Gas Injection Capacity of Slotted Liner and Perforation Completion in Underground Natural Gas Storage Reservoirs

Abstract

:1. Introduction

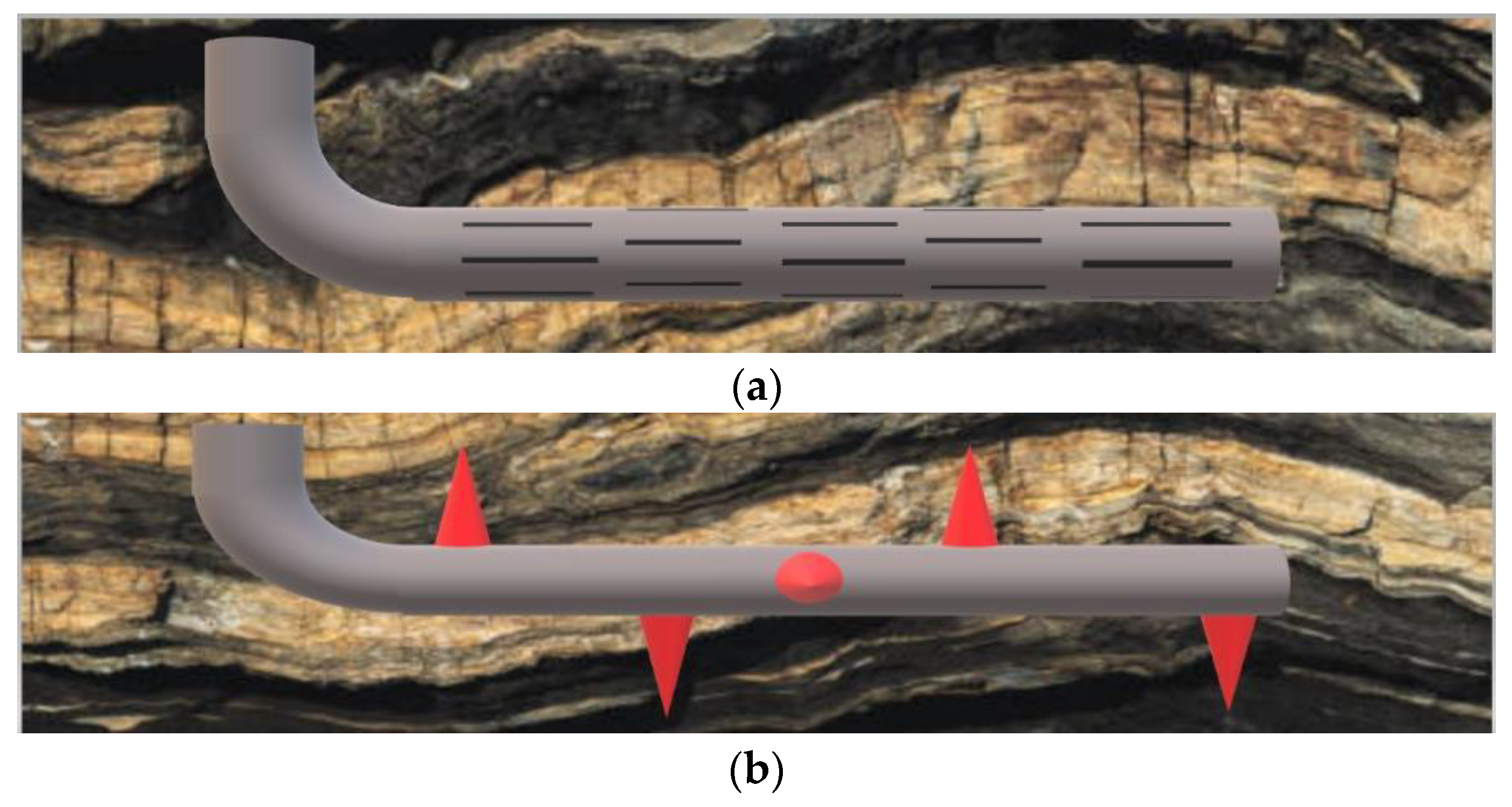

2. Model Development

2.1. Model Assumptions

- the reservoir is isothermal, and the temperature is not affected by the injection of natural gas;

- the frictional resistance to flow in the wellbore is neglected;

- the dissolution of natural gas in formation water is neglected;

- the interfacial tension is ignored;

- the natural fractures are ignored.

