Life Cycle Assessment and Cumulative Energy Demand Analyses of a Photovoltaic/Thermal System with MWCNT/Water and GNP/Water Nanofluids

Abstract

1. Introduction

- A comprehensive LCA analysis from cradle to grave of the PV and PV/T systems was conducted;

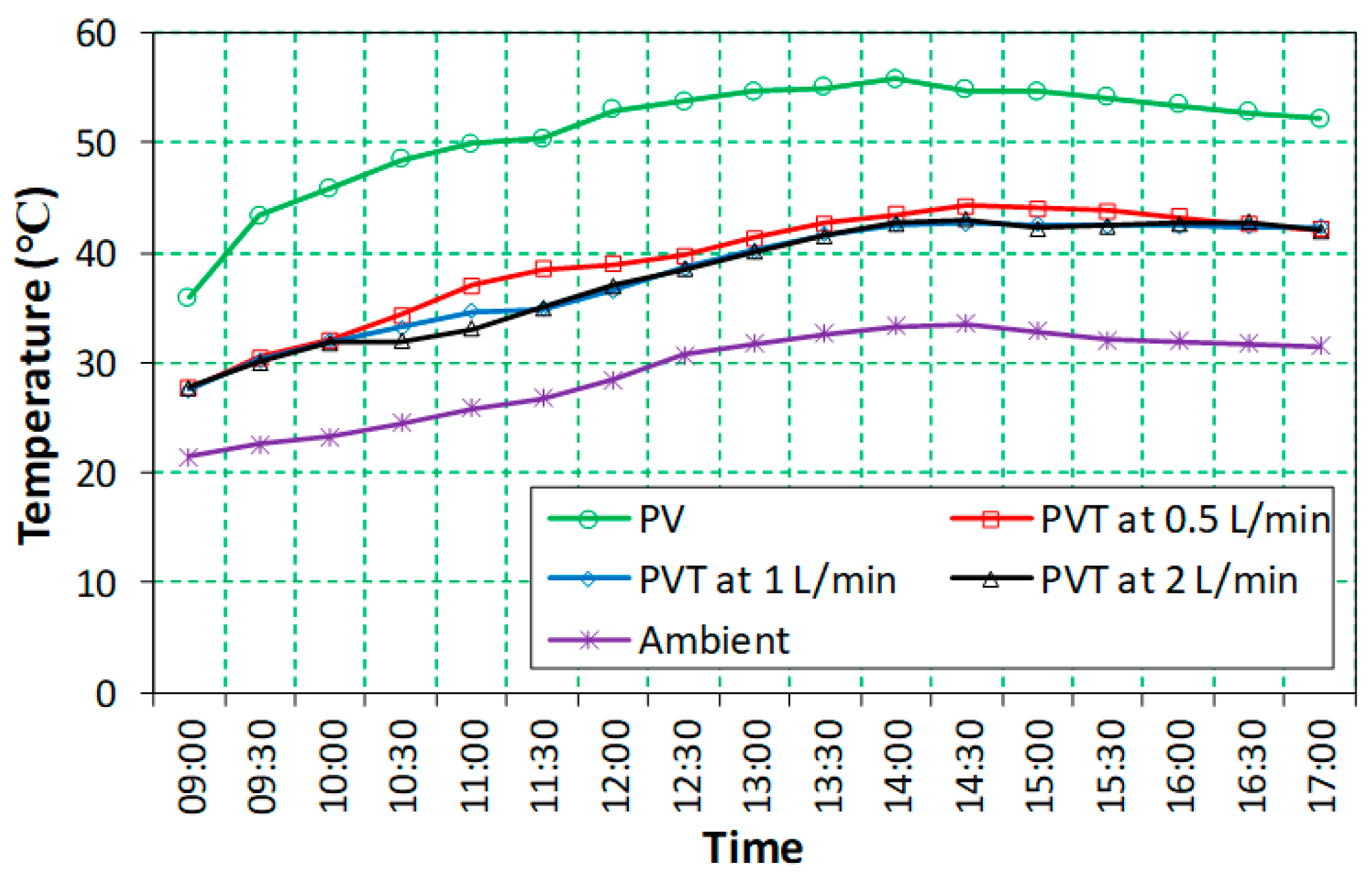

- PV and PV/T experiments were conducted under the same environmental conditions to understand the differences in total energy efficiency;

