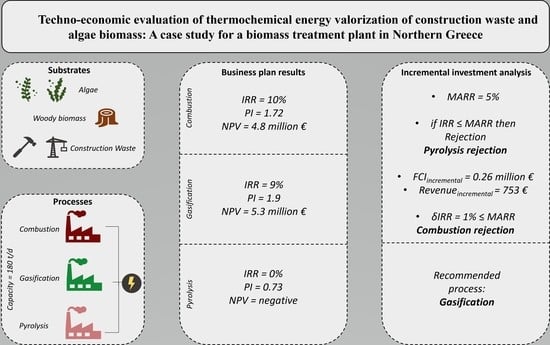

Techno-Economic Evaluation of the Thermochemical Energy Valorization of Construction Waste and Algae Biomass: A Case Study for a Biomass Treatment Plant in Northern Greece

Abstract

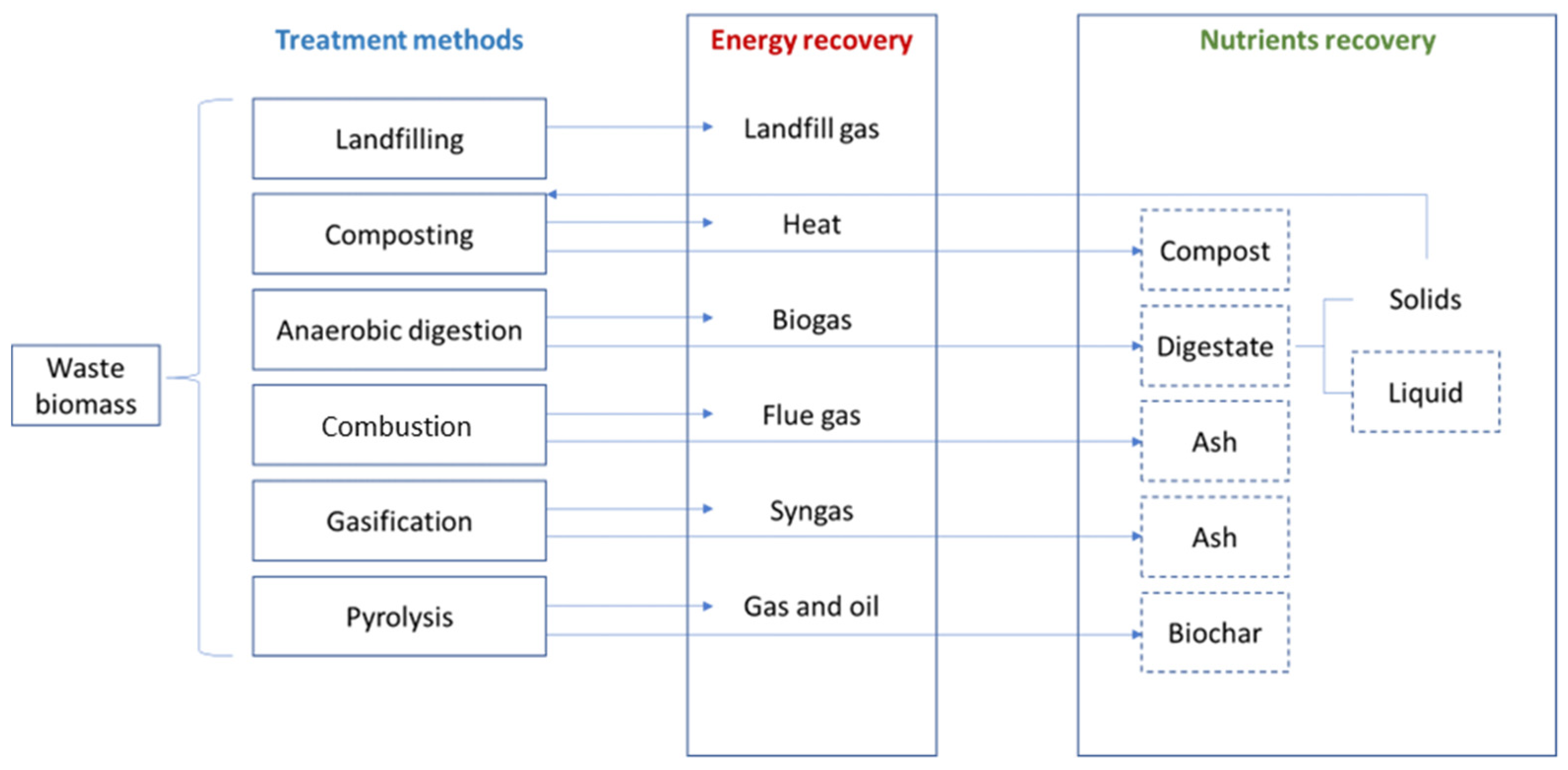

:1. Introduction

2. Materials and Methods

2.1. Feed Material and Pretreatment

2.2. Analytical Techniques

2.3. Description of the Proposed Processes

3. Results and Discussion

3.1. Biomass Characterization

3.2. Techno−Economic Evaluation of Alternative Treatment Methods of Biomass

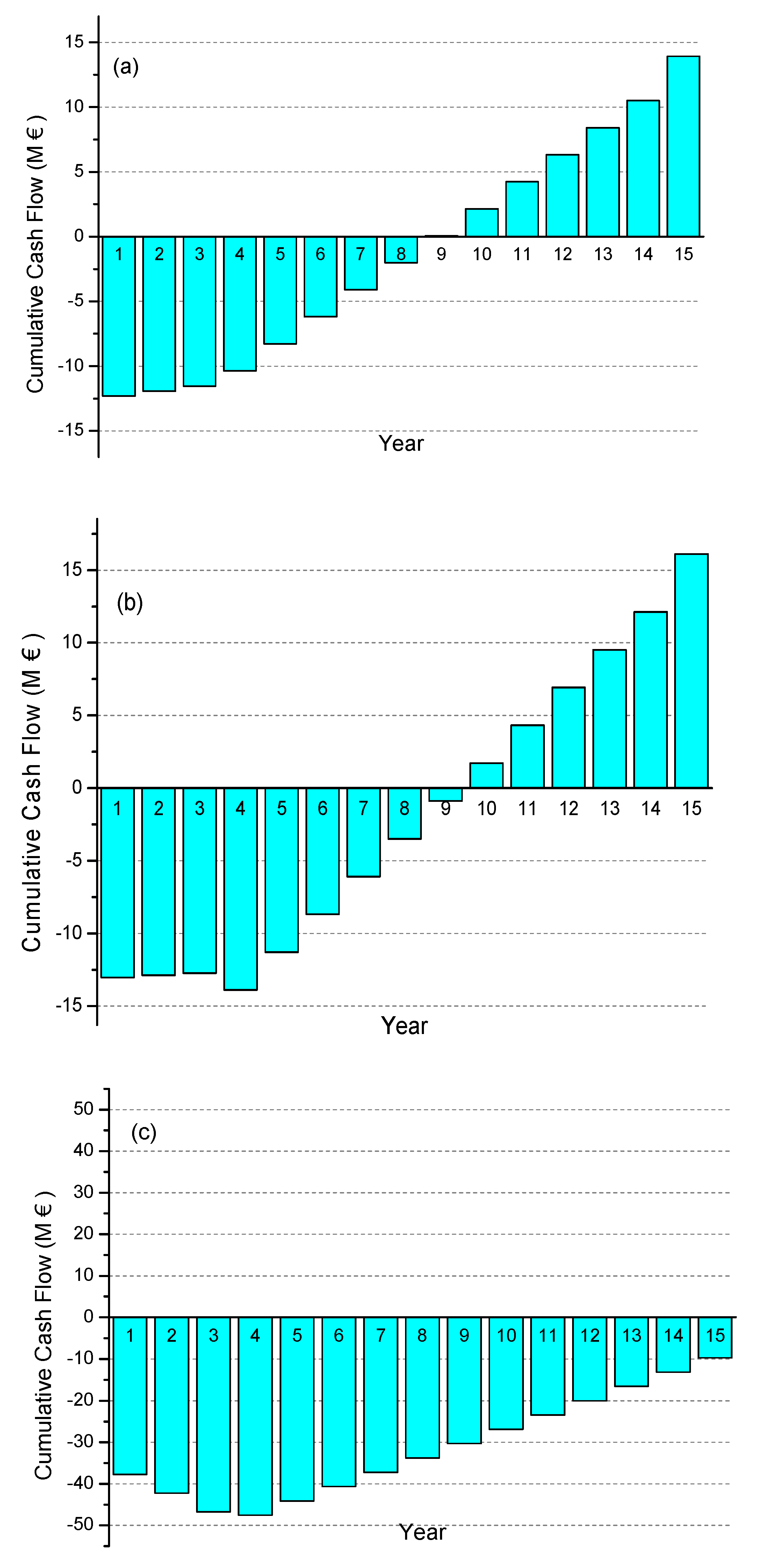

3.2.1. Biomass Combustion Unit

3.2.2. Biomass Gasification Unit

3.2.3. Biomass Pyrolysis Unit

3.3. Comparison of the Sustainability of the Business Plans

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Mass flow of dry biomass [kg/d] | |

| Molar flow [mol/d] | |

| ΔHDM | Enthalpy of dry biomass [MJ/kgDM] |

| ΔHf | Enthalpy of formation [MJ/mol] |

| AB | Algal biomass |

| CHP | Combined heat and power unit |

| CM | Construction materials |

| CV | Calorific Value [MJ/kgDM] |

| Col | Labor cost |

| Cp | Equipment cost |

| Cwt | Waste treatment cost |

| EP | Energy produced |

