Experimental Simulation on the Stress Disturbance Mechanism Caused by Hydraulic Fracturing on the Mechanical Properties of Shale Formation

Abstract

:1. Introduction

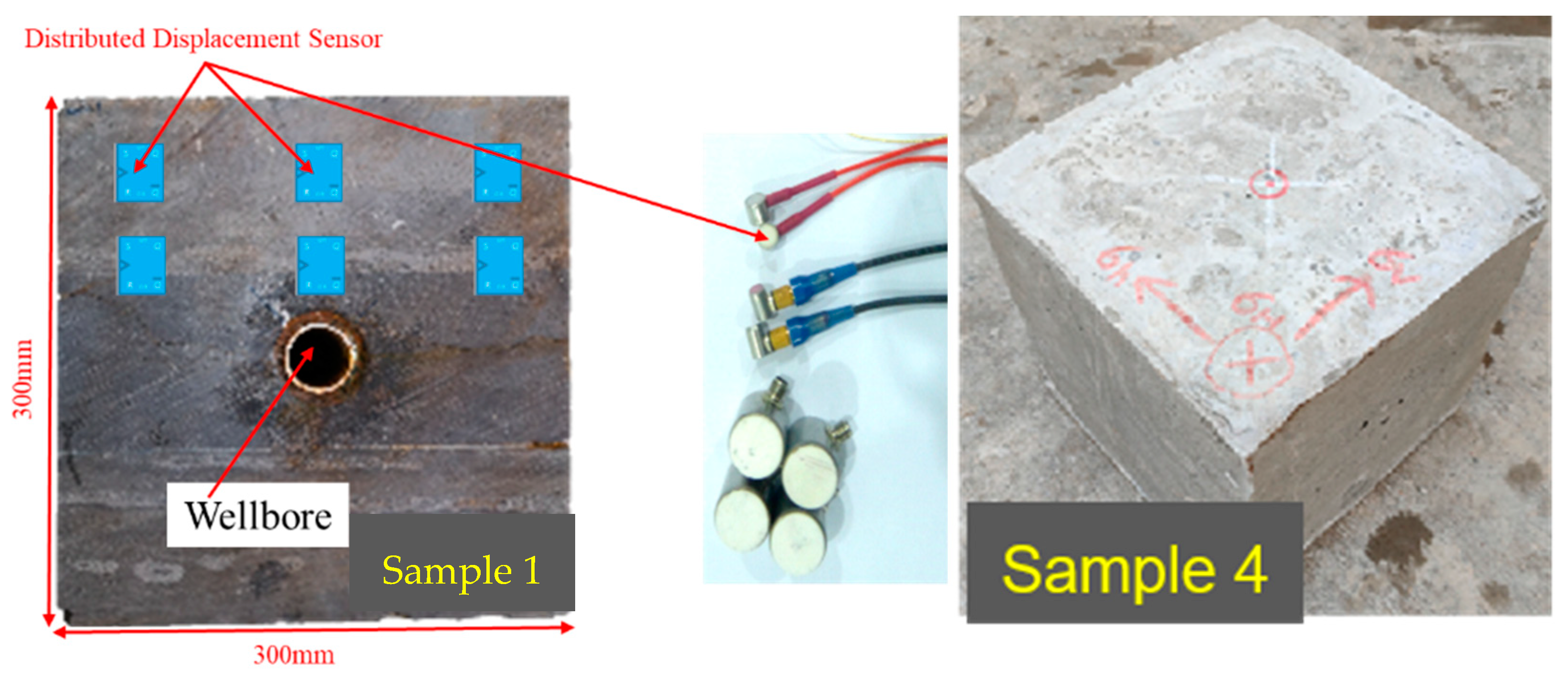

2. Experimental Simulation

2.1. Experimental Devices

2.2. Experimental Method and Schedule

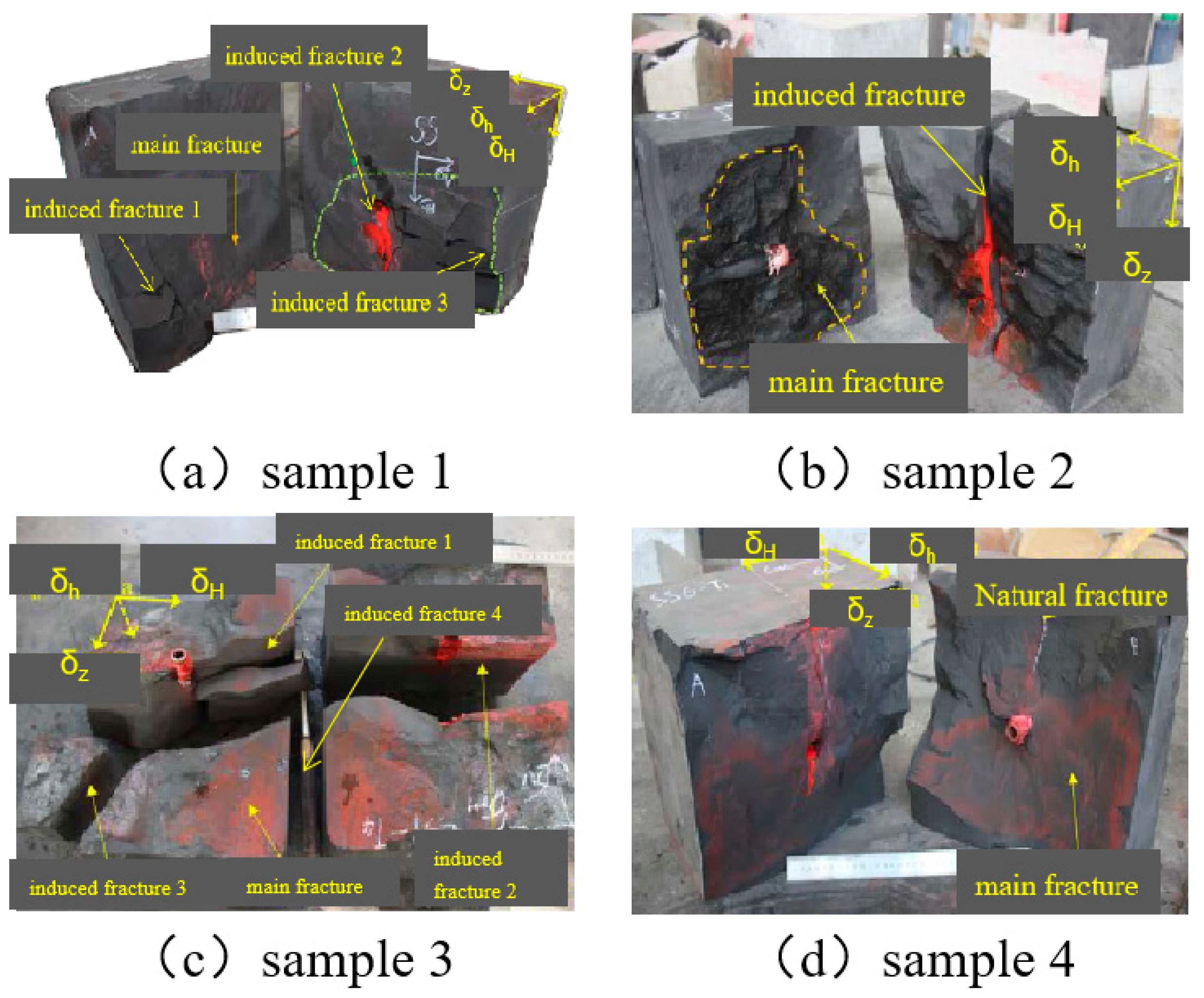

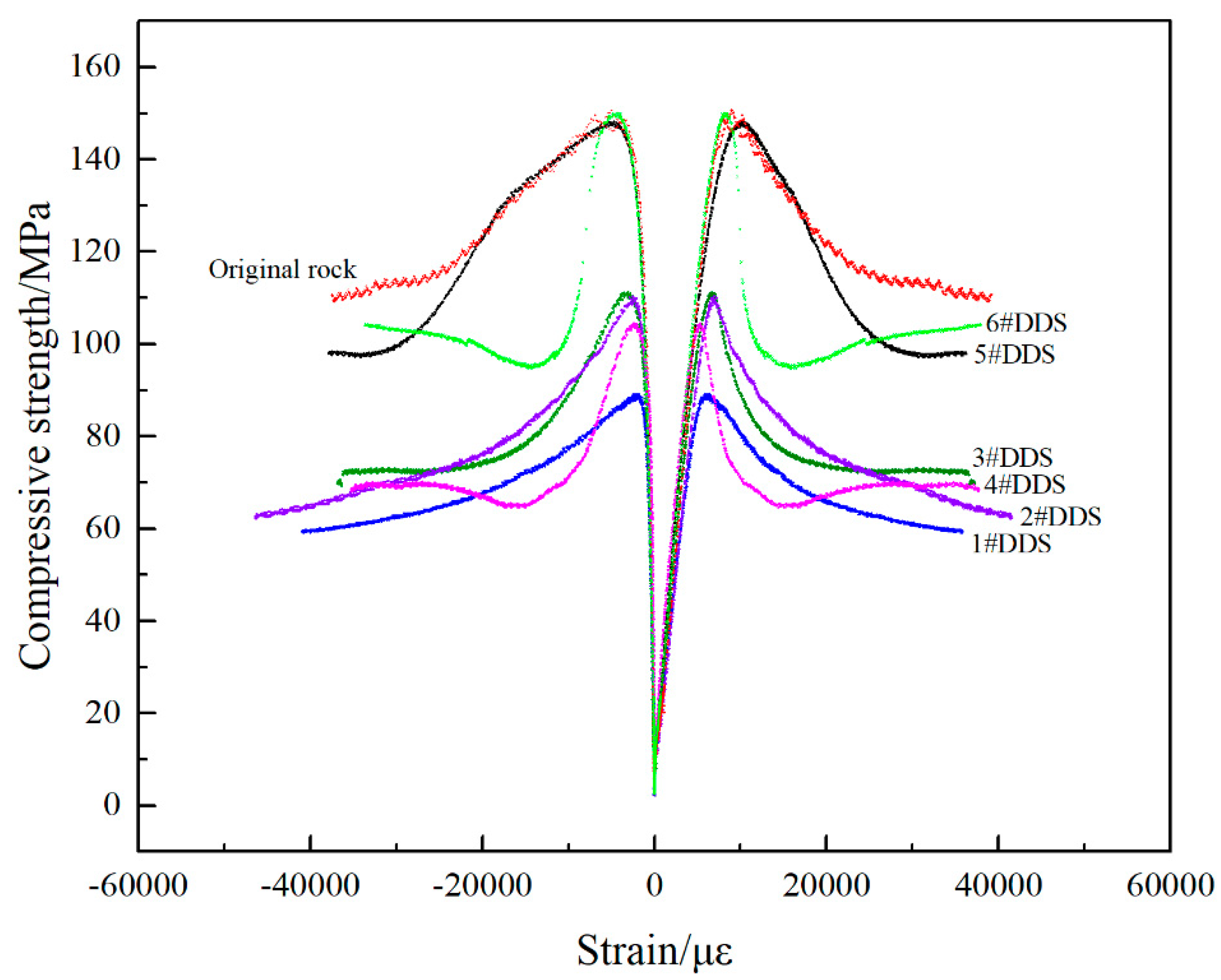

2.3. Experimental Results

3. Discussion

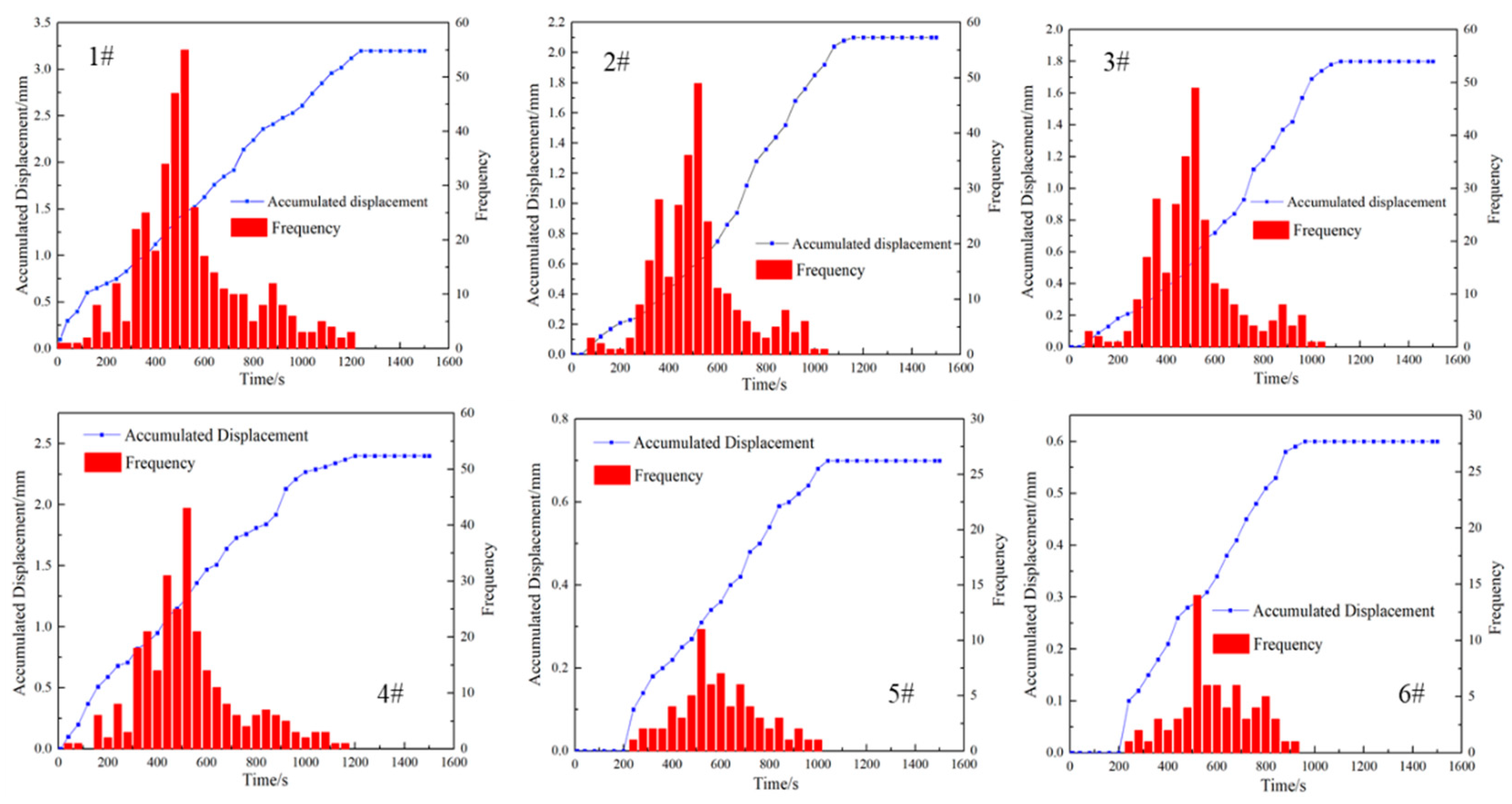

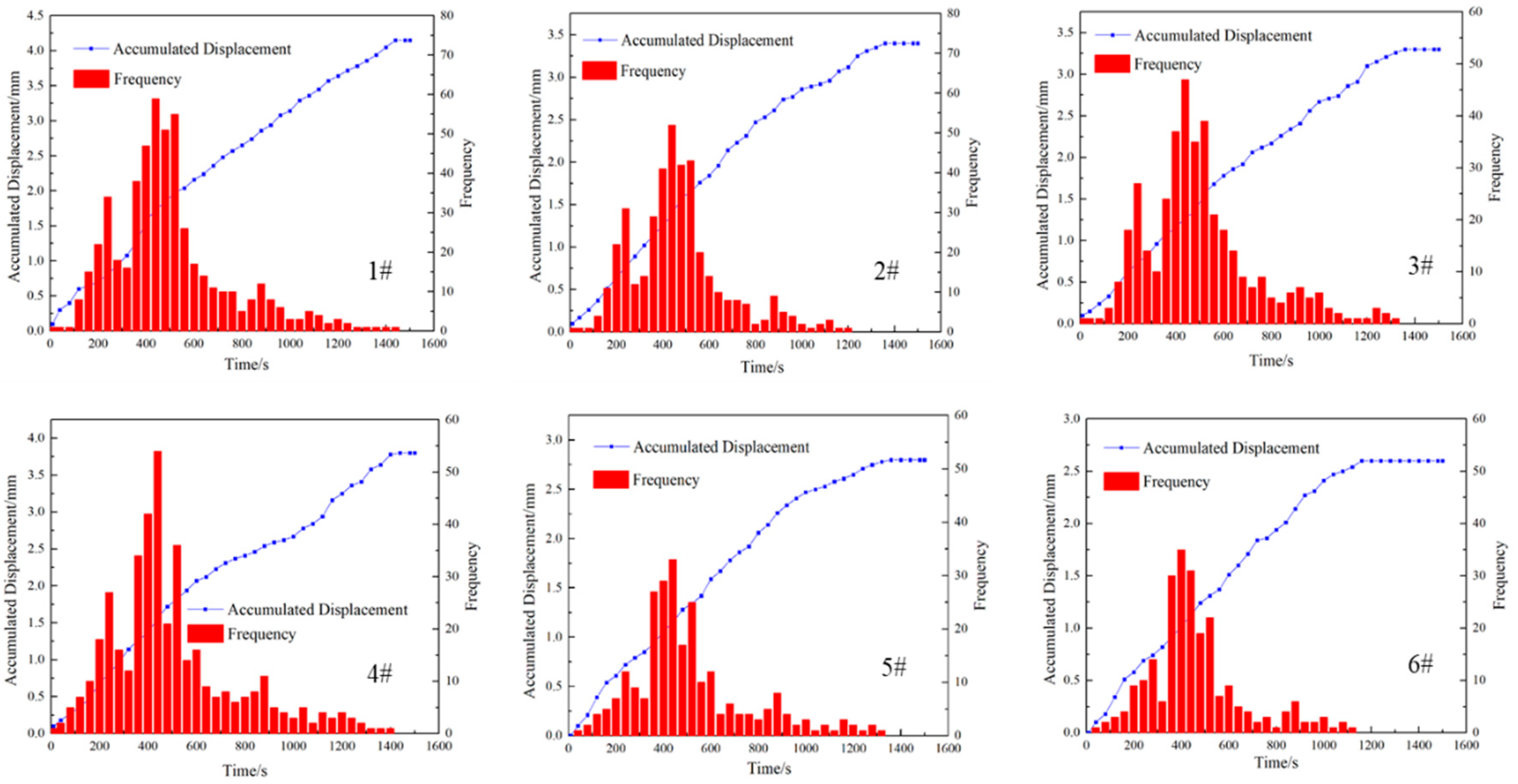

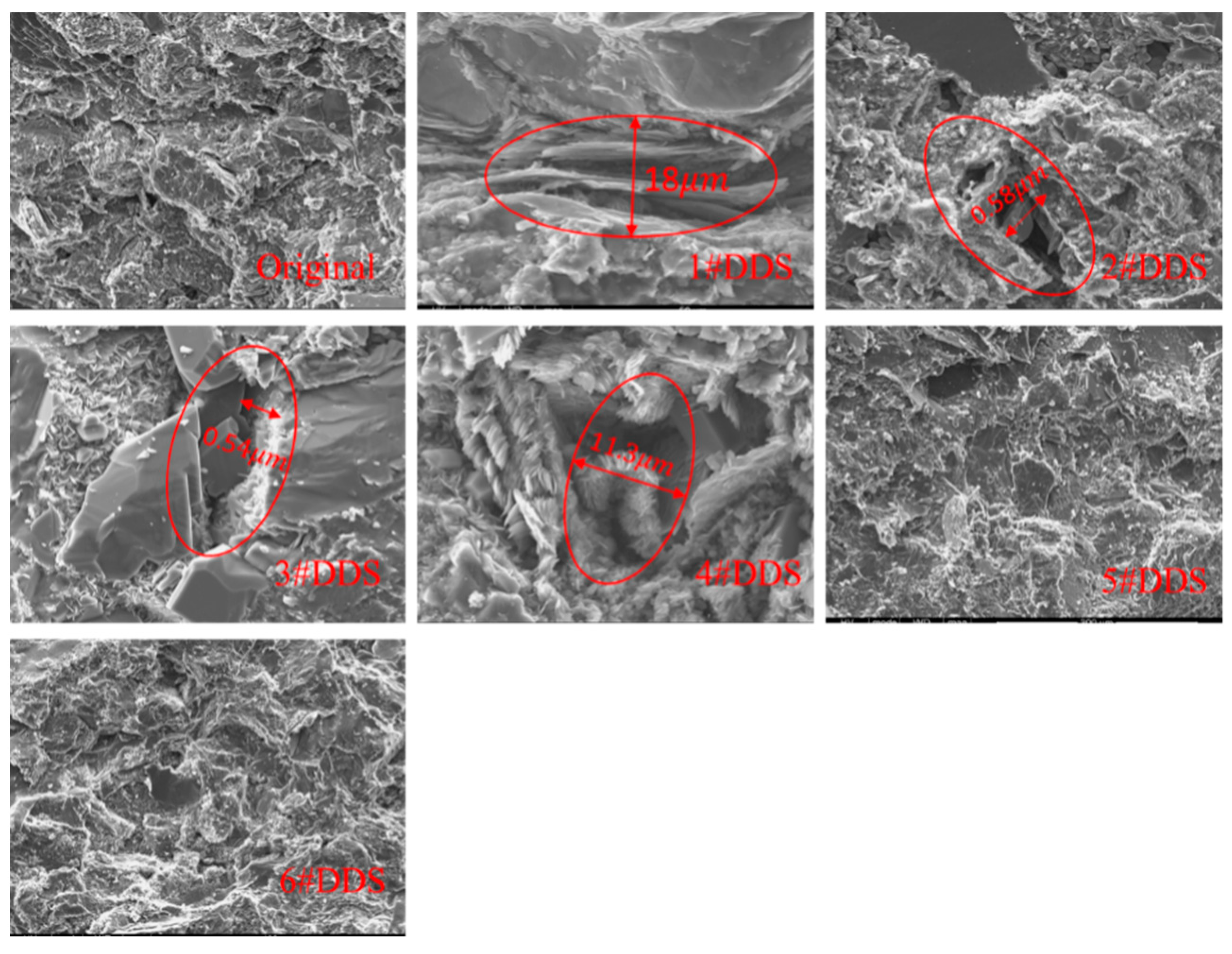

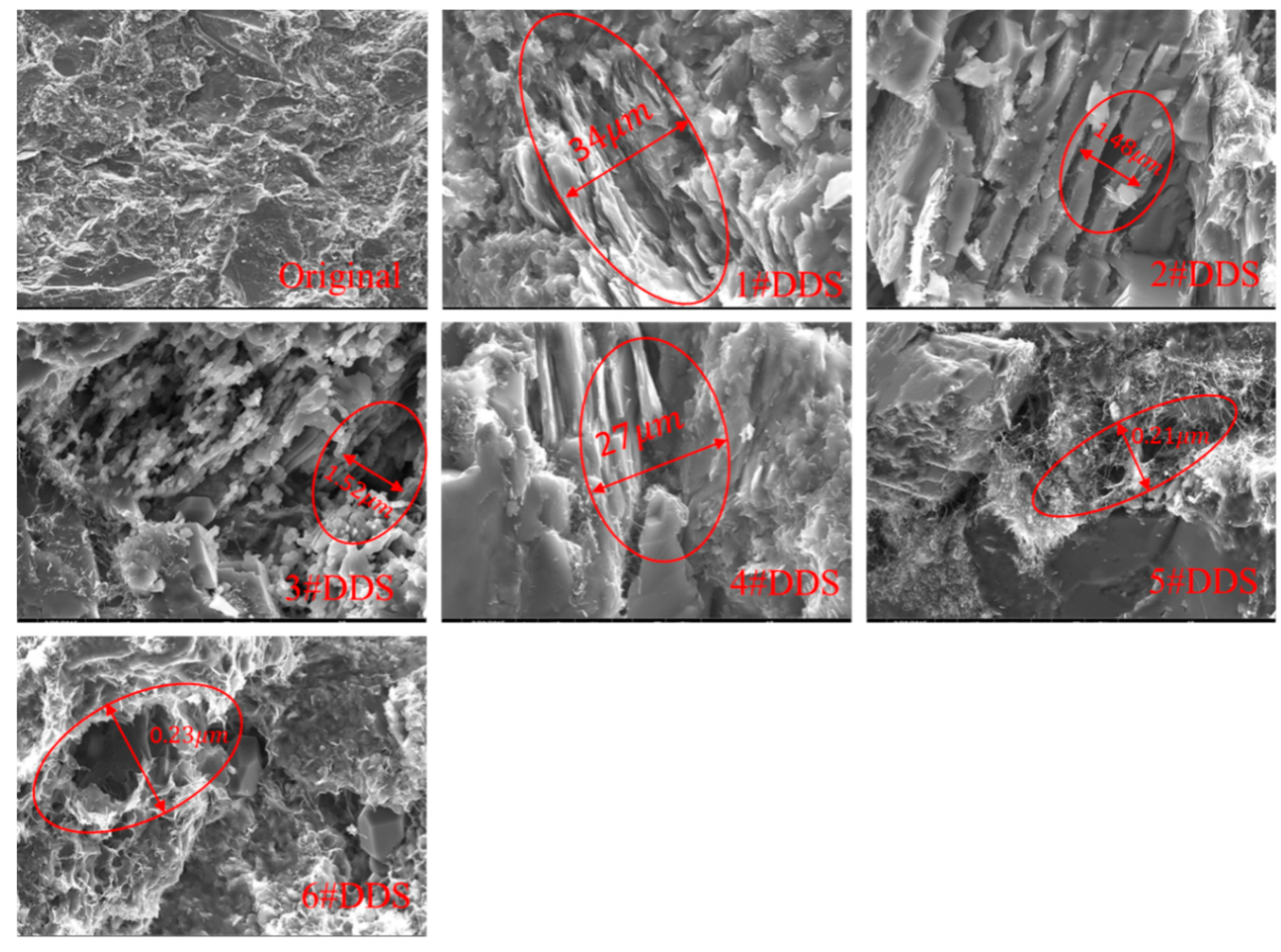

3.1. Microstructural Deformation under Stress Differences

3.2. Microstructural Deformation under Different Pumping Rates