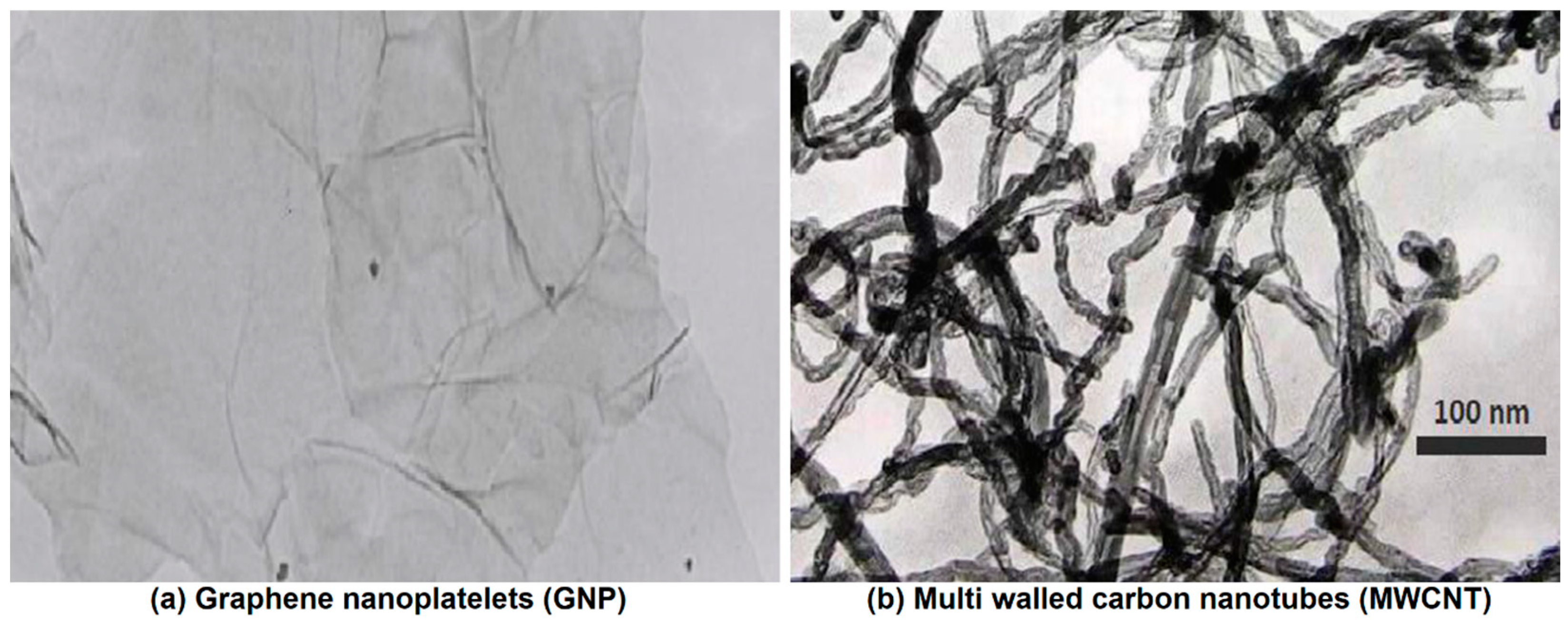

- The use of three different working fluids: distilled water, MWCNT/water mixture, and GNP/water mixture;

- Important indicators, such as the efficiency, energy return factor, energy payback time, and the environmental impact of electricity generation were presented;

- How energy systems whose environmental impact is thought to be close to zero increase their environmental impact was demonstrated.

