Flow Potential Analysis-Based Gas Channeling Control for Enhanced Artificial Gas Cap Drive in Fractured-Vuggy Reservoirs

Abstract

:1. Introduction

2. Methods

2.1. Theory

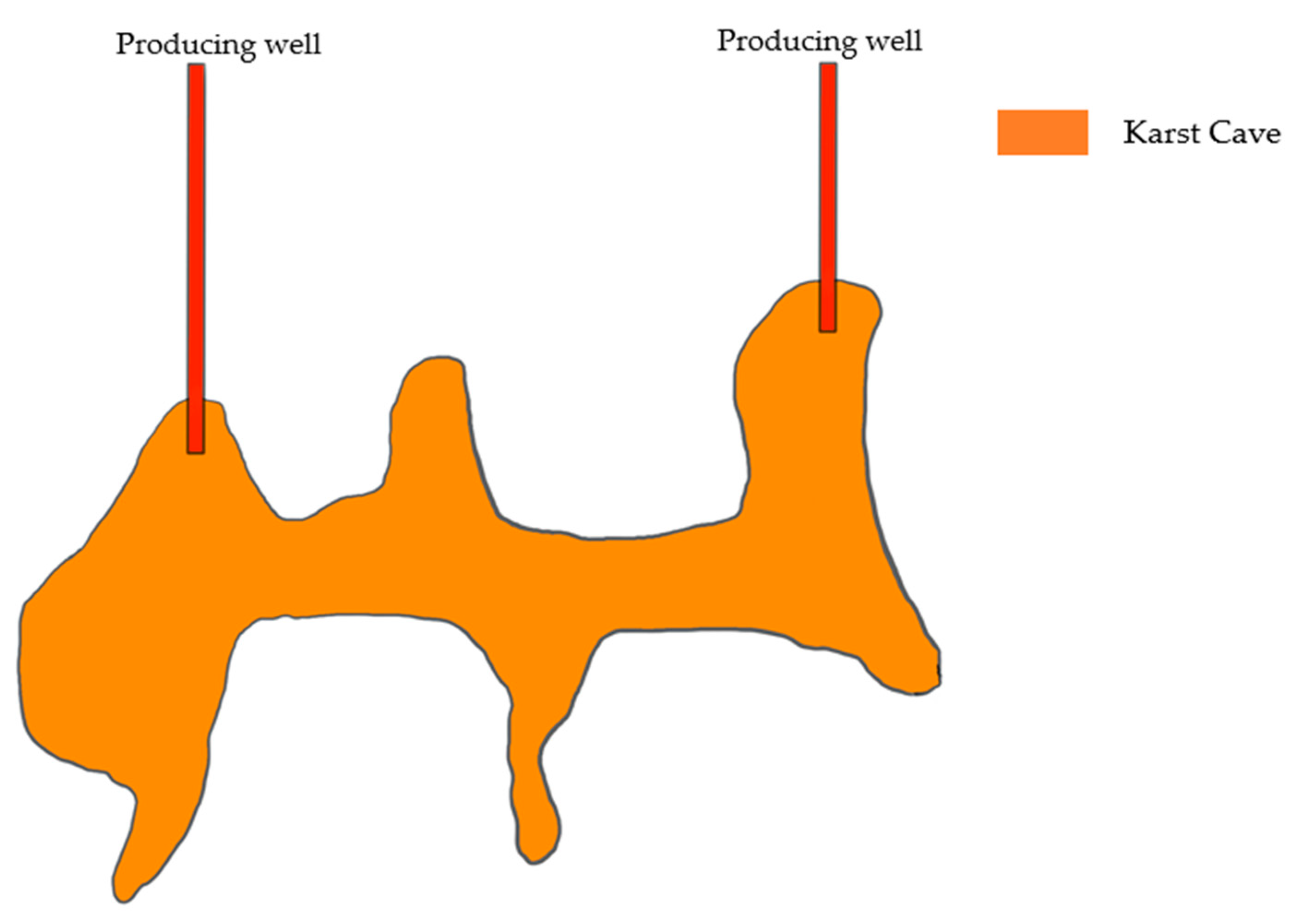

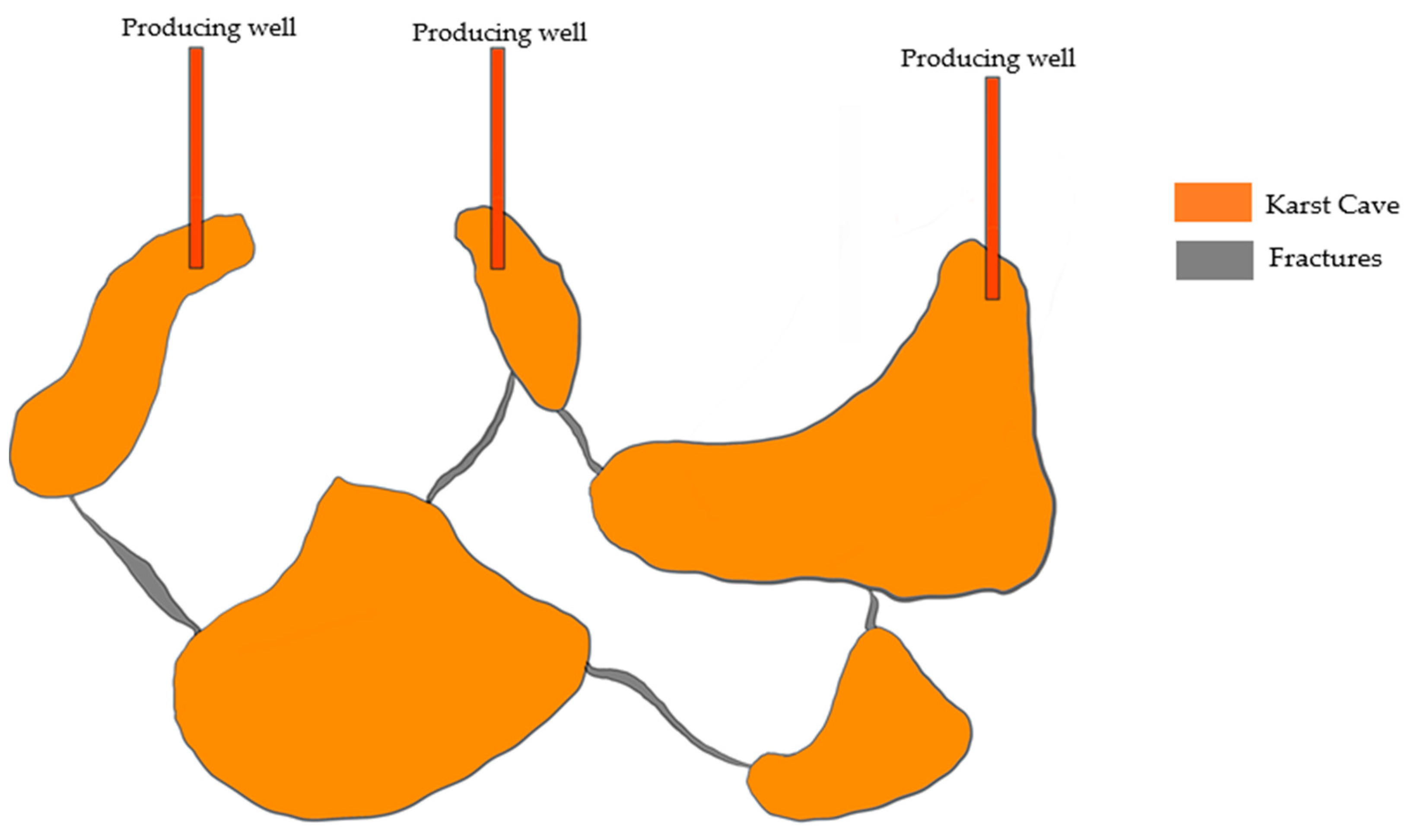

2.2. Establishment of Mechanism Model