2.2. Mathematical Equations

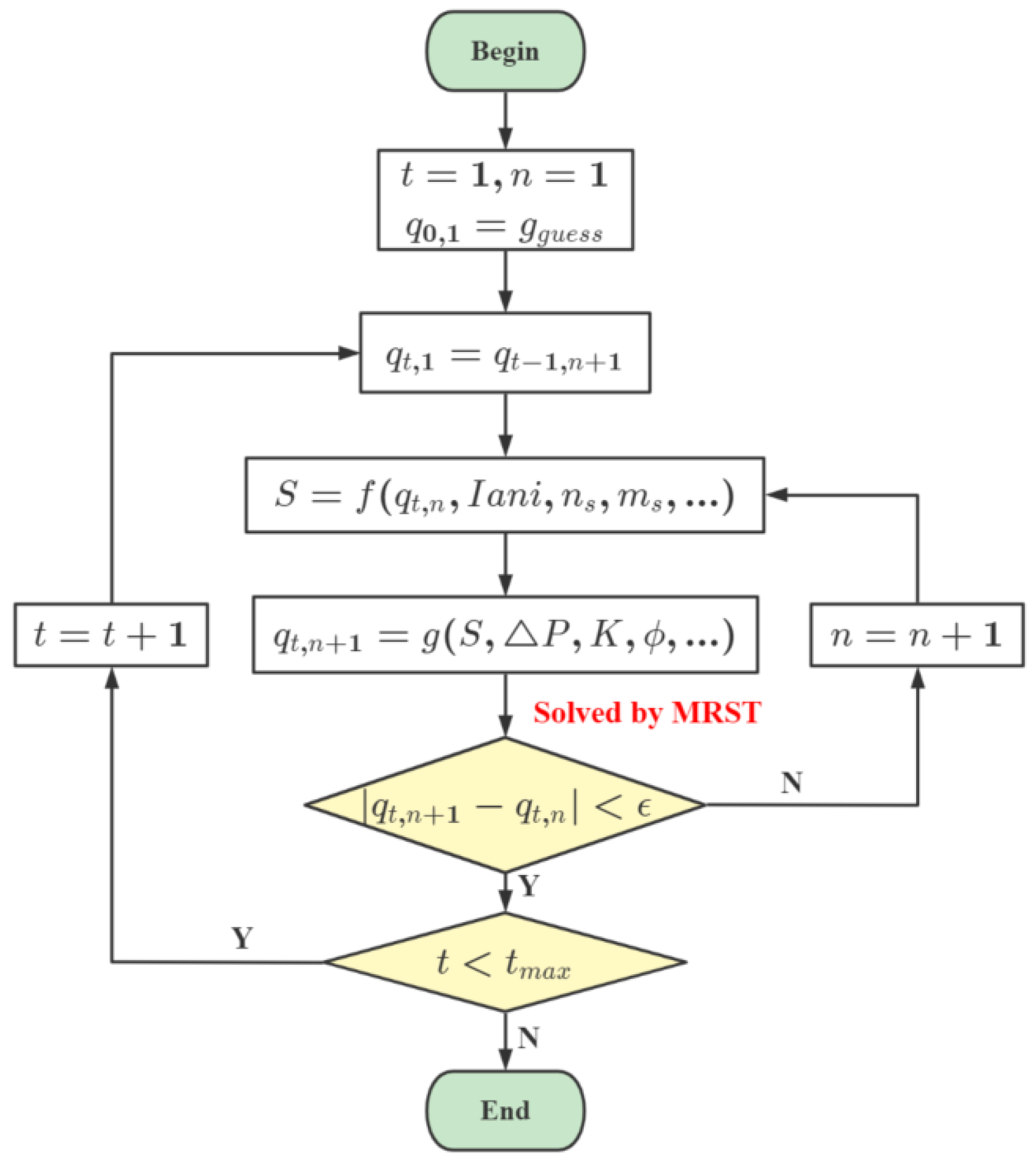

2.3. Numerical Calculation Method

3. Parameters of Upper Wuerhe Formation, K75 Gas Reservoir

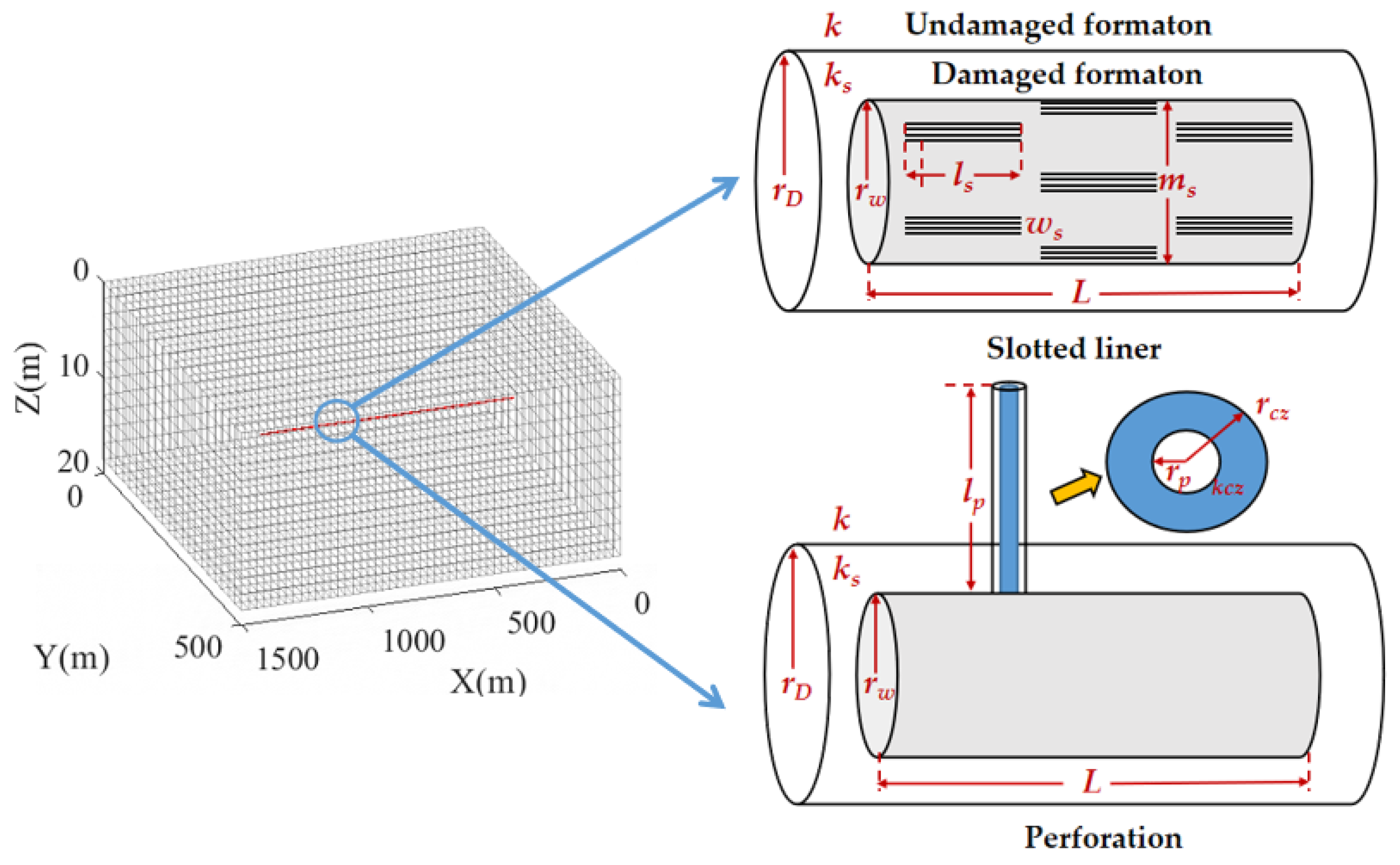

3.1. Numerical Model

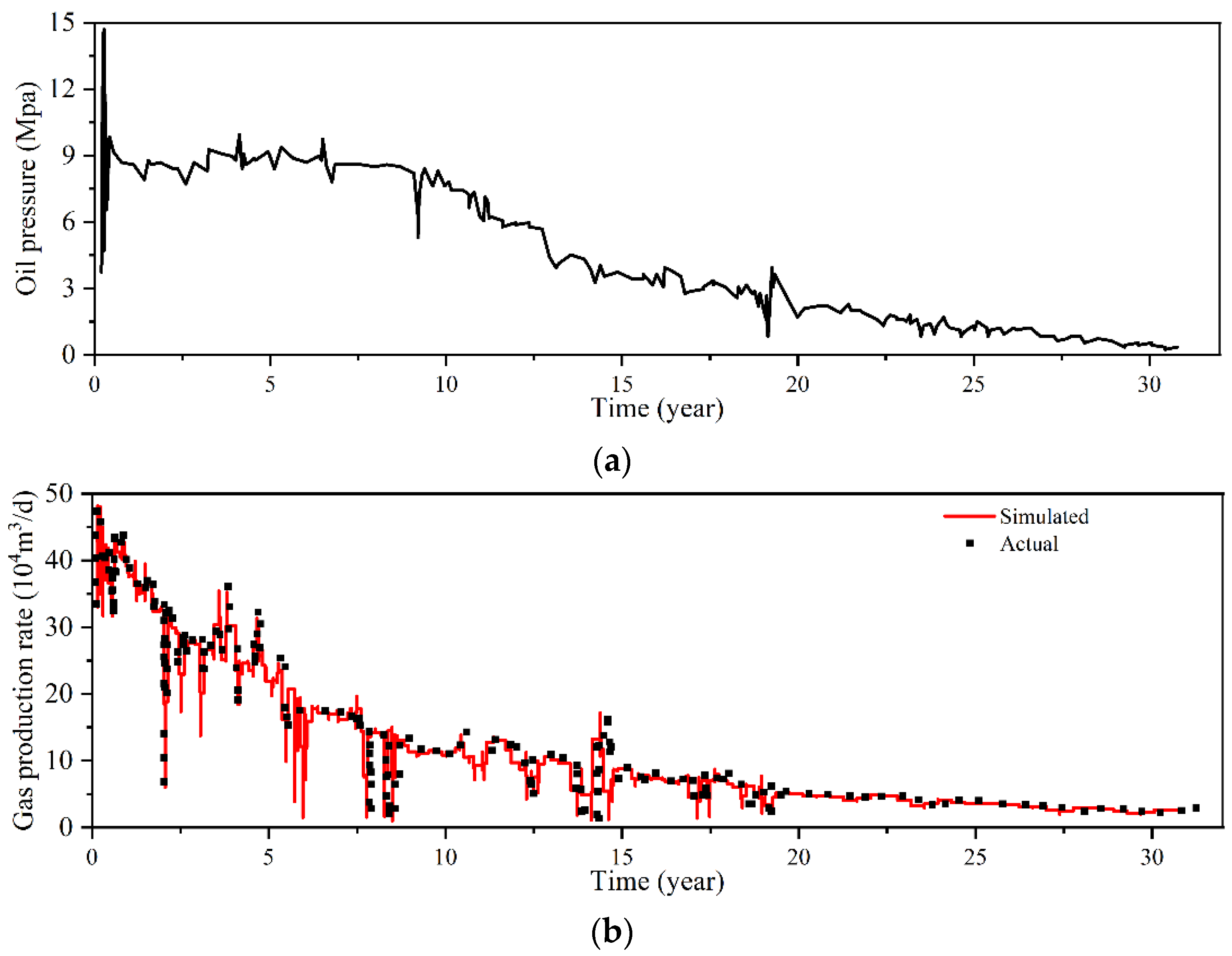

3.2. Model Validation