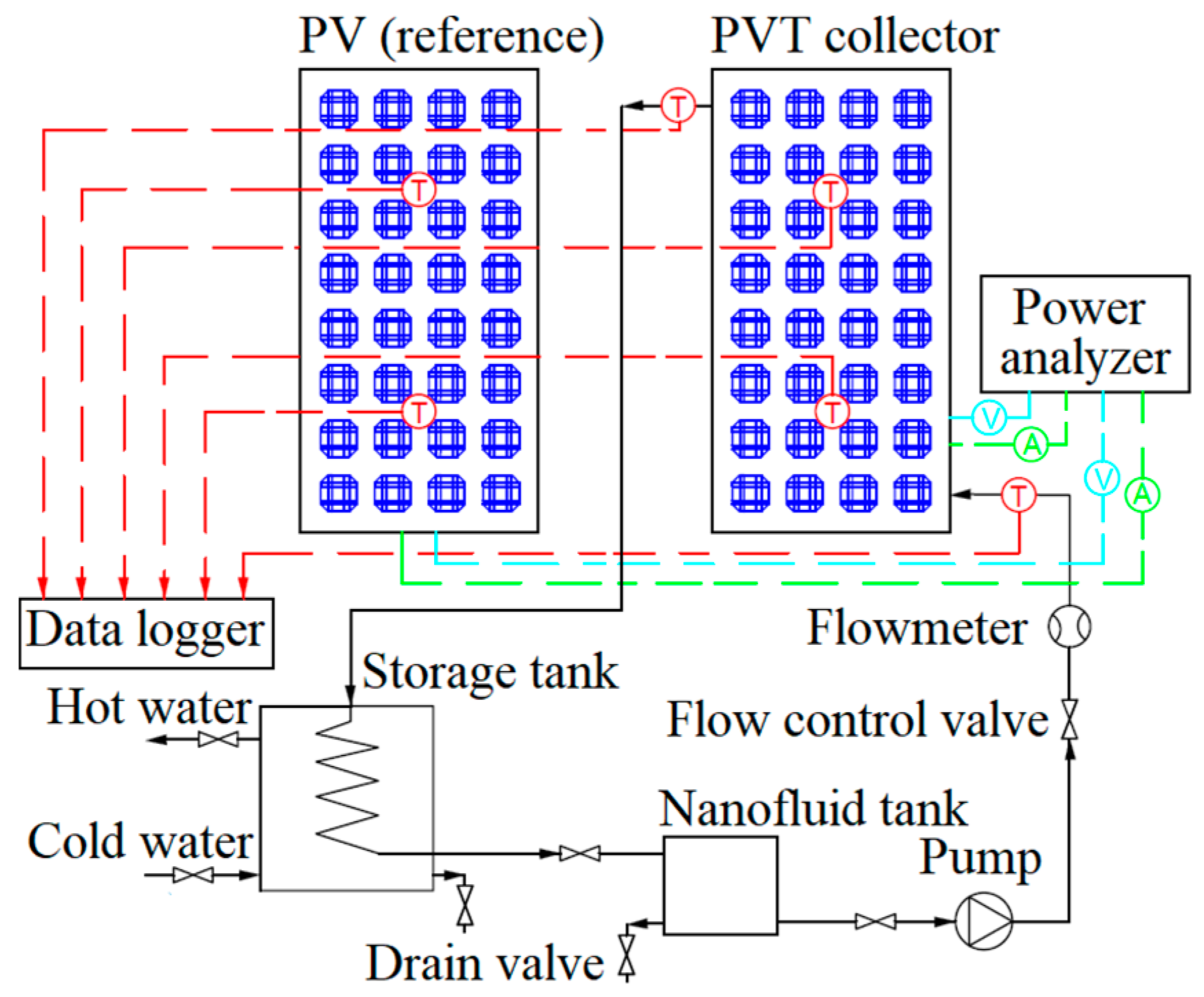

2. Experimental Setup and Experimental Procedure

3. Analysis Methodology

3.1. Thermal Analysis

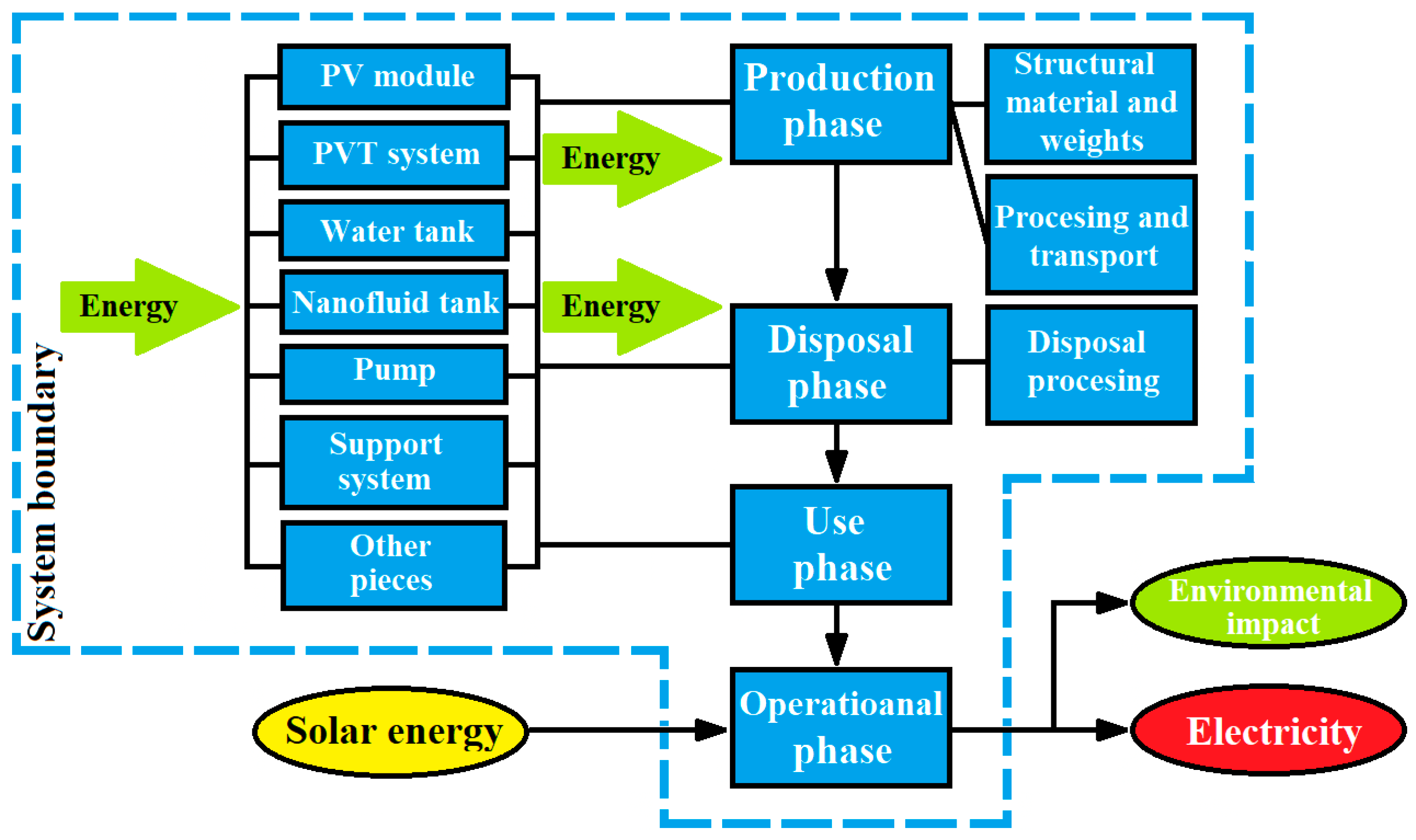

3.2. Life Cycle Assessment

3.3. Cumulative Energy Demand

4. Results and Discussion

5. Conclusions

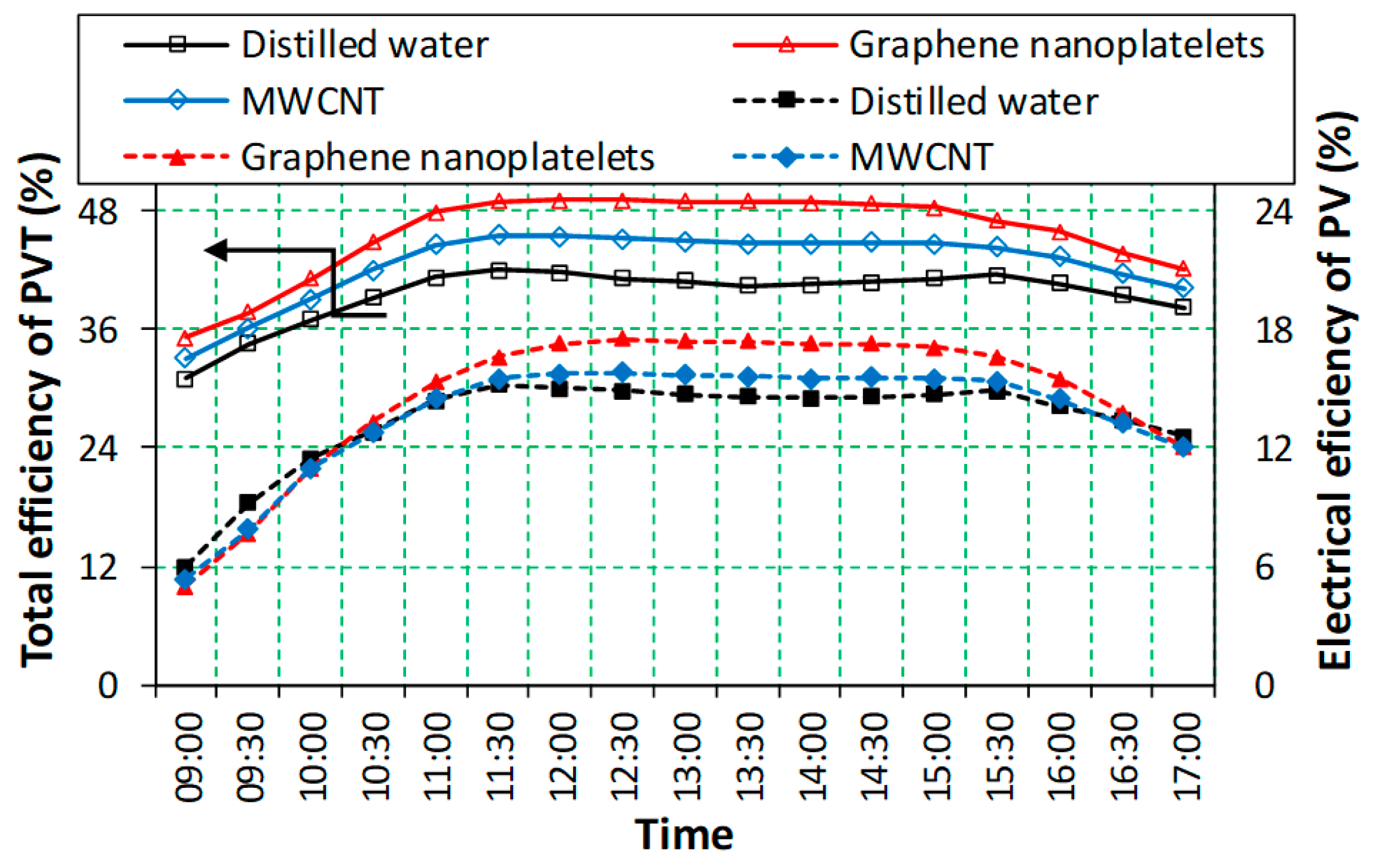

- According to the PV module, electrical efficiency increased in the PV/T system. The electrical and total efficiencies changed between 13.5–14.4% and 39.5–45.7%, respectively, in the PV/T system. Among