True Triaxial Test and Research into Bolting Support Compensation Stresses for Coal Roadways at Different Depths

Abstract

:1. Introduction

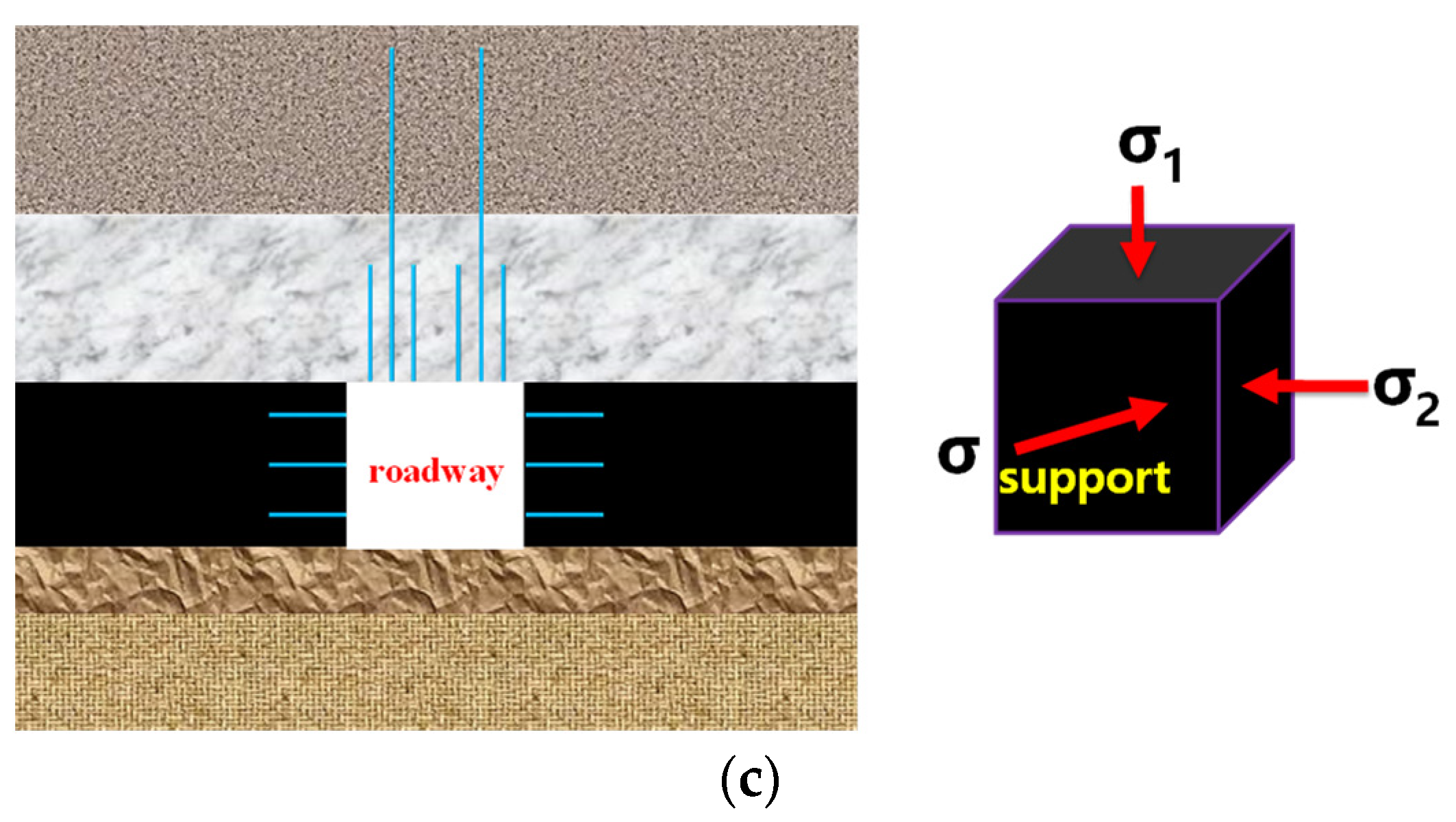

2. Experiment Scheme Design

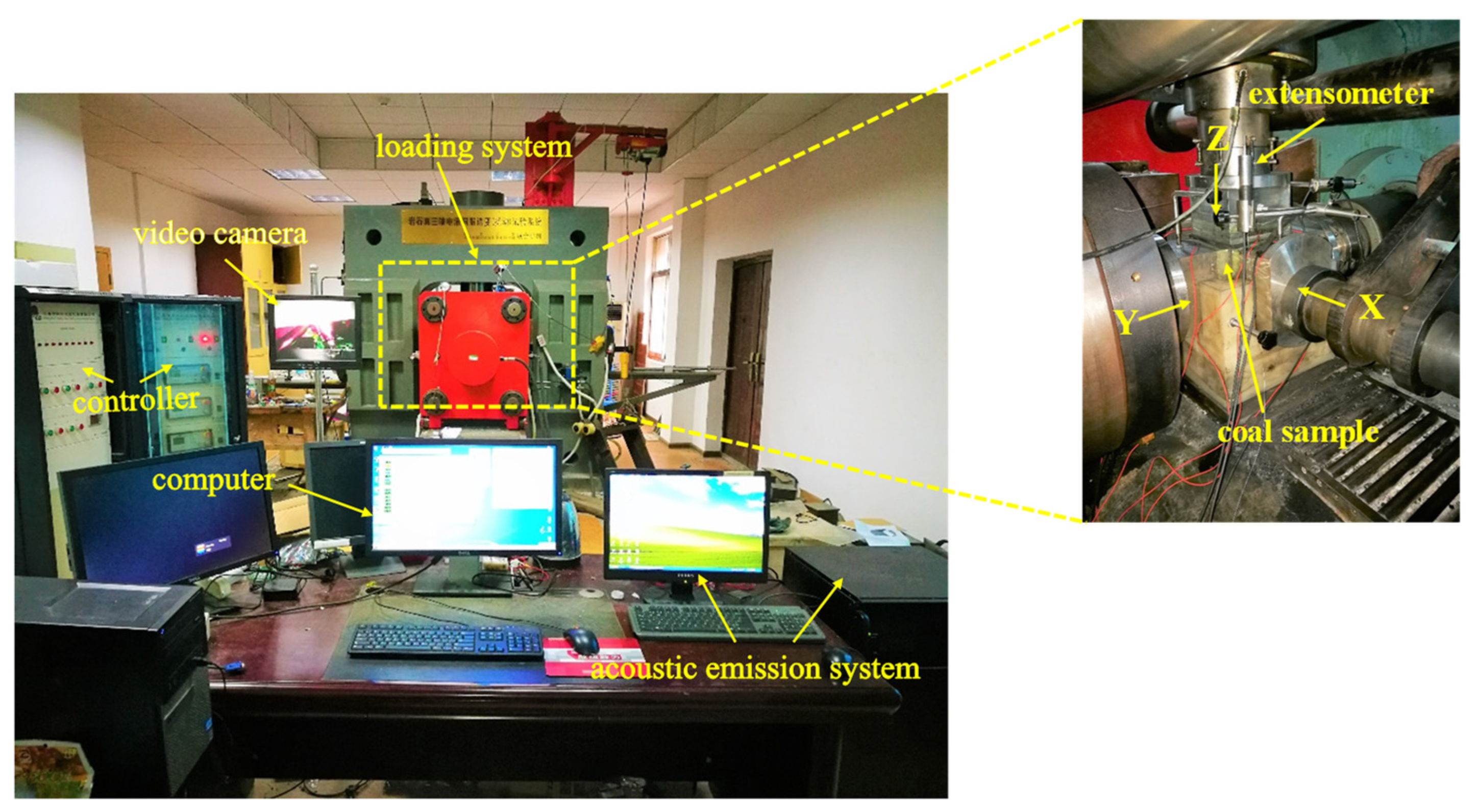

2.1. Experiment Equipment

2.2. Coal Sample Collection and Processing

2.3. Test Programme

2.3.1. Determination of Confining Pressure

2.3.2. Determination of Support Stress

2.3.3. Stress Path Design

- (1)

- Synchronize loading of X, Y, and Z triaxial stresses to σ3;

- (2)

- Keep σ3 constant and synchronously load the stress in the other two directions to σ2;

- (3)

- Keep σ2 and σ3 constant and load the Z direction stress to σ1;

- (4)

- Lock the oil cylinder and hold it until the sample is stable and keep σ3, σ2 unchanged, quickly adjusting σ3 unloading to 0;

- (5)

- Reduce σ2 by 10% to maintain stability, and load σ1 to the coal sample near the failure state;

- (6)

- Quickly compensate σ3 to 0.2 MPa to observe whether the deformation of the coal sample tends to be stable;

- (7)

- If the deformation of the coal sample is stable, unload σ3 to 0.1 MPa and continue to observe whether the deformation of the coal sample remains stable;

- (8)

- If the deformation is still stable, further unload σ3 to 0, and if it is stable, repeat steps 5, 6, 7, and 8 until the coal sample is broken.

