Deformation Characteristics and Permeability Properties of Cap Rocks in Gas Storage of Depleted Reservoirs under Alternating Load

Abstract

:1. Introduction

2. Experimental Methodology

2.1. Rock Material and Sample Preparation

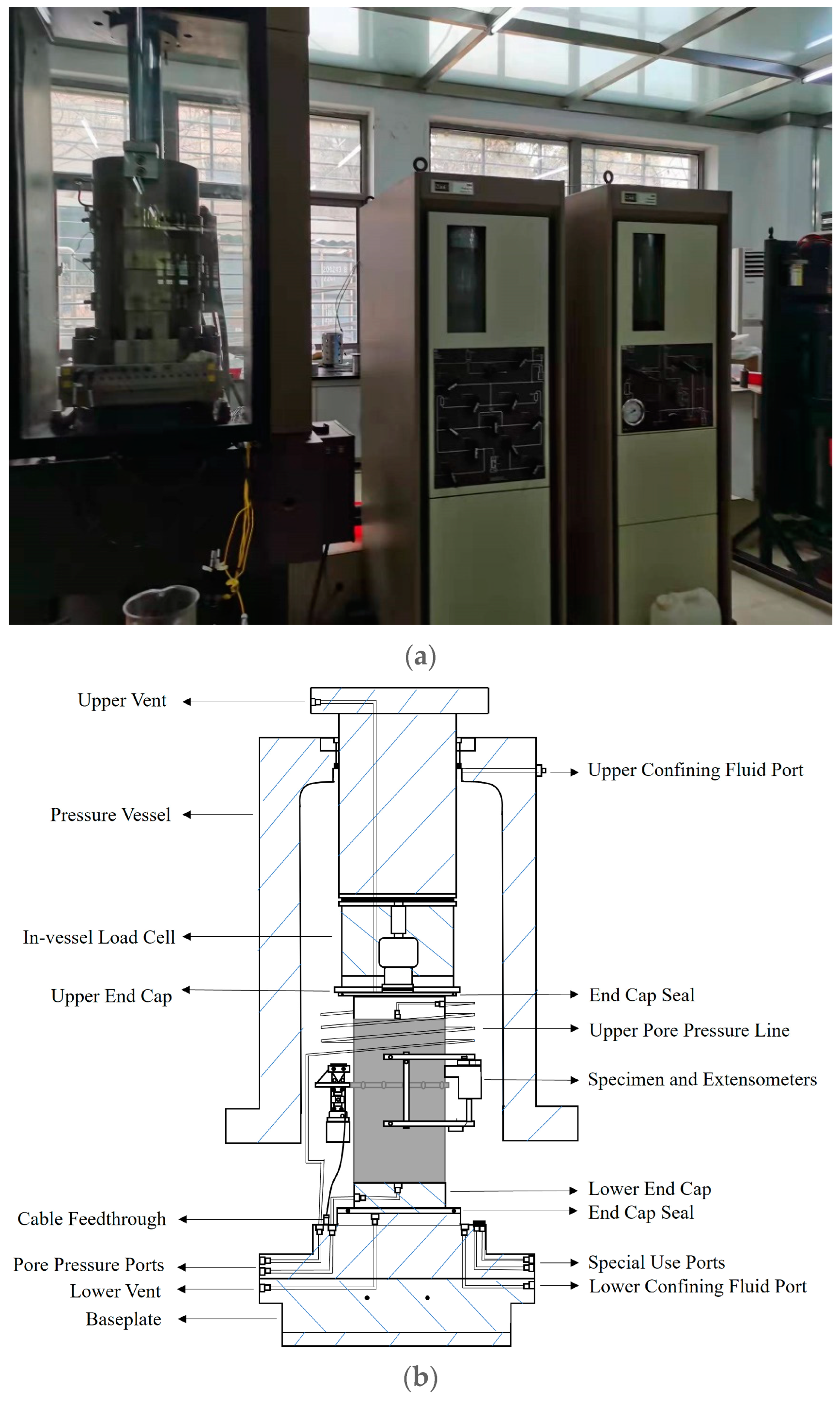

2.2. Lab Test Apparatus

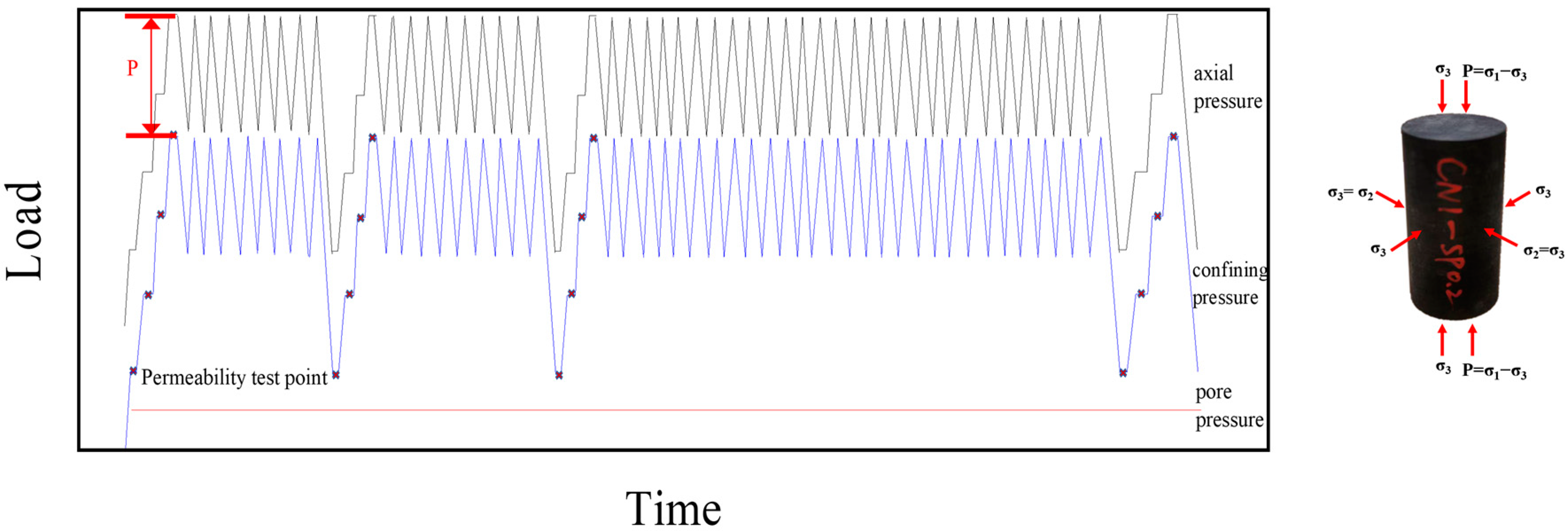

2.3. Test Scheme

2.4. Test Procedure

3. Results and Discussion

3.1. Deformation Characteristics Analysis

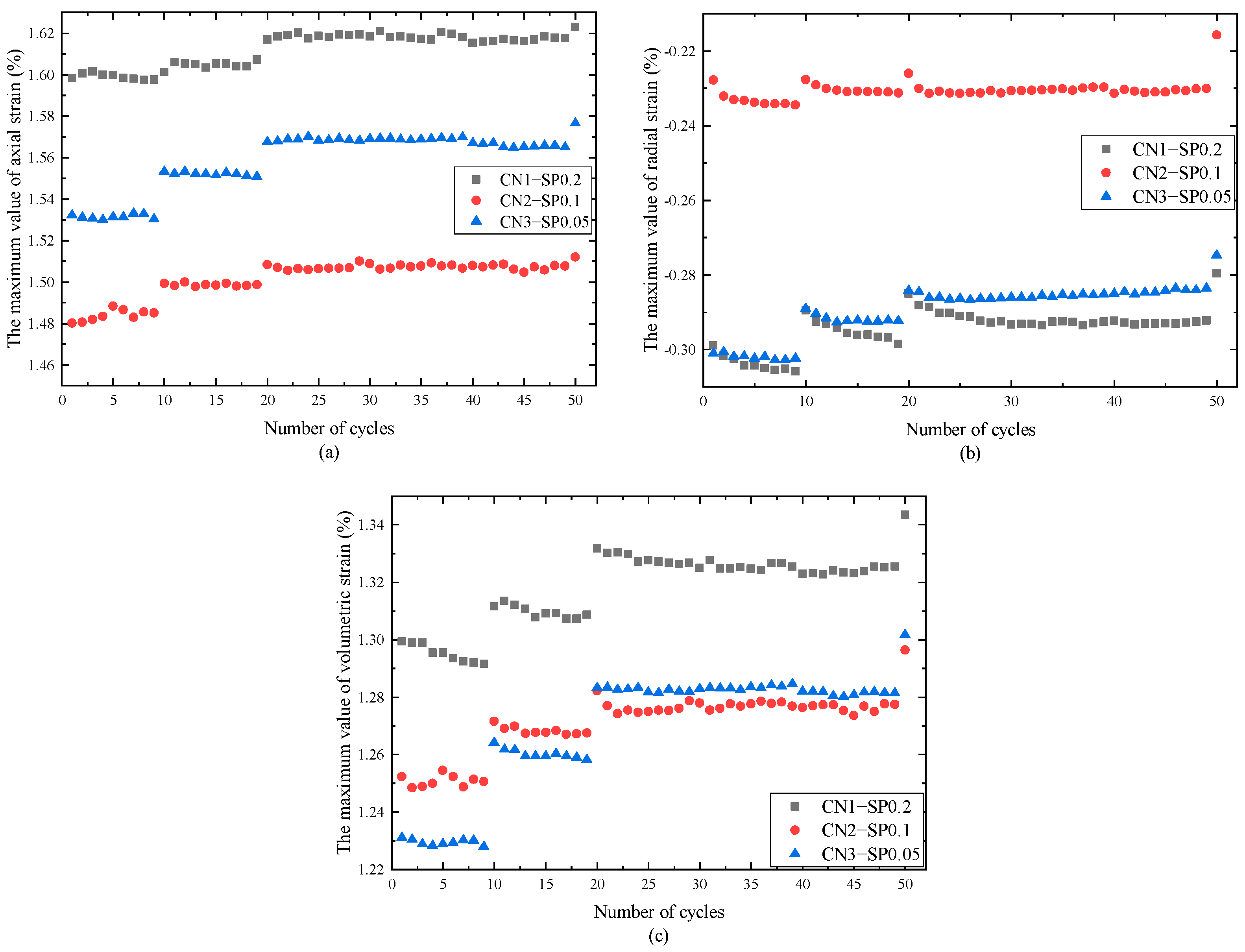

3.1.1. Analysis of Strain Characteristics in the Process of Confining Pressure Loading

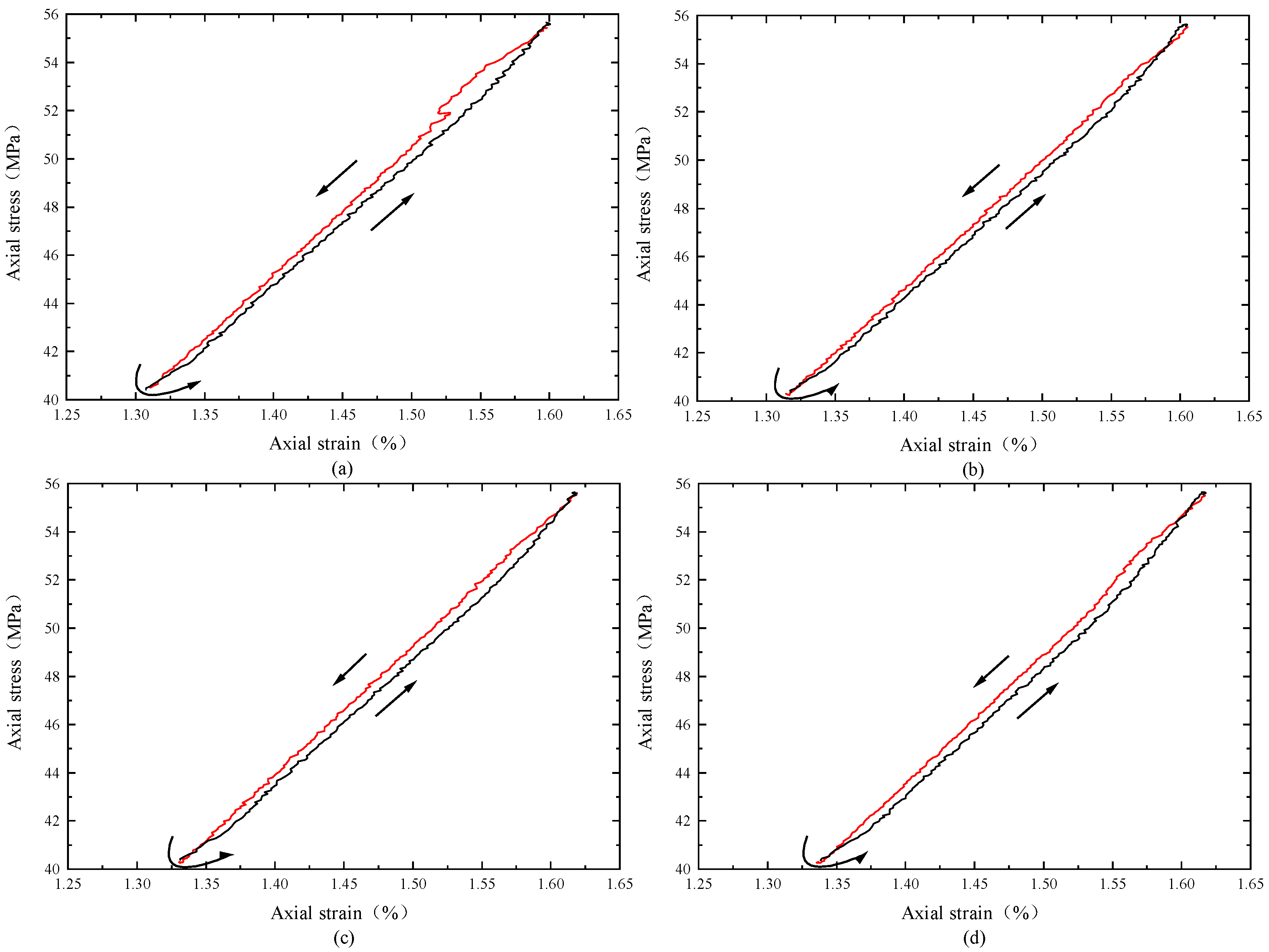

3.1.2. Hysteresis Loop Curve Analysis