the three working fluids, the PV/T system with the graphene nanoplatelets/water mixture had the highest efficiency values.

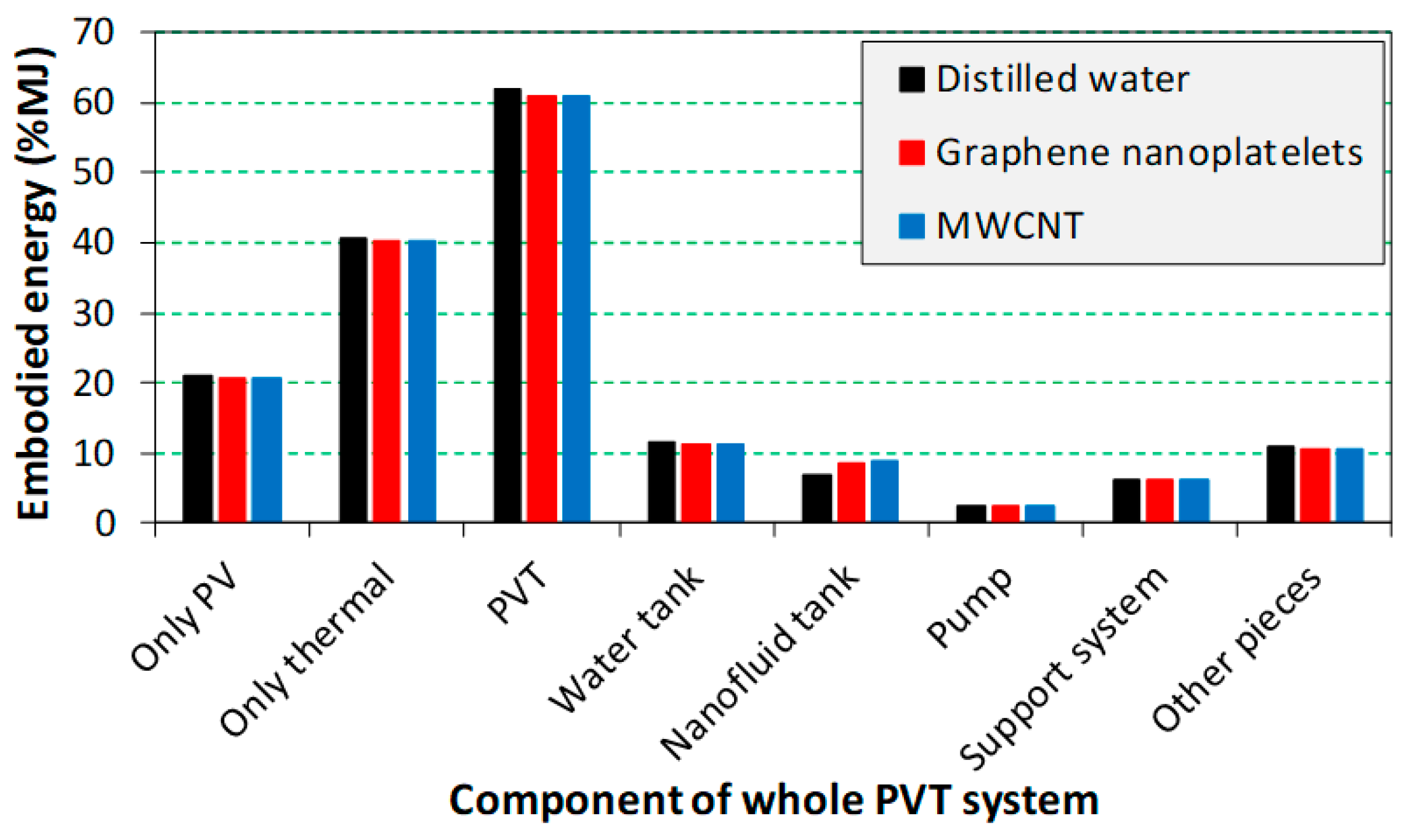

- The embodied energy values were 3975.08 MJ for the PV/T with distilled water, 4081.06 MJ for the PV/T with a MWCNT/water mixture, and 4077.86 MJ for the PV/T system with a graphene nanoplatelets/water mixture. This result relates to the large amount of silicon, galvanized iron, and aluminum used in the manufacture of the PV module and PV/T system, respectively.

