3D Printing Multi-Channel Large Volume Microchannel Reactor for Enhanced Removal of Low-Concentration NOx Flue Gas

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Materials

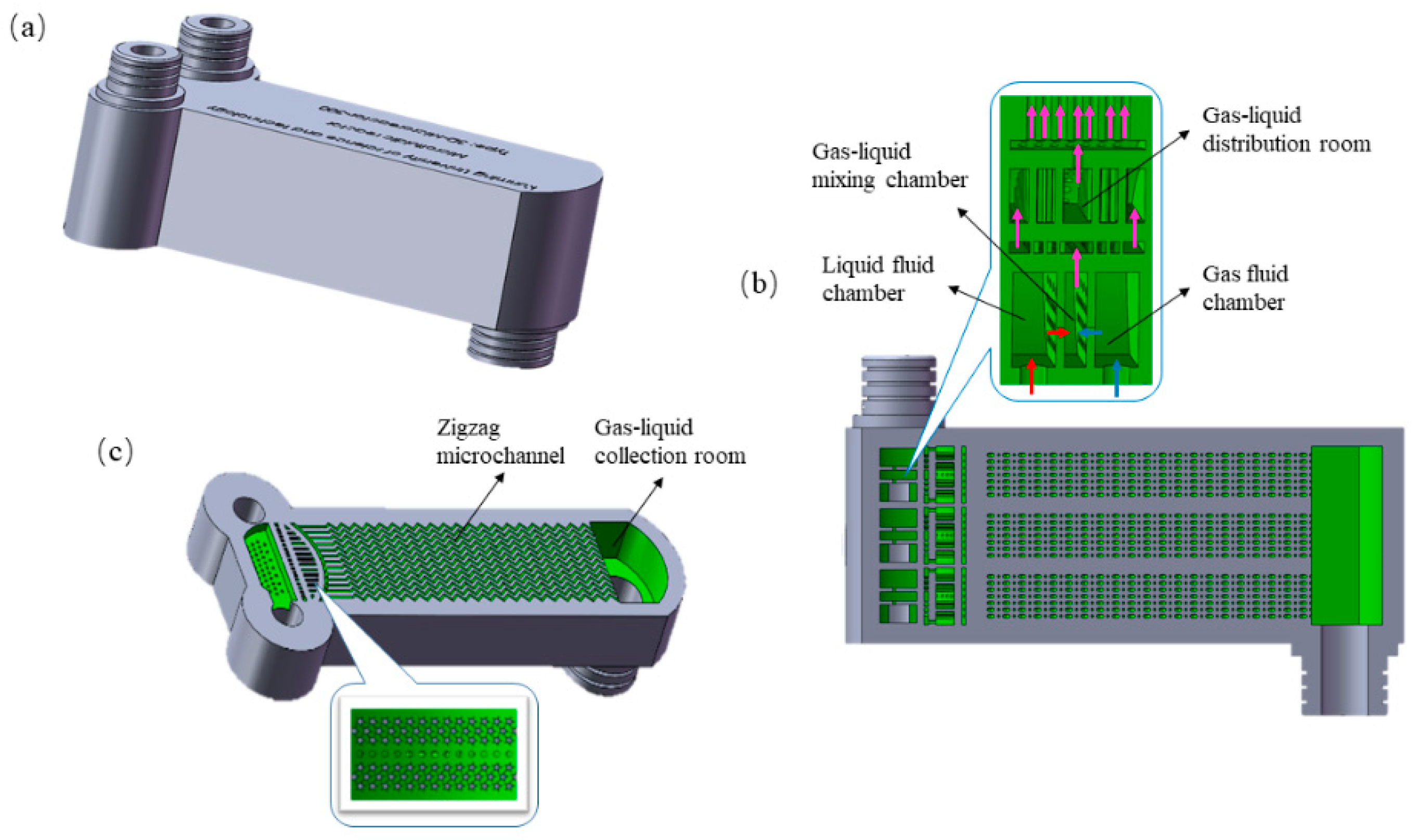

2.2. Microchannel Reactor Design and 3D Printing

2.3. Multi-Channel High-Throughput Microchannel Reactor for NOX Removal

