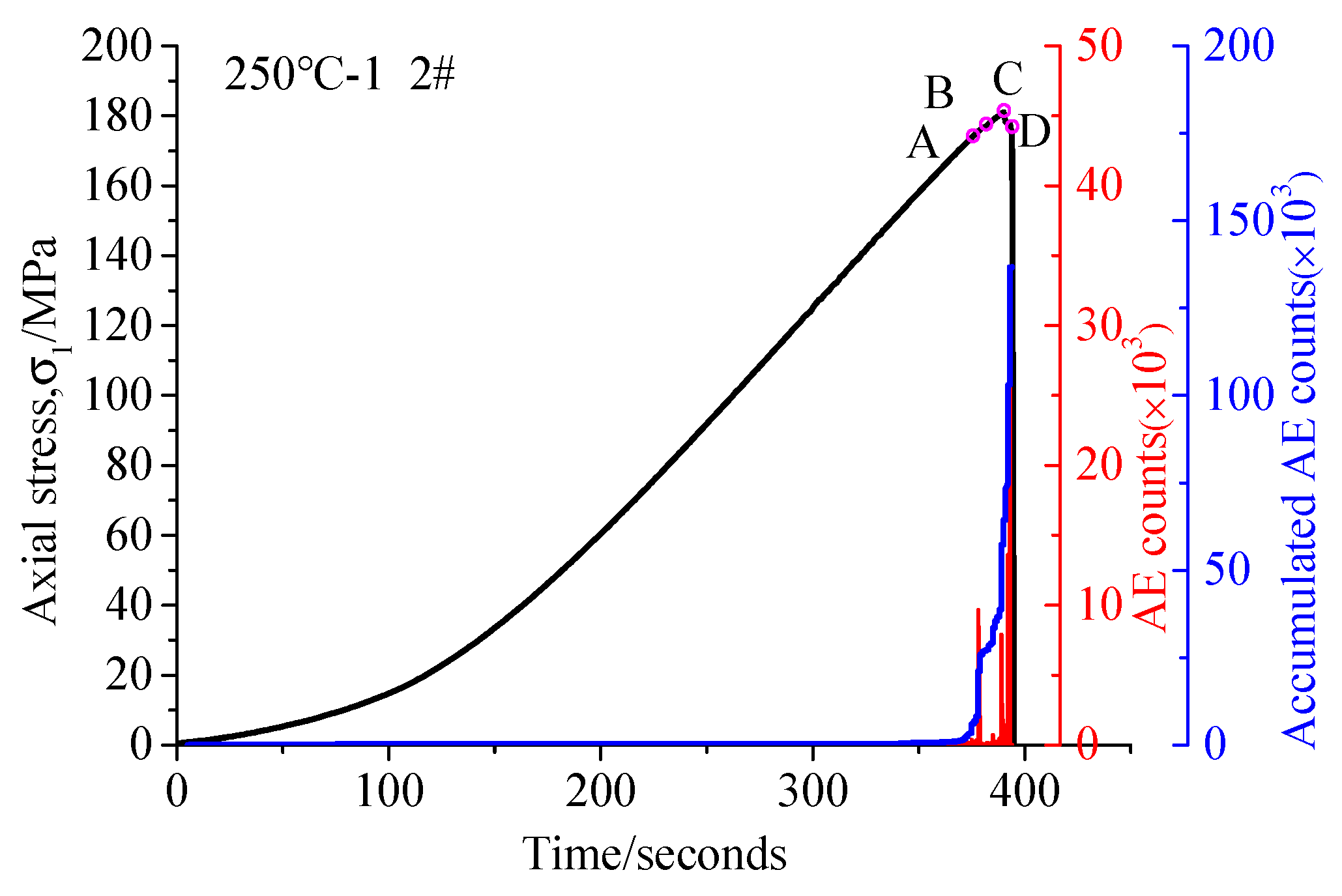

3.1. Characteristics of Basic Mechanical Parameters, Number of Acoustic Emission Events and Maximum Amplitude Variation

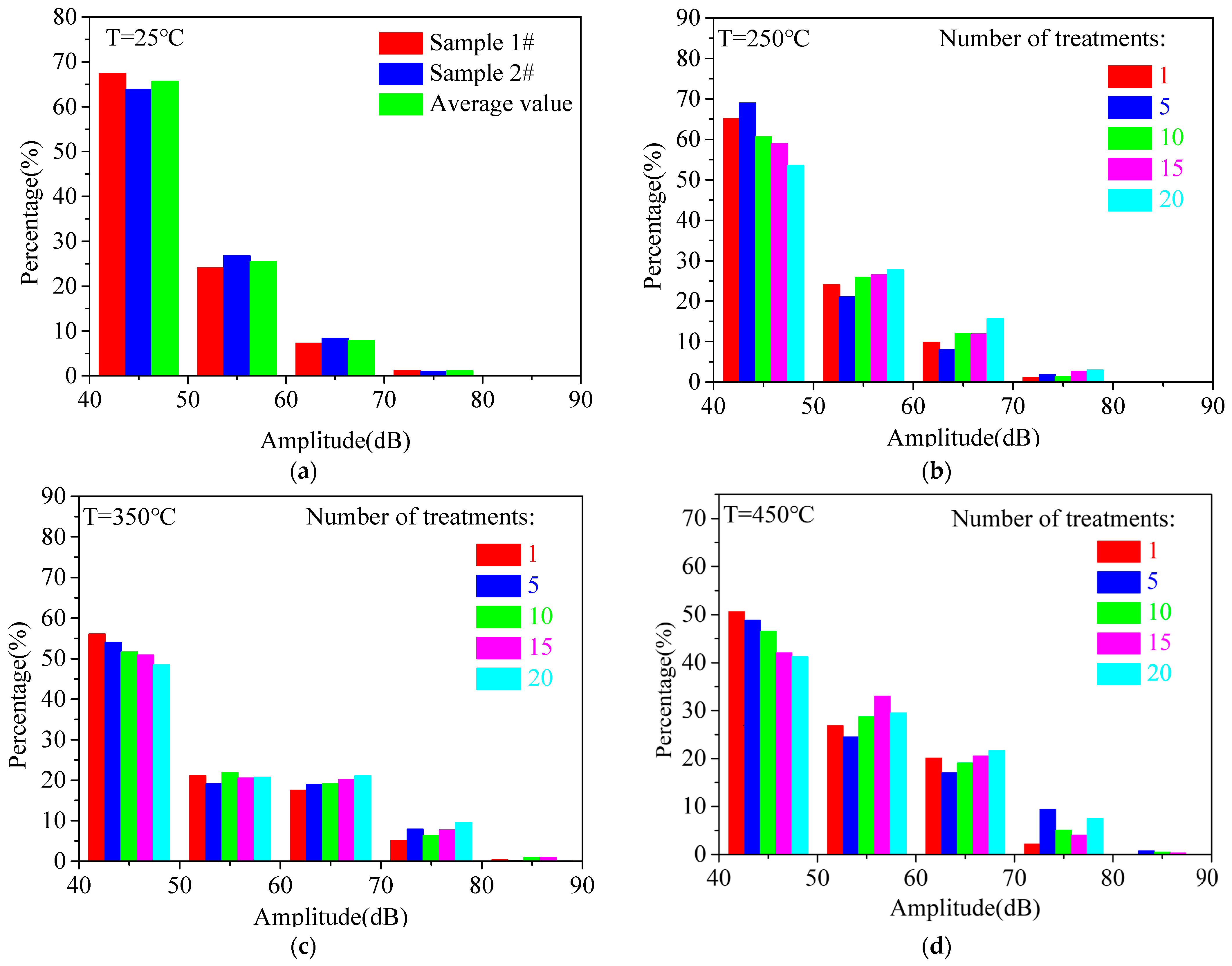

3.2. Maximum Amplitude Frequency Distribution Characteristics

3.3. Acoustic Emission Maximum Energy Analysis

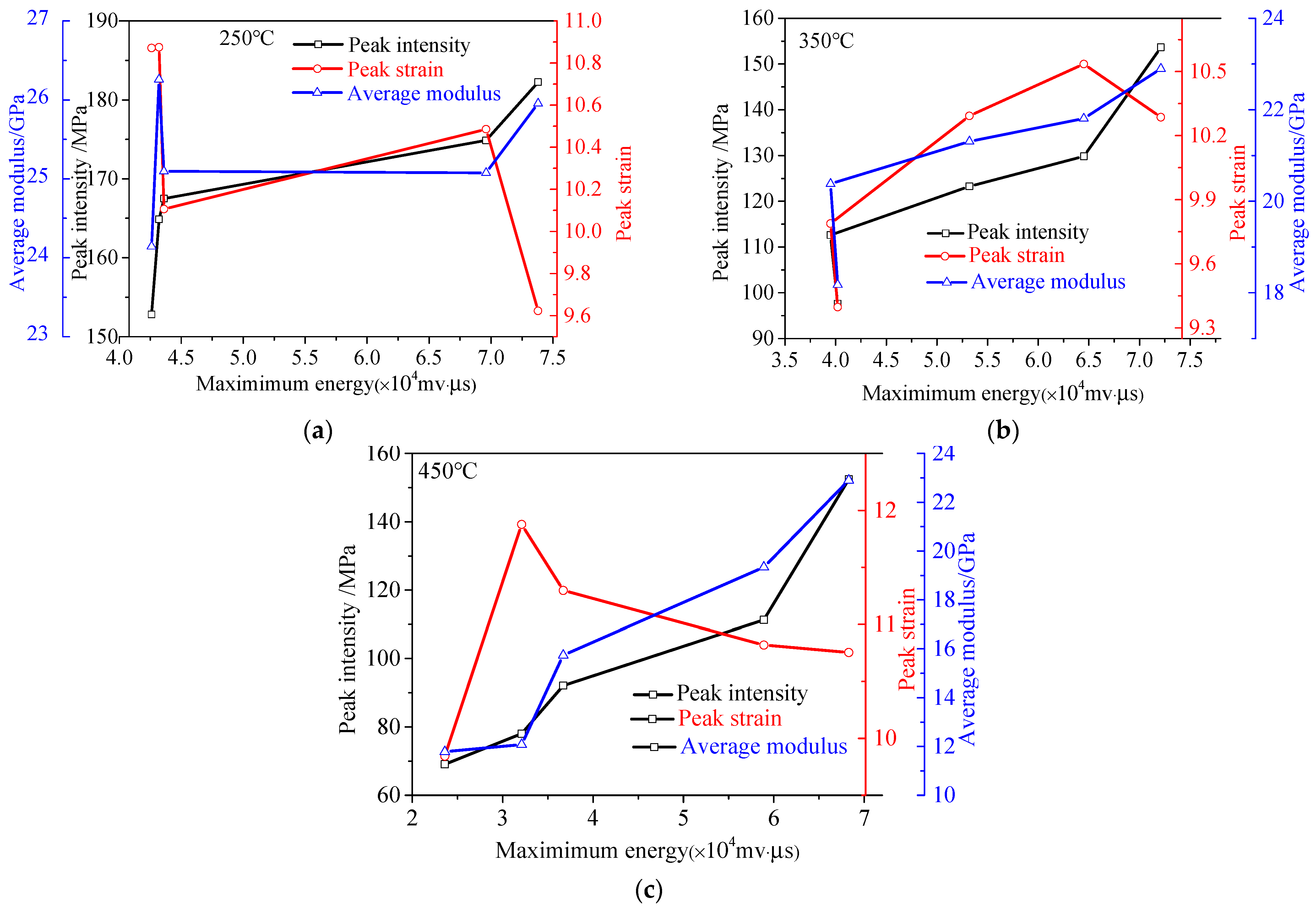

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kumari, W.G.P.; Ranjith, P.G.; Perera, M.S.A.; Li, X.; Li, L.H.; Chen, B.K.; Avanthi Isaka, B.L.; De Silva, V.R.S. Hydraulic frac-turing under high temperature and pressure conditions with micro CT applications: Geothermal energy from hot dry rocks. Fuel 2018, 230, 138–154. