Prediction of Oxygen Content in Boiler Flue Gas Based on a Convolutional Neural Network

Abstract

1. Introduction

2. Data Acquisition and Analysis

2.1. Data Acquisition

2.2. Data Analysis

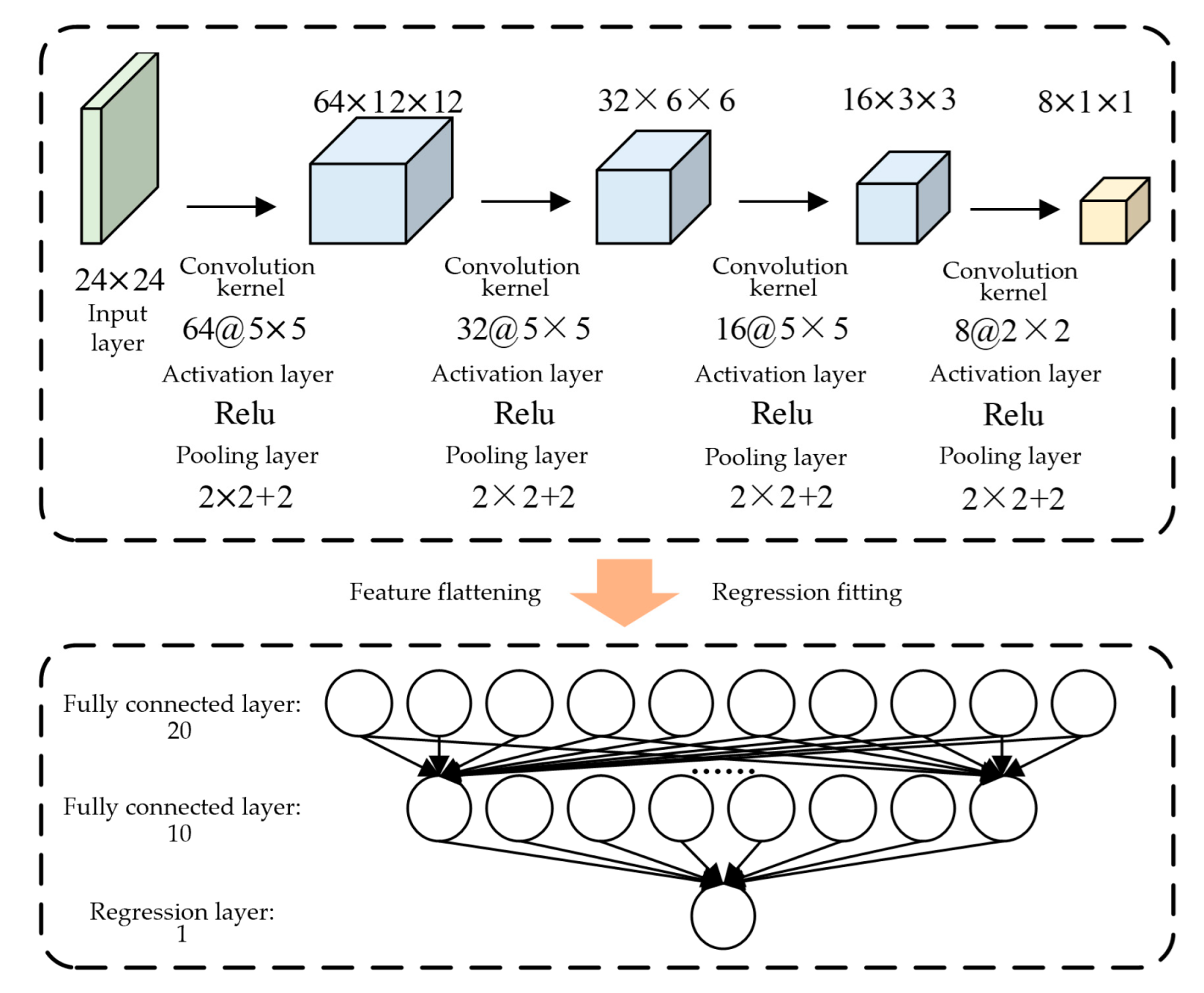

3. Basic Principles of the Convolutional Neural Network

3.1. Convolution Layer

3.2. Activation Layer

3.3. Pooling Layer

3.4. Full Connection Layer

4. Case Analysis

