Abstract

This study aimed to evaluate the effect of the sous vide and electric oven cooking methods on the physical and sensory characteristics of camel meat. A combination of 4 cooking temperatures (70, 80, 90, and 100 °C) and 6 cooking times (30, 60, 90, 120, 150, and 180 min) was applied. Both methods significantly affected the meat’s physical properties (pH, cooking loss, density, lightness, redness, and yellowness color components), except for water activity. Furthermore, the cooking temperature and time significantly affected all the sensory properties (tenderness, flavor, juiciness, and general acceptance). The cooking loss was the only parameter affected significantly by the interaction of the cooking method, cooking temperature, and cooking time. It is concluded that the sous vide method is the more suitable method for cooking camel meat compared to the electric oven method considering the cooking temperature and time. Further studies are recommended to estimate energy consumption for both cooking methods evaluated in this study aiming at reducing the overall power expenditure.

1. Introduction

Camel meat has a great taste with many health benefits. The importance of camel as a meat-producing animal is increasing due to the high nutritive-value meat produced by this animal, besides its ability to survive in harsh environments [1]. Moreover, camel meat has many qualities and tastes similar to beef, with a great similarity between them in color and smell [2]. Camel is a good source of meat in many countries in the Far and Middle East, Mediterranean, and North African countries. The main three countries with a major number of one-humped camels are Somalia (7.43 million), Sudan (4.94 million), and Kenya (4.43 million) [3]. The consumption of red meat in Saudi Arabia is of great importance that is derived by the citizen’s standard of living, high-income levels, and customs and dietary traditions prevailing, which require the availability of red meat as a core item in daily life. In Saudi Arabia, camel meat occupies a niche position where it is the third most common source of meat after sheep meat and beef [4]. In addition, Saudi Arabia comes first in camel meat production with 108,679 metric tons, followed by Kenya with 102,073 metric tons, and then Somalia with 47,404 metric tons [3]. In contrast, camel meat differs from other types of meat in its tough nature, especially when produced from older animals, which is a common practice in Saudi Arabia. Thus, it needs a longer time to cook [5].

One of the cooking techniques that is widely used today is the sous vide method, which in French means under vacuum. The technique encompasses cooking raw meat in vacuum-sealed food-grade plastic pouches submerged in a circulating water bath at precisely controlled low temperatures for an extended period of 72 h, followed by rapid cooling [6,7,8]. The advantages of this technique include good heating and uniform texture [9,10], improved sensory characteristics of meat [11], uniform and consistent texture [10], and greater water-holding capacity. It also ensures the preservation of the nutritional quality of food by promoting higher retention rates of water compared to other conventional cooking methods [12,13,14]. This cooking method has been actively studied since the 1990s [15,16] and a huge increase in its use has been seen in the last two decades in restaurants and homes [17,18,19]. Although the sous vide cooking method appeared in the 1990s, it has become increasingly more acceptable since 2010 onwards [20]. The technique has widespread usage in cooking different types of meat including beef [14,21], pork [11], chicken breast meat [13], and crab lump meat [22]. The sous vide technique has been utilized in achieving meat tenderness, a primary quality issue for consumer preference for meat [23,24].

In Saudi Arabia, consumers prefer tender cooked meat as a criterion for tasty meat. The tenderness of camel meat could therefore be achieved using the sous vide cooking technique. The approximation of the exact temperature and time of sous vide cooking is essential for improving the quality characteristics of camel meat. Therefore, this research was conducted to compare the sous vide and electric oven cooking methods at different temperatures and times and their effects on camel meat quality, as well as the physical and sensory characteristics.

2. Materials and Methods

2.1. Experimental Meat Samples

Camel meat (shoulder brisket muscle: Latissimus dorsi) samples were selected 24 h post-mortem. The animals were 6 male camels of the Majaheem breed of around 6–7 months of age raised under similar environmental conditions and feeding management. The meat samples were chosen to be free of visible fat and connective tissues. Then, they were sliced into 6 × 8 × 1.3 cm steaks, individually labeled with a color pen, weighed, sealed in nylon/polyethylene bags, and stored at −20 °C. The frozen steaks were thawed overnight at 3 °C one day before starting the experiment [5].

2.2. Cooking of Meat Samples

Cooking of camel meat samples was done by applying the sous vide technique in high-quality plastic pouches (15.2 × 20.3 cm and 85 µm thickness) specially designed for cooking at high temperatures (Vacuum seal cooking pouches, Sous Vide Supreme®, Eades Appliance Technology, LLC 4347 W. Northwest Hwy Suite 130, Dallas, TX 75220, USA). Forty-eight combinations of temperatures (70, 80, 90, 100 °C) and cooking times (30, 60, 90, 120, 150, and 180 min) were managed for sous vide cooking with vacuumed pouches (Sous vide Supreme Vacuum Sealer VS3000, Eades Appliance Technology, LLC 4347 W. Northwest Hwy Suite 130, Dallas, TX 75220,USA) in a circulating water bath (GFL Water bath, Model 1083, GFL Technology Laboratory Equipment–LAUDA, Laudaplatz 1-97922 Lauda-Königshofen Germany), and conventional cooking of camel meat samples was performed in a forced convection oven (Drying oven Binder, Model E240. BINDER GmbH Im Mittleren Ösch 5-78532 Tuttlingen, Germany). Each treatment was carried out in triplicates [25], whereas the cooking temperature, time, and weight of cooked samples were recorded for all sessions.

2.3. Measurements of the Physical Properties

2.3.1. Cooking Loss

The cooking loss of camel meat samples was performed as a difference between the weights of samples before and after cooking. A sensitive balance with a precision of 0.01 g (Sensitive Balance, model 2100/C/2, Radwag Wagi Elektroniczne, Toruńska 5-Radom 26-600, Poland) was used to obtain the weights of samples. The following equation was applied to calculate cooking loss [26]:

where is the raw meat sample (g) and is the cooked meat sample (g).

2.3.2. pH

The pH-Meter (Oakton® Instruments, Model WD-35634-50 Replacement Electrode, Washington Street Melrose, MA, USA) was used to measure pH scores of camel meat samples before and after cooking. The meat sample was pierced by the sensor connected to the device, and the displayed readings were recorded. Three replicates were taken for each meat sample, and the average pH value was then calculated [27].

2.3.3. Water Activity (aw)

The water activity (aw) of fresh and cooked camel meat samples was determined using Aqua Lab Device (Series 3, Decagon Devices, Inc., 2365 NE Hopkins Court, Pullman WA 99163, USA). An approximately 20 g sample was cut and packed in the plastic container of the device, and the sample room was closed to start measuring aw. The measurements were carried out three times for each sample; then, the mean value was calculated.

2.3.4. Density (ρ)

Fresh and cooked meat densities were measured using a density balance (Mettler Toledo PA 203-S, Toledo Comp., Mettler-Toledo (Schweiz) GmbH-Im Langacher 44, 8606 Greifensee, Schweiz, Switzerland). The meat sample was weighed in air and then in water by using an immersion rod. The difference in the mass reading of the container and water before and after immersion was calculated. The difference in reading equals the mass of displaced water (sample volume), so the density was readily calculated.

2.3.5. Color Values

A portable Colorimeter (CR-400 Chroma Meter, Konica Minolta, Inc., Marunouchi, Chiyoda, Tokyo, Japan: Measuring aperture: 8 mm; Illuminant: CIE D65; Observer angle: CIE 2° Standard Observer) was used for reading basic color values of cooked meat samples at room temperature (22 °C ± 2). At least thirty minutes were needed after cooking the meat for obtaining the color measurement. The basic color components L* (lightness), a* (redness), and b* (yellowness) on CIELAB scales were measured on the middle at the surface of the cooked sample. Measurements were performed in triplicates for each steak sample.

2.4. Sensory Evaluation

The sensory evaluation test of the cooked camel meat using the sous vide and electric oven methods were performed at room temperature (22 °C ± 2) by 10 trained individuals from King Saud University employees who were chosen for their ability to differentiate between meat properties under consideration and practiced how to score them. The test was held in the sensory evaluation room. The cooked camel meat samples and a sensory evaluation form were presented to the referees. The sensory evaluation form was designed to evaluate tenderness (very tough-very tender), flavor (very mild-very strong) juiciness (very dry-very juicy), and general acceptance (very unacceptable-very acceptable), based on 6-point category scaling (1–6) where 1 point represented the lowest value and 6 the highest value [28]. The participants performed all the tests according to the guidelines set by the American Meat Science Association [29]. The panelists were asked to avoid food and smoking 2 h before meat tasting. Tap water and crackers were accessible to them to strip any residual flavor of the previous samples.

2.5. Statistical Analysis

The experiment was set in a 3-way factorial arrangement (2 × 4 × 6) in a complete randomized design (CRD). The data were analyzed using ANOVA in GLM (SPSS Software Program, IBM Corp. Released 2020. IBM SPSS Statistics for Windows, Version 27.0. Armonk, NY, USA: IBM Corp). The normal distribution of data was checked, and the results were expressed as means. A post hoc using least significant difference (LSD) was run if there were any significant differences at p < 0.05. The following statistical model was applied:

where:

- Yijkl = value of any observation,

- μ = population mean,

- αi = cooking method main effect (sous vide vs. electric oven),

- βj = cooking temperature main effect (70, 80, 90, and 100 °C),

- γk = cooking time main effect (30, 60, 90, 120, 150, and 180 min),

- (αβ)ij + (αγ)ik + (βγ)jk = are the two-way interactions,

- (αβγ)ijk = is the three-way interaction,

- εijkl = random error.

3. Results and Discussion

3.1. The Physical Properties of Fresh Camel Meat

Table 1 shows the physical properties, pH, water activity, density, and color components lightness (L*), redness (a*), and yellowness (b*) of fresh camel meat that was selected from the shoulder cut. The meat pH was 5.96, which agreed with the results from previous studies [1,30,31,32,33] that reported a pH of 5.5–6.6. The values of meat color lightness (L*) and redness (a*) were 53.12 and 18.54, respectively, which agreed with previous results [32,34], while yellowness (b*) was 3.96, in line with results from other studies [32,35]. The meat water activity was 0.99, which agreed with previous results [36]. The density of the fresh camel meat was 1070 kg/m3.

Table 1.

The physical properties, pH, water activity, density, and color components of fresh camel meat.

3.2. Effects of the Sous Vide and Electric Oven Cooking Methods on the Physical Properties of Camel Meat

Table 2 represents the effects of the cooking methods (CMD) at different cooking temperatures (CTM) and cooking times (CTI) on the physical properties (pH, cooking loss, water activity, density, and color components) of camel meat. The obtained results showed that all physical properties of camel meat were statistically (p ≤ 0.05) affected by the cooking methods (sous vide and electric oven), temperature (70, 80, 90, and 100 °C), and time (30, 60, 90, 120, 150, and 180 min), except for water activity. The insignificant difference (p ≥ 0.05) in water activity between the two cooking methods could be assigned to the use of cooking bags (vacuum-sealed cooking) that maintained water activity. Moreover, sous vide depends on water, which has a high thermal conductivity coefficient, leading to rapid changes in the physical properties of cooked meat, whereas the electric oven method relied on dry hot air that has a low thermal conductivity coefficient, which induced loss of water, minerals, and free amino acids from protein fibers.

Table 2.

Effects of the cooking method (CMD) at different cooking temperatures (CTM) and cooking times (CTI) on the physical properties of camel meat.

The pH, cooking loss, and yellowness increased as the cooking temperature increased. A previous study [37] reported the effect of cooking temperature on duck meat muscle cooked in a plastic bag that was put inside a water bath at different temperatures. They reported that cooking loss was increased with high temperatures. The lowest values of pH, cooking loss, and yellowness at 70 °C were 6.10, 31.82%, and 6.89, respectively, while the highest values for the same parameters at 100 °C were 6.30, 38.12%, and 11.74, respectively, all of which agreed with the findings of a previous study [38]. In contrast, the density, lightness (L*), and redness (a*) decreased as the cooking temperatures increased. These findings were in line with that of a previous study [39]. The highest values of density, L*, and a* at 70 °C were 1046 kg/m3, 48.17, and 11.51, respectively, while the lowest values for the same parameters at 100 °C were 1027 kg/m3, 36.31, and 8.01, respectively. The increase in pH, cooking loss, and yellowness with increasing cooking temperature could be attributed to water and mineral loss from meat as liquid or steam. A previous study [40] about the effect of different temperatures on the physical properties of mutton meat reported higher pH and cooking loss with higher cooking temperatures.