2.4. Calculation of NOx Removal Efficiency

2.5. Calculation of Gas-Liquid Contact Time (T)

3. Experimental Results and Discussion

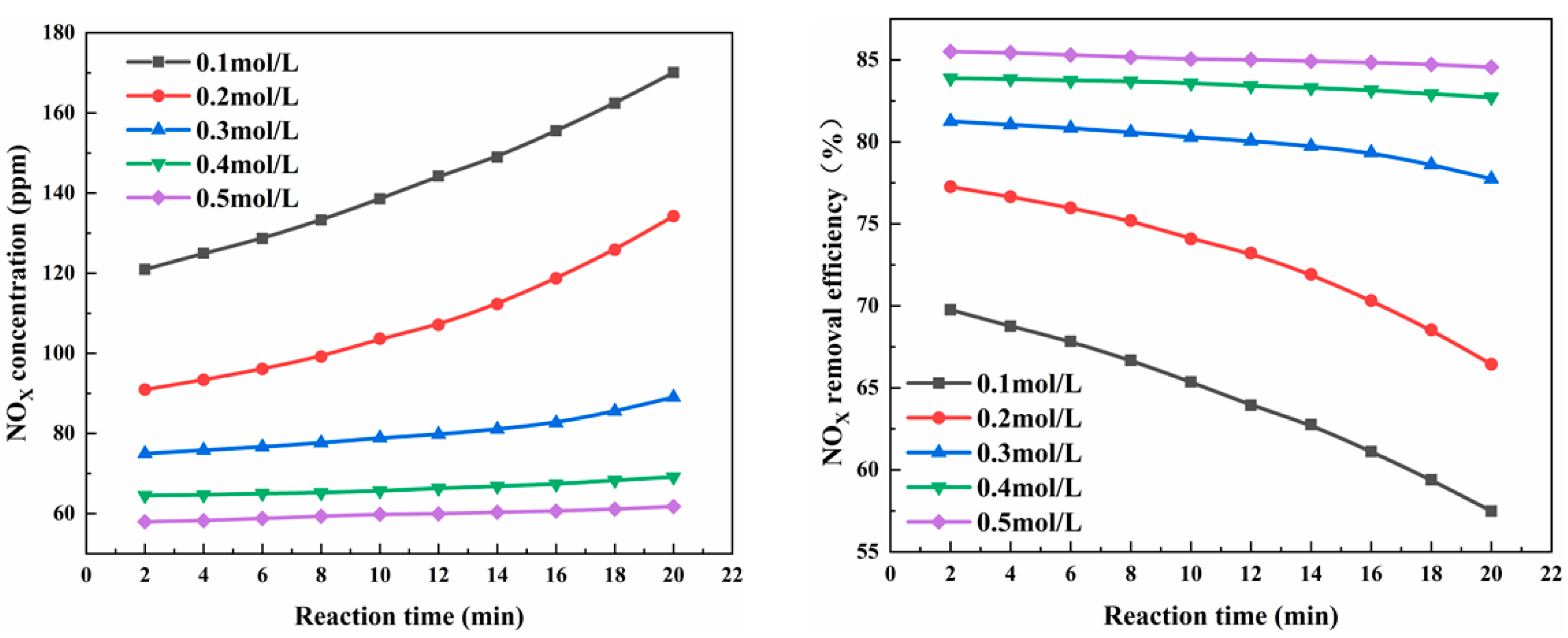

3.1. Effects of Different Concentrations of (NH2)2CO and H2O2 on NOX Removal Efficiency

3.2. Effect of Initial pH Value on NOX Removal Efficiency

