Fast Deflagration-to-Detonation Transition in Helical Tubes

Abstract

1. Introduction

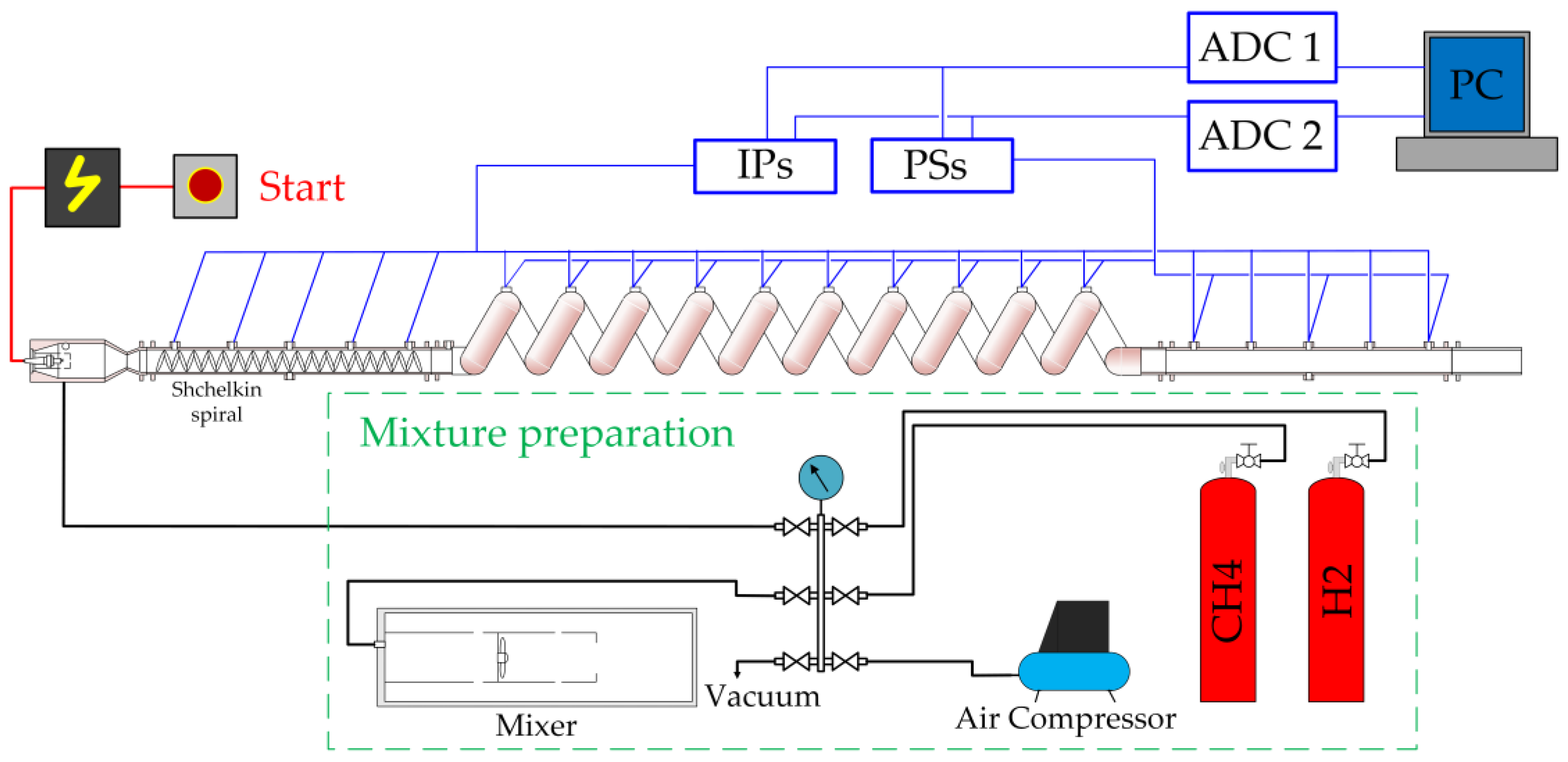

2. Materials and Methods

2.1. Pulsed Detonation Tubes

2.2. Experimental Setup and Procedure

2.3. Gases

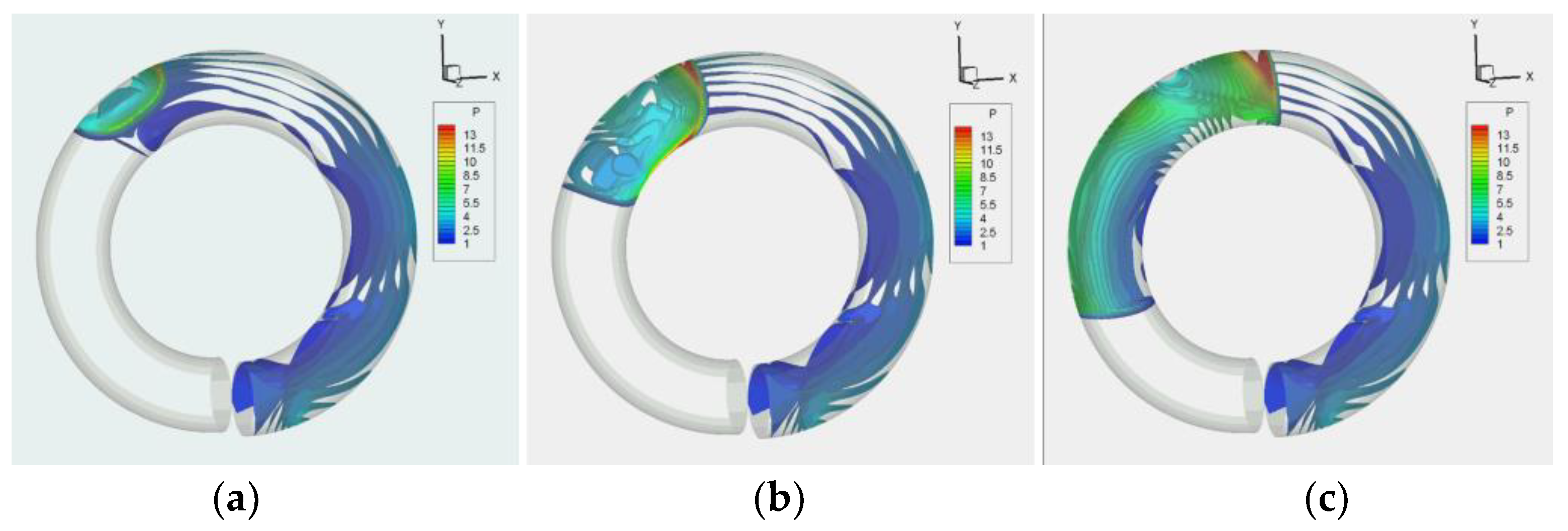

