Application of Fuzzy Multi-Objective Programming to Regional Sewer System Planning

Abstract

:1. Introduction

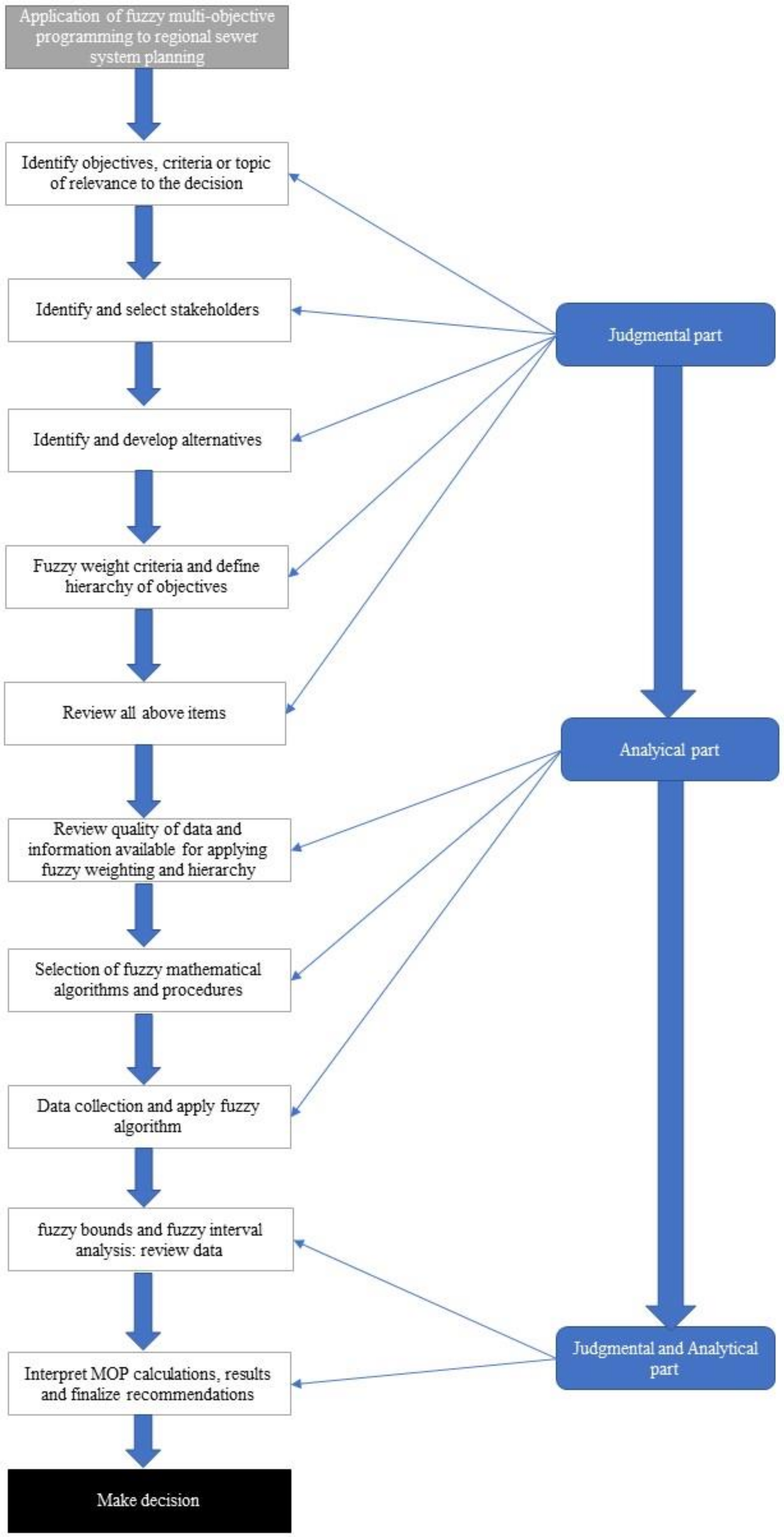

2. Methodology

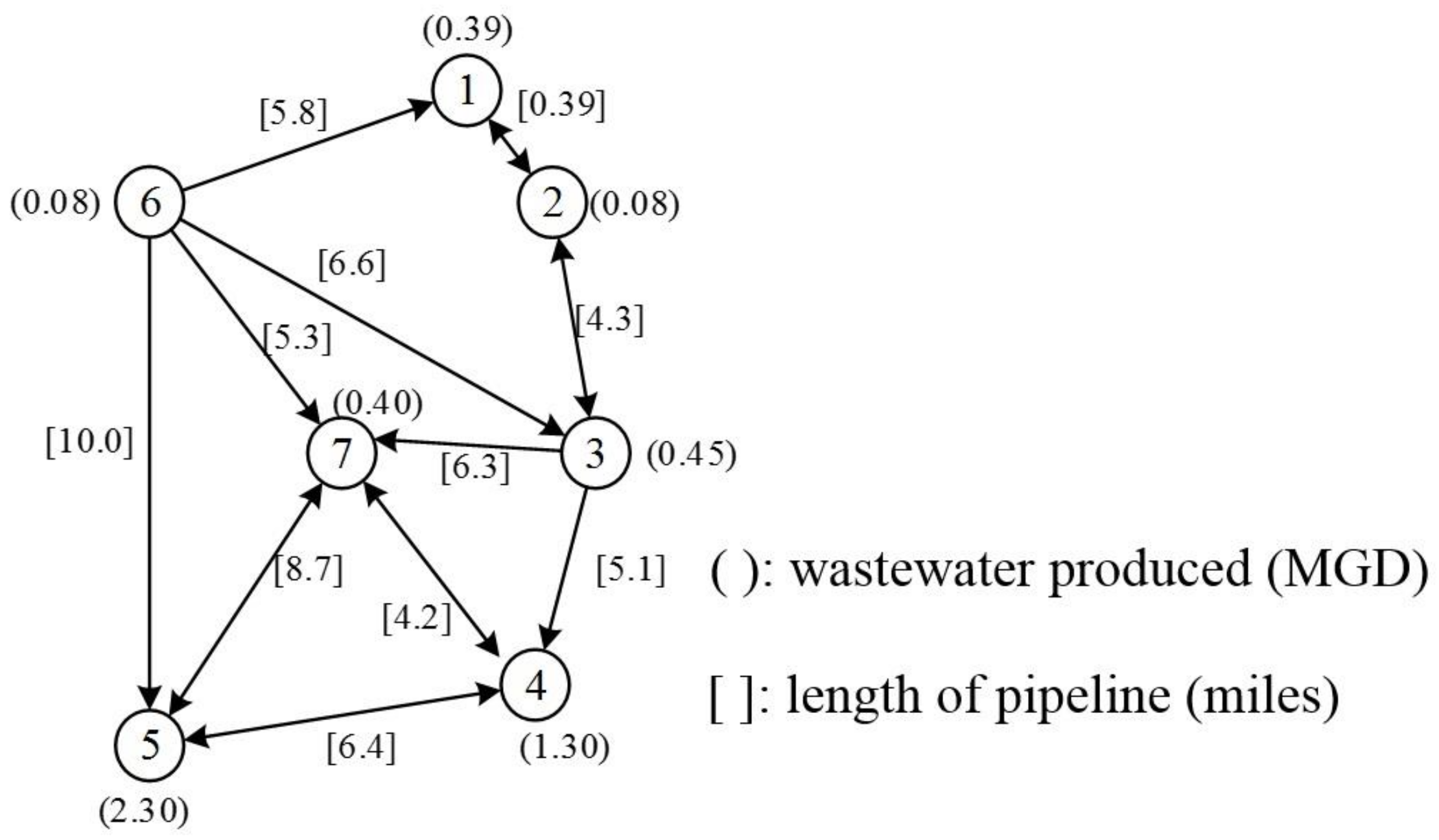

2.1. Mixed-Integer Programming

2.2. Fuzzy Programming

2.3. Compromise Fuzzy Programming

2.4. Analysis of Model Scheme

2.4.1. Objective Function

- A.

- Objective 1: The total cost, including the construction cost of plants and the pipeline cost, shall be the minimum, as written as Equation (8).

- B.

- Objective 2: Maximize the total removal of BOD, as written as Equation (9).

- C.

- Objective 3: Minimize the number of treatment plants required.

2.4.2. Decision Variables

2.4.3. Constant Parameters

2.4.4. Constraints

- A.

- Constraint of constant flow rate

- B.

- Limit on minimum capacity of treatment plant

- C.

- Constraint for treatment level selection

- D.

- Constraint for compromise fuzzy programming

- E.

