A Semi-Analytical Model for Production Prediction of Deep CBM Wells Considering Gas-Water Two-Phase Flow

Abstract

:1. Introduction

2. Methodology

2.1. Physical Model Assumption

2.2. Mathematical Model

2.2.1. Fluid Flow in the Outer Zone

2.2.2. Fluid Flow in the Inner Zone

2.2.3. Fluid Flow in the Hydraulic Fractures

2.3. Solution to Mathematical Model

2.3.1. Solution for Gas and Water Flow in the Outer Zone

2.3.2. Solution for Gas and Water Flow in the Inner Zone

2.3.3. Solution for Gas and Water Flow in the Hydraulic Fracture

2.3.4. Flowing Material Balance Method

3. Results and Discussion

3.1. Model Validation

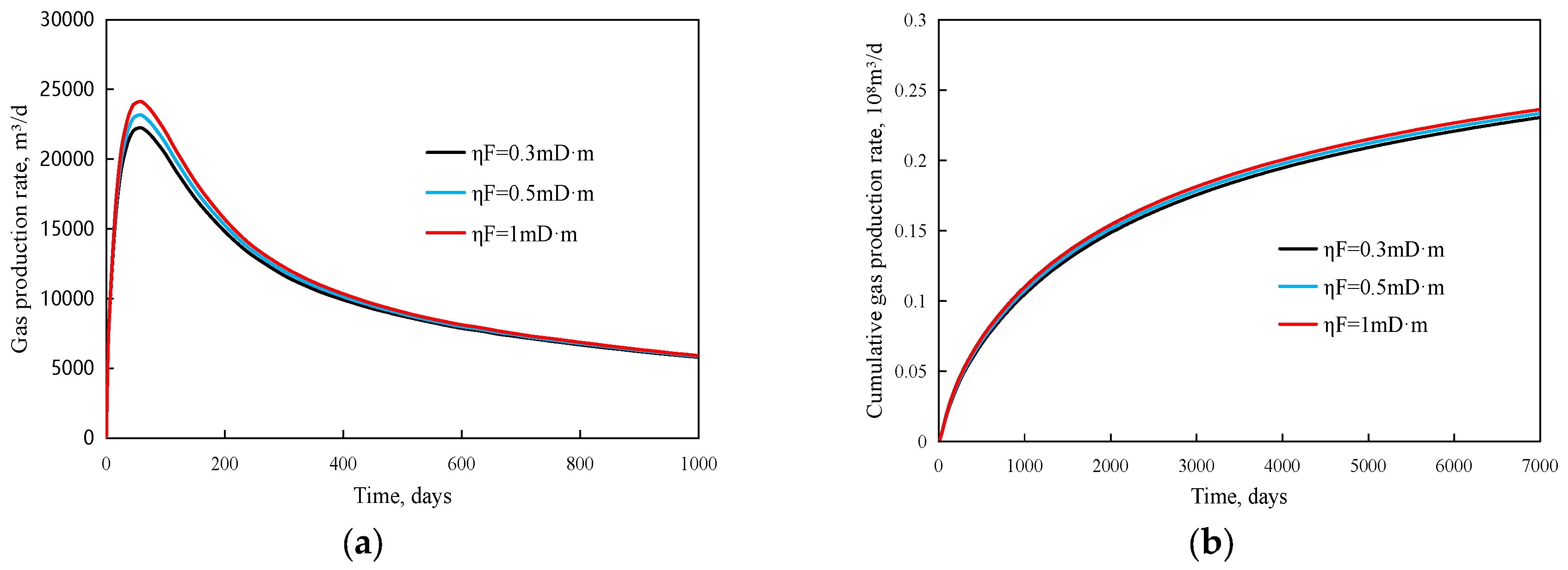

3.2. Sensitivity Analysis

3.3. Field Application

4. Conclusions

- Employing the flowing material balance method for computing the average pressure and average saturation of the reservoir, and iteratively updating the non-linear parameters in the seepage model, facilitates the accurate handling of the non-linear seepage problem associated with gas-water dual-phase flow. This results in an efficient and precise resolution of the seepage model;

- The verification of the numerical model and field applications together suggest that the semi-analytical method investigated in this study offers a high degree of prediction accuracy and can be employed to forecast the production rate of deep CBM wells;

- Critical seepage parameters of hydraulic fractures significantly influence the production dynamics of gas-water dual-phase. Therefore, hydraulic fracturing should aim to enhance the degree and extent of modification to boost the production capacity of deep CBM wells;

- The stress-sensitive effect of the coal cleats has an impact on the production capacity of deep CBM wells. Therefore, it is necessary to judiciously control the production pressure differential during production to effectively mitigate the adverse influence of stress-sensitive effects.

