Numerical Simulation of a Class I Gas Hydrate Reservoir Depressurized by a Fishbone Well

Abstract

1. Introduction

2. Mathematical Model and Validation

2.1. Mathematical Model

2.2. Validation

3. Numerical Models and Simulation Approach

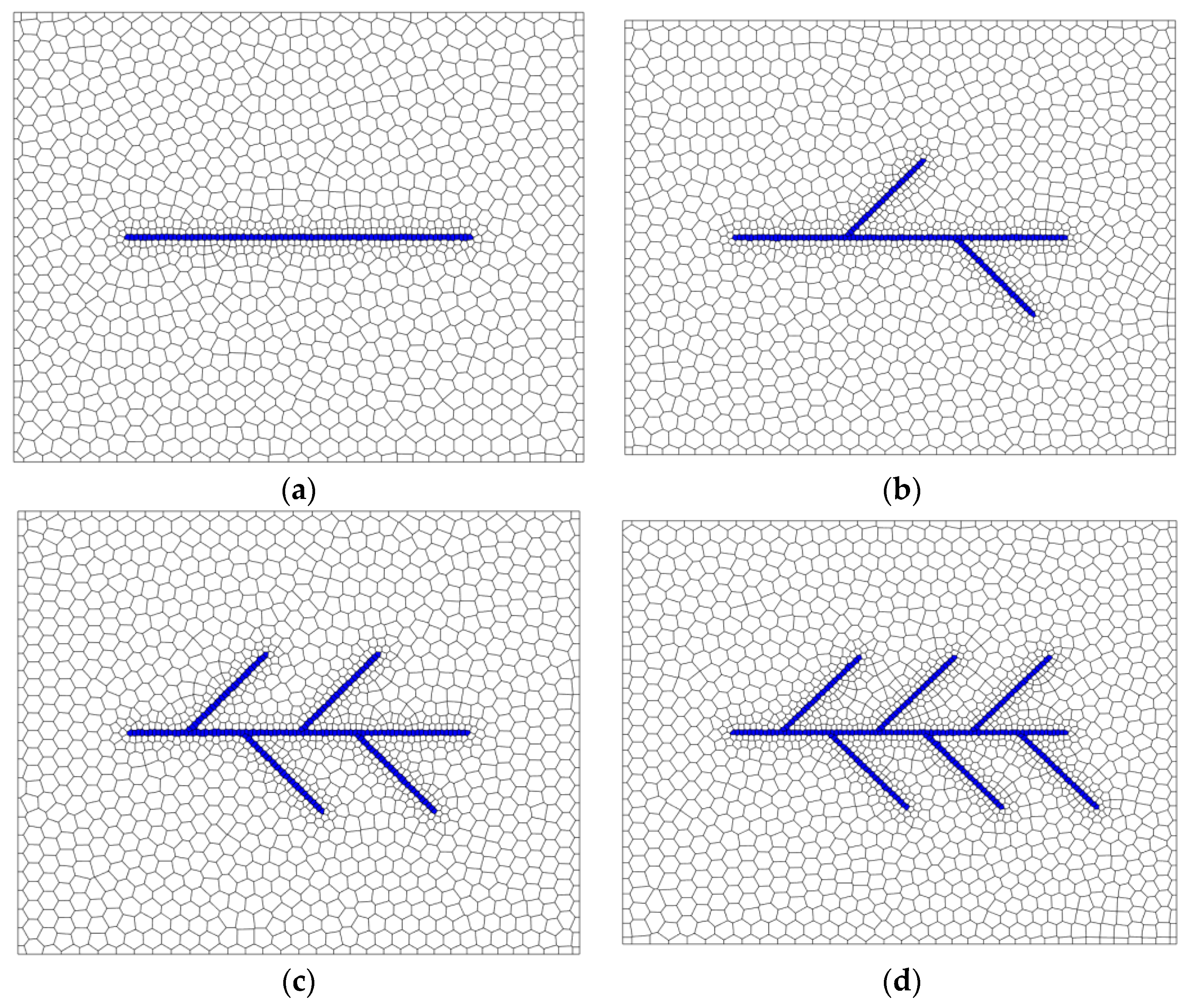

3.1. PEBI Unstructured Grid Generation

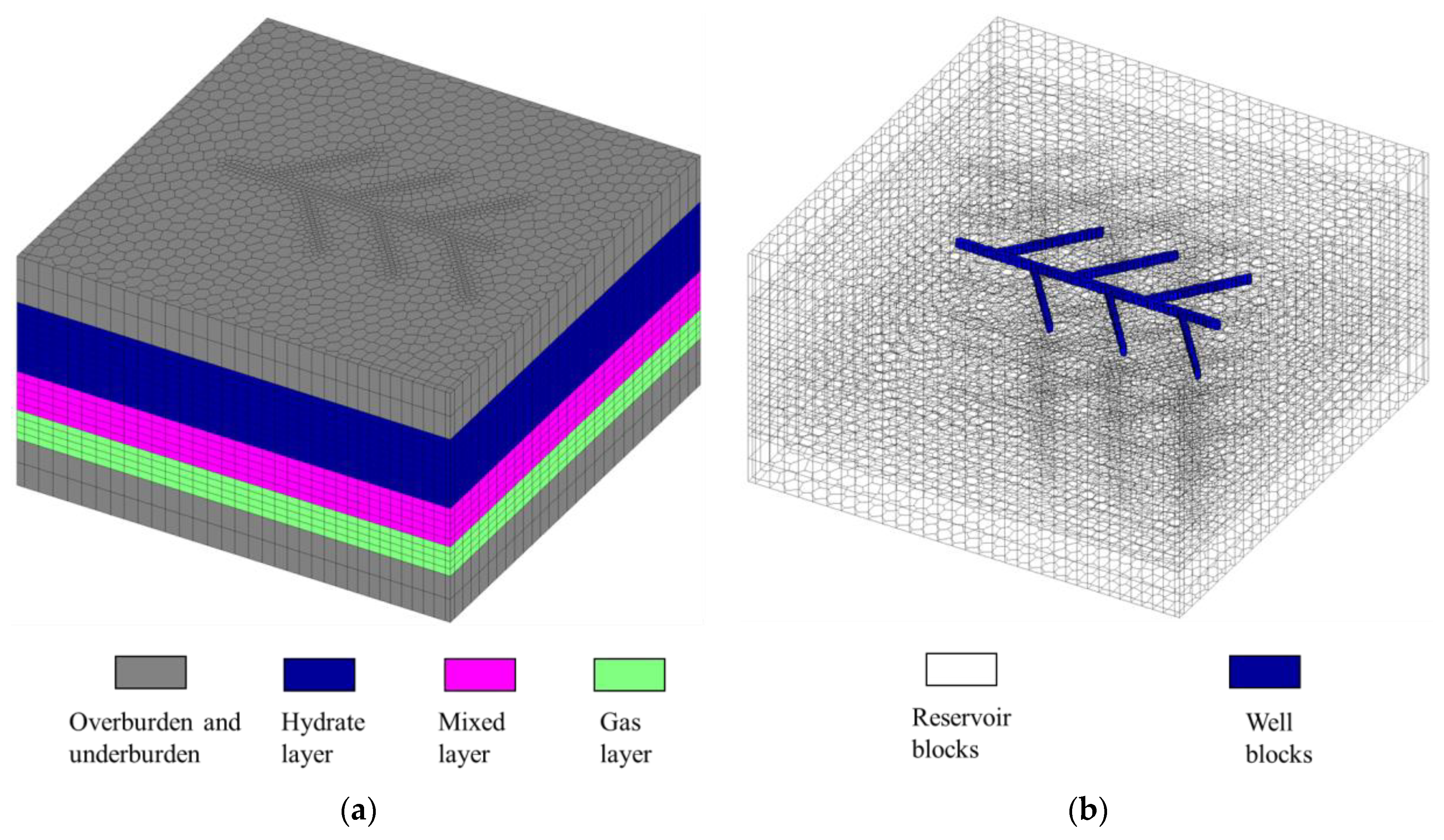