2.3. Simulation of Gas Channeling Flow Potential in Fractured-Vuggy Reservoir

2.3.1. Variation Law of Flow Potential Difference under Different Energy of Position and Energy of Pressure

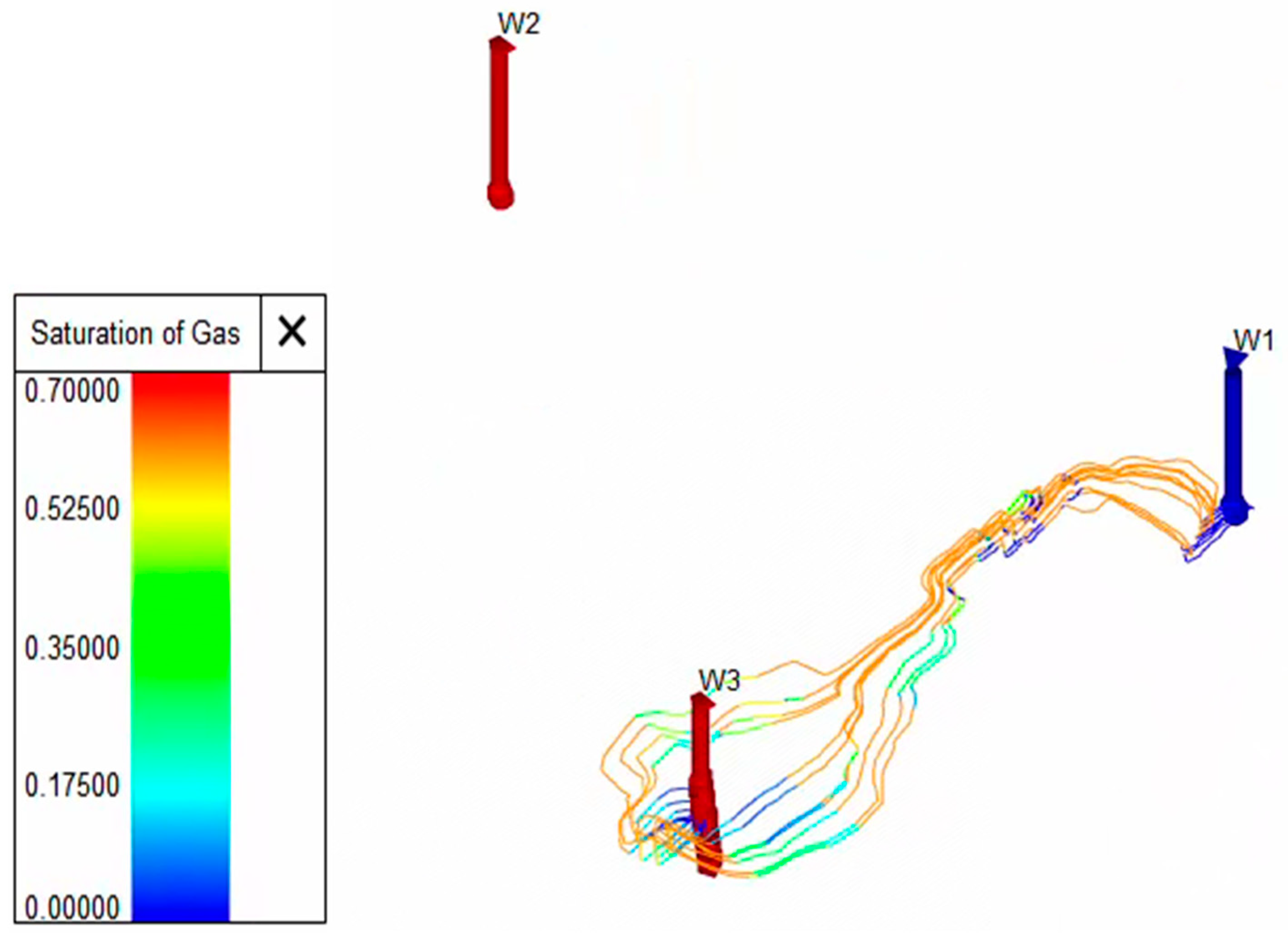

2.3.2. Simulation of Gas Channeling under Different Flow Potential Difference Ratios between Injection and Production Wells