3.2. Analysis of Factors Influencing Permeability

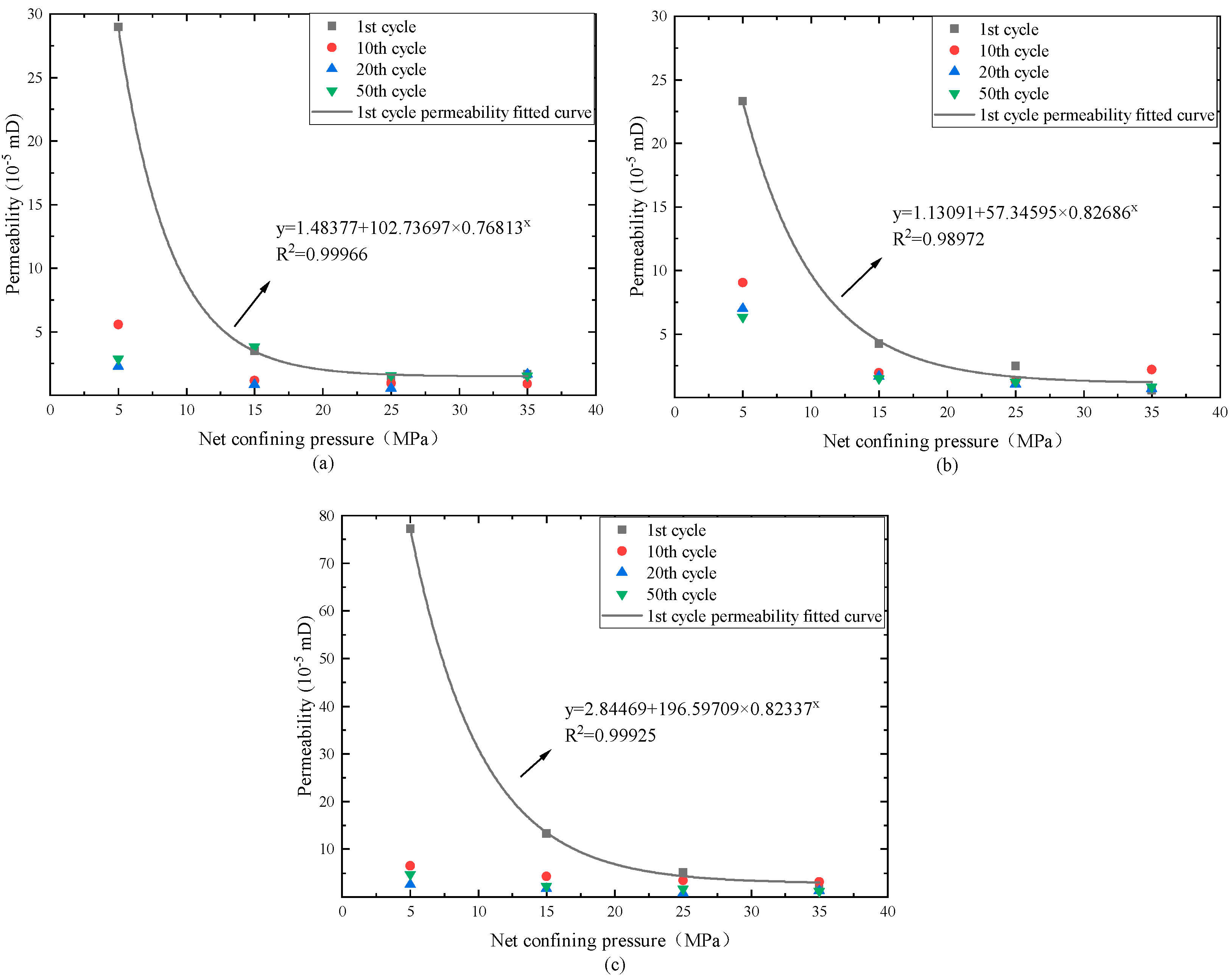

3.2.1. Relationship between Permeability and Confining Pressure

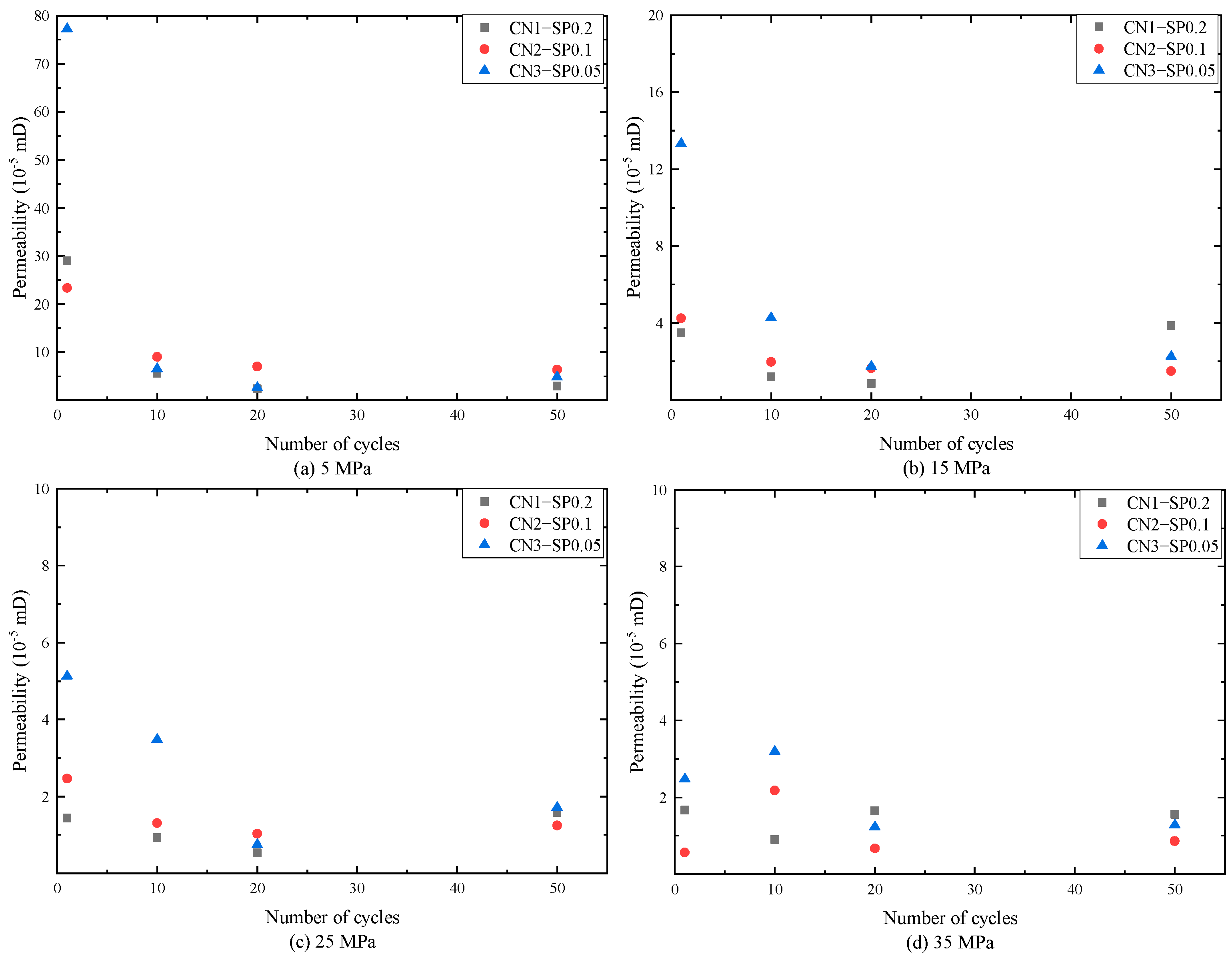

3.2.2. Relationship between Permeability and Loading/Unloading Rate

3.2.3. Relationship between Permeability and Number of Cycles

4. Conclusions

- (1)

- Only minor fluctuations in the strain maximum occur during the rapid cyclic stage of the confining pressure. Significant changes in the strain maximum occur during the steady pressure stage, where a large number of cracks and pores within the specimen are closed.

- (2)