3. Test Results and Analysis

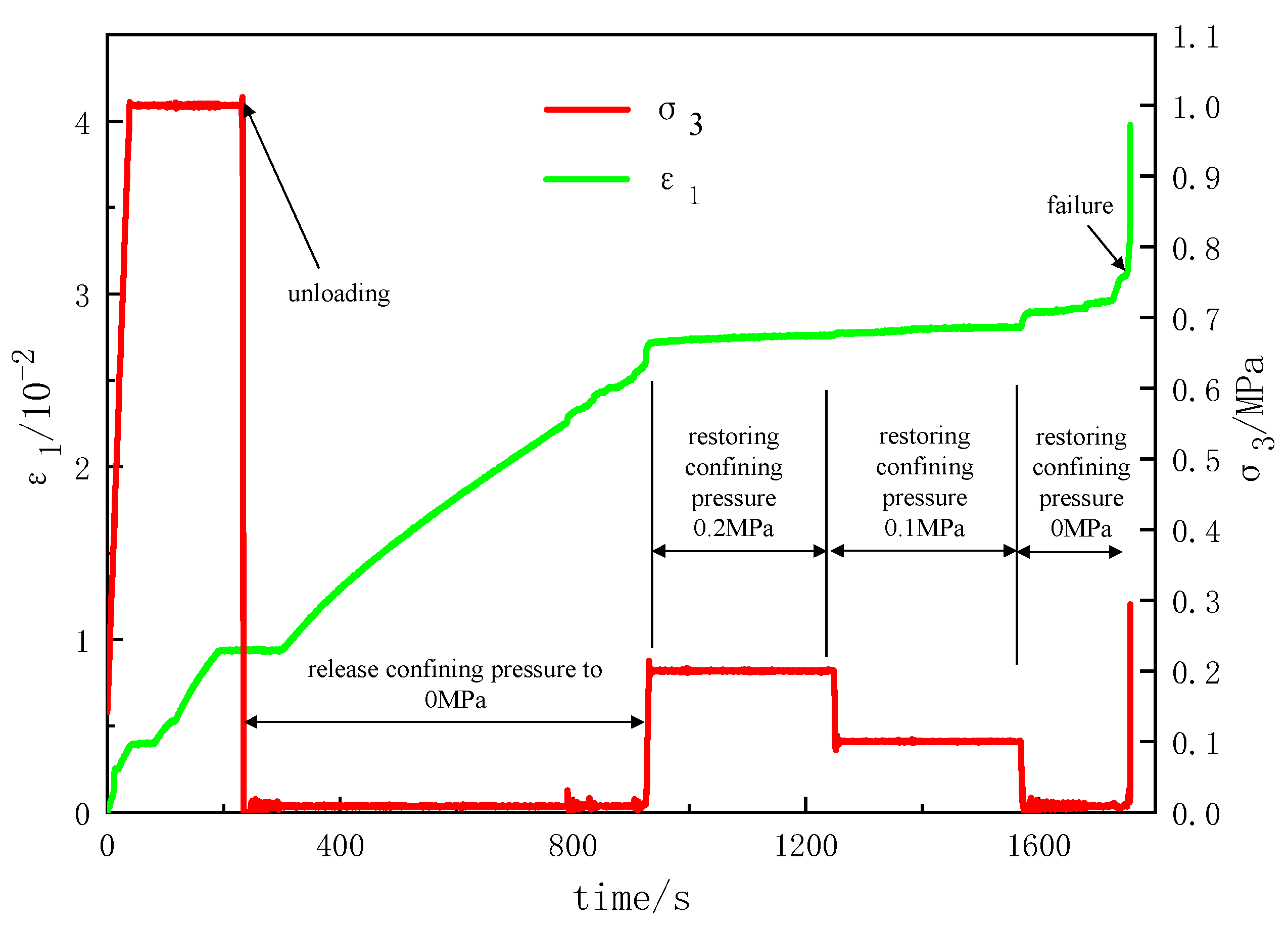

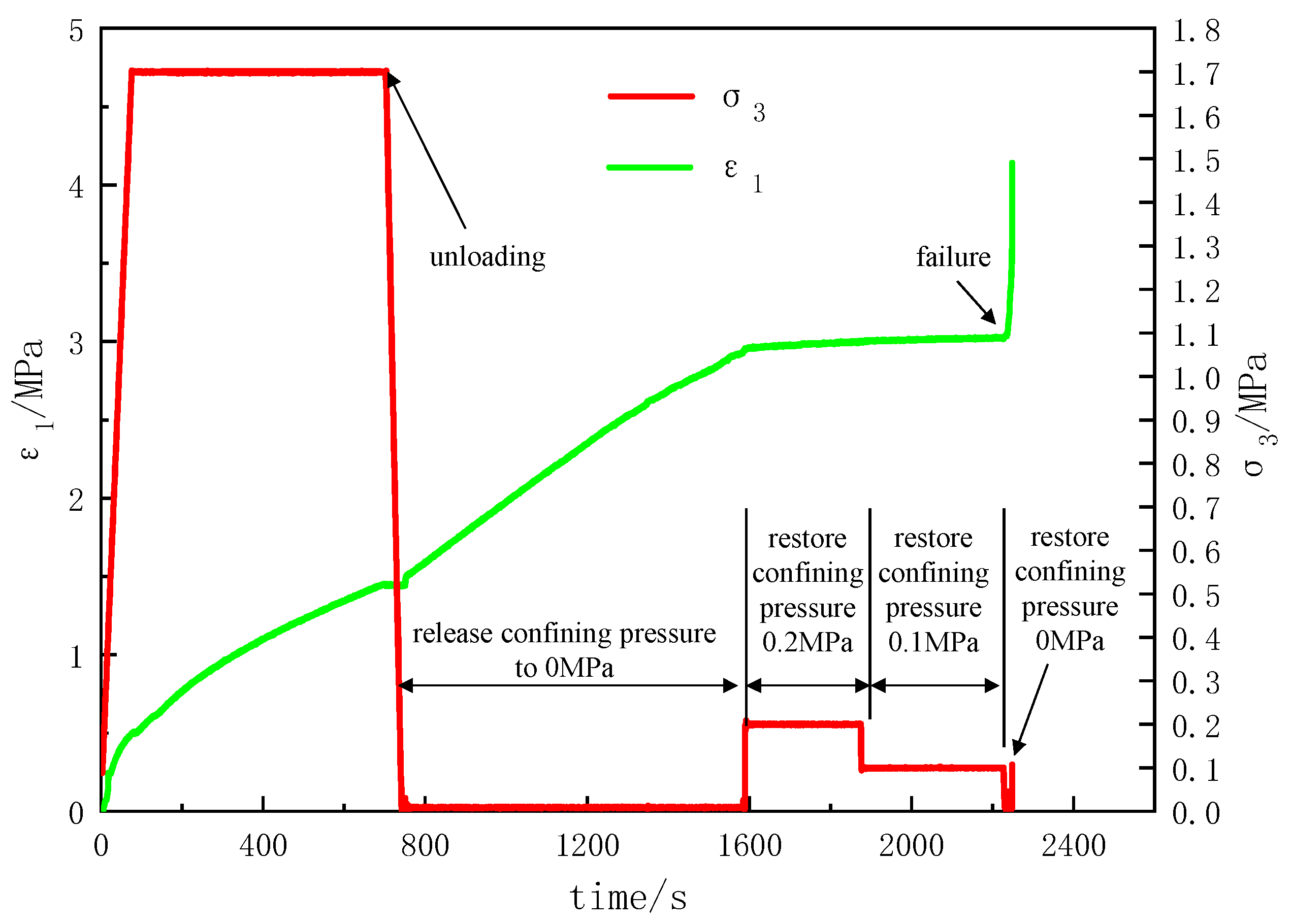

3.1. Reasonable Support and Compensation Stress for 200 m Buried Deep Coal Roadway

- (1)

- Deformation law

- ①

- During the three directions’ loading process, the strain of the coal sample increases continuously in the direction of the minimum principal stress due to the continued loading in the other two directions. The confining pressure unloading operation can be carried out until the end of the whole three-way loading process, and the slope of the strain curve is basically 0.

- ②

- After the minimum principal stress is unloaded to 0 MPa, the slope of the strain curve remains basically 0 within 1 min. After 1 min, the strain begins to increase, but the slope of the strain curve is significantly lower than that of the curve under the three directions of loading before the failure.

- ③

- When the compensation stress is applied to 0.2 MPa immediately before the coal sample is near to failure, the strain curve quickly changes from vertical to horizontal, and the deformation of the coal sample changes from rapid growth to stability, indicating that the application of 0.2 MPa compensation stress can keep the coal sample stable.

- ④

- When the compensated stress is reduced to 0.1 MPa, the coal sample deforms immediately when the compensated stress is reduced, and the strain of the coal sample basically remains unchanged when the compensated stress is maintained at 0.1 MPa, indicating that the compensated stress at 0.1 MPa can also keep the coal sample stable.

- ⑤

- When the compensated stress is reduced to 0, the deformation of the coal sample increases rapidly in the process of reducing the compensated stress, and then the deformation speed slows down. After 3 min, the deformation speed increases rapidly until the coal sample is destroyed, indicating that the stability of the coal sample cannot be guaranteed under the condition of no compensated stress.