The effects of cooking time on the physical properties of camel meat followed the same trend as cooking temperature. The pH, cooking loss, and yellowness increased with increasing cooking time, whereas density, lightness, and redness decreased as cooking time increased. The lowest values of pH, cooking loss, and yellowness at 30 min were 6.06, 24.26%, and 5.41, respectively, while the highest values for the same parameters at 180 min were 6.34, 45.11%, and 12.96, respectively. The highest values of density, L*, and a* at 30 min were 1053 kg/m3, 48.12, and 14.01, respectively, while the lowest values for the same parameters at 180 min were 1022 kg/m3, 35.53, and 7.02, respectively. The results obtained here also agreed with that noted in a previous study [25] that showed an increase in cooking loss as cooking temperature and cooking time increased. It was also reported [41,42] that beef’s pH and cooking loss gradually increased with an increase in cooking time, while the color of beef changed with the increase in cooking time and cooking temperature [43]. Conversely, our data exhibited a decrease in water activity, density, lightness, and redness as cooking time increased, while yellowness increased.

Significant (p ≤ 0.05) differences were observed in cooking loss, lightness, and yellowness color components as a result of the two-way interaction between the cooking method and cooking temperature. It also reported a significant (p ≤ 0.05) two-way interaction between the cooking method and cooking time regarding cooking loss only. In contrast, all the physical properties of camel meat were significantly (p ≤ 0.05) affected by the interaction between cooking temperature and cooking time, except for water activity and density. This result coincided with the findings of a previous study [11]. The result indicated a three-way interaction (CMD × CTM × CTI) with respect to cooking loss only.