Author Contributions

Funding

Conflicts of Interest

References

- Yang, Z.; Wang, H.; Liu, N.; Li, J. Simulation study of characteristics of hydraulic fracturing propagation of low permeability coal seam. Disaster Adv. 2012, 5, 717–720. [Google Scholar]

- Sun, Z.; Shi, J.; Wu, K.; Zhang, T.; Feng, D.; Li, X. Effect of pressure-propagation behavior on production performance: Implication for advancing low-permeability coalbed-methane recovery. SPE J. 2019, 24, 681–697. [Google Scholar] [CrossRef]

- Chen, Y.; Pan, Z. Reservoir properties of Chinese tectonic coal: A review. Fuel 2020, 260, 116350. [Google Scholar] [CrossRef]

- Ren, J.; Zhang, L.; Ren, S.; Lin, J.; Meng, S.; Ren, G.; Gentzis, T. Multi-branched horizontal wells for coalbed methane production: Field performance and well structure analysis. Int. J. Coal Geol. 2014, 131, 52–64. [Google Scholar] [CrossRef]

- Ma, J.; Chen, J.; Guan, J.; Lin, Y.; Chen, W.; Huang, L. Implementation of Johnson-Holmquist-Beissel model in four-dimensional lattice spring model and its application in projectile penetration. Int. J. Impact Eng. 2022, 170, 104340. [Google Scholar] [CrossRef]

- Ma, J.; Zhao, J.; Lin, Y.; Liang, J.; Chen, J.; Chen, W.; Huang, L. Study on Tamped Spherical Detonation-Induced Dynamic Responses of Rock and PMMA Through Mini-Chemical Explosion Tests and a Four-Dimensional Lattice Spring Model. Rock Mech. Rock Eng. 2023, 56, 7357–7375. [Google Scholar] [CrossRef]

- Wu, X.; Xi, C.; Wang, G. The mathematic model research of complicated fractures system in coalbed methane wells. Nat. Gas Ind. 2006, 26, 124–126. [Google Scholar]

- Pant, L.M.; Huang, H.; Secanell, M.; Larter, S.; Mitra, S.K. Multi scale characterization of coal structure for mass transport. Fuel 2015, 159, 315–323. [Google Scholar] [CrossRef]

- Pan, Z.; Wood, D.A. Coalbed methane (CBM) exploration, reservoir characterisation, production, and modelling: A collection of published research (2009–2015). J. Nat. Gas Sci. Eng. 2015, 26, 1472–1484. [Google Scholar] [CrossRef]

- Zhang, J.; Feng, Q.; Zhang, X.; Hu, Q.; Wen, S.; Chen, D.; Yan, X. Multi-fractured horizontal well for improved coalbed methane production in eastern Ordos basin, China: Field observations and numerical simulations. J. Pet. Sci. Eng. 2020, 194, 107488. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, S. Integrated modeling of multi-scale transport in coal and its application for coalbed methane recovery. Fuel 2021, 300, 120971. [Google Scholar] [CrossRef]

- Sun, Z.; Huang, B.; Li, Y.; Yu, W.; Ji, L. Production forecast of fractured vertical wells in coalbed methane reservoirs: Coupling dynamic drainage area. Arab. J. Geosci. 2022, 15, 7. [Google Scholar] [CrossRef]

- Shi, X.; Pan, J.; Hou, Q.; Jin, Y.; Wang, Z.; Niu, Q.; Li, M. Micrometer-scale fractures in coal related to coal rank based on micro-CT scanning and fractal theory. Fuel 2018, 212, 162–172. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, L.; Zhao, Y.; Zhang, R.; Zhang, D.; He, X.; Ge, F.; Wu, J.; Javadpour, F. Ganglia dynamics during imbibition and drainage processes in nanoporous systems. Phys Fluids. 2022, 34, 042016. [Google Scholar] [CrossRef]

