1. Introduction

China, one of the major contributors to global greenhouse gas emissions, has pledged to meet its peak carbon emissions by 2030 and to work toward becoming carbon neutral by 2060 [

1]. As the main source of carbon emissions, about 40% of China’s total emissions of carbon dioxide are produced by the power industry [

2]. Therefore, building a new power system with renewable energy as the main body is a crucial step and measure for China to take in order to reach its carbon neutrality target.

However, the need for regulation capacity in the new power system is gradually growing as a result of the randomness, volatility, and intermittent nature of renewable energy generation [

3]. The gap in system regulation capacity is widening as a result of the installed scale of traditional regulation resources with high carbon attributes. In order to contribute to the balance of the power system, more novel flexible regulation resources are required, such as energy storage systems (ESSs) with low carbon properties, big regulation ranges, quick regulation speeds, and long duration [

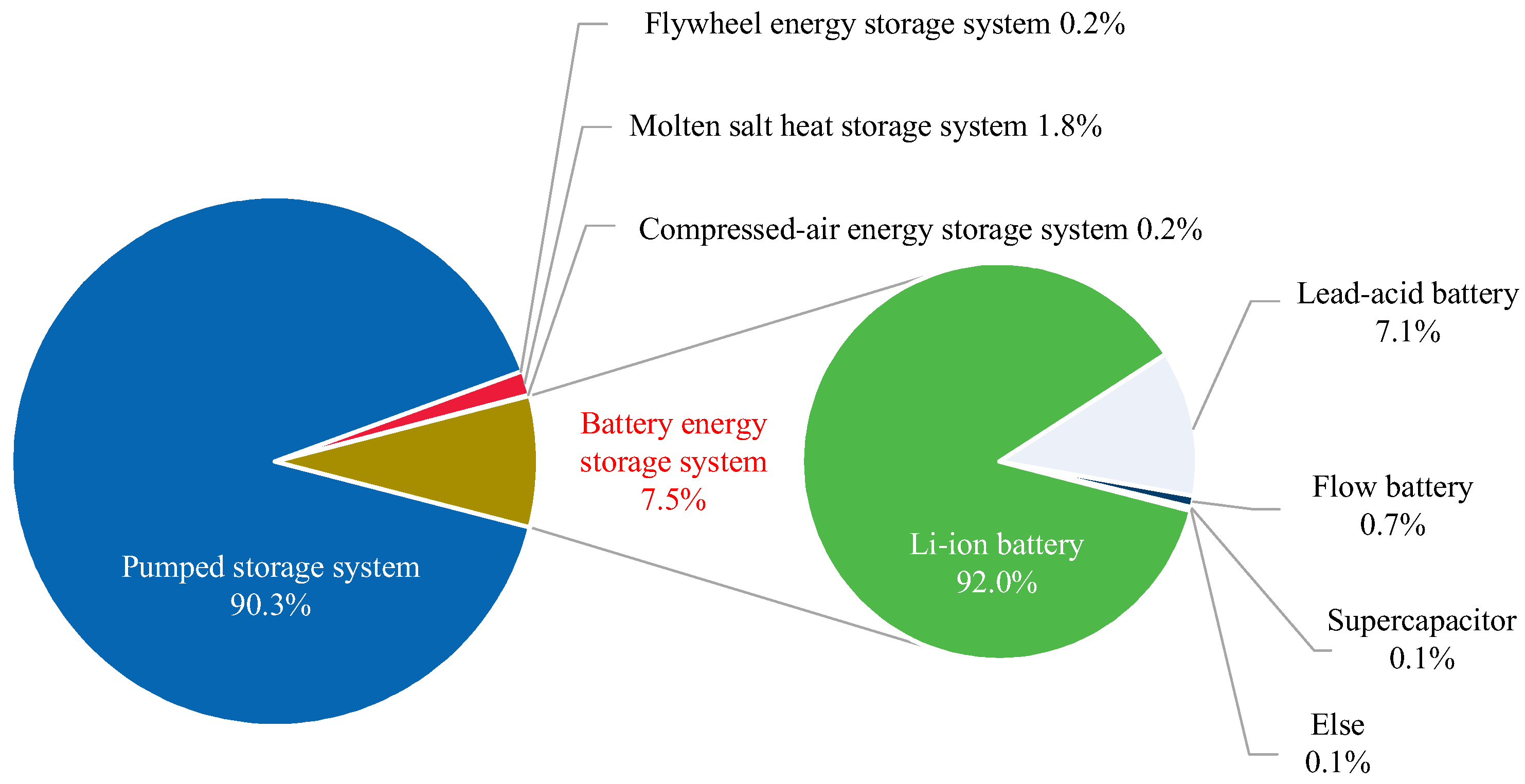

4]. By 2020, China’s installed ESSs’ capacity totaled 35.1 million kilowatts, accounting for 18.5% of the global ESSs’ installed capacity. In China, the battery energy storage system (BESS) is the second-largest ESS, followed by the pumped storage system (PSS), which accounts for 90.3% of all ESSs usage (DOE Global Energy Storage Database:

https://sandia.gov/ess-ssl/gesdb/public/ (accessed on 14 March 2023)).

Figure 1 depicts the classification and installed capacity of China’s ESSs in 2021.

Scholars have long been interested in the research on ESSs, which includes topics such as location planning [

5], capacity planning [

6], and optimal operation [

7]. However, an increasing number of researchers have discovered that the conventional cost-oriented ESSs study primarily examines financial gains and does not provide a thorough examination of the multidimensional value of ESSs [

8]. As a result, some researchers study ESSs from a value-driven perspective. From the standpoint of environmental value, ESSs can successfully lower the system’s carbon dioxide emissions [

9], improve the utilization efficiency of clean energy [

10], and increase the utilization rate of intelligent environment-friendly equipment [

11]. From the perspective of economic value, ESSs can help realize peak-valley arbitrage [

12] and lessen the system’s energy loss by storing electric energy during the valley period and releasing it during the peak period [

13]. Additionally, the ESS’s capacity for charging and discharging can ensure the power system’s instantaneous power quality [

14] and power balance [

15]. This adds a great deal of flexibility to the power system. The aforementioned research, however, mostly focuses on the single value of ESSs or the optimization of pursuing a small number of goals, making it impossible to fully assess the multi-dimensional worth of ESS.