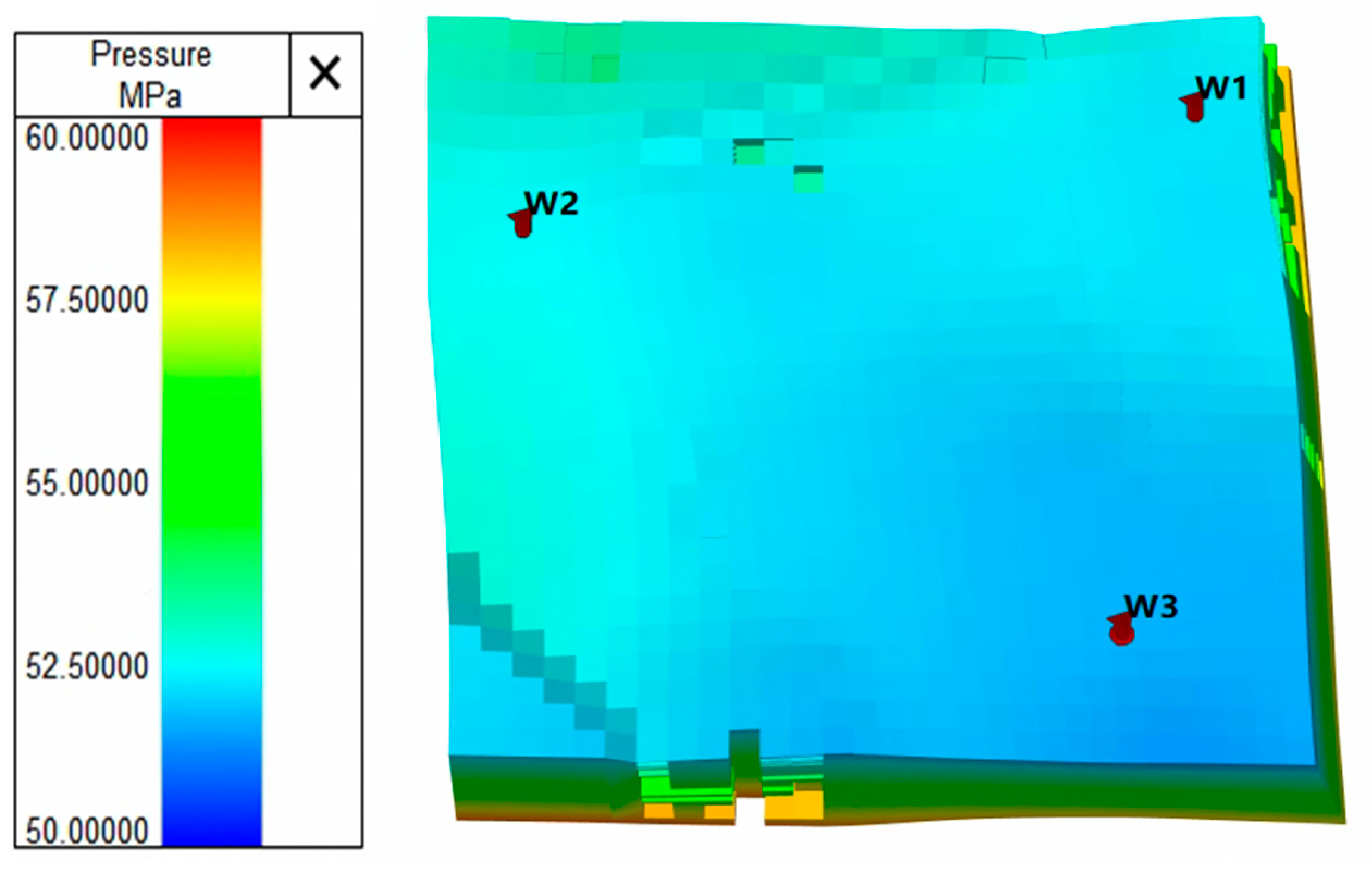

2.4. Numerical Simulation of Gas Channeling Control in Oilfield A

3. Simulation Results

3.1. Law of Gas Channeling Flow Potential in the Fractured-Vuggy Reservoir

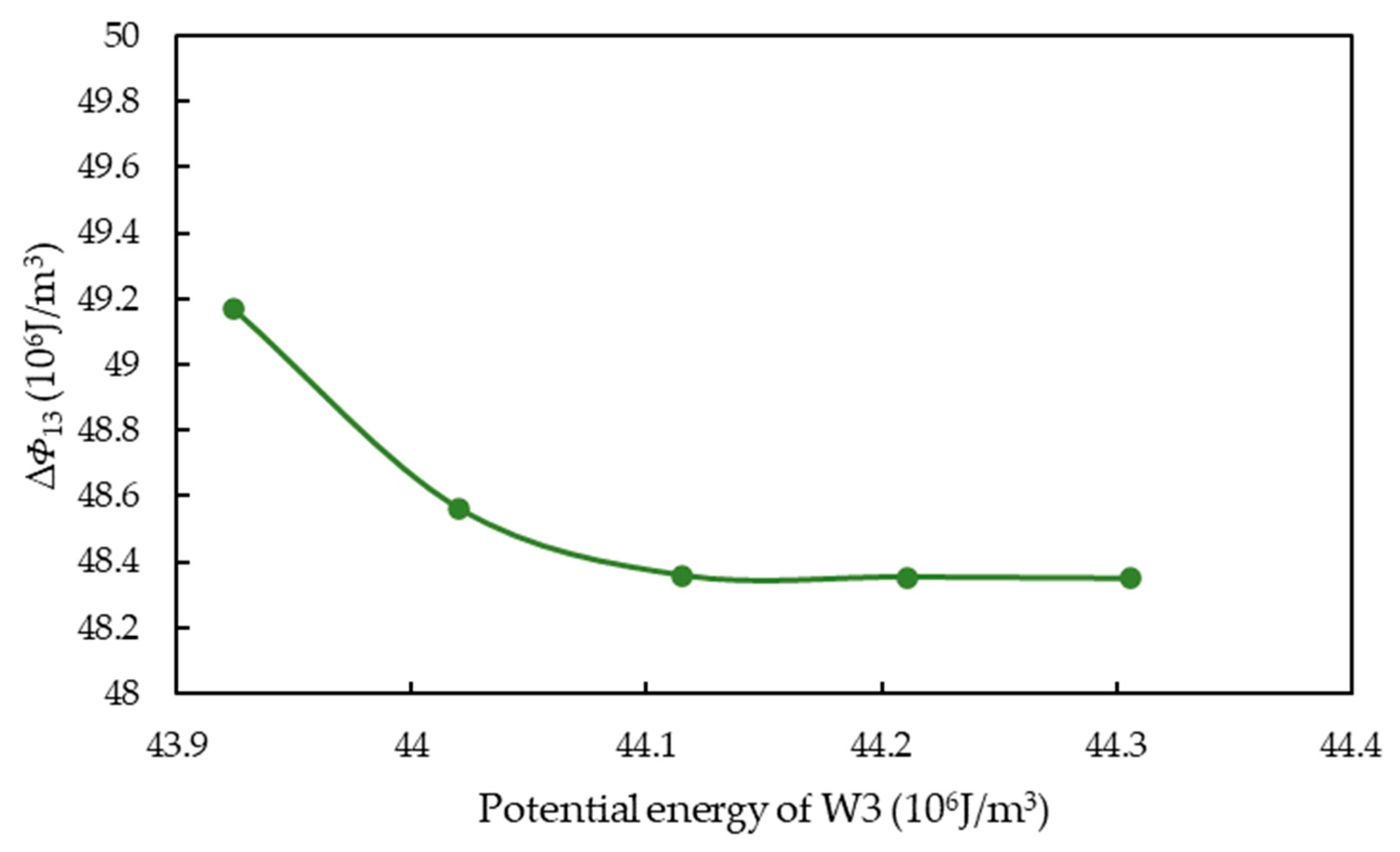

3.1.1. Variation Law of Flow Potential Difference under Different Potential Energy

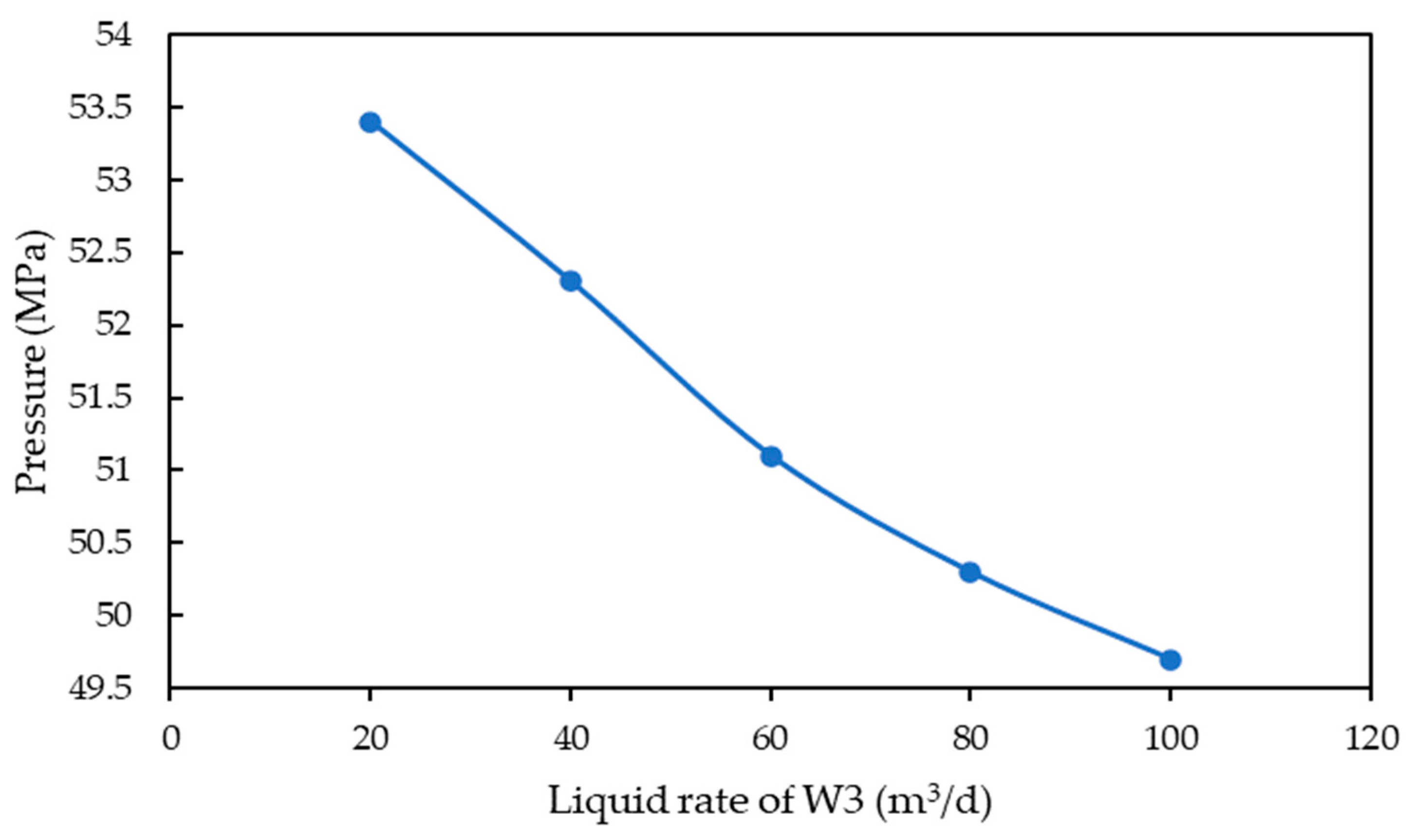

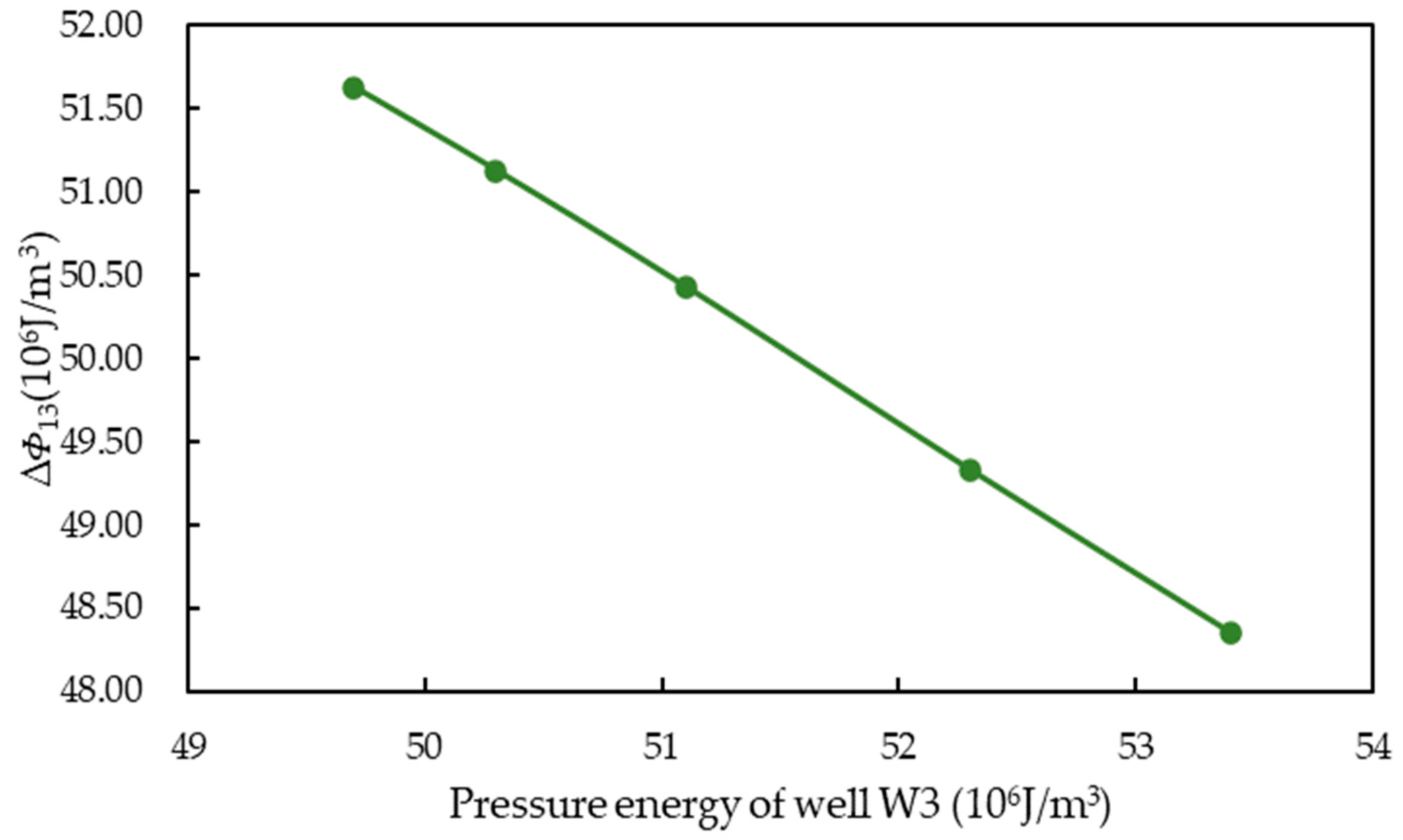

3.1.2. Variation Law of Flow Potential Difference under Different Pressure Energy

3.1.3. Gas Channeling under Different Flow Potential Difference Ratios

3.2. Simulation Results of Gas Channeling Control in Oilfield A

4. Discussion

4.1. Control Countermeasures of Gas Channeling Potential in Fractured-Vuggy Reservoir

4.1.1. Position Energy Regulation

4.1.2. Pressure Energy Regulation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Φ | Flow potential (J/m3) |

| Fluid potential difference between Well W1 and Well W2 (J/m3) | |

| Fluid potential difference between Well W1 and Well W3 (J/m3) | |

