Analyzing Local Shear Rate Distribution in a Dual Coaxial Mixing Bioreactor Handling Herschel–Bulkley Biopolymer Solutions through Computational Fluid Dynamics

Abstract

:1. Introduction

2. Material and Methods

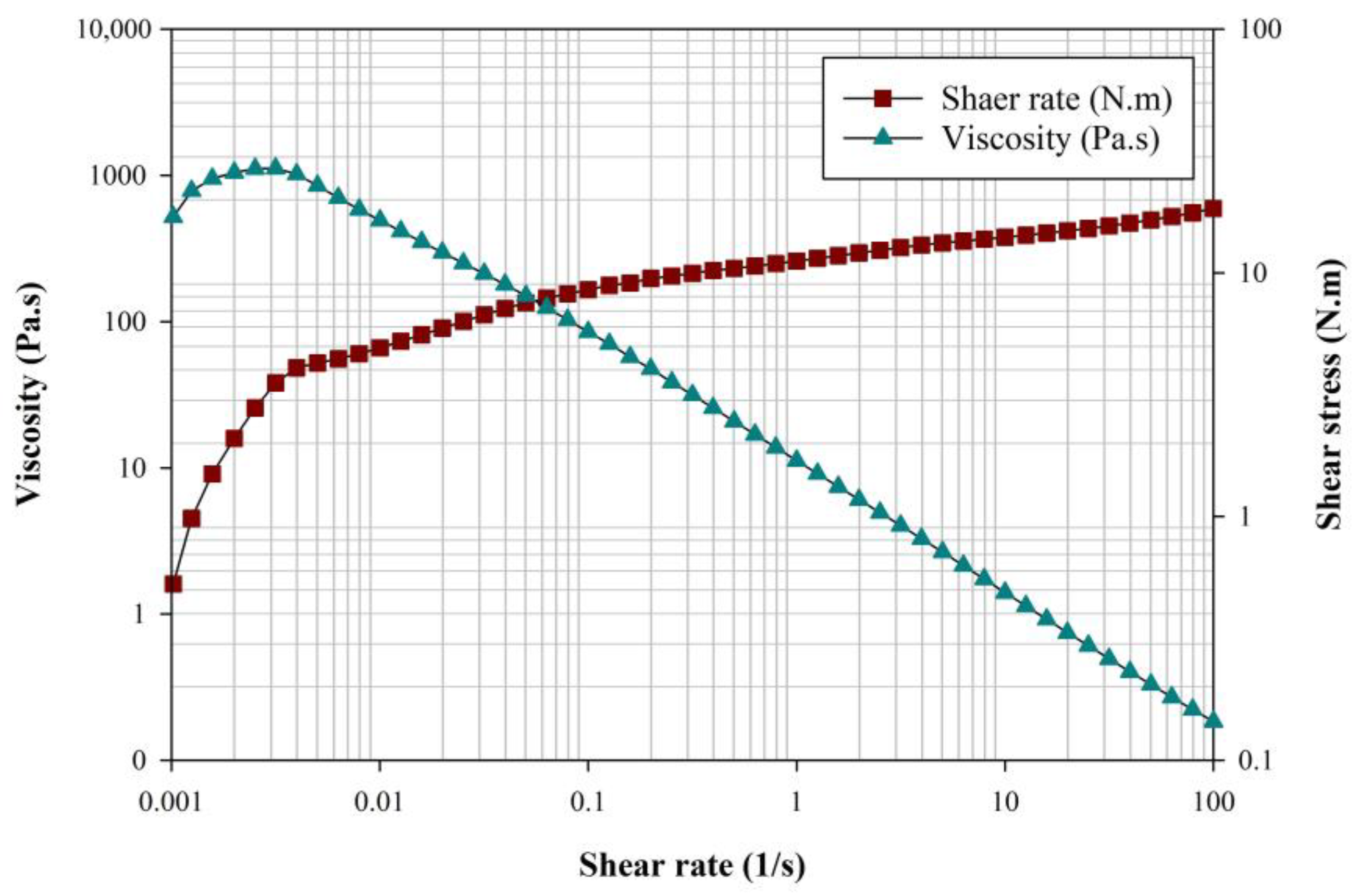

2.1. Working Liquid

2.2. Electrical Resistance Tomography (ERT)

2.3. Numerical Model

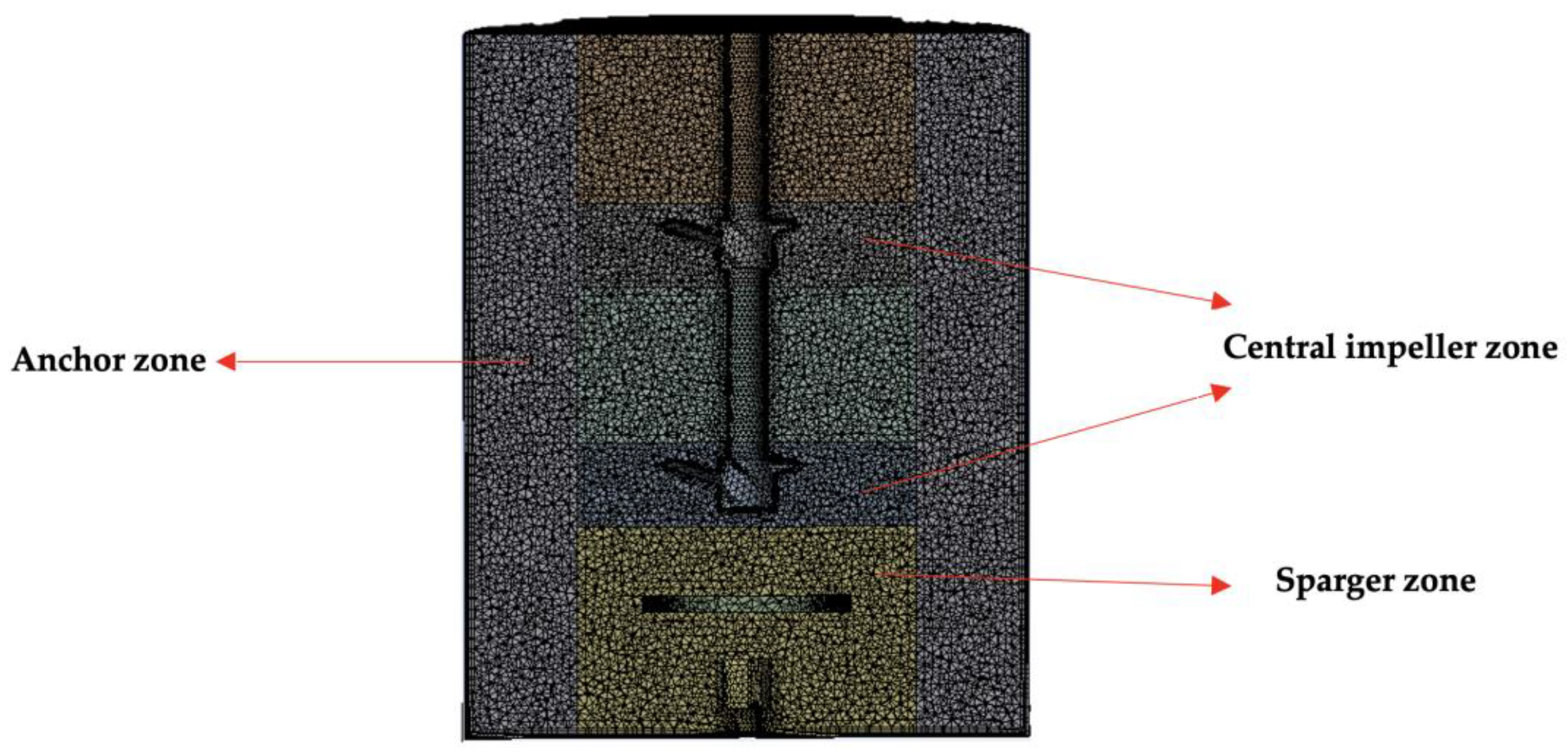

2.4. CFD Model

3. Results and Discussion

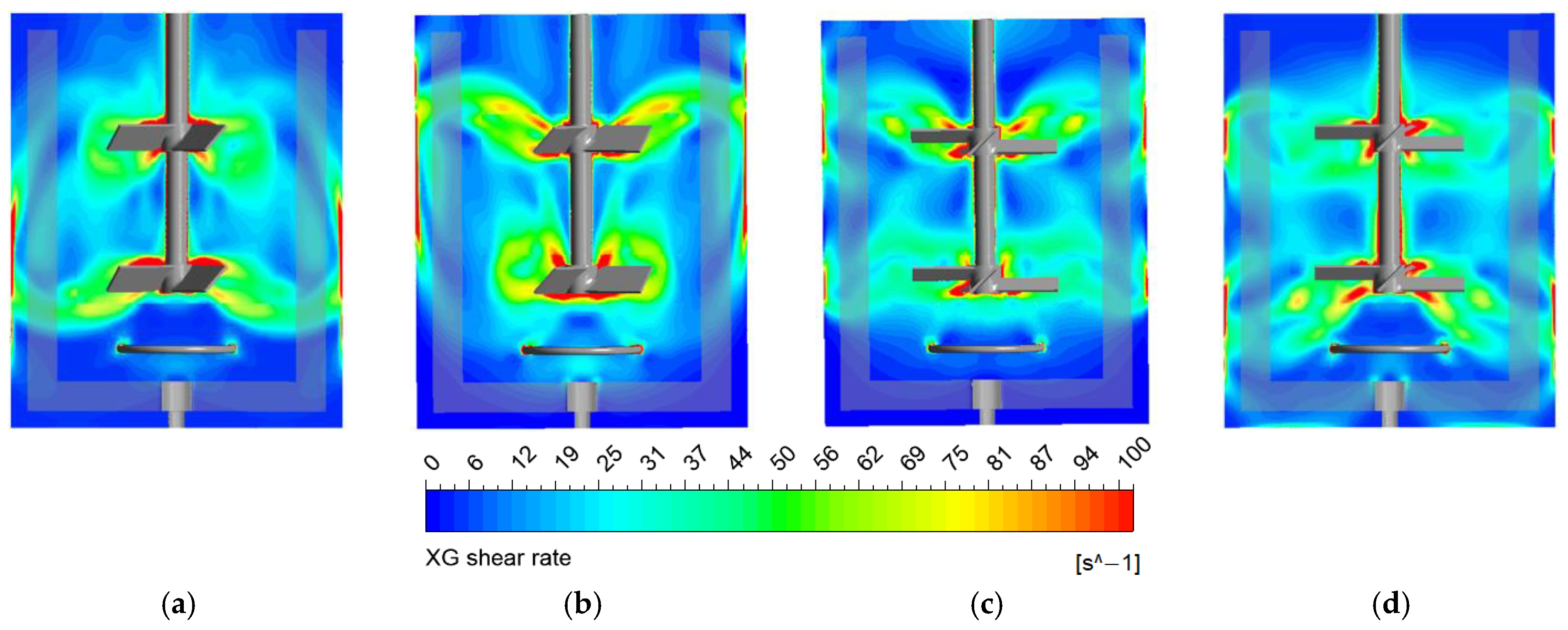

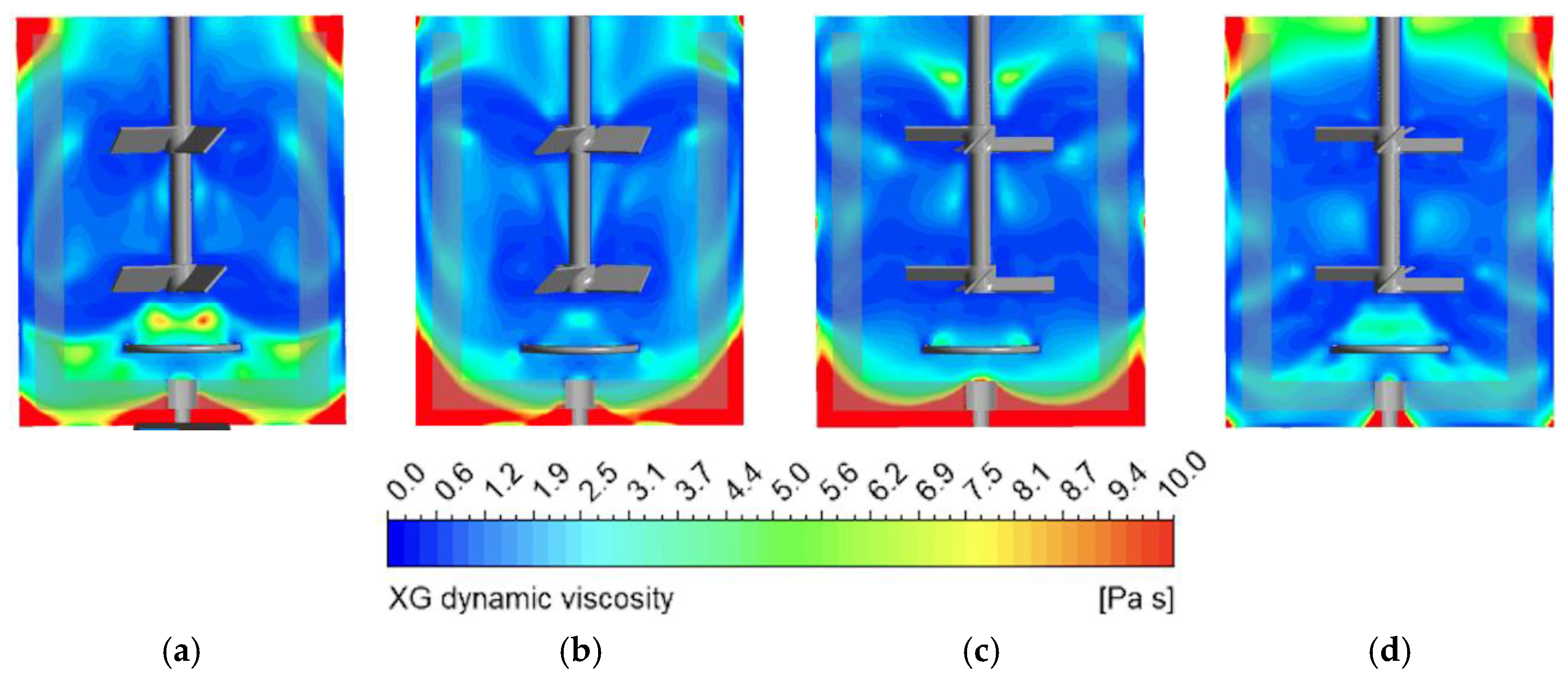

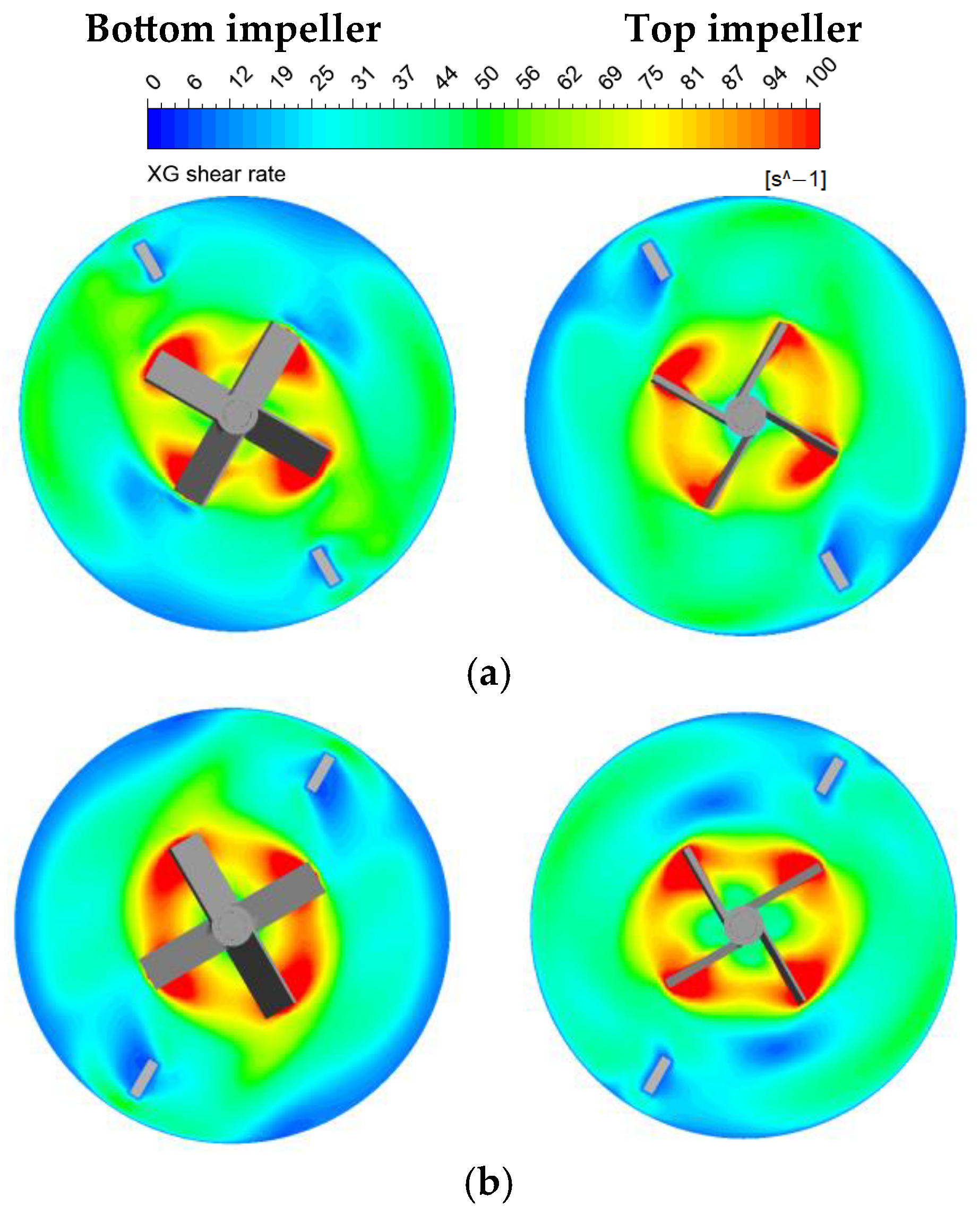

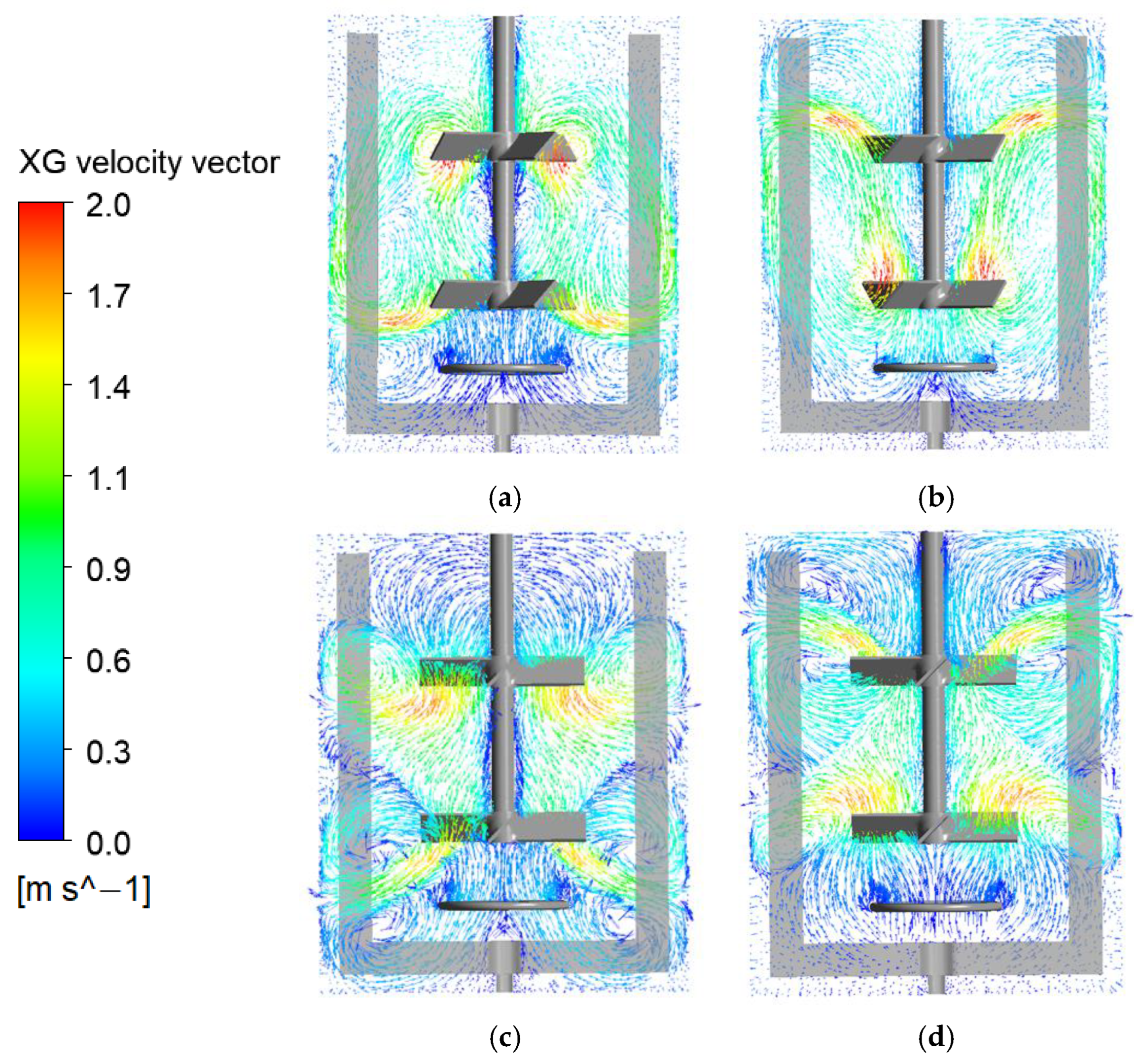

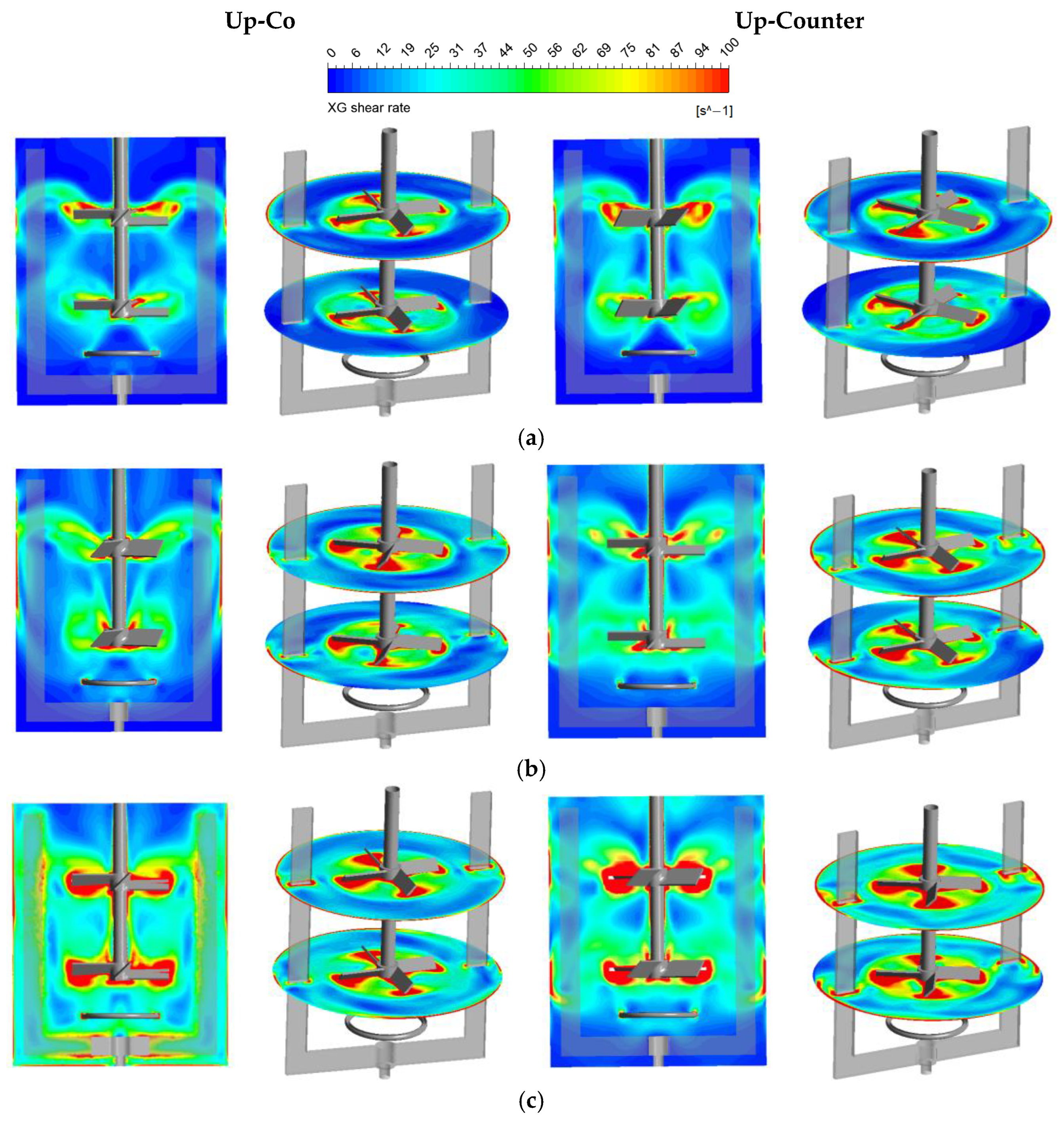