3. Results and Discussion

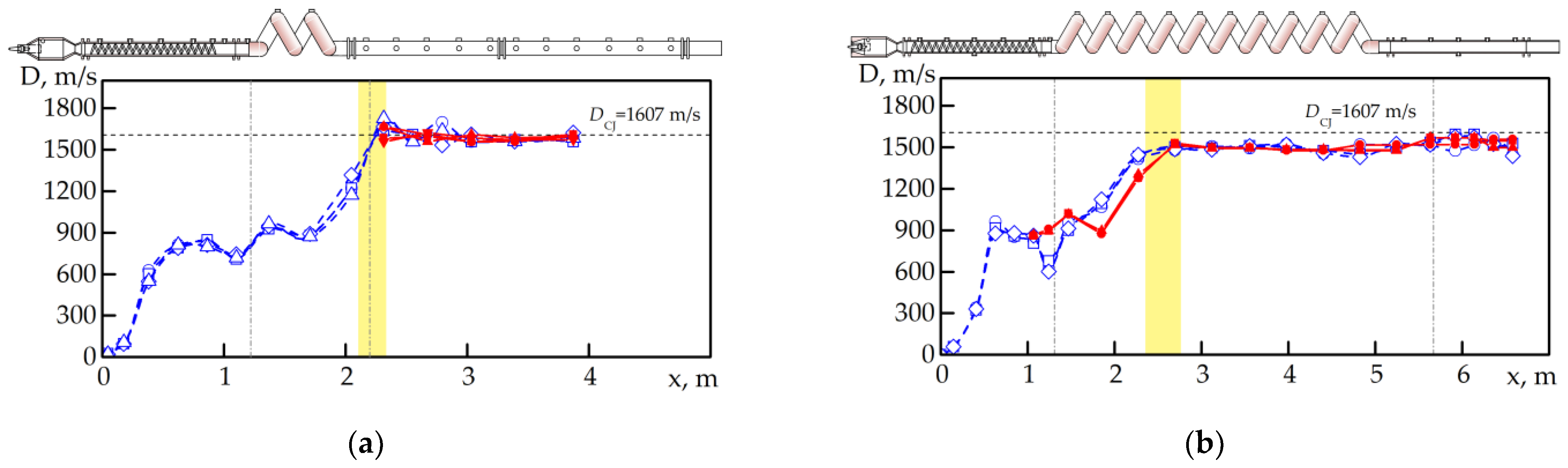

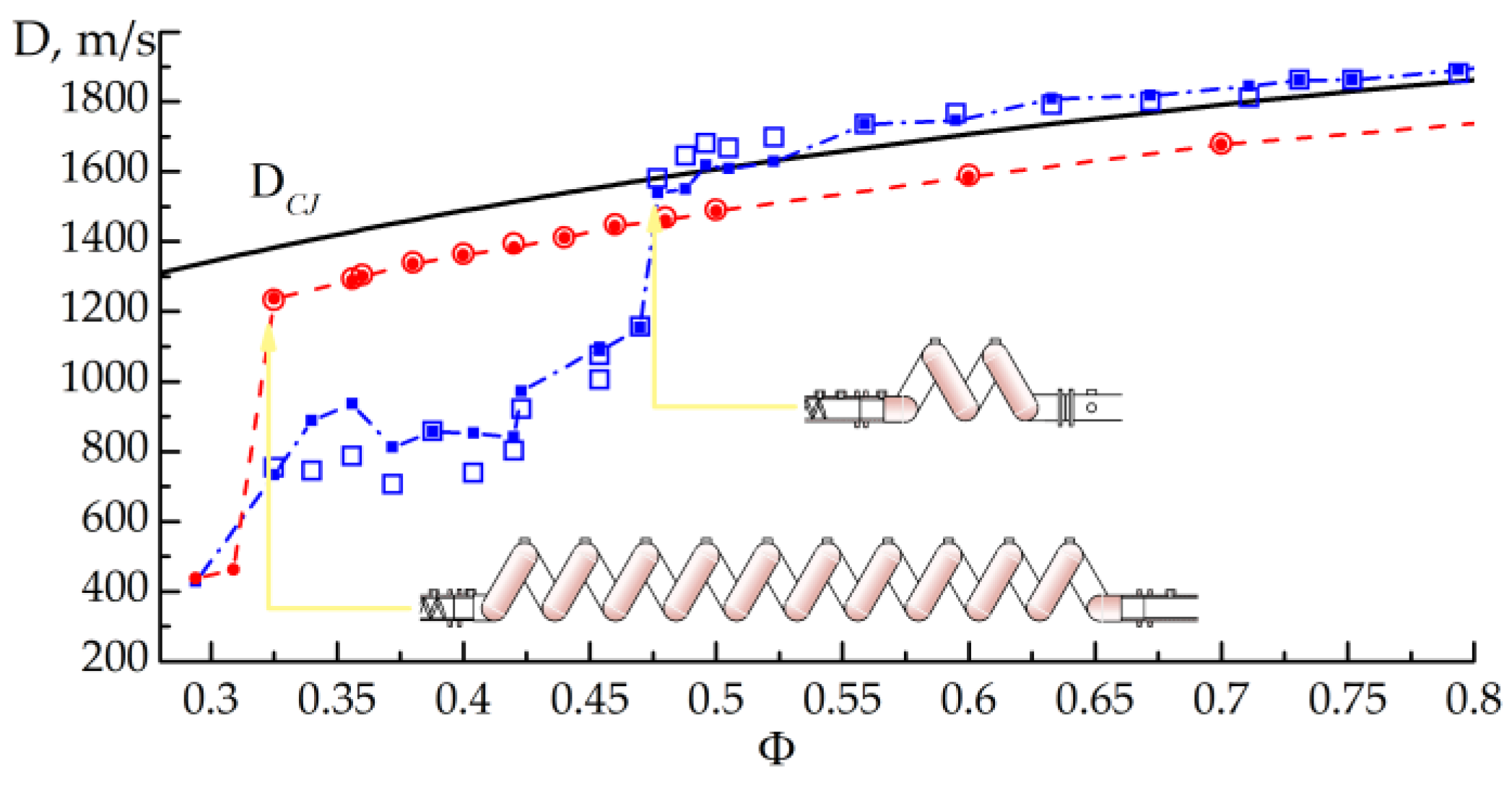

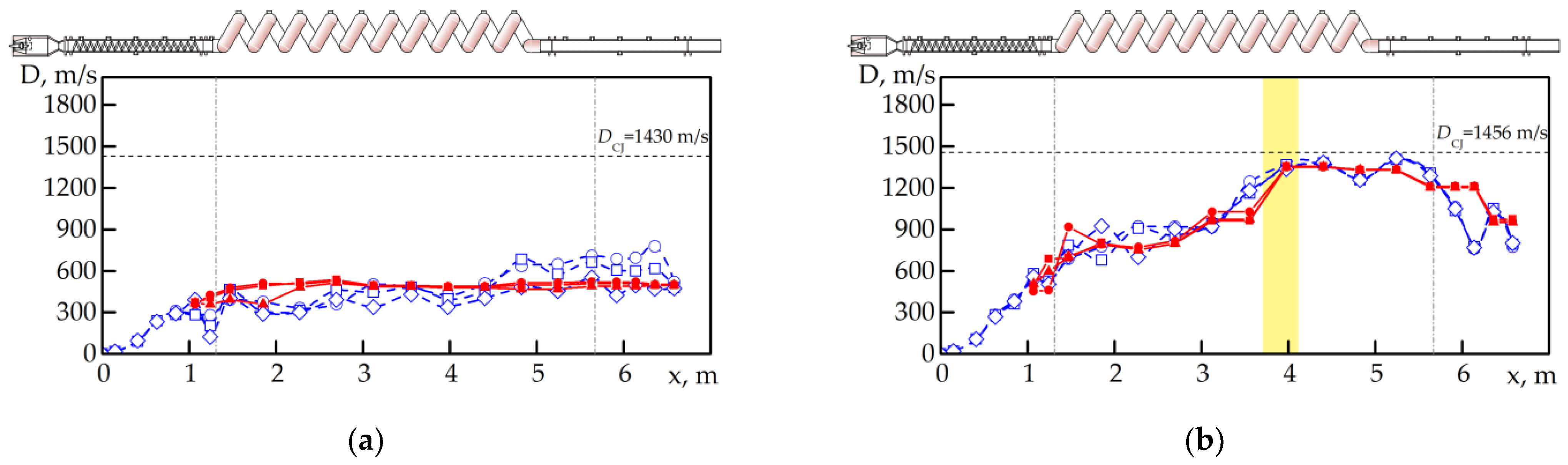

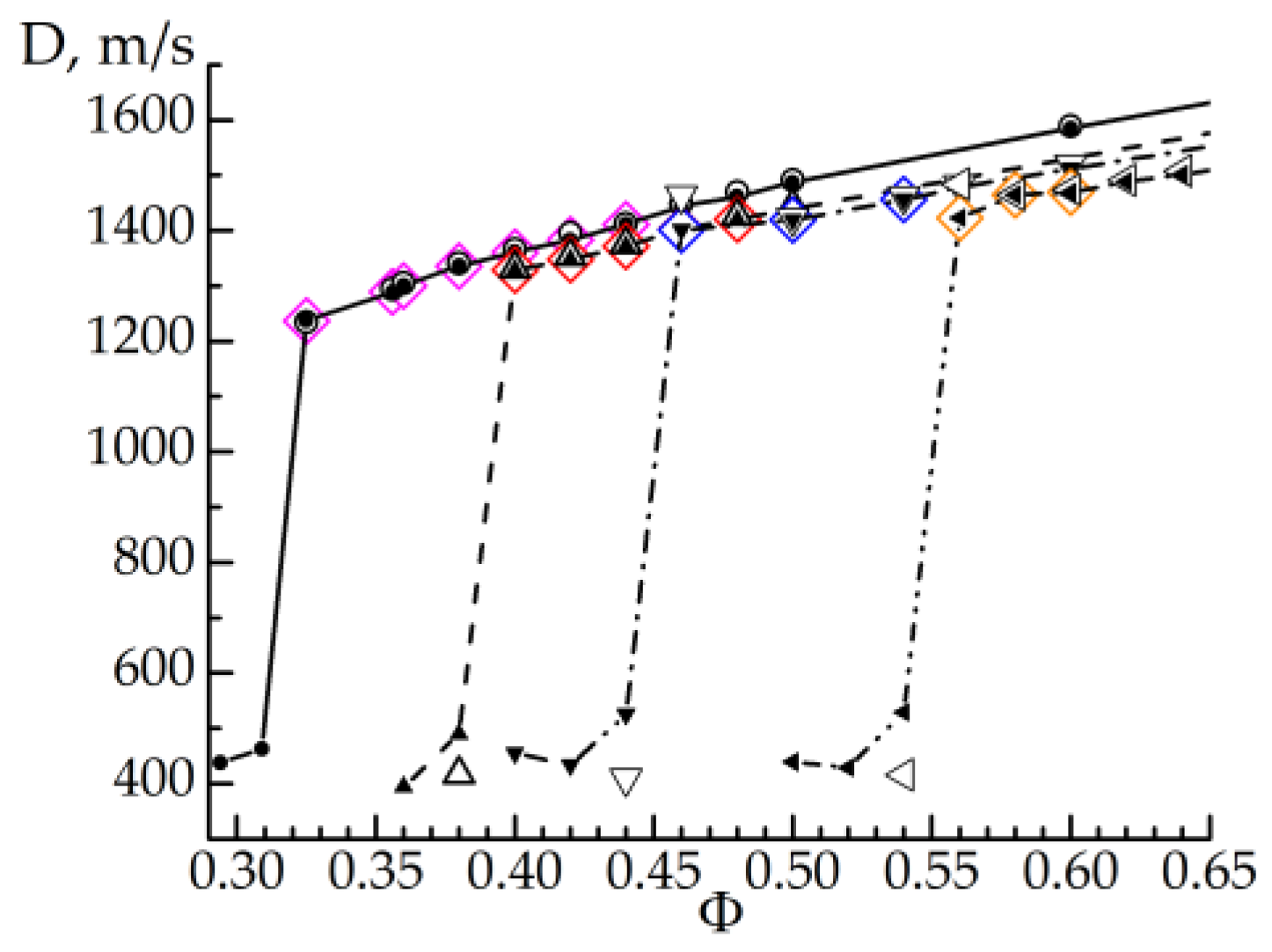

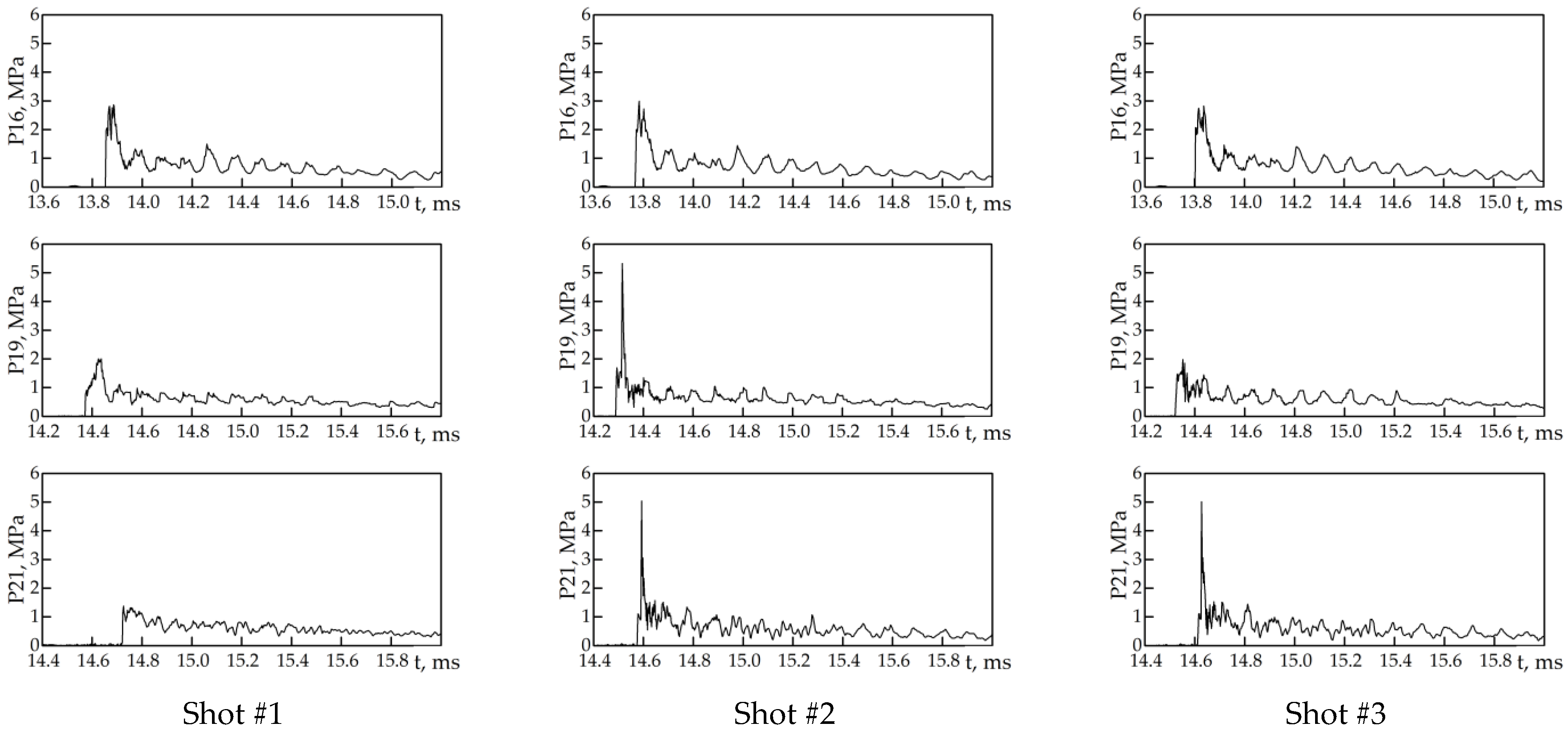

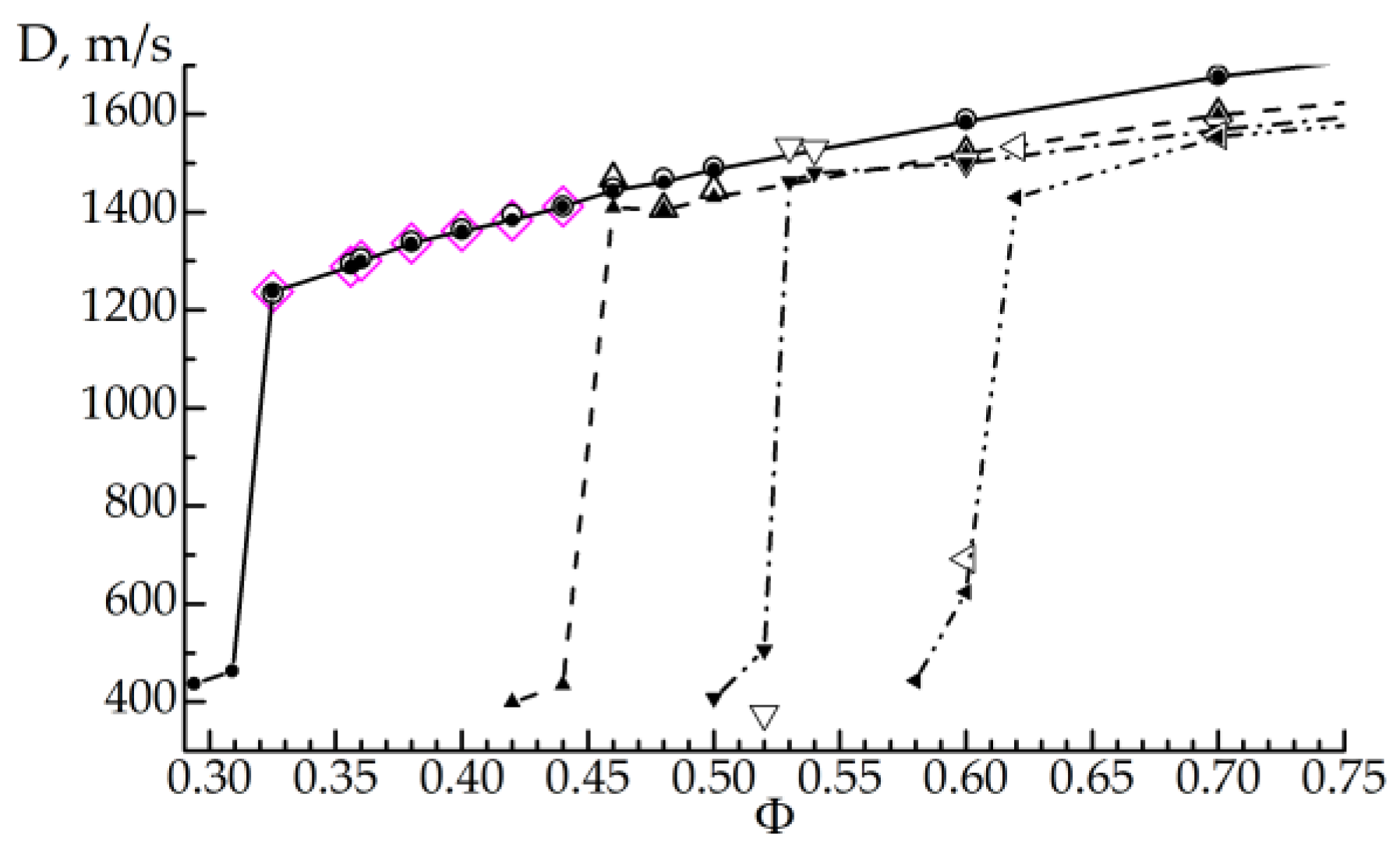