3.3. Effect of Solution Temperature on NOX Removal Efficiency

3.4. Influence of Inlet Flow on NOx Removal Efficiency

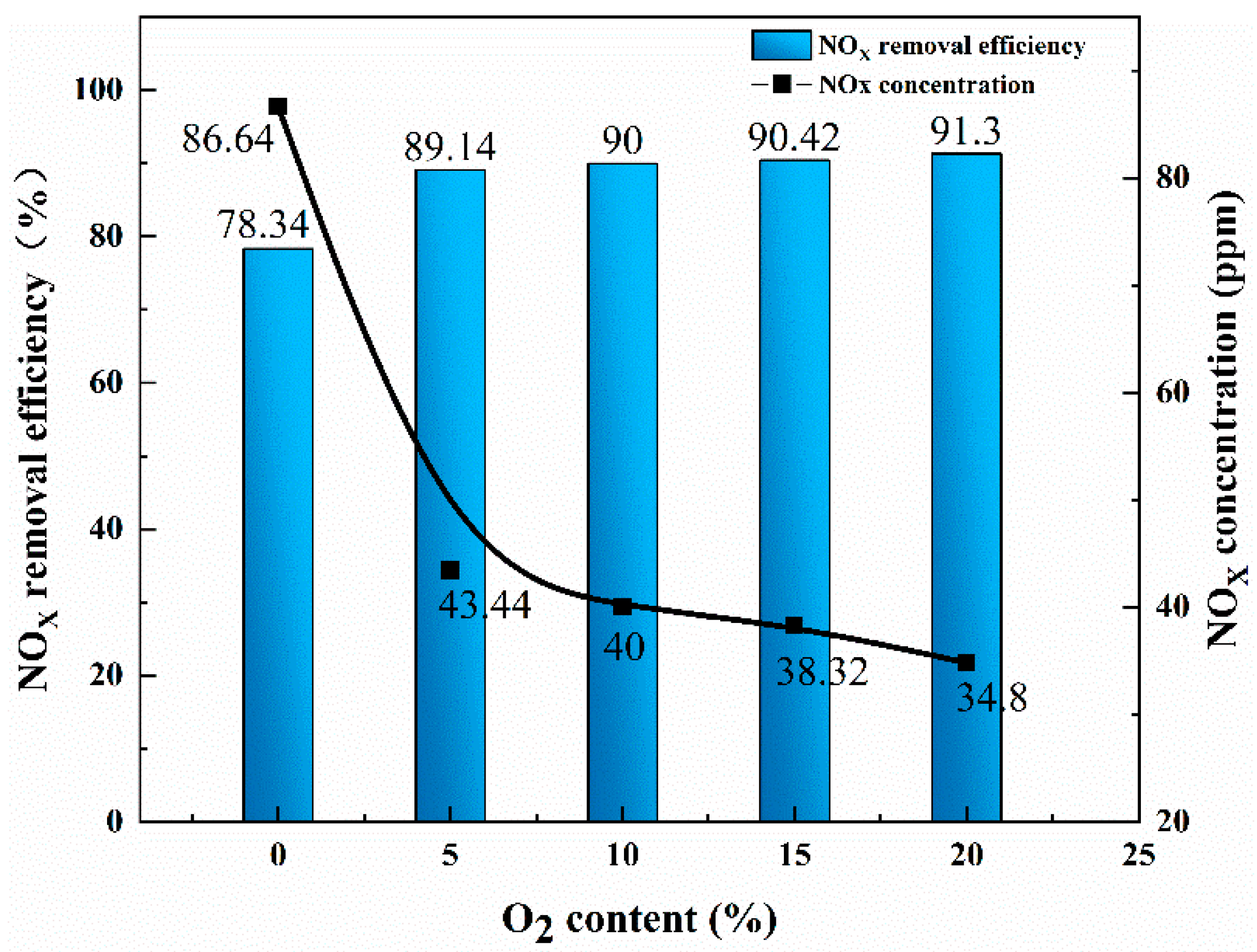

3.5. Influence of O2 Content in Flue Gas on NOX Removal Efficiency

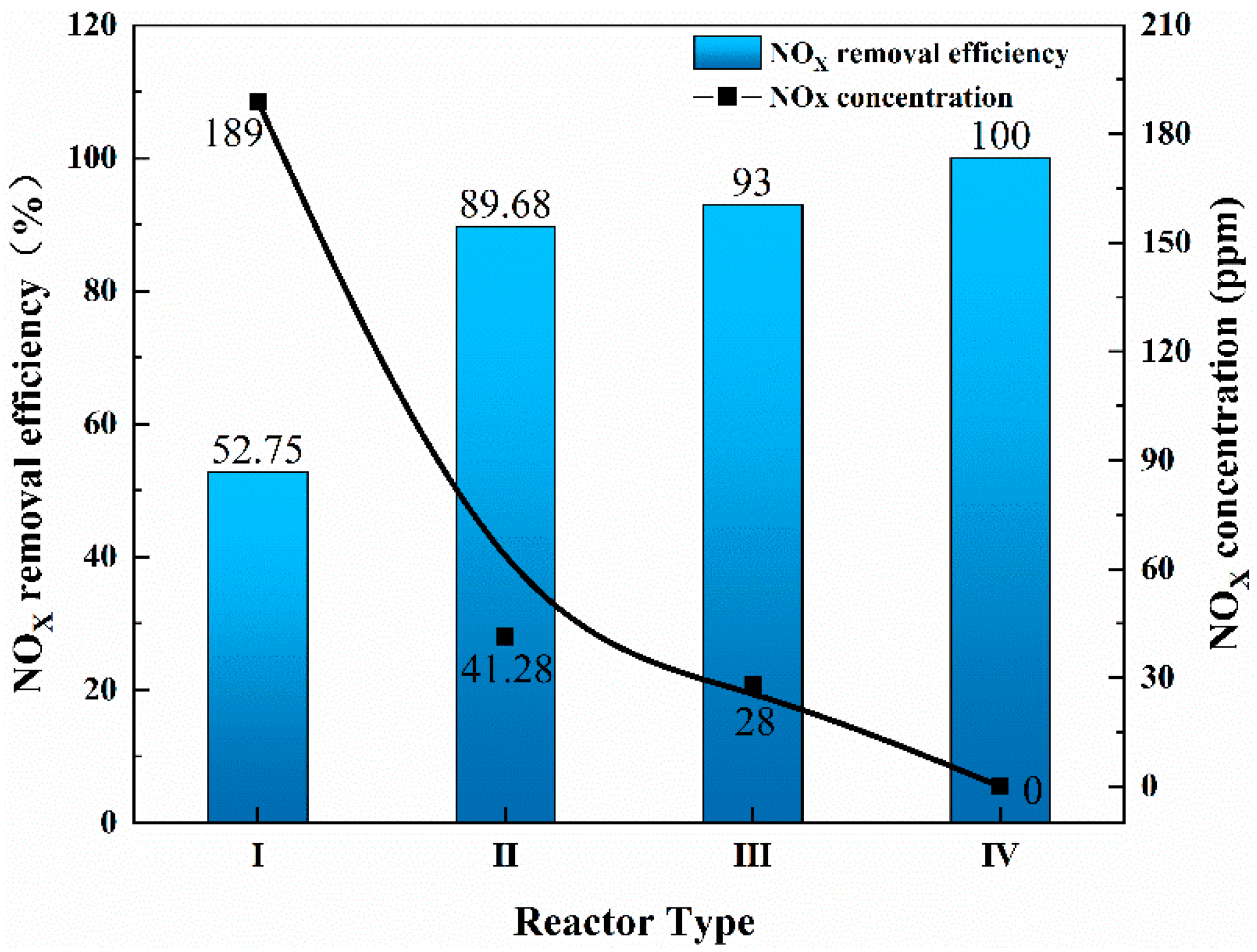

3.6. Effects of Different Types of Reactors on NOX Removal

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lei, D.; Chao, L.; Chen, K.; Huang, Y.; Diao, B. Atmospheric pollution reduction effect and regional predicament: An empirical analysis based on the Chinese provincial NOx emissions. J. Environ. Manag. 2017, 196, 178–187. [Google Scholar]