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, Z.; Xi, B.; Zhao, J.; Wan, Z.; Zhou, A. Prospect of HDR geothermal energy exploitation in Yangbajing, Tibet, China, and experimental investigation of granite under high temperature and high pressure. J. Rock Mech. Geotech. Eng. 2011, 3, 260–269. [Google Scholar] [CrossRef]

- Zhang, W.; Guo, T.; Qu, Z.; Wang, Z. Research of fracture initiation and propagation in HDR fracturing under thermal stress from meso-damage perspective. Energy 2019, 178, 508–521. [Google Scholar] [CrossRef]

- Pathiranagei, S.V.; Gratchev, I.; Kong, R. Engineering properties of four different rocks after heat treatment. Geomech. Geophys. Geo-Energy Geo-Resour. 2021, 7, 1–21. [Google Scholar] [CrossRef]

- Asai, P.; Panja, P.; McLennan, J.; Moore, J. Efficient workflow for simulation of multifractured enhanced geothermal systems (EGS). Renew. Energy 2019, 131, 763–777. [Google Scholar] [CrossRef]

- Bertani, R. Geothermal power generation in the world 2010–2014 update report. Geothermics 2016, 60, 31–43. [Google Scholar] [CrossRef]

- Shi, X.; Jing, H.; Yin, Q.; Zhao, Z.; Gao, Y. Investigation on physical and mechanical properties of bedded sandstone after high-temperature exposure. Bull. Eng. Geol. Environ. 2020, 79, 2591–2606. [Google Scholar] [CrossRef]

- Zhao, F.; Sun, Q.; Zhang, W. Thermal damage analysis based on physical and mechanical indices of granodiorite. Géotechnique Lett. 2020, 10, 1–6. [Google Scholar] [CrossRef]

- Yin, Q.; Jing, H.; Liu, R.; Yu, L.; Su, H.; Han, G. Pore characteristics and nonlinear flow behaviors of granite exposed to high temperature. Bull. Eng. Geol. Environ. 2020, 79, 1239–1257. [Google Scholar] [CrossRef]