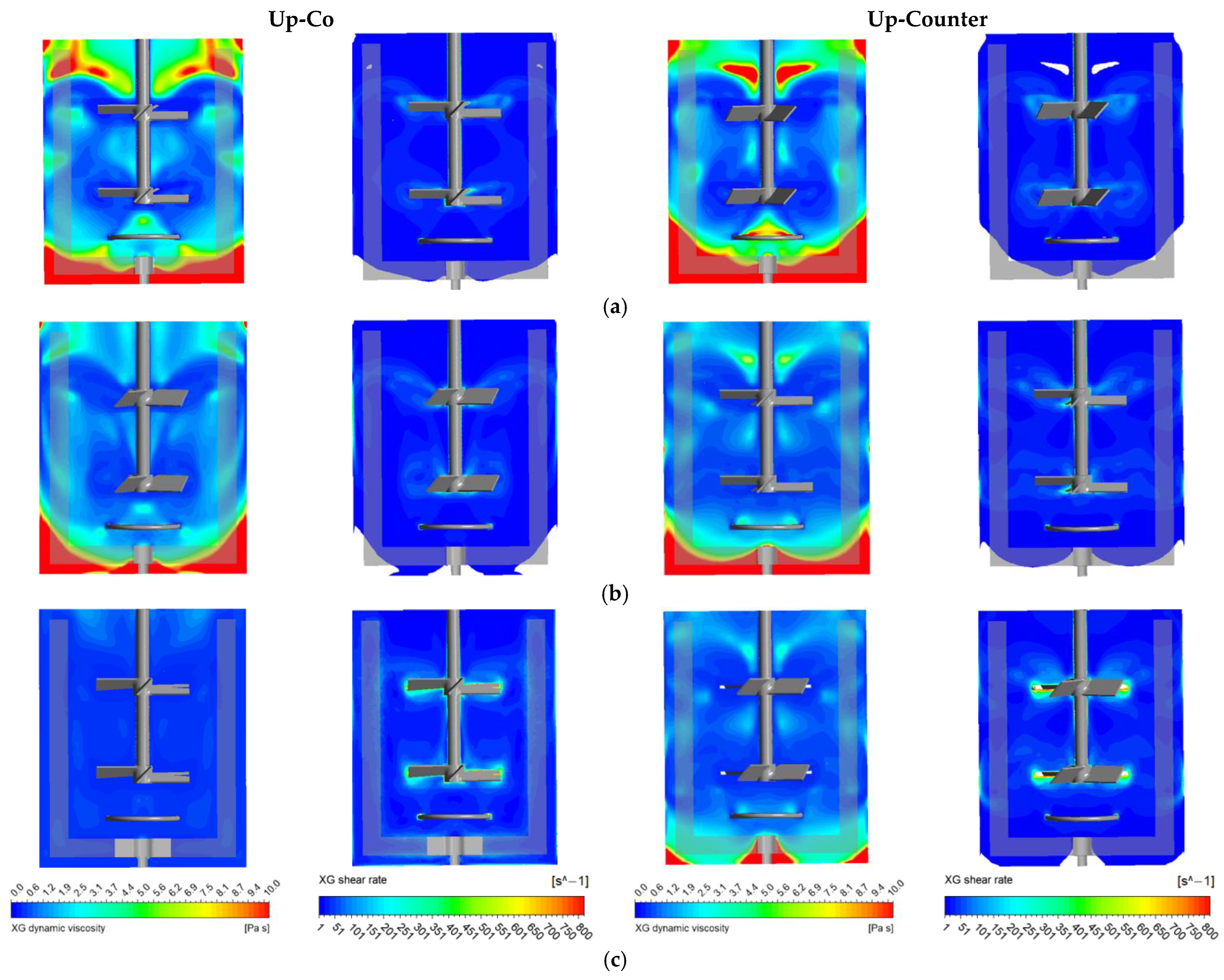

3.1. Comparing Different Mixing Configurations

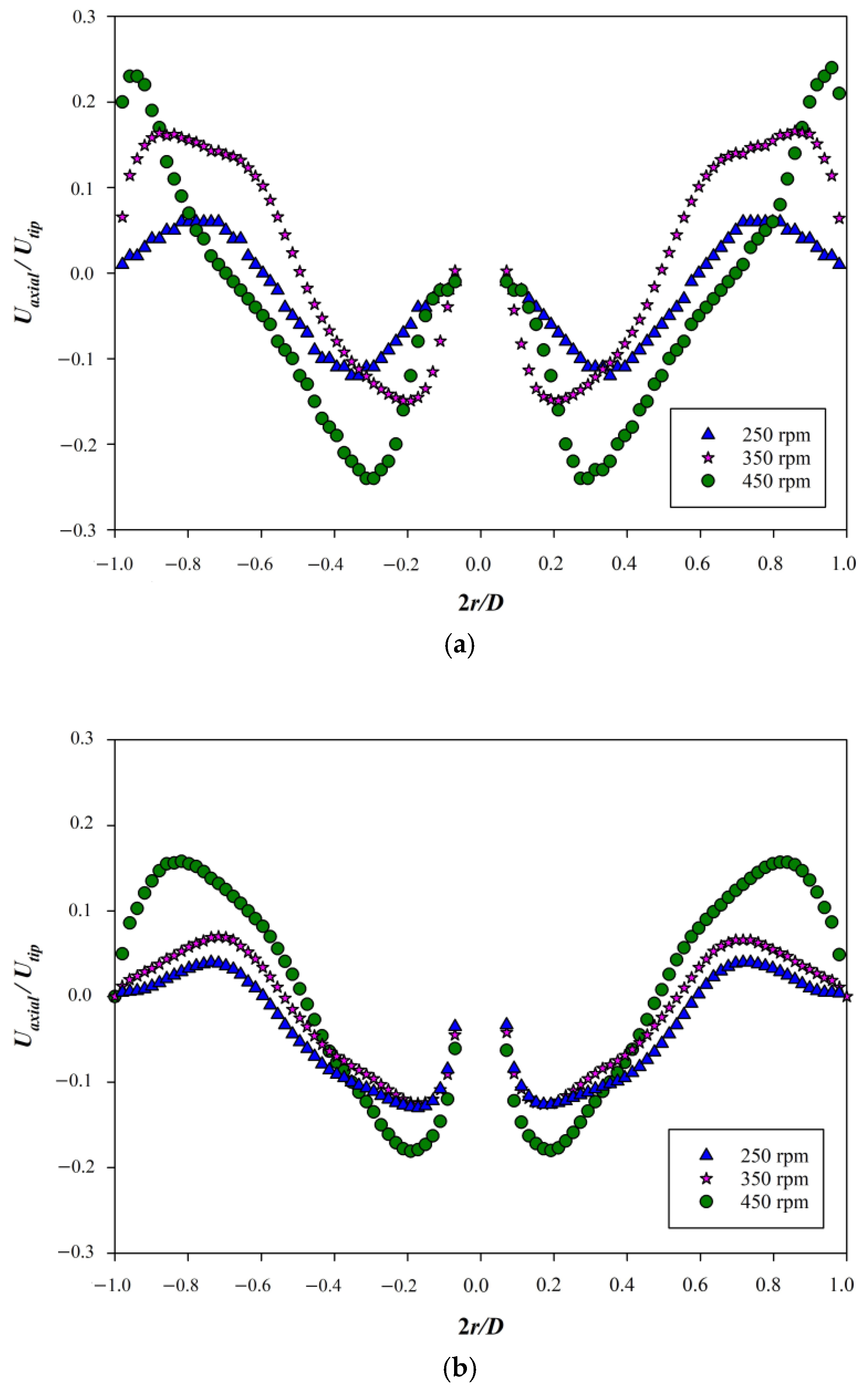

3.2. The Effect of Central Impeller Speed

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| D | Tank diameter, m |

| Dc | Diameter of the central impeller, m |

| fpa | The ratio of the anchor power to the total power, dimensionless |

| fpc | The ratio of the central impeller power to the total power, dimensionless |

| Interface momentum exchange, N | |

| H | Height of the tank, m |

| k | Consistency index, Pa.sn |

| Ks | Metzner and Otto constant |