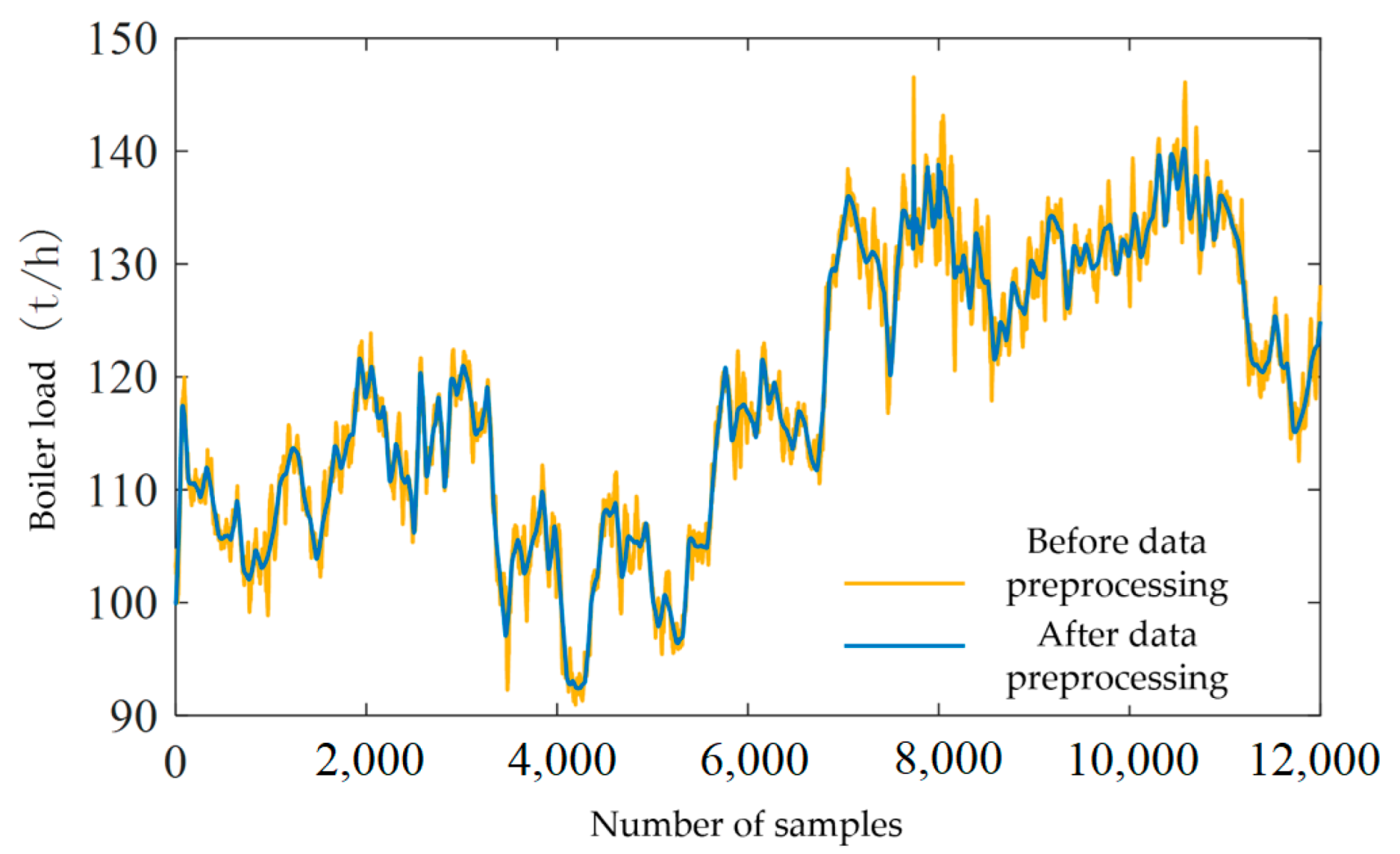

4.1. Data Pre-Processing

4.2. Model Evaluation Indicators

4.3. Modeling and Result Analysis

- (1)

- Time series prediction model (TS-CNN), ;

- (2)

- Conventional prediction model (CNN), ;

- (3)

- BP neural network model (BPNN) with a single hidden layer and 10 neurons;

- (4)

- Least squares support vector machine model with model parameter (LSSVM).