- Zhang, T.; Luo, S.; Zhou, H.; Hu, H.; Zhang, L.; Zhao, Y.; Javadpour, F. Pore-scale modelling of water sorption in nanopore systems of shale. Int. J. Coal Geol. 2023, 27, 104266. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Qanbari, F. Transient flow analysis and partial water relative permeability curve derivation for low permeability undersaturated coalbed methane wells. Int. J. Coal Geol. 2015, 152, 110–124. [Google Scholar] [CrossRef]

- Zhao, J.; Tang, D.; Lin, W.; Xu, H.; Li, Y.; Tao, S.; Lv, Y. Permeability dynamic variation under the action of stress in the medium and high rank coal reservoir. J. Nat. Gas Sci. Eng. 2015, 26, 1030–1041. [Google Scholar] [CrossRef]

- Tang, X.; Wang, Z.; Ripepi, N.; Kang, B.; Yue, G. Adsorption affinity of different types of coal: Mean isosteric heat of adsorption. Energy Fuels 2015, 29, 3609–3615. [Google Scholar] [CrossRef]

- Zeng, Q.; Wang, Z. Stress and temperature sensitivity of coal permeability in the Eastern Ordos Basin. Pet. Sci. Bull. 2020, 4, 512–519. [Google Scholar]

- Yu, P.; Dempsey, D.; Archer, R. Techno-Economic feasibility of enhanced geothermal systems (EGS) with partially bridging multi-stage fractures for district heating applications. Energy Convers. Manag. 2022, 257, 115405. [Google Scholar] [CrossRef]

- Aminian, K.; Ameri, S. Predicting production performance of CBM reservoirs. J. Nat. Gas Sci. Eng. 2009, 1, 25–30. [Google Scholar] [CrossRef]

- Salmachi, A.; Yarmohammadtooski, Z. Production data analysis of coalbed methane wells to estimate the time required to reach to peak of gas production. Int. J. Coal Geol. 2015, 141, 33–41. [Google Scholar] [CrossRef]

- Yan, X.; Zhang, S.; Tang, S.; Li, Z.; Guan, W.; Zhang, Q.; Wang, J. A prediction model for pressure propagation and production boundary during coalbed methane development. Energy Fuels 2021, 35, 1219–1233. [Google Scholar] [CrossRef]

- Shi, J.; Jia, Y.; Wu, J.; Xu, F.; Sun, Z.; Liu, C.; Liu, C. Dynamic performance prediction of coalbed methane wells under the control of bottom-hole pressure and casing pressure. J. Pet. Sci. Eng. 2021, 196, 107799. [Google Scholar] [CrossRef]

- Yu, P.; Dempsey, D.; Rinaldi, A.P.; Calibugan, A.; Ritz, V.A.; Archer, R. Association between Injection and Microseismicity in Geothermal Fields with Multiple Wells: Data-driven Modelling of Rotokawa, New Zealand, and Húsmúli, Iceland. J. Geophys. Res. Solid Earth 2022, 128, e2022JB025952. [Google Scholar] [CrossRef]

- Ibrahim, A.F.; Nasr-El-Din, H.A. A comprehensive model to history match and predict gas/water production from coal seams. Int. J. Coal Geol. 2015, 146, 79–90. [Google Scholar] [CrossRef]

- Ma, T.; Rutqvist, J.; Oldenburg, C.M.; Liu, W.; Chen, J. Fully coupled two-phase flow and poromechanics modeling of coalbed methane recovery: Impact of geomechanics on production rate. J. Nat. Gas Sci. Eng. 2017, 45, 474–486. [Google Scholar] [CrossRef]

- Sun, Z.; Shi, J.; Zhang, T.; Wu, K.; Feng, D.; Sun, F.; Li, X. A fully-coupled semi-analytical model for effective gas/water phase permeability during coal-bed methane production. Fuel 2018, 223, 44–52. [Google Scholar] [CrossRef]