Some researchers developed multi-criteria decision-making (MCDM) models to assess, thoroughly and methodically, the multi-dimensional value of ESSs in order to address the aforementioned issues. Zhao et al. [

16] proposed a comprehensive evaluation strategy for the value of BESS based on the best–worst method (BWM) and fuzzy cumulative prospect theory (CPT). The result shows that the Li-ion battery overperforms the other types of BESSs. Ramya et al. [

17] determined the best thermal ESS through the step-wise weight assessment ratio analysis (SWARA) and weighted aggregated sum product assessment (WASPAS). Through the constructed five-dimensional value evaluation model, the results show that the latent-heat ESS has the best performance. However, the methods used in the above literature are subjective weighting methods, which means that the results are easily affected by the subjective emotions of experts. Therefore, some scholars have introduced objective weighting methods. Mosetlhe et al. [

18] adopted the Heuristic weighting model and TOPSIS–VIKOR approach to assessing the comprehensive value of PSS. Liu [

19] used the entropy weight method (EWM) and gray relational analysis model (GRA) to evaluate the ESS based on the Internet of Things (IoT). However, the objective weighting method has higher requirements for sample size and data richness. Considering the differentiated characteristics of the above weighting methods, some scholars attempt to combine the two types of weighting methods. Xuan et al. [

20] used the analytic hierarchy process (AHP) and information entropy method (IEM) to evaluate the values of ESSs in the integrated energy system. However, the AHP method used is complicated and has too many index comparisons, which will decrease the computation efficiency [

21]. The indicators for comprehensive evaluation of ESSs’ value based on MCDM in the above literature are shown in

Table 1, and the review of the above literature is shown in

Figure 2.

The need for flexible resources such as ESSs in the new power system is growing as a result of the extensive integration of renewable energy sources. For increasing the effectiveness of energy usage, lowering economic losses, and maintaining the safe and stable operation of the power system, it is crucial to investigate the multi-dimensional value of ESSs. The three key features of this paper’s innovation and contribution are as follows:

- (1)

In this study, a multi-dimensional value evaluation index system for ESSs is constructed from the viewpoints of flexible value, technological value, economic value, and environmental value. It is more thorough and comprehensive than the previous studies on the single value of ESS. In addition, various innovative metrics are taken into consideration, including response time and wind power curtailment rate.