- The energy payback time was changed between 10.83 and 11.39 years and had the lowest value in the PV/T system with graphene nanoplatelets/water mixture. The use of nanoparticles could shorten the energy return time.

- The environmental impact of the produced electricity was 0.046, 0.044, and 0.043 Pts/kWh for the PV/T systems with distilled water, MWCNT/water, and graphene nanoplatelets/water, respectively. These values were 0.0097 and 0.0072 Pts/kWh for small installations with monocrystalline cells on a façade and on a building roof, respectively. Thus, although the values of the PV/T system were very high, the use of nanoparticles decreased the environmental impact somewhat compared with the use of distilled water.

- Based on the LCA results, it was evident that the PV/T systems were less environmentally friendly compared with PV modules due to the increased amount of copper and aluminum used during their fabrication.

- The installation and operation of the PV/T systems require less energy-intensive materials (nanoparticles), resulting in lower environmental impacts during their processing compared with the PV/T system with distilled water.

- The energy consumed and environmental impacts of all manufacturing, installation, and operation processes to be followed were increased when the electrical efficiency of the PV module was increased. Therefore, for even the smallest improvement in the PV module and/or PV/T system, its energy and environmental impact should be considered.

- Nanofluids should be used in the cooling of PV/T systems, increasing their electrical efficiency and decreasing their environmental impact.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hossain, F.; Karim, M.R.; Bhuiyan, A.A. A review on recent advancements of the usage of nano fluid in hybrid photovoltaic/thermal (PV/T) solar systems. Renew. Energy 2022, 188, 114–131. [Google Scholar] [CrossRef]

- Todde, G.; Murgia, L.; Carrelo, I.; Hogan, R.; Pazzona, A.; Ledda, L.; Narvarte, L. Embodied energy and environmental impact of large-power stand-alone photovoltaic irrigation systems. Energies 2018, 11, 2110. [Google Scholar] [CrossRef]

- Arnaoutakis, N.; Souliotis, M.; Papaefthimiou, S. Comparative experimental Life Cycle Assessment of two commercial solar thermal devices for domestic applications. Renew. Energy 2017, 111, 187–200. [Google Scholar] [CrossRef]

- Souliotis, M.; Arnaoutakis, N.; Panaras, G.; Kavga, A.; Papaefthimiou, S. Experimental study and Life Cycle Assessment (LCA) of Hybrid Photovoltaic/Thermal (PV/T) solar systems for domestic applications. Renew. Energy 2018, 126, 708–723. [Google Scholar] [CrossRef]

- Wong, J.H.; Royapoor, M.; Chan, C.W. Review of life cycle analyses and embodied energy requirements of single-crystalline and multi-crystalline silicon photovoltaic systems. Renew. Sustain. Energy Rev. 2016, 58, 608–618. [Google Scholar] [CrossRef]

- Carnevale, E.; Lombardi, L.; Zanchi, L. Life cycle assessment of solar energy systems: Comparison of photovoltaic and water thermal heater at domestic scale. Energy 2014, 77, 434–446. [Google Scholar] [CrossRef]

- Ehtiwesh, I.A.S.; Coelho, M.C.; Sousa, A.C.M. Exergetic and environmental life cycle assessment analysis of concentrated solar power plants. Renew. Sustain. Energy Rev. 2016, 56, 145–155. [Google Scholar] [CrossRef]

- Santoyo-Castelazo, E.; Solano-Olivares, K.; Martínez, E.; García, E.O.; Santoyo, E. Life cycle assessment for a grid-connected multi-crystalline silicon photovoltaic system of 3 kWp: A case study for Mexico. J. Clean. Prod. 2021, 316, 128314. [Google Scholar] [CrossRef]

- Krebs-Moberg, M.; Pitz, M.; Dorsette, T.L.; Gheewala, S.H. Third generation of photovoltaic panels: A life cycle assessment. Renew. Energy 2021, 164, 556–565. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, W.; Xie, L.; Wang, W.; Tian, H.; Chen, M.; Li, J. Life cycle assessment of semi-transparent photovoltaic window applied on building. J. Clean. Prod. 2021, 295, 126403. [Google Scholar] [CrossRef]

- Tirupati Rao, V.; Sekhar, Y.R. Comparative analysis on embodied energy and CO2 emissions for stand-alone crystalline silicon photovoltaic thermal (PVT) systems for tropical climatic regions of India. Sustain. Cities Soc. 2022, 78, 103650. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, W.; He, B.; Xie, L.; Chen, M.; Li, J.; Zhao, O.; Wu, X. A Comprehensive life cycle assessment study of innovative bifacial photovoltaic applied on building. Energy 2022, 245, 123212. [Google Scholar] [CrossRef]

- Goel, S.; Sharma, R.; Jena, B. Life cycle cost and energy assessment of a 3.4 kWp rooftop solar photovoltaic system in India. Int. J. Amb. Energy 2022, 43, 1913221. [Google Scholar] [CrossRef]

- Jurčević, M.; Nižetić, S.; Čoko, D.; Arıcı, M.; Hoang, A.T.; Giama, E.; Papadopoulos, A. Techno-economic and environmental evaluation of photovoltaic-thermal collector design with pork fat as phase change material. Energy 2022, 254, 124284. [Google Scholar] [CrossRef]

- Lamnatou, C.; Notton, G.; Chemisana, D.; Cristofari, C. Life cycle analysis of a building-integrated solar thermal collector, based on embodied energy and embodied carbon methodologies. Energy Build. 2014, 84, 378–387. [Google Scholar] [CrossRef]

- Hassani, S.; Saidur, R.; Mekhilef, S.; Taylor, R.A. Environmental and exergy benefit of nanofluid-based hybrid PV/T systems. Energy Convers. Manag. 2016, 123, 431–444. [Google Scholar] [CrossRef]

- Ren, M.; Mitchell, C.R.; Mo, W. Dynamic life cycle economic and environmental assessment of residential solar photovoltaic systems. Sci. Total Environ. 2020, 722, 137932. [Google Scholar] [CrossRef]