| EU | European Union |

| FCI | Fixed capital investment |

| HCV | High calorific value |

| IRR | Internal rate of return |

| LH | Latent heat |

| MARR | Minimum allowable rate of return |

| NPV | Net present value |

| O/C | Oxygen/carbon ratio |

| PI | Profitability index |

| TAR | Total annual revenue |

| TOC | Total organic carbon |

| TTC | Total treatment cost |

| UH | Useful heat |

| WB | Woody biomass |

References

- European Commission Roadmap to a Resource Efficient Europe. COM. 2011, 571. Available online: https://www.eea.europa.eu/policy-documents/com-2011-571-roadmap-to (accessed on 1 February 2023).

- European Parliament and Council Directive 2000/76/EC of the European Parliament and of the Council of 4 December 2000 on the Incineration of Waste. Off. J. Eur. Communities L 2000, 332, 91–111.

- Mønster, J.; Kjeldsen, P.; Scheutz, C. Methodologies for Measuring Fugitive Methane Emissions from Landfills—A Review. Waste Manag. 2019, 87, 835–859. [Google Scholar] [CrossRef] [PubMed]

- Awasthi, M.K.; Sarsaiya, S.; Patel, A.; Juneja, A.; Singh, R.P.; Yan, B.; Awasthi, S.K.; Jain, A.; Liu, T.; Duan, Y.; et al. Refining Biomass Residues for Sustainable Energy and Bio-Products: An Assessment of Technology, Its Importance, and Strategic Applications in Circular Bio-Economy. Renew. Sustain. Energy Rev. 2020, 127, 109876. [Google Scholar] [CrossRef]

- Fan, S.; Li, A.; ter Heijne, A.; Buisman, C.J.N.; Chen, W.-S. Heat Potential, Generation, Recovery and Utilization from Composting: A Review. Resour. Conserv. Recycl. 2021, 175, 105850. [Google Scholar] [CrossRef]

- Zagklis, D.; Tsigkou, K.; Tsafrakidou, P.; Zafiri, C.; Kornaros, M. Life Cycle Assessment of the Anaerobic Co-Digestion of Used Disposable Nappies and Expired Food Products. J. Clean. Prod. 2021, 304, 127118. [Google Scholar] [CrossRef]

- Smith, M.; Smit, T.; Gardiner, A. Financial Support for Electricity Generation & CHP from Solid Biomass; Natural Resources Defense Council: Rotterdam, The Netherlands, 2019. [Google Scholar]

- Jenkins, B.M.; Baxter, L.L.; Koppejan, J. Biomass Combustion. In Thermochem Process Biomass Convers into Fuels, Chemicals and Power; Willey Online Library: Hoboken, NJ, USA, 2019; pp. 49–83. [Google Scholar] [CrossRef]

- Vainio, E. Fate of Fuel-Bound Nitrogen and Sulfur in Biomass-Fired Industrial Boilers; 2014. [Google Scholar]