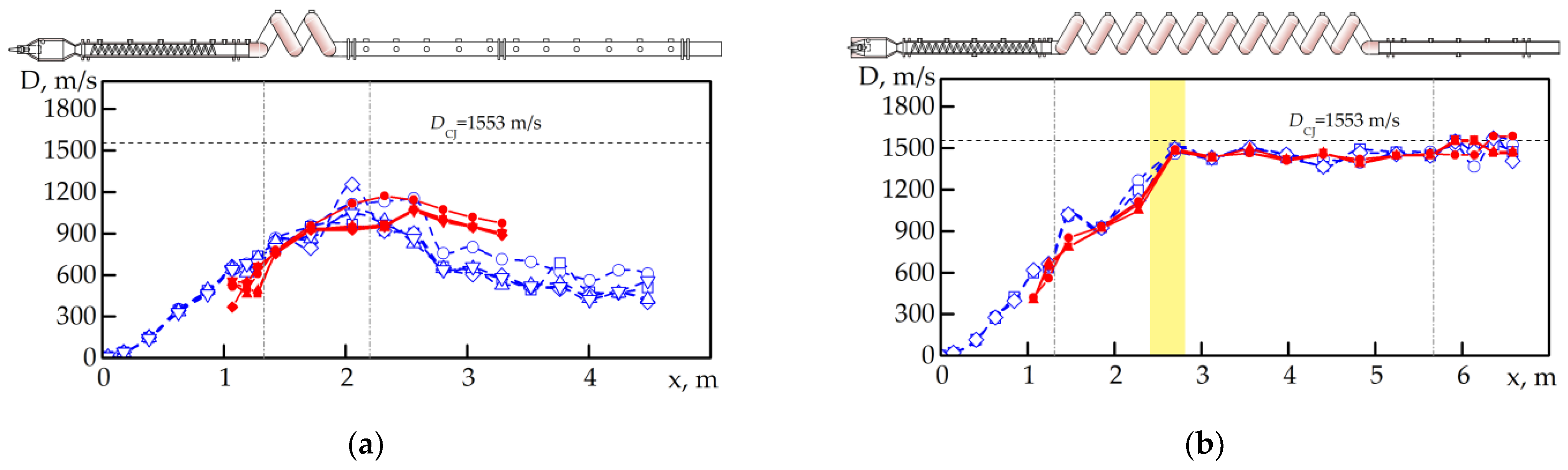

3.1. Hydrogen-Air Mixtures

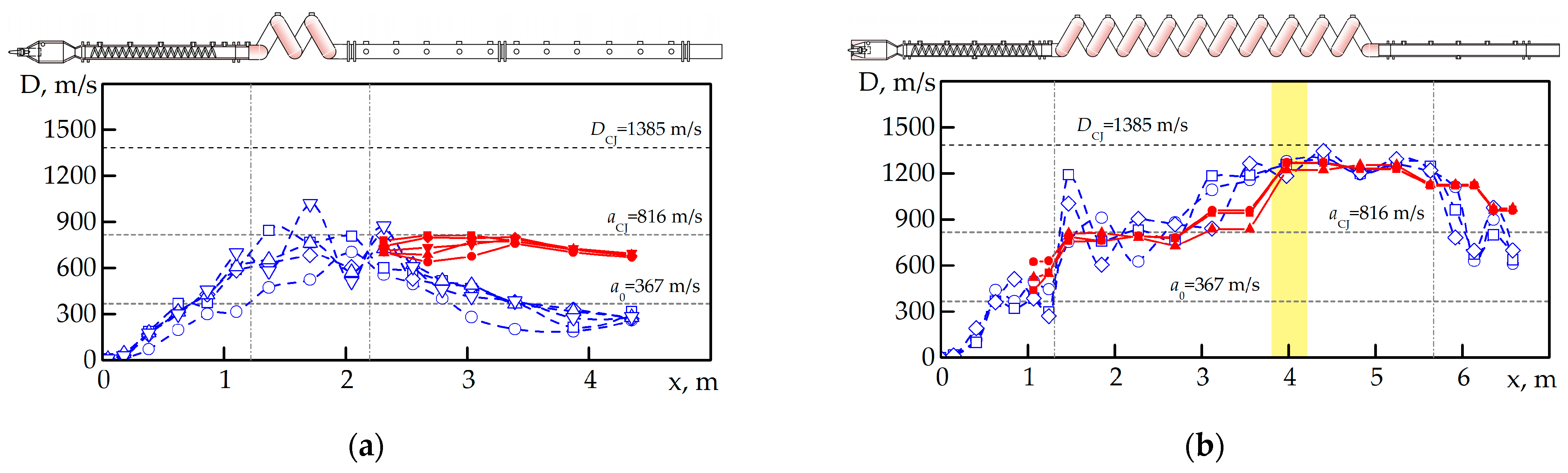

3.2. Methane-Air Mixtures

3.3. Methane-Hydrogen-Air Mixtures

3.4. Propane-Hydrogen-Air Mixtures

3.5. Ethylene-Hydrogen-Air Mixtures

4. Conclusions

- (1)