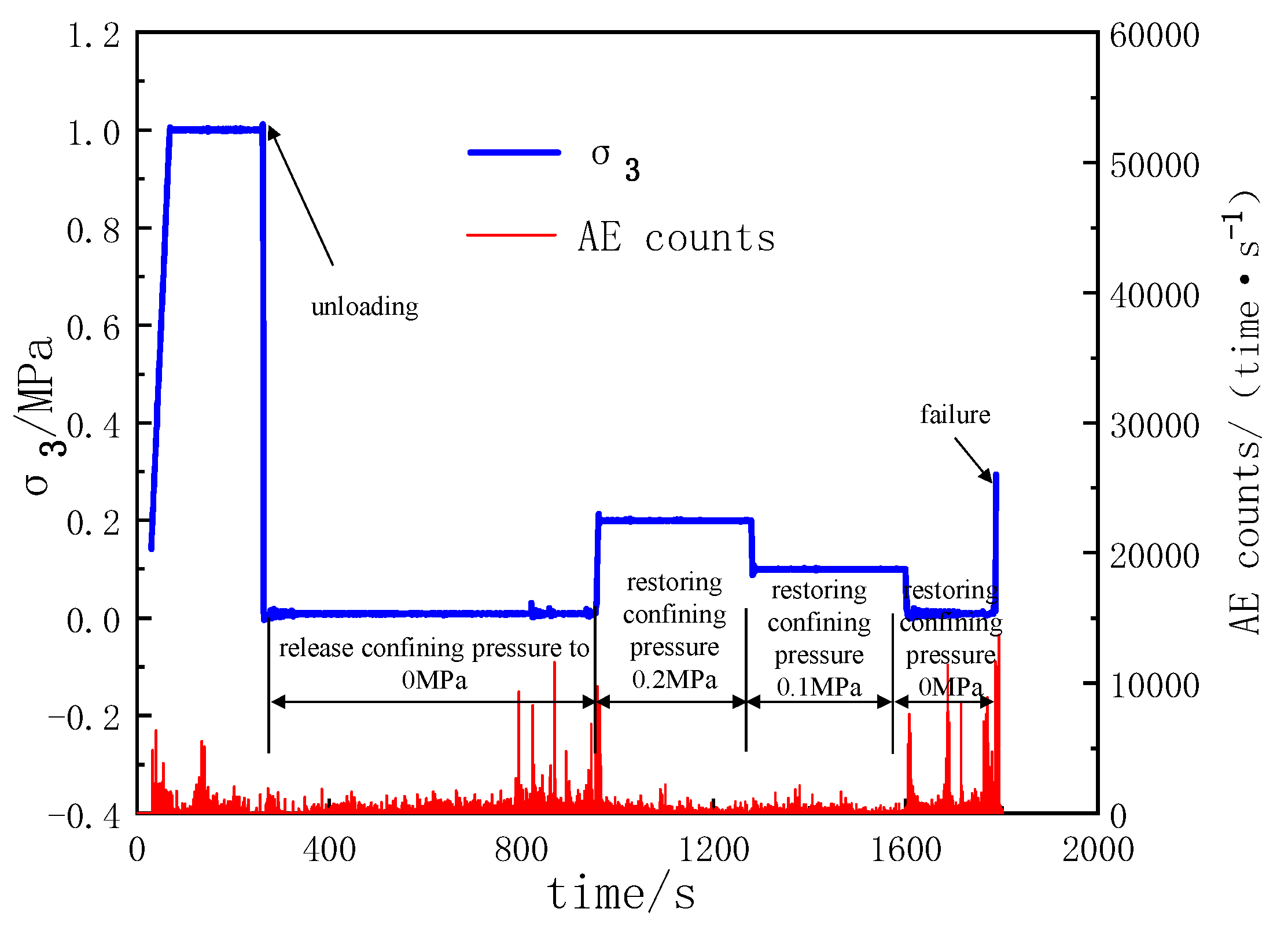

- (2)

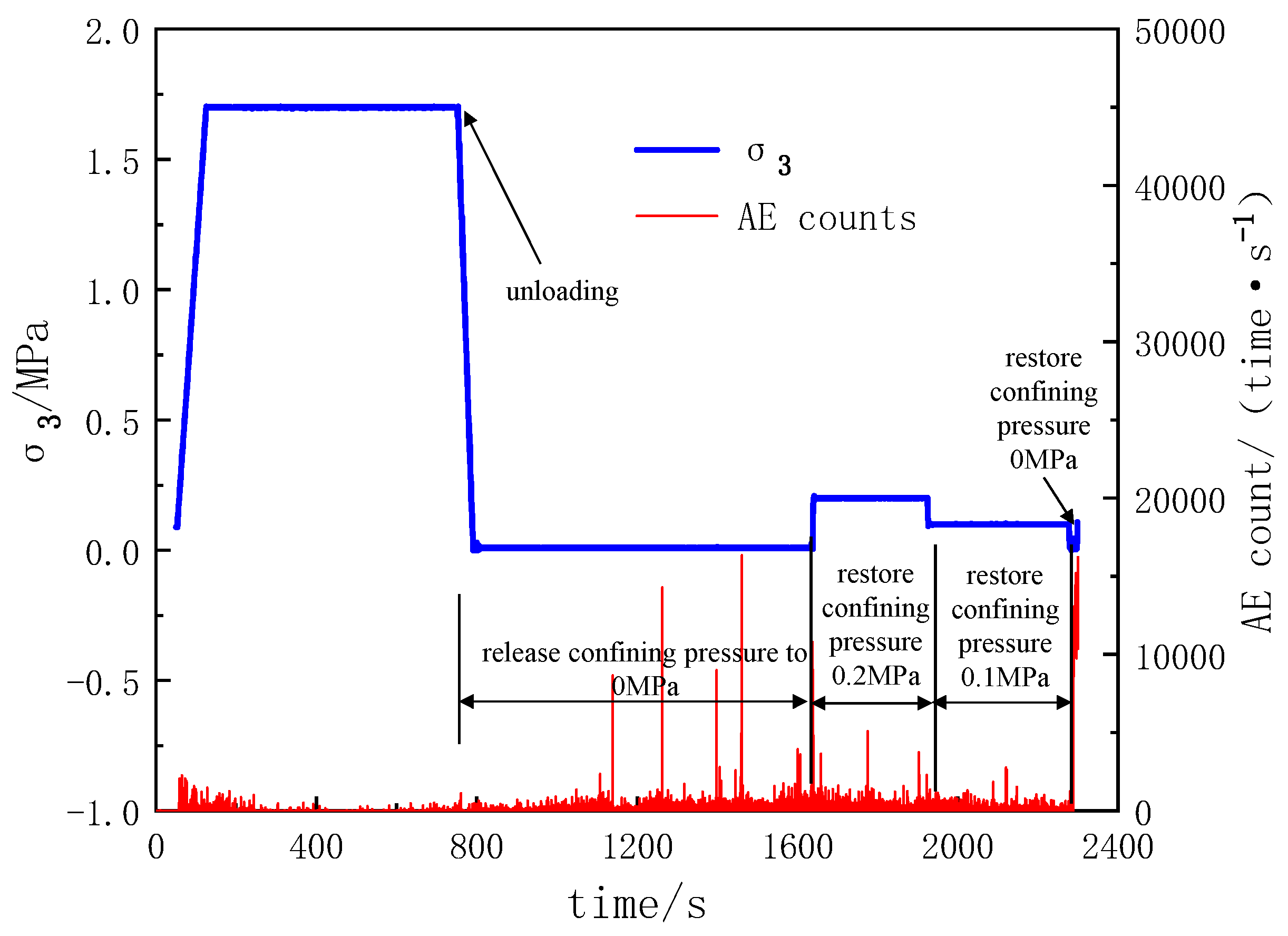

- Acoustic emission characteristics

- ①

- Less than 9 min after unidirectional confining pressure unloading, the acoustic emission count is less, and the coal sample is in a relatively stable period. After this point, the acoustic emission counts increase sharply, and the coal sample is in a critical failure and instability state. At this time, the stress is quickly compensated to 0.2 MPa, and the acoustic emission counts are rapidly reduced from active to calm. The results show that the compensation stress of 0.2 MPa can keep the coal sample stable and effectively restrain the propagation of internal cracks.