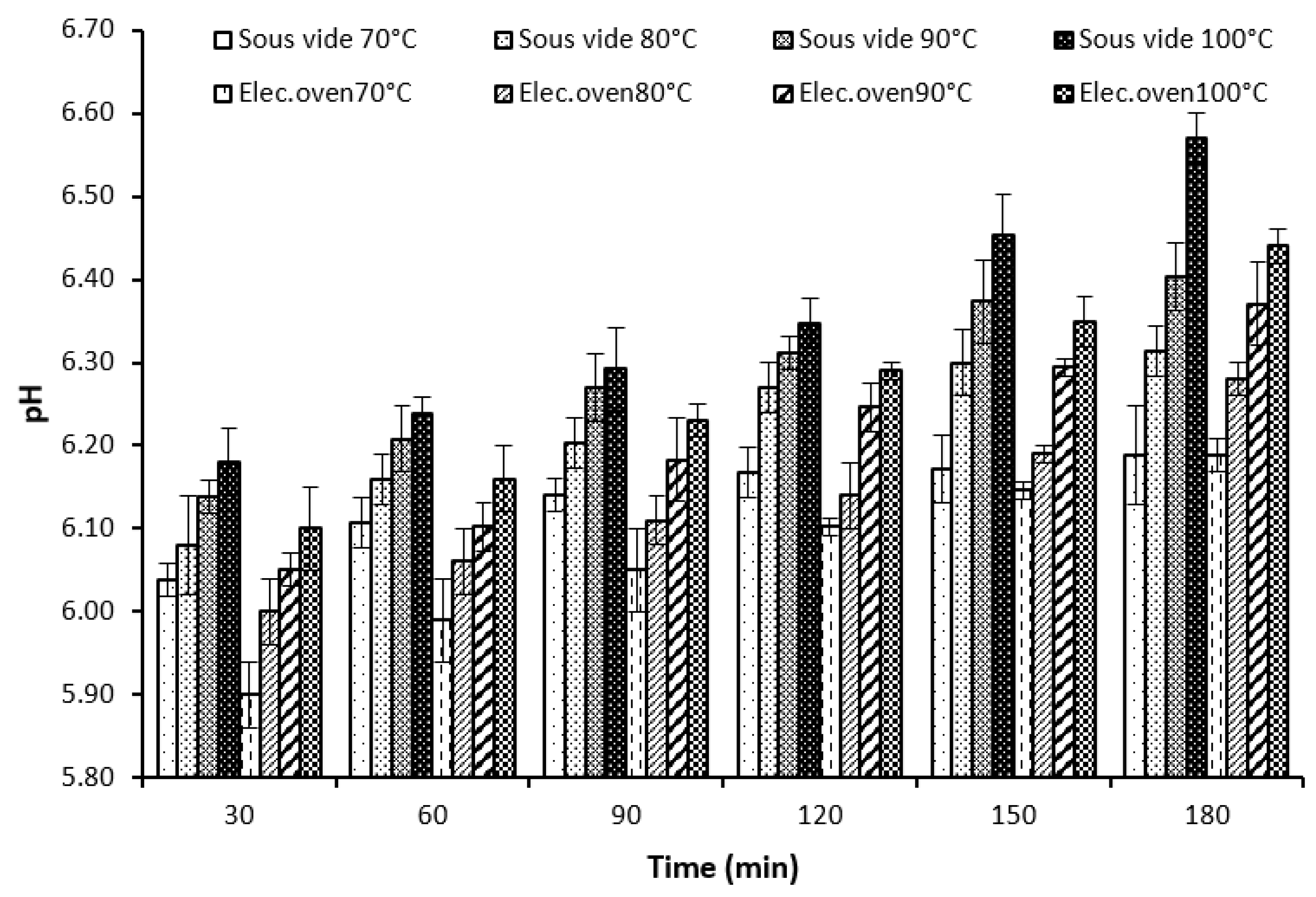

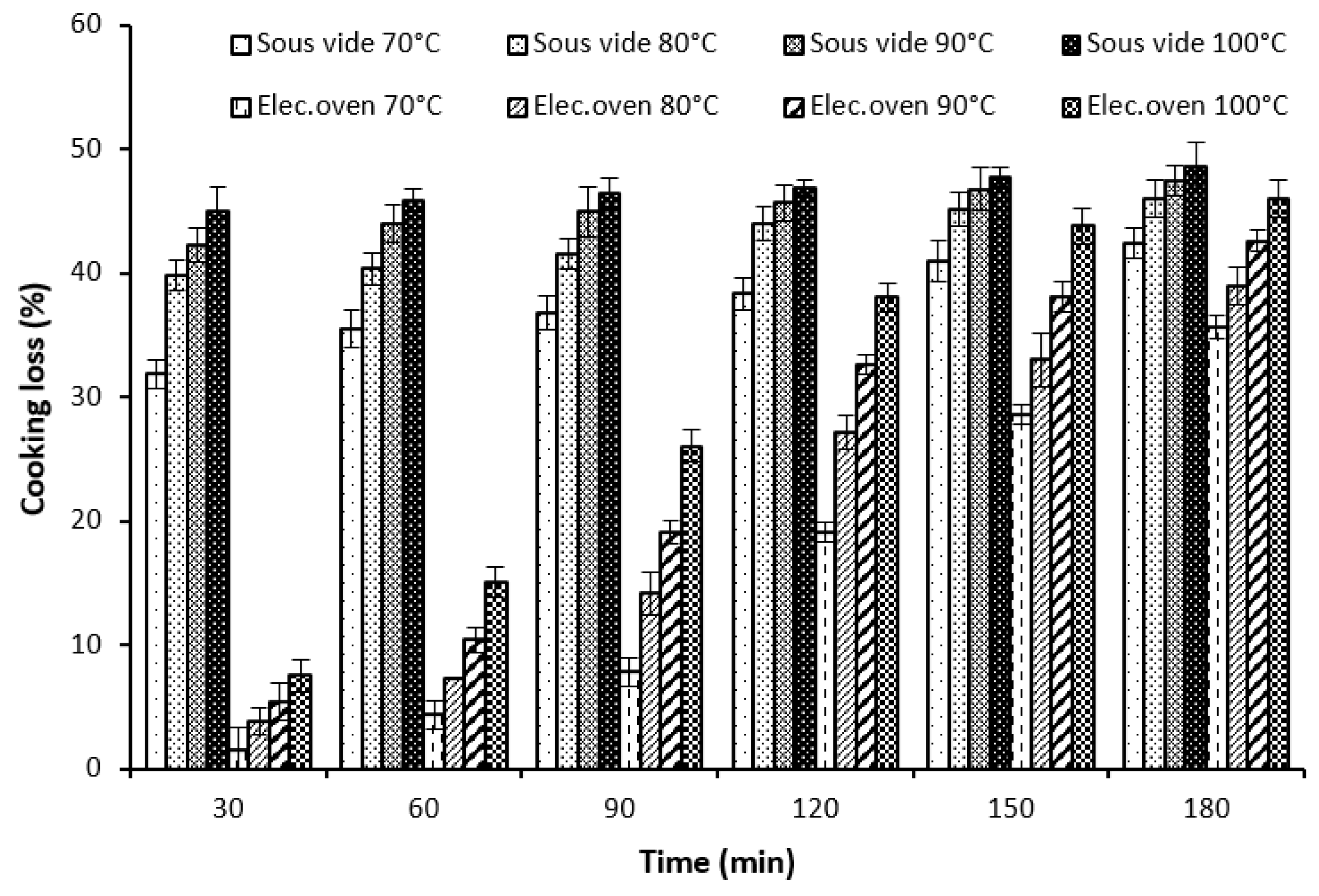

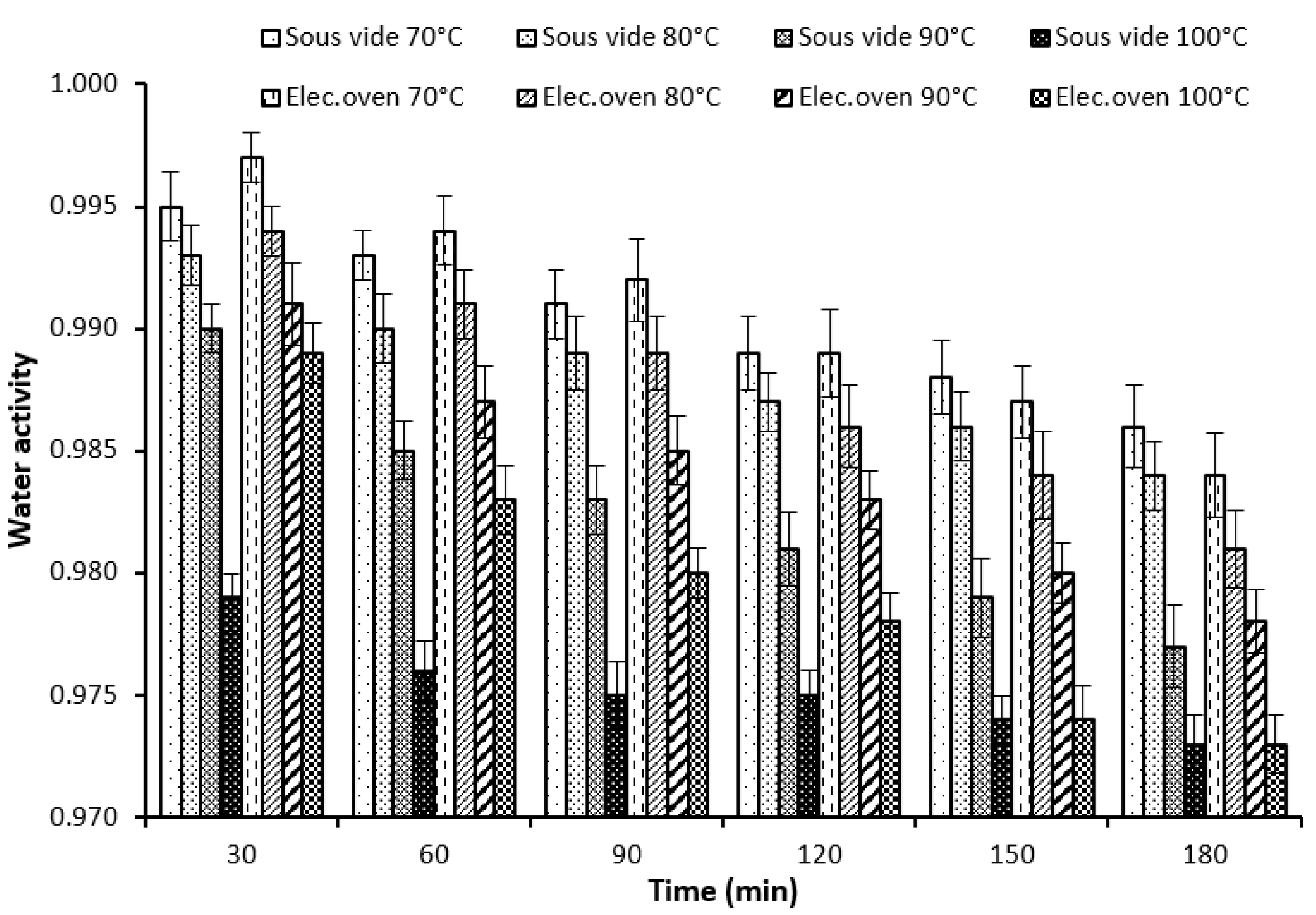

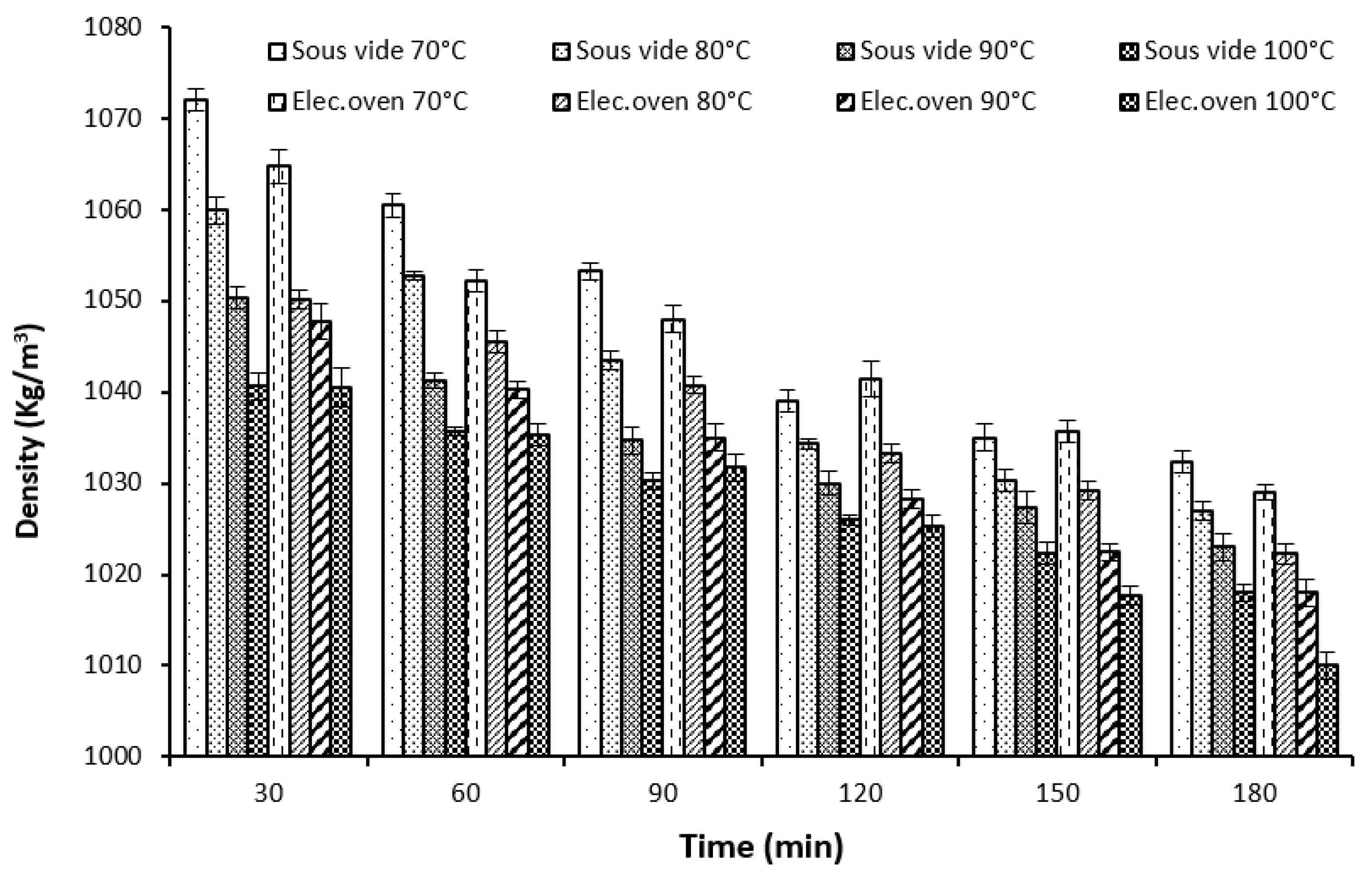

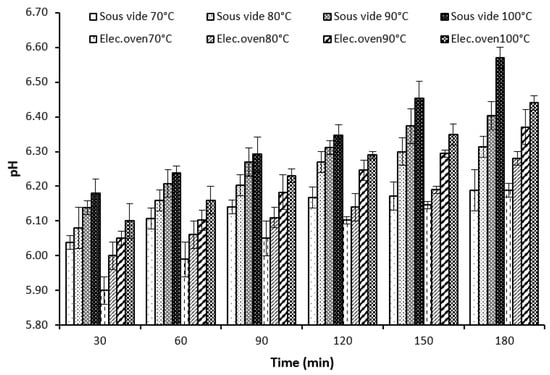

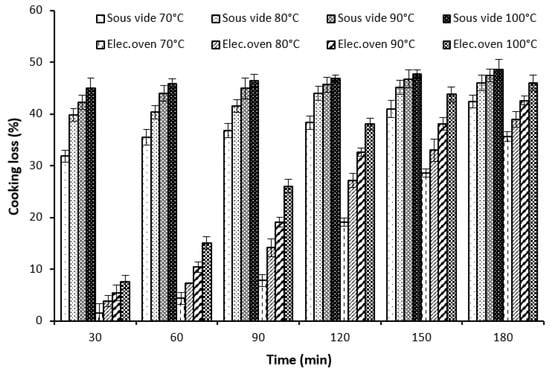

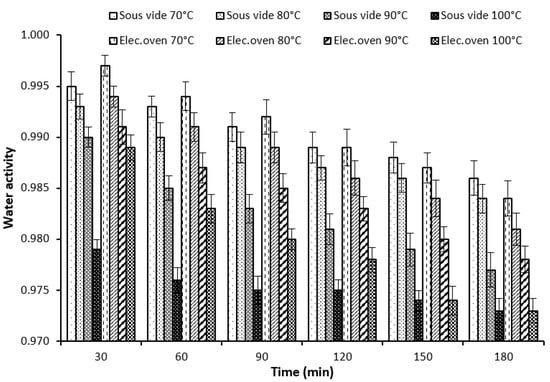

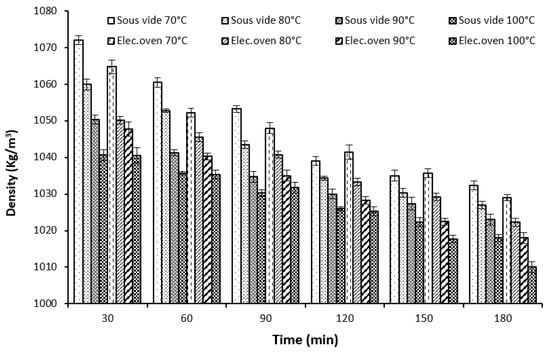

Figure 1, Figure 2, Figure 3 and Figure 4 show the effect of cooking method (sous vide vs. electrical oven) on the camel meat physical properties (pH, cooking loss, water activity, and density) at different combinations of temperature and time.

Figure 1.

The effect of the cooking method (sous vide vs. electrical oven) on the camel meat physical properties (pH) at different combinations of temperature and time.

Figure 2.

The effect of the cooking method (sous vide vs. electrical oven) on the camel meat physical properties (cooking loss) at different combinations of temperature and time.

Figure 3.

The effect of the cooking method (sous vide vs. electrical oven) on the camel meat physical properties (water activity) at different combinations of temperature and time.

Figure 4.

The effect of the cooking method (sous vide vs. electrical oven) on the camel meat physical properties (density) at different combinations of temperature and time.

The pH of meat cooked using the two cooking methods of sous vide and electric oven increased from 6.04 and 5.90 at 70 °C to 6.57 and 6.44 at 100 °C, respectively (Figure 1). This increase could be attributed to cooking at a high temperature for a long period, so some free amino acids were lost with water and minerals, leading to an increase in hydrogen sulfide, thereby resulting in a high pH [44]. The result obtained here was consistent with the findings of previous studies that showed an increase in pH as cooking temperature and time increased [11,45]. The pH of camel meat cooked using the sous vide method was higher (6.57) than that cooked using the electric oven method (5.41) at 100 °C and 180 min. Thus, the cooking of meat using the sous vide method was more effective than cooking using the electric oven method. This result was concurrent with the findings of a previous study [25].

In Figure 2, the cooking loss of meat prepared using the sous vide and electric oven methods increased from 31.87% and 1.52 at 70 °C to 48.56% and 46.1% at 100 °C, respectively. This could be due to the high temperatures applied to meat for an extended time, so damage, shrinkage, and melting of the cells occurred, resulting in loss of water, minerals, and protein fibers [46]. In a previous study [46], the increase in temperatures in different methods of cooking led to a loss of 70% to 80% of water. Moreover, an increase in the cooking loss of duck meat was reported when cooked in plastic bags inside a water bath when the temperature increased [37].

In the current study, the cooking loss of cooked camel meat using the sous vide method at 70 °C at different times was higher than that obtained using the electric oven method. This is due to the high thermal conductivity coefficient in the sous vide method where water is involved in cooking, so heat transfers faster and meat ripens rapidly. However, cooking using the electric oven depends on circulating dry air, so the cooking loss was lower compared to that observed using the sous vide method. Our findings agreed with those of previous research that studied the physical properties of Najdi camel meat [5].

In Figure 3, the water activity (aw) of the cooked camel meat using the sous vide and electric oven methods decreased from 0.995 and 0.997 at 70 °C to 0.973 and 0.973 at 100 °C, respectively. The increase in both temperature and time during cooking was associated with low water activity. This happens because of water and minerals loss from the meat after exposure to high temperatures for a long time [5]. Interestingly, the values of water activity of cooked camel meat for both cooking methods evaluated in this study at 100 °C for 180 min were typical (0.973).

Figure 4 shows the decrease in density of the cooked camel meat using the sous vide and electric oven methods from 1072 and 1064.75 kg/m3 at 70 °C to 1018 and 1018 kg/m3 at 100 °C, respectively. This was ascribed to the cooking of meat at higher temperatures for long time intervals, which led to water reduction on the outer surface of the meat as a result of many changes in protein structure that causes shrinkage of muscle fibers [11]. The density of cooked camel meat at 100 °C using the sous vide method was higher (1018 kg/m3) than that of the electric oven method (1013 kg/m3). For all combinations of cooking temperature and cooking time, the camel meat density decreased in both types of cooking methods.

