Abstract

Machine learning assists with food process optimization techniques by developing a model to predict the optimal solution for given input data. Machine learning includes unsupervised and supervised learning, data pre-processing, feature engineering, model selection, assessment, and optimization methods. Various problems with food processing optimization could be resolved using these techniques. Machine learning is increasingly being used in the food industry to improve production efficiency, reduce waste, and create personalized customer experiences. Machine learning may be used to improve ingredient utilization and save costs, automate operations such as packing and labeling, and even forecast consumer preferences to develop personalized products. Machine learning is also being used to identify food safety hazards before they reach the consumer, such as contaminants or spoiled food. The usage of machine learning in the food sector is predicted to rise in the near future as more businesses understand the potential of this technology to enhance customer experience and boost productivity. Machine learning may be utilized to enhance nano-technological operations and fruit and vegetable preservation. Machine learning algorithms may find trends regarding various factors that impact the quality of the product being preserved by examining data from prior tests. Furthermore, machine learning may be utilized to determine optimal parameter combinations that result in maximal produce preservation. The review discusses the relevance of machine learning in ready-to-eat foods and its use as a safety tool for preservation were highlighted. The application of machine learning in agriculture, food packaging, food processing, and food safety is reviewed. The working principle and methodology, as well as the principles of machine learning, were discussed.

1. Introduction

Machine learning is a form of artificial intelligence (AI) that enables systems to learn and improve from experience without being explicitly programmed. It focuses on the development of computer programs that can access data and use it to learn for themselves. Machine learning algorithms can detect patterns in data and use predictive models to make decisions and predictions. Examples of applications of machine learning include natural language processing, facial recognition, recommendation systems, and automated medical diagnosis. Machine learning is important because it can automate many mundane tasks and complete complex tasks that may be too difficult or time-consuming for humans to perform manually. It can also be used to make predictions and recommendations and uncover patterns in data that can be used to inform decision-making. Machine learning can also improve the efficiency and accuracy of existing processes and even be used to develop entirely new products and services [1]. The food industry is quickly utilizing machine learning technologies to improve the food supply chain. Machine learning algorithms are being used to predict food demand, optimize inventory management, and predict trends in food preferences. It can also be used to detect food fraud, monitor food safety, and predict food spoilage [2]. In addition, ML helps to optimize food production processes and automate food packaging. Finally, ML helps to develop new food products, optimize food storage, and even personalize food recommendations. Fruit preservation is a common practice in food industries, and ML makes it more efficient [3]. With machine learning, data can be collected from different fruit sources and analyzed to determine the best conditions for preserving each type of fruit. These data can include environmental factors such as temperature, humidity, light exposure, and other conditions that affect the rate of spoilage. The data can also include chemical information such as pH levels, sugar content, and other components that can affect the longevity of the fruit. With this information, machine learning algorithms can be used to create predictive models that can be used to predict the optimal conditions for preserving a given type of fruit [4]. This could help reduce waste, save energy, and improve the fruit’s shelf-life and quality. Machine learning (ML) can be used to identify ready-to-eat fruits. ML algorithms can be used to detect the ripeness of the fruit using digital images [5]. The ML algorithms can be trained to recognize the various stages of ripeness and classify each fruit accordingly. Additionally, ML algorithms can be used to identify the shape, color, or size of the fruit, as well as any other distinguishing features. With this information, the ML algorithms can accurately predict the ripeness of the fruit and determine whether it is ready to eat. Machine learning has become increasingly important in the food safety industry, especially when it comes to ready-to-eat fruit safety [6]. By using machine learning algorithms, it is possible to detect problems in fruit before they reach the store shelves. For example, machine learning algorithms can detect contamination, spoilage, and other issues in fruits before they are sold to customers. This helps to ensure that customers are receiving safe and healthy fruits, as well as providing producers with valuable insights into the quality of their products. Additionally, ML helps to automate processes such as sorting and grading fruits, improving efficiency, and reducing costs [7].