- ②

- When the compensated stress is reduced from 0.2 MPa to 0.1 MPa, the acoustic emission counts do not increase significantly, indicating that the compensated stress of 0.1 MPa can also keep the coal sample stable.

- ③

- When the compensated stress is reduced to 0 MPa, the acoustic emission counts increase sharply and become more and more involved in the process of pressure relief. After about 3 min, the coal sample becomes unstable and failure occurs, indicating that the coal sample without compensated stress cannot guarantee long-term stability.

- (3)

- Sound characteristics

- ①

- When the coal sample is near instability and failure, the severe sound of coal mass failure can be heard, the stress is quickly compensated to 0.2 MPa, and the sound of coal sample rupture disappears. Within 5 min, only a small sound occasionally appears, indicating that 0.2 MPa stress compensation can keep the coal sample stable.

- ②

- When the compensation stress is reduced to 0.1 MPa, the coal sample has a certain sound, and there is almost no sound within 5 min of the pressure holding, indicating that the compensation stress of 0.1 MPa can also keep the coal sample stable.

- ③

- When the compensated stress is reduced to 0, there is a small amount of sound in the coal sample, and then there is a non-violent sound. About 3 min later, the coal sample suddenly makes a dramatic sound and becomes unstable, indicating that the coal sample without compensated stress cannot maintain stability.

- ④

- To sum up, the reasonable support compensation stress of the coal roadway buried at a 200 m depth is much lower than 0.1 MPa.

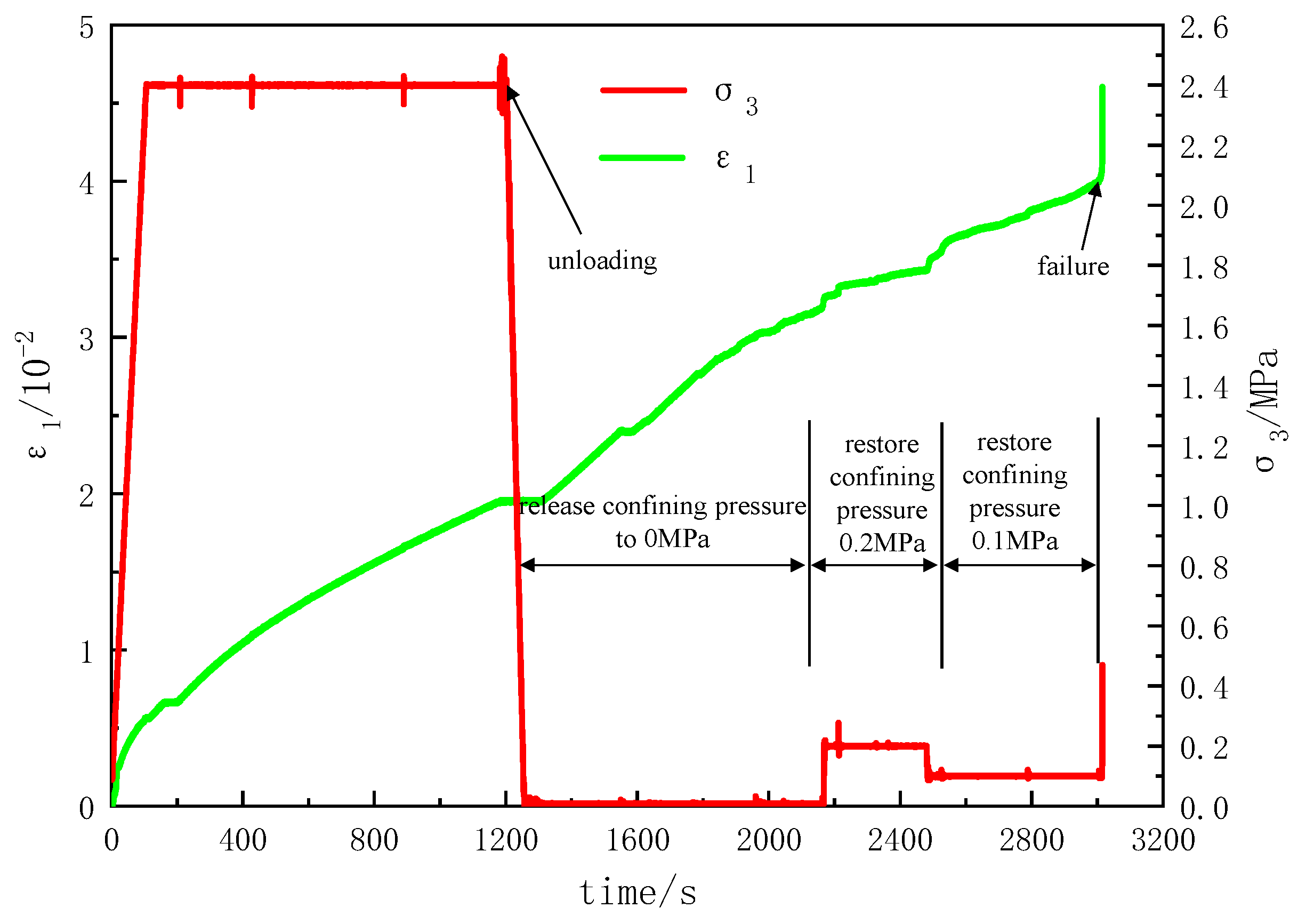

3.2. Reasonable Support and Compensation for Stress in a 600 m Deep Coal Roadway

- (1)

- Deformation law

- ①

- After three-dimensional loading, the minimum principal stress is unloaded to 0 MPa, and during the unloading process, the strain increases sharply in a short period of time, with the strain curve basically showing a vertical shape. Afterwards, the rate of the strain curve decreased and remained basically constant, but the slope of the strain curve was significantly greater than that during the three-dimensional loading period before failure.