| n | Power index, dimensionless |

| Nc | Central impeller rotational speed, rpm |

| Na | Anchor impeller rotational speed, rpm |

| Qg | Volumetric flow rate of the gas, L/min |

| Re | Reynolds number, dimensionless |

| r | Radius, m |

| R | Tank radius, m |

| Uaxial | Liquid axial velocity, m/s |

| Utip | Impeller tip velocity, m/s |

| U | Liquid velocity in stationary frame, m/s |

| z | Height, m |

| Greek letters | |

| Shear rate, L/s | |

| Gas hold-up, dimensionless | |

| Bulk viscosity, Pa.s | |

| μ | Laminar viscosity, Pa.s |

| μT | Turbulent viscosity, Pa.s |

| ρ | Density of liquid, kg/m3 |

| σg | Gas conductivity, S/cm |

| σl | Liquid conductivity, S/cm |

| σmc | Mixture conductivity, S/cm |

| τ | Shear stress, Pa |

| Reynolds stress tensor, Pa | |

| τy | Yield stress, Pa |

| ϕ | Volume fraction, dimensionless |

References

- Paulová, L.; Patáková, P.; Brányik, T. Advanced fermentation processes. In Engineering Aspects of Food Biotechnology; CRC Press: Boca Raton, FL, USA, 2013; pp. 89–110. [Google Scholar] [CrossRef]

- Wang, S.J.; Zhong, J.J. Bioreactor engineering. In Bioprocessing for Value-Added Products from Renewable Resources; Elsevier: Amsterdam, The Netherlands, 2007; pp. 131–161. [Google Scholar]