3.2. Modeling of Class I Gas Hydrate Reservoirs

3.3. Results and Discussions

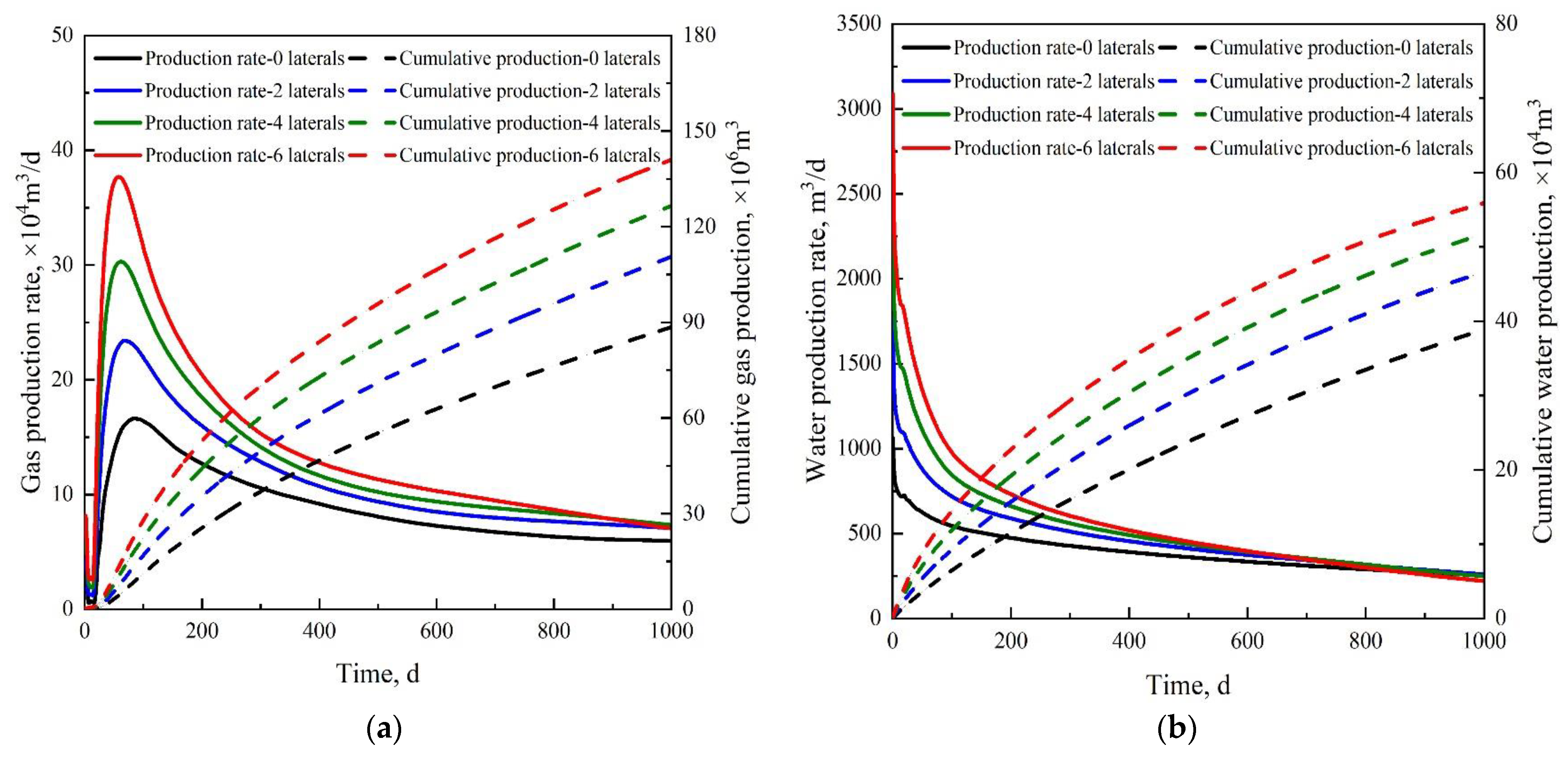

3.3.1. Evolution of the Gas and Water Productions

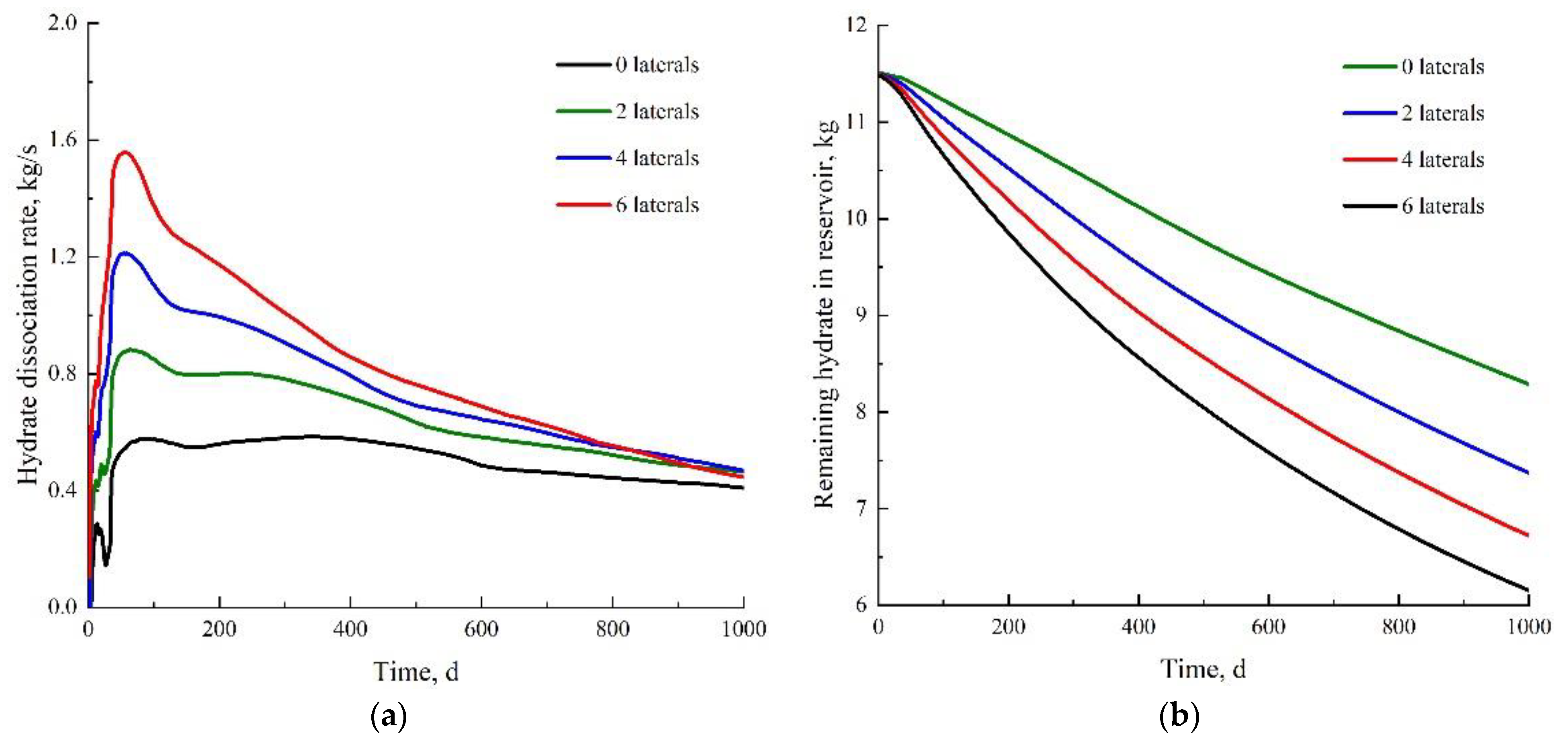

3.3.2. Evolution of the Hydrate Reserves

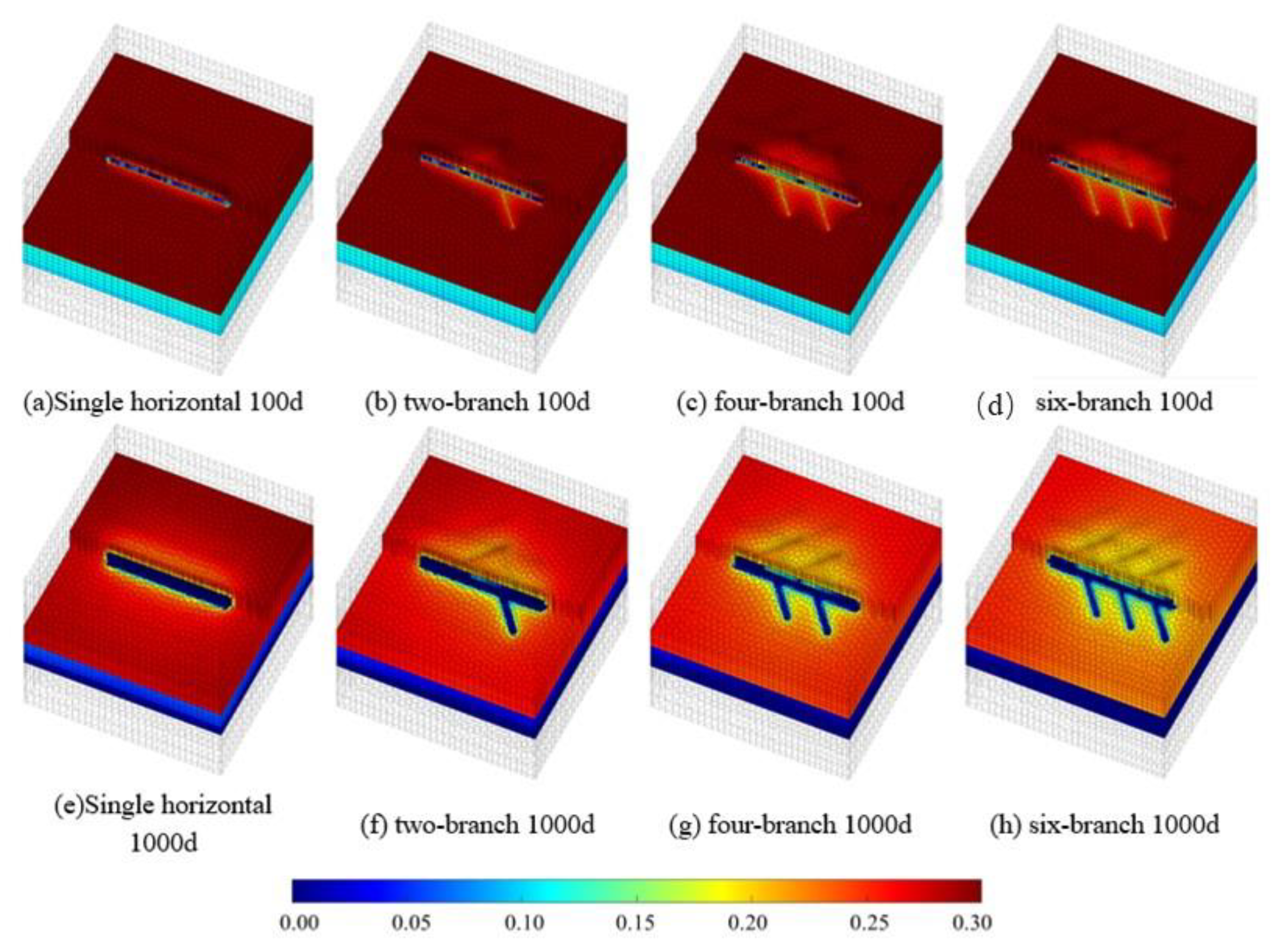

3.3.3. Evolution of the Physical Field

4. Conclusions

- (1)

- The PEBI unstructured grid can ensure the orthogonality of the grids as much as possible while adapting to the complex shape of the fishbone well. Compared with the conventional Cartesian grid system and corner grid system, the PEBI unstructured grid can effectively avoid the grid distortion caused by complex well or complex boundaries and ensure the convergence of the simulation;

- (2)

- The multi-branch fishbone well can effectively increase the contact area between wellbore and reservoir, promote the rapid production of primary water and the rapid reduction of reservoir pressure in the initial stage of depressurization, and promote the decomposition of the hydrate and the upward return of free gas in gas and mixed layers. Compared with a single horizontal well, the cumulative gas production of the six-branch fishbone well increases by 59.3%. Therefore, using the multi-branch fishbone well depressurization to develop the Class I gas hydrate reservoir can effectively improve the productivity and development effect;

- (3)