3.3. Microstructural Deformation under Different Viscosities of Fracturing Fluid

3.4. Failure Mode Determination

4. Conclusions

- (1)

- The displacement of rock caused by hydraulic fracturing can make the pore throat structure change during hydraulic fracturing, and it also can reduce the rock mechanical strength in an unstimulated zone. According to the experimental results, it can be concluded that with the increase in the branch fractures, the displacement monitored by the DDSs also showed increases, the pore throat structure experienced severe changes, and the rock mechanical strength also experienced a sharp decrease.

- (2)

- From the simulation results, it was found that tensile failure was the main failure mode near the wellbore, and the percentage of shear failure experienced an obvious increase when the measurement point was further from the injection point.

- (3)

- Due to the porous medium of the reservoir rock, the enormous pressure generated during the injection of the fracturing fluid caused significant deformation of the fracture surface, leading to the tensile failure of the rock. The displacement of the fracture surface caused by the fracturing fluid injection also led to the deformation of the pore throat structure; thus, the shear failure increased when the measurement point was further from the injection point.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zou, C.; Zhu, R.; Dong, D.; Wu, S. Scientific and technological progress, development strategy and policy suggestion regarding shale oil and gas. Acta Pet. Sin. 2022, 43, 1675–1686. [Google Scholar]

- Jiang, T.; Bian, X.; Wang, H.; Li, S.; Jia, C.; Liu, H.; Sun, H. Volume fracturing of deep shale gas horizontal wells. Nat. Gas Ind. 2017, 37, 90–96. [Google Scholar] [CrossRef]

- Wei, Y.; Jia, A.; He, D.; Junlei, W. Comparative analysis of development characteristics and technologies between shale gas and tight gas in China. Nat. Gas Ind. 2017, 37, 43–52. [Google Scholar]

- Peng, T.; Yan, J.; Bing, H.; Yingcao, Z.; Ruxin, Z.; Zhi, C.; Meng, F. Laboratory investigation of shale rock to identify fracture propagation in vertical direction to bedding. J. Geophys. Eng. 2018, 15, 696. [Google Scholar] [CrossRef]