- Chen, L.; Liao, Y.; Xin, S.; Song, X.; Liu, G. Simultaneous removal of NO and volatile organic compounds (VOCs) by Ce/Mo doping-modified selective catalytic reduction (SCR) catalysts in denitrification zone of coal-fired flue gas. Fuel 2020, 262, 116485. [Google Scholar] [CrossRef]

- Liu, F.; Cai, M.; Liu, X.; Zhu, T.; Zou, Y. O3 oxidation combined with semi-dry method for simultaneous desulfurization and denitrification of sintering/pelletizing flue gas. J. Environ. Sci. 2021, 104, 253–263. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Lun, L.; Tan, Z.; Zhang, Y.; Li, Q. Simultaneous wet desulfurization and denitration by an oxidant absorbent of NaClO2/CaO2. Environ. Sci. Pollut. Res. 2019, 26, 29032–29040. [Google Scholar] [CrossRef] [PubMed]

- Song, L.; Yang, J.; Yu, S.; Xu, M.; Liang, Y.; Pan, X.; Yao, L. Ultra-high efficient hydrodynamic cavitation enhanced oxidation of nitric oxide with chlorine dioxide. Chem. Eng. J. 2019, 373, 767–779. [Google Scholar] [CrossRef]

- Wei, J.; Luo, Y.; Yu, P.; Cai, B.; Tan, H. Removal of NO from flue gas by wet scrubbing with NaClO2/(NH2)2CO solutions. J. Ind. Eng. Chem. 2009, 15, 16–22. [Google Scholar] [CrossRef]

- Adewuyi, Y.G.; Sakyi, N.Y.; Khan, M.A. Simultaneous removal of NO and SO2 from flue gas by combined heat and Fe2+ activated aqueous persulfate solutions. Chemosphere Environ. Toxicol. Risk Assess. 2018, 193, 1216–1225. [Google Scholar] [CrossRef]

- Hultén, A.; Nilsson, P.; Samuelsson, M.; Ajdari, S.; Normann, F.; Andersson, K. First evaluation of a multicomponent flue gas cleaning concept using chlorine dioxide gas—Experiments on chemistry and process performance. Fuel 2017, 210, 885–891. [Google Scholar] [CrossRef]

- Yan, J.; Zhou, F.; Ying, Z.; Wu, X.; Lu, H. Wet oxidation and absorption procedure for NOx mathContainer Loading Mathjax removal. Environ. Technol. Innov. 2018, 11, 41–48. [Google Scholar] [CrossRef]

- Wen, Z.; Huang, X.; Shen, H.; Ding, N.; Li, Y.; Xu, J. Quantum Chemical Study on the Reaction Mechanism of NO Removal by Urea Combined with Hydrogen Peroxide. Arab. J. Sci. Eng. 2020, 45, 543–550. [Google Scholar] [CrossRef]

- Fang, P.; Cen, C.; Tang, Z.; Zhong, P.; Chen, D.; Chen, Z. Simultaneous removal of SO2 and NOX by wet scrubbing using urea solution. Chem. Eng. J. 2011, 168, 52–59. [Google Scholar] [CrossRef]

- Guo, Q.; He, Y.; Sun, T.; Wang, Y.; Jia, J. Simultaneous removal of NOx and SO2 from flue gas using combined Na2SO3 assisted electrochemical reduction and direct electrochemical reduction. J. Hazard. Mater. 2014, 276, 371–376. [Google Scholar] [CrossRef]