- Qian, Y.; Jiangyu, W.; Zheng, J.; Chun, Z.; Haijian, S.; Hongwen, J.; Xiaowei, G. Investigating the effect of water quenching cycles on mechanical behaviors for granites after conventional triaxial compression. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 77. [Google Scholar]

- Salimzadeh, S.; Nick, H.M.; Zimmerman, R.W. Thermoporoelastic effects during heat extraction from low-permeability reservoirs. Energy 2018, 142, 546–558. [Google Scholar] [CrossRef]

- Pokhrel, S.; Sasmito, A.P.; Sainoki, A.; Tosha, T.; Tanaka, T.; Nagai, C.; Ghoreishi-Madiseh, S.A. Field-scale experimental and numerical analysis of a downhole coaxial heat exchanger for geothermal energy production. Renew. Energy 2022, 182, 521–535. [Google Scholar] [CrossRef]

- Ranjith, P.G.; Daniel, R.V.; JieChen, B.; Perera, M.S.A. Transformation plasticity and the effect of temperature on the mechanical behaviour of Hawkesbury sandstone at atmospheric pressure. Eng. Geol. 2012, 151, 120–127. [Google Scholar]

- Siratovich, P.A.; Villeneuve, M.C.; Cole, J.W.; Kennedy, B.M.; Bégué, F. Saturated heating and quenching of three crustal rocks and implications for thermal stimulation of permeability in geothermal reservoirs. Int. J. Rock Mech. Min. Sci. 2015, 80, 265–280. [Google Scholar] [CrossRef]

- Liu, S.; Xu, J. Mechanical properties of Qinling biotite granite after high temperature treatment. Int. J. Rock Mech. Min. Sci. 2014, 71, 188–193. [Google Scholar] [CrossRef]

- Gautam, P.K.; Verma, V.K.; Jha, M.K.; Sharma, P.; Singh, T.N. Effect of high temperature on physical and mechanical properties of Jalore granite. J. Appl. Geophys. 2018, 159, 460–474. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, G.F.; Li, Q. Acoustic Emission uncovers thermal damage evolution of rock. Int. J. Rock Mech. Min. Sci. 2020, 132, 104388. [Google Scholar] [CrossRef]

- Zhou, C.; Wan, Z.; Zhang, Y.; Gu, B. Experimental study on hydraulic fracturing of granite under thermal shock. Geothermics 2018, 71, 146–155. [Google Scholar] [CrossRef]

- Zhu, D.; Jing, H.; Yin, Q.; Ding, S.; Zhang, J. Mechanical Characteristics of Granite After Heating and Water-Cooling Cycles. Rock Mech. Rock Eng. 2020, 53, 2015–2025. [Google Scholar] [CrossRef]

- Xu, C.; Sun, Q. Effects of quenching cycle on tensile strength of granite. Géotechnique Lett. 2018, 8, 165–170. [Google Scholar] [CrossRef]

- Yin, T.; Li, Q.; Li, X. Experimental investigation on mode I fracture characteristics of granite after cyclic heating and cooling treatments. Eng. Fract. Mech. 2019, 222, 106740. [Google Scholar] [CrossRef]

- Wu, J.Y.; Jing, H.W.; Gao, Y.; Meng, Q.B.; Yin, Q.; Du, Y. Effects of carbon nanotube dosage and aggregate size distribution on mechanical property and microstructure of cemented rockfill. Cement Concr. Comp. 2022, 127, 104408. [Google Scholar] [CrossRef]

- Wu, J.Y.; Feng, M.M.; Mao, X.B.; Xu, J.M.; Zhang, L.W.; Ni, X.Y.; Han, G.S. Particle size distribution of aggregate effects on mechanical and structural properties of cemented rockfill: Experiments and modeling. Constr. Build. Mater. 2018, 193, 295–311. [Google Scholar] [CrossRef]

- Yin, Q.; Wu, J.; Zhu, C.; Wang, Q.; Xie, J. The role of multiple heating and water cooling cycles on physical and mechanical responses of granite rocks. Geomech. Geophys. Geo-Energy Geo-Resour. 2021, 7, 69. [Google Scholar] [CrossRef]

- Shen, Y.; Yuan, J.; Hou, X.; Hao, J.; Li, T. The strength changes and failure modes of high-temperature granite subjected to cooling shocks. Geomech. Geophys. Geo-Energy Geo-Resour. 2021, 7, 1–18. [Google Scholar] [CrossRef]

- Ganne, P.; Vervoort, A.; Wevers, M. Quantification of pre-peak brittle damage: Correlation between acoustic emission and observed micro-fracturing. Int. J. Rock Mech. Min. Sci. 2007, 44, 720–729. [Google Scholar] [CrossRef]