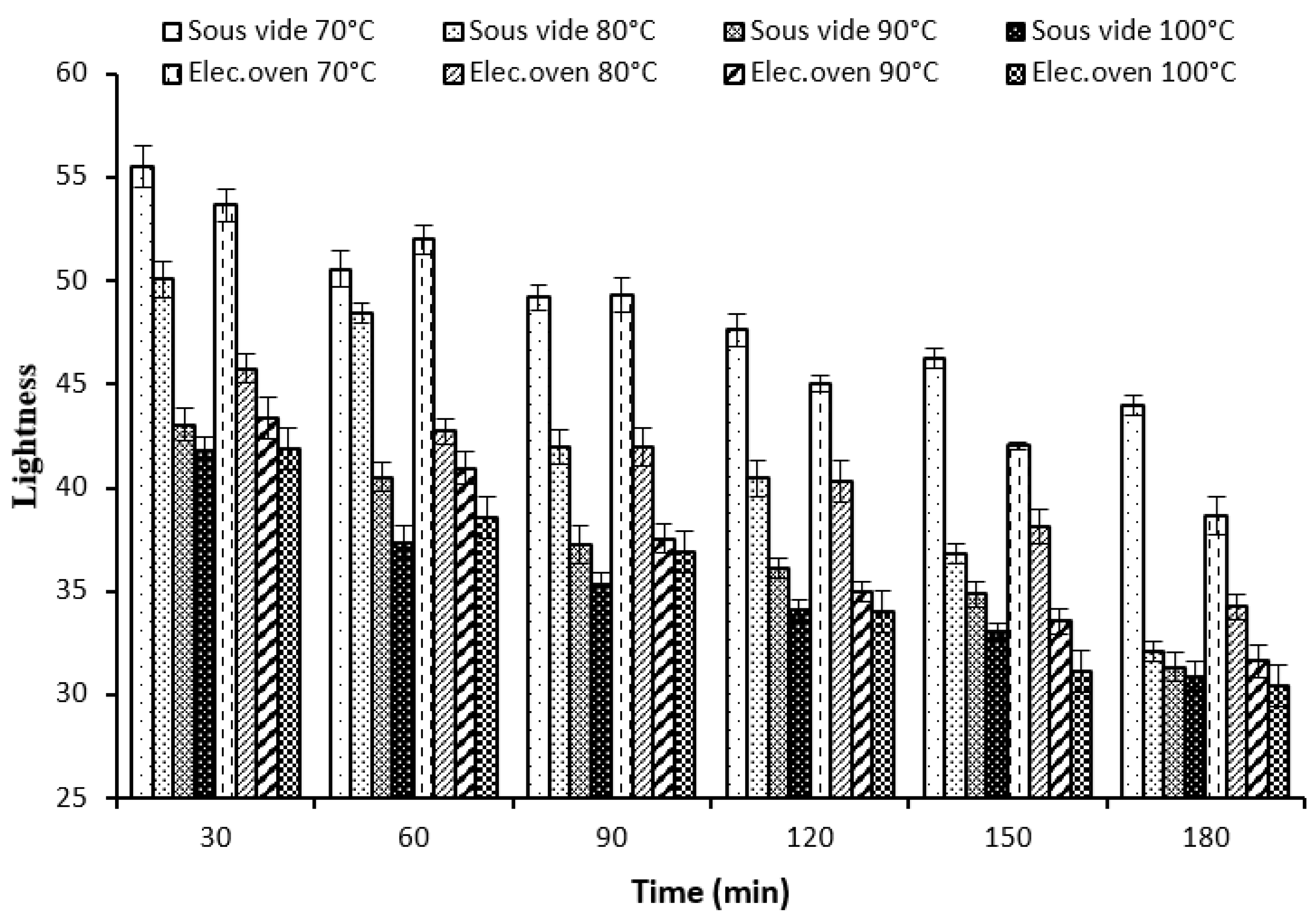

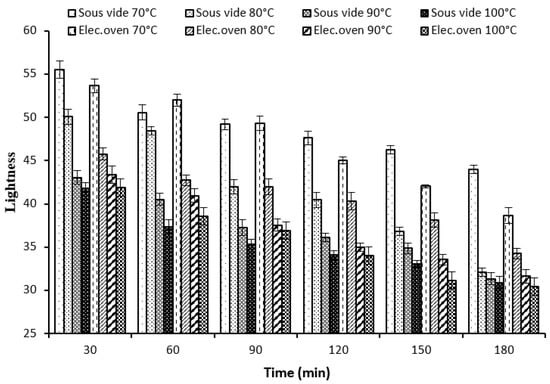

In Figure 5, the lightness color components (L*) of the camel meat cooked using the sous vide and electric oven methods decreased from 55.49 and 53.65 to 30.89 and 30.46, respectively. The lightness of cooked camel meat decreased with increased cooking temperature and cooking time, indicating a dark brown color of well-done cooked meat. The lightness of cooked camel meat at 100 °C for 180 min using the sous vide method was lower (30.89) than the lightness obtained using the electric oven method (31.89). Hence, the sous vide method preserved the color gradation of cooked camel meat better than the electric oven. This result was in line with that reported previously [25].

Figure 5.

The effect of the cooking method (sous vide vs. electrical oven) on the camel meat color components (lightness L*) at different combinations of temperature and time.

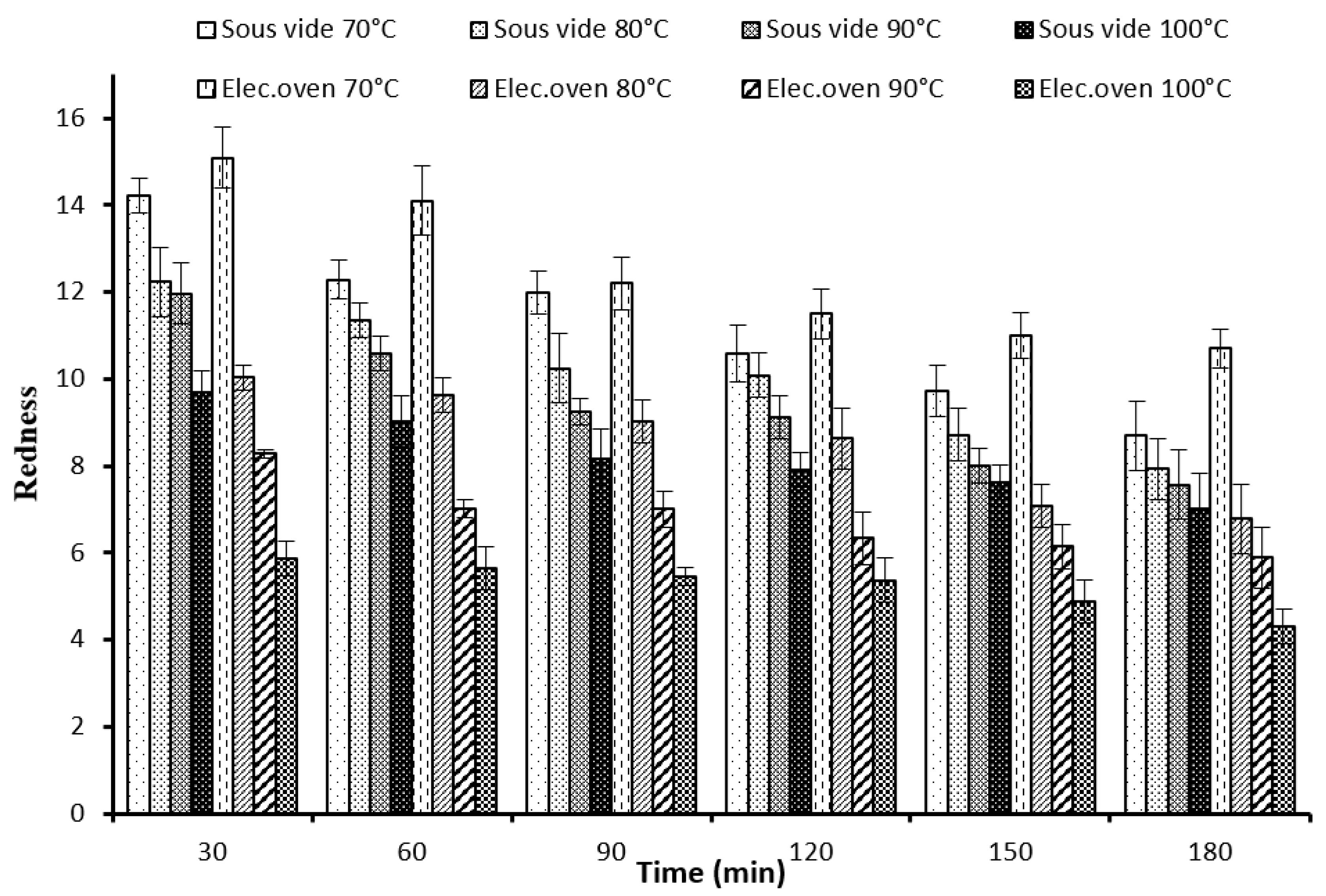

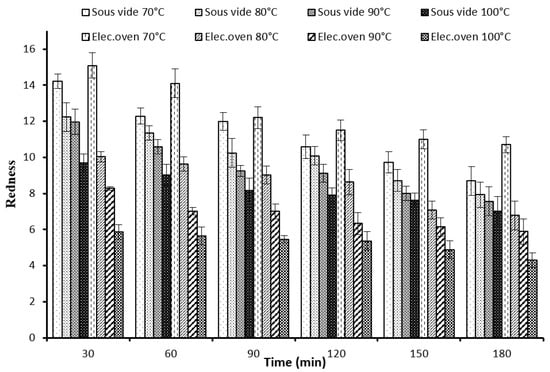

Figure 6 shows that the redness color components (a*) of the camel meat cooked using the sous vide and electric oven methods decreased from 14.21 and 15.09 to 7.02 and 4.31, respectively. With increasing temperature and cooking time, the redness value was reduced by both cooking methods. This could be due to several chemical reactions that had taken place as a result of the cooking temperature and time combination and their impact on myoglobin [25]. The redness value of the camel meat cooked at 100 °C for 180 min using the electric oven was lower (7.02) than that cooked using the sous vide method (4.31) at the same cooking temperature and time.

Figure 6.

The effect of the cooking method (sous vide vs. electrical oven) on the camel meat color components (redness a*) at different combinations of temperature and time.