- Non-negative constraint

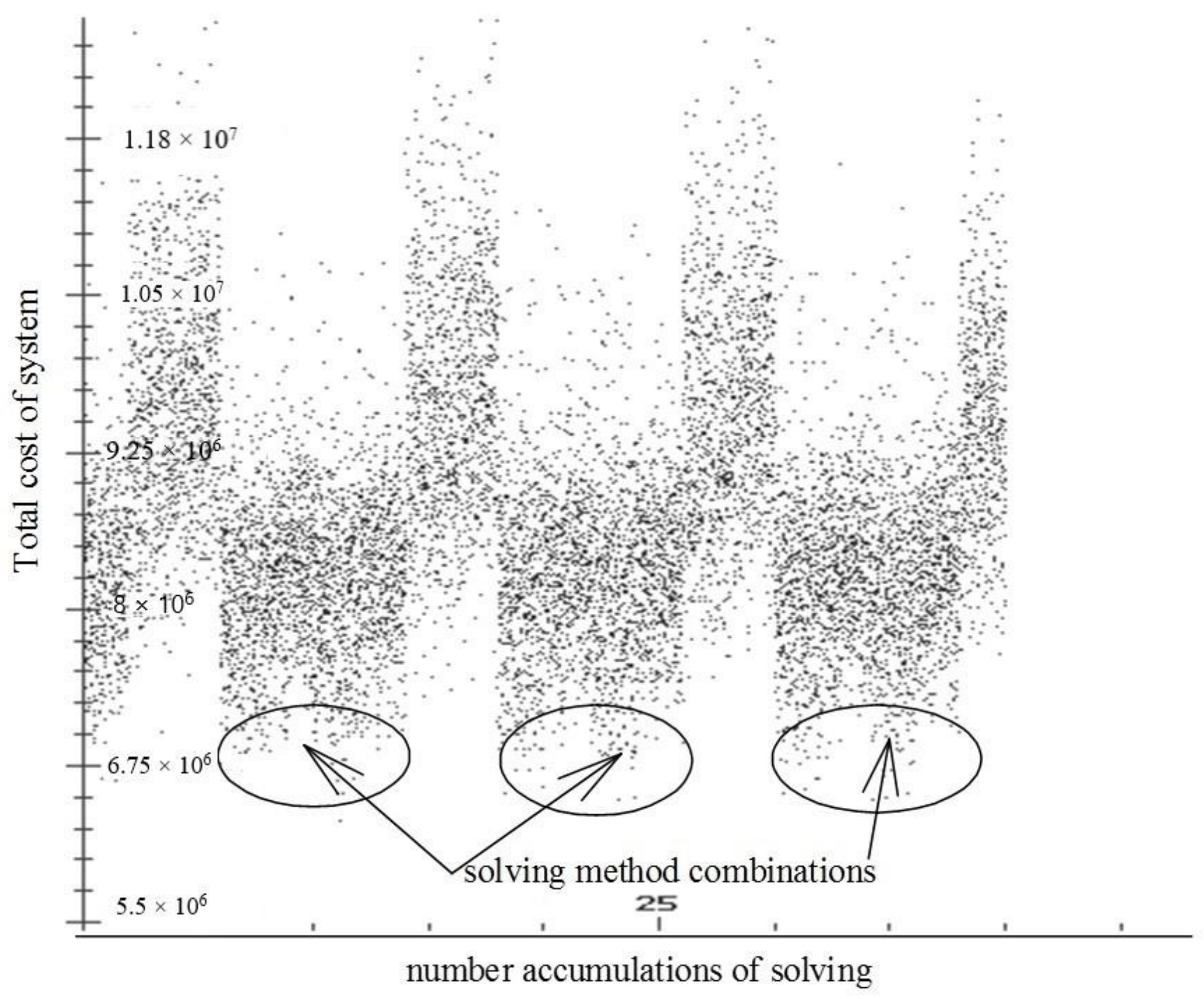

3. Results and Discussion

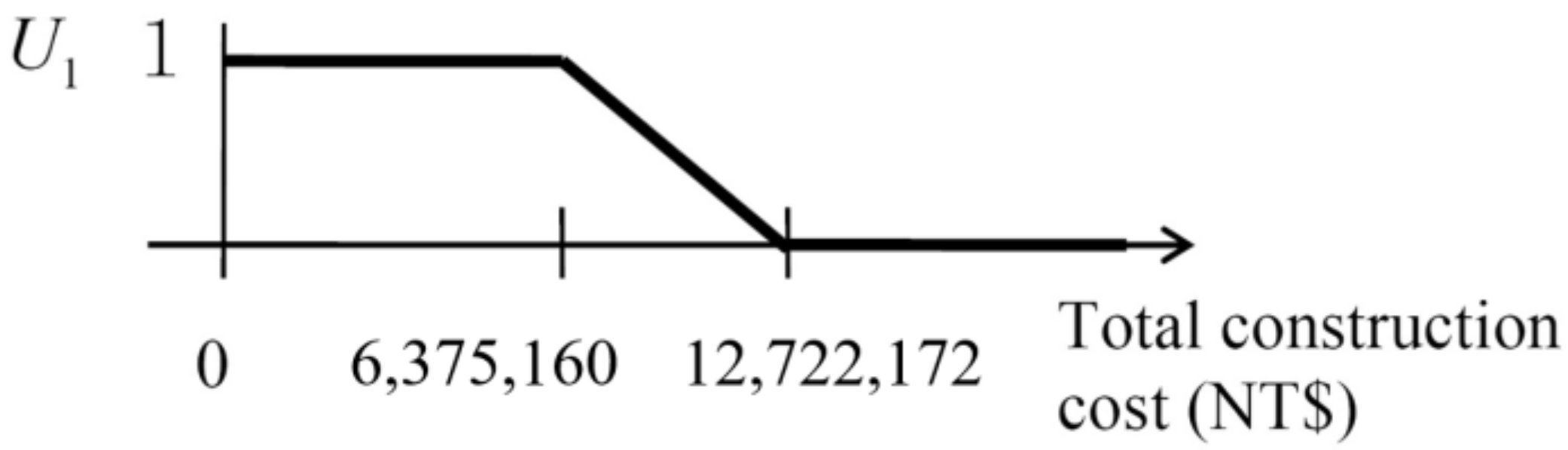

- A.

- Membership function of total cost.

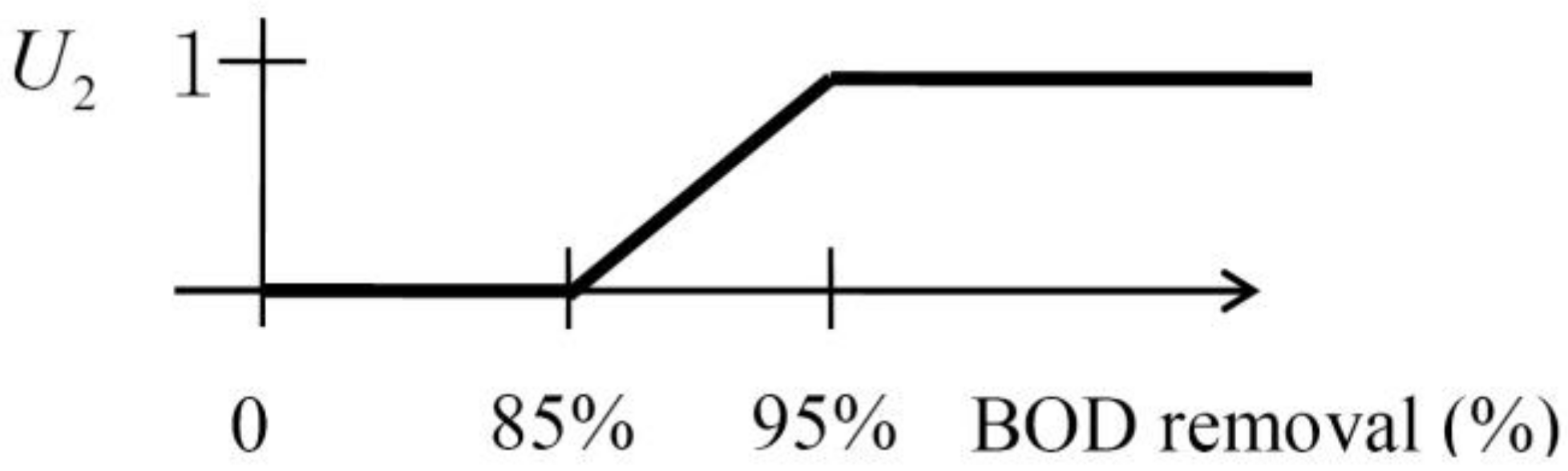

- B.

- The membership function is shown in Figure 3, and it is obtained by assuming that the BOD removal values of the secondary and the tertiary treatment systems are 85% and 95%, respectively.

- C.