- Zhang, D.; Ren, L.; Yao, Z.; Wan, X.; Lu, P.; Zhang, X. Removal of Nitrogen Oxide Based on Anammox through Fe(II)EDTA Absorption. Energy Fuels 2017, 31, 7247–7255. [Google Scholar] [CrossRef]

- Cheng, X.; Bi, X.T. A review of recent advances in selective catalytic NOx reduction reactor technologies. Particuology 2014, 16, 1–18. [Google Scholar] [CrossRef]

- Li, D.; Xiao, Z.; Aftab, T.B.; Xu, S. Flue Gas Denitration by Wet Oxidation Absorption Methods: Current Status and Development. Environ. Eng. Sci. 2018, 35, 1151–1164. [Google Scholar] [CrossRef]

- Falcone Miller, S.; Miller, B.G. 7-Advanced flue gas cleaning systems for sulfur oxides (SOx), nitrogen oxides (NOx) and mercury emissions control in power plants. In Advanced Power Plant Materials, Design and Technology; Roddy, D., Ed.; Woodhead Publishing: Cambridge, UK, 2010; pp. 187–216. [Google Scholar]

- Wang, Z.-P.; Wang, Z.-W.; Xu, K. Optimization of wet denitration by dual oxidant (H2O2/S2O82−) advanced oxidation process. Fuel Process. Technol. 2017, 156, 82–89. [Google Scholar] [CrossRef]

- Hardin, J.O.; Ober, T.J.; Valentine, A.D.; Lewis, J.A. 3D Printing: Microfluidic Printheads for Multimaterial 3D Printing of Viscoelastic Inks (Adv. Mater. 21/2015). Adv. Mater. 2015, 27, 3278. [Google Scholar] [CrossRef]

- Bhattacharjee, N.; Urrios, A.; Kang, S.; Folch, A. The upcoming 3D-printing revolution in microfluidics. Lab Chip 2016, 16, 1720–1742. [Google Scholar] [CrossRef]

- Waheed, S.; Cabot, J.M.; Macdonald, N.P.; Lewis, T.; Guijt, R.M.; Paull, B.; Breadmore, M.C. 3D printed microfluidic devices: Enablers and barriers. Lab Chip 2016, 16, 1993–2013. [Google Scholar] [CrossRef]

- Yang, L.; Dietrich, N.; Loubière, K.; Gourdon, C.; Hébrard, G. Visualization and characterization of gas-liquid mass transfer around a Taylor bubble right after the formation stage in microreactors. Chem. Eng. Sci. 2016, 143, 364–368. [Google Scholar] [CrossRef]

- Pohorecki, R.; Sobieszuk, P.; Kula, K.; Moniuk, W.; Zieliński, M.; Cygański, P.; Gawiński, P. Hydrodynamic regimes of gas-liquid flow in a microreactor channel. Chem. Eng. J. 2008, 135, S185–S190. [Google Scholar] [CrossRef]

- Zhu, C.; Guo, H.; Chu, C.; Fu, T.; Ma, Y. Gas-liquid distribution and mass transfer of CO2 absorption into sodium glycinate aqueous solution in parallel multi-channel microreactor. Int. J. Heat Mass Transf. 2020, 157, 119943. [Google Scholar] [CrossRef]

- Yang, L.; Xu, F.; Chen, G. Enhancement of gas-liquid mass transfer and mixing in zigzag microreactor under ultrasonic oscillation. Chem. Eng. Sci. 2022, 247, 117094. [Google Scholar] [CrossRef]

- Jang, S.; Vidyacharan, S.; Ramanjaneyulu, B.T.; Gyak, K.-W.; Kim, D.-P. Photocatalysis in a multi-capillary assembly microreactor: Toward up-scaling the synthesis of 2H-indazoles as drug scaffolds. React. Chem. Eng. 2019, 4, 1466–1471. [Google Scholar] [CrossRef]