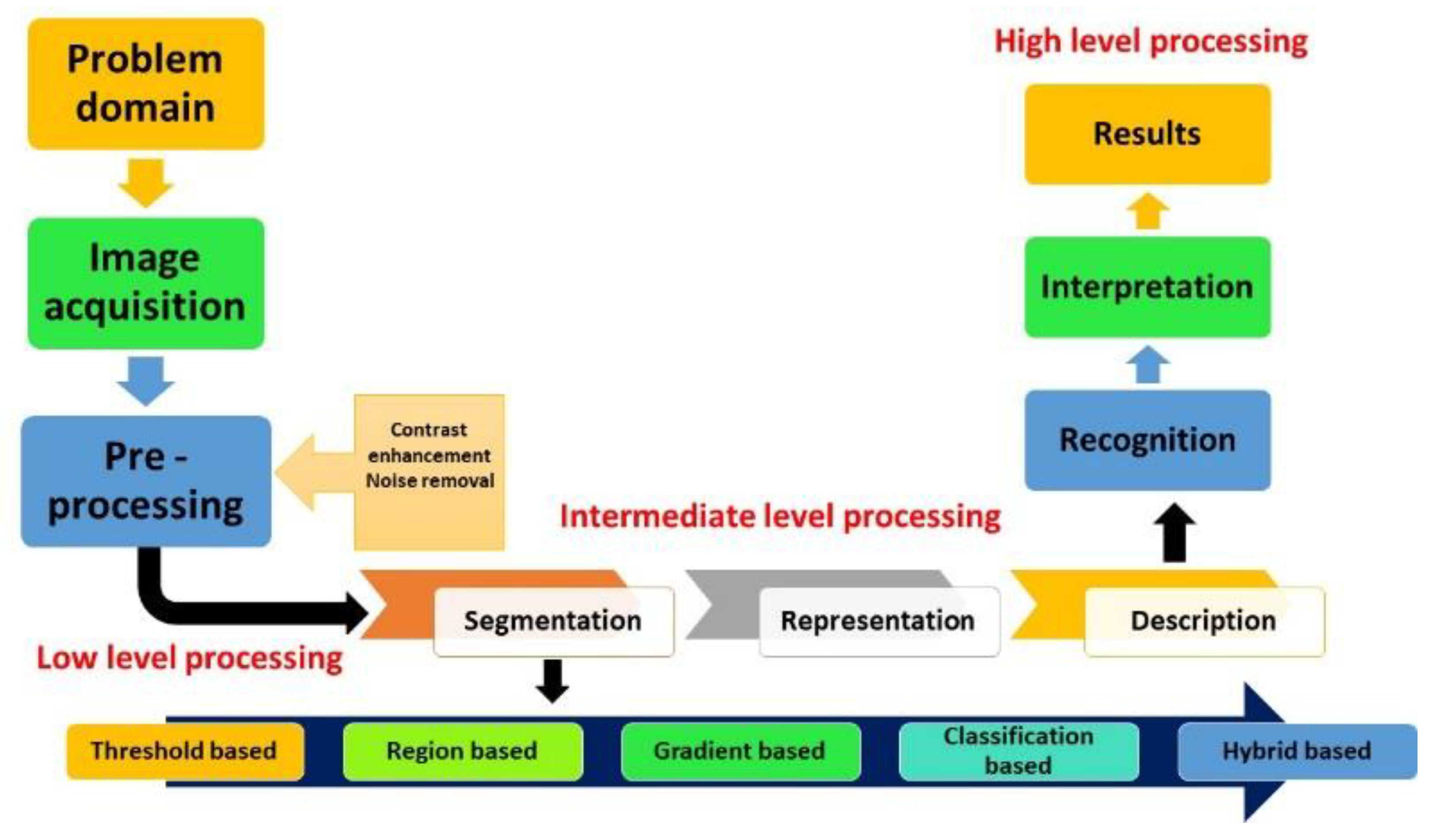

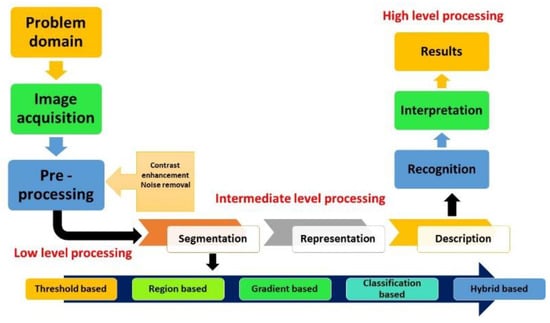

Machine learning is proving to be a huge asset in the food world, from helping food producers create more efficient plants and businesses to helping customers find the best restaurant for their needs. Machine learning is used to help automate and analyze food production processes, optimize recipes, reduce waste, and predict food trends [8]. Machine learning is also used to help cut costs, improve supply chains, and detect food fraud. Figure 1 shows various food processing stages where machine learning can be implemented.

Figure 1.

Implementation of machine learning in various stages of food processing.

2. Working Principle and Algorithm

Machine learning (ML) is an area of artificial intelligence (AI) that allows computers to learn and improve on their own without being explicitly programmed. Machine learning is concerned with the creation of computer programs that can acquire data and utilize it to learn on their own. The learning process starts with observation or data, such as examples, direct experience, or teaching, to search for trends in data and make better future decisions based on the examples we provide [9]. The fundamental goal is for computers to learn on their own without user intercession or support and then alter their activities accordingly. Building models capable of discovering trends and connections from training data includes machine learning, which does not require explicit programming. The models are trained using algorithms, which let them learn from the data and make predictions or judgments based on the learned patterns, as opposed to being directly coded. The model is given a labeled dataset during the training phase, where the input data are matched with the appropriate output or goal values. By changing its internal parameters, the model gains the ability to recognize patterns and correlations in the data. This method is frequently known as “learning from examples.” Once trained, the model can utilize the patterns and relationships it has discovered to generate predictions or judgments about fresh, unobserved data. Evaluation metrics, which gauge how closely the model’s predictions match the evaluation dataset’s actual values, are used to assess the model’s performance. This evaluation stage aids in determining the model’s correctness and generalizability. When used in real-world circumstances to make predictions or judgments based on fresh, unforeseen data, the model can be implemented if it exhibits good accuracy and performs well on the assessment data. The model’s learned patterns can be used for a variety of tasks, including image recognition, natural language processing, recommendation systems, and many other activities [10].

In a variety of ways, ML algorithms can be used to ensure the safety of fruits and vegetables. Support vector machines (SVMs), for example, are supervised learning algorithms that can be used to identify potential contaminants in food products. SVMs can also detect possible microbial contamination in fruits and vegetables [11]. Unsupervised learning algorithms such as k-means clustering can be used to group similar food items and identify outliers that could be contamination sources. Anomaly detection algorithms, such as isolation forests, can be used to identify unusual patterns that may indicate food safety concerns. Finally, reinforcement learning algorithms can be used to create an optimal inspection and response process to address fruit and vegetable safety concerns [12].