- Membership function of minimum plant capacity:

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mardani, A.; Jusoh, A.; Zavadskas, E.K. Fuzzy multiple criteria decision-making techniques and applications—Two decades’ review from 1994 to 2014. Expert Syst. Appl. 2015, 42, 4126–4148. [Google Scholar] [CrossRef]

- Marler, R.T.; Arora, J.S. Survey of multi-objective optimization methods for engineering. Struct. Multidiscip. Optim. 2004, 26, 369–395. [Google Scholar]

- Tan, K.C.; Lee, T.H.; Khor, E.F. Evolutionary algorithms for multi-objective optimization: Performance assessments and comparisons. Artif. Intell. Rev. 2002, 17, 253–290. [Google Scholar] [CrossRef]

- Zhang, R.; Xie, W.M.; Yu, H.Q.; Li, W.W. Optimizing municipal wastewater treatment plants using an improved multi-objective optimization method. Bioresour. Technol. 2014, 157, 161–165. [Google Scholar] [CrossRef] [PubMed]

- Koopmans, T.C. Activity analysis of production and allocation. J. Wiley. N. Y. 1951, 42, 33–97. [Google Scholar]

- Kuhn, H.W. Nonlinear programming: A historical view. In Traces and Emergence of Nonlinear Programming; Springer: Basel, Switzerland, 2014; pp. 393–414. [Google Scholar]

- Zadeh, L.A. Fuzzy set. Inf. Control. 1965, 8, 338–353. [Google Scholar] [CrossRef] [Green Version]

- Zimmermann, H.J. Fuzzy Programming and linear programming with several objective functions. Fuzzy Sets Syst. 1978, 1, 45–56. [Google Scholar] [CrossRef]

- Hannan, E.L. Linear programming with multiple goals. Fuzzy Sets Syst. 1981, 6, 235–248. [Google Scholar] [CrossRef]

- Leberling, H. On finding compromise solution in multi-criteria problem using the fuzzy min-operator. Fuzzy Sets Syst. 1981, 6, 105–118. [Google Scholar] [CrossRef]

- Sakawa, M. Interactive computer programming with multiple objectives. Int. J. Man Mach. Stud. 1983, 18, 489–503. [Google Scholar] [CrossRef]

- Bilbao-Terol, A.; Pérez-Gladish, B.; Antomil-lbias, J. Selecting the optimum portfolio using fuzzy compromise programming and Sharpe’s single-index model. Appl. Math. Comput. 2006, 182, 644–664. [Google Scholar] [CrossRef]

- Hsu, T.Y.; Tseng, Y.Z. The Integration and application constraint weighted methods in multi-objective decision-making interaction model. J. Manage. Sci. 1990, 7, 203–211. [Google Scholar]

- Tarafder, A.; Rangaiah, G.P.; Ray, A.K. Multiobjective optimization of an industrial styrene monomer manufacturing process. Chem. Eng. Sci. 2005, 60, 347–363. [Google Scholar] [CrossRef]

- Tan, Q.; Huang, G.; Cai, Y.; Yang, Z. A non-probabilistic programming approach enabling risk-aversion analysis for supporting sustainable watershed development. J. Clean Prod. 2016, 112, 4771–4788. [Google Scholar] [CrossRef]

- Chae, S.H.; Kim, S.H.; Yoon, S.G.; Park, S. Optimization of a waste heat utilization network in an eco-industrial park. Appl. Energy 2010, 87, 1978–1988. [Google Scholar] [CrossRef]

- Lovelady, E.M.; El-Halwagi, M.M. Design and integration of eco-industrial parks for managing water resources. Environ. Prog. Sustain. Energy 2009, 28, 265–272. [Google Scholar] [CrossRef]

- Sidiras, D.; Batzias, F.; Ranjan, R.; Tsapatsis, M. Simulation and optimization of batch autohydrolysis of wheat straw to monosaccharides and oligosaccharides. Bioresour. Technol. 2011, 102, 10486–10492. [Google Scholar] [CrossRef]

- Yang, M.; Sun, P.; Wang, R.; Han, J.; Wang, J.; Song, Y.; Cai, J.; Tang, X. Simulation and optimization of ammonia removal at low temperature for a double channel oxidation ditch based on fully coupled activated sludge model (FCASM): A full-scale study. Bioresour. Technol. 2013, 143, 538–548. [Google Scholar] [CrossRef]

- Fang, F.; Ni, B.J.; Li, W.W.; Sheng, G.P.; Yu, H.Q. A simulation-based integrated approach to optimize the biological nutrient removal process in a full-scale wastewater treatment plant. Chem. Eng. J. 2011, 174, 635–643. [Google Scholar] [CrossRef]