- Liu, Y.; Zheng, X.; Peng, X.; Zhang, Y.; Chen, H.; He, J. Influence of natural fractures on propagation of hydraulic fractures in tight reservoirs during hydraulic fracturing. Mar. Pet. Geol. 2022, 138, 105505. [Google Scholar] [CrossRef]

- Al-Rubaye, A.; Mahmud, H.K.B. A numerical investigation on the performance of hydraulic fracturing in naturally fractured gas reservoirs based on stimulated rock volume. J. Pet. Explor. Prod. Technol. 2020, 10, 3333–3345. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, M.; Zhang, G. Analysis of the Influence of a Natural Fracture Network on Hydraulic Fracture Propagation in Carbonate Formations. Rock Mech. Rock Eng. 2014, 47, 575–587. [Google Scholar] [CrossRef]

- Li, Q.; Wang, F.; Wang, Y.; Forson, K.; Cao, L.; Zhang, C.; Zhou, C.; Zhao, B.; Chen, J. Experimental investigation on the high-pressure sand suspension and adsorption capacity of guar gum fracturing fluid in low-permeability shale reservoirs: Factor analysis and mechanism disclosure. Environ. Sci. Pollut. Res. 2022, 29, 53050–53062. [Google Scholar] [CrossRef]

- Zou, Y.; Ma, X.; Zhang, S.; Zhou, T.; Li, H. Experimental investigation into the influence of bedding plane on hydraulic fracture network propagation in shale formations. Rock Mech. Rock Eng. 2016, 49, 3597–3614. [Google Scholar]