| σ | Interfacial tension (N/m) |

| θ | Wetting angle (°) |

| r | capillary radius (m) |

| g | Acceleration of gravity (9.8 m/s2) |

| ν | Velocity of flow (m/s) |

| ρ | Fluid density (kg/m3) |

| z | Distance of the measuring point from the datum (m) |

| z1 | Distances of Well W1 from the datum (m) |

| z2 | Distances of Well W2 from the datum (m) |

| z3 | Distances of Well W3 from the datum (m) |

| P | Pressure of the measuring point (Pa) |

| P1 | Measuring point pressure of W1 (Pa) |

| P2 | Measuring point pressure of W2 (Pa) |

| P3 | Measuring point pressure of W3 (Pa) |

| W1 | Gas injection well named W1 in mechanism model |

| W2 | Production well named W2 in mechanism model |

| W3 | Production well named W3 in mechanism model |

| G1 | Gas injection well named G1 in Oilfield A |

| T1 | Production well named T1 in Oilfield A |

| T4 | Production well named T2 in Oilfield A |

References

- Tong, X.; Zhang, G.; Wang, Z.; Wen, Z.; Tian, Z.; Wang, H.; Ma, F.; Wu, Y. Distribution and potential of global oil and gas resources. Pet. Explor. Dev. 2018, 45, 727–736. [Google Scholar] [CrossRef]

- Cheng, X. Study on Gas Injection Displacement Mechanism and Optimization of Injection-Production Parameters in Fractured-Vuggy Reservoir Unit. Ph.D. Thesis, Southwest Petroleum University, Chengdu, China, 2017. [Google Scholar] [CrossRef]

- Jin, Y.; Zhang, H.; Liu, Y.; Ji, Y. Discussion on development characteristics and typical karst model of strata-bound karst reservoir in Tahe oilfield. Earth Sci. Front. 2023, 30, 1–18. [Google Scholar] [CrossRef]

- Hu, W.; Li, X.; Yang, M.; Lu, X.; Liu, X.; Liu, H. Well pattern optimization of carbonate fractured-vuggy reservoir in Tahe oilfield. Xinjiang petroleum geology. Xinjiang Pet. Geol. 2023, 44, 429–434. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Q.; Li, B.; Liu, Z. Dynamic Characterization of Different Reservoir Types for a Fractured-Caved Carbonate Reservoir. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 24–27 April 2017. [Google Scholar] [CrossRef]

- Qin, G.; Bi, L.; Popov, P.; Efendiev, Y.; Espedal, M.S. An Efficient Upscaling Process Based on a Unified Fine-scale Multi-Physics Model for Flow Simulation in Naturally Fracture Carbonate Karst Reservoirs. In Proceedings of the International Oil and Gas Conference and Exhibition in China, Beijing, China, 8–10 June 2010. [Google Scholar] [CrossRef]

- Alblooshi, Y.A.; Wojtanowicz, A.K. Dynamic Water Control in Naturally Fractured Bottom Water-Drive Reservoirs via Downhole Water Sink Well Deployment: First Experimental Study. In Proceedings of the SEG/AAPG/EAGE/SPE Research and Development Petroleum Conference and Exhibition, Abu Dhabi, United Arab Emirates, 9–10 May 2018. [Google Scholar] [CrossRef]

- Lu, X.; Rong, Y.; Li, X.; Wu, F. Construction of injection-production well pattern in carbonate fractured-vuggy reservoir and its development significance—Taking Tahe oil field as an example. Pet. Nat. Gas Geol. 2017, 38, 658–664. [Google Scholar] [CrossRef]