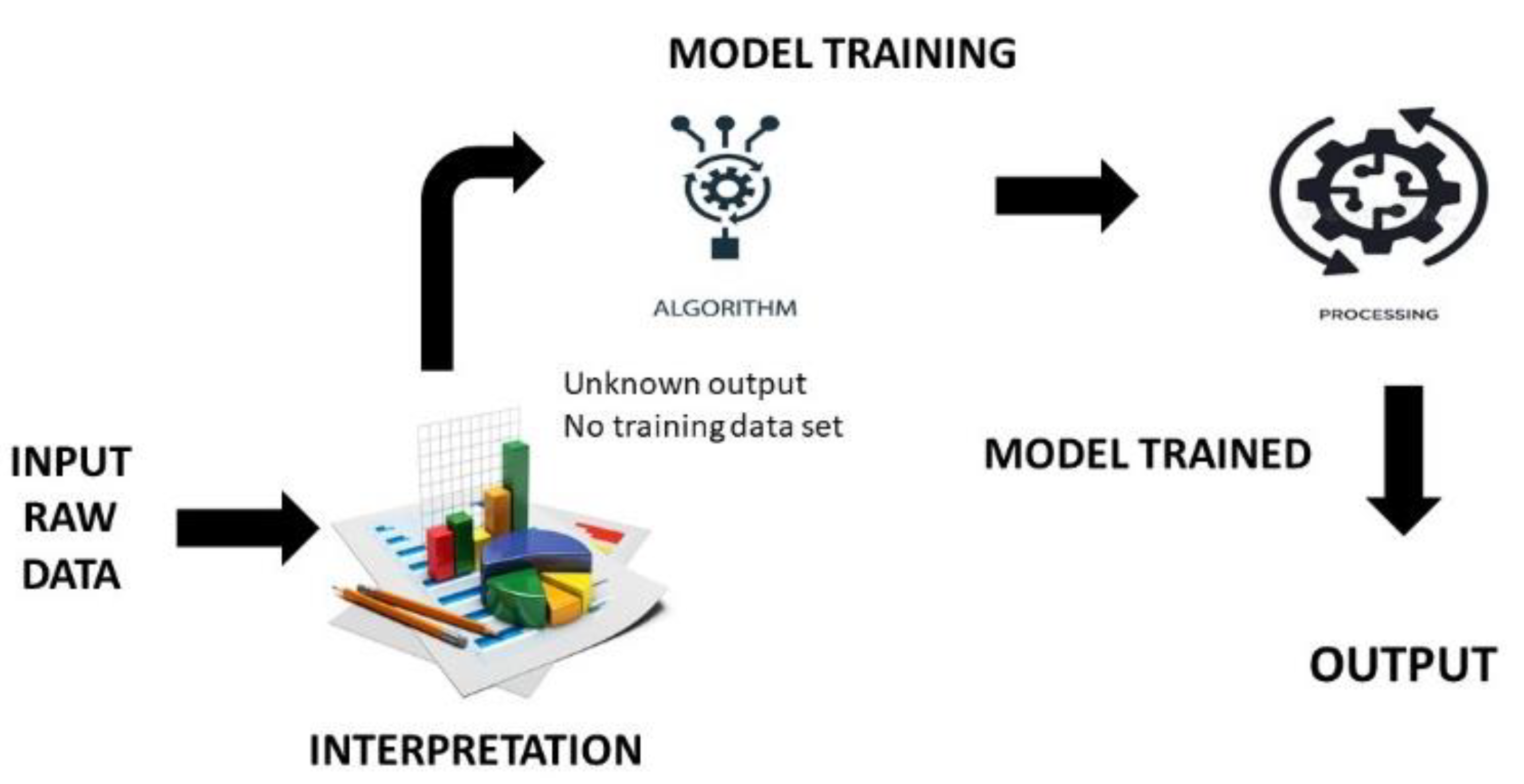

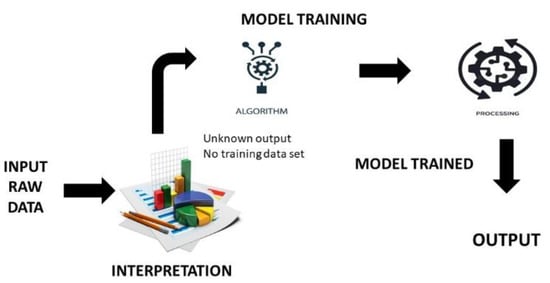

Machine learning can be used to help with fruit preservation in several ways. For example, machine learning algorithms can be used to monitor the quality of stored fruit and alert when conditions are not ideal. Machine learning can also monitor environmental conditions such as temperature and humidity and adjust the environment to optimize fruit preservation. ML helps to predict the optimal time for harvest, packaging, and distribution of the fruit to ensure it is fresh for the customer [13]. Figure 2 depicts the principle of machine learning.

Figure 2.

Principle behind working of machine learning in food interpretation.

The basic principle of machine learning applied to ready-to-eat fruits is to use large amounts of data to identify patterns, apply algorithms, and then create models that can be used to make predictions. For example, data regarding the soil, climate, and other factors that influence fruit quality can be used to create a predictive model that can recommend the best types of fruit to buy and even the best time of year to buy them [14].

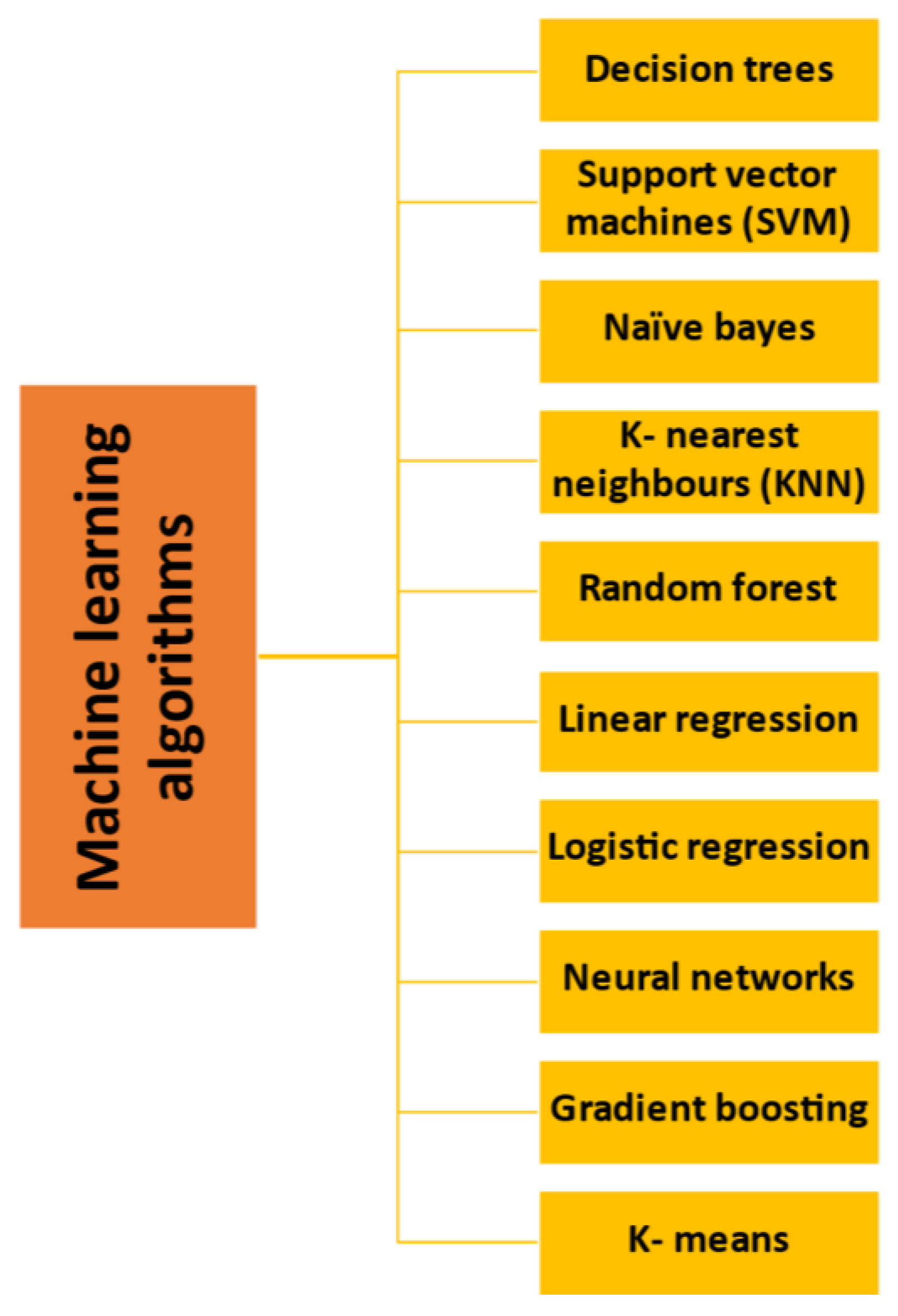

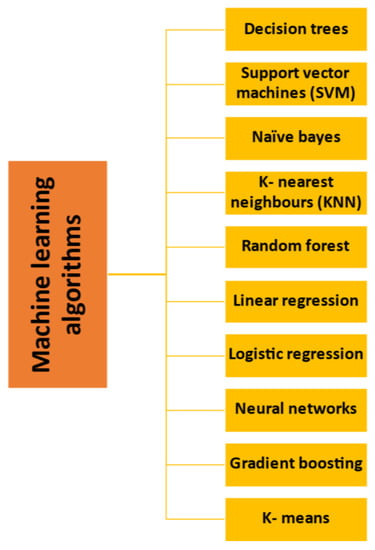

This model can then be applied to data gathered from numerous sources to make better decisions about the quality of the fruit or even the best time of year to purchase it. ML is used in fresh-cut fruits in various ways. It has the potential to monitor the quality of fresh-cut fruit by detecting and analyzing any visible defects. It can also be used to determine the physical properties of the fruits and their freshness. It can also be used to track the freshness of stored fruit and alert the user when it is no longer in optimal condition. This technology is used to forecast the life span of fresh-cut fruit based on its current condition [15]. Figure 3 represents various algorithms used in machine learning operations of food processing.