- Hupa, M.; Karlström, O.; Vainio, E. Biomass Combustion Technology Development–It Is All about Chemical Details. Proc. Combust. Inst. 2017, 36, 113–134. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Matias, J.C.O.; Catalão, J.P.S. Biomass Combustion Systems: A Review on the Physical and Chemical Properties of the Ashes. Renew. Sustain. Energy Rev. 2016, 53, 235–242. [Google Scholar] [CrossRef]

- Obaidullah, M.; Bram, S.; Verma, V.K.; De Ruyck, J. A Review on Particle Emissions from Small Scale Biomass Combustion. Int. J. Renew. Energy Res. 2012, 2, 147–159. [Google Scholar]

- Arena, U. Process and Technological Aspects of Municipal Solid Waste Gasification. A Review. Waste Manag. 2012, 32, 625–639. [Google Scholar] [CrossRef]

- AlNouss, A.; McKay, G.; Al-Ansari, T. A Comparison of Steam and Oxygen Fed Biomass Gasification through a Techno-Economic-Environmental Study. Energy Convers. Manag. 2020, 208, 112612. [Google Scholar] [CrossRef]

- Shahabuddin, M.; Alam, M.T.; Krishna, B.B.; Bhaskar, T.; Perkins, G. A Review on the Production of Renewable Aviation Fuels from the Gasification of Biomass and Residual Wastes. Bioresour. Technol. 2020, 312, 123596. [Google Scholar] [CrossRef]

- Wang, G.; Dai, Y.; Yang, H.; Xiong, Q.; Wang, K.; Zhou, J.; Li, Y.; Wang, S. A Review of Recent Advances in Biomass Pyrolysis. Energy Fuels 2020, 34, 15557–15578. [Google Scholar] [CrossRef]

- White, J.E.; Catallo, W.J.; Legendre, B.L. Biomass Pyrolysis Kinetics: A Comparative Critical Review with Relevant Agricultural Residue Case Studies. J. Anal. Appl. Pyrolysis 2011, 91, 1–33. [Google Scholar] [CrossRef]

- Kan, T.; Strezov, V.; Evans, T.J. Lignocellulosic Biomass Pyrolysis: A Review of Product Properties and Effects of Pyrolysis Parameters. Renew. Sustain. Energy Rev. 2016, 57, 1126–1140. [Google Scholar] [CrossRef]

- Hu, X.; Gholizadeh, M. Biomass Pyrolysis: A Review of the Process Development and Challenges from Initial Researches up to the Commercialisation Stage. J. Energy Chem. 2019, 39, 109–143. [Google Scholar] [CrossRef]

- Ascher, S.; Watson, I.; You, S. Machine Learning Methods for Modelling the Gasification and Pyrolysis of Biomass and Waste. Renew. Sustain. Energy Rev. 2022, 155, 111902. [Google Scholar] [CrossRef]

- European Environment Agency. EN34 Energy Subsidies; European Environment Agency: Copenhagen, Denmark, 2005; pp. 1–9. [Google Scholar]

- Eaton, A.D.; Clesceri, L.S.; Greenberg, A.E.; Franson, M.A.H. Standard Methods for the Examination of Water and Wastewater, 22nd ed.; APHA: American Water Works Association: Washington, DC, USA, 2012. [Google Scholar]

- Sohi, S.P.; Krull, E.; Lopez-Capel, E.; Bol, R. A Review of Biochar and Its Use and Function in Soil. Adv. Agron. 2010, 105, 47–82. [Google Scholar]

- Legan, M.; Gotvajn, A.Ž.; Zupan, K. Potential of Biochar Use in Building Materials. J. Environ. Manage. 2022, 309, 114704. [Google Scholar] [CrossRef]

- Schmidt, H.-P.; Hagemann, N.; Draper, K.; Kammann, C. The Use of Biochar in Animal Feeding. PeerJ 2019, 7, e7373. [Google Scholar] [CrossRef]

- Peters, M.S.; Timmerhaus, K.D.; West, R.E. Plant Design and Economics for Chemical Engineers; McGraw-Hill: New York, NY, USA, 2003; Volume 4. [Google Scholar]