- Moucha, T.; Linek, V.; Prokopová, E. Gas hold-up, mixing time and gas–liquid volumetric mass transfer coefficient of various multiple-impeller configurations: Rushton turbine, pitched blade and techmix impeller and their combinations. Chem. Eng. Sci. 2003, 58, 1839–1846. [Google Scholar] [CrossRef]

- Dhanasekharan, K.M.; Sanyal, J.; Jain, A.; Haidari, A. A generalized approach to model oxygen transfer in bioreactors using population balances and computational fluid dynamics. Chem. Eng. Sci. 2005, 60, 213–218. [Google Scholar] [CrossRef]

- Sharifi, F.; Behzadfar, E.; Ein-Mozaffari, F. Intensified gas-liquid mixing in bioreactors equipped with a dual coaxial mixer containing biopolymer solutions. Chem. Eng. Res. Des. 2023, 191, 109–126. [Google Scholar] [CrossRef]

- Terasaka, K.; Shibata, H. Oxygen transfer in viscous non-Newtonian liquids having yield stress in bubble columns. Chem. Eng. Sci. 2003, 58, 5331–5337. [Google Scholar] [CrossRef]

- De Jesus, S.S.; Neto, J.M.; Maciel Filho, R. Hydrodynamics and mass transfer in bubble column, conventional airlift, stirred airlift and stirred tank bioreactors, using viscous fluid: A comparative study. Biochem. Eng. J. 2017, 118, 70–81. [Google Scholar] [CrossRef]