- Zhao, X.G.; Wang, J.; Cai, M.; Cheng, C.; Ma, L.K.; Su, R.; Zhao, F.; Li, D.J. Influence of Unloading Rate on the Strainburst Characteristics of Beishan Granite Under True-Triaxial Unloading Conditions. Rock Mech. Rock Eng. 2014, 47, 467–483. [Google Scholar] [CrossRef]

- He, M.C.; Miao, J.L.; Feng, J.L. Rock burst process of limestone and its acoustic emission characteristics under true-triaxial unloading conditions. Int. J. Rock Mech. Min. Sci. 2010, 47, 286–298. [Google Scholar] [CrossRef]

- Ge, Z.; Sun, Q. Acoustic emission characteristics of granite after heating and cooling cycles. Eng. Fract. Mech. 2018, 200, 418–429. [Google Scholar] [CrossRef]

- Zhu, D.; Jing, H.; Yin, Q.; Han, G. Experimental Study on the Damage of Granite by Acoustic Emission after Cyclic Heating and Cooling with Circulating Water. Processes 2018, 6, 101. [Google Scholar] [CrossRef]

- Zhu, D.; Fan, Y.; Miao, L.; Jin, H.; Jing, H.; Liu, X. Study of tensilemechanical properties of granite after repeated action of high temperature-water cooling. Sustainability 2022, 14, 13601. [Google Scholar] [CrossRef]

- Yang, S.Q.; Yang, D.S.; Jing, H.W.; Li, Y.H.; Wang, S.Y. An Experimental Study of the Fracture Coalescence Behaviour of Brittle Sandstone Specimens Containing Three Fissures. Rock Mech. Rock Eng. 2012, 45, 563–582. [Google Scholar] [CrossRef]

- Zhu, D.; Jing, H.W.; Yin, Q.; Zong, Y.J. Experimental study on mechanical characteristics of sandstone containing arc fissures. Arab. J. Geosci. 2018, 11, 637. [Google Scholar] [CrossRef]

- Yin, P.; Wang, R.H.C.; Chau, K.T. Coalescence of two parallel pre-existing surface cracks in granite. Int. J. Rock Mech. Min. Sci. 2014, 68, 66–84. [Google Scholar] [CrossRef]

- Yang, S.Q.; Liu, X.R.; Jing, H.W. Experimental investigation on fracture coalescence behavior of red sandstone containing two unparallel fissures under uniaxial compression. Int. J. Rock Mech. Min. Sci. 2013, 63, 82–92. [Google Scholar] [CrossRef]

- Li, Q.; Liang, Y.; Zou, Q.; Li, Q. Acoustic Emission and Energy Dissipation Characteristics of Gas-Bearing Coal Samples Under Different Cyclic Loading Paths. Nat. Resour. Res. Off. J. Int. Assoc. Math. Geosci. 2020, 29, 1397–1412. [Google Scholar] [CrossRef]

- Yu, P.; Pan, P.; Feng, G.; Wu, Z.; Zhao, S. Physico-mechanical properties of granite after cyclic thermal shock. J. Rock Mech. Geotech. Eng. 2020, 12, 693–706. [Google Scholar] [CrossRef]

- Wang, H.; Liu, D.; Cui, Z.; Cheng, C.; Jian, Z. Investigation of the fracture modes of red sandstone using XFEM and Acoustic emissions. Theor. Appl. Fract. Mech. 2016, 85, 283–293. [Google Scholar] [CrossRef]

- Lin, Q.; Wang, S.; Wan, B.; Lu, Y.; Wang, Y. Characterization of Fracture Process in Sandstone: A Linear Correspondence Between Acoustic Emission Energy Density and Opening Displacement Gradient. Rock Mech. Rock Eng. 2020, 53, 975–981. [Google Scholar] [CrossRef]

- Li, P.; Ren, F.-H.; Cai, M.-F.; Guo, Q.-F.; Wang, H.-F.; Liu, K. Investigating the mechanical and Acoustic Emission characteristics of brittle failure around a circular opening under uniaxial loading. Int. J. Miner. Metall. Mater. 2019, 26, 1218–1230. [Google Scholar] [CrossRef]

- Moradian, O.; Wu, R.; Li, Y.; Leith, K.; Loew, S. Acoustic Emission and digital image correlation for damage evolution in brittle rocks under time-dependent tensile loading. IOP Conf. Ser. Earth Environ. Sci. 2021, 833, 012090. [Google Scholar] [CrossRef]