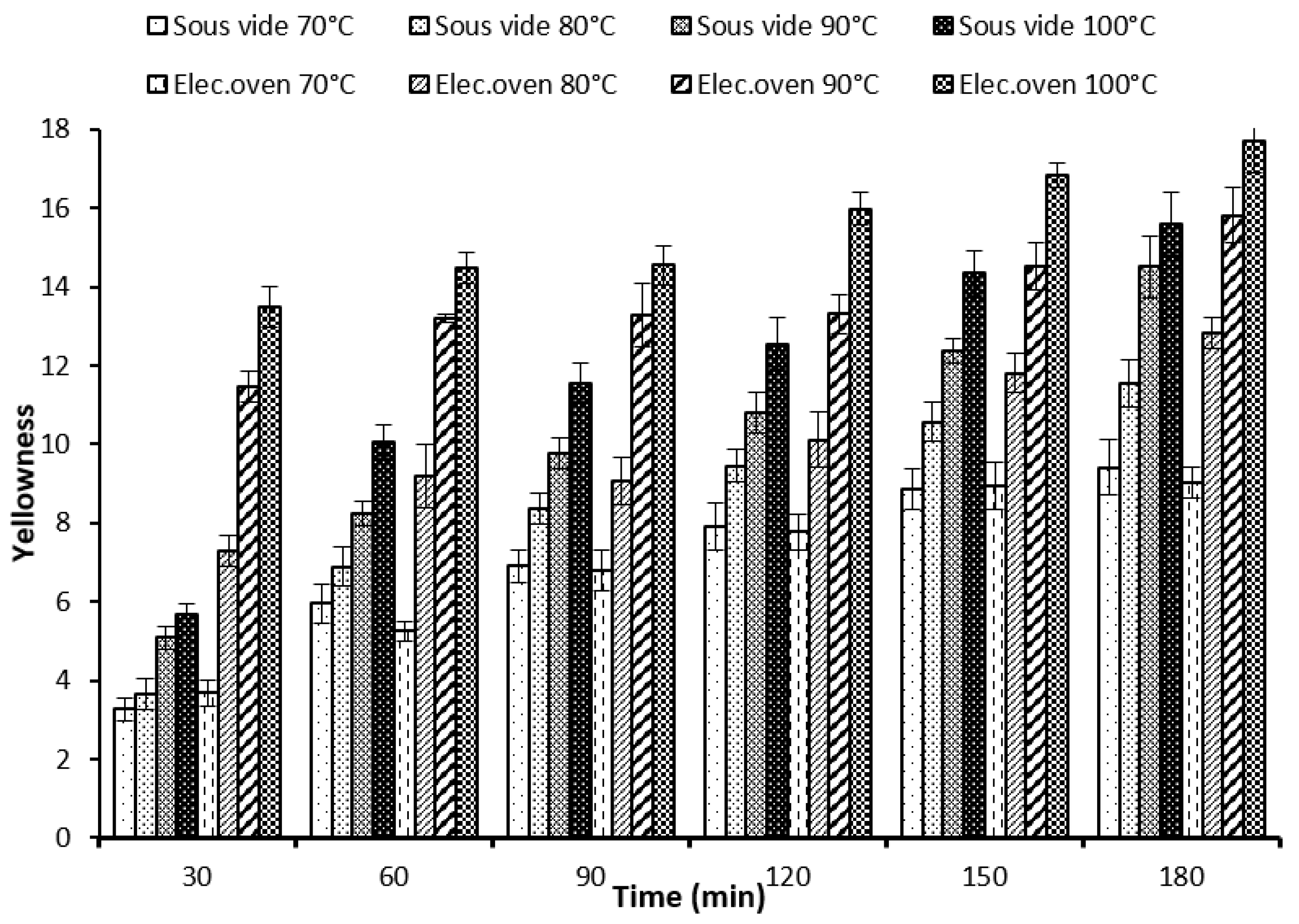

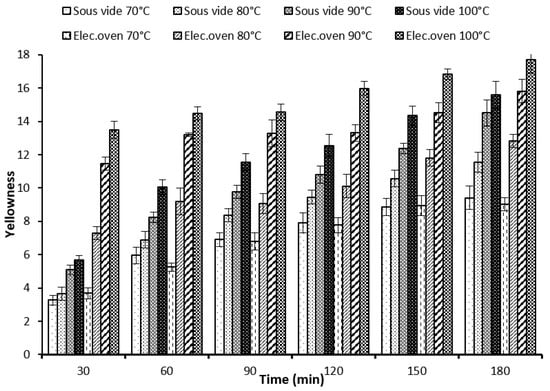

In Figure 7, the yellowness color components (b*) of the camel meat cooked using the sous vide and electric oven methods increased from 3.26 and 3.67 to 15.58 and 17.68, respectively. The results indicate that at higher temperatures and prolonged cooking time, the b* of the cooked camel meat continues to increase. Our findings regarding this parameter agreed with that obtained previously [25]. At 30 and 150 min, the yellowness of camel meat cooked using the electric oven method was higher than that cooked using the sous vide method at all the degrees of temperatures. Oppositely, the yellowness of camel meat cooked by the sous vide method exceed that cooked by the electric oven method at 70 °C for all remaining cooking times (60, 90, 120, and 180 min).

Figure 7.

The effect of the cooking method (sous vide vs. electrical oven) on the camel meat color components (yellowness b*) at different combinations of temperature and time.