- Dou, Z. Development Technology of Carbonate Slope-Cave Reservoir in Tahe Oilfield; Petroleum Industry Press: Beijing, China, 2012; pp. 61–68. [Google Scholar]

- Meng, Z.; Sun, S.Z. Integrated connectivity analysis for complex carbonate reservoir. In Proceedings of the 2018 SEG International Exposition and Annual Meeting, Anaheim, CA, USA, 14–19 October 2018. [Google Scholar] [CrossRef]

- Davletbaev, A.; Baikov, V.; Doe, T.; Emchenko, O.; Zainulin, A.; Igoshin, A.; Fedorov, A. Fracture-Based Strategies for Carbonate Reservoir Development. In Proceedings of the SPE Russian Oil and Gas Conference and Exhibition, Moscow, Russia, 26–28 October 2010. [Google Scholar] [CrossRef]

- Zhao, C.; Song, Z.; Yao, Y.; Li, Y.; Liu, Q.; Qi, M.; Hou, J.; Xu, L.; Han, B.; Song, L. Effect of Water-Alternating-Gas Injection on Gas and Water Production Control in Carbonate Reservoirs. In Proceedings of the Carbon Management Technology Conference, Houston, TX, USA, 15–18 July 2019. [Google Scholar] [CrossRef]

- Li, Q.; Wang, F.; Wang, Y.; Forson, K.; Cao, L.; Zhang, C.; Zhou, C.; Zhao, B.; Chen, J. Experimental investigation on the high-pressure sand suspension and adsorption capacity of guar gum fracturing fluid in low-permeability shale reservoirs: Factor analysis and mechanism disclosure. Environ. Sci. Pollut. Res. 2022, 29, 53050–53062. [Google Scholar] [CrossRef] [PubMed]

- Su, W.; Hou, J.; Zhao, F.; Xi, Y.; Zhao, T.; Ding, B. Feasibility and Influencing Factors of Oil Tolerant Nitrogen Foam on EOR Effect in the Fractured-Vuggy Carbonate Reservoir. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 13–16 November 2017. [Google Scholar] [CrossRef]

- Li, Y.; Wang, D.; Liu, Z.; Ma, X. Development Strategy Optimization of Gas Injection Huff and Puff for Fractured-Caved Carbonate Reservoirs. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 25–28 April 2016. [Google Scholar] [CrossRef]

- Zhang, H.; Ju, B.; Liu, Z.; Song, C.; Zhu, G. Feasibility analysis of nitrogen-assisted gravity flooding in fractured-vuggy reservoir. Fault Block Oil Gas Field 2022, 29, 399–403. [Google Scholar]

- Li, M. Experimental Study on the Mechanism of Nitrogen-Assisted Gravity Flooding in Fractured-Vuggy Reservoir. Master’s Thesis, China University of Petroleum, Beijing, China, 2022. [Google Scholar] [CrossRef]

- Qu, M.; Hou, J.; Zhao, F.; Song, Z.; Ma, S.; Wang, Q.; Li, M.; Yang, M. 3-D Visual Experiments on Fluid Flow Behavior of Water Flooding and Gas Flooding in Fractured-Vuggy Carbonate Reservoir. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 9–11 October 2017. [Google Scholar] [CrossRef]

- Liu, Z.; Hou, J.; Li, J.; Cheng, Q. Study of Residual Oil in Tahe 4th Block Karstic/Fractured Heavy Oil Reservoir. In Proceedings of the North Africa Technical Conference and Exhibition, Cairo, Egypt, 20–22 February 2012. [Google Scholar] [CrossRef]

- Zhang, S. Study on remaining oil type and production mode of fractured-vuggy reservoir. J. Guangdong Inst. Pet. Chem. Eng. 2023, 33, 13–16+21. [Google Scholar] [CrossRef]

- Zhao, L. Study on Technical Countermeasures of Artificial Gas Top Drive in Fault Block Reservoir. Master’s Thesis, China University of Petroleum, Beijing, China, 2021. [Google Scholar] [CrossRef]

- Kirby, J.E.; Stamm, H.E.; Schnitz, L.B. Calculation of the Depletion History and Future Performance of a Gas-Cap-Drive Reservoir. Trans. AIME 1957, 210, 218–226. [Google Scholar] [CrossRef]

- Daltaban, T.S.; Noyola, A.; Trejo, G.; Toledo, R. An Investigation into the Technical Feasibility of Gas Injection into Fractured CHUC Reservoir in the Gulf of Mexico. In Proceedings of the SPE International Petroleum Conference and Exhibition in Mexico, Villahermosa, Mexico, 10–12 February 2002. [Google Scholar] [CrossRef]

- Wang, Z.; Hou, J.; Yang, Y.; Zhu, G. Experimental study on the effect of water saturation of filling medium in fractured-vuggy reservoir on the dissolution and diffusion of CO2 and N2. Spec. Oil Gas Reserv. 2022, 29, 91–98. [Google Scholar] [CrossRef]

- Ma, B.; Bai, W.; Xiao, M.; Hu, J. Field test of nitrogen artificial gas cap oil displacement in the small-scale sandstone reservoir with high porosity, high permeability and strong edge water—By taking Chun 22 well block of Chunguang oilfield as an example. Pet. Geol. Eng. 2020, 34, 69–73. [Google Scholar] [CrossRef]