- Nozawa, T.; Koyanagi, T.; Katoh, Y.; Tanigawa, H. Failure evaluation of neutron-irradiated SiC/SiC composites by underwater Acoustic emission. J. Nucl. Mater. Mater. Asp. Fission Fusion 2022, 566, 1–14. [Google Scholar] [CrossRef]

| Specimens | Quality (kg) | Volume (×10−4 m3) | Density (×103 kg/m3) | Wave Velocity (×103 m/s) | Average Density (×103 kg/m3) | Average Wave Velocity (×103 m/s) |

|---|---|---|---|---|---|---|

| 25 °C 1# | 1.10 | 0.37 | 2.97 | 2.86 | 2.95 | 2.87 |

| 25 °C 2# | 1.11 | 0.38 | 2.92 | 2.87 | ||

| 250 °C-1 1# | 1.09 | 0.37 | 2.95 | 2.85 | 3.03 | 2.86 |

| 250 °C-1 2# | 1.12 | 0.36 | 3.11 | 2.86 | ||

| 250 °C-5 1# | 1.10 | 0.36 | 3.06 | 2.85 | 2.98 | 2.86 |

| 250 °C-5 2# | 1.10 | 0.38 | 2.89 | 2.86 | ||

| 250 °C-10 1# | 1.11 | 0.37 | 3.00 | 2.84 | 2.93 | 2.84 |

| 250 °C-10 2# | 1.09 | 0.38 | 2.87 | 2.83 | ||

| 250 °C-15 1# | 1.10 | 0.37 | 2.97 | 2.85 | 2.95 | 2.84 |

| 250 °C-15 2# | 1.08 | 0.37 | 2.92 | 2.83 | ||

| 250 °C-20 1# | 1.08 | 0.38 | 2.84 | 2.84 | 2.83 | 2.83 |

| 250 °C-20 2# | 1.07 | 0.38 | 2.82 | 2.85 | ||

| 350 °C-1 1# | 1.10 | 0.37 | 2.97 | 2.83 | 2.92 | 2.84 |

| 350 °C-1 2# | 1.09 | 0.38 | 2.87 | 2.83 | ||

| 350 °C-5 1# | 1.10 | 0.37 | 2.97 | 2.85 | 2.91 | 2.82 |

| 350 °C-5 2# | 1.08 | 0.38 | 2.84 | 2.83 | ||

| 350 °C-10 1# | 1.08 | 0.38 | 2.84 | 2.82 | 2.89 | 2.82 |

| 350 °C-10 2# | 1.09 | 0.37 | 2.95 | 2.81 | ||

| 350 °C-15 1# | 1.07 | 0.38 | 2.82 | 2.83 | 2.84 | 2.82 |

| 350 °C-15 2# | 1.09 | 0.38 | 2.87 | 2.80 | ||

| 350 °C-20 1# | 1.08 | 0.38 | 2.84 | 2.82 | 2.83 | 2.81 |

| 350 °C-20 2# | 1.07 | 0.38 | 2.82 | 2.82 | ||

| 450 °C-1 1# | 1.08 | 0.37 | 2.92 | 2.82 | 2.99 | 2.81 |

| 450 °C-1 2# | 1.10 | 0.36 | 3.06 | 2.80 | ||

| 450 °C-5 1# | 1.08 | 0.38 | 2.84 | 2.81 | 2.89 | 2.81 |

| 450 °C-5 2# | 1.09 | 0.37 | 2.95 | 2.80 | ||

| 450 °C-10 1# | 1.11 | 0.38 | 2.92 | 2.82 | 2.87 | 2.80 |

| 450 °C-10 2# | 1.07 | 0.38 | 2.82 | 2.79 | ||

| 450 °C-15 1# | 1.10 | 0.39 | 2.82 | 2.82 | 2.80 | 2.80 |

| 450 °C-15 2# | 1.06 | 0.38 | 2.79 | 2.78 | ||

| 450 °C-20 1# | 1.09 | 0.39 | 2.79 | 2.74 | 2.81 | 2.75 |

| 450 °C-20 2# | 1.10 | 0.39 | 2.82 | 2.76 |

| Samples | Destruction of Characteristic Point | σ1 (MPa) | σ1/σmax (%) | ε1 (10−3) | ε1/εmax (%) |