3.3. Effects of the Sous Vide and Electric Oven Cooking Methods on the Sensory Properties of Camel Meat

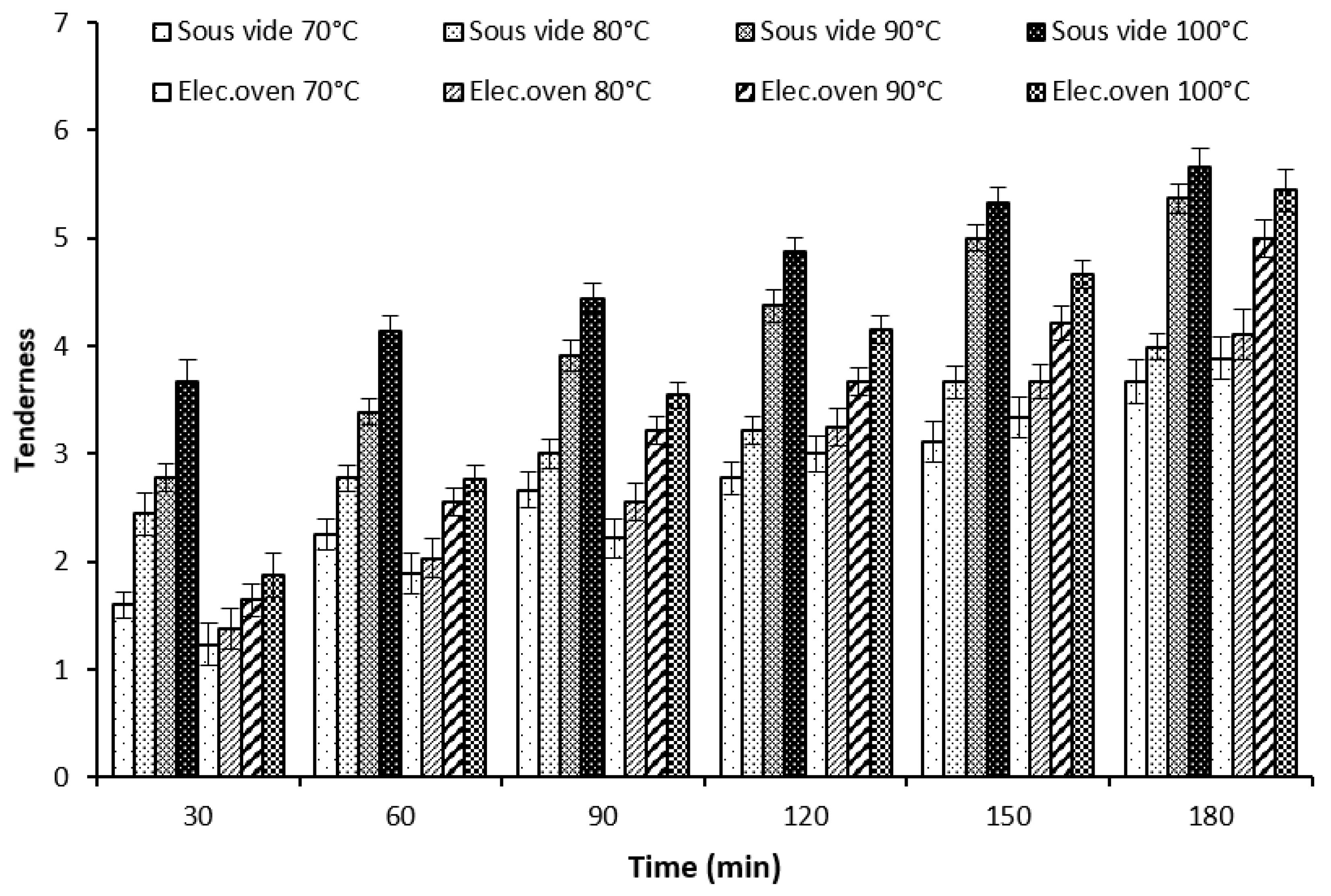

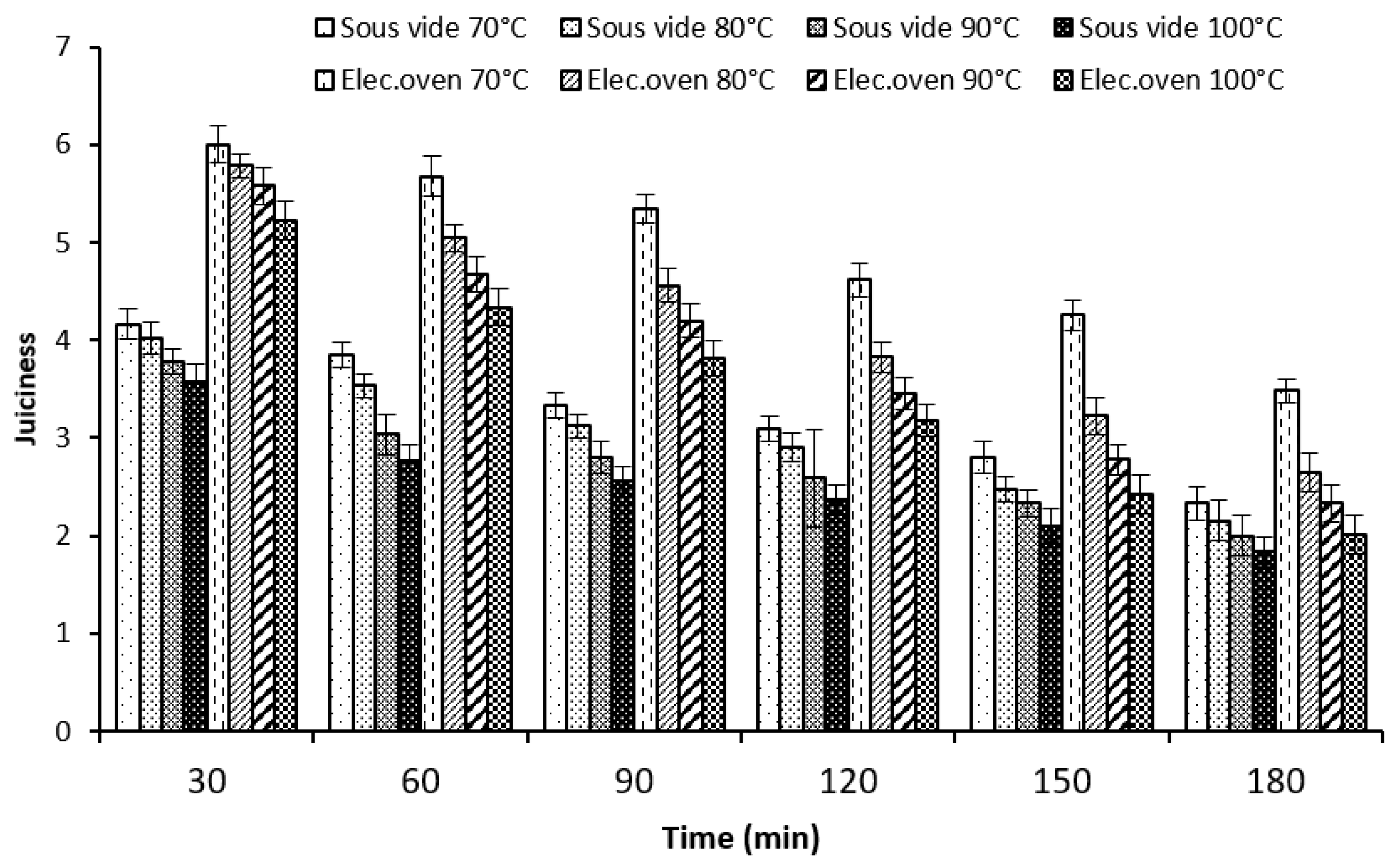

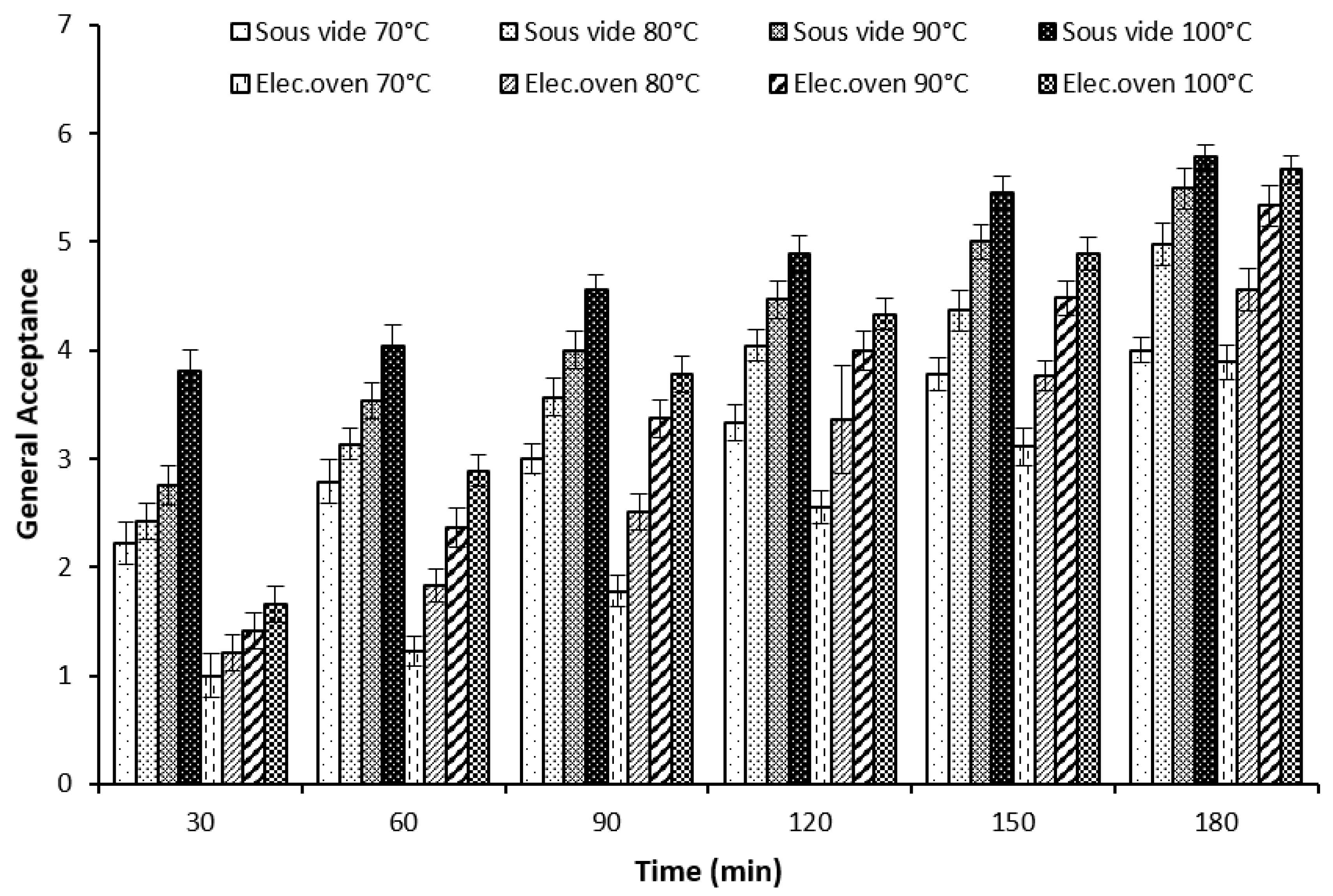

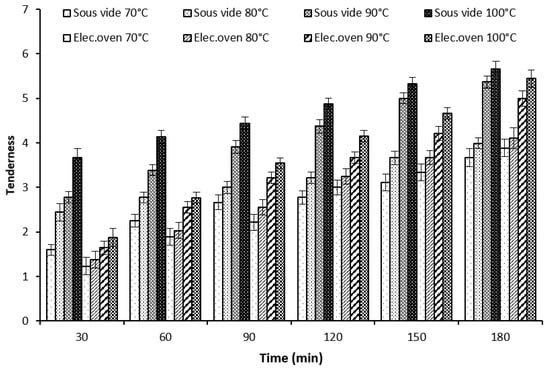

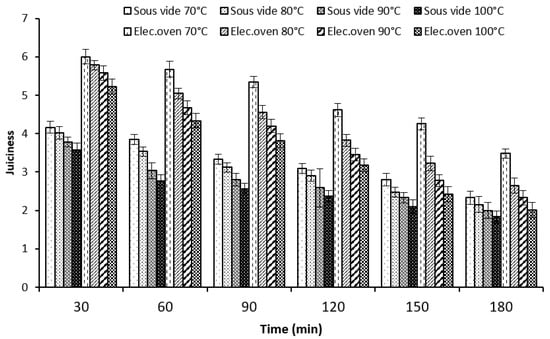

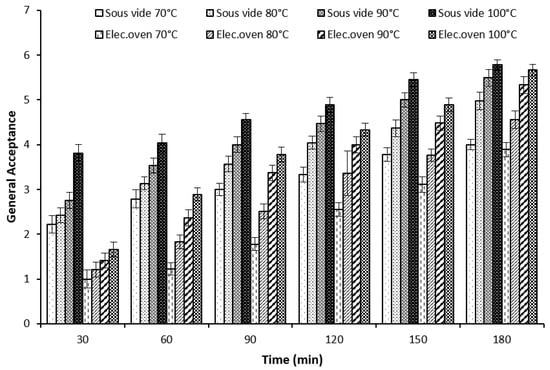

Table 3 illustrates the effect of the cooking method (CMD), cooking temperature (CTM), and cooking time (CTI) on the sensory properties of camel meat. The sensory properties under investigation included tenderness, flavor, juiciness, and general acceptance. The two cooking methods, sous vide and electric oven, were significantly (p ≤ 0.05) different in response to all the sensory properties of cooked camel meat. The highest values of tenderness (3.68), flavor (4.03) and general acceptance (3.98) were reported using the sous vide method. The electric oven method attained the highest value (4.08) of juiciness. The different responses of sensory properties could be ascribed to the nature of each cooking method. The sous vide cooking method is characterized by rapid changes in the structural properties of the cooked meat because of low levels of cooking temperature for an extended time. This generally leads to a clear and distinctive flavor of the meat as well as a homogeneous texture, which reflects positively on the general acceptability. In contrast, the electric oven cooking method requires high temperatures for a relatively short time that resulted in increasing tenderness, flavor, and general acceptance. The subjective tenderness, flavor, and general acceptance increased (p ≤ 0.05) as the cooking temperature increased. The lowest reported values of tenderness, flavor, and general acceptance at 70 °C were 2.64, 2.65 and 2.72, respectively, whereas the highest values of the same parameters at 100 °C were 4.22, 4.39 and 4.32, respectively. The juiciness of cooked camel meat decreased (p ≤ 0.05) as the cooking temperature increased. The highest value of juiciness at 70 °C was 4.09, while the lowest value at 100 °C was 3.01. The results obtained in this study revealed that the cooking time significantly (p ≤ 0.05) affected all the sensory properties of camel meat. It is noteworthy that the tendency of the sensory properties with respect to cooking temperature was typically shown with the cooking time. The tenderness, flavor, and general acceptance increased (p ≤ 0.05) as the cooking time increased. The lowest tenderness, flavor, and general acceptance values at 30 min were 2.05, 2.19, and 2.06, respectively, whereas the highest values of the same parameters at 180 min were 4.65, 4.88, and 4.96, respectively. In contrast, the juiciness of cooked camel meat decreased (p ≤ 0.05) as the cooking time increased. The highest value of juiciness at 30 min was 4.76, while the lowest value at 180 min was 2.34. The camel meat’s sensory properties of tenderness, flavor, and juiciness showed significant (p ≤ 0.05) responses to the interaction between the cooking method and cooking temperature, while the general acceptance did not. Furthermore, all the sensory properties reacted significantly (p ≤ 0.05) with the interaction between the cooking method and cooking time. No significant responses were observed in sensory properties due to the interactions between CTM × CTI and between CMD × CTM × CTI.

Table 3.

Effects of the cooking method (CMD) at different cooking temperatures (CTM) and cooking times (CTI) on the sensory properties of camel meat.

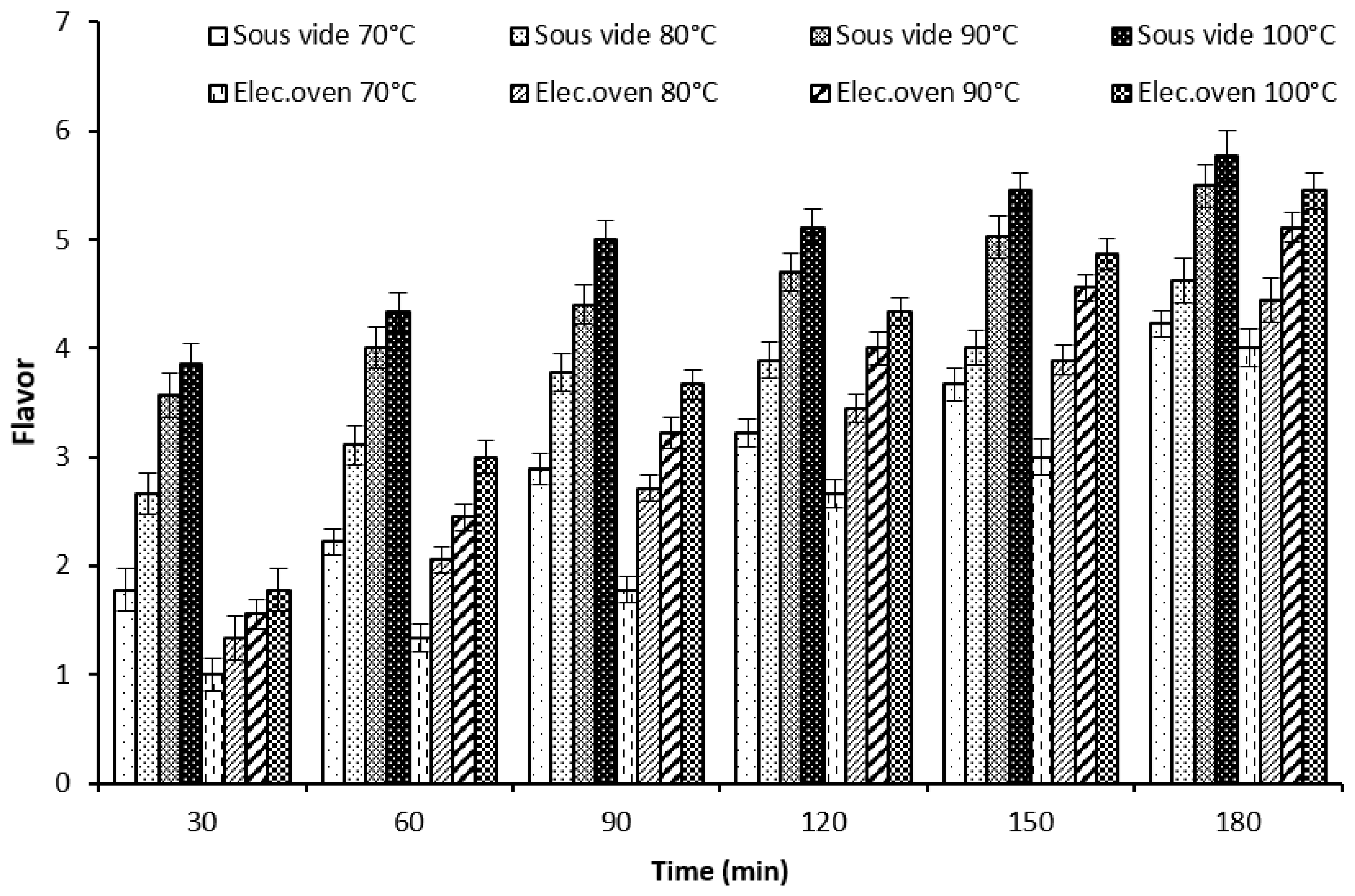

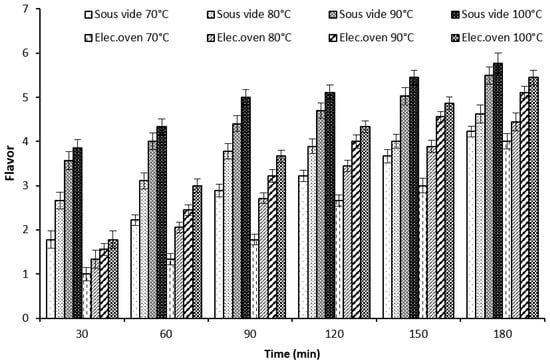

Figure 8, Figure 9, Figure 10 and Figure 11 show the effect of the cooking method (sous vide vs. electrical oven) on the camel meat sensory properties (tenderness, flavor, juiciness, and general acceptance) at different combinations of temperature and time. Figure 8 presents the impact on the degree of subjective tenderness of camel meat cooked using the sous vide method compared to the electric oven method at different temperatures and times. The increase in cooking temperature was associated with an increase in meat tenderness. This took place because the properties of the proteins have changed during cooking as a result of cellular membrane damage and accumulation of gelatinous fibers [37]. Moreover, the sous vide method increases the tenderness of meat, giving it a homogenous texture [47]. The highest score of tenderness (5.7) was obtained using the sous vide method at the combination between cooking temperature and time of 100 °C and 180 min, respectively, when compared to the electric oven method at the same combination. In contrast, the lowest score of tenderness (5.4) was obtained using the electric oven method at the combination between cooking temperature and time of 70 °C and 30 min, respectively.