- (2)

Due to the different characteristics of the subject and object weighting methods, utilizing just one type of procedure for weighting can lead to unjustifiable indicator weights. The combined weighting method built on criteria importance though intercriteria correlation, best–worst method, and minimum relative entropy (CRITIC–BWM–MRE) that is suggested in this paper can avoid the subjective nature of subjective weighting methods and the onerous constraints of objective weighting methods on the data, leading to more reasonable weighting outcomes;

- (3)

Previous studies have mostly relied on static analysis of a specific scenario to determine the overall value evaluation of energy storage. The positioning and demand of ESSs in power systems vary significantly depending on the scenario. In this paper, three scenarios that represent the various phases of the development of the new power system are designed. For each scenario, study and comparison are conducted to determine the overall value of various types of ESSs;

This paper is organized as follows. The introduction is elaborated in

Section 1 and the multi-dimensional value evaluation index system for ESSs is constructed in

Section 2.

Section 3 mainly introduces the method applied in this paper and

Section 4 presents the empirical analysis. The conclusion is presented in

Section 5.

2. Multi-Dimensional Value Evaluation Index System for ESSs

A multi-dimensional value evaluation index system for ESSs is used to assess the comprehensive value of the system from four perspectives: flexible value, technical value, economic value, and environmental value. The indicators and instructions are as follows.

- ➢

Flexible value

The main benefit of the ESS, which may be viewed as a flexible resource, is that it gives the system some regulatory capabilities that can be used to solve problems such as the generation deviation of renewable energy sources and frequent unit breakdowns. Response time (C1) and response capability (C2) are chosen as the two indicators for assessing the flexibility of ESSs [

22], of which the response capability can be expressed as follows:

where

represents the response capability of ESS,

represents the rated capacity of the ESS at time

, and

represents the system regulation requirements at time

. In this paper,

is approximated as the regulatory demand caused by bias in renewable energy generation prediction.

- ➢

Technical value

While the flexible value concentrates on the function of the ESS in the power system, the technical value highlights the technical and material properties of the ESS itself. Power density (C3) and energy density (C4) are the main technical characteristic indicators of ESSs [

23]. Whereas the former relates to the quantity of energy stored per unit weight of the device; the latter denotes the pace at which a unit-weight device discharges its stored energy. Energy conversion efficiency (C5) is another important element that reflects the technological worth of ESS.

- ➢

Economic value

Another important thing to consider is the economic value of the ESS in addition to its flexibility value and technical value. In other words, even if ESSs have strong technical response characteristics and flexibility, they nonetheless need to have a relatively lower cost. Thus, unit power cost (C6) and cycle life (C7) are chosen to present the economic value of the ESS [

24].

- ➢

Environmental value

When renewable energy generation exceeds expectations and is prone to waste. The ESS can store this portion of electricity, thereby reducing wind power abandonment rates (using wind power as an example), Hence, the wind power curtailment rate (C8) is chosen to present the environmental value of the ESS [

25].

The multi-dimensional value evaluation index system for ESSs is shown in

Figure 3.

Considering that all the indicators selected are quantitative, both objective and subjective weighting methods can be applied in this paper. If qualitative indicators exist, only subjective weighting methods can be used.

4. Empirical Analysis

4.1. Scenario Setting

The building of new power systems faces significant difficulties due to the intermittent nature of renewable energy sources. The growth of renewable energy can be separated into three stages based on the various rates of penetration [

35]. Accordingly, three ESS application scenarios are created based on these three steps, as shown in

Table 2.

Different scenarios have drastically variable levels of renewable energy permeability, which has an impact on the flexibility requirements of the system. However, the three situations discussed in this research cannot be supported by enough genuine cases due to data restrictions. To this end, we converted various possibilities of the penetration of renewable energy into various scenarios of the generation prediction errors of renewable energy. In other words, we think that the forecast error is low and the system’s requirement for flexibility is low when the penetration rate of renewable energy is low. The prediction inaccuracy will increase and the system’s requirement for flexibility will rise when the penetration rate of renewable energy is high.

Figure 4 displays the expected generation for the three scenarios along with the actual power generation curve of a certain wind farm.