- Ahn, G.-N.; Yu, T.; Lee, H.-J.; Gyak, K.-W.; Kang, J.-H.; You, D.; Kim, D.-P. A numbering-up metal microreactor for the high-throughput production of a commercial drug by copper catalysis. Lab Chip 2019, 19, 3535–3542. [Google Scholar] [CrossRef] [PubMed]

- Yim, S.J.; Ramanjaneyulu, B.T.; Vidyacharan, S.; Yang, Y.D.; Kang, I.S.; Kim, D.-P. Compact reaction-module on a pad for scalable flow-production of organophosphates as drug scaffolds. Lab Chip 2020, 20, 973–978. [Google Scholar] [CrossRef]

- Dong, Z.; Wen, Z.; Zhao, F.; Kuhn, S.; Noël, T. Scale-up of micro- and milli-reactors: An overview of strategies, design principles and applications. Chem. Eng. Sci. X 2021, 10, 100097. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, K.; Teixeira, A.R.; Jensen, K.F.; Luo, G. Design and Scaling Up of Microchemical Systems: A Review. Annu. Rev. Chem. Biomol. Eng. 2017, 8, 285–305. [Google Scholar] [CrossRef]

- Wang, K.; Lu, Y.; Luo, G. Strategy for scaling-up of a microsieve dispersion reactor. Chem. Eng. Technol. 2014, 37, 2116–2122. [Google Scholar] [CrossRef]

- Hessel, V.; Ehrfeld, W.; Herweck, T.; Haverkamp, V.; Lutz, N. Gas/liquid microreactors: Hydrodynamics and mass transfer. In Proceedings of the 4th International Conference on Microreaction Technology, IMRET 4, Atlanta, GA, USA, 5–9 March 1999. [Google Scholar]

- Su, H.; Wang, S.; Niu, H.; Pan, L.; Wang, A.; Hu, Y. Mass transfer characteristics of H2S absorption from gaseous mixture into methyldiethanolamine solution in a T-junction microchannel. Sep. Purif. Technol. 2010, 72, 326–334. [Google Scholar] [CrossRef]

- Eskin, D.; Mostowfi, F. A model of a bubble train flow accompanied with mass transfer through a long microchannel. Int. J. Heat Fluid Flow 2012, 33, 147–155. [Google Scholar] [CrossRef]

- Pennemann, H.; Hessel, V.; Kost, H.J.; Löwe, H.; De Bellefon, C. Investigations on pulse broadening for catalyst screening in gas/liquid systems. AIChE J. 2004, 50, 1814–1823. [Google Scholar] [CrossRef]

- Chasanis, P.; Kehrmann, K.; Kern, J.; Zecirovic, R.; Grünewald, M.; Kenig, E.Y. Investigation of a microstructured high efficiency contactor. Chem. Eng. Process. Process Intensif. 2011, 50, 1244–1251. [Google Scholar] [CrossRef]

- Li, X.; Jiang, F.; Ravindra, A.V.; Zhou, J.; Zhou, A.; Le, T.; Peng, J.; Ju, S. Mixing processes in a 3D printed large-flow microstructured reactor: Finite element simulations and experimental study. Chem. Eng. J. 2019, 370, 295–304. [Google Scholar] [CrossRef]

- de Mas, N.; Günther, A.; Kraus, T.; Schmidt, M.A.; Jensen, K. Scaled-out multilayer gas–liquid microreactor with integrated velocimetry sensors. Ind. Eng. Chem. Res. 2005, 44, 8997–9013. [Google Scholar] [CrossRef]

- Link, D.; Anna, S.L.; Weitz, D.; Stone, H. Geometrically mediated breakup of drops in microfluidic devices. Phys. Rev. Lett. 2004, 92, 054503. [Google Scholar] [CrossRef]

- Kreutzer, M.T.; Bakker, J.J.; Kapteijn, F.; Moulijn, J.A.; Verheijen, P.J.T. Scaling-up multiphase monolith reactors: Linking residence time distribution and feed maldistribution. Ind. Eng. Chem. Res. 2005, 44, 4898–4913. [Google Scholar] [CrossRef]