Figure 3.

Various algorithms used in machine learning interpretation in the food industry.

2.1. Spoilage Prediction

To forecast the possibility of rotting, machine learning algorithms can examine previous data on variables such as temperature, humidity, storage time, and quality characteristics. The model can notify food producers or suppliers when specific circumstances are about to occur that could cause spoilage by considering patterns and correlations in the data. This makes it possible to act quickly to change storage conditions, speed up distribution, or get rid of possibly ruined goods from the supply chain [11]. The machine learning model may be trained to recognize rotten food indicators such as discoloration, mold, strange odors, and sliminess. This can be achieved by examining food image data and applying computer vision algorithms to recognize visual characteristics linked to deterioration. When food may be rotting and needs to be thrown out, this might be used to warn vendors and customers. It is possible to estimate how quickly food will spoil under various circumstances using machine learning. The program can identify key variables and how they interact to forecast how quickly food will decay by learning from historical data on food deterioration [16].

2.2. Quality Monitoring

To evaluate the quality and freshness of food goods, machine learning algorithms can examine a variety of quality indicators, including color, texture, and chemical composition. The algorithm can learn to detect and recognize symptoms of deterioration or spoilage by training models on labeled data that indicate varying levels of quality. Using computer vision techniques, real-time monitoring can also be used to find visual signs of spoiling such as mold growth or color changes [17]. It is possible to monitor the temperature, humidity, and other environmental conditions that impact food quality and freshness using other technologies, such as sensors, automated imaging, and blockchain. Using these data, it is possible to forecast when food may go bad and warn customers and retailers about potential food safety risks. Food may be tracked via blockchain technology from farm to consumer, enhancing openness and accountability throughout the food supply chain [18].

2.3. Shelf-Life Estimation

Perishable food items’ remaining shelf life can be estimated using machine learning models based on a variety of variables, including storage circumstances, initial quality, and product attributes [19]. The algorithm can provide precise estimates of how long a specific product will remain fresh and safe to consume by analyzing the deterioration patterns in the data. Utilizing this knowledge can improve inventory control, cut down on waste, and stop customers from buying spoiled goods [12]. Machine learning algorithms can calculate the remaining shelf life of perishable foods depending on a range of factors, such as storage conditions, initial quality, and product characteristics. By analyzing the patterns of deterioration in the data, the computer can give precise estimations of how long a certain product will stay fresh and safe to ingest. Utilizing this information can enhance inventory management, reduce waste, and prevent customers from purchasing defective goods [20].

2.4. Intelligent Storage Optimization

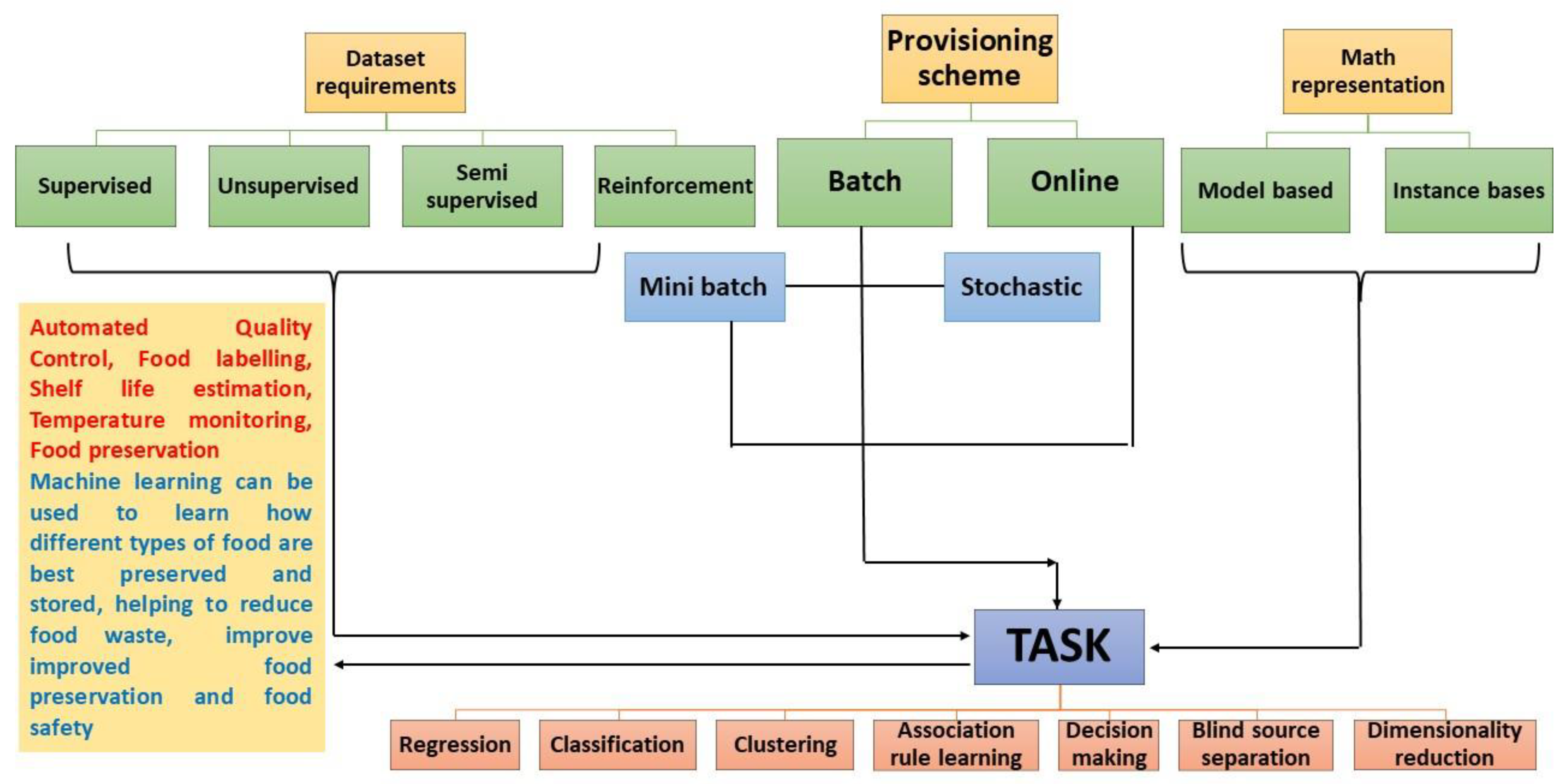

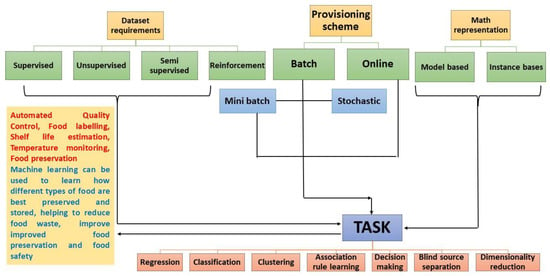

By examining vast volumes of data on temperature, humidity, ventilation, and other pertinent parameters, machine learning algorithms can optimize storage conditions. In light of each type of fruit and vegetable’s unique preservation needs, the models can determine the best storage conditions. The danger of spoilage can be reduced by continuously monitoring and modifying these variables based on real-time data and projections [21]. Producers and merchants may decrease losses from spoiling, enhance inventory management, and boost productivity by utilizing machine learning to forecast the ideal storage conditions. The algorithms can also identify environmental changes that would endanger the stored produce, enabling farmers and retailers to take action to safeguard their stock. Machine-learning-driven recommendations can enhance the quality and shelf life of produce that is being stored, enabling farmers and retailers to increase earnings and reduce waste [22]. Figure 4 represents the taxonomic hierarchy of the machine learning.