According to

Figure 4, the three scenarios’ respective mean absolute percentage errors (MAPE) for the prediction of wind power generation are 1.73%, 3.51%, and 6.07%. The demand intervals for system regulation in three scenarios are [0.29,9.83], [3.03,16.60], and [0.50,42.13], respectively.

This study is mostly focused on flywheel, supercapacitor, flow battery, lead–acid battery, and Li-ion battery energy storage systems due to the enormous capacity and high site selection requirements of pumped storage systems and compressed-air energy storage systems.

4.2. Multi-Dimensional Value Evaluation of ESSs in Scenario 1

4.2.1. Objective Weight Determination

The initial decision matrix is constructed as

Table 3.

Then, the normalized decision matrix can be expressed as in

Table 4.

Then, the variability, conflict, information content, and weights of the indicators can be calculated by Equations (4)–(9), as shown in

Table 5.

According to

Table 5, energy conversion efficiency (C5) is regarded as the most important indicator for evaluating the comprehensive value of ESSs, followed by the response capability (C2), wind power curtailment rate (C8), and cycle life (C7). While the differences are not statistically significant, the weights of these three indicators are essentially between 0.8 and 0.9.

4.2.2. Subjective Weight Determination

We have invited five experts to create an expert panel, as stated in

Section 3.1.2. The expert group is made up of employees from energy storage operators, power grid firms, and academics working on relevant projects from institutions. The multi-dimensional value evaluation index system for ESSs’ best and worst indicators is first discovered, as illustrated in

Table 6.

The “Best-to-Others” importance comparison vector

and the “Others-to-Worst” importance comparison vector

can be constructed as follows:

Then, the indicator weights determined by the expert group are calculated by the BWM model, as shown in

Table 7.

As shown in

Table 7, the indicator weight ranking is C5 > C6 > C3 > C4 > C1 > C2 > C7 > C8. Similar to the objective weights determined by CRITIC, the energy conversion efficiency (C5) and unit power cost (C6) are considered the most important indicators.

4.2.3. Weight Combination and Comprehensive Value Evaluation

According to the MRE introduced in

Section 3.1.3, the combined weights of indicators are shown in

Table 8.

Then, the multi-dimensional value of each ESS is evaluated by the TOPSIS model, as shown in

Figure 5.

As shown in

Figure 5, the ranking of multi-dimensional value of each ESS is as follows: flywheel > supercapacitor > Li-ion battery > lead–acid battery > flow battery. The reason for this phenomenon is the high energy conversion efficiency of flywheel and supercapacitor ESSs. In contrast, although the flow battery performs better in response capability and wind power curtailment rate, the weights of these two indicators are relatively lower (i.e., 0.0820 and 0.0662).

4.3. Multi-Dimensional Value Evaluation of ESSs in Scenario 2

4.3.1. Objective Weight Determination

The initial decision matrix is constructed as in

Table 9.

Then, the normalized decision matrix is expressed as

Table 10.

Then, the variability, conflict, information content, and weights of the indicators can be calculated via Equations (4)–(9), as shown in

Table 11.

According to

Table 11, energy conversion efficiency (C5) is regarded as the most important indicator for evaluating the comprehensive value of ESSs, followed by the response capability (C2), wind power curtailment rate (C8), and cycle life (C7). This result is basically the same as the one in Scenario 1.

4.3.2. Subjective Weight Determination

The best and worst indicators of the multi-dimensional value evaluation index system for ESSs are first obtained, as shown in

Table 12.

The “Best-to-Others” importance comparison vector

and the “Others-to-Worst” importance comparison vector

can be constructed as follows:

Then, the indicator weights determined by the expert group are calculated by the BWM model, as shown in

Table 13.

As shown in

Table 13, the indicator weight ranking is C2 > C5 > C1 > C6 > C3 > C4 > C7 > C8. Different from the objective weights determined by CRITIC, the response capability (C2) and energy conversion efficiency (C5) are considered the most important indicators.

4.3.3. Weight Combination and Comprehensive Value Evaluation

According to the MRE introduced in

Section 3.1.3, the combined weights of indicators are shown in

Table 14.

Then, the multi-dimensional value of each ESS is evaluated by the TOPSIS model, as shown in

Figure 6.