Figure 8.

The effect of the cooking method (sous vide vs. electrical oven) on the camel meat sensory properties (tenderness) at different combinations of temperature and time.

Figure 9.

The effect of the cooking method (sous vide vs. electrical oven) on the camel meat sensory properties (flavor) at different combinations of temperature and time.

Figure 10.

The effect of the cooking method (sous vide vs. electrical oven) on the camel meat sensory properties (juiciness) at different combinations of temperature and time.

Figure 11.

The effect of the cooking method (sous vide vs. electrical oven) on the camel meat sensory properties (general acceptance) at different combinations of temperature and time.

In Figure 9, the impact on the degree of the subjective flavor of camel meat cooked using the sous vide method compared to the electric oven method at different temperatures and times is illustrated. It is observed that the flavor clarity of the cooked camel meat is directly proportional to the cooking temperature and time where the attribute is greater with a higher cooking temperature and a longer time. The reason behind this is due to the dispersion of fats that give the desired and distinctive flavor and smell of cooked meat. Our findings in the current study are consistent with those of a previous study about the effect of cooking temperature and time on the physicochemical, histological, and sensory properties of the meat from female buffalos. The buffalo meat was cooked at temperatures of 80–100 °C for 30–60 min [38]. It is clear that the flavor clarity of camel meat cooked using the sous vide method was better than that obtained using the electric oven. The best flavor score using the sous vide method was attained while cooking at a temperature of 100 °C for 180 min, while the lowest score using the electric oven method was attained while cooking at a temperature of 70 °C for 30 min.

In Figure 10, the juiciness of camel meat is reduced with the increase in temperature and cooking time. The loss of water and minerals during cooking is the main reason for this finding [48]. Moreover, the degree of juiciness using the sous vide method is less than that obtained using the electric oven. At a cooking temperature of 70 °C and cooking time of 30 min, the subjective juiciness of cooked camel meat using the sous vide method was somewhat less juicy compared to the very juicy camel meat cooked using the electric oven. This indicates that, at lower temperatures and times, cooking camel meat in an electric oven is superior to cooking with the sous vide method.

Figure 11 displays the general acceptance of cooked camel meat using the sous vide and electric oven methods at different combinations of temperature and time. It is observed that the general acceptance increased with increasing temperature and cooking time. This finding is comparable to the findings of a previous study [10] about the effect of temperature and time on the sensory properties of beef muscle. Furthermore, the score of general acceptance of the sous vide method was better than that of the electric oven method. This could be ascribed to the dependence of the sous vide method on water as a medium during cooking, while the electric oven depends on air. It is a fact that water has a higher conductivity coefficient than air, which leads to the acceleration of spoilage and denaturation of the meat protein [5]. However, the dry cooking method takes more time than the wet cooking method. The best acceptance record for both cooking methods was reported at 100 °C and 180 min.

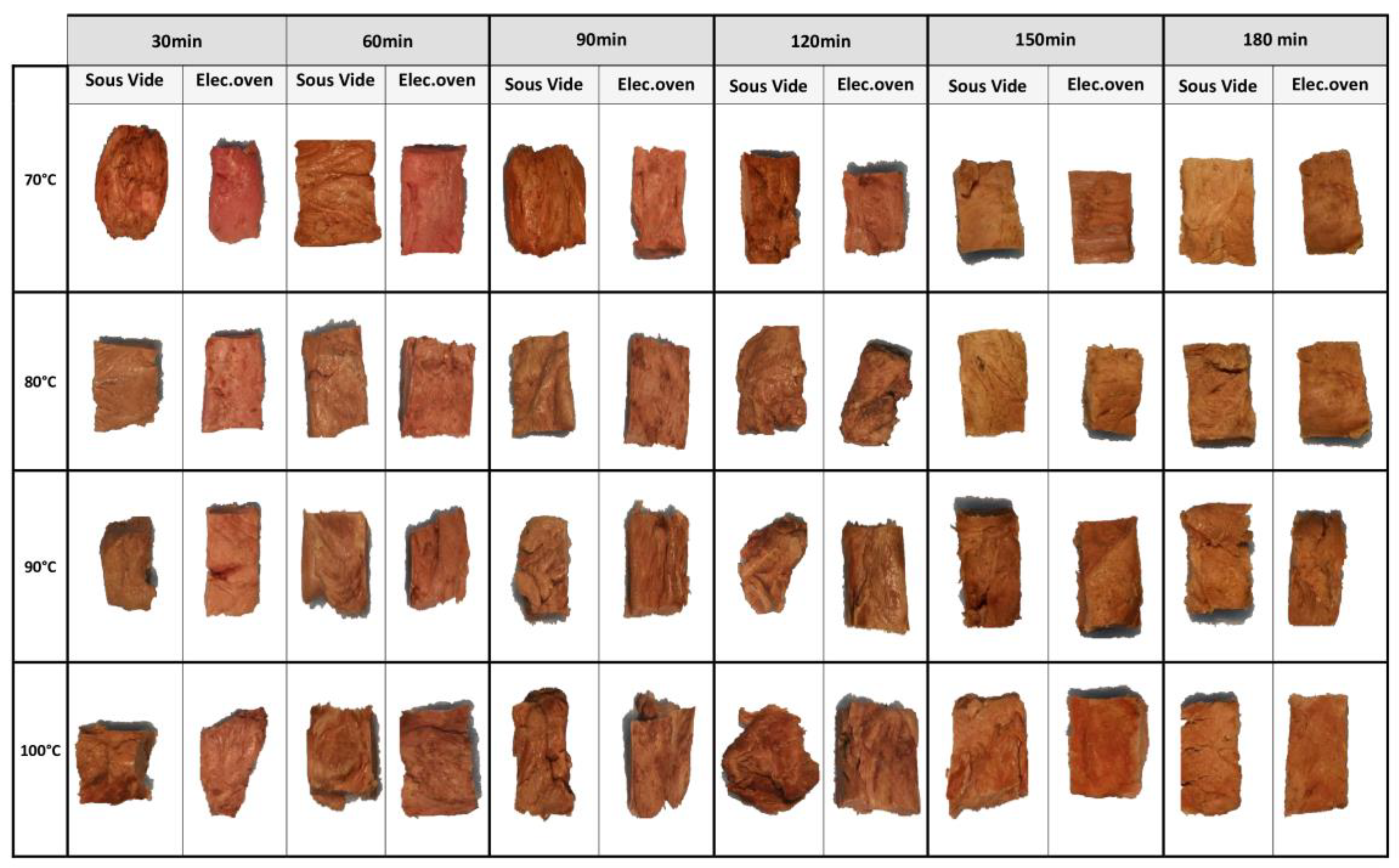

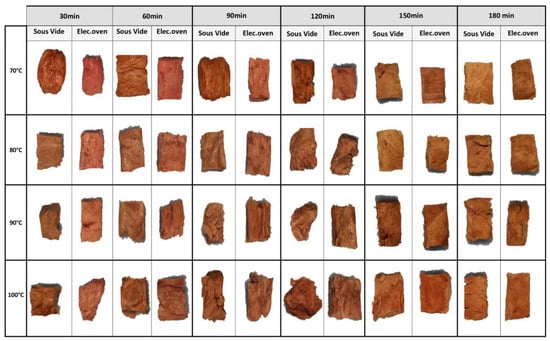

3.4. Variations in Colors of Cooked Camel Meat Using the Sous Vide and Electric Oven Methods at Different Cooking Temperatures and Cooking Times

Figure 12 exhibits the color of cooked camel meat using the sous vide and electric oven cooking methods at different cooking temperatures and cooking times. The color of cooked camel meat using the sous vide method changed faster than that observed after cooking with an electric oven. This can be elucidated by the dependence of the sous vide method on water, which has a high thermal conductivity coefficient; in contrast, the electric oven relies on dry heated air, which has a low thermal conductivity coefficient. Furthermore, when a longer cooking time coincides with a higher temperature, the meat color tends to be darker. The meat that underwent cooking at 70 °C for 30 min for both cooking methods appeared red in color, indicating an undercooked state. However, when the temperature was raised to 100 °C for 180 min, the meat color changed to brown. The main reason for color change is the iron oxidation in muscle myoglobin and the sugar and amine group reaction. Similar results were obtained by [49] when cooking Thai local beef using sous vide at different temperature and time combinations.

Figure 12.

Color of the cooked camel meat using the sous vide and electric oven methods at different cooking temperatures and cooking times.

4. Conclusions

This study was carried out to investigate the effects of the sous vide cooking method at different temperatures and cooking times on the quality traits, as well as physical and sensory characteristics of camel meat compared to a traditional electric oven method. The results showed that the cooking method significantly affected pH, cooking loss, density, and color components of camel meat. Moreover, all the physical properties of camel meat were significantly affected by the cooking temperature and cooking time, except for water activity. Furthermore, all the sensory properties of camel meat significantly responded to the cooking method as well as the cooking temperature and cooking time. The cooking loss was the only parameter that was affected significantly by the interaction of the method, temperature, and time of cooking. Interestingly, all the sensory properties were in favor of using the sous vide method compared to the electric oven method, except for juiciness, as consumers in this region preferred well-done meats over other types of doneness. Hence, higher temperatures and relatively prolonged times are recommended for cooking meats. Furthermore, camel meat cooked with the sous vide method showed significantly higher density than that cooked with the electric oven method. The best combination between cooking temperature and time resulting in the highest density value obtained in this study was at 70 °C for 30 min. Density is very important in different food industries, as it ensures quality for both raw and finished materials with respect to moisture, protein, and fat contents.

In conclusion, the sous vide method is the more suitable method for cooking camel meat compared to the electric oven method considering the cooking temperature and time. Further studies are recommended to estimate the energy consumption for both cooking methods evaluated in this study, aiming at reducing the overall power expenditure.

Author Contributions

Conception and methodology, A.I.H., A.A.F. and M.B.O.; experimental setup, M.B.O.; writing—original draft preparation, A.I.H. and M.B.O.; review and editing, A.I.H., A.A.F. and G.M.S. All authors have read and agreed to the published version of the manuscript.

Funding

The authors extend their appreciation to the Deputyship for Research & Innovation, Ministry of Education in Saudi Arabia for funding this research work through the project No. (IFKSURG-2-784).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data collected in this study are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kadim, I.T.; Mahgoub, O.; Al-Marzooqi, W.; Al-Zadgali, S.; Annamali, K.; Mansour, M. H Effects of age on composition and quality of muscle Longissimus thoracis of the Omani Arabian camel (Camelus dromedaries). Meat Sci. 2006, 73, 619–625. [Google Scholar] [CrossRef]

- Baba, W.N.; Rasool, N.; Selvamuthukumara, M.; Maqsood, S. A review on nutritional composition, health benefits, and technological interventions for improving consumer acceptability of camel meat: An ethnic food of Middle East. J. Ethn. Foods 2021, 8, 18. [Google Scholar] [CrossRef]

- FAO. Food and Agriculture Organization, FAOSTAT. 2021. Available online: http://www.fao.org/faostat/en/#data/QCL (accessed on 20 December 2022).