- The more branches of the fishbone well, the higher the rate of hydrate decomposition. However, due to the large amount of heat absorption caused by hydrate decomposition, the hydrate decomposition rate decreases rapidly after the heat energy in the reservoir is consumed in the late stage of development. The simulation results show that the hydrate decomposition rate of all schemes is lower than 50%. Therefore, in the later stage of depressurization development, the combined development method of heat injection and depressurization is expected to further provide sufficient heat energy for hydrate decomposition and thus promote the decomposition of the hydrate.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lu, S. A global survey of gas hydrate development and reserves: Specifically in the marine field. Renew. Sustain. Energy Rev. 2015, 41, 884–900. [Google Scholar] [CrossRef]

- Wei, J.; Fang, Y.; Lu, H.; Lu, J.; Liang, J.; Yang, S. Distribution and characteristics of natural gas hydrates in the Shenhu Sea Area, South China Sea. Mar. Pet. Geol. 2018, 98, 622–628. [Google Scholar] [CrossRef]

- Liu, Y.; Hou, J.; Zhao, H.; Liu, X.; Xia, Z. A method to recover natural gas hydrates with geothermal energy conveyed by CO2. Energy 2018, 144, 265–278. [Google Scholar] [CrossRef]

- Li, Q.; Wang, F.; Wang, Y.; Bai, B.; Zhang, J.; Lili, C.; Sun, Q.; Wang, Y.; Forson, K. Adsorption behavior and mechanism analysis of siloxane thickener for CO2 fracturing fluid on shallow shale soil. J. Mol. Liq. 2023, 276, 121394. [Google Scholar] [CrossRef]

- Li, S.; Wu, D.; Wang, X.; Hao, Y. Enhanced gas production from marine hydrate reservoirs by hydraulic fracturing assisted with sealing burdens. Energy 2021, 232, 120889. [Google Scholar] [CrossRef]

- Anderson, B.J.; Kurihara, M.; White, M.D.; Moridis, G.J.; Wilson, S.J.; Pooladi-Darvish, M.; Gaddipati, M.; Masuda, Y.; Collett, T.S.; Hunter, R.B.; et al. Regional long-term production modeling from a single well test, Mount Elbert Gas Hydrate Stratigraphic Test Well, Alaska North Slope. Mar. Pet. Geol. 2011, 28, 493–501. [Google Scholar] [CrossRef]

- Yamamoto, K.; Wang, X.; Tamaki, M.; Suzuki, K. The second offshore production of methane hydrate in the Nankai Trough and gas production behavior from a heterogeneous methane hydrate reservoir. RSC Adv. 2019, 9, 25987. [Google Scholar] [CrossRef] [PubMed]

- Moridis, G. Numerical studies of gas production from class 2 and class 3 hydrate accumulations at the Mallik Site, Mackenzie Delta, Canada. SPE Reserv. Eval. Eng. 2004, 7, 175–183. [Google Scholar] [CrossRef]

- Hou, J.; Xia, Z.; Li, S.; Zhou, K.; Lu, N. Operation parameter optimization of a gas hydrate reservoir developed by cyclic hot water stimulation with a separated-zone horizontal well based on particle swarm algorithm. Energy 2016, 96, 581–591. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, L.; Cai, W.; He, J.; Lu, H. Study on the characteristic spectral bands of water molecule and hydrogen bond of methane hydrate. Chem. Eng. Sci. 2022, 248, 117117. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, X.; He, J.; Cen, X.; Liu, Y. Parameter optimization study of gas hydrate reservoir development based on a surrogate model assisted particle swarm algorithm. Geofluids 2022, 203, 2056323. [Google Scholar] [CrossRef]

- Nair, V.; Ramesh, S.; Ramadass, G.; Sangwai, J. Influence of thermal stimulation on the methane hydrate dissociation in porous media under confined reservoir. J. Pet. Sci. Eng. 2016, 147, 547–559. [Google Scholar] [CrossRef]

- Yu, T.; Guan, G.; Wang, D.; Song, Y.; Abudula, A. Gas Production Enhancement from a multilayered hydrate reservoir in the south china sea by hydraulic fracturing. Energy Fuels 2021, 35, 12104–12118. [Google Scholar] [CrossRef]