- Tsigkou, K.; Zagklis, D.; Tsafrakidou, P.; Zapanti, P.; Manthos, G.; Karamitou, K.; Zafiri, C.; Kornaros, M. Expired Food Products and Used Disposable Adult Nappies Mesophilic Anaerobic Co-Digestion: Biochemical Methane Potential, Feedstock Pretreatment and Two-Stage System Performance. Renew. Energy 2021, 168, 309–318. [Google Scholar] [CrossRef]

- Olanders, B.; Steenari, B.-M. Characterization of Ashes from Wood and Straw. Biomass Bioenergy 1995, 8, 105–115. [Google Scholar] [CrossRef]

- Bourgois, J.; Guyonnet, R. Characterization and Analysis of Torrefied Wood. Wood Sci. Technol. 1988, 22, 143–155. [Google Scholar] [CrossRef]

- Rispoli, A.L.; Verdone, N.; Vilardi, G. Green Fuel Production by Coupling Plastic Waste Oxy-Combustion and PtG Technologies: Economic, Energy, Exergy and CO2-Cycle Analysis. Fuel Process. Technol. 2021, 221, 106922. [Google Scholar] [CrossRef]

- Gala, A.; Guerrero, M.; Serra, J.M. Characterization of Post-Consumer Plastic Film Waste from Mixed MSW in Spain: A Key Point for the Successful Implementation of Sustainable Plastic Waste Management Strategies. Waste Manag. 2020, 111, 22–33. [Google Scholar] [CrossRef]

- Bae, Y.J.; Ryu, C.; Jeon, J.-K.; Park, J.; Suh, D.J.; Suh, Y.-W.; Chang, D.; Park, Y.-K. The Characteristics of Bio-Oil Produced from the Pyrolysis of Three Marine Macroalgae. Bioresour. Technol. 2011, 102, 3512–3520. [Google Scholar] [CrossRef]

- Zagklis, D.; Konstantinidou, E.; Zafiri, C.; Kornaros, M. Assessing the Economic Viability of an Animal Byproduct Rendering Plant: Case Study of a Slaughterhouse in Greece. Sustainability 2020, 12, 5870. [Google Scholar] [CrossRef]

- Manelis, G.C. Techno-Economic Evaluation of Energy Crops for the Production and Exploitation of Biomass; 2012. [Google Scholar]

- Chau, J.; Sowlati, T.; Sokhansanj, S.; Preto, F.; Melin, S.; Bi, X. Techno-Economic Analysis of Wood Biomass Boilers for the Greenhouse Industry. Appl. Energy 2009, 86, 364–371. [Google Scholar] [CrossRef]

- Ghafghazi, S.; Sowlati, T.; Sokhansanj, S.; Melin, S. Techno-economic Analysis of Renewable Energy Source Options for a District Heating Project. Int. J. Energy Res. 2010, 34, 1109–1120. [Google Scholar] [CrossRef]

- Semple, L.; Carriveau, R.; Ting, D.S.-K. A Techno-Economic Analysis of Seasonal Thermal Energy Storage for Greenhouse Applications. Energy Build. 2017, 154, 175–187. [Google Scholar] [CrossRef]

- Chau, J.; Sowlati, T.; Sokhansanj, S.; Preto, F.; Melin, S.; Bi, X. Economic Sensitivity of Wood Biomass Utilization for Greenhouse Heating Application. Appl. Energy 2009, 86, 616–621. [Google Scholar] [CrossRef]

- Sagani, A.; Hagidimitriou, M.; Dedoussis, V. Techno-Economic Evaluation of Tree Pruning Biomass Fired Power Plants for Electricity Generation: The Case of Three Prefectures in Greece. In Proceedings of the 22nd European Biomass Conference and Exhibition, Hamburg, Germany, 23–26 June 2014; pp. 2282–5819. [Google Scholar]

- Goverment, G. 4414/2016- New Support Regime for Power Plants from Renewable Energy Sources and High-Efficiency Cogeneration of Electricity and Heat—Provisions for the Legal and Operational Separation of Supply Sectors 2016. Available online: https://www.rae.gr/7089-2/?lang=en (accessed on 2 January 2023).