- Bahlawan, H.; Poganietz, W.R.; Spina, P.R.; Venturini, M. Cradle-to-gate life cycle assessment of energy systems for residential applications by accounting for scaling effects. Appl. Therm. Eng. 2020, 171, 115062. [Google Scholar] [CrossRef]

- Herrando, M.; Elduque, D.; Javierre, C.; Fueyo, N. Life cycle assessment of solar energy systems for the provision of heating, cooling and electricity in buildings: A comparative analysis. Energy Convers. Manag. 2022, 257, 115402. [Google Scholar] [CrossRef]

- Morini, A.A.; Hotza, D.; Ribeiro, M.J. Embodied energy and carbon footprint comparison in wind and photovoltaic power plants. Int. J. Energy Environ. Eng. 2022, 13, 457–467. [Google Scholar] [CrossRef]

- Khanjari, Y.; Pourfayaz, F.; Kasaeian, A.B. Numerical investigation on using of nanofluid in a water-cooled photovoltaic thermal system. Energy Convers. Manag. 2016, 122, 263–278. [Google Scholar] [CrossRef]

- Yazdanifard, F.; Ameri, M.; Ebrahimnia-Bajestan, E. Performance of nanofluid-based photovoltaic/thermal systems: A review. Renew. Sustain. Energy Rev. 2017, 76, 323–352. [Google Scholar] [CrossRef]

- Fayaz, H.; Nasrin, R.; Rahim, N.A.; Hasanuzzaman, M. Energy and exergy analysis of the PVT system: Effect of nanofluid flow rate. Sol. Energy 2018, 169, 217–230. [Google Scholar] [CrossRef]

- Abdallah, S.R.; Saidani-Scott, H.; Abdellatif, O.E. Performance analysis for hybrid PV/T system using low concentration MWCNT (water-based) nanofluid. Sol. Energy 2019, 181, 108–115. [Google Scholar] [CrossRef]

- Alous, S.; Kayfeci, M.; Uysal, A. Experimental investigations of using MWCNTs and graphene nanoplatelets water-based nanofluids as coolants in PVT systems. Appl. Therm. Eng. 2019, 162, 114265. [Google Scholar] [CrossRef]

- Sangeetha, M.; Manigandan, S.; Ashok, B.; Brindhadevi, K.; Pugazhendhi, A. Experimental investigation of nanofluid based photovoltaic thermal (PV/T) system for superior electrical efficiency and hydrogen production. Fuel 2021, 286, 119422. [Google Scholar] [CrossRef]

- Chow, T.T.; Pei, G.; Fong, K.F.; Lin, Z.; Chan, A.L.S.; Ji, J. Energy and exergy analysis of photovoltaic-thermal collector with and without glass cover. Appl. Energy 2009, 86, 310–316. [Google Scholar] [CrossRef]

- Kline, S.J.; McClintock, F.A. Describing uncertainties in single-sample experiments. Mech. Eng. 1953, 75, 3–8. [Google Scholar]

- SimaPro. User’s Manual; Pre Consultants BV: Amersfoort, The Netherlands, 2007. [Google Scholar]

- Meyer, L.; Tsatsaronis, G.; Buchgeister, J.; Schebek, L. Exergoenvironmental analysis for evaluation of the environmental impact of energy conversion systems. Energy 2009, 34, 75–89. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management-Life Cycle Assessment-Principles and Framework. ISO (International Organization for Standardization): Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management-Life Cycle Assessment-Requirements and Guidelines. ISO (International Organization for Standardization): Geneva, Switzerland, 2006.

- Pantzali, M.N.; Kanaris, A.G.; Antoniadis, K.D.; Mouza, A.A.; Paras, S.V. Effect of nanofluids on the performance of a miniature plate heat exchanger with modulated surface. Int. J. Heat Fluid Flow 2009, 30, 691–699. [Google Scholar] [CrossRef]

- Shalaby, S.M.; Elfakharany, M.K.; Moharram, B.M.; Abosheiasha, H.F. Experimental study on the performance of PV with water cooling. Energy Rep. 2022, 8, 957–961. [Google Scholar] [CrossRef]

- Zilli, B.M.; Lenz, A.M.; de Souza, S.N.M.; Secco, D.; Nogueira, C.E.C.; Junior, O.H.A.; Nadaleti, W.C.; Siqueira, J.A.C.; Gurgacz, F. Performance and effect of water-cooling on a microgeneration system of photovoltaic solar energy in Paraná Brazil. J. Clean. Prod. 2018, 192, 477–485. [Google Scholar] [CrossRef]

- Nasrin, R.; Rahim, N.A.; Fayaz, H.; Hasanuzzaman, M. Water/MWCNT nanofluid based cooling system of PVT: Experimental and numerical research. Renew. Energy 2018, 121, 286–300. [Google Scholar] [CrossRef]

- Naghdbishi, A.; Yazdi, M.E.; Akbari, G. Experimental investigation of the effect of multi-wall carbon nanotube–Water/glycol based nanofluids on a PVT system integrated with PCM-covered collector. Appl. Therm. Eng. 2020, 178, 115556. [Google Scholar] [CrossRef]

- Gundala, S.; Basha, M.M.; Madhurima, V.; Praveena, N.; Kumar, S.V. An experimental performance on solar photovoltaic thermal collector with nanofluids for sustainable development. J. Nanomater. 2021, 2021, 6946540. [Google Scholar] [CrossRef]

- Hassan, A.; Wahab, A.; Qasim, M.A.; Janjua, M.M.; Ali, M.A.; Ali, H.M.; Jadoon, T.R.; Ali, E.; Raza, A.; Javaid, N. Thermal management and uniform temperature regulation of photovoltaic modules using hybrid phase change materials-nanofluids system. Renew. Energy 2020, 145, 282–293. [Google Scholar] [CrossRef]

- Goedkoop, M.; Spriensma, R. The Eco-Indicator 99: A Damage Oriented Method for Life Cycle Impact Assessment. 2000. Available online: www.pre.nl (accessed on 31 October 2022).

