Accelerating Plastic Circularity: A Critical Assessment of the Pathways and Processes to Circular Plastics

Abstract

:1. Introduction

2. Methods

2.1. Determining Plastics’ Circularity Pathways

2.2. Assessing the State of Plastics Recycling

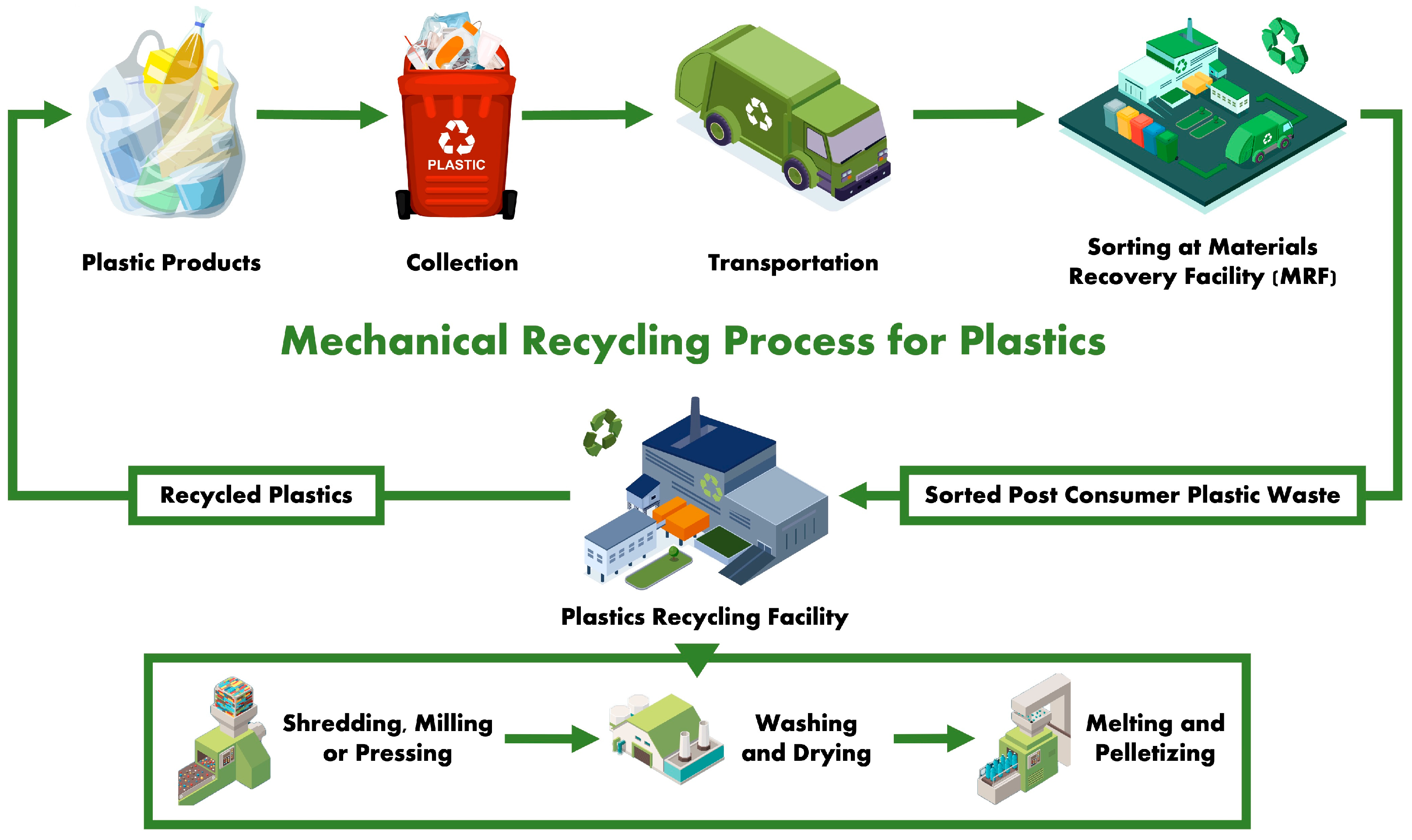

3. Mechanical Recycling

3.1. Advances in Enhancing Properties of Mechanically Recycled Plastics

3.2. Advances in Eliminating Contaminants and Impurities

4. Chemical Recycling

4.1. Solvent-Based Purification

4.2. Depolymerization

4.3. Pyrolysis

5. Discussion

5.1. Product Design

5.2. Collection and Sorting

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Mohanty, A.K.; Vivekanandhan, S.; Pin, J.M.; Misra, M. Composites from renewable and sustainable resources: Challenges and innovations. Science 2018, 362, 536–542. [Google Scholar] [CrossRef] [PubMed]

- Kakadellis, S.; Rosetto, G. Achieving a circular bioeconomy for plastics Designing plastics for assembly and disassembly is essential to closing the resource loop. Science 2021, 373, 49–50. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.-Q.; Ciacci, L.; Sun, N.-N.; Yoshioka, T. Sustainable cycles and management of plastics: A brief review of RCR publications in 2019 and early 2020. Resour. Conserv. Recycl. 2020, 159, 104822. [Google Scholar] [CrossRef]