- Al-Rikabi, N.S. Profitability Index and Its Impact on Short And Long–Term Decisions. J. Leg. Ethical Regul. Issues 2021, 24, 1–14. [Google Scholar]

- Candia, R.A.R.; Subieta, S.L.B.; Ramos, J.A.A.; Miquélez, V.S.; Balderrama, J.G.P.; Florero, H.J.; Quoilin, S. Techno-Economic Assessment of High Variable Renewable Energy Penetration in the Bolivian Interconnected Electric System. Int. J. Sustain. Energy Plan. Manag. 2019, 22. [Google Scholar]

- Morató, T.; Vaezi, M.; Kumar, A. Techno-Economic Assessment of Biomass Combustion Technologies to Generate Electricity in South America: A Case Study for Bolivia. Renew. Sustain. Energy Rev. 2020, 134, 110154. [Google Scholar] [CrossRef]

- Luz, F.C.; Rocha, M.H.; Lora, E.E.S.; Venturini, O.J.; Andrade, R.V.; Leme, M.M.V.; del Olmo, O.A. Techno-Economic Analysis of Municipal Solid Waste Gasification for Electricity Generation in Brazil. Energy Convers. Manag. 2015, 103, 321–337. [Google Scholar] [CrossRef]

- Rentizelas, A.; Karellas, S.; Kakaras, E.; Tatsiopoulos, I. Comparative Techno-Economic Analysis of ORC and Gasification for Bioenergy Applications. Energy Convers. Manag. 2009, 50, 674–681. [Google Scholar] [CrossRef]

- Wang, S.; Mukhambet, Y.; Esakkimuthu, S. Integrated Microalgal Biorefinery–Routes, Energy, Economic and Environmental Perspectives. J. Clean. Prod. 2022, 131245. [Google Scholar] [CrossRef]

- Solarte-Toro, J.C.; González-Aguirre, J.A.; Giraldo, J.A.P.; Alzate, C.A.C. Thermochemical Processing of Woody Biomass: A Review Focused on Energy-Driven Applications and Catalytic Upgrading. Renew. Sustain. Energy Rev. 2021, 136, 110376. [Google Scholar] [CrossRef]

- Burrell, L.D.; Zehetner, F.; Rampazzo, N.; Wimmer, B.; Soja, G. Long-Term Effects of Biochar on Soil Physical Properties. Geoderma 2016, 282, 96–102. [Google Scholar] [CrossRef]

- Tan, X.; Liu, S.; Liu, Y.; Gu, Y.; Zeng, G.; Hu, X.; Wang, X.; Liu, S.; Jiang, L. Biochar as Potential Sustainable Precursors for Activated Carbon Production: Multiple Applications in Environmental Protection and Energy Storage. Bioresour. Technol. 2017, 227, 359–372. [Google Scholar] [CrossRef]

- Pighinelli, A.L.M.T.; Schaffer, M.A.; Boateng, A.A. Utilization of Eucalyptus for Electricity Production in Brazil via Fast Pyrolysis: A Techno-Economic Analysis. Renew. Energy 2018, 119, 590–597. [Google Scholar] [CrossRef]

- He, S.; Barati, B.; Hu, X.; Wang, S. Carbon Migration of Microalgae from Cultivation towards Biofuel Production by Hydrothermal Technology: A Review. Fuel Process. Technol. 2023, 240, 107563. [Google Scholar] [CrossRef]

- Kookos, Ι. Introduction to Chemical Plant Design; Tziolas: Thessaloniki, Greece, 2009; ISBN 978-960-418-173-5. [Google Scholar]

- Ramos, J.S.; Ferreira, A.F. Techno-Economic Analysis and Life Cycle Assessment of Olive and Wine Industry Co-Products Valorisation. Renew. Sustain. Energy Rev. 2022, 155, 111929. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, J.; Chong, K.; Bridgwater, A. V A Techno-Economic Analysis of Energy Recovery from Organic Fraction of Municipal Solid Waste (MSW) by an Integrated Intermediate Pyrolysis and Combined Heat and Power (CHP) Plant. Energy Convers. Manag. 2018, 174, 406–416. [Google Scholar] [CrossRef]