- Tan, T.; Guo, C.; Chen, Y.; Dou, L.; Hui, J. Study and practice on enhanced oil recovery mechanism of N2 flooding in fractured-vuggy reservoir with high temperature and high pressure. Oil Gas Reserv. Eval. Dev. 2020, 10, 60–64. [Google Scholar]

- Soliz, J.; Enab, K.; Lopez, I.; Elmasry, Y. Experimental Investigation of Gas Injection Performance with Different Fluid Types. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Houston, TX, USA, 20–22 June 2022. [Google Scholar] [CrossRef]

- Hou, J.; Zhang, L.; Li, H.; Li, W.; Yuan, D.; Yuan, Y.; Zheng, Z.; Luo, M. Influencing factors on EOR nitrogen flooding in fractured-vuggy carbonate reservoir. Oil Gas Geol. Oil Recovery 2015, 22, 64–68. [Google Scholar] [CrossRef]

- Li, Q.; Han, Y.; Liu, X.; Ansari, U.; Cheng, Y.; Yan, C. Hydrate as a by-product in CO2 leakage during the long-term sub-seabed sequestration and its role in preventing further leakage. Environ. Sci. Pollut. Res. 2022, 29, 77737–77754. [Google Scholar] [CrossRef] [PubMed]

- Cui, C.; Yan, D.; Yao, T.; Wang, J.; Zhang, C.; Wu, Z. Prediction method of migration law and gas channeling time of CO2 flooding front: A case study of G89-1 Block in Shengli Oilfield. Pet. Reserv. Eval. Dev. 2022, 12, 741–747. [Google Scholar] [CrossRef]

- Peng, H.; Chen, Z.; Tian, J.; Liu, D.; Xin, Z. Discrimination method and control countermeasure of circulating gas injection gas channeling in Dalaoba. West-China Explor. Eng. 2016, 28, 93–95. [Google Scholar] [CrossRef]

- England, W.A.; Mackenzie, A.S.; Mann, D.M.; Quigley, T.M. The movement and entrapment of petroleum fluids in the subsurface. J. Geol. Soc. 1987, 144, 327–347. [Google Scholar] [CrossRef]

- Ren, W. Application of flow potential control in water control and oil stabilization of fractured-vuggy carbonate reservoirs. Lithol. Reserv. 2019, 31, 127–134. [Google Scholar] [CrossRef]

- Du, C.H.; Qiu, H.; Chen, X.F.; Tian, L.; Yue, P.; Li, L.; Yao, J.B.; Wei, B. Application of flow potential analysis technique based on numerical simulation in the development of fractured-vuggy reservoir. Pet. Reserv. Eval. Dev. 2020, 10, 83–89. [Google Scholar] [CrossRef]

(106 J/m3) | (106 J/m3) | Initial Gas-Oil Ratio | W3 Gas-Oil Ratio in April 2024 | |

|---|---|---|---|---|

| 0.972 | 46.98 | 35.12 | 34.62 | |

| 48.35 | ||||

| 0.952 | 46.98 | 257.47 | ||

| 49.33 | ||||

| 0.932 | 46.98 | 261.70 | ||

| 50.43 | ||||

| 0.919 | 46.98 | 499.33 | ||

| 51.13 | ||||

| 0.910 | 46.98 | 690.03 | ||

| 51.63 |

| Well Name | Z (m) | P (MPa) | (kg/m3) | (kg/m3) | (106 J/m3) | (106 J/m3) | (106 J/m3) | |

|---|---|---|---|---|---|---|---|---|

| G1 | −4557.5 | 54.9 | 977 | 1.25 | 44.27 | 45.93 | <0 | 0.964 |

| T1 | −4535.5 | 54.0 | ||||||

| T4 | −4614.4 | 53.1 |

| Well Name | Z (m) | P (MPa) | (kg/m3) | (kg/m3) | (106 J/m3) | (106 J/m3) | (106 J/m3) | |

|---|---|---|---|---|---|---|---|---|

| G1 | −4557.5 | 54.6 | 977 | 1.25 | 45.808 | 45.257 | >0 | 0.988 |

| T1 | −4612.6 | 52.9 | ||||||

| T4 | −4586.4 | 53.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, J.; Hu, R.; Xin, X.; Lu, H.; Yu, G. Flow Potential Analysis-Based Gas Channeling Control for Enhanced Artificial Gas Cap Drive in Fractured-Vuggy Reservoirs. Processes 2023, 11, 3301. https://doi.org/10.3390/pr11123301

Ye J, Hu R, Xin X, Lu H, Yu G. Flow Potential Analysis-Based Gas Channeling Control for Enhanced Artificial Gas Cap Drive in Fractured-Vuggy Reservoirs. Processes. 2023; 11(12):3301. https://doi.org/10.3390/pr11123301

Chicago/Turabian StyleYe, Jinxi, Rongrong Hu, Xiankang Xin, Hao Lu, and Gaoming Yu. 2023. "Flow Potential Analysis-Based Gas Channeling Control for Enhanced Artificial Gas Cap Drive in Fractured-Vuggy Reservoirs" Processes 11, no. 12: 3301. https://doi.org/10.3390/pr11123301

APA StyleYe, J., Hu, R., Xin, X., Lu, H., & Yu, G. (2023). Flow Potential Analysis-Based Gas Channeling Control for Enhanced Artificial Gas Cap Drive in Fractured-Vuggy Reservoirs. Processes, 11(12), 3301. https://doi.org/10.3390/pr11123301