- Yang, R.; Wang, X.D.; Yan, S.J.; Dong, A.; Luan, S.F.; Yin, J.H. Advances in design and biomedical application of hierarchical polymer brushes. Prog. Polym. Sci. 2021, 118, 30. [Google Scholar] [CrossRef]

- Li, X.M.; Xu, W.J.; Xin, Y.; Yuan, J.W.; Ji, Y.C.; Chu, S.N.; Liu, J.Q.; Luo, Q. Supramolecular Polymer Nanocomposites for Biomedical Applications. Polymers 2021, 13, 17. [Google Scholar] [CrossRef]

- OECD. Global Plastics Outlook; OECD Publishing: Paris, France, 2022. [Google Scholar]

- Zheng, J.; Suh, S. Strategies to reduce the global carbon footprint of plastics. Nat. Clim. Change 2019, 9, 374–378. [Google Scholar] [CrossRef]

- United Nations Environment Programme (UNEP). Plastics Science; UNEP/PP/INC.1/7; United Nations Environment Programme (UNEP): Punta del Este, Uruguay, 2022. [Google Scholar]

- Lebreton, L.; Andrady, A. Future scenarios of global plastic waste generation and disposal. Palgrave Commun. 2019, 5, 1–11. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. The New Plastics Economy: Rethinking the Future of Plastics & Catalysing Action; Ellen MacArthur Foundation: Cowes, UK, 2017. [Google Scholar]

- McCauley, D.; Parker, G.; Simms, A.; Jain, S.; Sharma, A.; Nag, D.S. Peak Plastics: Bending the Consumption Curve; Economist Impact and The Nippon Foundation: London, UK, 2023. [Google Scholar]

- Tan, J.; Cha, V. Innovation for Circular Economy. In An Introduction to Circular Economy; Springer: Singapore, 2021; pp. 369–395. [Google Scholar]

- Noble, K. The True Cost of Plastics. Available online: https://www.wwf.org.au/news/blogs/the-true-cost-of-plastics (accessed on 10 April 2022).

- Sutton, J. Why Is It Cheaper to Make New Plastic Bottles than to Recycle Old Ones? Available online: https://engineering.mit.edu/engage/ask-an-engineer/why-is-it-cheaper-to-make-new-plastic-bottles-than-to-recycle-old-ones/ (accessed on 7 April 2022).

- Lim, B.K.H.; San Thian, E. Biodegradation of polymers in managing plastic waste-A review. Sci. Total Environ. 2022, 813, 25. [Google Scholar] [CrossRef]

- Xu, G.Q.; Wang, Q.G. Chemically recyclable polymer materials: Polymerization and depolymerization cycles. Green Chem. 2022, 24, 2321–2346. [Google Scholar] [CrossRef]

- Tan, J.; Tan, F.J.; Ramakrishna, S. Transitioning to a Circular Economy: A Systematic Review of Its Drivers and Barriers. Sustainability 2022, 14, 1757. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Single-Use Plastics: A Roadmap for Sustainability; United Nations Environment Programme (UNEP): Nairobi, Kenya, 2018. [Google Scholar]

- Tan, J.; Tiwari, S.K.; Ramakrishna, S. Single-Use Plastics in the Food Services Industry: Can It Be Sustainable? Mater. Circ. Econ. 2021, 3, 7. [Google Scholar] [CrossRef]

- Campanale, C.; Massarelli, C.; Savino, I.; Locaputo, V.; Uricchio, V.F. A Detailed Review Study on Potential Effects of Microplastics and Additives of Concern on Human Health. Int. J. Environ. Res. Public Health 2020, 17, 1212. [Google Scholar] [CrossRef]

- Carrington, D. Microplastics Found Deep in Lungs of Living People for First Time. Available online: https://www.theguardian.com/environment/2022/apr/06/microplastics-found-deep-in-lungs-of-living-people-for-first-time (accessed on 6 April 2022).

- Carrington, D. Microplastics Found in Human Blood for First Time. Available online: https://www.theguardian.com/environment/2022/mar/24/microplastics-found-in-human-blood-for-first-time (accessed on 2 April 2022).

- Excell, C.; Viña, C.S.-L.; Worker, J.; Moses, E. Legal Limits on Single-Use Plastics and Microplastics: A Global Review of National Laws and Regulations; United Nations Environment Programme and World Resources Institute: Geneva, Switzerland, 2018. [Google Scholar]

- Knoblauch, D.; Mederake, L. Government policies combatting plastic pollution. Curr. Opin. Toxicol. 2021, 28, 87–96. [Google Scholar] [CrossRef]

- Rashingkar, G. Global Plastics and Composites Outlook, 2022; Frost & Sullivan: San Antonio, TX, USA, 2022. [Google Scholar]

- Mellor, M. Why is It so Damn Hard to Make A Climate Crisis-Friendly Plastic? Available online: https://www.wired.co.uk/article/plastic-alternatives (accessed on 10 April 2022).