- Li, X.; Hofmann, H.; Yoshioka, K.; Luo, Y.; Liang, Y. Phase-Field Modelling of Interactions Between Hydraulic Fractures and Natural Fractures. Rock Mech. Rock Eng. 2022, 55, 6227–6247. [Google Scholar] [CrossRef]

- Zhang, F.; Dontsov, E.; Mack, M. Fully coupled simulation of a hydraulic fracture interacting with natural fractures with a hybrid discrete-continuum method. Int. J. Numer. Anal. Methods Geomech. 2017, 41, 1430–1452. [Google Scholar] [CrossRef]

- Wu, M.; Wang, W.; Song, Z.; Liu, B.; Feng, C. Exploring the influence of heterogeneity on hydraulic fracturing based on the combined finite–discrete method. Eng. Fract. Mech. 2021, 252, 107835. [Google Scholar] [CrossRef]

- Cheng, W.; Jin, Y.; Lin, Q.; Chen, M.; Zhang, Y.; Diao, C.; Hou, B. Experimental Investigation About Influence of Pre-existing Fracture on Hydraulic Fracture Propagation Under Tri-axial Stresses. Geotech. Geol. Eng. 2015, 33, 467–473. [Google Scholar] [CrossRef]

- Tan, P.; Chen, G.; Wang, Q.; Zhao, Q.; Chen, Z.; Xiang, D.; Xu, C.; Feng, X.; Zhai, W.; Yang, Z.; et al. Simulation of hydraulic fracture initiation and propagation for glutenite formations based on discrete element method. Front. Earth Sci. 2023, 10, 1116492. [Google Scholar] [CrossRef]

- Fu, L.; Hu, J.; Zhang, Y. Study on fracture initiation pressure of a horizontal well considering the influence of stress shadow in tight sand reservoirs. J. Nat. Gas Sci. Eng. 2022, 101, 104537. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Q.; He, J.; Liu, H.; Zhao, Z.; Du, S.; Wang, B. Pressure transient analysis of volume-fractured vertical well with complex fracture network in the reservoir. J. Nat. Gas Sci. Eng. 2022, 101, 104556. [Google Scholar] [CrossRef]

- Zheng, H.; Pu, C.; Xu, E.; Sun, C. Numerical investigation on the effect of well interference on hydraulic fracture propagation in shale formation. Eng. Fract. Mech. 2020, 228, 106932. [Google Scholar] [CrossRef]

- Zheng, H.; Pu, C.; Sun, C. Numerical investigation on the hydraulic fracture propagation based on combined finite-discrete element method. J. Struct. Geol. 2020, 130, 103926. [Google Scholar] [CrossRef]

- Taheri-Shakib, J.; Ghaderi, A.; Hosseini, S.; Hashemi, A. Debonding and coalescence in the interaction between hydraulic and natural fracture: Accounting for the effect of leak-off. J. Nat. Gas Sci. Eng. 2016, 36, 454–462. [Google Scholar] [CrossRef]

- Guo, T.; Zhang, S.; Qu, Z. Experimental study of hydraulic fracturing for shale by Stimulated reservoir volume. Fuel 2014, 128, 373–380. [Google Scholar] [CrossRef]

- Heng, S.; Liu, X.; Li, X.; Zhang, X.; Yang, C. Experimental and numerical study on the non-planar propagation of hydraulic fractures in shale. J. Pet. Sci. Eng. 2019, 179, 410–426. [Google Scholar] [CrossRef]

- Yushi, Z.; Shicheng, Z.; Tong, Z.; Xiang, Z.; Tiankui, G. Experimental Investigation into Hydraulic Fracture Network Propagation in Gas Shales Using CT Scanning Technology. Rock Mech. Rock Eng. 2016, 49, 33–45. [Google Scholar] [CrossRef]

- Stanchits, S.; Burghardt, J.; Surdi, A. Hydraulic Fracturing of Heterogeneous Rock Monitored by Acoustic Emission. Rock Mech. Rock Eng. 2015, 48, 2513–2527. [Google Scholar] [CrossRef]

- Cruz, F.; Roehl, D.; Vargas, E.D.A. An XFEM element to model intersections between hydraulic and natural fractures in porous rocks. Int. J. Rock Mech. Min. Sci. 2018, 112, 385–397. [Google Scholar] [CrossRef]

- Cheng, W.; Jin, Y.; Chen, M. Reactivation mechanism of natural fractures by hydraulic fracturing in naturally fractured shale reservoirs. J. Nat. Gas Sci. Eng. 2015, 23, 431–439. [Google Scholar] [CrossRef]

- Fatahi, H.; Hossain, M.M.; Sarmadivaleh, M. Numerical and experimental investigation of the interaction of natural and propagated hydraulic fracture. J. Nat. Gas Sci. Eng. 2017, 37, 409–424. [Google Scholar] [CrossRef]

- Rysak, B.; Gale, J.F.; Laubach, S.E.; Ferrill, D.A. Mechanisms for the Generation of Complex Fracture Networks: Observations from Slant Core, Analog Models, and Outcrop. Front. Earth Sci. 2022, 10, 848012. [Google Scholar] [CrossRef]