- Shi, J.; Hou, C.; Wang, S.; Xiong, X.; Wu, S.; Liu, C. The semi-analytical productivity equations for vertically fractured coalbed methane wells considering pressure propagation process, variable mass flow, and fracture conductivity decrease. J. Pet. Sci. Eng. 2019, 178, 528–543. [Google Scholar] [CrossRef]

- Zou, M.; Wei, S.; Huang, Z.; Lv, X.; Guo, B. Simulations on recoverability performances for a coalbed methane field in SE edge of Ordos basin, China. Fuel 2018, 233, 354–360. [Google Scholar] [CrossRef]

- Zhu, S.; Salmachi, A.; Du, Z. Two phase rate-transient analysis of a hydraulically fractured coal seam gas well: A case study from the Ordos Basin, China. Int. J. Coal Geol. 2018, 195, 47–60. [Google Scholar] [CrossRef]

- Peng, X.; Zhu, S.; You, Z.; Du, Z.; Deng, P.; Wang, C.; Wang, M. Numerical simulation study of fines migration impacts on an early water drainage period in undersaturated coal seam gas reservoirs. Geofluids 2019, 2019, 5723694. [Google Scholar] [CrossRef]

- Yu, P.; Dempsey, D.; Archer, R. A three-dimensional coupled thermo-hydro-mechanical numerical model with partially bridging multi-stage contact fractures in horizontal-well enhanced geothermal system. Int. J. Rock Mech. Min. Sci. 2021, 143, 104787. [Google Scholar] [CrossRef]

- Sun, Z.; Huang, B.; Liu, Y.; Jiang, Y.; Zhang, Z.; Hou, M.; Li, Y. Gas-phase production equation for CBM reservoirs: Interaction between hydraulic fracturing and coal orthotropic feature. J. Pet. Sci. Eng. 2022, 213, 110428. [Google Scholar] [CrossRef]

- Song, P.; Li, Y.; Yin, Z.; Yuan, Q. Hydrogen generation from heavy oils via in-situ combustion gasification. In SPE Western Regional Meeting; SPE: Kuala Lumpur, Malaysia, 2023; p. D031S007R003. [Google Scholar]

- Nossent, J.; Elsen, P.; Bauwens, W. Sobol’sensitivity analysis of a complex environmental model. Environ. Model. Softw. 2011, 26, 1515–1525. [Google Scholar] [CrossRef]

- Yin, Z.; Feng, T.; MacBeth, C. Fast assimilation of frequently acquired 4D seismic data for reservoir history matching. Comput. Geosci. 2019, 128, 30–40. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Qanbari, F. A semi-analytical forecasting method for unconventional gas and light oil wells: A hybrid approach for addressing the limitations of existing empirical and analytical methods. SPE Reserv. Eval. Eng. 2014, 18, 260–263. [Google Scholar]