- Stillman, J. Ikea, Lego, and Coca-Cola Are All Discovering How Hard It Is to Replace Plastic. Available online: https://www.inc.com/jessica-stillman/ikea-lego-coca-cola-are-all-discovering-how-hard-it-is-to-replace-plastic.html (accessed on 10 April 2022).

- Ahamed, A.; Vallam, P.; Iyer, N.S.; Veksha, A.; Bobacka, J.; Lisak, G. Life cycle assessment of plastic grocery bags and their alternatives in cities with confined waste management structure: A Singapore case study. J. Clean. Prod. 2021, 278, 123956. [Google Scholar] [CrossRef]

- Watkins, E.; Schweitzer, J.-P. Moving towards A Circular Economy for Plastics in the EU by 2030; Institute for European Environmental Policy (IEEP): Brussels, Belgium, 2018. [Google Scholar]

- Afanasieva, D. Plastic Pollution Could Trigger $20 Billion in Payouts. Available online: https://www.bloomberg.com/news/articles/2022-10-14/plastic-pollution-could-trigger-20-billion-in-lawsuit-payouts (accessed on 1 November 2022).

- Ministry of Foreign Affairs of Japan. G7 Climate, Energy and Environment Ministers’ Communiqué; Ministry of Foreign Affairs of Japan: Hiroshima, Japan, 2023. [Google Scholar]

- Moad, G.; Solomon, D.H. The Critical Importance of Adopting Whole-of-Life Strategies for Polymers and Plastics. Sustainability 2021, 13, 8218. [Google Scholar] [CrossRef]

- Ramesh, P.; Vinodh, S. State of art review on Life Cycle Assessment of polymers. Int. J. Sustain. Eng. 2020, 13, 411–422. [Google Scholar] [CrossRef]

- Walker, S.; Rothman, R. Life cycle assessment of bio-based and fossil-based plastic: A review. J. Clean. Prod. 2020, 261, 121158. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Visualising Circularity. Available online: https://buildingcircularity.org/ (accessed on 10 December 2022).

- Jehanno, C.; Alty, J.W.; Roosen, M.; De Meester, S.; Dove, A.P.; Chen, E.Y.X.; Leibfarth, F.A.; Sardon, H. Critical advances and future opportunities in upcycling commodity polymers. Nature 2022, 603, 803–814. [Google Scholar] [CrossRef] [PubMed]

- Collias, D.I.; James, M.I.; Layman, J.M. Introduction—Circular Economy of Polymers and Recycling Technologies. In Circular Economy of Polymers: Topics in Recycling Technologies; American Chemical Society: Washington, DC, USA, 2021; Volume 1391, pp. 1–21. [Google Scholar]

- Rudolph, N.; Kiesel, R.; Aumnate, C. 3-Plastics Recycling—Conservation of Valuable Resources. In Understanding Plastics Recycling; Rudolph, N., Kiesel, R., Aumnate, C., Eds.; Hanser: Munich, Germany, 2017; pp. 13–38. [Google Scholar] [CrossRef]

- ISO 15270:2008; Plastics—Guidelines for the Recovery and Recycling of Plastics Waste. International Organization for Standardization: Geneva, Switzerland, 2008.

- Kerkhoven, T.V.; Horvath, A.; Devriendt, A. Pathways towards Circular Plastics: Point of View; Deloitte Belgium: Deloitte, Belgium, 2021; p. 26. [Google Scholar]

- Lam, C.-S.; Ramanathan, S.; Carbery, M.; Gray, K.; Vanka, K.S.; Maurin, C.; Bush, R.; Palanisami, T. A Comprehensive Analysis of Plastics and Microplastic Legislation Worldwide. Water Air Soil Pollut. 2018, 229, 345. [Google Scholar] [CrossRef]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [PubMed]

- Nikiema, J.; Asiedu, Z. A review of the cost and effectiveness of solutions to address plastic pollution. Environ. Sci. Pollut. Res. 2022, 29, 24547–24573. [Google Scholar] [CrossRef]

- Briassoulis, D.; Hiskakis, M.; Babou, E. Technical specifications for mechanical recycling of agricultural plastic waste. Waste Manag. 2013, 33, 1516–1530. [Google Scholar] [CrossRef]

- Jiang, J.; Shi, K.; Zhang, X.; Yu, K.; Zhang, H.; He, J.; Ju, Y.; Liu, J.L. From plastic waste to wealth using chemical recycling: A review. J. Environ. Chem. Eng. 2022, 10, 106867. [Google Scholar] [CrossRef]

- Sica, C.; Dimitrijevic, A.; Scarascia-Mugnozza, G.; Picuno, P. Technical Properties of Regenerated Plastic Material Bars Produced from Recycled Agricultural Plastic Film. PPTEn 2015, 54, 1207–1214. [Google Scholar] [CrossRef]

- Yu, L.C.; Zhao, D.F.; Wang, W. Mechanical properties and long-term durability of recycled polysulfone plastic. Waste Manag. 2019, 84, 402–412. [Google Scholar] [CrossRef]