- Kowalsky, M.; Moridis, G. Comparison of kinetic and equilibrium reaction models in simulating gas hydrate behavior in porous media. Energy Convers. Manag. 2007, 48, 1850–1863. [Google Scholar] [CrossRef]

- Li, G.; Moridis, G.; Zhang, K.; Li, X. Evaluation of gas production potential from marine gas hydrate deposits in Shenhu Area of South China Sea. Energy Fuels 2010, 24, 6018–6033. [Google Scholar] [CrossRef]

- Li, J.-F.; Ye, J.-L.; Qin, X.-W.; Qiu, H.-J.; Wu, N.-Y.; Lu, H.-L.; Xie, W.-W.; Lu, J.-A.; Peng, F.; Xu, Z.-Q.; et al. The first offshore natural gas hydrate production test in South China Sea. China Geol. 2018, 1, 5–16. [Google Scholar] [CrossRef]

- Ye, J.-L.; Survey, M.O.N.R.C.G.; Qin, X.-W.; Xie, W.-W.; Lu, H.-L.; Ma, B.-J.; Qiu, H.-J.; Liang, J.-Q.; Lu, J.-A.; Kuang, Z.-G.; et al. The second natural gas hydrate production test in the South China Sea. China Geol. 2020, 3, 197–209. [Google Scholar] [CrossRef]

- Liu, Y.; Hou, J.; Zhao, H.; Liu, X.; Xia, Z. Numerical simulation of simultaneous exploitation of geothermal energy and natural gas hydrates by water injection into a geothermal heat exchange well. Renew. Sustain. Energy Rev. 2019, 109, 467–481. [Google Scholar] [CrossRef]

- Liu, Y.; Li, G.; Chen, J.; Bai, Y.; Hou, J.; Xu, H.; Zhao, E.; Chen, Z.; He, J.; Zhang, L.; et al. Numerical simulation of hydraulic fracturing-assisted depressurization development in hydrate bearing layers based on discrete fracture models. Energy 2023, 263, 126146. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, L.; He, J.; Zhou, T. The Development of natural gas hydrate exploitation technology from perspective of patents. Front. Energy Res. 2022, 10, 860591. [Google Scholar] [CrossRef]

- Huang, X.; Li, Z.; Zhang, L.; He, J.; Lu, H. Molecular insights into the effect of nitrogen bubbles on the formation of tetrahydrofuran hydrates. Molecules 2022, 27, 4945. [Google Scholar] [CrossRef]

- Sasaki, K.; Ono, S.; Sugai, Y.; Ebinuma, T.; Narita, H.; Yamaguchi, T. Gas production system from methane hydrate layers by hot water injection using dual horizontal wells. J. Can. Pet. Technol. 2009, 48, 21–26. [Google Scholar] [CrossRef]

- Li, X.; Yang, B.; Duan, L.; Li, G.; Huang, N.; Zhang, Y. Experimental study on gas production from methane hydrate in porous media by SAGD method. Appl. Energy 2013, 112, 1233–1240. [Google Scholar] [CrossRef]

- Feng, Y.; Chen, L.; Suzuki, A.; Kogawa, T.; Okajima, J.; Komiya, A.; Maruyama, S. Enhancement of gas production from methane hydrate reservoirs by the combination of hydraulic fracturing and depressurization method. Energy Convers. Manag. 2019, 184, 194–204. [Google Scholar] [CrossRef]

- Choudhary, N.; Phirani, J. Effect of well configuration, well placement and reservoir characteristics on the performance of marine gas hydrate reservoir. Fuel 2022, 310, 122377. [Google Scholar] [CrossRef]

- Moridis, G.; Silpngarmlert, S.; Reagan, M.; Collett, T.; Zhang, K. Gas production from a cold, stratigraphically-bounded gas hydrate deposit at the Mount Elbert Gas Hydrate Stratigraphic Test Well, Alaska North Slope: Implications of uncertainties. Mar. Pet. Geol. 2011, 28, 517–534. [Google Scholar] [CrossRef]

- Hassen, A.; Elkatatny, S.; Abdulraheem, A. Application of artificial intelligence techniques to predict the well productivity of fishbone wells. Sustainability 2019, 11, 6083. [Google Scholar] [CrossRef]