- With the increase in the cycle number, the hysteresis loop moves in the direction of increasing axial strain, and the overall morphology appears to be elongated, indicating that the specimen is less damaged within the confining pressure range of the cycle.

- (3)

- In the first cycle, the permeability decreases negatively and exponentially with the increase in the circumferential pressure. The permeability at a net confining pressure of 35 MPa decreases by about 95% compared with that at a net confining pressure of 5 MPa. After the tenth cycle, the permeability basically remains unchanged and is maintained at a low level.

- (4)

- At low confining pressure, the permeability decreases in a negative exponential form with the increase in the number of cycles of confining pressure.

- (5)

- The greater the loading and unloading rate at the beginning of the cycle, the more the permeability decreases. The rate of loading and unloading is not the main controlling factor for permeability change in the later stages of the cycle.

- (6)

- There is a tendency for sealing improvement under cyclic loading in the gas storage of depleted reservoirs with mud shale as the cap layer. If the pressure of the cycle does not reach the fatigue damage threshold of the cap rock, the cap rock can remain intact and the sealing performance of the reservoir is guaranteed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| σ1 | First principal stress |

| σ2 | Second principal stress |

| σ3 | Third principal stress |

| P | Deviatoric stress |

| σ | Stress |

| σdmax | Maximum stress |

| σdmin | Minimum stress |

| ε | Strain |

| εdmax | Maximum strain |

| εdmin | Minimum strain |

| V | Volume of chambers |

| ΔPi | Initial differential pressure |

| ΔPf | Final differential pressure |

| Δt | Time difference |

| Ls | Length of the specimen |

| As | cross-sectional area of the specimen |

| μ | Gas viscosity |

| β | Gas compression coefficient |

| a,b,c | Parameters fitted |

| n | Cycle number |

References

- Zhang, G.X.; Li, B.; Zheng, D.W.; Ding, G.S.; Wei, H.; Qian, P.S.; Li, C. Challenges to and proposals for underground gas storage(UGS)business in China. Nat. Gas Ind. 2017, 37, 153–159. [Google Scholar] [CrossRef]

- Hong, B.; Cong, W.; Fu, D.H.; Song, Z. Lessons for China from U.S. and European natural gas storage management and pricing practices. Int. Pet. Econ. 2014, 22, 23–29, 109. [Google Scholar]

- Su, X.; Zhang, L.; Li, Y. Status and development trend of foreign underground gas storages. Nat. Gas Oil 2007, 7, 1–4. [Google Scholar]

- Evans, D.J. A review of underground fuel storage events and putting risk into perspective with other areas of the energy supply chain. Geol. Soc. Lond. Spec. Publ. 2009, 313, 173–216. [Google Scholar] [CrossRef]