- The possibility of a significant reduction in the detonation run-up distance in the studied fuel-air mixtures in comparison with that of the SDT-1 was demonstrated;

- (2)

- The possibility of a significant extension of the fuel-lean concentration limit of the fast deflagration-to-detonation transition in the studied fuel-air mixtures in comparison with that of the SDT-1 was demonstrated; in sufficiently long helical tubes, fast deflagration-to-detonation transition is possible in explosive mixtures of such a composition, for which classical DDT is impossible in straight tubes with smooth or rough walls;

- (3)

- The minimum apparent propagation velocity of the reaction front at the entrance to the helical tube section at the fuel-lean concentration limit of fast deflagration-to-detonation transition turned out to be virtually constant and close to 400–500 m/s for all studied fuel-air mixtures;

- (4)

- For all studied fuel-air mixtures, steady-state propagation of detonation in the helical tube section with a velocity deficit above 10% was recorded, which is impossible when detonation propagates in a straight tube with smooth walls.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CJ | Chapman-Jouguet |

| DDT | Deflagration-to-detonation transition |

| FDDT | Fast deflagration-to-detonation transition |

| IP | Ionization probe |

| NPT | Normal pressure and temperature |

| PS | Pressure sensor |

| SDT-1 | Standard pulsed detonation tube (version 1) |

| SDT-2 | Standard pulsed detonation tube (version 2) |

Appendix

| Gas | XH2 | Φ | Xf1 | Xf2 | Xf | Df,in | Mode | DCJ | DSW1 | DSW2 | LDDT | TDDT |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| % | % | % | % | m/s | *) | m/s | m/s | m/s | m | ms | ||