- Zafar, M.; Kumar, S.; Kumar, S.; Dhiman, A.K. Artificial intelligence based modeling and optimization of poly (3-hydroxybutyrate-co-3-hydroxyvalerate) production process by using Azohydromonas lata MTCC 2311 from cane molasses supplemented with volatile fatty acids: A genetic algorithm paradigm. Bioresour. Technol. 2012, 104, 631–641. [Google Scholar] [CrossRef]

- Tripathi, P.K.; Bandyopadhyay, S.; Pal, S.K. Multi-objective particle swarm optimization with time variant inertia and acceleration coefficients. Inf. Sci. 2007, 177, 5033–5049. [Google Scholar] [CrossRef] [Green Version]

- Lamas, W.D. Fuzzy thermoeconomic optimisation applied to a small waste water treatment plant. Renew. Sust. Energ. Rev. 2013, 19, 214–219. [Google Scholar] [CrossRef]

- Xie, W.M.; Zhang, R.; Li, W.W.; Ni, B.J.; Fang, F.; Sheng, G.P.; Yu, H.Q.; Song, J.; Le, D.Z.; Bi, X.J.; et al. Simulation and optimization of a full-scale Carrousel oxidation ditch plant for municipal wastewater treatment. Biochem. Eng. J. 2011, 56, 9–16. [Google Scholar] [CrossRef]

- Yetilmezsoy, K. Integration of kinetic modeling and desirability function approach for multi-objective optimization of UASB reactor treating poultry manure wastewater. Bioresour. Technol. 2012, 118, 89–101. [Google Scholar] [CrossRef] [PubMed]

- Rajabalipour Cheshmehgaz, H.; Desa, M.I.; Wibowo, A. A flexible three-level logistic network design considering cost and time criteria with a multi-objective evolutionary algorithm. J. Intell. Manuf. 2013, 24, 277–293. [Google Scholar] [CrossRef]

- Rajkovi´c, R.; Zrni´c, N.; Kirin, S.; Transactions, B.D.F. A review of multi-objective optimization of container flow using sea and land legs together. FME Trans. 2016, 44, 204–211. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.; Zhou, Y.; Feng, Y.; Xiao, Y.; He, S.; Zhou, J.; Lin, F. Urban traffic signal control based on multiobjective joint optimization. Sci. Program 2020, 2020, 8839720. [Google Scholar] [CrossRef]

- Huang, Z.; Fang, B.; Deng, J. Multi-objective optimization strategy for distribution network considering V2G-enabled electric vehicles in building integrated energy system. Prot. Control. Mod. Power Syst. 2020, 5, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Ma, W.; Wan, L.; Yu, C.; Zou, L.; Zheng, J. Multi-objective optimization of traffic signals based on vehicle trajectory data at isolated intersections. Transp. Res. Part C Emerg. Technol. 2020, 120, 102821. [Google Scholar] [CrossRef]

- Bagheri, M.; Ebrahimnejad, A.; Razavyan, S.; Lotfi, F.H.; Malekmohammadi, N. Fuzzy arithmetic DEA approach for fuzzy multi-objective transportation problem. Oper. Res. 2020, 22, 1479–1509. [Google Scholar] [CrossRef]

- Yang, C.; Wang, Z.; Oh, S.K.; Pedrycz, W.; Yang, B. Ensemble fuzzy radial basis function neural networks architecture driven with the aid of multi-optimization through clustering techniques and polynomial-based learning. Fuzzy Sets Syst. 2020, 438, 62–83. [Google Scholar] [CrossRef]

- Da Silva, S.F.; Eckert, J.J.; Silva, F.L.; Silva, L.C.; Dedini, F.G. Multi-objective optimization design and control of plug-in hybrid electric vehicle powertrain for minimization of energy consumption, exhaust emissions and battery degradation. Energy Convers. Manag. 2021, 234, 113909. [Google Scholar] [CrossRef]

- Yue, Q.; Zhang, F.; Wang, Y.; Zhang, X.; Guo, P. Fuzzy multi-objective modelling for managing water-food-energy-climate change-land nexus towards sustainability. J. Hydrol. 2021, 596, 125704. [Google Scholar] [CrossRef]

- Jafarian-Moghaddam, A.R. Economical speed for optimizing the travel time and energy consumption in train scheduling using a fuzzy multi-objective model. Urban Rail Transit 2021, 7, 191–208. [Google Scholar] [CrossRef]