|---|---|---|---|---|---|

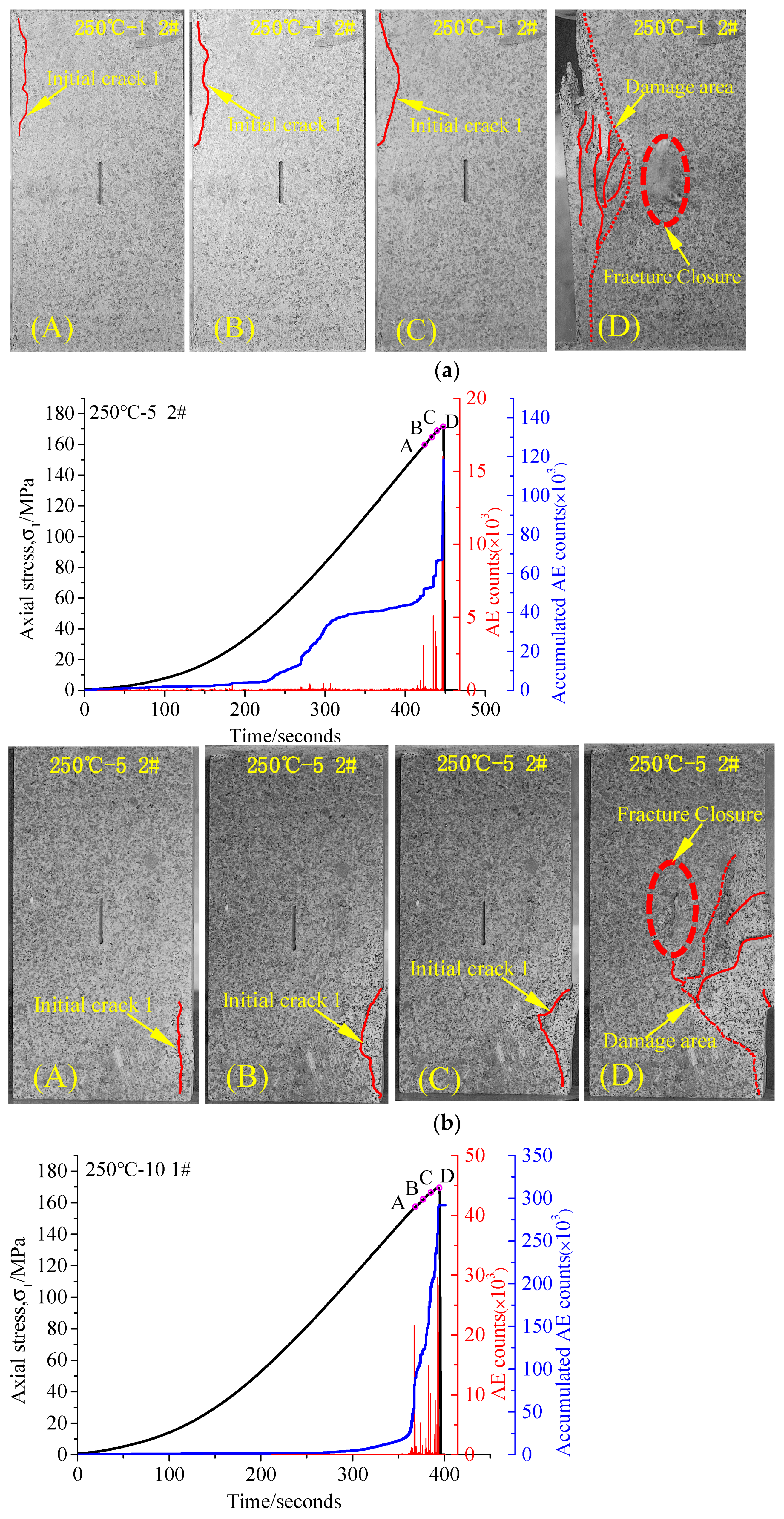

| 250 °C-1 2# | A | 174.43 | 96.35 | 9.32 | 93.95 |

| B | 177.17 | 97.87 | 9.48 | 95.56 | |

| C | 180.65 | 99.79 | 9.65 | 97.28 | |

| D | 177.52 | 98.06 | 9.74 | 98.19 | |

| 250 °C-5 2# | A | 159.46 | 92.99 | 10.58 | 94.21 |

| B | 164.84 | 96.13 | 10.80 | 96.17 | |

| C | 168.63 | 98.34 | 10.98 | 97.77 | |

| D | 171.47 | 100.00 | 11.18 | 99.55 | |

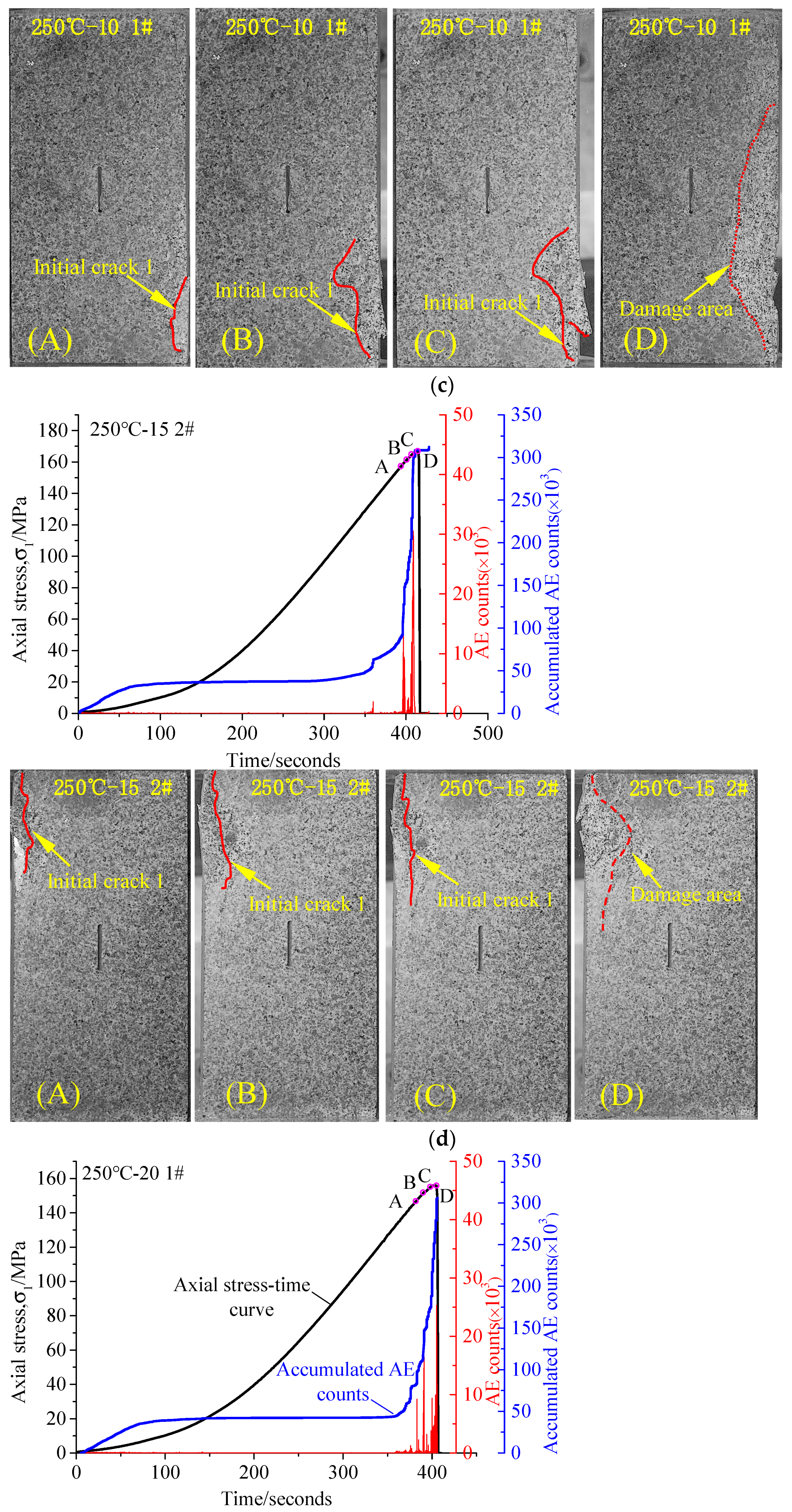

| 250 °C-10 1# | A | 157.19 | 92.73 | 9.21 | 92.10 |

| B | 162.04 | 95.59 | 9.43 | 94.30 | |

| C | 166.13 | 98.01 | 9.63 | 96.30 | |

| D | 169.51 | 100.00 | 9.85 | 98.50 | |

| 250 °C-15 2# | A | 157.23 | 94.03 | 9.90 | 92.61 |

| B | 160.60 | 96.04 | 10.05 | 94.01 | |

| C | 164.98 | 98.66 | 10.24 | 95.79 | |

| D | 167.22 | 100.00 | 10.40 | 97.29 | |

| 250 °C-20 1# | A | 146.67 | 94.03 | 9.56 | 93.09 |

| B | 152.04 | 97.47 | 9.79 | 95.33 | |

| C | 155.36 | 99.60 | 9.99 | 97.27 | |