| CH4 | 0 | 0.7 | 6.83 | — | 6.83 | 152 ± 4 | F | 1655 | 374 ± 127 | 468 ± 23 | – | – |

| CH4 | 0 | 0.8 | 7.73 | — | 7.73 | 573 ± 76 | D/F | 1718 | 1567 ± 27 | 1162 ± 104 | 4.04 | 19.38 |

| CH4 | 0 | 0.9 | 8.61 | — | 8.61 | 707 ± 45 | D/F | 1766 | 1611 ± 9 | 1245 ± 145 | 2.44 | 14.18 |

| CH4 | 0 | 1 | 9.48 | — | 9.48 | 671 ± 18 | D | 1802 | 1644 ± 10 | 1720 ± 16 | 2.55 | 13.62 |

| CH4 | 10 | 0.7 | 6.61 | 0.73 | 7.34 | 247 ± 117 | F | 1659 | 539 ± 368 | 496 ± 5 | – | – |

| CH4 | 10 | 1 | 9.15 | 1.02 | 10.17 | 819 ± 29 | D | 1806 | 1642 ± 24 | 1773 ± 33 | 2.43 | 12.13 |

| CH4 | 20 | 0.7 | 6.35 | 1.59 | 7.94 | 346 ± 44 | F | 1664 | 840 ± 72 | 1067 ± 70 | – | – |

| CH4 | 20 | 1 | 8.7 | 2.18 | 10.88 | 909 ± 32 | D | 1811 | 1645 ± 9 | 1730 ± 17 | 2.47 | 10.92 |

| CH4 | 30 | 0.7 | 6.05 | 2.59 | 8.64 | 547 ± 34 | D/F | 1669 | 1528 ± 33 | 1150 ± 97 | 4.33 | 18.60 |

| CH4 | 30 | 1 | 8.34 | 3.57 | 11.91 | 880 ± 31 | D | 1818 | 1655 ± 4 | 1796 ± 45 | 2.48 | 9.89 |

| CH4 | 40 | 0.6 | 4.94 | 3.30 | 8.24 | 172 ± 23 | F | 1598 | 433 ± 24 | 489 ± 10 | – | – |

| CH4 | 40 | 0.7 | 5.69 | 3.79 | 9.48 | 755 ± 36 | D/F | 1675 | 1535 ± 16 | 1201 ± 93 | 2.55 | 13.78 |

| CH4 | 40 | 1 | 7.81 | 5.21 | 13.02 | 798 ± 20 | D | 1825 | 1667 ± 7 | 1779 ± 26 | 2.57 | 8.73 |

| CH4 | 50 | 0.58 | 4.43 | 4.43 | 8.86 | 308 ± 72 | F | 1588 | 664 ± 161 | 807 ± 34 | – | – |

| CH4 | 50 | 0.6 | 4.57 | 4.57 | 9.14 | 496 ± 10 | D/F | 1606 | 1461 ± 371 | 1546 ± 20 | 5.24 | 20.83 |

| CH4 | 50 | 0.62 | 4.71 | 4.71 | 9.42 | 580 ± 25 | D/F | 1622 | 1505 ± 2 | 1153 ± 141 | 3.90 | 17.71 |

| CH4 | 50 | 0.64 | 4.84 | 4.84 | 9.68 | 672 ± 29 | D/F | 1638 | 1493 ± 7 | 1191 ± 97 | 2.66 | 14.88 |

| CH4 | 50 | 0.66 | 4.98 | 4.98 | 9.96 | 798 ± 28 | D | 1654 | 1499 ± 7 | 1589 ± 14 | 2.75 | 13.82 |

| CH4 | 50 | 0.7 | 5.25 | 5.25 | 10.50 | 818 ± 28 | D | 1683 | 1544 ± 5 | 1635 ± 26 | 2.68 | 11.86 |

| CH4 | 50 | 1 | 7.18 | 7.18 | 14.36 | 769 ± 10 | D | 1835 | 1681 ± 12 | 1771 ± 16 | 2.50 | 7.71 |

| CH4 | 60 | 0.5 | 3.48 | 5.21 | 8.69 | 151 ± 80 | F | 1521 | 439 ± 94 | 426 ± 10 | – | – |

| CH4 | 60 | 0.52 | 3.60 | 5.41 | 9.01 | 172 ± 26 | F | 1541 | 429 ± 13 | 454 ± 4 | – | – |

| CH4 | 60 | 0.54 | 3.73 | 5.60 | 9.33 | 210 ± 13 | F | 1561 | 529 ± 41 | 508 ± 13 | – | – |

| CH4 | 60 | 0.56 | 3.86 | 5.78 | 9.64 | 523 ± 23 | D | 1580 | 1423 ± 113 | 1553 ± 24 | 5.25 | 21.30 |

| CH4 | 60 | 0.58 | 3.98 | 5.97 | 9.95 | 637 ± 4 | D/F | 1598 | 1464 ± 23 | 1252 ± 114 | 3.56 | 17.18 |

| CH4 | 60 | 0.6 | 4.10 | 6.16 | 10.26 | 806 ± 179 | D/F | 1615 | 1469 ± 13 | 1414 ± 83 | 2.89 | 14.80 |

| CH4 | 60 | 0.62 | 4.22 | 6.34 | 10.56 | 848 ± 56 | D | 1632 | 1488 ± 24 | 1554 ± 9 | 2.71 | 13.35 |

| CH4 | 60 | 0.64 | 4.34 | 6.52 | 10.86 | 789 ± 31 | D | 1648 | 1501 ± 20 | 1585 ± 10 | 2.77 | 12.44 |

| CH4 | 60 | 0.7 | 4.70 | 7.06 | 11.76 | 711 ± 10 | D | 1693 | 1548 ± 12 | 1676 ± 48 | 2.95 | 10.46 |

| CH4 | 60 | 0.8 | 5.29 | 7.93 | 13.22 | 725 ± 8 | D | 1757 | 1608 ± 5 | 1709 ± 19 | 2.57 | 8.09 |

| CH4 | 60 | 0.9 | 5.85 | 8.78 | 14.63 | 767 ± 58 | D | 1808 | 1668 ± 30 | 1762 ± 14 | 2.36 | 6.88 |

| CH4 | 60 | 1 | 6.40 | 9.60 | 16.00 | 767 ± 8 | D | 1847 | 1694 ± 8 | 1768 ± 18 | 2.33 | 6.58 |

| CH4 | 70 | 0.48 | 2.87 | 6.71 | 9.58 | 165 ± 51 | F | 1512 | 469 ± 8 | 465 ± 4 | – | – |

| CH4 | 70 | 0.5 | 2.98 | 6.95 | 9.93 | 423 ± 79 | D | 1533 | 903 ± 19 | 1546 ± 64 | 5.61 | 23.68 |

| CH4 | 70 | 0.54 | 3.19 | 7.45 | 10.64 | 700 ± 14 | D/F | 1573 | 1442 ± 0 | 1260 ± 95 | 2.88 | 15.60 |

| CH4 | 70 | 0.6 | 3.50 | 8.18 | 11.68 | 672 ± 9 | D/F | 1627 | 1485 ± 9 | 1439 ± 76 | 2.88 | 11.96 |

| CH4 | 70 | 0.7 | 4.02 | 9.37 | 13.39 | 714 ± 16 | D | 1706 | 1570 ± 3 | 1635 ± 14 | 2.58 | 8.33 |

| CH4 | 70 | 1 | 5.42 | 12.65 | 18.07 | 753 ± 24 | D | 1863 | 1723 ± 7 | 1813 ± 9 | 2.24 | 5.49 |

| CH4 | 80 | 0.40 | 1.90 | 7.58 | 9.48 | 85 ± 3 | F | 1435 | 455 ± 58 | 412 ± 9 | – | – |

| CH4 | 80 | 0.42 | 1.98 | 7.93 | 9.91 | 68 ± 6 | F | 1459 | 433 ± 9 | 434 ± 6 | – | – |

| CH4 | 80 | 0.44 | 2.07 | 8.26 | 10.33 | 226 ± 22 | F | 1483 | 525 ± 23 | 498 ± 5 | – | – |

| CH4 | 80 | 0.46 | 2.15 | 8.60 | 10.75 | 502 ± 28 | D/F | 1506 | 1401 ± 20 | 998 ± 84 | 4.66 | 21.15 |

| CH4 | 80 | 0.5 | 2.32 | 9.26 | 11.58 | 759 ± 75 | D/F | 1549 | 1419 ± 14 | 1359 ± 77 | 2.69 | 14.60 |

| CH4 | 80 | 0.54 | 2.48 | 9.91 | 12.39 | 689 ± 23 | D/F | 1589 | 1456 ± 9 | 1429 ± 68 | 2.99 | 12.14 |

| CH4 | 80 | 0.56 | 2.56 | 10.23 | 12.79 | 685 ± 17 | D | 1608 | 1478 ± 7 | 1537 ± 12 | 2.76 | 10.93 |

| CH4 | 80 | 0.6 | 2.72 | 10.86 | 13.58 | 658 ± 10 | D | 1644 | 1512 ± 4 | 1584 ± 10 | 2.60 | 9.27 |

| CH4 | 80 | 0.7 | 3.10 | 12.39 | 15.49 | 669 ± 5 | D | 1724 | 1592 ± 6 | 1669 ± 8 | 2.29 | 6.75 |

| CH4 | 80 | 1 | 4.15 | 16.60 | 20.75 | 763 ± 15 | D | 1885 | 1748 ± 0 | 1813 ± 14 | 2.22 | 4.61 |

| CH4 | 90 | 0.36 | 1.04 | 9.36 | 10.40 | 38 ± 1 | F | 1403 | 394 ± 10 | 431 ± 5 | – | – |

| CH4 | 90 | 0.38 | 1.09 | 9.85 | 10.94 | 202 ± 78 | F | 1430 | 489 ± 52 | 497 ± 7 | – | – |

| CH4 | 90 | 0.40 | 1.14 | 10.28 | 11.42 | 513 ± 11 | D/F | 1456 | 1329 ± 7 | 960 ± 82 | 3.93 | 21.40 |

| CH4 | 90 | 0.42 | 1.19 | 10.73 | 11.92 | 714 ± 23 | D/F | 1481 | 1348 ± 6 | 1025 ± 82 | 2.94 | 17.31 |

| CH4 | 90 | 0.44 | 1.24 | 11.18 | 12.42 | 720 ± 14 | D/F | 1505 | 1372 ± 16 | 1055 ± 78 | 2.88 | 15.17 |

| CH4 | 90 | 0.46 | 1.29 | 11.61 | 12.90 | 638 ± 16 | D/F | 1528 | 1403 ± 0 | 1277 ± 71 | 3.06 | 13.79 |

| CH4 | 90 | 0.48 | 1.34 | 12.06 | 13.40 | 635 ± 5 | D/F | 1550 | 1421 ± 3 | 1400 ± 47 | 3.01 | 12.39 |

| CH4 | 90 | 0.5 | 1.39 | 12.49 | 13.88 | 657 ± 16 | D | 1572 | 1439 ± 7 | 1501 ± 4 | 2.93 | 11.16 |

| CH4 | 90 | 0.7 | 1.84 | 16.57 | 18.41 | 731 ± 27 | D | 1750 | 1622 ± 3 | 1664 ± 25 | 2.24 | 5.51 |

| CH4 | 90 | 1 | 2.44 | 21.93 | 24.37 | 1407 ± 131 | D | 1917 | 1791 ± 5 | 1855 ± 18 | 1.33 | 3.08 |

| C2H4 | 0 | 0.7 | 4.66 | — | 4.66 | 775 ± 48 | D | 1692 | 1570 ± 9 | 1664 ± 9 | 2.24 | 12.97 |

| C2H4 | 0 | 1 | 6.53 | — | 6.53 | 1407 ± 194 | D | 1822 | 1703 ± 3 | 1824 ± 5 | 1.32 | 6.01 |

| C2H4 | 10 | 0.7 | 4.55 | 0.51 | 5.06 | 791 ± 36 | D | 1694 | 1566 ± 13 | 1662 ± 8 | 2.38 | 12.49 |

| C2H4 | 10 | 1 | 6.37 | 0.71 | 7.08 | 1464 ± 29 | D | 1825 | 1706 ± 8 | 1825 ± 8 | 1.32 | 5.74 |

| C2H4 | 20 | 0.7 | 1.43 | 1.11 | 5.54 | 737 ± 22 | D | 1696 | 1572 ± 5 | 1679 ± 5 | 2.28 | 11.47 |

| C2H4 | 20 | 1 | 6.18 | 1.55 | 7.73 | 1305 ± 163 | D | 1828 | 1705 ± 0 | 1813 ± 1 | 1.35 | 5.57 |

| C2H4 | 30 | 0.7 | 4.28 | 1.84 | 6.12 | 740 ± 21 | D | 1699 | 1570 ± 1 | 1666 ± 3 | 2.39 | 10.86 |

| C2H4 | 30 | 1 | 5.96 | 2.56 | 8.52 | 1350 ± 75 | D | 1831 | 1710 ± 3 | 1817 ± 5 | 1.34 | 5.29 |

| C2H4 | 40 | 0.7 | 4.1 | 2.73 | 6.83 | 724 ± 9 | D | 1702 | 1572 ± 12 | 1664 ± 8 | 2.28 | 10.12 |

| C2H4 | 40 | 1 | 5.69 | 3.79 | 9.48 | 1188 ± 290 | D | 1836 | 1714 ± 6 | 1836 ± 6 | 1.37 | 5.10 |

| C2H4 | 50 | 0.5 | 2.82 | 2.82 | 5.65 | 218 ± 11 | F | 1542 | 521 ± 45 | 489 ± 5 | – | – |

| C2H4 | 50 | 0.7 | 3.86 | 3.86 | 7.73 | 708 ± 25 | D | 1706 | 1581 ± 5 | 1684 ± 7 | 2.25 | 9.26 |

| C2H4 | 50 | 1 | 5.34 | 5.34 | 10.7 | 1276 ± 85 | D | 1842 | 1721 ± 5 | 1837 ± 5 | 1.35 | 4.74 |

| C2H4 | 60 | 0.46 | 2.41 | 3.62 | 6.04 | 122 ± 33 | F | 1519 | 437 ± 85 | 452 ± 17 | – | – |

| C2H4 | 60 | 0.48 | 2.51 | 3.77 | 6.28 | 196 ± 55 | F | 1526 | 406 ± 32 | 456 ± 27 | – | – |

| C2H4 | 60 | 0.5 | 2.61 | 3.92 | 6.53 | 408 ± 88 | D | 1547 | 1454 ± 33 | 1580 ± 41 | 4.26 | 25.82 |