- Hundertmark, T.; Mayer, M.; McNally, C.; Simons, T.J.; Witte, C. How Plastics Waste Recycling Could Transform the Chemical Industry; McKinsey & Company: Dallas, TX, USA, 2018. [Google Scholar]

- Panashe, J.A.; Danyuo, Y. Recycling of plastic waste materials: Mechanical properties and implications for road construction. MRS Adv. 2020, 5, 1305–1312. [Google Scholar] [CrossRef]

- Basalp, D.; Tihminlioglu, F.; Sofuoglu, S.C.; Inal, F.; Sofuoglu, A. Utilization of Municipal Plastic and Wood Waste in Industrial Manufacturing of Wood Plastic Composites. Waste Biomass Valorization 2020, 11, 5419–5430. [Google Scholar] [CrossRef]

- Signorini, C.; Volpini, V. Mechanical Performance of Fiber Reinforced Cement Composites Including Fully-Recycled Plastic Fibers. Fibers 2021, 9, 15. [Google Scholar] [CrossRef]

- Beghetto, V.; Sole, R.; Buranello, C.; Al-Abkal, M.; Facchin, M. Recent Advancements in Plastic Packaging Recycling: A Mini-Review. Materials 2021, 14, 4782. [Google Scholar] [CrossRef]

- Lange, J.-P. Managing Plastic Waste—Sorting, Recycling, Disposal, and Product Redesign. ACS Sustain. Chem. Eng. 2021, 9, 15722–15738. [Google Scholar] [CrossRef]

- Schyns, Z.O.G.; Shaver, M.P. Mechanical Recycling of Packaging Plastics: A Review. Macromol. Rapid Commun. 2021, 42, 2000415. [Google Scholar] [CrossRef] [PubMed]

- Royal Society of Chemistry. Mechanical Recycling; Royal Society of Chemistry: London, UK, 2020; p. 1. [Google Scholar]

- Maris, J.; Bourdon, S.; Brossard, J.M.; Cauret, L.; Fontaine, L.; Montembault, V. Mechanical recycling: Compatibilization of mixed thermoplastic wastes. Polym. Degrad. Stab. 2018, 147, 245–266. [Google Scholar] [CrossRef]

- Abu-Saleem, M.; Zhuge, Y.; Hassanli, R.; Ellis, M.; Rahman, M.M.; Levett, P. Microwave radiation treatment to improve the strength of recycled plastic aggregate concrete. Case Stud. Constr. Mater. 2021, 15, 14. [Google Scholar] [CrossRef]

- Najafi, S.K.; Hamidinia, E.; Tajvidi, M. Mechanical properties of composites from sawdust and recycled plastics. J. Appl. Polym. Sci. 2006, 100, 3641–3645. [Google Scholar] [CrossRef]

- Delva, L.; Hubo, S.; Cardon, L.; Ragaert, K. On the role of flame retardants in mechanical recycling of solid plastic waste. Waste Manag. 2018, 82, 198–206. [Google Scholar] [CrossRef]

- Bajracharya, R.M.; Manalo, A.C.; Karunasena, W.; Lau, K.T. An overview of mechanical properties and durability of glass-fibre reinforced recycled mixed plastic waste composites. Mater. Des. 2014, 62, 98–112. [Google Scholar] [CrossRef]

- Ozasik, N.; Eren, O. Influence of recycled polyethylene terephthalate fibres on plastic shrinkage and mechanical properties of concrete. Front. Struct. Civ. Eng. 2022, 16, 792–802. [Google Scholar] [CrossRef]

- Guo, S.; Zheng, D.; Zhao, L.; Lu, Q.; Liu, X. Mechanical test and constitutive model of recycled plastic fiber reinforced recycled concrete. Constr. Build. Mater. 2022, 348, 128578. [Google Scholar] [CrossRef]

- Pešić, N.; Živanović, S.; Garcia, R.; Papastergiou, P. Mechanical properties of concrete reinforced with recycled HDPE plastic fibres. Constr. Build. Mater. 2016, 115, 362–370. [Google Scholar] [CrossRef]

- Zhuo, G.M.; Zhang, X.L.; Liu, Y.T.; Wang, M. Effect of multiple recycling on properties of poplar fiber reinforced high density polyethylene wood-plastic composites. Mater. Res. Express. 2019, 6, 9. [Google Scholar] [CrossRef]

- Davidson, M.G.; Furlong, R.A.; Mcmanus, M.C. Developments in the life cycle assessment of chemical recycling of plastic waste —A review. J. Clean. Prod. 2021, 293, 126163. [Google Scholar] [CrossRef]

- Briassoulis, D.; Pikasi, A.; Hiskakis, M. Recirculation potential of post-consumer /industrial bio-based plastics through mechanical recycling-Techno-economic sustainability criteria and indicators. Polym. Degrad. Stab. 2021, 183, 109217. [Google Scholar] [CrossRef]

- Larrain, M.; Van Passel, S.; Thomassen, G.; Van Gorp, B.; Nhu, T.T.; Huysveld, S.; Van Geem, K.M.; De Meester, S.; Billen, P. Techno-economic assessment of mechanical recycling of challenging post-consumer plastic packaging waste. Resour. Conserv. Recycl. 2021, 170, 105607. [Google Scholar] [CrossRef]

- Cai, K. Rise of the Recycling Robots. Available online: https://www.forbes.com/sites/kenrickcai/2020/11/12/rise-of-the-recycling-robots/?sh=6a21747065f9 (accessed on 15 December 2022).