- Ozdemir, R.; Sarigol, I.; AlMutairi, S.; AlMeea, S.; Murad, A.; Naqi, A.; AlNasser, N. Fuzzy multi-objective model for assembly line balancing with ergonomic risks consideration. Int. J. Prod. Econ. 2021, 239, 108188. [Google Scholar] [CrossRef]

- Ghosh, S.; Roy, K.S.; Jos´e, V.L. Fixed-charge solid transportation problem with budget constraints based on carbon emission in neutrosophic environment. Soft Comput. 2021, 26, 11611–11625. [Google Scholar] [CrossRef]

- Giri, K.B.; Roy, K.S. Neutrosophic multiobjective green four-dimensional fixed-charge transportation problem’. Int. J. Mach. Learn. Cybern. 2022, 13, 3089–3112. [Google Scholar] [CrossRef]

- Maiti, K.S.; Roy, K.S. Analysing interval and multi-choice bi-level programming for Stackelberg game using intuitionistic fuzzy programming. Int. J. Math. Oper. Res. 2020, 16, 354–375. [Google Scholar] [CrossRef]

- Downey Brill, E.; Nakamura, M. A branch and bound method for use in planning regional wastewater treatment systems. Water Resour. Res. 1978, 4, 109–118. [Google Scholar] [CrossRef]

- Zeferino, A.J.; Cunha, C.M.; Antunes, P.A. Robust optimization approach to regional wastewater system planning. J. Environ. Manage. 2012, 109, 113–122. [Google Scholar]

- Brand, N.; Qstfeld, A. Optimal design of regional wastewater pipelines and treatment plant systems. Water Environ. Res. 2011, 83, 53–64. [Google Scholar] [CrossRef] [PubMed]

- Chang, N.B.; Hernandez, A.E. Optimal expansion strategy for a sewer system under uncertainty. Environ. Model Assess. 2008, 13, 93–113. [Google Scholar] [CrossRef]

- Sun, Y.; Garrido-Baserba, M.; Molinos-Senante, M.; Donikian, A.N.; Poch, M.; Rosso, D. A composite indicator approach to assess the sustainability and resilience of wastewater management alternatives. Sci. Total Environ. 2020, 725, 138286. [Google Scholar] [CrossRef] [PubMed]

- Rezaei, N.; Sierra-Altamiranda, A.; Diaz-Elsayed, N.; Charkhgard, H.; Zhang, Q. A multi-objective optimization model for decision support in water reclamation system planning. J. Clean. Prod. 2019, 240, 118227. [Google Scholar] [CrossRef]

| Fuzzy Bounds | Fuzzy Intervals dj | |

|---|---|---|

| Total cost of system BOD Removal Lower limit of Plant Capacity | [6401978, 12722172] [85%, 95%] [0, 2.51] | 6320194 10% 2.51 |

| Scheme | Variables Considered | Total Cost (Z1) | BOD Removal (Z2) | Min Number of Plants | Total Cost | BOD Removal (%) | Required Min. Capacity of Plant (MGD) | No. of Plants |

|---|---|---|---|---|---|---|---|---|

| Scheme 1 | The compromise weighted w | 0.33 | 0.33 | 0.33 | 10,362,600 | 92.6% | 0.894 | 4 |

| The approximate membership value f | 0.80 | 0.80 | 0.80 | |||||

| Scheme 2 | The compromise weighted w | 0.10 | 0.45 | 0.45 | 9,395,210 | 89.6% | 0.346 | 5 |

| The approximate membership value f | 0.90 | 0.60 | 0.60 | |||||

| Scheme 3 | The compromise weighted w | 0.45 | 0.10 | 0.45 | 9,628,680 | 94.0% | 0.500 | 4 |

| The approximate membership value f | 0.60 | 0.90 | 0.60 | |||||

| Scheme 4 | The compromise weighted w | 0.45 | 0.45 | 0.10 | 9,822,130 | 85.0% | 2.444 | 2 |

| The approximate membership value f | 0.60 | 0.60 | 0.90 | |||||

| Scheme 5 | The compromise weighted w | 0.20 | 0.20 | 0.60 | 9,822,130 | 87.9% | 0.914 | 4 |

| The approximate membership value f | 0.90 | 0.90 | 0.60 | |||||

| Scheme 6 | The compromise weighted w | 0.50 | - | 0.50 | 8,076,930 | 85.0% | 0.998 | 3 |