| D | 155.99 | 100.00 | 10.09 | 98.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, D.; Fan, Y.; Bai, Y.; Tao, X.; Miao, L.; Jin, H. Experimental Study on the Acoustic Emission Characteristics of Fractured Granite after Repeated High Temperature-Water Cooling. Processes 2023, 11, 139. https://doi.org/10.3390/pr11010139

Zhu D, Fan Y, Bai Y, Tao X, Miao L, Jin H. Experimental Study on the Acoustic Emission Characteristics of Fractured Granite after Repeated High Temperature-Water Cooling. Processes. 2023; 11(1):139. https://doi.org/10.3390/pr11010139

Chicago/Turabian StyleZhu, Dong, Yuqing Fan, Yang Bai, Xiangling Tao, Leigang Miao, and Huiwu Jin. 2023. "Experimental Study on the Acoustic Emission Characteristics of Fractured Granite after Repeated High Temperature-Water Cooling" Processes 11, no. 1: 139. https://doi.org/10.3390/pr11010139

APA StyleZhu, D., Fan, Y., Bai, Y., Tao, X., Miao, L., & Jin, H. (2023). Experimental Study on the Acoustic Emission Characteristics of Fractured Granite after Repeated High Temperature-Water Cooling. Processes, 11(1), 139. https://doi.org/10.3390/pr11010139