- RCCI. Riyadh Chamber of Commerce and Industry: A Comprehensive Study and Realistic Results Red Meat Needs to be Integrated between Its Economic Sectors; Riyadh Chamber, Research and Information Center: Riyadh, Saudi Arabia, 2015; Available online: https://marsad.chamber.sa/en/Pages/default.aspx (accessed on 20 December 2022).

- Dawood, A.A. Physical and sensory characteristics of Najdi camel meat. Meat Sci. 1995, 39, 59–69. [Google Scholar] [CrossRef]

- Baldwin, D.E. Sous vide cooking: A review. Int. J. Gastron. Food Sci. 2012, 1, 15–30. [Google Scholar] [CrossRef]

- James, B.J.; Yang, S.W. Effect of cooking method on the toughness of bovine m. semitendinosus. Int. J. Food Eng. 2012, 8, 2. [Google Scholar] [CrossRef]

- Zielbauer, B.I.; Franz, J.; Viezens, B.; Vilgis, T.A. Physical aspects of meat cooking: Time dependent thermal protein denaturation and water loss. Food Biophys. 2016, 11, 34–42.–42. [Google Scholar] [CrossRef]

- Schmidt, C.V.; Plankensteiner, L.; Faxholm, P.L.; Olsen, K.; Mouritsen, O.G.; Frøst, M.B. Physicochemical characterization of sous vide cooked squid (Loligo forbesii and Loligo vulgaris) and the relationship to selected sensory properties and hedonic response. Int. J. Gastron. Food Sci. 2021, 23, 100298. [Google Scholar] [CrossRef]

- Mortensen, L.M.; Frøst, M.B.; Skibsted, L.H.; Risbo, J. Effect of time and temperature on sensory properties in low-temperature long-time sous vide cooking of beef. J. Culin. Sci. Technol. 2012, 10, 75–90.–90. [Google Scholar]

- Del Pulgar, J.S.; Gázquez, A.; Ruiz-Carrascal, J. Physico-chemical, textural and structural characteristics of sous vide cooked pork cheeks as affected by vacuum, cooking temperature, and cooking time. Meat Sci. 2012, 90, 828–835. [Google Scholar] [CrossRef]

- Rinaldi, M.; Dall’Asta, C.; Paciulli, M.; Cirlini, M.; Manzi, C.; Chiavaro, E. A novel time/temperature approach to sous vide cooking of beef muscle. Food Bioprocess Technol. 2014, 7, 2969–2977. [Google Scholar] [CrossRef]

- Park, C.H.; Lee, B.; Oh, E.; Kim, Y.S.; Choi, Y.M. Combined effects of sous vide cooking conditions on meat and sensory quality characteristics of chicken breast meat. Poult. Sci. 2020, 99, 3286–3291.–3291. [Google Scholar] [CrossRef] [PubMed]

- Naqvi, Z.B.; Thomson, P.C.; Ha, M.; Campbell, M.A.; McGill, D.M.; Friend, M.A.; Warner, R.D. Effect of sous vide cooking and ageing on tenderness and water-holding capacity of low-value beef muscles from young and older animals. Meat Sci. 2021, 175, 108435. [Google Scholar] [CrossRef]

- Mossel, D.A.A.; Struijk, C.B. Public health implication of refrigerated pasteurized (‘sous vide’) foods. Int. J. Food Microbiol. 1991, 13, 187–206.–206. [Google Scholar] [CrossRef]

- Schellekens, M. New research issues in sous vide cooking. Trends Food Sci. Technol. 1996, 7, 256–262.–262. [Google Scholar] [CrossRef]

- Baldwin, D.E. Sous Vide for the Home Cook, 2nd ed.; Paradox Press: Incline Village, NV, USA, 2013. [Google Scholar]

- Potter, J. Cooking for Geeks: Real Science, Great Hacks and Good Food; O’Reilly Media: Sebastopol, CA, USA, 2010. [Google Scholar]

- Myhrvold, N.; Young, C.; Bilet, M. Modernist Cuisine: The Artand Science of Cooking; The Cooking Lab: Bellevue, WA, USA, 2011. [Google Scholar]

- Roascio-Albistur, A.; Gámbaro, A. Consumer perception of a non-traditional market on sous vide dishes. Int. J. Gastron. Food Sci. 2018, 11, 20–24.–24. [Google Scholar] [CrossRef]

- Botinestean, C.; Keenan, D.F.; Kerry, J.P.; Hamill, R.M. The effect of thermal treatments including sou vide, blast freezing and their combinations on beef tenderness of M. semitendinosus steaks targeted at elderly consumers. LWT Food Sci. Technol. 2016, 74, 154–159.–159. [Google Scholar] [CrossRef]

- Olatunde, O.O.; Benjakul, S. Sous vide cooking as a systematic approach for quality maintenance and shelf-life extension of crab lump meat. LWT Food Sci. Technol. 2021, 142, 111004. [Google Scholar] [CrossRef]

- Dominguez-Hernandez, E.; Salaseviciene, A.; Ertbjerg, P. Low-temperature long-time cooking of meat: Eating quality and underlying mechanisms. Meat Sci. 2018, 143, 104–113.–113. [Google Scholar] [CrossRef]

- O’Quinn, T.G.; Legako, J.F.; Brooks, J.C.; Miller, M.F. Evaluation of the contribution of tenderness, juiciness, and flavor to the overall consumer beef eating experience. Transl. Anim. Sci. 2018, 2, 26–36.–36. [Google Scholar] [CrossRef]

- García-Segovia, P.; Andrés-Bello, A.; Martínez-Monzó, J. Effect of cooking method on mechanical properties, color and structure of beef muscle (M. pectoralis). J. Food Eng. 2007, 80, 813–821. [Google Scholar] [CrossRef]

- Jeong, S.H.; Kim, E.C.; Lee, D.U. The impact of a consecutive process of pulsed electric field, sous vide cooking, and reheating on the properties of beef semitendinosus muscle. Foods 2020, 9, 1674. [Google Scholar] [CrossRef]

- Hussein, E.O.S.; Suliman, G.M.; Al-Owaimer, A.N.; Ahmed, S.H.; Abudabos, A.M.; Abd El-Hack, M.E.; Taha, A.E.; Saadeldin, I.M.; Swelum, A.A. Effects of stock, sex, and muscle type on carcass characteristics and meat quality attributes of parent broiler breeders and broiler chickens. Poult. Sci. 2019, 98, 6586–6592.–6592. [Google Scholar] [CrossRef]

- Suliman, G.M.; Al-Owaimer, A.N.; El-Waziry, A.M.; Hussein, E.O.S.; Abuelfatah, K.; Swelum, A.A.A. Comparative Study of Sheep Breeds: Fattening Performance, Carcass Characteristics, Meat Chemical Composition and Quality Attributes. Front. Vet. Sci. 2021, 8, 1–9. [Google Scholar] [CrossRef]

- AMSA. Research Guidelines for Cookery, Sensory Evaluation, and Instrumental Tenderness Measurements of Fresh Meat; American Meat Science Association National Livestock and Meat Board: Chicago, IL, USA, 2016. [Google Scholar]

- Yousif, O.K.; Babiker, S.A. The desert camel as meat animals. Meat Sci. 1989, 26, 245–254. [Google Scholar] [CrossRef]

- Al-Sheddy, I.; Al-Dagal, M.; Bazaraa, W.A. Microbial and sensory quality of fresh camel meat treated with organic acid salts and/or bifidobacteria. J. Food Sci. 1999, 64, 336–339. [Google Scholar] [CrossRef]

- Al-Owaimer, A.N.; Suliman, G.M.; Sami, A.S.; Picard, B.; Hocquette, J.F. Chemical composition and structural characteristics of Arabian camel (Camelus dromedarius) m. longissimus thoracis. Meat Sci. 2014, 96, 1233–1241. [Google Scholar] [CrossRef] [PubMed]

- Eskandari, M.H.; Majlesi, M.; Gheisari, H.R.; Farahnaky, A.; Khaksar, Z. Comparison of some physicochemical properties and toughness of camel meat and beef. J. Appl. Anim. Res. 2013, 41, 442–447. [Google Scholar] [CrossRef]

- Maqsood, S.; Abushelaibi, A.; Manheem, K.; Kadim, I.T. Characterization of the lipid and protein fraction of fresh camel meat and the associated changes during refrigerated storage. J. Food Compos. Anal. 2015, 41, 212–220. [Google Scholar] [CrossRef]

- Kadim, I.T.; Purchas, R. Camel carcass and meat quality characteristics. In More Than Beef, Pork and Chicken–The Production, Processing, and Quality Traits of Other Sources of Meat for Human Diet; Springer: Cham, Switzerland, 2019; pp. 69–94. [Google Scholar]

- Barbosa-Cánovas, G.V.; Fontana Jr, A.J.; Schmidt, S.J.; Labuza, T.P. (Eds.) Water Activity in Foods: Fundamentals and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

- Li, C.; Wang, D.; Xu, W.; Gao, F.; Zhou, G. Effect of final cooked temperature on tenderness, protein solubility and microstructure of duck breast muscle. LWT Food Sci. Technol. 2013, 51, 266–274. [Google Scholar] [CrossRef]

- Vasanthi, C.; Venkataramanujam, V.; Dushyanthan, K. Effect of cooking temperature and time on the physico-chemical, histological, and sensory properties of female carabeef (buffalo) meat. Meat Sci. 2007, 76, 274–280. [Google Scholar] [CrossRef]

- Marcotte, M.; Taherian, A.R.; Karimi, Y. Thermophysical properties of processed meat and poultry products. J. Food Eng. 2008, 88, 315–322. [Google Scholar] [CrossRef]

- Roldán, M.; Antequera, T.; Martín, A.; Mayoral, A.I.; Ruiz, J. Effect of different temperature–time combinations on physicochemical, microbiological, textural, and structural features of sous vide cooked lamb loins. Meat Sci. 2013, 93, 572–578. [Google Scholar] [CrossRef] [PubMed]

- Becker, A.; Boulaaba, A.; Pingen, S.; Krischek, C.; Klein, G. Low temperature cooking of pork meat—Physicochemical and sensory aspects. Meat Sci. 2016, 118, 82–88. [Google Scholar] [CrossRef] [PubMed]

- Laakonen, E.; Wellington, G.H.; Sherbon, J.W. Low-temperature, long-time heating of bovine muscle. 1. Changes in tenderness, water-binding capacity, pH and amount of water-soluble components. J. Food Sci. 1970, 35, 175–180. [Google Scholar] [CrossRef]

- Roldán, M.; Antequera, T.; Hernández, A.; Ruiz, J. Physicochemical and microbiological changes during the refrigerated storage of lamb loins sous-vide cooked at different combinations of time and temperature. Food Sci. Technol. Int. 2015, 21, 512–522. [Google Scholar] [CrossRef]

- Bouton, P.E.; Harris, P.V.; Macfarlane, J.J.; Shorthose, W.R. Influence of pH on the Warner-Bratzler shear properties of mutton. Meat Sci. 1982, 6, 27–36. [Google Scholar] [CrossRef] [PubMed]

- Kurp, L.; Danowska-Oziewicz, M.; Kłębukowska, L. Sous Vide Cooking Effects on Physicochemical, Microbiological and Sensory Characteristics of Pork Loin. Appl. Sci. 2022, 12, 2365. [Google Scholar] [CrossRef]

- Palka, K.; Daun, H. Changes in texture, cooking losses, and myofibrillar structure of bovine M. semitendinosus during heating. Meat Sci. 1999, 51, 237–243. [Google Scholar] [CrossRef]

- Tornberg, E. Effects of heat on meat proteins–Implications on structure and quality of meat products. Meat Sci. 2005, 70, 493–508. [Google Scholar] [CrossRef]

- Christensen, M.; Purslow, P.P.; Larsen, L.M. The effect of cooking temperature on mechanical properties of whole meat, single muscle fibers and perimysial connective tissue. Meat Sci. 2000, 55, 301–307. [Google Scholar] [CrossRef]

- Supaphon, P.; Astruc, T.; Kerdpiboon, S. Physical characteristics and their relationship with surface-physical properties of Thai local beef during sous vide processing. Agr. Nat. Resour. 2020, 54, 25–32. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).