- Bruno, M.S.; Lao, K.; Diessl, J.; Childers, B.; Xiang, J.; White, N.; van der Veer, E. Development of improved caprock integrity analysis and risk assessment techniques. Energy Procedia 2014, 63, 4708–4744. [Google Scholar] [CrossRef]

- Wang, S.J. Micropore Structure and Remaining Oil Distribution Characteristics of Clastic Reservoir Based on Digital Core. Master’s Thesis, Northeast Petroleum University, Daqing, China, 2023. [Google Scholar] [CrossRef]

- Zheng, D.W.; Xu, H.C.; Wang, J.M.; Sun, J.C.; Zhao, K.; Li, C.; Shi, L.; Tang, L.G. Key evaluation techniques in the process of gas reservoir being converted into underground gas storage. Pet. Explor. Dev. Online 2017, 44, 840–849. [Google Scholar] [CrossRef]

- Sun, J.C.; Xu, H.C.; Wang, J.M.; Shi, L.; Li, C.; Tang, L.G.; Zhong, R. Injection-production mechanisms and key evaluation technologies for underground gas storages rebuilt from gas reservoirs. Nat. Gas Ind. B 2018, 5, 616–622. [Google Scholar] [CrossRef]

- Fatt, I.; Davis, D.H. Reduction in Permeability With Overburden Pressure. J. Pet. Technol. 1952, 4, 16. [Google Scholar] [CrossRef]

- Zhang, D.M.; Yang, Y.S.; Chu, Y.P.; Zhang, X.; Xue, Y.G. Influence of loading and unloading velocity of confining pressure on strength and permeability characteristics of crystalline sandstone. Results Phys. 2018, 9, 1363–1370. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Zhang, L.M.; Sun, H.; Zhang, Y.H.; Kuang, S.Y. Experimental study of mechanical properties of limestone under different unloading velocities. Rock Soil Mech. 2011, 32, 1045–1050, 1277. [Google Scholar] [CrossRef]

- Dong, J.J.; Hsu, J.Y.; Wu, W.J.; Shimamoto, T.; Hung, J.H.; Yeh, E.C.; Wu, Y.H.; Sone, H. Stress-dependence of the permeability and porosity of sandstone and shale from TCDP Hole-A. Int. J. Rock Mech. Min. Sci. 2010, 47, 1141–1157. [Google Scholar] [CrossRef]

- Liu, H.; Wang, W.H.; Chen, M.J.; Hu, X.H.; Guo, Y.D.; Zeng, Y. Research on the stress sensitivity experiment of Fuling Longmaxi shale reservoirs. Petrochem. Ind. Technol. 2019, 26, 155–158. [Google Scholar] [CrossRef]

- Zhang, G.Q.; Fan, Z.W.; Zeng, D.Q.; Zhang, J.F.; Mao, H.J.; Mi, L.D.; Jia, Y.W.; Yang, X.S.; Jing, X. Damage law of reservoir cap rock of gas storage under alternating load. Fault-Block Oil Gas Field 2021, 28, 769–774. [Google Scholar]

- Jiang, C.B.; Duan, M.K.; Yin, G.Z.; Wang, J.G.; Lu, T.Y.; Xu, J.; Zhang, D.M.; Huang, G. Experimental study on seepage properties, AE characteristics and energy dissipation of coal under tiered cyclic loading. Eng. Geol. 2017, 221, 114–123. [Google Scholar] [CrossRef]

- Meng, Q.B.; Liu, J.F.; Ren, L.; Pu, H.; Chen, Y.L. Experimental Study on Rock Strength and Deformation Characteristics Under Triaxial Cyclic Loading and Unloading Conditions. Rock Mech. Rock Eng. 2021, 54, 777–797. [Google Scholar] [CrossRef]

- Chu, Y.P.; Sun, H.T.; Zhang, D.M. Experimental study on evolution in the characteristics of permeability, deformation, and energy of coal containing gas under triaxial cyclic loading-unloading. Energy Sci. Eng. 2019, 7, 2112–2123. [Google Scholar] [CrossRef]