| Parameters | Symbol | Definition |

|---|---|---|

| Dimensionless pseudo pressure of the hydraulic fracture | ||

| Dimensionless pseudo pressure of the cleat in the outer zone | ||

| Dimensionless pseudo pressure of the cleat in the inner zone | ||

| Dimensionless pseudo pressure of the coal matrix in the outer zone | ||

| Dimensionless pseudo pressure of the coal matrix in the inner zone | ||

| Dimensionless pseudo time | ||

| Dimensionless pressure of the hydraulic fracture | ||

| Dimensionless pressure of the cleat in the outer zone | ||

| Dimensionless pressure of the cleat in the inner zone | ||

| Dimensionless time | ||

| Dimensionless hydraulic fracture conductivity | ||

| Dimensionless hydraulic fracture pressure transmitting coefficient | ||

| Dimensionless fracture aperture | ||

| Dimensionless distance in the x direction | ||

| Dimensionless distance in the y direction | ||

| Dimensionless distance in the z direction | ||

| Dimensionless outer boundary in the x direction | ||

| Dimensionless outer boundary in the y direction | ||

| Dimensionless half-length of the hydraulic fracture | ||

| Dimensionless adsorption concentration of the coal matrix | ||

| Dimensionless equilibrium adsorption concentration | ||

| Capacitance coefficient of the coal cleat in the outer zone | ||

| Diffusion flow coefficient | ||

| Capacitance coefficient of coal cleat in the inner zone | ||

| Inter-porosity flow factor of coal matrix system into coal cleat system |

| Parameters | Symbol | Units | Value |

|---|---|---|---|

| Initial formation pressure | pi | MPa | 20 |

| Initial formation temperature | Ti | K | 323 |

| Bottom-hole pressure | pwf | MPa | 4 |

| Formation thickness | h | m | 9.1 |

| Permeability of hydraulic fractures | kF | mD | 500 |

| Number of hydraulic fractures | NF | Dimensionless | 12 |

| Half length of hydraulic fractures | yF | m | 100 |

| Width of hydraulic fractures | wF | m | 0.001 |

| Porosity of hydraulic fractures | ΦF | Fraction | 0.4 |

| Length of the horizontal well | L | m | 1000 |

| Half-width of the reservoir | ye | m | 200 |

| Porosity of the coal cleat | Φf | Fraction | 0.05 |

| Permeability of the coal cleat in the inner reservoir | kf | mD | 0.22 |

| Permeability of the outer reservoir | ko | mD | 0.12 |

| Permeability modulus of the coal cleat | γf | MPa−1 | 0.02 |

| Langmuir pressure | pL | MPa | 3.1 |

| Langmuir volume | VL | m3/t | 12.9 |

| Gas content in coal seams | V | m3/t | 14.8 |

| Parameters | Symbol | Units | Value |

|---|---|---|---|

| Conductivity of hydraulic fractures | ηF | mD·m | 0.3, 0.5, 1 |

| Half length of hydraulic fractures | yF | m | 50, 80, 100 |

| Number of hydraulic fractures | NF | Dimensionless | 9, 12, 15 |

| Permeability of the coal cleat in the inner reservoir | kf | mD | 0.2, 0.3, 0.4 |

| Permeability of the outer reservoir | ko | mD | 0.1, 0.2, 0.3 |

| Permeability modulus of the coal cleat | γf | MPa−1 | 0.01, 0.02, 0.03 |

| Parameters | Symbol | Units | Value |

|---|---|---|---|

| Initial formation pressure | pi | MPa | 22.3 |

| Initial formation temperature | Ti | K | 320.2 |

| Bottom-hole pressure | pwf | MPa | 4 |

| Formation thickness | h | m | 13.2 |

| Number of hydraulic fractures | NF | Dimensionless | 14 |

| Width of hydraulic fractures | wF | m | 0.001 |

| Porosity of hydraulic fractures | ΦF | Fraction | 0.4 |

| Length of the horizontal well | L | m | 1200 |

| Half-width of the reservoir | ye | m | 220 |

| Porosity of the coal cleat | Φf | Fraction | 0.03 |

| Langmuir pressure | pL | MPa | 2.9 |

| Langmuir volume | VL | m3/t | 13.3 |

| Gas content in coal seams | V | m3/t | 15.7 |

| Parameters | Symbol | Units | Value |

|---|---|---|---|

| Conductivity of hydraulic fractures | ηF | mD·m | 0.32 |

| Half length of hydraulic fractures | yF | m | 82 |

| Permeability of the coal cleat in the inner reservoir | kf | mD | 0.25 |

| Permeability of the outer reservoir | ko | mD | 0.13 |

| Permeability modulus of the coal cleat | γf | MPa−1 | 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Li, D.; Li, W. A Semi-Analytical Model for Production Prediction of Deep CBM Wells Considering Gas-Water Two-Phase Flow. Processes 2023, 11, 3022. https://doi.org/10.3390/pr11103022

Wang S, Li D, Li W. A Semi-Analytical Model for Production Prediction of Deep CBM Wells Considering Gas-Water Two-Phase Flow. Processes. 2023; 11(10):3022. https://doi.org/10.3390/pr11103022

Chicago/Turabian StyleWang, Suran, Dongjun Li, and Wenlan Li. 2023. "A Semi-Analytical Model for Production Prediction of Deep CBM Wells Considering Gas-Water Two-Phase Flow" Processes 11, no. 10: 3022. https://doi.org/10.3390/pr11103022

APA StyleWang, S., Li, D., & Li, W. (2023). A Semi-Analytical Model for Production Prediction of Deep CBM Wells Considering Gas-Water Two-Phase Flow. Processes, 11(10), 3022. https://doi.org/10.3390/pr11103022