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Da, B.-W. Strategies for Clean Coal Technologies and Carbon Reduction Investment of Coal-Electric Supply Chain under Cap-and-Trade Model; China University of Mining and Technology: Xuzhou, China, 2021. [Google Scholar]

- Liu, C.-L.; Li, S.-N. Soft measurement of flue gas oxygen content based on LS-SVM and simplex. J. Eng. Therm. Energy Power 2010, 25, 292–296. [Google Scholar]

- Zhao, C.-Y. Discussion on logic calculation of oxygen content in boiler flue gas for 300MW unit. North China Electr. Power 2007, 8, 12–15. [Google Scholar]

- Luo, J.; Wu, L. Research status of soft measurement technology of typical thermal parameters for utility boilers. Therm. Power Gener. 2015, 44, 1–9+13. [Google Scholar]

- Liu, F.-G.; Hao, W.-D.; Yang, J.-Z.; Guo, Y.-Q.; Zhang, Q.-G.; Hou, F.-J. Economic analyze for utility boiler operated in different oxygen content outlet furnace and it’s optimization. Proc. CSEE 2003, 23, 172–176. [Google Scholar]

- Peng, X.; Lv, Y.-K. Study on analytical solutions on optimal economics of power boiler based on flue gas oxygen content. Electr. Power Sci. Eng. 2009, 25, 40–44. [Google Scholar]

- Liang, T.; Jin, Y.-J.; Jiang, W.; Liu, Z.-H. Optimization of NOx emissions from coal-fired boilers based on improved MVO and WLSSVM. China Meas. Test 2021, 47, 148–154. [Google Scholar]

- Xie, L.; Mao, G.-M.; Jin, X.-M.; Su, H.-Y. Predictive control and economic performance optimization of CFBB combustion process. CIESC J. 2016, 67, 695–700. [Google Scholar]

- Chui, E.-H.; Gao, H. Estimation of NOx emissions from coal-fired utility boilers. Fuel 2010, 89, 2977–2984. [Google Scholar] [CrossRef]

- Ma, L.Y.; Wang, Y.; Zuo, X. ANN-based soft sensing of oxygen content in boiler air-flue gas system. In Proceedings of the 2019 Chinese Control and Decision Conference, Nanchang, China, 3–5 June 2019. [Google Scholar]

- Zhang, W.; Chen, C.-B.; Wang, J.-C.; Li, J.-C.; Hao, S.-J. Prediction of the oxygen content in flue gas of power plant based on PSO-elman model. Autom. Instrum. 2020, 35, 75–79+85. [Google Scholar]

- Geng, M.-Y.; Hu, R.; Li, L. Prediction of oxygen content in boiler flue gas of thermal power unit. J. Univ. Shanghai Sci. Technol. 2021, 43, 319–324+359. [Google Scholar]

- Su, T.; Pan, H.-G.; Huang, X.-D.; Shao, X.-Q.; Ma, B. Soft sensor of flue gas oxygen content based on improved PSO-SVM in coal-fired power plant. J. Xi’an Univ. Sci. Technol. 2020, 40, 342–348. [Google Scholar]

- Zhang, Y.-F.; Wang, J.-C.; Shi, Y.-H.; Fei, L. Soft sensors model based on state constrained moving window. Control. Eng. China 2014, 21 (Suppl. 1), 115–117+120. [Google Scholar]

- Li, J.-Q.; Zhang, Y.-Y.; Niu, C.-L. Prediction of the oxygen content in flue gas of power plant based on PSO-LSSVM model. J. Eng. Therm. Energy Power 2018, 33, 49–55. [Google Scholar] [CrossRef]

- Tang, Z.-H.; Chai, X.-Y.; Cao, S.-X.; Mou, Z.-H.; Pang, X.-Y. Deep learning modeling for the NOx emissions of coal-fired boiler considering time-delay characteristics. Proc. CSEE 2020, 40, 6633–6644. [Google Scholar]

- Tang, Z.-H.; Li, Y.; Kusiak, A. A deep learning model for measuring oxygen content of boiler flue gas. IEEE Access 2020, 8, 12268–12278. [Google Scholar] [CrossRef]