- ②

- After unidirectional unloading of confining pressure, stress compensation is immediately changed to 0.2 MPa when the coal sample is approaching instability and failure. The strain curve quickly changes from vertical to nearly horizontal, indicating that the deformation of the coal sample increases sharply and decreases rapidly due to the effect of compensating stress. The strain remains unchanged during the pressure-maintaining process, indicating that 0.2 MPa compensating stress can maintain the stability of the coal sample.

- ③

- During the process of reducing the compensation stress to 0.1 MPa, although the strain increased in the short term, it remained almost unchanged thereafter, indicating that a compensation stress of 0.1 MPa can also maintain the stability of the coal sample.

- ④

- During the process of reducing the compensation stress to 0, the maximum principal strain of the coal sample increases sharply, and the coal sample rapidly becomes unstable and fails.

- (2)

- Acoustic emission characteristics

- ①

- During the process of the three-dimensional loading of coal samples, a small amount of acoustic emission behavior occurs, and during the stable period of three-dimensional loading, there is very little acoustic emission behavior. After the unidirectional unloading of the confining pressure, the acoustic emission behavior gradually increases until it approaches an unstable state. When the coal sample is near failure and the stress is immediately compensated to 0.2 MPa, the acoustic emission counts gradually decrease. When the compensated stress is maintained at 0.2 MPa, the acoustic emission behavior occurs only occasionally and is basically in a calm period, indicating that the compensated stress of 0.2 MPa can effectively inhibit internal crack generation and the expansion of the coal sample, and the coal sample can maintain stability.

- ②

- When the compensated stress is reduced to 0.1 MPa, only a small amount of acoustic emission behavior appears, indicating that the acoustic emission activity is still in a calm period, indicating that 0.1 MPa of compensated stress can also effectively inhibit internal crack fracture and the expansion of the coal sample, no continuous deterioration occurs, and the coal sample can still remain stable.

- ③

- When the compensation stress is reduced to 0, the acoustic emission counts suddenly increased sharply, and the coal sample quickly became unstable and damaged.

- (3)

- Sound characteristics

- ①

- After the unidirectional unloading of coal samples, the frequency and sound of cracks increase gradually. When the coal sample is near to failure, the stress is compensated to 0.2 MPa immediately, and the sound gradually disappears. Within 5 min of maintaining the 0.2 MPa compensation stress, only occasional slight sound appears, indicating that the 0.2 MPa compensation stress can restrain the further damage of the coal sample and maintain stability.

- ②

- When the compensated stress is reduced to 0.1 MPa and the pressure is stabilized for 5 min, the coal sample continues to have a slight sound, indicating that the compensated stress of 0.1 MPa can basically keep the coal sample stable, and the internal part does not crack in a wide range, but micro-cracks still occur.

- ③

- In the process of reducing the compensation stress to 0, the coal sample has a violent sound and rapidly loses stability.

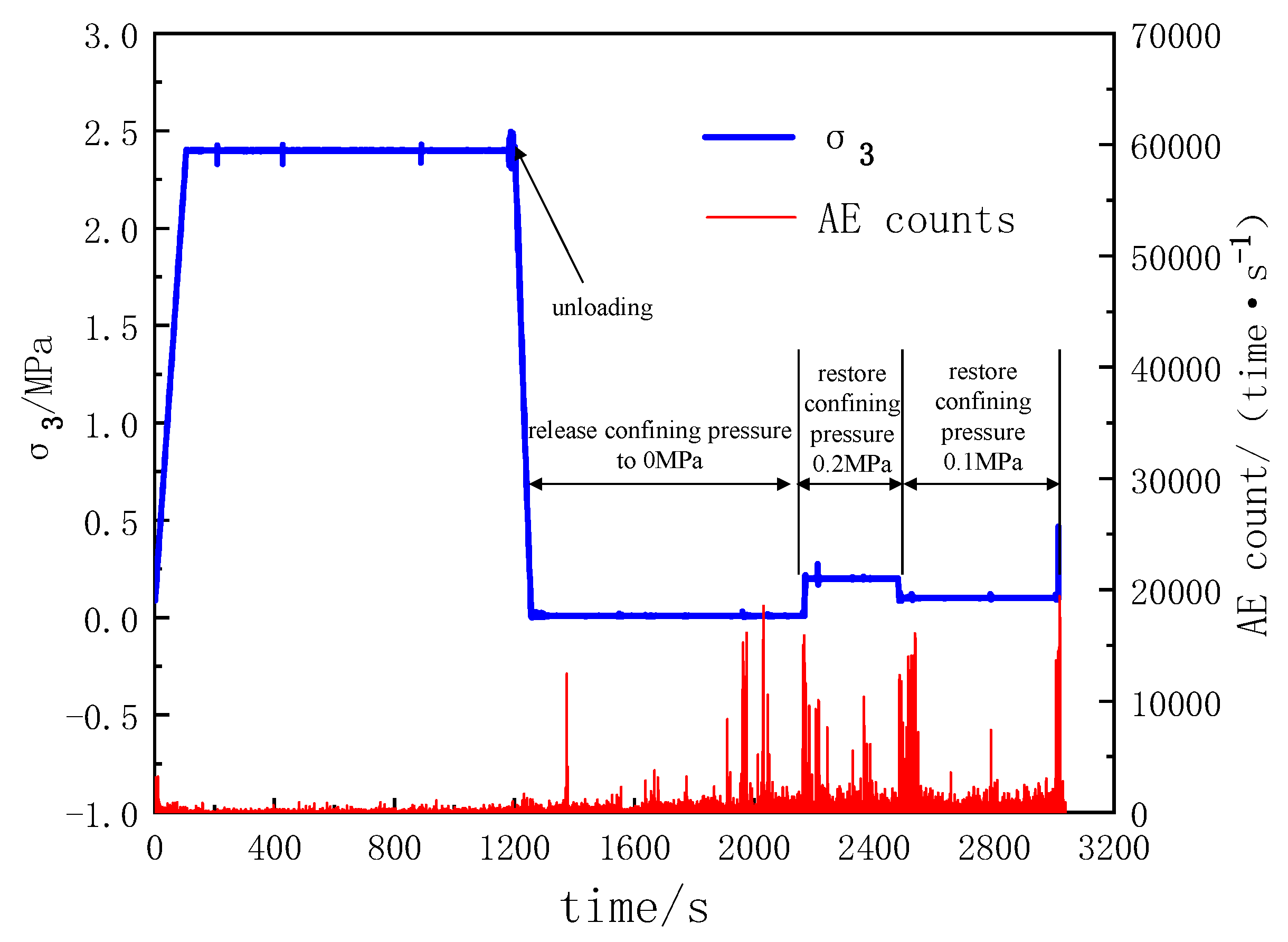

3.3. Reasonable Support and Stress Compensation for 1000 m Buried Coal Roadway

- (1)

- Deformation law

- ①

- After the three-dimensional loading is completed and the maximum principal strain remains stable, the minimum principal stress is unloaded to 0 MPa, the maximum principal strain increases rapidly, and the slope of the strain curve is significantly greater than the slope during the three-dimensional loading period before the failure.