As shown in

Figure 6, the ranking of multi-dimensional value of each ESS is as follows: flywheel > supercapacitor > Li-ion battery > lead–acid battery > flow battery, which is the same as the one of Scenario 1.

4.4. Multi-Dimensional Value Evaluation of ESSs in Scenario 3

4.4.1. Objective Weight Determination

The initial decision matrix is constructed as

Table 15.

Then, the normalized decision matrix can be expressed as

Table 16.

Then, the variability, conflict, information content, and weights of the indicators can be calculated by Equations (4)–(9), as shown in

Table 17.

According to

Table 17, the energy density (C4) is considered the most important indicator for evaluating the comprehensive value of ESSs, followed by the response capability (C2), cycle life (C7), and wind power curtailment rate (C8). While the weights of these three indicators are basically around 0.10, and the difference is not significant.

4.4.2. Subjective Weight Determination

The best and worst indicators of the multi-dimensional value evaluation index system for ESSs are first obtained, as shown in

Table 18.

The “Best-to-Others” importance comparison vector

and the “Others-to-Worst” importance comparison vector

can be constructed as follows:

Then, the indicator weights determined by the expert group are calculated by the BWM model, as shown in

Table 19.

As shown in

Table 19, the indicator weight ranking is C2 > C1 > C5 > C6 > C8 > C3 > C4 > C7. Different from the objective weights determined by CRITIC, the response capability (C2) and response time (C1) are considered the most important indicators.

4.4.3. Weight Combination and Comprehensive Value Evaluation

According to the MRE introduced in

Section 3.1.3, the combined weights of indicators are shown in

Table 20.

Then, the multi-dimensional value of each ESS is evaluated by the TOPSIS model, as shown in

Figure 7.

As shown in

Figure 7, the ranking of multi-dimensional value of each ESS is as follows: supercapacitor > flywheel > Li-ion battery > flow battery > lead–acid battery.

4.5. Discussion of the Results in Three Scenarios

The final indicator weights under three scenarios are summarized in

Table 21.

Due to the fewer renewable energy installations in the early stages of the development of the new power system (Scenario 1), the need for system flexibility is relatively low. At this point, the technical and economic values of the ESSs, particularly the quest for improved energy conversion efficiency and lower unit power generation costs, are of greater importance to specialists. In Scenario 2, the flexible value of ESSs has progressively become obvious, and the significance of the flexibility value has further expanded, along with the gradual development in the installed scale of renewable energy sources. The response capacity and response time now rank third and fourth in importance. In the later stage of the development of the new power system (Scenario 3), renewable power sources have become the main power generation entity. Therefore, experts believe that flexibility value is a key indicator reflecting the core value of ESSs at this stage.

The comprehensive value of different ESSs under three scenarios is summarized in

Table 22.

It is important to note that there is only a negligible overall difference between Scenario 1 and Scenario 2 in terms of the comprehensive value rankings of the five ESSs. The resemblance between Scenario 1 and Scenario 2 could be the cause of this. Specifically, there is a difference in the penetration of renewable energy between Scenario 1 and Scenario 2, which is almost 20%, and between Scenario 2 and Scenario 3, which is roughly 35%. As a result, between Scenario 1 and Scenario 2, the difference in the renewable energy prediction error is approximately 1.78%, while between Scenario 2 and Scenario 3, the difference in the renewable energy prediction error is 2.56%.

The magnitude of prediction error directly affects the flexibility requirements of the system, indirectly resulting in different flexibility utilities of various ESS. In Scenario 1, the flexibility capacity that the flow battery can provide is the same as lead–acid and Li-ion batteries, while the lack of value in other aspects results in its overall value ranking last among various alternative solutions. The flow battery’s flexible capacity in Scenario 2 is 26.32% more than that of the other two battery kinds, but other parts of its value have not changed all that much; therefore, its total value ranking has not changed. The situation radically changes in Scenario 3, where flexibility is significantly essential. The flow battery’s flexibility capacity outperforms the flexibility capacities of the other two types of batteries by about 112.80%, directly raising the flow battery’s overall value rating of the battery by two levels.

However, given the rising demand for power system flexibility, flow batteries with greater capacities are more valuable than the other two battery ESS. Additionally, the value gap between conventional mechanical and electrical ESSs and electrochemical ESSs has shrunk even more. This implies that the electrochemical ESSs will play a greater role in the advancement of power systems in the future.