4. Results and Discussions

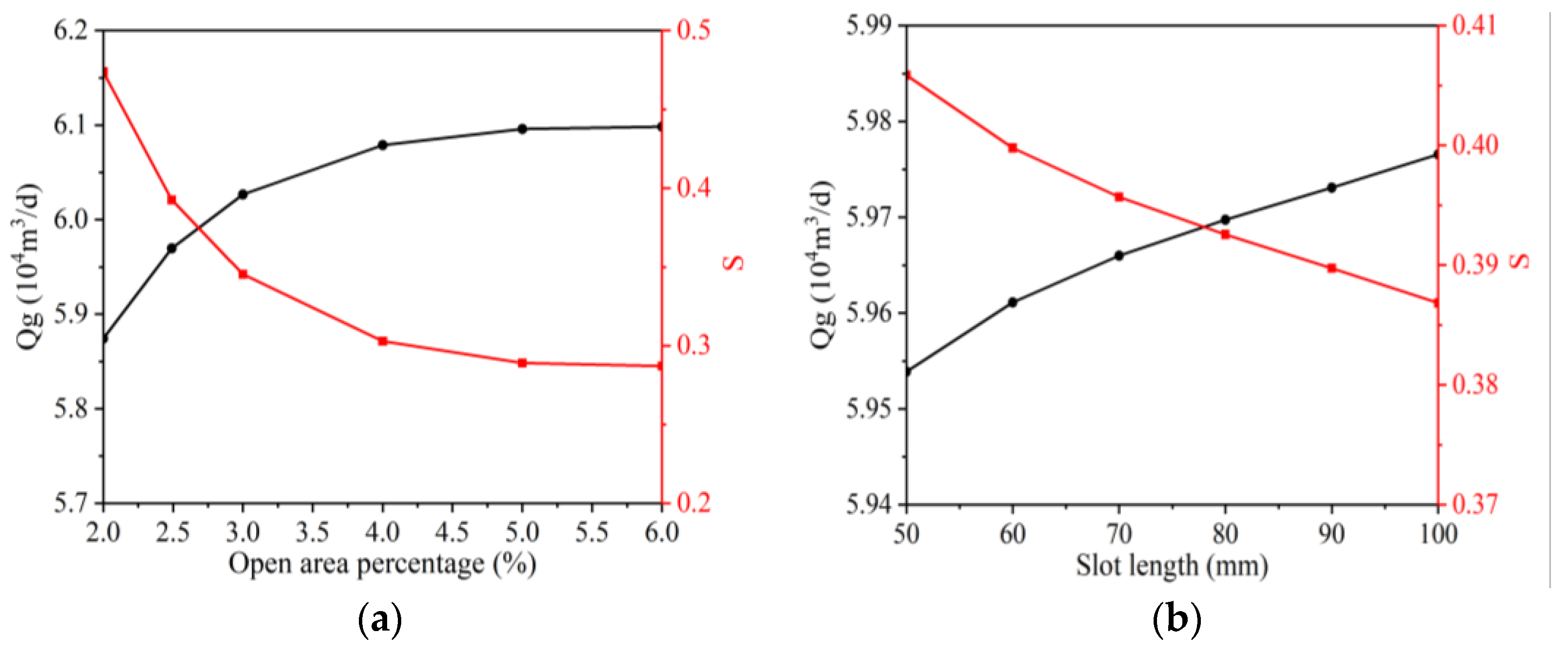

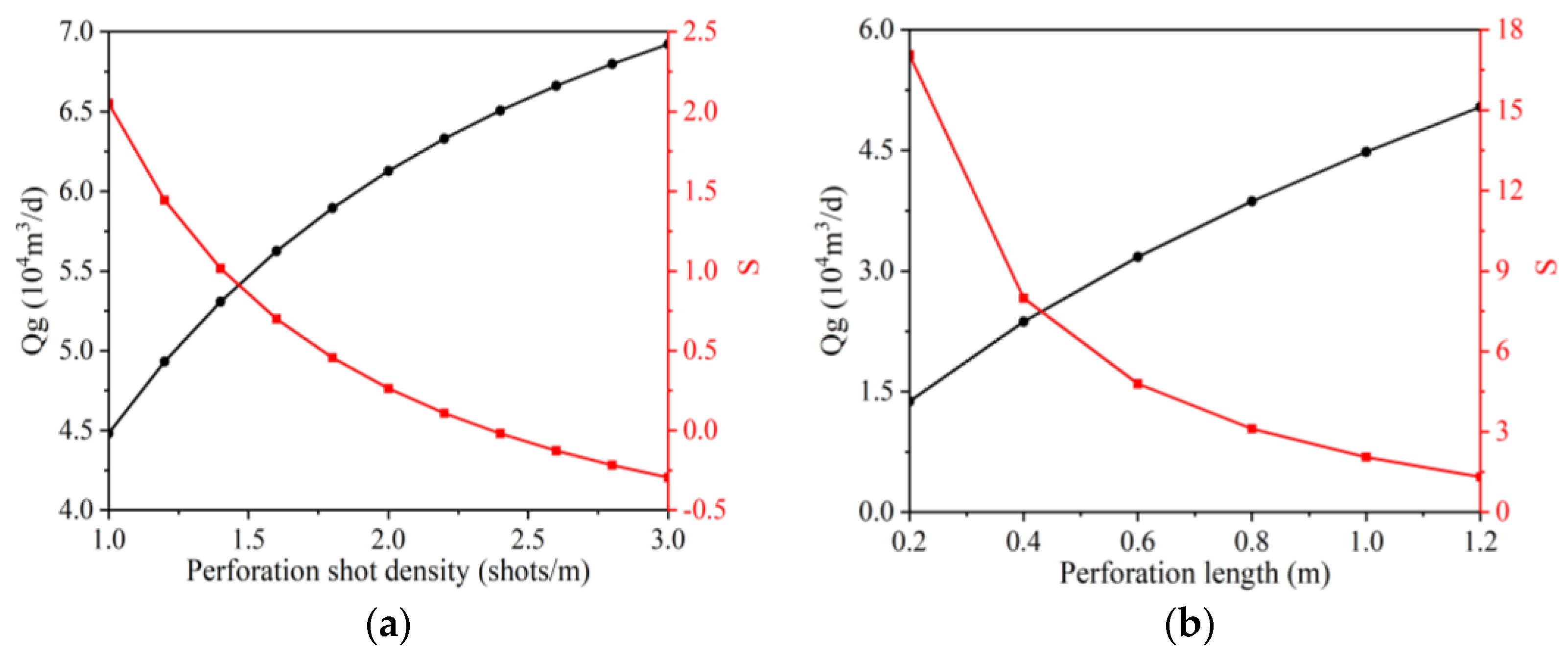

4.1. Effect of Intrinsic Design Parameters

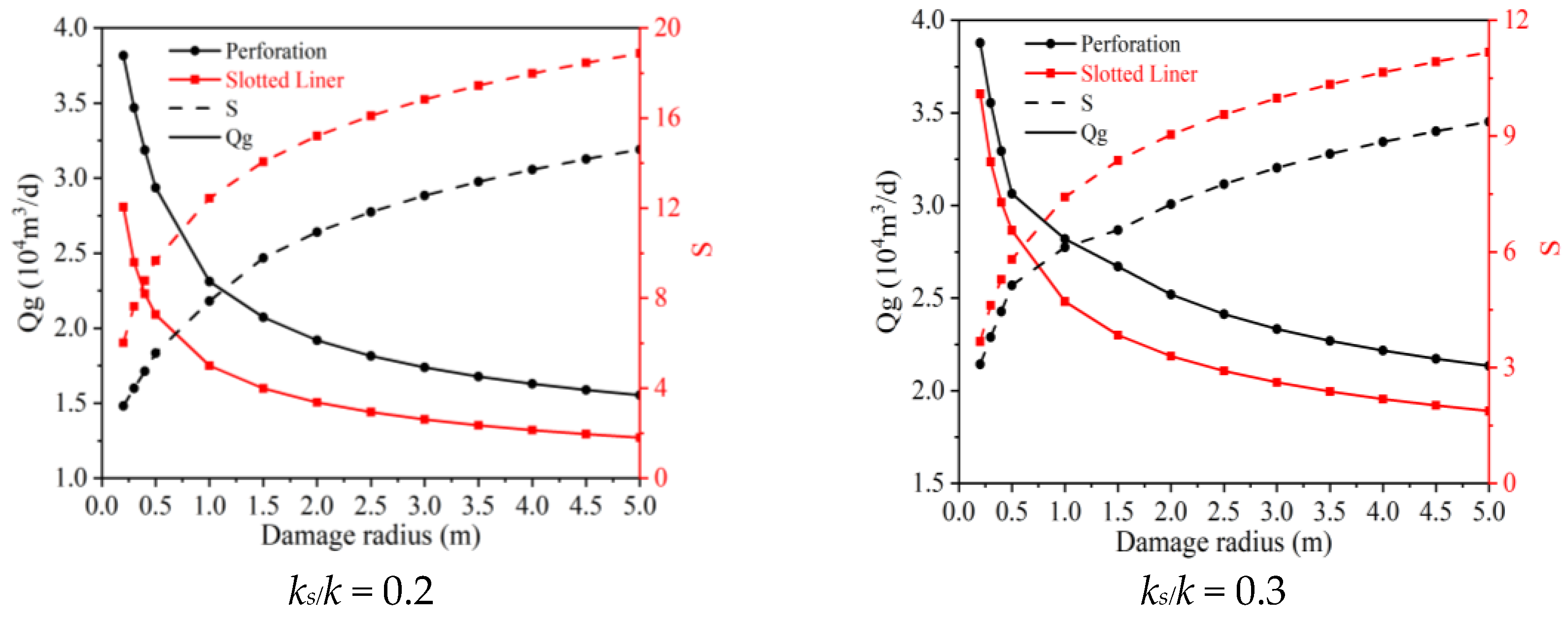

4.2. Effect of Formation Damage

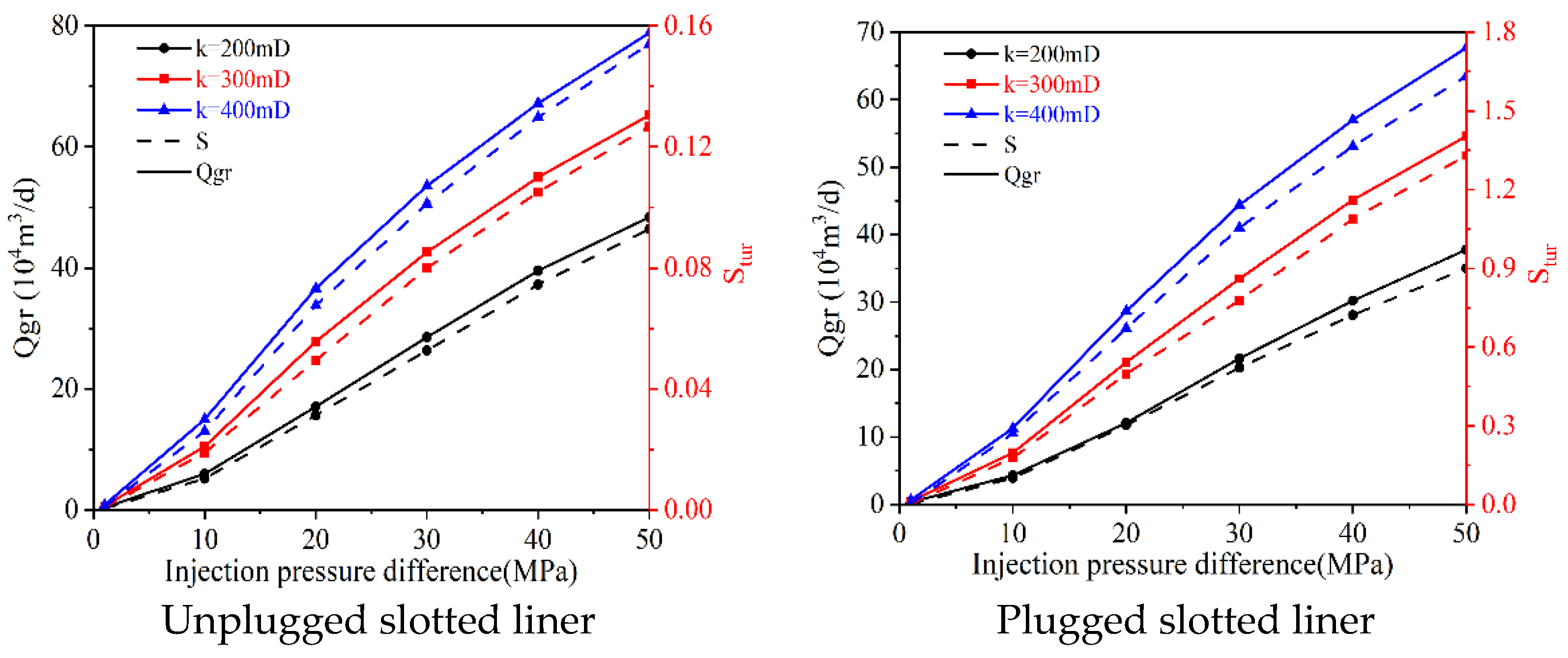