| The approximate membership value f | 0.80 | - | 0.80 | |||||

| Scheme 7 | The compromise weighted w | 0.20 | - | 0.80 | 7,517,060 | 85.0% | 0.50 | 5 |

| The approximate membership value f | 0.80 | - | 0.20 | |||||

| Scheme 8 | The compromise weighted w | 0.80 | - | 0.20 | 9,468,140 | 85.0% | 1.905 | 1 |

| Titles | Methods | Objective | Objective Function | Variables and Constant Parameters |

|---|---|---|---|---|

| Robust optimization approach to regional wastewater system planning [42] | Robust optimization | Multi-objective | 1. The minimum total cost; 2. the minimum cost and dissolved oxygen; 3. the maximum predicted dissolved oxygen of rivers | 1. Production of wastewater; 2. flow of pipeline; 3. length of pipeline; 4. flow of rivers; 5. dissolved oxygen of stream segment; 6. length of stream segment; 7. possibility of any scenario’s occurrence; 8. the maximum treatment capacity of wastewater plants; 9. cost of discount for wastewater systems; 10. forfeit for disobeying the standard of water quality parameters. |

| Optimal Design of Regional Wastewater Pipelines and Treatment Plant Systems [43] | Genetic algorithm | Single-objective | 1. The minimum total cost | 1. The minimum depth of pipeline; 2. cost of energy; 3. coefficients of pipeline cost; 4. coefficients of pump cost; 5. coefficients of wastewater plants; 6. the minimum depth of the digging hole; 7. operational hours of water pumping; 8. interest of total cost; 9. gradient; 10. width of pipeline excavation; 11. length of pipeline connection; 12. production of wastewater at nodes; 13. life-span of pump; 14. life-span of wastewater plants; 15. the minimum and maximum velocity of pipeline. |

| Optimal Expansion Strategy for a Sewer System under Uncertainty [44] | Grey mixed integer programming | Single-objective | 1. The minimum total cost | 1. The maintained and operational cost of facilities; 2. recovery cost for maintaining sewer facilities; 3. cost of construction of the new facilities; 4. cost of wastewater transportation; 5. cost of facilities expansion; 6. income of population; 7. size of population. |

| A composite indicator approach to assess the sustainability and resilience of wastewater management alternatives [45] | Analytic hierarchy process | Multi-objective | 1. The total cost; 2. the carbon emission amount; 3. the values of chemical oxygen demand, and total nitrogen content, total phosphate; 4. recovery ability after disasters; 5. the consecutively comprehensive indexes | 1. Flow of untreated wastewater; 2. concentration of untreated wastewater; 3. operational cost; 4. capital cost; 5. size of population |

| A multi-objective optimization model for decision support in water reclamation system planning [45] | Triangle Splitting Method | Multi-objective | 1.The minimum cost of wastewater treatment; 2. the minimum greenhouse gas emission of the sewer system | 1. The capacity of wastewater plants; 2. the maintained and operational cost of facilities; 3. transportation cost of reclaimed water; 4. transportation cost of wastewater; 5. greenhouse gas emissions of the sewer system; 6. greenhouse gas emissions of reclaimed water; 7. greenhouse gas emissions of wastewater transportation; 8. the maximum capacity of greenhouse gas emissions for the sewer system; 9. life-span of facilities; 10. price of reclaimed water; 11. usage ratio of reclaimed water; 12. distance between citizen center location and wastewater plant; 13. size of population in the citizen center; 14. amount of recycled wastewater produced from customers. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, C.-F.; Chen, W.-T.; Kao, C.-K.; Chang, H.-J.; Kao, P.-M.; Wan, T.-J. Application of Fuzzy Multi-Objective Programming to Regional Sewer System Planning. Processes 2023, 11, 183. https://doi.org/10.3390/pr11010183

Huang C-F, Chen W-T, Kao C-K, Chang H-J, Kao P-M, Wan T-J. Application of Fuzzy Multi-Objective Programming to Regional Sewer System Planning. Processes. 2023; 11(1):183. https://doi.org/10.3390/pr11010183

Chicago/Turabian StyleHuang, Chung-Fu, Wei-Ting Chen, Chuan-Ksing Kao, Han-Jung Chang, Po-Min Kao, and Terng-Jou Wan. 2023. "Application of Fuzzy Multi-Objective Programming to Regional Sewer System Planning" Processes 11, no. 1: 183. https://doi.org/10.3390/pr11010183