- Tang, Z.-H.; Zhu, D.-Y.; Li, Y. Data driven based dynamic correction prediction model for NOx emission of coal fired boiler. Proc. CSEE 2022, 42, 5182–5193. [Google Scholar]

- Li, G.Q.; Qi, X.B.; Chan, K.-C.-C.; Chen, B. Deep bidirectional learning machine for predicting NOx emissions and boiler efficiency from a coal-fired boiler. Energy Fuels 2017, 31, 11471–11480. [Google Scholar] [CrossRef]

- Pan, H.; Su, T.; Huang, X.-D.; Wang, Z. LSTM-based soft sensor design for oxygen content of flue gas in coal-fired power plant. Trans. Inst. Meas. Control 2021, 43, 78–87. [Google Scholar] [CrossRef]

- Hu, H.-Z.; Zhang, J.-B.; Liu, H.-Q.; Li, M.-D.; Yang, Q.-Y. Power plant boiler combustion efficiency modeling approach based on convolutional neural networks. J. Xi’an Jiaotong Univ. 2019, 53, 10–15. [Google Scholar]

- Wang, Z.-Y.; Song, C.-F.; Chen, T. Deep learning based monitoring of furnace combustion state and measurement of heat release rate. Energy 2017, 131, 106–112. [Google Scholar] [CrossRef]

- Liu, Y.; Fan, Y.; Chen, J.-H. Flame images for oxygen content prediction of combustion systems using DBN. Energy Fuels 2017, 31, 8776–8783. [Google Scholar] [CrossRef]

- Han, Z.-Z.; Li, J.; Zhang, B.; Hossain, M.-M.; Xu, C.-L. Prediction of combustion state through a semi-supervised learning model and flame imaging. Fuel 2020, 289, 119745. [Google Scholar] [CrossRef]

- Xing, H.-T.; Guo, J.-L.; Liu, S.-A.; Yan, B.; Yang, Y.-Y. NOx emission forecasting based on CNN-LSTM hybrid neural network. Electron. Meas. Technol. 2022, 45, 98–103. [Google Scholar]

- Li, N.; Hu, Y. The deep convolutional neural network for NOx emission prediction of a coal-fired boiler. IEEE Access 2020, 8, 85912–85922. [Google Scholar] [CrossRef]

- Jia, X.-J.; Sang, Y.-C.; Li, Y.-J.; Du, W.; Zhang, G.-L. Short-term forecasting for supercharged boiler safety performance based on advanced data-driven modelling framework. Energy 2022, 239, 122449. [Google Scholar] [CrossRef]

| Variable Name | Unit | Scope |

|---|---|---|

| Main steam flow rate | t/h | [90.84, 162.25] |

| Main steam temperature | °C | [452.63, 470.31] |

| Main steam pressure | MPa | [4.45, 5.04] |

| Boiler load | t/h | [92.40, 140.22] |

| Drum pressure | MPa | [4.95, 5.51] |

| Furnace chamber differential pressure | Pa | [683.05, 1292.18] |

| Lower furnace temperature | °C | [854.78, 946.58] |

| Furnace outlet gas temperature | °C | [793.60, 919.27] |

| Furnace outlet air pressure | kPa | [−607.46, −203.32] |

| Economizer inlet temperature | °C | [269.64, 290.63] |

| Economizer inlet pressure | kPa | [−2767.96, −1463.91] |

| Secondary fan outlet temperature | °C | [4.07, 13.34] |

| Primary fan outlet temperature | kPa | [7.34, 8.46] |

| Secondary fan outlet pressure | kPa | [2.64, 5.64] |

| Feed water pressure | MPa | [5.36, 6.03] |

| Feed water temperature | °C | [149.52, 156.53] |

| Exhaust outlet temperature | °C | [123.43, 132.61] |

| Primary air volume | Nm3/h | [94,450.76, 102,729.19] |

| Secondary air volume | Nm3/h | [69,768.91, 136,108.61] |

| Feed water flow | t/h | [85.39, 160.62] |

| Total coal feed flow | t/h | [14.09, 23.66] |

| Current of 1# induced draft fan | A | [23.86, 32.37] |

| Current of 2# induced draft fan | A | [21.84, 33.74] |

| Oxygen content in boiler flue gas | % | [3.62, 7.09] |

| Variable | Unit | Sample 1 | Sample 2 | Sample 12,000 | Variable | Unit | Sample 1 | Sample 2 | Sample 12,000 |