- Núñez EG, F.; Leme, J.; de Almeida Parizotto, L.; Chagas, W.A.; de Rezende, A.G.; da Costa BL, V.; Monteiro DC, V.; Boldorini VL, L.; Jorge SA, C.; Astray, R.M.; et al. Influence of aeration–homogenization system in stirred tank bioreactors, dissolved oxygen concentration and pH control mode on BHK-21 cell growth and metabolism. Cytotechnology 2014, 66, 605–617. [Google Scholar] [CrossRef]

- Tang, W.; Pan, A.; Lu, H.; Xia, J.; Zhuang, Y.; Zhang, S.; Chu, J.; Noorman, H. Improvement of glucoamylase production using axial impellers with low power consumption and homogeneous mass transfer. Biochem. Eng. J. 2015, 99, 167–176. [Google Scholar] [CrossRef]

- Arratia, P.E.; Kukura, J.; Lacombe, J.; Muzzio, F.J. Mixing of shear-thinning fluids with yield stress in stirred tanks. AIChE J. 2006, 52, 2310–2322. [Google Scholar] [CrossRef]

- Jaworski, Z.; Pacek, A.W.; Nienow, A.W. On flow close to cavern boundaries in yield stress fluids. Chem. Eng. Sci. 1994, 49, 3321–3324. [Google Scholar] [CrossRef]

- Adams, L.W.; Barigou, M. CFD analysis of caverns and pseudo-caverns developed during mixing of non-Newtonian fluids. Chem. Eng. Res. Des. 2007, 85, 598–604. [Google Scholar] [CrossRef]

- Wang, S.; Li, H.; Tao, C.; Liu, R.; Wang, Y.; Liu, Z. Study on cavern evolution and performance of three mixers in agitation of yield-pseudoplastic fluids. Chin. J. Chem. Eng. 2023, 55, 111–122. [Google Scholar] [CrossRef]

- Jamshidzadeh, M.; Ein-Mozaffari, F.; Lohi, A. Local and overall gas holdup in an aerated coaxial mixing system containing a non-Newtonian fluid. AIChE J. 2020, 66, e17016. [Google Scholar] [CrossRef]

- Garcia-Ochoa, F.; Gomez, E. Bioreactor scale-up and oxygen transfer rate in microbial processes: An overview. Biotechnol. Adv. 2009, 27, 153–176. [Google Scholar] [CrossRef]

- Foucault, S.; Ascanio, G.; Tanguy, P.A. Power characteristics in coaxial mixing: Newtonian and non-Newtonian fluids. Ind. Eng. Chem. Res. 2005, 44, 5036–5043. [Google Scholar] [CrossRef]

- Thibault, F.; Tanguy, P.A. Power-draw analysis of a coaxial mixer with Newtonian and non-Newtonian fluids in the laminar regime. Chem. Eng. Sci. 2002, 57, 3861–3872. [Google Scholar] [CrossRef]

- Rahimzadeh, A.; Ein-Mozaffari, F.; Lohi, A. Scale-up study of aerated coaxial mixing reactors containing non-newtonian power-law fluids: Analysis of gas holdup, cavity size, and power consumption. J. Ind. Eng. Chem. 2022, 113, 293–315. [Google Scholar] [CrossRef]

- Rahimzadeh, A.; Ein-Mozaffari, F.; Lohi, A. Investigation of power consumption, torque fluctuation, and local gas hold-up in coaxial mixers containing a shear-thinning fluid: Experimental and numerical approaches. Chem. Eng. Process.-Process Intensif. 2022, 177, 108983. [Google Scholar] [CrossRef]

- Amiraftabi, M.; Khiadani, M.; Mohammed, H.A. Performance of a dual helical ribbon impeller in a two-phase (gas-liquid) stirred tank reactor. Chem. Eng. Process.-Process Intensif. 2020, 148, 107811. [Google Scholar] [CrossRef]

- Ameur, H.; Bouzit, M. Mixing in shear thinning fluids. Braz. J. Chem. Eng. 2012, 29, 349–358. [Google Scholar] [CrossRef]

- Sossa-Echeverria, J.; Taghipour, F. Computational simulation of mixing flow of shear thinning non-Newtonian fluids with various impellers in a stirred tank. Chem. Eng. Process. Process Intensif. 2015, 93, 66–78. [Google Scholar] [CrossRef]

- Ciou, Z.Y.; Wu, C.Y. Investigation of the flow patterns and mixing efficiency in a stirred tank through particle image velocimetry. J. Taiwan Inst. Chem. Eng. 2023, 149, 104988. [Google Scholar] [CrossRef]

- Laakkonen, M.; Honkanen, M.; Saarenrinne, P.; Aittamaa, J. Local bubble size distributions, gas–liquid interfacial areas and gas holdups in a stirred vessel with particle image velocimetry. Chem. Eng. J. 2005, 109, 37–47. [Google Scholar] [CrossRef]

- Fontaine, A.; Guntzburger, Y.; Bertrand, F.; Fradette, L.; Heuzey, M.C. Experimental investigation of the flow dynamics of rheologically complex fluids in a Maxblend impeller system using PIV. Chem. Eng. Res. Des. 2013, 91, 7–17. [Google Scholar] [CrossRef]

- Alberini, F.; Liu, L.; Stitt, E.H.; Simmons MJ, H. Comparison between 3-D-PTV and 2-D-PIV for determination of hydrodynamics of complex fluids in a stirred vessel. Chem. Eng. Sci. 2017, 171, 189–203. [Google Scholar] [CrossRef]

- Ayala, J.S.; de Moura, H.L.; de Lima Amaral, R.; Júnior FD, A.O.; Nunhez, J.R.; de Castilho, G.J. Two-dimensional shear rate field and flow structures of a pseudoplastic fluid in a stirred tank using particle image velocimetry. Chem. Eng. Sci. 2022, 248, 117198. [Google Scholar] [CrossRef]

- Wang, H.; Jia, X.; Wang, X.; Zhou, Z.; Wen, J.; Zhang, J. CFD modeling of hydrodynamic characteristics of a gas–liquid two-phase stirred tank. Appl. Math. Model. 2014, 38, 63–92. [Google Scholar] [CrossRef]