- ②

- In the process of compensating stress to 0.2 MPa and holding for 5 min, the slope of maximum principal strain–time curve decreases by about 50%, and the strain of coal sample continues to grow slowly, but there is no damage in the short term, indicating that although the compensated stress of 0.2 MPa can keep the coal sample relatively stable, an obvious creep phenomenon has occurred.

- ③

- When the compensated stress is reduced to 0.1 MPa, the slope of the strain curve of the coal sample increases sharply and then decreases, but the slope of the strain curve is still larger than that of the 0.2 MPa stress compensation, indicating that the creep rate of the coal sample is further increased, and the coal sample becomes unstable after about 8 min. The results show that the compensation stress of 0.1 MPa can only slow down crack generation and the expansion rate of coal sample, but it cannot maintain stability.

- (2)

- Acoustic emission characteristics

- ①

- During the three-dimensional loading period, both the acoustic emission counts and the energy are low. After unidirectional unloading, the acoustic emission counts gradually increase, and the energy increases until the adjacent coal sample is destroyed.

- ②

- When the stress is immediately compensated to 0.2 MPa when the coal sample is near to failure, the acoustic emission counts and energy are significantly reduced, and the activity is also reduced, but there are still small energy acoustic emission events that occur constantly, indicating that there are still small cracks in the coal sample under the 0.2 MPa compensated stress, and the coal sample can basically maintain stability in a certain period of time.

- ③

- When the compensated stress is reduced to 0.1 MPa, the acoustic emission counts increase sharply in the process of compensation stress reduction, and then the small energy acoustic emission events continuously continue. At the 8th minute, the large energy acoustic emission is frequent, and the coal sample is unstable and destroyed.

- (3)

- Sound characteristics

- ①

- After the unidirectional unloading of the coal sample, intermittent sound is heard, and with the passage of time, the frequency of sound gradually increases, and the sound becomes louder and louder until the coal sample is near destruction.

- ②

- When the coal sample is near instability, the stress is immediately compensated to 0.2 MPa, and the sound is immediately slowed down. Within the time of maintaining the 0.2 MPa compensated stress, only a slight sound occurs, indicating that the deformation of the coal sample is relatively stable, and micro-cracks only occasionally open.

- ③

- In the process of reducing the compensation stress to 0.1 MPa, the coal sample continued to crack, and the sound slowed down in the process of maintaining pressure. At the 8 min mark, the sound of the coal sample was extremely strong, and the coal sample was unstable and damaged.

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, B.X.; Zang, N.; Jing, H.W.; Kan, J.G.; Meng, B.; Li, N.; Xie, W.B.; Jiao, J.B. Large deformation theory of rheology and structural instability of the surrounding rock in deep mining roadway. J. China Coal. Soc. 2020, 45, 911–926. [Google Scholar]

- Hou, C.J. Effective approach for surrounding rock control in deep roadway. J. China Univ. Min. Technol. 2017, 46, 467–473. [Google Scholar]

- Li, D.; Ma, S.; Lane, M.; Chang, P.; Crompton, B.; Hagen, S.A. Laboratory Investigations into the Failure Mechanisms of New Yielding and Inflatable Rockbolts Under Axial and Shearing Loading Conditions. J. Rock. Mech. Rock. Eng. 2023, 56, 565–587. [Google Scholar] [CrossRef]

- Chen, J.; Liu, L.; Zeng, B.; Tao, K.; Zhang, C.; Zhao, H.; Li, D.; Zhang, J. A Constitutive Model to Reveal the Anchorage Mechanism of Fully Bonded Bolts. J. Rock. Mech. Rock. Eng. 2023, 56, 1739–1757. [Google Scholar] [CrossRef]

- Dyczko, A.; Kamiński, P.; Jarosz, J.; Rak, Z.; Jasiulek, D.; Sinka, T. Monitoring of Roof Bolting as an Element of the Project of the Introduction of Roof Bolting in Polish Coal Mines—Case Study. Energies 2022, 15, 95. [Google Scholar] [CrossRef]

- Majcherczyk, T.; Małkowski, P.; Niedbalski, Z. Rock mass movements around development workings in various density of standing-and-roof-bolting support. J. Coal Sci. Eng. China. 2008, 14, 356–360. [Google Scholar] [CrossRef]

- Ignacio, P.R.; Andrea, M.-I.; Manuel, A.G.-F.; Mauro, M.-M.; Miguel, H.P.; Xian, E.-V.; Jordi, D.; Leandro, R.A. Size effects on the tensile strength and fracture toughness of granitic rock in different tests. J. Rock. Mech. Geotech. Eng. 2023, 15, 2179–2192. [Google Scholar]

- Cheng, P.; Kang, H.P.; Ju, W.J. Experimental study on mechanical properties of thread end of rock bolts. J. China Coal Soc. 2013, 38, 1929–1933. [Google Scholar]

- Kang, H.P. Development and prospects of support and reinforcement materials for coal mine roadways. J. Coal Sci. Technol. 2021, 49, 1–11. [Google Scholar]

- Kang, H.P.; Wu, J.X. Analysis on mechanical performance and supporting function of rock bolt plates. J. China Coal Soc. 2012, 37, 8–16. [Google Scholar]

- Yuan, G.Y.; Gao, F.Q.; Lou, J.F.; Li, J.Z.; Wang, X.Q. Experimental study on mechanical properties and force transfer mechanism of bolt supported metal mesh. J. China Coal Soc. 2022, 47, 1512–1522. [Google Scholar]

- Lin, J.; Ren, S.; Yang, J.H. Laboratory research of resin full-length anchoring bolts dimension optimization. J. China Coal Soc. 2014, 39, 1009–1015. [Google Scholar]