Figure 4.

Taxonomical hierarchy of machine learning.

2.5. Supply Chain Optimization

Machine learning can analyze data from every step of the food supply chain, from production to storage, to spot bottlenecks or locations where food spoiling is more likely to happen. By locating key supply chain nodes that influence food deterioration, effective interventions can be taken to streamline procedures, cut down on handling time, or optimize transit and storage methods [23]. In order to determine which parts of a warehouse or transport vehicle are most likely to result in rotting, machine learning algorithms can analyze data on temperature, humidity, and other environmental conditions. Utilizing various packaging materials, altering the route taken for transportation, or improving humidity and temperature controls are just a few examples of how this information can be used to optimize storage and transportation techniques [24].

3. Machine Learning Fundamentals

Machine learning fundamentals refer to the general outcomes and techniques used to develop and implement machine learning algorithms. This includes supervised and unsupervised learning, data pre-processing, feature engineering, model selection and evaluation, and optimization algorithms [25]. Machine learning fundamentals include topics such as deep learning, reinforcement learning, and natural language processing.

3.1. Supervised and Unsupervised Learning

A dataset is labeled with the right answers in supervised learning, and an application is employed to train from data and create predictions. Unsupervised learning is where the data are not labeled, and the algorithm must find patterns and relationships within the data. The learning algorithm is a sort of artificial intelligence algorithm that makes predictions using a predefined set of information (called a training set) [26]. It applies a set of labeled data points to a function, which it then uses to identify patterns in new data points. The learning algorithm is a computer vision that seeks previously unnoticed similarities in a data set without pre-existing labels and depends on its own assessment to discover structure. It can be used to cluster populations based on similarities in their properties and behaviors and has been used to detect fraudulent activity in credit card transactions [27]. Unsupervised learning can also be used to segment customer data into distinct categories, such as age and gender, or group items into similar categories based on their features. Both supervised and unsupervised ML helps in ready-to-eat fruit preservation. Supervised learning is used to determine the best preservation methods for fruits, such as optimal temperature, humidity, and light levels. Unsupervised learning can be used to detect anomalies in the fruits, such as discoloration or spoilage, and alert the supply chain to take corrective action [28].

3.2. Data Pre-Processing

Machine learning is advantageous to automate data pre-processing tasks such as data cleaning, feature engineering, and characteristic selection. It may also be employed to locate and eliminate outliers, detect and correct errors, and generate synthetic data to supplement existing data sets. Machine learning can also be used to reduce the manual effort required for data pre-processing, making it an invaluable tool for data scientists [29]. For example, it can be used to identify and classify different types of fruits based on size, shape, color, texture, etc. Machine learning has the efficiency to detect and classify diseases or defects in fruits, such as spots or discoloration. Computer vision can be employed from before the data for the preservation of ready-to-eat fruits. Segmentation, classification, and regression are examples of machine learning methods and approaches. Data can be analyzed and processed to identify trends and patterns in freshness, shelf life, and other factors related to the preservation of fruits. This can help inform decisions on preserving the fruits and extending their shelf life [30].

3.3. Model Selection

Model selection involves testing and comparing different computer vision models, tuning their hyperparameters, and evaluating their performance to choose the best model for a given task. This process is crucial in obtaining optimal results from a machine learning system. Machine learning algorithms can be used to identify various aspects of fruits such as their nutritional content, cost-effectiveness, customer preferences, and health benefits. By analyzing data related to these factors, models can provide insights and predictions for decision-making in the fruit industry. Computer vision techniques can help in discovering optimal methods for preserving ready-to-eat fruits [31,32]. Classification algorithms can be used to determine the optimal parameters for storing and preserving fruits, including temperature, humidity, and pressure. Machine learning algorithms can also analyze collected data to identify the most effective preservation techniques. Machine learning algorithms can analyze data collected from preservation experiments to determine the most effective parameters. By learning patterns and relationships in the data, models can provide insights into the optimal preservation techniques for different types of fruits [32,33].

3.4. Evaluation

Machine learning algorithms can be used to evaluate and improve a variety of systems, from predicting customer preferences and trends to diagnosing medical conditions [33,34] ML helps as an evaluation tool by testing the performance of a system or process against a set of data and adjusting as needed. ML is used to evaluate the quality of fruits. For example, it can be used to measure the sweetness of fruit, the amount of acidity, the size and shape of the fruit, and other characteristics. In addition, machine learning can detect signs of spoilage, such as mold or bruising, and any contaminants or microorganisms present on the fruit. ML is also helpful to predict a fruit’s shelf life and make recommendations for storing and handling it to maximize its quality and shelf life. ML helps to evaluate the effectiveness of different preservation techniques for ready-to-eat fruits. For example, the machine can be trained to detect changes in the fruit’s color, texture, and flavor over time, as well as any microbial growth [34,35]. This will help identify which preservation techniques are most effective in maintaining the quality of the fruit for a more extended period. Additionally, Machine learning also identifies potential environmental factors that may affect the fruit’s shelf life, such as temperature, light, and humidity. This will help optimize the storage conditions for the fruit and ensure it is preserved for the longest possible time [36,37].

3.5. Optimization of Algorithms

Fruit maturity may be determined using supervised learning algorithms, and environmental factors such as temperature, humidity, and light can be changed to promote fruit growth. Anomalies in fruit development and health can be found using unsupervised learning algorithms, alerting farmers to potential problems. By discovering the ideal moment to harvest a particular type of fruit, reinforcement learning systems might enhance the harvesting procedure [35,38]. Machine learning algorithms can forecast the ideal circumstances needed to preserve fruits and keep them safe and fresh throughout time, including temperature, humidity, and environmental factors. Based on fruit attributes including size, freshness, and nutritional value, predictive models can decide the ideal preservation settings. The storage temperature, air exchange rates, and other preservation parameters can be determined using these models. Data-analysis algorithms can best preserve fruits that are ready to consume. The ideal temperature, humidity, and other factors for fruit preservation can be found using these algorithms. They can also determine which packaging is best for keeping fruit. The preservation of ready-to-eat fruits can be improved by using machine learning algorithms, and maintaining their safety and nutritional content [39,40].