4.3. Effect of Injection Pressure

5. Conclusions

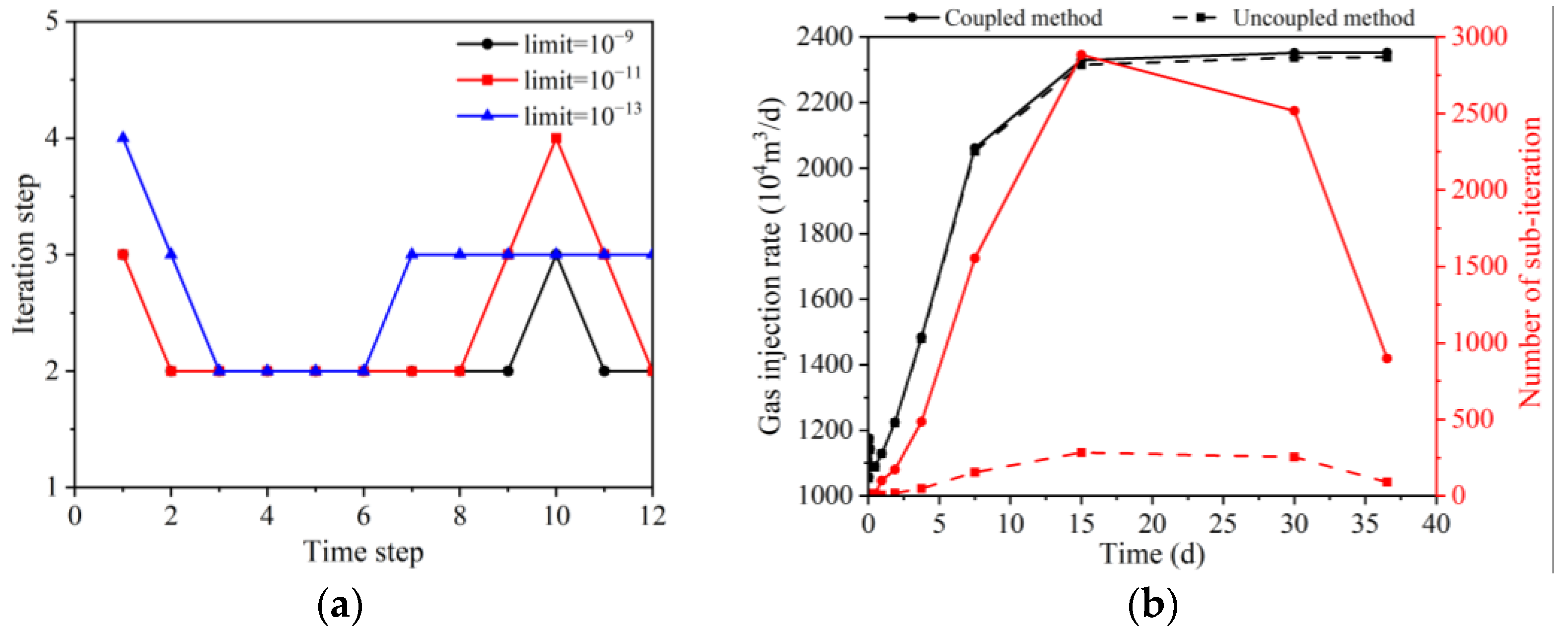

- The uncoupled model determines the turbulence damage associated with the gas injection rate by iterative means. The results show that, even when the convergence conditions are in the range of 10−14, the number of convergence steps required within each time step is no greater than 4. Moreover, the difference between the results of the coupled method and the uncoupled method is small, but the uncoupled method can significantly reduce computational costs, demonstrating the method’s feasibility.