- Kashid, M.N.; Gupta, A.; Renken, A.; Kiwi-Minsker, L.J.C.E.J. Numbering-up and mass transfer studies of liquid–liquid two-phase microstructured reactors. Chem. Eng. J. 2010, 158, 233–240. [Google Scholar] [CrossRef]

- Andersson, H.; van der Wijngaart, W.; Enoksson, P.; Stemme, G. Micromachined flow-through filter-chamber for chemical reactions on beads. Sens. Actuators B Chem. 2000, 67, 203–208. [Google Scholar] [CrossRef]

- Chiou, C.-H.; Lee, G.-B.; Hsu, H.-T.; Chen, P.-W.; Liao, P.-C. Micro devices integrated with microchannels and electrospray nozzles using PDMS casting techniques. Sens. Actuators B Chem. 2002, 86, 280–286. [Google Scholar] [CrossRef]

- Jiang, F.; Yin, S.; Zhang, L.; Peng, J.; Ju, S.; Miller, J.D.; Wang, X. Solvent extraction of Cu(II) from sulfate solutions containing Zn(II) and Fe(III) using an interdigital micromixer. Hydrometallurgy 2018, 177, 116–122. [Google Scholar] [CrossRef]

- Lasalle, A.; Roizard, C.; Midoux, N.; Bourret, P.; Dyens, P.J. Removal of nitrogen oxides (NOx) from flue gases using the urea acidic process: Kinetics of the chemical reaction of nitrous acid with urea. Ind. Eng. Chem. Res. 1992, 31, 777–780. [Google Scholar] [CrossRef]

- Ding, J.; Zhong, Q.; Zhang, S.; Song, F.; Bu, Y. Simultaneous removal of NOX and SO2 from coal-fired flue gas by catalytic oxidation-removal process with H2O2. Chem. Eng. J. 2014, 243, 176–182. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J.; Sheng, C.; Zhang, Y.; Zhao, L.L. Simultaneous removal of NO and SO2 from coal-fired flue gas by UV/H2O2 advanced oxidation process. Chem. Eng. J. 2010, 162, 1006–1011. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, J.; Baral, A.; Ju, S.; Gu, Y. High-efficiency absorption of low NOX concentration in metallurgical flue gas using a three dimensional printed large-flow microstructured reactor-ScienceDirect. Arab. J. Chem. 2022, 15, 103711. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, K.; Ju, S.; Zhou, Y.; Zhang, J.; Wan, X.; Li, N.; Gu, Y. 3D Printing Multi-Channel Large Volume Microchannel Reactor for Enhanced Removal of Low-Concentration NOx Flue Gas. Processes 2023, 11, 158. https://doi.org/10.3390/pr11010158

Han K, Ju S, Zhou Y, Zhang J, Wan X, Li N, Gu Y. 3D Printing Multi-Channel Large Volume Microchannel Reactor for Enhanced Removal of Low-Concentration NOx Flue Gas. Processes. 2023; 11(1):158. https://doi.org/10.3390/pr11010158

Chicago/Turabian StyleHan, Kai, Shaohua Ju, Yu Zhou, Jingxi Zhang, Xiaoxi Wan, Na Li, and Yongwan Gu. 2023. "3D Printing Multi-Channel Large Volume Microchannel Reactor for Enhanced Removal of Low-Concentration NOx Flue Gas" Processes 11, no. 1: 158. https://doi.org/10.3390/pr11010158

APA StyleHan, K., Ju, S., Zhou, Y., Zhang, J., Wan, X., Li, N., & Gu, Y. (2023). 3D Printing Multi-Channel Large Volume Microchannel Reactor for Enhanced Removal of Low-Concentration NOx Flue Gas. Processes, 11(1), 158. https://doi.org/10.3390/pr11010158