| C2H4 | 60 | 0.52 | 2.70 | 4.06 | 6.76 | 570 ± 9 | D | 1567 | 1448 ± 4 | 1489 ± 13 | 2.72 | 20.38 |

| C2H4 | 60 | 0.54 | 2.81 | 4.21 | 7.02 | 744 ± 28 | D | 1586 | 1469 ± 5 | 1513 ± 10 | 2.47 | 16.92 |

| C2H4 | 60 | 0.7 | 3.56 | 5.34 | 8.90 | 707 ± 37 | D | 1712 | 1585 ± 6 | 1694 ± 3 | 2.24 | 8.36 |

| C2H4 | 60 | 1 | 4.90 | 7.35 | 12.25 | 1168 ± 189 | D | 1850 | 1732 ± 2 | 1843 ± 15 | 1.37 | 4.42 |

| C2H4 | 70 | 0.44 | 2.06 | 4.81 | 6.87 | 126 ± 9 | F | 1488 | 476 ± 20 | 507 ± 24 | – | – |

| C2H4 | 70 | 0.46 | 2.15 | 5.01 | 7.16 | 243 ± 42 | F | 1511 | 480 ± 32 | 490 ± 6 | – | – |

| C2H4 | 70 | 0.48 | 2.23 | 5.21 | 7.44 | 453 ± 73 | D | 1556 | 1437 ± 17 | 1496 ± 15 | 4.53 | 24.14 |

| C2H4 | 70 | 0.5 | 2.32 | 5.40 | 7.72 | 647 ± 15 | D | 1553 | 1439 ± 7 | 1505 ± 35 | 2.61 | 18.58 |

| C2H4 | 70 | 0.54 | 2.49 | 5.81 | 8.30 | 736 ± 20 | D | 1592 | 1471 ± 10 | 1585 ± 46 | 2.58 | 14.51 |

| C2H4 | 70 | 0.56 | 2.57 | 6.01 | 8.58 | 737 ± 56 | D | 1610 | 1493 ± 6 | 1585 ± 19 | 2.60 | 13.00 |

| C2H4 | 70 | 0.58 | 2.66 | 6.20 | 8.85 | 744 ± 42 | D | 1628 | 1516 ± 7 | 1630 ± 13 | 2.58 | 11.49 |

| C2H4 | 70 | 0.7 | 3.15 | 7.34 | 10.49 | 767 ± 49 | D | 1720 | 1593 ± 4 | 1654 ± 20 | 2.24 | 7.54 |

| C2H4 | 70 | 1 | 4.30 | 10.03 | 14.33 | 1406 ± 129 | D | 1862 | 1742 ± 3 | 1846 ± 7 | 1.33 | 4.02 |

| C2H4 | 70 | 1.4 | 5.70 | 13.30 | 19.00 | 1445 ± 108 | D | 1935 | 1803 ± 8 | 1905 ± 6 | 1.33 | 4.85 |

| C2H4 | 80 | 0.42 | 1.62 | 6.47 | 8.09 | 125 ± 5 | F | 1473 | 466 ± 23 | 445 ± 7 | – | – |

| C2H4 | 80 | 0.44 | 1.69 | 6.75 | 8.44 | 467 ± 48 | D | 1497 | 1399 ± 37 | 1447 ± 18 | 4.69 | 24.10 |

| C2H4 | 80 | 0.46 | 1.76 | 7.03 | 8.79 | 569 ± 21 | D | 1519 | 1398 ± 2 | 1485 ± 23 | 3.12 | 20.15 |

| C2H4 | 80 | 0.48 | 1.83 | 7.30 | 9.13 | 775 ± 24 | D | 1541 | 1418 ± 8 | 1435 ± 22 | 2.53 | 16.36 |

| C2H4 | 80 | 0.5 | 1.90 | 7.58 | 9.48 | 748 ± 51 | D | 1562 | 1429 ± 65 | 1533 ± 30 | 2.58 | 14.75 |

| C2H4 | 80 | 0.54 | 2.03 | 8.14 | 10.17 | 690 ± 49 | D | 1601 | 1479 ± 6 | 1630 ± 46 | 2.61 | 11.94 |

| C2H4 | 80 | 0.7 | 2.56 | 10.22 | 12.78 | 698 ± 11 | D | 1731 | 1601 ± 9 | 1674 ± 13 | 2.24 | 6.68 |

| C2H4 | 80 | 1 | 3.46 | 13.86 | 17.32 | 1483 ± 34 | D | 1879 | 1759 ± 4 | 1839 ± 13 | 1.32 | 3.55 |

| C2H4 | 90 | 0.38 | 0.96 | 8.63 | 9.59 | 166 ± 50 | F | 1436 | 441 ± 5 | 457 ± 21 | – | – |

| C2H4 | 90 | 0.4 | 1.00 | 9.04 | 10.05 | 446 ± 62 | D/F | 1462 | 1342 ± 6 | 976 ± 44 | 3.82 | 22.71 |

| C2H4 | 90 | 0.42 | 1.05 | 9.45 | 10.50 | 664 ± 28 | D/F | 1487 | 1362 ± 4 | 1062 ± 40 | 2.77 | 18.18 |

| C2H4 | 90 | 0.44 | 1.09 | 9.85 | 10.94 | 693 ± 21 | D/F | 1497 | 1389 ± 2 | 1477 ± 35 | 2.64 | 15.65 |

| C2H4 | 90 | 0.46 | 1.14 | 10.26 | 11.40 | 660 ± 34 | D | 1519 | 1403 ± 0 | 1454 ± 15 | 2.97 | 14.44 |

| C2H4 | 90 | 0.48 | 1.19 | 10.73 | 11.92 | 643 ± 33 | D | 1556 | 1428 ± 7 | 1541 ± 41 | 2.81 | 12.14 |

| C2H4 | 90 | 0.5 | 1.22 | 11.02 | 12.24 | 652 ± 10 | D | 1577 | 1453 ± 0 | 1518 ± 21 | 2.66 | 11.28 |

| C2H4 | 90 | 0.7 | 1.64 | 14.73 | 16.37 | 780 ± 71 | D | 1751 | 1624 ± 9 | 1768 ± 26 | 2.23 | 5.46 |

| C2H4 | 90 | 1 | 2.18 | 19.65 | 21.83 | 1513 ± 88 | D | 1908 | 1774 ± 6 | 1892 ± 4 | 0.62 | 2.63 |

| C3H8 | 0 | 0.7 | 2.85 | — | 2.85 | 285 ± 92 | F | 1660 | 624 ± 74 | 625 ± 60 | – | – |

| C3H8 | 0 | 0.71 | 2.89 | — | 2.89 | 383 ± 80 | F+D | 1667 | 917 ± 0 | 1669 ± 69 | 5.80 | 44.93 |

| C3H8 | 0 | 0.72 | 2.93 | — | 2.93 | 352 ± 78 | D | 1673 | 1635 ± 40 | 1633 ± 17 | 5.14 | 44.31 |

| C3H8 | 0 | 0.74 | 3.01 | — | 3.01 | 528 ± 37 | D | 1686 | 1561 ± 13 | 1669 ± 20 | 3.32 | 31.43 |

| C3H8 | 0 | 0.76 | 3.09 | — | 3.09 | 560 ± 27 | D | 1697 | 1571 ± 5 | 1684 ± 20 | 2.58 | 25.52 |

| C3H8 | 0 | 0.8 | 3.24 | — | 3.24 | 690 ± 17 | D | 1719 | 1591 ± 4 | 1674 ± 15 | 2.31 | 20.76 |

| C3H8 | 0 | 1 | 4.02 | — | 4.02 | 874 ± 25 | D | 1798 | 1660 ± 0 | 1773 ± 12 | 2.22 | 11.75 |

| C3H8 | 10 | 0.7 | 2.81 | 0.31 | 3.12 | 336 ± 46 | D | 1662 | 1430 ± 184 | 1638 ± 17 | 4.62 | 39.42 |

| C3H8 | 10 | 1 | 3.96 | 0.44 | 4.40 | 830 ± 33 | D | 1800 | 1664 ± 3 | 1779 ± 6 | 2.22 | 11.30 |

| C3H8 | 20 | 0.7 | 2.76 | 0.69 | 3.45 | 447 ± 52 | D | 1663 | 1540 ± 11 | 1676 ± 46 | 3.98 | 33.67 |

| C3H8 | 20 | 1 | 3.89 | 0.97 | 4.86 | 817 ± 28 | D | 1802 | 1667 ± 4 | 1786 ± 9 | 2.23 | 10.80 |

| C3H8 | 30 | 0.7 | 2.7 | 1.16 | 3.86 | 543 ± 76 | D | 1665 | 1537 ± 10 | 1676 ± 21 | 3.34 | 26.95 |

| C3H8 | 30 | 1 | 3.8 | 1.63 | 5.43 | 800 ± 21 | D | 1805 | 1668 ± 6 | 1779 ± 7 | 2.24 | 10.15 |

| C3H8 | 40 | 0.7 | 2.63 | 1.75 | 4.38 | 523 ± 19 | D | 1668 | 1545 ± 13 | 1694 ± 38 | 2.58 | 22.51 |

| C3H8 | 40 | 1 | 3.69 | 2.46 | 6.15 | 774 ± 10 | D | 1809 | 1670 ± 0 | 1802 ± 11 | 2.24 | 9.60 |

| C3H8 | 50 | 0.7 | 2.53 | 2.53 | 5.06 | 669 ± 30 | D | 1672 | 1547 ± 4 | 1674 ± 35 | 2.53 | 19.34 |

| C3H8 | 50 | 1 | 3.54 | 3.54 | 7.08 | 772 ± 10 | D | 1814 | 1678 ± 6 | 1825 ± 20 | 2.22 | 8.82 |

| C3H8 | 60 | 0.5 | 1.74 | 2.62 | 4.36 | – | X | 1510 | – | – | – | – |

| C3H8 | 60 | 0.58 | 2.01 | 3.01 | 5.02 | 219 ± 43 | F | 1585 | 443 ± 68 | 479 ± 8 | – | – |

| C3H8 | 60 | 0.6 | 2.07 | 3.11 | 5.18 | 293 ± 62 | F | 1602 | 624 ± 192 | 821 ± 56 | – | – |

| C3H8 | 60 | 0.62 | 2.14 | 3.21 | 5.35 | 475 ± 56 | D | 1618 | 1429 ± 7 | 1563 ± 10 | 4.13 | 27.47 |

| C3H8 | 60 | 0.7 | 2.40 | 3.60 | 6.00 | 814 ± 14 | D | 1677 | 1554 ± 0 | 1735 ± 54 | 2.22 | 15.88 |

| C3H8 | 60 | 1 | 3.34 | 5.01 | 8.35 | 773 ± 21 | D | 1820 | 1687 ± 3 | 1825 ± 17 | 2.22 | 8.07 |

| C3H8 | 70 | 0.5 | 1.61 | 3.75 | 5.36 | 42 ± 5 | F | 1517 | 356 ± 10 | 356 ± 2 | – | – |

| C3H8 | 70 | 0.6 | 1.91 | 4.45 | 6.36 | 563 ± 8 | D | 1609 | 1445 ± 75 | 1550 ± 19 | 3.94 | 23.25 |

| C3H8 | 70 | 0.7 | 2.20 | 5.14 | 7.34 | 766 ± 10 | D | 1685 | 1543 ± 4 | 1709 ± 49 | 2.56 | 14.03 |

| C3H8 | 70 | 1 | 3.05 | 7.12 | 10.17 | 773 ± 30 | D | 1830 | 1698 ± 4 | 1819 ± 6 | 2.23 | 7.16 |

| C3H8 | 80 | 0.5 | 1.39 | 5.57 | 6.96 | 134 ± 36 | F | 1528 | 408 ± 13 | 455 ± 10 | – | – |

| C3H8 | 80 | 0.52 | 1.44 | 5.78 | 7.22 | 200 ± 25 | F | 1548 | 505 ± 38 | 498 ± 6 | – | – |

| C3H8 | 80 | 0.53 | 1.47 | 5.88 | 7.35 | 402 ± 47 | D | 1558 | 1461 ± 27 | 1517 ± 12 | 4.71 | 25.96 |

| C3H8 | 80 | 0.54 | 1.50 | 5.98 | 7.48 | 465 ± 63 | D | 1567 | 1480 ± 15 | 1559 ± 30 | 4.73 | 24.46 |

| C3H8 | 80 | 0.6 | 1.65 | 6.59 | 8.24 | 805 ± 41 | D | 1621 | 1500 ± 6 | 1576 ± 10 | 2.28 | 15.10 |

| C3H8 | 80 | 0.7 | 1.90 | 7.58 | 9.48 | 721 ± 10 | D | 1698 | 1568 ± 3 | 1635 ± 12 | 2.57 | 10.49 |

| C3H8 | 80 | 1 | 2.60 | 10.42 | 13.02 | 763 ± 34 | D | 1846 | 1718 ± 0 | 1813 ± 25 | 2.23 | 6.11 |

| C3H8 | 90 | 0.42 | 0.85 | 7.63 | 8.48 | 106 ± 10 | F | 1460 | 399 ± 24 | 432 ± 3 | – | – |

| C3H8 | 90 | 0.44 | 0.88 | 7.96 | 8.84 | 143 ± 32 | F | 1484 | 435 ± 24 | 465 ± 10 | – | – |

| C3H8 | 90 | 0.46 | 0.92 | 8.29 | 9.21 | 513 ± 28 | D/F | 1506 | 1409 ± 39 | 1072 ± 85 | 4.20 | 23.34 |

| C3H8 | 90 | 0.48 | 0.96 | 8.61 | 9.57 | 622 ± 12 | D | 1528 | 1404 ± 4 | 1466 ± 10 | 2.86 | 18.83 |

| C3H8 | 90 | 0.5 | 0.99 | 8.94 | 9.93 | 743 ± 24 | D | 1549 | 1430 ± 8 | 1529 ± 30 | 2.53 | 16.02 |

| C3H8 | 90 | 0.6 | 1.16 | 10.52 | 11.68 | 700 ± 28 | D | 1644 | 1520 ± 4 | 1616 ± 14 | 2.58 | 10.18 |

| C3H8 | 90 | 0.7 | 1.34 | 12.03 | 13.37 | 708 ± 34 | D | 1722 | 1598 ± 9 | 1704 ± 9 | 2.26 | 7.22 |

| C3H8 | 90 | 1 | 1.81 | 16.26 | 18.07 | 1061 ± 88 | D | 1878 | 1749 ± 11 | 1813 ± 15 | 1.50 | 4.19 |

| — | 100 | 0.295 | — | 11 | 11 | –**) | F | 1337 | 437 ± 17 | 425 ± 7 | – | – |