- The design parameters of slotted liner and perforation completions mainly determine the value of the intrinsic skin factor of the horizontal well, especially the open area, and perforation density determines the connection degree between the horizontal well and the reservoir. However, a larger perforation density results in a negative skin factor, which means a better gas injection capability than an open hole completion.

- Perforation is more suitable than slotted liner for application in severe reservoir damage formations due to the fact that they can penetrate a particular damage zone. When ks/k = 0.05, the difference in skin factor between the two can reach a value of 40.87, and the gas injection rate of perforation is 3.44 times that of the slotted liner.

- It is easier to reduce turbulence damage for slotted liner completions than for perforation completions. At k = 400 mD, dp = 50 MPa, the turbulence damage of the slotted liner is 15.9% of that of the perforation. However, the slotted liner must be prevented from being plugged because the damage from plugging can rise to 3 to 10 times the original level.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kirschen, M.; Risonarta, V.; Pfeifer, H. Energy efficiency and the influence of gas burners to the energy related carbon dioxide emissions of electric arc furnaces in steel industry. Energy 2009, 34, 1065–1072. [Google Scholar] [CrossRef]

- Li, Q.; Wu, J. Factors affecting the lower limit of the safe mud weight window for drilling operation in hydrate-bearing sediments in the Northern South China Sea. Géoméch. Geophys. Geo-Energy Geo-Resour. 2022, 8, 82. [Google Scholar] [CrossRef]

- Li, Q.; Han, Y.; Liu, X.; Ansari, U.; Cheng, Y.; Yan, C. Hydrate as a by-product in CO2 leakage during the long-term sub-seabed sequestration and its role in preventing further leakage. Environ. Sci. Pollut. Res. 2022, 29, 77737–77754. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Wang, F.; Wang, Y.; Zhou, C.; Chen, J.; Forson, K.; Miao, R.; Su, Y.; Zhang, J. Effect of reservoir characteristics and chemicals on filtration property of water-based drilling fluid in unconventional reservoir and mechanism disclosure. Environ. Sci. Pollut. Res. 2023, 30, 55034–55043. [Google Scholar] [CrossRef]

- Dudley, B. BP statistical review of world energy 2022. In British Petroleum Statistical Review of World Energy; BP p.l.c., Ed.; Pureprint Group Limited: Uckfield, UK, 2022. [Google Scholar]

- Chen, Z.; Wang, H.; Li, T.; Si, I. Demand for storage and import of natural gas in China until 2060: Simulation with a dynamic model. Sustainability 2021, 13, 8674. [Google Scholar] [CrossRef]

- Katz, D.L.; Tek, M.R. Overview on underground storage of natural gas. J. Pet. Technol. 1981, 33, 943–951. [Google Scholar] [CrossRef]

- Xue, C.; Zhang, G.; Luo, T.; Wu, G.; Dai, L. Research and Application of One-Trip Casing Completion Technology in Hutubi Gas Storage. Xinjiang Oil Gas 2014, 10, 4. [Google Scholar]

- Abdel-Ghany, M.A.; Siso, S.; Hassan, A.M.; Pierpaolo, P.; Roberto, C. New Technology Application, Radial Drilling Petrobel, First Well in Egypt. In Proceedings of the Offshore Mediterranean Conference and Exhibition, Ravenna, Italy, 29–30 March 2011; OnePetro: Richardson, TX, USA, 2011. [Google Scholar]

- Zhang, J.; Tan, Y.; Zhang, T.; Yu, K.; Wang, X.; Zhao, Q. Natural gas market and underground gas storage development in China. J. Energy Storage 2020, 29, 101338. [Google Scholar] [CrossRef]

- Eren, T.; Polat, C. Natural gas underground storage and oil recovery with horizontal wells. J. Pet. Sci. Eng. 2020, 187, 106753. [Google Scholar] [CrossRef]

- Ferrandis, J.; Mateeva, A.; Jorgensen, P.; Lopez, J.; Dijkerman, H. Application of virtual-source technology to the Zuidwending gas storage project. Lead. Edge 2009, 28, 296–301. [Google Scholar] [CrossRef]

- Riddiford, F.; Wright, I.; Bishop, C.; Espie, T.; Tourqui, A. Monitoring geological storage: The in salah gas CO2 storage project. In Proceedings of the 7th International Conference on Greenhouse Gas Control Technologies, Vancouver, BC, Canada, 5–9 September 2004; pp. 1353–1359. [Google Scholar]

- Rutqvist, J. The geomechanics of CO2 storage in deep sedimentary formations. Geotech. Geol. Eng. 2012, 30, 525–551. [Google Scholar] [CrossRef]

- Sahin, S.; Abravci, S.; Tirek, A. Design and Status of the only Underground Gas Storage Project in Turkey after Three Years of Operation. In Proceedings of the SPE Russian Oil and Gas Exploration and Production Technical Conference and Exhibition, Moscow, Russia, 16–18 October 2012; OnePetro: Richardson, TX, USA, 2012. [Google Scholar]

- Fokker, P.; Wassing, B.; Van Leijen, F.; Hanssen, R.; Nieuwland, D. Application of an ensemble smoother with multiple data assimilation to the Bergermeer gas field, using PS-InSAR. Geomech. Energy Environ. 2016, 5, 16–28. [Google Scholar] [CrossRef]

- Oldenburg, C.M.; Bryant, S.L.; Nicot, J.-P. Certification framework based on effective trapping for geologic carbon sequestration. Int. J. Greenh. Gas Control. 2009, 3, 444–457. [Google Scholar] [CrossRef]

- Jones, V.; Drozd, R. Predictions of oil or gas potential by near-surface geochemistry. AAPG Bull. 1983, 67, 932–952. [Google Scholar]

- Gumrah, F.; Izgec, Ö.; Gokcesu, U.; Bagci, S. Modeling of underground gas storage in a depleted gas field. Energy Sources 2005, 27, 913–920. [Google Scholar] [CrossRef]

- Bagci, A.S.; Ozturk, B. Performance analysis of horizontal wells for underground gas storage in depleted gas fields. In Proceedings of the Eastern Regional Meeting, Lexington, KY, USA, 17–18 October 2007; OnePetro: Richardson, TX, USA, 2007. [Google Scholar]

- Zheng, D.; Hongcheng, X.; Jieming, W.; Junchang, S.; Kai, Z.; Chun, L.; Lei, S.; Ligen, T. Key evaluation techniques in the process of gas reservoir being converted into underground gas storage. Pet. Explor. Dev. 2017, 44, 840–849. [Google Scholar] [CrossRef]