- Feng, X.T.; Gao, Y.H.; Zhang, X.W.; Wang, Z.F.; Zhang, Y.; Han, Q. Evolution of the mechanical and strength parameters of hard rocks in the true triaxial cyclic loading and unloading tests. Int. J. Rock Mech. Min. Sci. 2020, 131, 104349. [Google Scholar] [CrossRef]

- Yuan, X.; Zhang, J.W. Deformation and permeability characteristic of outburst coal under step unloading conditions. J. China Coal Soc. 2017, 42, 1451–1457. [Google Scholar] [CrossRef]

- Zhang, L.Y.; Zhang, Q.Y.; Yang, S.Y.; Sui, B.; Yang, W.D.; Wang, Y.F.; Wang, C.; Yuan, S.B. Analysis of unloading confining pressure triaxial rheological tests of diabase in Dagangshan Dam side. J. Cent. South Univ. (Sci. Technol.) 2015, 46, 1034–1042. [Google Scholar] [CrossRef]

- Ma, X.H.; Zheng, D.W.; Shen, R.C.; Wang, C.Y.; Luo, J.H.; Sun, J.C. Key technologies and practice for gas field storage facility construction of complex geological conditions in China. Pet. Explor. Dev. 2018, 45, 507–520. [Google Scholar]

- Wei, G.Q.; Zheng, Y.L.; Qiu, X.S.; Sun, J.C.; Shi, L.; Lai, X. Geological theory and application of underground gas storage in China. Acta Pet. Sin. 2019, 40, 1519–1530. [Google Scholar] [CrossRef]

- Chen, J.; Du, C.; Jiang, D.Y.; Fan, J.Y.; He, Y. The mechanical properties of rock salt under cyclic loading-unloading experiments. Geomech. Eng. 2016, 10, 325–334. [Google Scholar] [CrossRef]

- Roberts, L.A.; Buchholz, S.A.; Mellegard, K.D.; Düsterloh, U. Cyclic Loading Effects on the Creep and Dilation of Salt Rock. Rock Mech. Rock Eng. 2015, 48, 2581–2590. [Google Scholar] [CrossRef]

- Miao, S.J.; Duan, Y.X.; Liu, C.K.; Lu, X.A. Mechanical characteristics of siltstone under staged cyclic unloading-loading confining pressure. J. Civ. Environ. Eng. 2022, 91, 1–9. [Google Scholar]

| Mineral Composition | Quartz | Potash Feldspar | Plagioclase | Calcite | Dolomite | Clay Minerals |

|---|---|---|---|---|---|---|

| Content (%) | 35.4 | 8.6 | 4.1 | 21.5 | 5.8 | 24.6 |

| Specimen ID | Confining Pressure (MPa) | Pore Pressure (MPa) | Deviatoric Stress (MPa) | Confining Pressure Loading Rate (MPa/s) |

|---|---|---|---|---|

| CN1−SP0.2 | 25−40 | 5 | 15 | 0.2 |

| CN2−SP0.1 | 25−40 | 5 | 15 | 0.1 |

| CN3−SP0.05 | 25−40 | 5 | 15 | 0.05 |

| Specimen ID | Fitting Equation between Permeability and Number of Cycles at a Net Confining Pressure of 5 MPa | R2 |

|---|---|---|

| CN1−SP0.2 | 0.99762 | |

| CN2−SP0.1 | 0.9991 | |

| CN3−SP0.05 | 0.99804 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ying, Q.; Wang, D.; Zhang, H.; Guo, Y.; Liu, H.; Song, Y.; Chang, X. Deformation Characteristics and Permeability Properties of Cap Rocks in Gas Storage of Depleted Reservoirs under Alternating Load. Processes 2023, 11, 3114. https://doi.org/10.3390/pr11113114

Ying Q, Wang D, Zhang H, Guo Y, Liu H, Song Y, Chang X. Deformation Characteristics and Permeability Properties of Cap Rocks in Gas Storage of Depleted Reservoirs under Alternating Load. Processes. 2023; 11(11):3114. https://doi.org/10.3390/pr11113114

Chicago/Turabian StyleYing, Qiqi, Duocai Wang, Hong Zhang, Yintong Guo, Hejuan Liu, Yujia Song, and Xin Chang. 2023. "Deformation Characteristics and Permeability Properties of Cap Rocks in Gas Storage of Depleted Reservoirs under Alternating Load" Processes 11, no. 11: 3114. https://doi.org/10.3390/pr11113114