| — | 100 | 0.310 | — | 11.5 | 11.5 | –**) | F | 1362 | 463 ± 6 | 447 ± 6 | – | – |

| — | 100 | 0.326 | — | 12 | 12 | 339 ± 94 | D/F | 1385 | 1237 ± 35 | 964 ± 53 | 3.97 | 24.66 |

| — | 100 | 0.357 | — | 13 | 13 | 740 ± 88 | D/F | 1431 | 1289 ± 19 | 977 ± 69 | 3.06 | 18.29 |

| — | 100 | 0.36 | — | 13.11 | 13.11 | 642 ± 33 | D/F | 1434 | 1300 ± 12 | 982 ± 70 | 3.04 | 17.63 |

| — | 100 | 0.38 | — | 13.73 | 13.73 | 583 ± 9 | D/F | 1462 | 1336 ± 18 | 1008 ± 97 | 3.14 | 15.39 |

| — | 100 | 0.4 | — | 14.35 | 14.35 | 509 ± 16 | D/F | 1488 | 1361 ± 6 | 1114 ± 60 | 3.11 | 13.74 |

| — | 100 | 0.42 | — | 14.96 | 14.96 | 548 ± 32 | D/F | 1514 | 1383 ± 10 | 1434 ± 26 | 3.04 | 12.03 |

| — | 100 | 0.44 | — | 15.57 | 15.57 | 505 ± 95 | D/F | 1539 | 1411 ± 7 | 1448 ± 68 | 3.01 | 10.89 |

| — | 100 | 0.46 | — | 16.16 | 16.16 | 548 ± 50 | D | 1562 | 1444 ± 10 | 1521 ± 20 | 2.68 | 9.39 |

| — | 100 | 0.48 | — | 16.74 | 16.74 | 572 ± 35 | D | 1585 | 1461 ± 5 | 1531 ± 9 | 2.61 | 8.68 |

| — | 100 | 0.5 | — | 17.32 | 17.32 | 632 ± 40 | D | 1607 | 1487 ± 21 | 1551 ± 17 | 2.56 | 7.87 |

| — | 100 | 0.6 | — | 20.09 | 20.09 | 1194 ± 40 | D | 1707 | 1585 ± 32 | 1690 ± 27 | 1.60 | 4.83 |

| — | 100 | 0.7 | — | 22.68 | 22.68 | 1349 ± 51 | D | 1791 | 1677 ± 18 | 1772 ± 39 | 1.34 | 3.64 |

| — | 100 | 1 | — | 29.57 | 29.57 | 1759 ± 36 | D | 1967 | 1858 ± 13 | 1960 ± 23 | 0.62 | 2.05 |

References

- Bone, W.A.; Fraser, R.P. A photographic investigation of flame movements in carbonic oxide-oxygen explosions. Philos. Trans. R. Soc. London. Ser. A Contain. Pap. A Math. Or Phys. Character 1929, 228, 197–234. [Google Scholar] [CrossRef]

- Zel’dovich, Y.B. The Theory of Combustion and Detonation of Gases; Academy of Sciences of the Soviet Union: Moscow, Russia, 1944. [Google Scholar]

- Oppenheim, A.K. Introduction to Gasdynamics of Explosions; Springer: New York, NY, USA, 1972. [Google Scholar]

- Shchelkin, K.I. Fast Combustion and Spinning Detonation of Gases; Voenizdat: Moscow, Russia, 1949. [Google Scholar]

- Lindstedt, R.P.; Michels, H.J. Deflagration to detonation transitions and strong deflagrations in alkane and alkene air mixtures. Combust. Flame 1989, 76, 169–181. [Google Scholar] [CrossRef]

- Sorin, R.; Zitoun, R.; Desbordes, D. Optimization of the deflagration to detonation transition: Reduction of length and time of transition. Shock Waves 2006, 15, 137–145. [Google Scholar] [CrossRef]

- Theodorczyk, A.; Lee, J.H.S.; Knystautas, R. Propagation Mechanism of Quasidetonations. Symp. Int. Combustion 1988, 22, 1723–1731. [Google Scholar] [CrossRef]

- Lee, J.H.S. The Detonation Phenomenon; The Cambridge University Press: New York, NY, USA, 2008. [Google Scholar]

- Feng, X.; Huang, X. Influence of variable blocking ratio on DDT process. Energies 2022, 15, 7706. [Google Scholar] [CrossRef]

- Frolov, S.M. Initiation of strong reactive shocks and detonation by traveling ignition pulses. J. Loss Prev. Process Ind. 2006, 19, 238–244. [Google Scholar] [CrossRef]

- Frolov, S.M. Fast deflagration-to-detonation transition. Russ. J. Phys. Chem. B 2008, 2, 442–455. [Google Scholar] [CrossRef]

- Frolov, S.M.; Semenov, I.V.; Komissarov, P.V.; Utkin, P.S.; Markov, V.V. Reduction of the deflagration-to-detonation transition distance and time in a tube with regular shaped obstacles. Doklady Phys. Chem. 2007, 415, 209–213. [Google Scholar] [CrossRef]

- Li, J.-M.; Teo, C.J.; Lim, K.S.; Wen, C.-S.; Khoo, B.C. Deflagration to detonation transition by hybrid obstacles in pulse detonation engines. In Proceedings of the 49th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, San Jose, CA, USA, 14–17 July 2013; pp. 2013–3657. [Google Scholar] [CrossRef]

- Coates, A.M.; Mathias, D.L.; Cantwell, B.J. Numerical investigation of the effect of obstacle shape on deflagration to detonation transition in a hydrogen–air mixture. Combust. Flame 2019, 209, 278–290. [Google Scholar] [CrossRef]

- Xiao, H.; Oran, E.S. Flame acceleration and deflagration-to-detonation transition in hydrogen-air mixture in a channel with an array of obstacles of different shapes. Combust. Flame 2020, 220, 378–393. [Google Scholar] [CrossRef]

- Liu, Z.; Li, X.; Li, M.; Xiao, H. Flame acceleration and DDT in a channel with fence-type obstacles: Effect of obstacle shape and arrangement. Proc. Combust. Inst. 2022, in press. [Google Scholar] [CrossRef]

- Li, T.; Wang, X.; Xu, B.; Kong, F. An efficient approach to achieve flame acceleration and transition to detonation. Phys. Fluids 2021, 33, 056103. [Google Scholar] [CrossRef]

- Frolov, S.M.; Smetanyuk, V.A.; Aksenov, V.S.; Koval’, A.S. Deflagration-to-detonation transition in crossed-flow fast jets of propellant components. Doklady Phys. Chem. 2017, 476, 153–156. [Google Scholar] [CrossRef]

- Wang, Y.; Fan, W.; Li, S.; Zhang, Q.; Li, H. Numerical simulations of flame propagation and DDT in obstructed detonation tubes filled with fluidic obstacles. In Proceedings of the 21st AIAA International Space Planes and Hypersonics Technologies Conference, Xiamen, China, 6–9 March 2017; pp. 2017–2382. [Google Scholar]

- Peng, H.; Huang, Y.; Deiterding, R.; You, Y.; Luan, Z. Effects of transverse jet parameters on flame propagation and detonation transition in hydrogen–oxygen–argon mixture. Combust. Sci. Technol. 2019, 193, 1516–1537. [Google Scholar] [CrossRef]

- Starikovskaia, S. Plasma assisted ignition and combustion. J. Phys. D Appl. Phys. 2006, 39, R265–R299. [Google Scholar] [CrossRef]

- Zhukov, V.; Starikovskii, A. Effect of a nanosecond gas discharge on deflagration to detonation transition. Combust. Explos. Shock Waves 2006, 42, 195–204. [Google Scholar] [CrossRef]

- Gray, J.A.T.; Lacoste, D.A. Enhancement of the transition to detonation of a turbulent hydrogen–air flame by nanosecond repetitively pulsed plasma discharges. Combust. Flame 2019, 199, 258–266. [Google Scholar] [CrossRef]

- Ciccarelli, G.; de Witt, B. Detonation initiation by shock reflection from an orifice plate. Shock Waves 2006, 15, 259–265. [Google Scholar] [CrossRef]

- Frolov, S.M.; Aksenov, V.S. Initiation of gas detonation in a tube with a shaped obstacle. Doklady Phys. Chem. 2009, 427, 129–132. [Google Scholar] [CrossRef]

- Habicht, F.E.; Yücel, F.C.; Gray, J.A.; Paschereit, C.O. Detonation initiation by shock focusing at elevated pressure conditions in a pulse detonation combustor. Intern. J. Spray Combust. Dynamics 2020, 12, 175682772092171. [Google Scholar] [CrossRef]

- Frolov, S.M.; Shamshin, I.O.; Medvedev, S.N.; Dubrovskii, A.V. Initiation of detonation in a tube with a profiled central body. Dokl. Phys. Chem. 2011, 438, 114–117. [Google Scholar] [CrossRef]

- Frolov, S.M.; Aksenov, V.S.; Shamshin, I.O. Initiation of gaseous detonation in tubes with sharp U-bends. Dokl. Phys. Chem. 2007, 417, 22–25. [Google Scholar] [CrossRef]

- Frolov, S.M.; Aksenov, V.S.; Shamshin, I.O. Shock wave and detonation propagation through U-bend tubes. Proc. Combust. Inst. 2007, 31, 2421–2428. [Google Scholar] [CrossRef]

- Frolov, S.M.; Aksenov, V.S.; Shamshin, I.O. Propagation of shock and detonation waves in channels with U-shaped bends of limiting curvature. Russ. J. Phys. Chem. B 2008, 2, 759–774. [Google Scholar] [CrossRef]

- Gwak, M.-C.; Yoh, J.J. Effect of multi-bend geometry on deflagration to detonation transition of a hydrocarbon-air mixture in tubes. Int. J. Hydrogen Energy 2013, 38, 11446–11457. [Google Scholar] [CrossRef]