- Tang, Y.; Ozkan, E.; Kelkar, M.; Sarica, C.; Yildiz, T. Performance of horizontal wells completed with slotted liners and perforations. In Proceedings of the SPE/CIM International Conference on Horizontal Well Technology, Calgary, AB, Canada, 6 November 2000; OnePetro: Richardson, TX, USA, 2000. [Google Scholar]

- Yang, G.; Wang, Z.M.; Peng, R.J.; Chen, T.; Ren, Z.X. Selection of Coal-Bed Methane Well Completion Method Based on Grey System Theory. Appl. Mech. Mater. 2013, 295–298, 3171–3174. [Google Scholar] [CrossRef]

- Bai, M.; Shen, A.; Meng, L.; Zhu, J.; Song, K. Well completion issues for underground gas storage in oil and gas reservoirs in China. J. Pet. Sci. Eng. 2018, 171, 584–591. [Google Scholar] [CrossRef]

- Roostaei, M.; Soroush, M.; Mohammadtabar, F.; Mohammadtabar, M.; Hosseini, S.A.; Mahmoudi, M.; Sadrzadeh, M.; Ghalambor, A.; Fattahpour, V. Design for reliability: Experimental and numerical simulation of cased and perforated completions with standalone screen. SPE Drill. Complet. 2021, 36, 680–706. [Google Scholar] [CrossRef]

- Szanyi, M.L.; Hemmingsen, C.S.; Yan, W.; Walther, J.H.; Glimberg, S.L. Near-wellbore modeling of a horizontal well with Computational Fluid Dynamics. J. Pet. Sci. Eng. 2018, 160, 119–128. [Google Scholar] [CrossRef]

- Li, B.; Sun, D.; Satti, R. Statistical analysis of significant factors affecting perforation flow at well scale. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LO, USA, 21–23 February 2012; OnePetro: Richardson, TX, USA, 2012. [Google Scholar]

- Shareef, N.F.; Abdulwahid, M.A. Experimental and numerical study of slug flow in horizontal perforated wellbore. Geoenergy Sci. Eng. 2023, 221, 111239. [Google Scholar] [CrossRef]

- Furui, K. A Comprehensive Skin Factor Model for Well Completions Based on Finite Element Simulations; The University of Texas at Austin: Austin, TX, USA, 2004. [Google Scholar]

- Ibrahim, M.A.; Jaafar, M.Z.; Yusof, M.A.M.; Idris, A.K. A review on the effect of nanoparticle in drilling fluid on filtration and formation damage. J. Pet. Sci. Eng. 2022, 217, 110922. [Google Scholar] [CrossRef]

- Bennion, D.B. An overview of formation damage mechanisms causing a reduction in the productivity and injectivity of oil and gas producing formations. J. Can. Pet. Technol. 2002, 41, 29–35. [Google Scholar] [CrossRef]

- Wang, X.; Economides, M.J. Horizontal well deliverability with turbulence effects. In Proceedings of the 8th European Formation Damage Conference, Scheveningen, The Netherlands, 27–29 May 2009; OnePetro: Richardson, TX, USA, 2009. [Google Scholar]

- Abobaker, E.; Elsanoose, A.; Khan, F.; Rahman, M.A.; Aborig, A.; Butt, S. Comparison of crushed-zone skin factor for cased and perforated wells calculated with and without including a tip-crushed zone effect. Geofluids 2021, 2021, 3689964. [Google Scholar] [CrossRef]

- Tang, Y.; Yildiz, T.; Ozkan, E.; Kelkar, M. Effects of formation damage and high-velocity flow on the productivity of perforated horizontal wells. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 29 September–2 October 2002; OnePetro: Richardson, TX, USA, 2002. [Google Scholar]

- Mahmoudi, M.; Fattahpour, V.; Nouri, A.; Yao, T.; Baudet, B.A.; Leitch, M.; Fermaniuk, B. New criteria for slotted liner design for heavy oil thermal production. In Proceedings of the SPE Thermal Well Integrity and Design Symposium; Banff, AB, Canada, 28 November–1 December 2016, OnePetro: Richardson, TX, USA, 2016. [Google Scholar]

- Furui, K.; Zhu, D.; Hill, A.D. A comprehensive skin-factor model of horizontal-well completion performance. SPE Prod. Facil. 2005, 20, 207–220. [Google Scholar] [CrossRef]

- Bahrami, H.; Rezaee, R.; Ostojic, J.; Nazhat, D.; Clennell, B. Evaluation of damage mechanisms and skin factor in tight gas reservoirs. In Proceedings of the SPE European Formation Damage Conference, Noordwijk, The Netherlands, 7–10 June 2011; OnePetro: Richardson, TX, USA, 2011. [Google Scholar]

- Forchheimer, P. Wasserbewegung durch boden. Z. Des Ver. Dtsch. Ing. 1901, 45, 1781–1788. [Google Scholar]

- Shi, W.; Yang, T.; Liu, H.; Yang, B. Numerical modeling of non-Darcy flow behavior of groundwater outburst through fault using the Forchheimer equation. J. Hydrol. Eng. 2018, 23, 04017062. [Google Scholar] [CrossRef]

- Jeirani, Z.; Mohebbi, A. Estimating the initial pressure, permeability and skin factor of oil reservoirs using artificial neural networks. J. Pet. Sci. Eng. 2006, 50, 11–20. [Google Scholar] [CrossRef]

- Whitaker, S. Flow in porous media I: A theoretical derivation of Darcy’s law. Transp. Porous Media 1986, 1, 3–25. [Google Scholar] [CrossRef]

- Ahmed, T. Reservoir Engineering Handbook; Gulf Professional Publishing: Houston, TX, USA, 2018. [Google Scholar]

- Peaceman, D.W. Representation of a horizontal well in numerical reservoir simulation. SPE Adv. Technol. Ser. 1993, 1, 7–16. [Google Scholar] [CrossRef]

- Wan, J.; Penmatcha, V.; Arbabi, S.; Aziz, K. Effects of grid systems on predicting horizontal-well productivity. SPE J. 2000, 5, 309–314. [Google Scholar] [CrossRef]

- Zeng, F.; Zhao, G.; Xu, X. Transient pressure behaviour under non-Darcy flow, formation damage and their combined effect for dual porosity reservoirs. J. Can. Pet. Technol. 2009, 48, 54–65. [Google Scholar] [CrossRef]

- Karacan, C.; Halleck, P.M. Comparison of shaped-charge perforating induced formation damage to gas- and liquid-saturated sandstone samples. J. Pet. Sci. Eng. 2003, 40, 61–75. [Google Scholar] [CrossRef]