- Ramirez, J.A.; Rainey, T.J. Comparative Techno-Economic Analysis of Biofuel Production through Gasification, Thermal Liquefaction and Pyrolysis of Sugarcane Bagasse. J. Clean. Prod. 2019, 229, 513–527. [Google Scholar] [CrossRef]

| Fixed Capital Investment (EUR) | Direct Cost (EUR) | Onsite | Purchased equipment | Cp |

| Equipment installation | 0.06 FCI | |||

| Automatic control and instruments | 0.02 FCI | |||

| Piping | 0.04 FCI | |||

| Electrical equipment | 0.02 FCI | |||

| Offsite | Buildings | 0.02 FCI | ||

| Yard improvements | 0.02 FCI | |||

| Service facilities | 0.08 FCI | |||

| Land | 0.01 FCI | |||

| Indirect Cost (EUR) | Engineering and supervision | 0.04 FCI | ||

| Construction expenses | 0.04 FCI | |||

| Contractor’s fee | 0.02 FCI | |||

| Contingency | 0.05 FCI | |||

| FCI (EUR) | 1.724 Cp | |||

| Total Product Cost (EUR) | Direct Cost (EUR/y) | Energy requirements | 0.1 TTC | |

| Waste treatment | Cwt | |||

| Direct work | Col | |||

| Operating supervision | 0.1 Col | |||

| Maintenance and repairs | 0.02 FCI | |||

| Operating supplies | 0.005 FCI | |||

| Laboratory charges | 0.1 Col | |||

| Royalties and patents | 0.01 FCI | |||

| Depreciation | 0.082 Cp + 0.06 FCI | |||

| Taxes and insurances | 0.03 FCI | |||

| Fixed charges | 0.05 FCI | |||

| General expenses (EUR/y) | Administrative expenses | 0.02 TTC | ||

| Distribution and marketing expenses | 0.02 TTC | |||

| Research and development | 0.05 TTC | |||

| Characteristic | WB | CW | AB | MIXTURE | Reference |

|---|---|---|---|---|---|

| C (% DM *) | 50.20 ± 0.9 | 14.93 ± 3.1 | 37.14 ± 1.1 | 51.53 ± 0.6 | This work |

| O (% DM *) | 41.57 ± 1.2 | 3.20 ± 4.0 | 50.38 ± 8.9 | 38.11 ± 9.7 | [28,29,30,31,32] |

| H (% DM *) | 5.49 ± 0.2 | 12.59 ± 1.2 | 5.28 ± 0.2 | 6.60 ± 0.1 | [28,29,30,31,32] |

| N (% DM *) | 0.30 ± 0.1 | 0.49 ± 0.7 | 3.04 ± 1.9 | 1.24 ± 3.0 | This work |

| Moisture (%) | 11.95 ± 6.2 | 2.25 ± 0.3 | 81.58 ± 0.1 | 33.53 ± 9.5 | This work |

| Ash (%) | 6.78 ± 4.7 | 65.52 ± 3.3 | 1.10 ± 0.1 | 14.67 ± 5.8 | This work |

| Calorific value (MJ/kgDM) | 18.31 ± 0.6 | 43.53 ± 2.7 | 12.33 ± 3.0 | 20.11 ± 1.8 | Calculated |

| Characteristic | Combustion | Gasification | Pyrolysis |

|---|---|---|---|

| IRR | 10% | 9% | 0% |

| PI | 1.72 | 1.9 | 0.73 |

| NPV (M EUR) | 4.8 | 5.3 | −21.1 |

| Payback Time | 8.9 | 9.3 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manthos, G.; Zagklis, D.; Ali, S.S.; Zafiri, C.; Kornaros, M. Techno-Economic Evaluation of the Thermochemical Energy Valorization of Construction Waste and Algae Biomass: A Case Study for a Biomass Treatment Plant in Northern Greece. Processes 2023, 11, 1549. https://doi.org/10.3390/pr11051549

Manthos G, Zagklis D, Ali SS, Zafiri C, Kornaros M. Techno-Economic Evaluation of the Thermochemical Energy Valorization of Construction Waste and Algae Biomass: A Case Study for a Biomass Treatment Plant in Northern Greece. Processes. 2023; 11(5):1549. https://doi.org/10.3390/pr11051549

Chicago/Turabian StyleManthos, Georgios, Dimitris Zagklis, Sameh S. Ali, Constantina Zafiri, and Michael Kornaros. 2023. "Techno-Economic Evaluation of the Thermochemical Energy Valorization of Construction Waste and Algae Biomass: A Case Study for a Biomass Treatment Plant in Northern Greece" Processes 11, no. 5: 1549. https://doi.org/10.3390/pr11051549