- Zheng, H.; Zhu, W.; Jia, X.; Zhao, N. Eulerian–Lagrangian modeling of deflagration to detonation transition in n-decane/oxygen/nitrogen mixtures. Phys. Fluids 2022, 34, 126110. [Google Scholar] [CrossRef]

- Pan, Z.; Zhang, Z.; Yang, H.; Gui, M.; Zhang, P.; Zhu, Y. Experimental and numerical investigation on flame propagation and transition to detonation in curved channel. Aerospace Sci. Technol. 2021, 118, 107036. [Google Scholar] [CrossRef]

- Gai, J.; Qiu, H.; Xiong, C.; Huang, Z. Experimental investigation on the propagation process of combustion wave in the annular channel filled with acetylene-air/oxygen mixture. Flow Turbul. Combust. 2022, 108, 797–817. [Google Scholar] [CrossRef]

- Frolov, S.M.; Basevich, V.Y.; Aksenov, V.S.; Polikhov, S.A. Optimization study of spray detonation initiation by electric discharge. Shock Waves 2005, 14, 175–186. [Google Scholar] [CrossRef]

- Frolov, S.M.; Aksenov, V.S.; Basevich, V.Y. Initiation of heterogeneous detonation in tubes with coils and Shchelkin spiral. High Temp. 2006, 44, 283–290. [Google Scholar] [CrossRef]

- Frolov, S.M.; Aksenov, V.S. Deflagration-to-detonation transition in a kerosene–air mixture. Doklady Phys. Chem. 2007, 416, 261–264. [Google Scholar] [CrossRef]

- Frolov, S.M.; Semenov, I.V.; Ahmedyanov, I.F.; Markov, V.V. Shock-to-Detonation Transition in Tube Coils. In Shock Waves: 26th International Symposium on Shock Waves; Hannemann, K., Seiler, F., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; Volume 1, pp. 365–370. ISBN 978-3-540-85167-7. [Google Scholar]

- Frolov, S.M.; Basevich, V.Y.; Aksenov, V.S.; Polikhov, S.A. Detonation initiation by controlled triggering of electric discharges. J. Propuls. Power 2003, 19, 573–580. [Google Scholar] [CrossRef]

- Frolov, S.M.; Basevich, V.Y.; Aksenov, V.S.; Polikhov, S.A. Spray detonation initiation by controlled triggering of electric discharges. J. Propuls. Power 2005, 21, 54–64. [Google Scholar] [CrossRef]

- Frolov, S.M.; Basevich, V.Y.; Aksenov, V.S.; Polikhov, S.A. Initiation of gaseous detonation by a traveling forced ignition pulse. Doklady Phys. Chem. 2004, 394, 16–18. [Google Scholar]

- Frolov, S.M.; Basevich, V.Y.; Aksenov, V.S.; Polikhov, S.A. Initiation of gas detonation by a travelling ignition source. Russ. J. Chem. Phys. 2004, 23, 61–67. [Google Scholar]

- Ciccarelli, G.; Johansen, C.; Hickey, M. Flame acceleration enhancement by distributed ignition points. J. Propuls. Power 2005, 21, 1029–1034. [Google Scholar] [CrossRef]

- Frolov, S.M.; Aksenov, V.S.; Basevich, V.Y. Detonation initiation by shock wave interaction with the prechamber jet ignition zone. Doklady Phys. Chem. 2006, 410, 255–259. [Google Scholar] [CrossRef]

- Frolov, S.M.; Aksenov, V.S.; Basevich, V.Y. Shock-to-Detonation Transition Due to Shock Interaction with Prechamber-Jet Cloud. In Shock Waves: 26th Intern Symp. on Shock Waves; Hannemann, K., Seiler, F., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; Volume 1, pp. 359–364. ISBN 978-3-540-85167-7. [Google Scholar]

- Frolov, S.M.; Zvegintsev, V.I.; Aksenov, V.S.; Bilera, I.V.; Kazachenko, M.V.; Shamshin, I.O.; Gusev, P.A.; Belotserkovskaya, M.S.; Koverzanova, E.V. Detonability of air mixtures of the polypropylene pyrolysis products. Combust. Explos. 2018, 11, 44–60. [Google Scholar] [CrossRef]

- Frolov, S.M.; Shamshin, I.O.; Aksenov, V.S.; Kazachenko, M.V.; Gusev, P.A. Ranking of gaseous fuel–air mixtures according to their detonability using a standard pulsed detonation tube. Combust. Explos. 2019, 12, 78–90. [Google Scholar] [CrossRef]

- Frolov, S.M.; Zvegintsev, V.I.; Shamshin, I.O.; Kazachenko, M.V.; Aksenov, V.S.; Bilera, I.V.; Semenov, I.V. Detonability of air mixtures of polyethylene pyrolysis products. Combust. Explos. 2020, 13, 48–61. [Google Scholar] [CrossRef]

- Frolov, S.M.; Zvegintsev, V.I.; Aksenov, V.S.; Bilera, I.V.; Kazachenko, M.V.; Shamshin, I.O.; Gusev, P.A.; Belotserkovskaya, M.S. Detonability of fuel–air mixtures. Shock Waves 2020, 30, 721–739. [Google Scholar] [CrossRef]

- Frolov, S.M.; Shamshin, I.O.; Kazachenko, M.V.; Aksenov, V.S.; Bilera, I.V.; Ivanov, V.S.; Zvegintsev, V.I. Polyethylene pyrolysis products: Their detonability in air and applicability to solid-fuel detonation ramjets. Energies 2021, 14, 820. [Google Scholar] [CrossRef]

- Shamshin, I.O.; Kazachenko, M.V.; Frolov, S.M.; Basevich, V.Y. Deflagration-to-detonation transition in air mixtures of hydrogen–methane fuel. Combust. Explos. 2020, 13, 60–75. [Google Scholar] [CrossRef]

- Shamshin, I.O.; Kazachenko, M.V.; Frolov, S.M.; Basevich, V.Y. Deflagration-to-detonation transition in stochiometric mixtures of the binary methane–hydrogen fuel with air. Int. J. Hydrog. Energy 2021, 46, 34046–34058. [Google Scholar] [CrossRef]

- Shamshin, I.O.; Kazachenko, M.V.; Frolov, S.M.; Basevich, V.Y. Deflagration-to-detonation transition in air mixtures of propane–hydrogen fuel. Combust. Explos. 2021, 14, 8–25. [Google Scholar] [CrossRef]

- Shamshin, I.O.; Kazachenko, M.V.; Frolov, S.M.; Basevich, V.Y. Deflagration-to-detonation transition in stochiometric propane–hydrogen–air mixtures. Fuels 2022, 3, 667–681. [Google Scholar] [CrossRef]

- Shamshin, I.O.; Kazachenko, M.V.; Frolov, S.M.; Basevich, V.Y. Deflagration-to-detonation transition in air mixtures of ethylene–hydrogen fuel. Combust. Explos. 2021, 14, 26–39. [Google Scholar] [CrossRef]

- Shamshin, I.O.; Kazachenko, M.V.; Frolov, S.M.; Basevich, V.Y. Transition of deflagration to detonation in ethylene-hydrogen-air mixtures. Int. J. Hydrogen Energy 2022, 47, 16676–16685. [Google Scholar] [CrossRef]

- Zhang, B. The influence of wall roughness on detonation limits in hydrogen–oxygen mixture. Combust. Flame 2016, 169, 333–339. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, H. The effects of large scale perturbation-generating obstacles on the propagation of detonation filled with methane–oxygen mixture. Combust. Flame 2017, 182, 279–287. [Google Scholar] [CrossRef]

- Frolov, S.M.; Shamshin, I.O.; Aksenov, V.S.; Ivanov, V.S.; Vlasov, P.A. Ion sensors for pulsed and continuous detonation combustors. Chemosensors 2023, 11, 33. [Google Scholar] [CrossRef]

- Borisov, A.A.; Loban’, S.A. Detonation limits of hydrocarbon-air mixtures in tubes. Combust. Explos. Shock Waves 1977, 13, 618–621. [Google Scholar] [CrossRef]

- Borisov, A.A.; Gel’fand, B.E.; Loban’, S.A.; Mailkov, A.E.; Khomik, S.V. Detonation limits of fuel–air mixtures in smooth and rough tubes. Khim. Fiz. 1982, 2, 848–853. [Google Scholar]

- Nettleton, M.A. Gaseous Detonations: Their Nature, Effects and Control; Chapman and Hall: London, UK, 1987. [Google Scholar]

| Port# | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SDT-1 | ||||||||||||||||||||||

| IP | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | x |

| PS | x | − | − | − | + | + | + | + | + | + | + | + | + | + | + | + | − | − | − | − | − | x |

| SDT-2 | ||||||||||||||||||||||

| IP | x | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + |

| PS | x | − | − | − | + | + | + | + | + | + | + | − | + | − | + | − | + | − | − | + | − | + |

| CH4 | C2H6 | C3H8 | i-C4H10 | n-C4H10 | C5H12(1) | C6H14(2) | CxHy(3) | N2 |

|---|---|---|---|---|---|---|---|---|

| 94.8 | 2.8 | 0.84 | 0.12 | 0.14 | 0.05 | 0.02 | 0.03 | 1.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shamshin, I.O.; Aksenov, V.S.; Kazachenko, M.V.; Gusev, P.A.; Frolov, S.M. Fast Deflagration-to-Detonation Transition in Helical Tubes. Processes 2023, 11, 1719. https://doi.org/10.3390/pr11061719

Shamshin IO, Aksenov VS, Kazachenko MV, Gusev PA, Frolov SM. Fast Deflagration-to-Detonation Transition in Helical Tubes. Processes. 2023; 11(6):1719. https://doi.org/10.3390/pr11061719

Chicago/Turabian StyleShamshin, Igor O., Viktor S. Aksenov, Maxim V. Kazachenko, Pavel A. Gusev, and Sergey M. Frolov. 2023. "Fast Deflagration-to-Detonation Transition in Helical Tubes" Processes 11, no. 6: 1719. https://doi.org/10.3390/pr11061719

APA StyleShamshin, I. O., Aksenov, V. S., Kazachenko, M. V., Gusev, P. A., & Frolov, S. M. (2023). Fast Deflagration-to-Detonation Transition in Helical Tubes. Processes, 11(6), 1719. https://doi.org/10.3390/pr11061719