- Jia, Z.; Xu, L.; Duan, X.; Mao, Z.S.; Zhang, Q.; Yang, C. CFD simulation of flow and mixing characteristics in a stirred tank agitated by improved disc turbines. Chin. J. Chem. Eng. 2022, 50, 95–107. [Google Scholar] [CrossRef]

- 37 Wang, H.; Duan, X.; Feng, X.; Mao, Z.S.; Yang, C. Effect of impeller type and scale-up on spatial distribution of shear rate in a stirred tank. Chin. J. Chem. Eng. 2022, 42, 351–363. [Google Scholar] [CrossRef]

- Ihejirika, I.; Ein-Mozaffari, F. Using CFD and ultrasonic velocimetry to study the mixing of pseudoplastic fluids with a helical ribbon impeller. Chem. Eng. Technol. Ind. Chem.-Plant Equip.-Process Eng.-Biotechnol. 2007, 30, 606–614. [Google Scholar] [CrossRef]

- Kumaresan, T.; Joshi, J.B. Effect of impeller design on the flow pattern and mixing in stirred tanks. Chem. Eng. J. 2006, 115, 173–193. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, L.; Huo, H.; Li, Z.; Gao, Z. Computational and experimental investigation of flow fields in a Rushton turbine stirred tank with shear-thinning fluid. Asia-Pac. J. Chem. Eng. 2022, 17, e2735. [Google Scholar] [CrossRef]

- Maxwell, J.C. A Treatise on Electricity and Magnetism: Pt. III. Magnetism. pt. IV. Electromagnetism; Clarendon Press: Oxford, UK, 1881; Volume 2. [Google Scholar]

- Ansys Fluent. Ansys Fluent Theory Guide; Ansys Inc.: Canonsburg, PA, USA, 2011; Volume 15317, pp. 724–746. [Google Scholar]

- Sharifi, F.; Behzadfar, E.; Ein-Mozaffari, F. Investigating the Power Consumption for the Intensification of Gas Dispersion in a Dual Coaxial Mixer Containing Yield-Pseudoplastic Fluids. Chem. Eng. Process.-Process Intensif. 2023, 191, 109461. [Google Scholar] [CrossRef]

- Kelly, W.; Gigas, B. Using CFD to predict the behavior of power law fluids near axial-flow impellers operating in the transitional flow regime. Chem. Eng. Sci. 2003, 58, 2141–2152. [Google Scholar] [CrossRef]

- Scargiali, F.; D’Orazio, A.; Grisafi, F.; Brucato, A. Modelling and simulation of gas–liquid hydrodynamics in mechanically stirred tanks. Chem. Eng. Res. Des. 2007, 85, 637–646. [Google Scholar] [CrossRef]

- Jahoda, M.; Tomášková, L.; Moštěk, M. CFD prediction of liquid homogenisation in a gas–liquid stirred tank. Chem. Eng. Res. Des. 2009, 87, 460–467. [Google Scholar] [CrossRef]

- Khopkar, A.R.; Kasat, G.R.; Pandit, A.B.; Ranade, V.V. CFD simulation of mixing in tall gas–liquid stirred vessel: Role of local flow patterns. Chem. Eng. Sci. 2006, 61, 2921–2929. [Google Scholar] [CrossRef]

- Lins Barros, P.; Ein-Mozaffari, F.; Lohi, A. Gas Dispersion in Non-Newtonian Fluids with Mechanically Agitated Systems: A Review. Processes 2022, 10, 275. [Google Scholar] [CrossRef]

- Jamshidzadeh, M.; Ein-Mozaffari, F.; Lohi, A. Local distribution of oxygen mass transfer coefficient in CMC solutions in bioreactors furnished with different types of coaxial mixers. Chem. Eng. Res. Des. 2021, 174, 213–224. [Google Scholar] [CrossRef]

| Density, ρ (kg/m3) | Yield Stress, τy (Pa) | Consistency Index, k (Pa·sn) | Power-Law Index (n) |

|---|---|---|---|

| 983 | 3.22 | 10.16 | 0.13 |

| Mixing Configuration | Power Consumption (W) | Local Gas Hold-Up | |||||

|---|---|---|---|---|---|---|---|

| EXP | CFD | Error% | EXP | CFD | Error% | ||

| Up-Co | 155.9 | 142.3 | 8.72 | Plane 1 | 0.0520 | 0.0474 | 8.85 |

| Plane 2 | 0.0534 | 0.0496 | 7.12 | ||||

| Plane 3 | 0.0509 | 0.0477 | 6.29 | ||||

| Plane 4 | 0.0500 | 0.0472 | 5.60 | ||||

| Up-Counter | 181.9 | 167.9 | 7.69 | Plane 1 | 0.0407 | 0.0349 | 14.25 |

| Plane 2 | 0.0402 | 0.0370 | 7.96 | ||||

| Plane 3 | 0.0386 | 0.0359 | 6.99 | ||||

| Plane 4 | 0.0333 | 0.0310 | 6.91 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharifi, F.; Behzadfar, E.; Ein-Mozaffari, F. Analyzing Local Shear Rate Distribution in a Dual Coaxial Mixing Bioreactor Handling Herschel–Bulkley Biopolymer Solutions through Computational Fluid Dynamics. Processes 2023, 11, 3387. https://doi.org/10.3390/pr11123387

Sharifi F, Behzadfar E, Ein-Mozaffari F. Analyzing Local Shear Rate Distribution in a Dual Coaxial Mixing Bioreactor Handling Herschel–Bulkley Biopolymer Solutions through Computational Fluid Dynamics. Processes. 2023; 11(12):3387. https://doi.org/10.3390/pr11123387

Chicago/Turabian StyleSharifi, Forough, Ehsan Behzadfar, and Farhad Ein-Mozaffari. 2023. "Analyzing Local Shear Rate Distribution in a Dual Coaxial Mixing Bioreactor Handling Herschel–Bulkley Biopolymer Solutions through Computational Fluid Dynamics" Processes 11, no. 12: 3387. https://doi.org/10.3390/pr11123387

APA StyleSharifi, F., Behzadfar, E., & Ein-Mozaffari, F. (2023). Analyzing Local Shear Rate Distribution in a Dual Coaxial Mixing Bioreactor Handling Herschel–Bulkley Biopolymer Solutions through Computational Fluid Dynamics. Processes, 11(12), 3387. https://doi.org/10.3390/pr11123387