- Tiwari, A.; Raman, V.; Tiwari, G.N. Embodied energy analysis of hybrid photovoltaic thermal (PV/T) water collector. Int. J. Ambien. Energy 2007, 28, 181–188. [Google Scholar] [CrossRef]

- Chow, T.T.; Ji, J. Environmental life-cycle analysis of hybrid solar photovoltaic/thermal systems for use in Hong Kong. Int. J. Photoenergy 2012, 2012, 101968. [Google Scholar] [CrossRef]

- Kim, B.J.; Lee, J.Y.; Kim, K.H.; Hur, T. Evaluation of the environmental performance of sc-Si and mc-Si PV systems in Korea. Sol. Energy 2014, 99, 100–114. [Google Scholar] [CrossRef]

- Chen, W.; Hong, J.; Yuan, X.; Liu, J. Environmental impact assessment of monocrystalline silicon solar photovoltaic cell production: A case study in China. J. Clean. Prod. 2016, 112, 1025–1032. [Google Scholar] [CrossRef]

- Hou, G.; Sun, H.; Jiang, Z.; Pan, Z.; Wang, Y.; Zhang, X.; Zhao, Y.; Yao, Q. Life cycle assessment of grid-connected photovoltaic power generation from crystalline silicon solar modules in China. Appl. Energy 2016, 164, 882–890. [Google Scholar] [CrossRef]

- Sagani, A.; Mihelis, J.; Dedoussis, V. Techno-economic analysis and life-cycle environmental impacts of small-scale building-integrated PV systems in Greece. Energy Build. 2017, 139, 277–290. [Google Scholar] [CrossRef]

| Equipment | Parameter | Maximum Experimental Uncertainty |

|---|---|---|

| Pyranometer (MS-602, EKO instruments) | Solar irradiance | ±5.2 W/m2 |

| K-types thermocouple | Temperature | ±0.6 °C |

| Flowmeter (YF-S201, Sea company) | Volumetric flow rate | ±0.003 L/min |

| Data collecting board | Voltage | ±0.06 V |

| (USB TC-08, Pico) | Current | ±0.02 A |

| PV/T System (0.23146 m2) | Water (Storage) Tank (30 L) | Nanofluid Tank (6 L) | Pump (2.55 kg) | Support System | Other Parts | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Mass (kg) | Material | Mass (kg) | Material | Mass (kg) | Material | Mass (kg) | Material | Mass (kg) | Material | Mass (kg) |

| Solar glass | 2.93 | Main frame (galvanized iron) | 2.35 | Main frame (galvanized iron) | 2.76 | Copper | 0.20 | Main frame (galvanized iron) | 7.15 | Copper | 1.25 |

| PV cell | 0.02 | Insulation (PUR) | 1.03 | Insulation (PUR) | 1.23 | Steel | 0.68 | Plastic tube | 2.55 | ||

| Back sheet | 0.13 | Water | 30.17 | Water | 5.982 | Cast iron | 1.63 | Insulation (PUR) | 0.97 | ||

| Only PV module | 3.08 | Aluminum | 0.03 | ||||||||

| PV frame (aluminum) | 4.32 | Plastic cover | 0.01 | ||||||||

| Tube (copper) | 3.525 | ||||||||||

| Sheet (copper) | 3.525 | ||||||||||

| Main frame (galvanized iron) | 2.33 | ||||||||||

| Insulation (PUR) | 1.73 | ||||||||||

| Water | 1.85 | ||||||||||

| Only thermal system | 17.28 | ||||||||||

| Total weight | 20.36 | 33.55 | 9.97 | 2.55 | 7.15 | 4.77 | |||||

| Components | Indicators for the LCA Analysis | Energy for the CED Analysis | Processing Details | ||

|---|---|---|---|---|---|

| Material (mPts/kg) | Process (mPts/kg) | Disposal (mPts/kg) | Energy per Unit (MJ/kg) | ||

| PV module | |||||

| Solar glass (40.4%) | 58.00 | 0.00 | 2.20 | 15.00 | - |

| PV cell (2%) | 58.00 | 10.00 | 2.20 | 39714.50 | Electricity roof, packing glass |

| Backsheet (Polyethylene) (1.2%) | 360.00 | 35.90 | −1.00 | 32.88 | Blow foil extrusion, injection molding, milling/turning/drilling, and pressure forming |

| PV/T system | |||||

| Tube (Copper) (23%) | 1400.00 | 72.00 | 0.00 | 57.00 | Extruction |

| Water (6%) | 0.03 | 0.00 | 0.00 | 9.20 | - |

| Insulation (PUR) (5.6%) | 420.00 | 35.90 | 3.10 | 101.50 | Blow foil extrusion, injection molding, milling/turning/drilling, and pressure forming |

| Frame (aluminum) (14.1%) | 780.00 | 74.70 | −23.00 | 218.00 | Extruction, bending, shearing/stamping, spot welding |

| Galvanized iron (%0.5 zinc coating steel) (7.6%) | 241.70 | 243.50 | −5.61 | 34.80 | Sheet production, shearing/stamping, bending, and band zinc coating |

| Water tank | |||||

| Galvanized iron (%0.5 zinc coating steel) | 241.70 | 243.50 | −5.61 | 34.80 | Sheet production, shearing/stamping, bending, and band zinc coating |

| Insulation (PUR) | 420.00 | 35.90 | 3.10 | 101.50 | Blow foil extrusion, injection molding, milling/turning/drilling, and pressure forming |

| Water | 0.03 | 0.00 | 0.00 | 9.20 | |

| Nanofluid tank | |||||

| Galvanized iron (%0.5 zinc coating steel) | 241.70 | 243.50 | −5.61 | 34.80 | Sheet production, shearing/stamping, bending, and band zinc coating |

| Insulation (PUR) | 420.00 | 35.90 | 3.10 | 101.50 | Blow foil extrusion, injection molding, milling/turning/drilling, and pressure forming |

| Water | 0.03 | 0.00 | 0.00 | 9.20 | |

| Pump | |||||

| Copper (8%) | 1400.00 | 72.00 | −23.00 | 57.00 | Extruction |

| Steel (26.5%) | 86.00 | 30.00 | 0.00 | 35.40 | Sheet production, shearing/stamping, and bending |