4.6. Model Comparison and Sensitivity Analysis

4.6.1. Model Comparison

To verify the effectiveness of the combined weighting method proposed in this article, a comparison was made with using a single weighting method. Due to the design of multiple scenarios in this paper, the workload of model comparison for all scenarios is significant. Therefore, scenario 3 is taken as an example. Each comparative model is shown in

Table 23, and the comprehensive value of different ESSs by each model under Scenario 3 is shown in

Table 24.

The comprehensive value of the flywheel and supercapacitor, which are relevant to each of the three types of models, scores reasonably high among the five ESSs, as shown in

Table 24. However, there are variances in each ESS’s comprehensive value depending on the model. Flywheel, supercapacitor, and Li-ion battery perform significantly well in terms of energy density (C4), energy conversion efficiency (C5), and unit power cost (C6), which contributes to their overall high-value rating. Despite the fact that the flow battery performs well in terms of response capability (C2) and wind power curtailment rate (C8), their respective weights of 0.0978 and 0.1025 make them significantly less important than other indicators. The ranking of each ESS significantly changed when BWM is used for indicator weighting. In particular, even though the comprehensive values of the flywheel and supercapacitor are still good, the gap between the comprehensive values of the flow battery and their two components has greatly shrunk as a result of decision-makers’ understanding of the significance of the response capability (C2) indicator. The final scores and ranks of the comprehensive values of each ESS are more logical following weight fusion.

4.6.2. Sensitivity Analysis

Further sensitivity analysis is required, which can confirm the logic of the suggested model and has the potential to be widely promoted and applied [

36,

37]. Sensitivity analysis typically focuses on two key areas: first, assessing the effects of changes in indicator value; second, assessing the effects of changes in indicator weight on evaluation outcomes [

38]. Similarly, we perform a sensitivity analysis using Scenario 3 as the reference case. By modifying the flywheel ESS’s performance across all metrics, we may evaluate the changes in the comprehensive value of each ESS.

Figure 8 displays the result.

Figure 8 illustrates how little the performance of the flywheel and flow battery has altered when the flywheel’s index value rises. The performances of the other three types of ESSs, however, exhibit a definite declining tendency. In addition, the evaluation results of the flywheel comprehensive value demonstrate a considerable fall when the values of several flywheel indicators decline, although the other ESSs are not significantly impacted.

Similarly, we will adjust the weights of each indicator to determine the changes in the comprehensive value of each ESS. Taking the C2 indicator as an example,

Figure 9 shows the impact of the C2 indicator weight changes on the comprehensive value evaluation results of each ESS (note that the weights of other indicators change synchronously to ensure that the sum of all indicator weights remains 1).

According to

Figure 9, while the performances of the other three types of ESSs have dramatically altered, the overall value of lead–acid and lithium-ion batteries appears not to have changed much. Particularly, the comprehensive value of liquid flow batteries rises as the C2 index weight increases, whereas the comprehensive values of flywheels and supercapacitors fall as the C2 index weight rises.

5. Conclusions

A crucial step for China in achieving the carbon neutrality climate change target is the construction of a new power system with renewable energy as its core component. One of the most effective ways to deal with the randomness and instability of renewable energy generation is to use flexible resources, such as ESSs. It is of great significance to discover and evaluate the multidimensional value of ESSs. So, using several criteria for decision-making, this research constructs a multi-dimensional value evaluation model of ESSs. The following conclusions can be drawn:

- (1)

There are distinct variances in indicator weights among various scenarios as a result of the differing emphasis on ESS value in each scenario. With the stages of development of new power systems, the significance of the flexibility value represented by response time (C1) and response capacity (C2), in particular, gradually grows;

- (2)

The overall value gap between electrochemical ESSs and conventional ESSs is gradually closing due to the ongoing development of new power systems. When the demand for system flexibility is strong, flow battery ESSs with a bigger capacity can perform better than lead–acid and Li-ion battery ESSs.

The computational time is increased even though a more creative combination weighting method is used in this paper. In an upcoming study, we will look into better weighting methodologies in more detail. Due to data restrictions, this report only focuses on five common ESS, but we plan to broaden the research’s coverage in the future.