4. Machine Learning as Safety Tool for Preservation

Fruit safety is a major issue in the food sector. There are numerous risks involved with eating tainted fruit, such as foodborne illness and other health concerns. In order to help mitigate these risks, ML can also detect and identify contaminants in fruit before it reaches the consumer [41]. Machine learning models can be trained to detect contaminants in images of fruit, identify specific types of contamination in fruit, and even detect the presence of harmful bacteria and other pathogens in fruit. These data can then be used to inform decisions about which fruits should be sold and which should be removed from the market. Additionally, fruit production operations may be monitored using machine learning and identify potential sources of contamination. This can help ensure that only safe and healthy fruit reaches consumers [37,42]. ML helps to improve food safety by providing insights into food safety risks. For example, machine learning algorithms can be used to analyze large datasets of food safety data to identify patterns and correlations that can help inform food safety decisions. This can help identify areas of risk and help improve food safety management systems [43,44]. Furthermore, computer vision can be used to create forecasts that can be employed to identify possible food safety problems before they happen. By monitoring food safety status, machine learning can help identify potential food safety issues before they become a problem. Using machine learning for vegetable safety has become increasingly important in the food industry [45,46]. Machine learning can help to identify and classify potentially harmful vegetables, detect foodborne pathogens and toxins, and detect spoilage or contamination issues. It also detects and identifies specific food safety hazards, such as pesticide residues. By incorporating machine learning into food safety systems, food safety professionals can quickly and accurately identify potential safety risks and take the necessary steps to mitigate them [47,48]. Machine learning can act as a shield for food. Machine learning can detect food fraud, contamination, and spoilage by analyzing various data sources such as production records, images, and chemical composition of food products. It can also be used to monitor food safety and quality throughout the supply chain, giving companies the ability to identify and address issues quickly [49,50]. Additionally, ML helps to identify and track allergens in food products, helping to ensure that consumers are not exposed to potentially harmful ingredients [51,52].

Machine learning is a novel methodology that is favorable to help with preservation in a variety of ways. One example is using machine learning to help identify which artifacts should be preserved and which should not [53,54]. This could be performed by analyzing the artifacts’ visual characteristics and comparing them to known artifacts and other similar items to determine their potential historical value [14,55]. Additionally, machine learning algorithms could be used to analyze text-based documents and other records to identify which ones should be preserved [56,57,58]. This could be performed by looking for patterns in the text and comparing them to other similar documents and records to determine which ones should be considered for preservation. Finally, machine learning could also be used to help preserve digital artifacts by creating algorithms that can detect when digital artifacts are being degraded or corrupted [59,60]. These algorithms could then be used to create backup copies of the digital artifacts before they are lost forever. It also helps the food industry in a variety of ways [61]. For example, ML helps to develop predictive models that can help identify customer preferences and trends. These models can be used to help cater to customer demands and create new products. Additionally, ML helps to develop algorithms that can automate tasks such as inventory management, pricing, and ordering [62,63]. This can help cut expenses, increase productivity, and ensure clients receive what they require. Finally, deep learning can be utilized to improve food safety processes and ensure safe food processing [64,65].

4.1. Methods of Machine Learning in Food Industry

ML is also helpful in the food industry in image recognition, recommendation systems, production optimization, quality control, nutritional analysis, supply chain optimization, food fraud detection, inventory management, and automating food production processes [66,67]. Machine learning algorithms can be used to identify food items in images. This is useful for food labeling, nutrition analysis, and ingredient identification. Machine learning algorithms can recognize customer preferences and recommend food items they could appreciate. Machine learning algorithms can assist in optimizing manufacturing operations in order to decrease costs and waste [68,69]. By recognizing possible pollutants and deficiencies, machine learning algorithms can be employed to improve food safety and quality assurance [70,71]. The nutritional composition of food products may be analyzed using machine learning techniques. Machine learning algorithms can assist in optimizing the supply chain to reduce costs and increase efficiency [72]. Food piracy may be detected using machine learning by evaluating data from many sources to acquire insights into possibly fraudulent behaviors. Machine learning may assist food firms in better managing their inventories by anticipating demand and forecasting shortages. Machine learning has the potential to automate manufacturing processes and cut labor expenses [73,74].

4.2. Approach behind Machine Learning in Food Industry

For the development of an automated machine learning system, there should be an automated ML system that can be used to continuously monitor data streams and automatically detect patterns, anomalies, and trends in food industry data. This can be used to identify new opportunities and optimize existing processes [75,76]. We need to create predictive models where predictive models can be used to identify patterns and trends in data to predict future outcomes. This can be used to address potential problems proactively and to identify new opportunities in the food industry. Moreover, the development of an AI-based decision support system will be beneficial to assist food industry professionals in making informed decisions [77]. This can be used to identify potential problems and optimize existing processes. Using data-driven optimization is also beneficial since it can be used to streamline operations and find new possibilities in the food industry. This can be used to reduce waste and increase efficiency. Utilization of deep learning can be used to develop ML models that are able to understand complex data patterns. This can be used to create more accurate predictive models and to identify new opportunities in the food industry. Leveraging data mining and analytics can be used to uncover insights from data sets. This can help improve product offerings, target more relevant marketing activities, and optimize customer service processes. Computer vision implementation can be used to develop automated food recognition systems that can identify food-related objects and ingredients. This can help automate food-related tasks such as food categorization, ingredient detection, and calorie counting. Natural language processing can be used to develop systems that can understand and respond to customer queries. This can enable customer service automation and allow for more personalized experiences. Recommender systems can be used to provide customers with personalized product recommendations. This can help increase sales and customer satisfaction [78].

5. Potential Outcomes of Machine Learning in Food Industry

Deep learning techniques have completely transformed computer vision, natural language processing, and robotics. Train neural networks to recognize images, identify objects, and even produce new images. Algorithms based on reinforcement learning can be used to address complicated challenges in real-world domains such as robotics and autonomous driving. To create new data from existing data sets, generative models can be utilized. Complex associations between data points can be learned using graph-based approaches. Transfer learning allows robots to learn from prior knowledge to tackle new challenges. Models and hyperparameters can be optimized using Bayesian optimization approaches. Natural language processing algorithms can process enormous amounts of text and generate meaning from it [79,80].