- Paben, J. Another AI-Driven Sorter Hits the MRF Market. Available online: https://resource-recycling.com/recycling/2020/03/03/another-ai-driven-sorter-hits-the-mrf-market/ (accessed on 16 December 2022).

- Conner-Simons, A. Robots that can Sort Recycling. Available online: https://news.mit.edu/2019/mit-robots-can-sort-recycling-0416 (accessed on 16 December 2022).

- Gasde, J.; Woidasky, J.; Moesslein, J.; Lang-Koetz, C. Plastics Recycling with Tracer-Based-Sorting: Challenges of a Potential Radical Technology. Sustainability 2020, 13, 258. [Google Scholar] [CrossRef]

- Association des Industries de Marque (AIM). Digital Watermarks Initiative HolyGrail 2.0. Available online: https://www.digitalwatermarks.eu/ (accessed on 16 December 2022).

- Olscher, C.; Jandric, A.; Zafiu, C.; Part, F. Evaluation of Marker Materials and Spectroscopic Methods for Tracer-Based Sorting of Plastic Wastes. Polymers 2022, 14, 3074. [Google Scholar] [CrossRef]

- Woidasky, J.; Sander, I.; Schau, A.; Moesslein, J.; Wendler, P.; Wacker, D.; Gao, G.; Kirchenbauer, D.; Kumar, V.; Busko, D.; et al. Inorganic fluorescent marker materials for identification of post-consumer plastic packaging. Resour. Conserv. Recycl. 2020, 161, 104976. [Google Scholar] [CrossRef]

- Chemical Recycling Europe. Definition. Available online: https://www.chemicalrecyclingeurope.eu/copy-of-about-chemical-recycling-1 (accessed on 21 December 2022).

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef]

- Jiang, H.B.; Liu, W.L.; Zhang, X.H.; Qiao, J.L. Chemical Recycling of Plastics by Microwave-Assisted High-Temperature Pyrolysis. Glob. Chall. 2020, 4, 4. [Google Scholar] [CrossRef]

- Maisels, A.; Hiller, A.; Simon, F.G. Chemical Recycling for Plastic Waste: Status and Perspectives. Chem. Bio. Eng. Rev. 2022, 9, 541–555. [Google Scholar] [CrossRef]

- Quicker, P.; Seitz, M.; Vogel, J. Chemical recycling: A critical assessment of potential process approaches. Waste Manag. Res. 2022, 40, 1494–1504. [Google Scholar] [CrossRef]

- Tullo, A. Plastic has A Problem; is Chemical Recycling the Solution? Available online: https://cen.acs.org/environment/recycling/Plastic-problem-chemical-recycling-solution/97/i39 (accessed on 20 December 2022).

- Peng, Z.; Simons, T.J.; Wallach, J.; Youngman, A. Advanced Recycling: Opportunities for Growth. Available online: https://www.mckinsey.com/industries/chemicals/our-insights/advanced-recycling-opportunities-for-growth (accessed on 24 December 2022).

- Garcia-gutierrez, P.; Amadei, A.M.; Klenert, D.; Nessi, S.; Tonini, D.; Tosches, D.; Ardente, F.; Saveyn, H. Environmental and Economic Assessment of Plastic Waste Recycling A Comparison of Mechanical, Physical, Chemical Recycling and Energy Recovery of Plastic Waste; Publications Office of the European Union: Luxembourg, 2023. [Google Scholar] [CrossRef]

- Jeswani, H.; Krüger, C.; Russ, M.; Horlacher, M.; Antony, F.; Hann, S.; Azapagic, A. Life cycle environmental impacts of chemical recycling via pyrolysis of mixed plastic waste in comparison with mechanical recycling and energy recovery. Sci. Total Environ. 2021, 769, 144483. [Google Scholar] [CrossRef] [PubMed]

- Collins, R. Chemical Recycling and Dissolution of Plastics 2023–2033; IDTechEx: Cambridge, UK, 2022. [Google Scholar]

- Roosen, M.; Mys, N.; Kusenberg, M.; Billen, P.; Dumoulin, A.; Dewulf, J.; Van Geem, K.M.; Ragaert, K.; De Meester, S. Detailed Analysis of the Composition of Selected Plastic Packaging Waste Products and Its Implications for Mechanical and Thermochemical Recycling. Environ. Sci. Technol. 2020, 54, 13282–13293. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.-B.; Lv, X.-D.; Ni, H.-G. Solvent-based separation and recycling of waste plastics: A review. Chemosphere 2018, 209, 707–720. [Google Scholar] [CrossRef] [PubMed]