- Zheng, Y.; He, R.; Huang, L.; Bai, Y.; Wang, C.; Chen, W.; Wang, W. Exploring the effect of engineering parameters on the penetration of hydraulic fractures through bedding planes in different propagation regimes. Comput. Geotech. 2022, 146, 104736. [Google Scholar] [CrossRef]

- Dehghan, A.N. An experimental investigation into the influence of pre-existing natural fracture on the behavior and length of propagating hydraulic fracture. Eng. Fract. Mech. 2020, 240, 107330. [Google Scholar] [CrossRef]

- Wu, S.; Li, T.; Ge, H.; Wang, X.; Li, N.; Zou, Y. Shear-tensile fractures in hydraulic fracturing network of layered shale. J. Pet. Sci. Eng. 2019, 183, 106428. [Google Scholar] [CrossRef]

- Sun, C.; Zheng, H.; Liu, W.D.; Lu, W. Numerical simulation analysis of vertical propagation of hydraulic fracture in bedding plane. Eng. Fract. Mech. 2020, 232, 107056. [Google Scholar] [CrossRef]

- Joseph, P.F.; Loghin, A. Letter to the Editor of Engineering Fracture Mechanics. Eng. Fract. Mech. 2020, 232, 107049. [Google Scholar] [CrossRef]

- Shi, S.; Zheng, H.; Kong, H.; Luo, Y.; Chen, F. Study on the failure mechanism in shale-sand formation based on hybrid finite-discrete element method. Eng. Fract. Mech. 2022, 272, 108718. [Google Scholar] [CrossRef]

- Wang, L. Study on the influence of temperature on fracture propagation in ultra-deep shale formation. Eng. Fract. Mech. 2023, 281, 109118. [Google Scholar] [CrossRef]

| Item | Parameters | Sample 1 | Sample 2 | Sample 3 | Sample 4 |

|---|---|---|---|---|---|

| Stress Field | Vertical stress/MPa | 18.0 | 18.0 | 18.0 | 18.0 |

| Maximum horizontal principal stress/MPa | 13.0 | 15.0 | 13.0 | 13.0 | |

| Minimum horizontal principal stress/MPa | 11.0 | 11.0 | 11.0 | 11.0 | |

| Rock Mechanical Properties | Young’s Modulus/GPa | 34.2 | 34.2 | 34.2 | 34.2 |

| Poisson’s Rate | 0.264 | 0.264 | 0.264 | 0.264 | |

| Injection Parameters | Injection rate/(mL/min) | 5.0 | 5.0 | 8.0 | 5.0 |

| Viscosity of fracturing fluid/(mPa·s) | 1.0 | 1.0 | 1.0 | 25.0 |

| Samples | DDS | Tensile Failure Percentage/% | Shear Failure Percentage/% |

|---|---|---|---|

| Sample 1 | DDS #1 | 73.51 | 26.39 |

| DDS #2 | 68.16 | 32.84 | |

| DDS #4 | 71.24 | 28.76 | |

| DDS #5 | 54.52 | 44.48 | |

| Sample 2 | DDS #1 | 81.24 | 18.76 |

| DDS #2 | 67.24 | 32.76 | |

| DDS #4 | 71.83 | 28.17 | |

| DDS #5 | 56.23 | 44.77 | |

| Sample 3 | DDS #1 | 86.15 | 13.85 |

| DDS #2 | 56.34 | 43.66 | |

| DDS #4 | 68.27 | 31.73 | |

| DDS #5 | 38.92 | 61.08 | |

| Sample 4 | DDS #1 | 71.26 | 28.74 |

| DDS #2 | 61.24 | 38.76 | |

| DDS #4 | 68.12 | 31.88 | |

| DDS #5 | 39.45 | 60.55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, Y.; Zheng, H.; Xiang, H.; Nie, X.; Liao, R. Experimental Simulation on the Stress Disturbance Mechanism Caused by Hydraulic Fracturing on the Mechanical Properties of Shale Formation. Processes 2023, 11, 2931. https://doi.org/10.3390/pr11102931

Tang Y, Zheng H, Xiang H, Nie X, Liao R. Experimental Simulation on the Stress Disturbance Mechanism Caused by Hydraulic Fracturing on the Mechanical Properties of Shale Formation. Processes. 2023; 11(10):2931. https://doi.org/10.3390/pr11102931

Chicago/Turabian StyleTang, Yu, Heng Zheng, Hong Xiang, Xiaomin Nie, and Ruiquan Liao. 2023. "Experimental Simulation on the Stress Disturbance Mechanism Caused by Hydraulic Fracturing on the Mechanical Properties of Shale Formation" Processes 11, no. 10: 2931. https://doi.org/10.3390/pr11102931

APA StyleTang, Y., Zheng, H., Xiang, H., Nie, X., & Liao, R. (2023). Experimental Simulation on the Stress Disturbance Mechanism Caused by Hydraulic Fracturing on the Mechanical Properties of Shale Formation. Processes, 11(10), 2931. https://doi.org/10.3390/pr11102931