ML can increase food spoilage prediction accuracy by up to 97%, saving money and minimizing food waste. Moreover, it has demonstrated an increased detection accuracy of up to 95% for food safety issues such as dangerous substances. Automated methods, such as image recognition for sorting and grading fruits and vegetables, increased production productivity by up to 20%. Improved consumer segmentation and targeted product recommendations resulted in increased sales and customer satisfaction. Automation of activities such as inventory management, order fulfillment, and delivery reduced costs and improved customer service. Accuracy in anticipating customer preferences and trends has increased, resulting in more efficient marketing efforts and better product suggestions. Quality control is improved through automated detection and classification of food products. Food safety has been improved by predictive analytics, real-time monitoring, and automated tracking of food production. Using AI-driven decision-making and automation, food product traceability and visibility are enhanced throughout the supply chain, as is production and supply chain efficiency. The customer experience has been enhanced through personalized product suggestions and automated customer care. Automated decision-making and production optimization may assist food manufacturers and suppliers. Machine learning is playing an increasingly important role in the production and distribution of ready-to-eat foods. From analyzing customer data to helping to identify food trends, ML can help food companies better understand their customers and what they want in a product. ML can also be used to automate part of the production process, reducing time and costs while improving quality. Additionally, machine learning monitors the freshness of ready-to-eat foods, helping to ensure that customers receive the freshest product possible. Finally, ML can help to identify any potential safety issues before the food reaches the public, helping to ensure the safety of consumers. Machine learning is becoming increasingly important in the production of ready-to-eat fruits, as it helps improve the production process’s efficiency, reduce costs, and provide a more consistent product. It helps to analyze data from sensors in production machines and provides insights into how the machines are functioning [81]. This can help identify and fix problems quickly and efficiently, ensuring that production runs smoothly. Additionally, ML also identifies patterns in customer data, allowing producers to understand the needs of their customers better and improve their products. Machine learning is becoming increasingly important in the food industry, especially in the area of ready-to-eat vegetables. By using machine learning algorithms, companies can gain insights into the customer demand for certain vegetables and predict what will be popular in the future [82].

Additionally, ML also optimizes the production processes and ensures that the vegetables are of the highest quality possible [83]. Finally, machine learning can help optimize the supply chain and ensure that the vegetables are delivered on time and with the freshest possible ingredients. This helps to reduce food waste and maximize profits for the companies. Machine learning is a powerful tool for food preservation, as it can help reduce food waste and optimize food production. It can be used for predictive analytics to help anticipate food supply needs and for automated sorting and grading to ensure quality control. It can also be used to predict spoilage and shelf life and optimize storage and transport conditions. In addition, ML helps to improve food safety and traceability by providing accurate and timely information about food production, processing, and distribution. Machine learning plays a very important role in the food industry. It helps the industry improve the food production process, from producing raw materials to packaging and distributing finished products. Machine learning can accurately predict the demand for certain products and analyze and optimize different production processes to ensure that resources are used efficiently. Machine learning can also recognize and classify different ingredients and identify potential contaminants in food products [84]. Finally, machine learning can create personalized menus and recipes based on individual preferences and develop new products and flavors. Artificial learning and machine learning are increasingly important in the food world as they help streamline processes, make them more efficient, as well as helping to reduce costs. For example, machine learning algorithms can be used to accurately predict customer preferences, which can, in turn, be used to improve marketing strategies and personalize customer experiences. Additionally, AI-powered robots can be used to automate food production processes, which can help reduce labor costs and enhance product quality. Finally, machine learning may detect pollutants in food, ensuring food safety and reducing the likelihood of food-borne illnesses [85].

6. Machine-Learning-Oriented Nanotechnology in Food Industry

Machine-learning-oriented nanotechnology is a new field of research that focuses on using machine-learning algorithms to optimize and control nanomaterials. This field has the potential to revolutionize many industries, from manufacturing to healthcare, by allowing us to create materials with unprecedented precision and control. Large volumes of data connected to nanomaterials can be analyzed using machine learning methods, such as their structural and chemical properties. Then, that data can be used to optimize their design and performance. This could lead to the development of new materials with enhanced properties and improved performance. Additionally, algorithms for ML help to automate nanomaterial manufacturing, thereby increasing its effectiveness and fee [86]. Nanotechnology is the study of matter manipulation at the subatomic, molecular, and supramolecular levels. It is a new technology that can transform a diverse range of industries, from wellness to computing. Machine learning is a subset of artificial intelligence in which computers may learn without really being explicitly programmed. Nanotechnology researchers can use machine learning to discover novel materials, develop technological advances, and produce more effective methods [87]. ML helps to analyze large datasets, identify patterns, and make predictions. It can also be used to optimize nanomaterials and create new devices. For example, machine learning algorithms can be used to study nanomaterials’ structure and properties to develop materials with specific characteristics. Additionally, ML helps to improve the efficiency of nanoscale manufacturing processes. Furthermore, it is a boon in the field of technology to develop nanotechnology-based applications such as nanobots and nanosensors. Nanobots are tiny robots that are programmed to perform specific tasks, such as delivering drugs to specific cells or monitoring environmental conditions. Nanosensors are tiny devices used to measure various parameters, such as temperature, humidity, and pressure [88].

By using machine learning, nanotechnology researchers can make predictions about the properties and behavior of nanomaterials. This is especially useful for predicting nanomaterials’ size, shape, and structure and for studying nanomaterials’ potential applications. For example, models can be created using machine learning that predict how nanoparticles interact with other materials, how they respond to external stimuli, and how they might be used for medical applications. Additionally, ML helps to develop algorithms for the automated synthesis of nanomaterials, allowing researchers to create new materials quickly and accurately with desired properties [88]. Machine learning can also be used to classify nanomaterials into different categories, helping researchers understand the different types of nanomaterials available and their potential applications.

Nanotechnology is an emerging technology that promises to revolutionize food processing and production. It has the potential to improve food safety, nutrition, and flavor. Using nanotechnology, the food industry can produce products with enhanced shelf life, improved quality, and greater efficiency. The use of computer vision in the food business has grown in popularity in recent years. ML is helpful to identify and classify food products, detect food contamination, and predict food spoilage. It can also be used to improve food processing techniques, optimize product packaging, and develop new food products. Combined with nanotechnology, artificial intelligence helps the food industry enhance product safety while lowering costs and increasing productivity. For example, machine learning algorithms can be used to detect food adulteration and contamination, whereas nanotechnology can be used to create sensor systems that can detect food contamination at the molecular level. Additionally, ML is helpful in optimizing food processing techniques and packaging, whereas nanotechnology can be used to create targeted packaging that preserves food for longer periods of time. Overall, the combination of machine learning and nanotechnology holds great potential for the food industry and could help to revolutionize the way food is produced and processed [89].

7. Future Perspectives and Challenges

The future of machine learning in the food industry is very promising. ML helps to improve food production, increase efficiency, and reduce waste. It can also be used to create new recipes and improve existing recipes. By analyzing customer data, companies can identify trends and create personalized menus and recipes tailored to the customer’s tastes. It is also used to increase the accuracy of food quality control, optimize food packaging and storage, and help reduce food waste. Automated sorting and grading systems can be used to detect and classify defects in fruits and vegetables, leading to improved shelf life and better product quality. Additionally, ML helps to identify optimal storage conditions and monitor the temperature and humidity of food packages, reducing spoilage and waste. Finally, machine learning can analyze customer feedback and assess the impact of various packaging and preservation techniques, helping companies optimize their processes and reduce food waste. Additionally, ML helps to detect food safety risks and prevent contamination. Finally, machine learning can optimize supply chain management, helping companies better manage their inventory and reduce costs.