- Ügdüler, S.; Van Geem, K.M.; Roosen, M.; Delbeke, E.I.P.; De Meester, S. Challenges and opportunities of solvent-based additive extraction methods for plastic recycling. Waste Manag. 2020, 104, 148–182. [Google Scholar] [CrossRef]

- Pohjakallio, M.; Vuorinen, T.; Oasmaa, A. Chapter 13-Chemical routes for recycling—Dissolving, catalytic, and thermochemical technologies. In Plastic Waste and Recycling; Letcher, T.M., Ed.; Academic Press: Cambridge, MA, USA, 2020; pp. 359–384. [Google Scholar]

- Crippa, M.; De Wilde, B.; Koopmans, R.; Leyssens, J.; Linder, M.; Muncke, J.; Ritschkoff, A.-C.; Van Doorsselaer, K.; Velis, C.; Wagner, M. A Circular Economy for Plastics: Insights from Research and Innovation to Inform Policy and Funding Decisions; European Commission EC: Brussels, Belgium, 2019. [Google Scholar]

- Patel, D.; Moon, D.; Tangri, N.; Wilson, M. All Talk and No Recycling: An Investigation of the U.S. “Chemical Recycling” Industry; Global Alliance for Incinerator Alternatives: Berkeley, CA, USA, 2020. [Google Scholar]

- Solis, M.; Silveira, S. Technologies for chemical recycling of household plastics—A technical review and TRL assessment. Waste Manag. 2020, 105, 128–138. [Google Scholar] [CrossRef]

- Manžuch, Z.; Akelytė, R.; Camboni, M.; Carlander, D. Chemical Recycling of Polymeric Materials from Waste in the Circular Economy; European Chemicals Agency (ECHA): Helsinki, Finland, 2021. [Google Scholar]

- Vollmer, I.; Jenks, M.J.F.; Roelands, M.C.P.; White, R.J.; Harmelen, T.; Wild, P.; Laan, G.P.; Meirer, F.; Keurentjes, J.T.F.; Weckhuysen, B.M. Beyond Mechanical Recycling: Giving New Life to Plastic Waste. Angew. Chem. Int. Ed. 2020, 59, 15402–15423. [Google Scholar] [CrossRef]

- Sherwood, J. Closed-Loop Recycling of Polymers Using Solvents: Remaking plastics for a circular economy. Johns. Matthey Technol. Rev. 2020, 64, 4–15. [Google Scholar] [CrossRef]

- ISO 472:2013; Plastics—Vocabulary. ISO: Geneva, Switzerland, 2013.

- Manžuch, Z.; Akelytė, R.; Camboni, M.; Carlander, D.; Dunn, R.; Krikščiūnaitė, G. Chemical Recycling of Polymeric Materials from Waste in the Circular Economy; RPA Europe: Milan, Italy, 2021. [Google Scholar]

- Datta, J.; Kopczyńska, P. From polymer waste to potential main industrial products: Actual state of recycling and recovering. Crit. Rev. Environ. Sci. Technol. 2016, 46, 905–946. [Google Scholar] [CrossRef]

- Farahat, M.S.; Nikles, D.E. On the UV curability and mechanical properties of novel binder systems derived from poly(ethylene terephthalate) (PET) waste for solventless magnetic tape manufacturing, 1-Acrylated oligoesters. Macromol. Mater. Eng. 2001, 286, 695–704. [Google Scholar] [CrossRef]

- Chen, C.H.; Chen, C.Y.; Lo, Y.W.; Mao, C.F.; Liao, W.T. Studies of glycolysis of poly(ethylene terephthalate) recycled from postconsumer soft-drink bottles. I. Influences of glycolysis conditions. J. Appl. Polym. Sci. 2001, 80, 943–948. [Google Scholar] [CrossRef]

- Shukla, S.R.; Harad, A.M. Glycolysis of polyethylene terephthalate waste fibers. J. Appl. Polym. Sci. 2005, 97, 513–517. [Google Scholar] [CrossRef]

- Pardal, F.; Tersac, G. Comparative reactivity of glycols in PET glycolysis. Polym. Degrad. Stab. 2006, 91, 2567–2578. [Google Scholar] [CrossRef]

- Lee, A.; Liew, M.S. Tertiary recycling of plastics waste: An analysis of feedstock, chemical and biological degradation methods. J. Mater. Cycles Waste Manag. 2021, 23, 32–43. [Google Scholar] [CrossRef]

- Fortman, D.J.; Sheppard, D.T.; Dichtel, W.R. Reprocessing Cross-Linked Polyurethanes by Catalyzing Carbamate Exchange. Macromolecules 2019, 52, 6330–6335. [Google Scholar] [CrossRef]

- Feghali, E.; Cantat, T. Room Temperature Organocatalyzed Reductive Depolymerization of Waste Polyethers, Polyesters, and Polycarbonates. ChemSusChem 2015, 8, 980–984. [Google Scholar] [CrossRef]