- Zhou, X.; Feng, F.; Zhang, L. Improving Steam-Assisted Gravity Drainage performance in oil sands with a top water zone using polymer injection and the fishbone well pattern. Fuel 2016, 184, 449–465. [Google Scholar] [CrossRef]

- Li, Q.; Wu, J. Factors affecting the lower limit of the safe mud weight window for drilling operation in hydrate-bearing sediments in the Northern South China Sea. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 82. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, X.; Wu, X.; Li, G.; Li, J.; Tian, S.; Shen, K. A study of swirling jet drilling and its specific energy for hydrate-bearing sediments. SPE J. 2022, 04, 1–15. [Google Scholar] [CrossRef]

- Moridis, G.J.; Collett, T.S.; Pooladi-Darvish, M.; Hancock, S.H.; Santamarina, C.; Boswell, R.; Kneafsey, T.J.; Rutqvist, J.; Kowalsky, M.B.; Reagan, M.T.; et al. Challenges, uncertainties, and issues facing gas production from gas-hydrate deposits. SPE Reserv. Eval. Eng. 2011, 14, 76–112. [Google Scholar] [CrossRef]

- Konno, Y.; Masuda, Y.; Hariguchi, Y.; Kurihara, M.; Ouchi, H. Key factors for depressurization-induced gas production from oceanic methane hydrates. Energy Fuels 2010, 24, 1736–1744. [Google Scholar] [CrossRef]

- Berge, R.; Klemetsdal, Ø.; Lie, K. Unstructured Voronoi grids conforming to lower dimensional objects. Comput. Geosci. 2019, 23, 169–188. [Google Scholar] [CrossRef]

- Mlacnik, M.; Louis, J. Durlofsky. Sequentially adapted flow-based PEBI grids for reservoir simulation. SPE J. 2006, 11, 317–327. [Google Scholar] [CrossRef]

- Zhang, L.; Li, D.; Wang, L.; Lu, D. Simulation of gas transport in tight/shale gas reservoirs by a multicomponent model based on PEBI grid. J. Chem. 2015, 2015, 572434. [Google Scholar] [CrossRef]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Hydrate layer water saturation | 0.69 | Gas layer permeability/mD | 6.8 |

| Hydrate layer hydrate saturation | 0.31 | Hydrate layer average temperature/°C | 12.73 |

| Mixed layer water saturation | 0.751 | Hydrate layer average pressure/MPa | 12.92 |

| Mixed layer gas saturation | 0.132 | Mixed layer average temperature/°C | 14.31 |

| Mixed layer hydrate saturation | 0.117 | Mixed layer average pressure/MPa | 13.98 |

| Gas layer water saturation | 0.927 | Gas layer average temperature/°C | 15.84 |

| Gas layer gas saturation | 0.073 | Gas layer average pressure/MPa | 14.89 |

| Salt mass fraction | 0.0305 | SirG | 0.05 |

| Hydrate layer porosity | 0.373 | Ng | 2.0 |

| Mixed layer porosity | 0.346 | SirW | 0.3 |

| Gas layer porosity | 0.347 | Nw | 2.0 |

| Hydrate layer permeability /mD | 2.38 | Pressure gradient/(MPa/100 m) | 1.0 |

| Mixed layer permeability /mD | 6.63 | Temperature gradient/(°C/100 m) | 4.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, J. Numerical Simulation of a Class I Gas Hydrate Reservoir Depressurized by a Fishbone Well. Processes 2023, 11, 771. https://doi.org/10.3390/pr11030771

He J. Numerical Simulation of a Class I Gas Hydrate Reservoir Depressurized by a Fishbone Well. Processes. 2023; 11(3):771. https://doi.org/10.3390/pr11030771

Chicago/Turabian StyleHe, Jiayuan. 2023. "Numerical Simulation of a Class I Gas Hydrate Reservoir Depressurized by a Fishbone Well" Processes 11, no. 3: 771. https://doi.org/10.3390/pr11030771

APA StyleHe, J. (2023). Numerical Simulation of a Class I Gas Hydrate Reservoir Depressurized by a Fishbone Well. Processes, 11(3), 771. https://doi.org/10.3390/pr11030771