|---|---|---|---|---|---|---|---|---|---|

| Main steam flow rate | t/h | 111.38 | 113.38 | 128.15 | Primary fan outlet temperature | kPa | 7.57 | 7.58 | 8.00 |

| Main steam temperature | °C | 464.18 | 464.18 | 464.76 | Secondary fan outlet pressure | kPa | 3.00 | 2.98 | 4.50 |

| Main steam pressure | MPa | 4.90 | 4.88 | 4.89 | Feed water pressure | MPa | 5.62 | 5.61 | 5.81 |

| Boiler load | t/h | 103.12 | 103.52 | 128.13 | Feed water temperature | °C | 151.84 | 151.94 | 153.75 |

| Drum pressure | MPa | 5.22 | 5.21 | 5.37 | Exhaust outlet temperature | °C | 124.88 | 124.91 | 128.18 |

| Furnace chamber differential pressure | kPa | 0.75 | 0.74 | 1.00 | Primary air volume | Nm3/h | 97,230.77 | 97,406.60 | 94,989.02 |

| Lower furnace temperature | °C | 899.78 | 899.68 | 914.63 | Secondary air volume | Nm3/h | 77,714.29 | 80,263.73 | 108,131.9 |

| Furnace outlet gas temperature | °C | 839.41 | 839.12 | 882.20 | Feed water flow | t/h | 98.11 | 98.29 | 111.91 |

| Furnace outlet air pressure | Pa | −257.02 | −255.80 | −479.24 | Total coal feed flow | t/h | 15.73 | 15.78 | 19.95 |

| Economizer inlet temperature | °C | 270.70 | 270.70 | 282.42 | Current of 1# induced draft fan | A | 26.43 | 26.50 | 28.37 |

| Economizer inlet pressure | kPa | −1.589 | −1.58 | −2.11 | Current of 2# induced draft fan | A | 21.94 | 21.96 | 26.58 |

| Secondary fan outlet temperature | °C | 12.19 | 12.11 | 9.21 | Oxygen content in boiler flue gas | % | 5.57 | 5.63 | 4.79 |

| Hyper-Parameter | Name | Value |

|---|---|---|

| Maximum number of iterations | MaxEpochs | 50 |

| Sample size of the minimum training batch | miniBatchSize | 25 |

| Initial learning rate | InitialLearnRate | 0.003 |

| Learning rate decline factor | LearnRateDropFactor | 0.2 |

| Learning rate decline frequency interval | LearnRateDropPeriod | 8 |

| Discard rate | dropout | 0.2 |

| Optimization algorithm | Gradient descent with momentum (SGDM) | |

| TS-CNN | CNN | BPNN | LSSVM | ||

|---|---|---|---|---|---|

| Training set | 0.9838 | 0.9798 | 0.9636 | 0.9660 | |

| 0.0903 | 0.0986 | 0.1283 | 0.1240 | ||

| Test set | 0.8929 | 0.8443 | 0.7963 | 0.8251 | |

| 0.1684 | 0.2070 | 0.3707 | 0.2448 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Li, G.; Shi, B. Prediction of Oxygen Content in Boiler Flue Gas Based on a Convolutional Neural Network. Processes 2023, 11, 990. https://doi.org/10.3390/pr11040990

Li Z, Li G, Shi B. Prediction of Oxygen Content in Boiler Flue Gas Based on a Convolutional Neural Network. Processes. 2023; 11(4):990. https://doi.org/10.3390/pr11040990

Chicago/Turabian StyleLi, Zhenhua, Guanghong Li, and Bin Shi. 2023. "Prediction of Oxygen Content in Boiler Flue Gas Based on a Convolutional Neural Network" Processes 11, no. 4: 990. https://doi.org/10.3390/pr11040990

APA StyleLi, Z., Li, G., & Shi, B. (2023). Prediction of Oxygen Content in Boiler Flue Gas Based on a Convolutional Neural Network. Processes, 11(4), 990. https://doi.org/10.3390/pr11040990