- Monsigny, L.; Berthet, J.-C.; Cantat, T. Depolymerization of Waste Plastics to Monomers and Chemicals Using a Hydrosilylation Strategy Facilitated by Brookhart’s Iridium(III) Catalyst. ACS Sustain. Chem. Eng. 2018, 6, 10481–10488. [Google Scholar] [CrossRef]

- Fernandes, A.C.; Romão, C.C. Silane/MoO2Cl2 as an efficient system for the reduction of esters. J. Mol. Catal. A Chem. 2006, 253, 96–98. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, F.-S. Degradation of brominated flame retardant in computer housing plastic by supercritical fluids. J. Hazard. Mater. 2012, 205–206, 156–163. [Google Scholar] [CrossRef]

- Panda, A.K.; Singh, R.K.; Mishra, D.K. Thermolysis of waste plastics to liquid fuel: A suitable method for plastic waste management and manufacture of value added products—A world prospective. Renew. Sustain. Energy Rev. 2010, 14, 233–248. [Google Scholar] [CrossRef]

- Kumagai, S.; Yoshioka, T. Feedstock Recycling via Waste Plastic Pyrolysis. J. Jpn. Pet. Inst. 2016, 59, 243–253. [Google Scholar] [CrossRef]

- Yousef, S.; Eimontas, J.; Zakarauskas, K.; Striugas, N. Microcrystalline paraffin wax, biogas, carbon particles and aluminum recovery from metallised food packaging plastics using pyrolysis, mechanical and chemical treatments. J. Cleaner Prod. 2021, 290, 125878. [Google Scholar] [CrossRef]

- Jha, K.K.; Kannan, T.T.M. Recycling of plastic waste into fuel by pyrolysis-a review. In Proceedings of the International Conference on Newer Trends and Innovations in Mechanical Engineering (ICONTIME)-Materials Science, Electr Network, Tiruchirappalli, India, 15–16 October 2020; pp. 3718–3720. [Google Scholar]

- Maqsood, T.; Dai, J.; Zhang, Y.; Guang, M.; Li, B. Pyrolysis of plastic species: A review of resources and products. J. Anal. Appl. Pyrolysis 2021, 159, 105295. [Google Scholar] [CrossRef]

- Jacoby, M. Recycling Plastic Waste Using A Low-Cost Catalyst. Available online: https://cen.acs.org/synthesis/catalysis/Recycling-plastic-waste-using-low/100/web/2022/12 (accessed on 26 February 2022).

- Lopez-Urionabarrenechea, A.; de Marco, I.; Caballero, B.M.; Laresgoiti, M.F.; Adrados, A. Catalytic stepwise pyrolysis of packaging plastic waste. J. Anal. Appl. Pyrolysis 2012, 96, 54–62. [Google Scholar] [CrossRef]

- Mio, H.; Saeki, S.; Kano, J.; Saito, F. Estimation of Mechanochemical Dechlorination Rate of Poly(vinyl chloride). Environ. Sci. Technol. 2002, 36, 1344–1348. [Google Scholar] [CrossRef] [PubMed]

- Miao, Y.; von Jouanne, A.; Yokochi, A. Current Technologies in Depolymerization Process and the Road Ahead. Polymers 2021, 13, 449. [Google Scholar] [CrossRef] [PubMed]

- Vanderreydt, I.; Rommens, T.; Tenhunen, A.; Mortensen, L.F.; Tange, I. ETC/WMGE Report 3/2021: Greenhouse Gas Emissions and Natural Capital Implications of Plastics (Including Biobased Plastics); European Topic Centre Waste and Materials in a Green Economy: Copenhagen, Denmark, 2021. [Google Scholar]

- Mohamed, H.H.; Alsanea, A.A.; Alomair, N.A.; Akhtar, S.; Bahnemann, D.W. ZnO@ porous graphite nanocomposite from waste for superior photocatalytic activity. Environ. Sci. Pollut. Res. 2019, 26, 12288–12301. [Google Scholar] [CrossRef]

- Ko, S.; Kwon, Y.J.; Lee, J.U.; Jeon, Y.-P. Preparation of synthetic graphite from waste PET plastic. J. Ind. Eng. Chem. 2020, 83, 449–458. [Google Scholar] [CrossRef]

- Erickson, C. Graphite Emissions Fuel Search for Solutions Along EV Supply Chain. Available online: https://www.spglobal.com/marketintelligence/en/news-insights/latest-news-headlines/graphite-emissions-fuel-search-for-solutions-along-ev-supply-chain-69599516 (accessed on 26 February 2022).