- Lie, K.-A. An Introduction to Reservoir Simulation Using MATLAB/GNU Octave: User Guide for the MATLAB Reservoir Simulation Toolbox (MRST); Cambridge University Press: Cambridge, UK, 2019. [Google Scholar]

- Nianzhou, L.; Bo, L.; Yi, Z.; Min, W.; Quan, W.; Hang, S. Sedimentary Characteristics and Connectivity of Upper Wuerhe Formation in Wellblock Ke 75, Karamay Oilfield. Xinjiang Pet. Geol. 2022, 43, 417. [Google Scholar]

- Tao, K.; Cao, J.; Wang, Y.; Ma, W.; Xiang, B.; Ren, J.; Zhou, N. Geochemistry and origin of natural gas in the petroliferous Mahu sag, northwestern Junggar Basin, NW China: Carboniferous marine and Permian lacustrine gas systems. Org. Geochem. 2016, 100, 62–79. [Google Scholar] [CrossRef]

- Wang, A.; Yi, L.; Xiang, B.; Li, J.; Fan, C.; Li, C.; Zhou, N.; Wang, Y. Origin of deep heavy oils in the northwestern Junggar Basin (NW China) and implications for gas migration. Energy Explor. Exploit. 2020, 38, 819–840. [Google Scholar] [CrossRef]

- Li, H.; Tang, H.-m.; Qin, Q.-r.; Fan, C.-h.; Han, S.; Yang, C.; Zhong, C. Reservoir characteristics and hydrocarbon accumulation of Carboniferous volcanic weathered crust of Zhongguai high area in the western Junggar Basin, China. J. Cent. South Univ. 2018, 25, 2785–2801. [Google Scholar] [CrossRef]

- Du Shekuan, L.J.; Dewen, L.; Mingchen, J.; Zhijie, N. Application of reservoir description technique in karamay oilfield. Xinjiang Pet. Geol. 1995, 16, 347. [Google Scholar]

- Xie, J. Slotted liner design optimization for sand control in SAGD wells. In Proceedings of the SPE Thermal Well Integrity and Design Symposium, Banff, AB, Canada, 23–25 November 2015; OnePetro: Richardson, TX, USA, 2015. [Google Scholar]

- Li, S.; Fan, Y.; Gou, B.; Zhang, H.; Ye, J.; Ren, J.; Xiao, Y. Simulation of filtration fields with different completion methods in carbonate gas reservoirs. Chem. Technol. Fuels Oils 2021, 57, 698–704. [Google Scholar] [CrossRef]

- Andrade, A.; Chango, M.; Atahualpa, G.; Correa, R.; Corona, G.; Calvopina, B.; Pico, J. Production Performance of Multiple Completion Designs: Openhole, Slotted Liner, ICD, and AICD: A Case Study for Water Control in Villano Field, Ecuador. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 24–26 September 2018; OnePetro: Richardson, TX, USA, 2018. [Google Scholar]

- Placido, J.C.R.; Pasqualino, I.P.; Fonseca, C.E. Strength Analysis of Liners for Horizontal Wells. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 9–12 October 2005; OnePetro: Richardson, TX, USA, 2005. [Google Scholar]

- Liu, X.; Morita, N. 3D Finite Element Analysis and Experimental Study of Stability of Slotted Liners. In Proceedings of the 52nd US Rock Mechanics/Geomechanics Symposium, Seattle, WA, USA, 17–20 June 2018; OnePetro: Richardson, TX, USA, 2018. [Google Scholar]

- Liu, X.; Morita, N. Collapse and bending analysis of slotted liners with laboratory tests and 3D FEM. SPE J. 2020, 25, 2353–2372. [Google Scholar] [CrossRef]

| Parameters | Value | Unit |

|---|---|---|

| Model dimension (x × y × z) | 1500 × 500 × 18.5 | m |

| Number of gridblocks (x × y × z) | 51 × 21 × 11 | — |

| Horizontal well length | 1000 | m |

| Horizontal well diameter (2rw) | 139.7 | mm |

| Initial reservoir pressure | 21 | MPa |

| Reservoir temperature | 76 | °C |

| Reservoir permeability (kv/kh) | 26/22 | mD |

| Rock compressibility | 1 × 10−6 | psi−1 |

| Gas specific gravity | 0.596 | — |

| Gas compressibility | 10−4 | /barsa |

| Initial water saturation | 17 | % |

| Parameters | Base Case Value | Range | Unit |

|---|---|---|---|

| Damage zone radius (ks) | 1 | 0.2–5 | m |

| Damage zone permeability | =k | =0.05 k–0.3 k | mD |

| Slotted liner | |||

| Slot width (ws) | 0.5 | 0.2–1 | mm |

| Slot length (wl) | 80 | 50–100 | mm |

| Slot angular distribution (ms) | 5 | 1–12 | - |

| Open area percentage | 2.49 | 2–6 | % |

| Slot Pattern | Staggered | - | - |

| Inline number | 1 | - | - |

| Perforation | |||

| Perforation length(lp) | 1 | 0.2–1 | mm |

| Perforation radius(wl) | 80 | 0.2–12.7 | mm |

| Number of slots per unit length (ns) | 1 | - | /m |

| α | 60 | 0–360 | ° |

| Crushed zone permeability | =k/10 | - | mD |

| Crushed zone radius (rcz) | =3 rp | - | mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Dai, J.; Xie, B.; Du, J.; Li, J.; Liu, H.; Wang, T.; Mu, Z.; Tian, S. Gas Injection Capacity of Slotted Liner and Perforation Completion in Underground Natural Gas Storage Reservoirs. Processes 2023, 11, 1471. https://doi.org/10.3390/pr11051471

Wang J, Dai J, Xie B, Du J, Li J, Liu H, Wang T, Mu Z, Tian S. Gas Injection Capacity of Slotted Liner and Perforation Completion in Underground Natural Gas Storage Reservoirs. Processes. 2023; 11(5):1471. https://doi.org/10.3390/pr11051471

Chicago/Turabian StyleWang, Jia, Jiacheng Dai, Bin Xie, Junjun Du, Jie Li, Hailong Liu, Tianyu Wang, Zongjie Mu, and Shouceng Tian. 2023. "Gas Injection Capacity of Slotted Liner and Perforation Completion in Underground Natural Gas Storage Reservoirs" Processes 11, no. 5: 1471. https://doi.org/10.3390/pr11051471

APA StyleWang, J., Dai, J., Xie, B., Du, J., Li, J., Liu, H., Wang, T., Mu, Z., & Tian, S. (2023). Gas Injection Capacity of Slotted Liner and Perforation Completion in Underground Natural Gas Storage Reservoirs. Processes, 11(5), 1471. https://doi.org/10.3390/pr11051471