| Cast iron (64%) | 240.00 | 5.30 | 0.00 | 34.80 | Heat gas (industrial furnace) |

| Aluminum (1%) | 780.00 | 74.70 | −23.00 | 218.00 | Extruction, bending, shearing/stamping, and spot welding |

| Plastic cover (0.5%) | 380.00 | 35.90 | 3.10 | 77.70 | Blow foil extrusion, injection molding, milling/turning/drilling, and pressure forming |

| Support structure | |||||

| Galvanized iron (%0.5 zinc coating steel) | 241.70 | 243.50 | −5.61 | 34.80 | Sheet production, shearing/stamping, bending, and band zinc coating |

| Other pieces | |||||

| Plastic tube (53.5%) | 240.00 | 35.90 | 3.10 | 101.50 | Blow foil extrusion, injection molding, milling/turning/drilling, and pressure forming |

| Copper (26.2%) | 1400.00 | 72.00 | 0.00 | 57.00 | Extruction |

| Insulation (PUR) (20.3%) | 420.00 | 35.90 | 3.10 | 101.50 | Blow foil extrusion, injection molding, milling/turning/drilling, and pressure forming |

| Parameters\Nanofluids | Distilled Water | MWCNT/Water Mixture | Graphene Nanoplatelets/Water Mixture |

|---|---|---|---|

| Electrical efficiency of PV, % | 13.5 | 13.6 | 14.4 |

| Total efficiency of PV/T, % | 39.5 | 42.6 | 45.7 |

| Daily instant power, W | 22.13 | 23.25 | 23.88 |

| Total embodied energy, MJ | 3975.88 | 4081.06 | 4077.86 |

| Energy return factor (ERF) | 1.76 | 1.80 | 1.85 |

| Energy payback time (EPT), year | 11.39 | 11.13 | 10.83 |

| Environmental impact of electricity produced (EIE), Pts/kWh | 0.046 | 0.044 | 0.043 |

| Authors | Location | PV Type—System | Efficiency % | System Lifetime (Year) | Embodied Energy CED | Energy Payback Time (Years) | Other Results |

|---|---|---|---|---|---|---|---|

| Tiwari et al. [41] | New Delhi and Leh, India | Monocrystalline silicon PV–PV/T system with and without glazed | 11 | - | 4968–7480.8 MJ/m2 | 11.4–14.33 | Energy return on investment (dimensionless) 2.4–6.6 |

| Chow and Ji [42] | Hong Kong | building-integrated PV/T system | 13 | - | 4690.8–6220.8 MJ/m2 | 2.8- 3.8 | Energy return on investment (dimensionless) 5.9–8 Embodied emissions 297 g CO2.eq/m2 |

| Kim et al. [43] | South Korea | Multi-crystalline silicon PV | 14.91 | 25 | 0.44 MJ/kWh | 3.68 | Global warming potential 31.5 g CO2.eq/kWh |

| Monocrystalline silicon PV | 15.96 | 30 | 0.56 MJ/kWh | 4.65 | Global warming potential 41.8 g CO2.eq/kWh | ||

| Chen et al. [44] | China | Monocrystalline silicon PV | 15.7 | 25 | - | 0.42–0.91 | GHG 5.60–12.07 g CO2/kWh |

| Hou et al. [45] | Northwest China and East China | Monocrystalline silicon PV | 15 | 25 | 1123–1186 MJ/m2 | 1.7–2.3 | GHG 65.2–87.3 g CO2/kWh |

| Multi-crystalline silicon PV | 17.5 | 25 | 1034–1094 MJ/m2 | 1.6–2.1 | GHG 60.1–80.5 g CO2/kWh | ||

| Sagani et al. [46] | Athens, Greece | Polycrystalline silicon PV | 14.4 | 25 | - | 1.8–4.1 | CO2 payback time 1.5–3.5 years Environmental benefits of PV are between 3.85–19.55 tons CO2.eq/year compared with the conventional technology |

| This study | Turkey | Monocrystalline silicon PV–PV/T system | 13.5–14.4 | 25 | 3975 MJ, 4077 MJ, and 4081 MJ for water, graphene, and MWCNT, respectively | 11.39, 10.83, and 11.13 for water, graphene, and MWCNT, respectively. | Energy return on investment values were 1.76, 1.85, and 1.80; environmental impacts of electricity produced were 0.046, 0.043, and 0.044 Pts/kWh; and total efficiencies were 39.5%, 45.7%, and 42.6%, for water, graphene, and MWCNT, respectively |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dolgun, G.K.; Koşan, M.; Kayfeci, M.; Georgiev, A.G.; Keçebaş, A. Life Cycle Assessment and Cumulative Energy Demand Analyses of a Photovoltaic/Thermal System with MWCNT/Water and GNP/Water Nanofluids. Processes 2023, 11, 832. https://doi.org/10.3390/pr11030832

Dolgun GK, Koşan M, Kayfeci M, Georgiev AG, Keçebaş A. Life Cycle Assessment and Cumulative Energy Demand Analyses of a Photovoltaic/Thermal System with MWCNT/Water and GNP/Water Nanofluids. Processes. 2023; 11(3):832. https://doi.org/10.3390/pr11030832

Chicago/Turabian StyleDolgun, Gülşah Karaca, Meltem Koşan, Muhammet Kayfeci, Aleksandar G. Georgiev, and Ali Keçebaş. 2023. "Life Cycle Assessment and Cumulative Energy Demand Analyses of a Photovoltaic/Thermal System with MWCNT/Water and GNP/Water Nanofluids" Processes 11, no. 3: 832. https://doi.org/10.3390/pr11030832

APA StyleDolgun, G. K., Koşan, M., Kayfeci, M., Georgiev, A. G., & Keçebaş, A. (2023). Life Cycle Assessment and Cumulative Energy Demand Analyses of a Photovoltaic/Thermal System with MWCNT/Water and GNP/Water Nanofluids. Processes, 11(3), 832. https://doi.org/10.3390/pr11030832