- Liu, Y.; Zhou, C.; Li, F.; Liu, H.; Yang, J. Stocks and flows of polyvinyl chloride (PVC) in China: 1980–2050. Resour. Conserv. Recycl. 2020, 154, 104584. [Google Scholar] [CrossRef]

- Lombardi, M.; Rana, R.; Fellner, J. Material flow analysis and sustainability of the Italian plastic packaging management. J. Clean. Prod. 2021, 287, 125573. [Google Scholar] [CrossRef]

- Eriksen, M.K.; Pivnenko, K.; Faraca, G.; Boldrin, A.; Astrup, T.F. Dynamic Material Flow Analysis of PET, PE, and PP Flows in Europe: Evaluation of the Potential for Circular Economy. Environ. Sci. Technol. 2020, 54, 16166–16175. [Google Scholar] [CrossRef]

- Picuno, C.; Alassali, A.; Chong, Z.K.; Kuchta, K. Flows of post-consumer plastic packaging in Germany: An MFA-aided case study. Resour. Conserv. Recycl. 2021, 169, 105515. [Google Scholar] [CrossRef]

- Mehta, N.; Cunningham, E.; Doherty, M.; Sainsbury, P.; Bolaji, I.; Firoozi-Nejad, B.; Smyth, B.M. Using regional material flow analysis and geospatial mapping to support the transition to a circular economy for plastics. Resour. Conserv. Recycl. 2022, 179, 106085. [Google Scholar] [CrossRef]

- Lee, M.-Y.; Cho, N.-H.; Lee, S.-J.; Um, N.; Jeon, T.-W.; Kang, Y.-Y. Application of material flow analysis for plastic waste management in the Republic of Korea. J. Environ. Manag. 2021, 299, 113625. [Google Scholar] [CrossRef]

- Brouwer, M.; Picuno, C.; Thoden van Velzen, E.U.; Kuchta, K.; De Meester, S.; Ragaert, K. The impact of collection portfolio expansion on key performance indicators of the Dutch recycling system for Post-Consumer Plastic Packaging Waste, a comparison between 2014 and 2017. Waste Manag. 2019, 100, 112–121. [Google Scholar] [CrossRef]

- Laird, K. Mass Balance can Ease the Way towards Circularity. Available online: https://www.sustainableplastics.com/news/mass-balance-can-ease-way-circularity (accessed on 12 March 2023).

- Ministry of Sustainability and the Environment of the Republic of Singapore. Recycle Right. Available online: https://www.towardszerowaste.gov.sg/recycle-right/ (accessed on 12 March 2023).

- Industries, S. Sembwaste Partners Singapore Polytechnic to Pilot Smart Recycling Initiative in Punggol Shore; Sembcorp Industries: Singapore, 2022. [Google Scholar]

- Lim, C. Sustainability as Behavioural Change: Nudging the Good, Discouraging the Bad. Available online: https://www.csc.gov.sg/articles/sustainability-as-behavioural-change-nudging-the-good-discouraging-the-bad (accessed on 12 March 2023).

- Antonopoulos, I.; Faraca, G.; Tonini, D. Recycling of post-consumer plastic packaging waste in the EU: Recovery rates, material flows, and barriers. Waste Manag. 2021, 126, 694–705. [Google Scholar] [CrossRef]

- Heller, M.C.; Mazor, M.H.; Keoleian, G.A. Plastics in the US: Toward a material flow characterization of production, markets and end of life. Environ. Res. Lett. 2020, 15, 094034. [Google Scholar] [CrossRef]

- Jang, Y.-C.; Lee, G.; Kwon, Y.; Lim, J.-H.; Jeong, J.-H. Recycling and management practices of plastic packaging waste towards a circular economy in South Korea. Resour. Conserv. Recycl. 2020, 158, 104798. [Google Scholar] [CrossRef]

- Organisation for Economic Co-Operation and Development. Extended Producer Responsibility. Available online: https://www.oecd.org/environment/extended-producer-responsibility.htm (accessed on 12 March 2023).

- Kosior, E.; Crescenzi, I. Chapter 16-Solutions to the plastic waste problem on land and in the oceans. In Plastic Waste and Recycling; Letcher, T.M., Ed.; Academic Press: Cambridge, MA, USA, 2020; pp. 415–446. [Google Scholar]

- Roosen, M.; Mys, N.; Kleinhans, K.; Lase, I.S.; Huysveld, S.; Brouwer, M.; Thoden van Velzen, E.U.; Van Geem, K.M.; Dewulf, J.; Ragaert, K.; et al. Expanding the collection portfolio of plastic packaging: Impact on quantity and quality of sorted plastic waste fractions. Resour. Conserv. Recycl. 2022, 178, 106025. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, J.; Jia, S.; Ramakrishna, S. Accelerating Plastic Circularity: A Critical Assessment of the Pathways and Processes to Circular Plastics. Processes 2023, 11, 1457. https://doi.org/10.3390/pr11051457

Tan J, Jia S, Ramakrishna S. Accelerating Plastic Circularity: A Critical Assessment of the Pathways and Processes to Circular Plastics. Processes. 2023; 11(5):1457. https://doi.org/10.3390/pr11051457

Chicago/Turabian StyleTan, Jovan, Shuyue Jia, and Seeram Ramakrishna. 2023. "Accelerating Plastic Circularity: A Critical Assessment of the Pathways and Processes to Circular Plastics" Processes 11, no. 5: 1457. https://doi.org/10.3390/pr11051457

APA StyleTan, J., Jia, S., & Ramakrishna, S. (2023). Accelerating Plastic Circularity: A Critical Assessment of the Pathways and Processes to Circular Plastics. Processes, 11(5), 1457. https://doi.org/10.3390/pr11051457