- Wu, Y.Z.; Kang, H.P. Failure mechanism study on tail of high strength bolt. J. China Coal Soc. 2013, 38, 1537–1541. [Google Scholar]

- Kang, H.P. Seventy years development and prospects of strata control technologies for coal mine roadways in China. J. Chin. J. Rock. Mech. Eng. 2021, 40, 1–30. [Google Scholar]

- Kang, H.P.; Jiang, T.M.; Gao, F.Q. Effect of pretensioned stress to rock bolting. J. China Coal Soc. 2007, 32, 673–678. [Google Scholar]

- Wu, Y.Z. Study on mechanical properties and compatibility of bolt components. J. Coal Sci. Technol. 2021, 49, 95–102. [Google Scholar]

- Wang, J.H.; Kang, H.P.; Gao, F.Q. Numerical simulation on load-transfer mechanisms and stress distribution characteristics of cable bolts. J. China Coal Soc. 2008, 33, 1–6. [Google Scholar]

- Kang, H.P. Sixty years development and prospects of rock bolting technology for underground coal mine roadways in China. J. China Univ. Min. Technol. 2016, 45, 1071–1081. [Google Scholar]

- Lin, J.; Shi, Y.; Sun, Z.Y.; Wang, Z.S. Large scale model test on the distribution characteristics of the prestressed field of end-anchored bolts. J. Chin. J. Rock. Mech. Eng. 2016, 35, 2237–2247. [Google Scholar]

- Gao, F.Q.; Stead, D.; Kang, H.P. Numerical simulation of squeezing failure in a coal mine roadway due to mining-induced stresses. J. Rock. Mech. Rock. Eng. 2015, 48, 1635–1645. [Google Scholar] [CrossRef]

- Chang, C.; Haimson, B.C. True triaxial strength and deformability of the KTB deep hole amphibolites. J. Geophys. Res. 2000, 105, 18999–19013. [Google Scholar] [CrossRef]

- He, M.M.; Miao, J.L.; Li, D.J.; Wang, C.G. Experimental study on rock burst processes of granite specimen at great depth. J. Chin. J. Rock. Mech. Eng. 2007, 26, 865–875. [Google Scholar]

- Tang, L.Z.; Pan, C.L.; Xie, X.B. Study on rockburst control in deep-seated hard ore deposit. J. Chin. J. Rock. Mech. Eng. 2003, 22, l067–l1071. [Google Scholar]

- Du, K.; Tao, M.; Li, X.B.; Zhou, J. Experimental study of slabbing and rockburst induced by true-triaxial unloading and local dynamic disturbance. J. Rock. Mech. Rock. Eng. 2016, 49, 3437–3453. [Google Scholar] [CrossRef]

- Yang, J.; Wang, L.J. Study on mechanism of rock burst by acousitc emission testing. J. Chin. J. Rock. Mech. Eng. 2005, 24, 3796–3802. [Google Scholar]

- Gong, F.Q.; Luo, Y.; Li, X.B.; Si, X.F.; Tao, M. Experimental simulation investigation on rockburst induced by spalling failure in deep circular tunnels. J. Tunn. Undergr. Space Technol. 2018, 81, 413–427. [Google Scholar] [CrossRef]

- Xiang, T.B.; Feng, X.T.; Chen, B.R.; Jiang, Q. True triaxial and acoustic emission experimental study of failure process of hard rock under excavating and supporting stress paths. J. Rock. Soil. Mech. 2008, 29, 500–506. [Google Scholar]

- Amadei, B.; Stephansson, O. Rock Stress and Its Measurement; Chapman & Hall: London, UK, 1997; pp. 23–94. [Google Scholar]

- Sheorey, P.R. A theory for in situ stresses in isotropic transversely isotropic rock. J. Int. J. Rock. Mech. Min. Sci. Geomech. Abstr. 1994, 31, 23–34. [Google Scholar] [CrossRef]

- Sheorey, P.R.; Murali Mohan, G.; Sinha, A. Influence of elastic constants on the horizontal in situ stress. Int. J. Rock. Mech. Min. Sci. 2001, 38, 1211–1216. [Google Scholar] [CrossRef]

- Cartwright, P.B. A Review of Recent in Situ Stress Measurements in United Kingdom COAL MEasure strata. In Proceedings of the International Symposium on Rock Stress, Kumamoto, Japan, 8–10 October 1997; pp. 469–482. [Google Scholar]

- Bai, S.W.; Li, G.Y. Research on stress field around area of Ertan hydropower station. Chin. J. Rock. Mech. Eng. 1982, 1, 45–56. [Google Scholar]

- Kang, H.P. Stress distribution characteristics and strata control technology for roadways in deep coal mines. J. Coal Sci. Technol. 2013, 41, 12–17. [Google Scholar]

- Shi, Y. Study on the Influence of Different COMPOSITE Parts on the Rockbolts Stress Field by Laboratory Studies; China Coal Research Institute: Beijing, China, 2016. [Google Scholar]

| Depth/m | σv/MPa | σH/MPa | σh/MPa |

|---|---|---|---|

| 189 | 4.73 | 11.86 | 6.2 |

| Depth/m | σv/MPa | σH/MPa | σh/MPa |

|---|---|---|---|

| 200 | 5 | 1.7 | 1.0 |

| Depth/m | σv/MPa | σH/MPa | σh/MPa |

|---|---|---|---|

| 600 | 15 | 2.6 | 1.7 |

| 1000 | 25 | 3.4 | 2.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Lin, J.; Jiang, P. True Triaxial Test and Research into Bolting Support Compensation Stresses for Coal Roadways at Different Depths. Processes 2023, 11, 3071. https://doi.org/10.3390/pr11113071

Yang J, Lin J, Jiang P. True Triaxial Test and Research into Bolting Support Compensation Stresses for Coal Roadways at Different Depths. Processes. 2023; 11(11):3071. https://doi.org/10.3390/pr11113071

Chicago/Turabian StyleYang, Jianwei, Jian Lin, and Pengfei Jiang. 2023. "True Triaxial Test and Research into Bolting Support Compensation Stresses for Coal Roadways at Different Depths" Processes 11, no. 11: 3071. https://doi.org/10.3390/pr11113071

APA StyleYang, J., Lin, J., & Jiang, P. (2023). True Triaxial Test and Research into Bolting Support Compensation Stresses for Coal Roadways at Different Depths. Processes, 11(11), 3071. https://doi.org/10.3390/pr11113071