One of the challenges in fruit preservation with machine learning is accurately predicting the shelf-life of different types of fruits. This requires machine learning models to be trained on large datasets of fruits and their shelf-life. It also supports automating the sorting and grading process of fruits to ensure that only the best quality fruits are selected for preservation. Contamination in fruits can significantly reduce their shelf-life and cause food safety issues. Machine learning models can be developed to detect contamination in fruits and alert the appropriate authorities. Machine learning models can be developed to detect the ripeness of fruits and alert the authorities or consumers when the fruits are no longer fresh. Machine learning models can be used to identify the optimal temperature, humidity, and other factors for storing different types of fruits to ensure the most extended shelf-life.

8. Conclusions

Machine learning has become increasingly important in the food industry, as it can be used to identify and categorize food items, optimize production processes, and even predict consumer preferences. ML helps to identify and categorize food items, such as identifying ingredients, nutrition facts, and allergens. This can help producers and manufacturers ensure that their products meet safety and regulatory standards. Additionally, it can be used to optimize production processes, such as streamlining the supply chain and reducing waste. Finally, ML helps to predict consumer preferences. This can help producers create products that are better tailored to consumer needs, resulting in higher sales and better customer satisfaction. Nanotechnology is a powerful and rapidly growing field, and its applications in the food industry are becoming increasingly significant. By leveraging machine learning algorithms, nanotechnology can be leveraged to create more efficient and effective food production, packaging, and delivery systems. It can be used to analyze food production data, such as ingredients and nutritional values, to identify trends and patterns. This can be used to develop more efficient production methods and ensure that food is produced in an optimal way. Additionally, machine learning algorithms can be used to identify flaws or potential problems in food production, as well as detect potential contamination. In terms of packaging and delivery, machine learning algorithms can be used to create packaging that is more efficient and better suited to food products, as well as more robust delivery systems. Additionally, machine learning algorithms can be used to identify any damage or deterioration in food products and any potential contamination. Finally, machine learning algorithms can be used to create better safety measures for food production, packaging, and delivery. This can help reduce the risk of foodborne illnesses and other food safety issues. Overall, machine learning and nanotechnology can be used in tandem to create more efficient and effective food production, packaging, and delivery systems.

Author Contributions

Conceptualization, V.K.P. and S.S.; methodology, R.S.; validation, K.K.D., R.S. and S.A.M.; writing—original draft preparation, V.K.P.; writing—review and editing, S.S.; visualization, B.K.; supervision, E.H.; project administration, S.A.M.; funding acquisition, B.K. All authors have read and agreed to the published version of the manuscript.

Funding

Project No. TKP2021-NKTA-32 has been implemented with support from the National Research, Development, and Innovation Fund of Hungary, financed under the TKP2021-NKTA funding scheme.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No data was involved in the conduction of this review.

Conflicts of Interest

The authors declare that they have no conflict of interest.

References

- Hashemi, H.; Parastouei, K.; Mokhtarian, M.; Rostami, H.; Niakousari, M.; Mohsenpour, Z. Application of Innovative Processing Methods for the Extraction of Bioactive Compounds from Saffron (Crocus sativus) Petals. J. Appl. Res. Med. Aromat. Plants 2020, 2020, 100264. [Google Scholar] [CrossRef]

- He, X.; Deng, H.; Hwang, H.M. The Current Application of Nanotechnology in Food and Agriculture. J. Food Drug Anal. 2019, 27, 1–21. [Google Scholar] [CrossRef]

- Hernández-Hernández, H.; Quiterio-Gutiérrez, T.; Cadenas-Pliego, G.; Ortega-Ortiz, H.; Hernández-Fuentes, A.D.; Cabrera de la Fuente, M.; Valdés-Reyna, J.; Juárez-Maldonado, A. Impact of Selenium and Copper Nanoparticles on Yield, Antioxidant System, and Fruit Quality of Tomato Plants. Plants 2019, 8, 355. [Google Scholar] [CrossRef]

- Morin-Crini, N.; Lichtfouse, E.; Torri, G.; Crini, G. Applications of Chitosan in Food, Pharmaceuticals, Medicine, Cosmetics, Agriculture, Textiles, Pulp and Paper, Biotechnology, and Environmental Chemistry. Environ. Chem. Lett. 2019, 17, 1667–1692. [Google Scholar] [CrossRef]

- Mousavi Khaneghah, A.; Hashemi Moosavi, M.; Oliveira, C.A.F.; Vanin, F.; Sant’Ana, A.S. Electron Beam Irradiation to Reduce the Mycotoxin and Microbial Contaminations of Cereal-Based Products: An Overview. Food Chem. Toxicol. 2020, 143, 111557. [Google Scholar] [CrossRef] [PubMed]

- Nakamura, H.; Oya, M.; Hanamoto, T.; Nagashio, D. Reviewing the 20 Years of Operation of Ozonation Facilities in Hanshin Water Supply Authority with Respect to Water Quality Improvements. Ozone Sci. Eng. 2017, 39, 397–406. [Google Scholar] [CrossRef]

- Naser-Sadrabadi, A.; Zare, H.R.; Benvidi, A. Photochemical Deposition of Palladium Nanoparticles on TiO2 Nanoparticles and Their Application for Electrocatalytic Measurement of Nitrate Ions in Potato, Onion and Cabbage Using Bipolar Electrochemical Method. Measurement 2020, 166, 108222. [Google Scholar] [CrossRef]

- Nayik, G.A.; Nanda, V. Effect of Thermal Treatment and pH on Antioxidant Activity of Saffron Honey Using Response Surface Methodology. J. Food Meas. Charact. 2016, 10, 64–70. [Google Scholar] [CrossRef]

- Ndlovu, N.; Mayaya, T.; Muitire, C.; Munyengwa, N. Nanotechnology Applications in Crop Production and Food Systems. Int. J. Plant Breed Crop Sci. 2020, 7, 624–634. [Google Scholar]

- Nguyen, N.T.; Lee, J.; Woo, S.M.; Kim, Y.H.; Min, J. The Response of Yeast Vacuolar Proteins: A Novel Rapid Tool for Salmonella sp. Screening. Biotechnol. Appl. Biochem. 2020, 1–12. [Google Scholar] [CrossRef]

- Kim, U.J.; Lee, S.; Kim, H.; Kim, H.; Kim, S.I.; Roh, Y.G.; Yun, S. Quantification for Food Inspection Enabled by Hyperspectral Imaging System and Machine Learning. Phys. Sci. 2023, preprint. [Google Scholar]

- Hu, G.; Ahmed, M.; L’Abbé, M.R. Natural Language Processing and Machine Learning Approaches for Food Categorization and Nutrition Quality Prediction Compared with Traditional Methods. Am. J. Clin. Nutr. 2023, 117, 553–563. [Google Scholar] [CrossRef] [PubMed]

- Nile, S.H.; Baskar, V.; Selvaraj, D.; Arti, N.; Jianbo, X.; Kai, G. Nanotechnologies in Food Science: Applications, Recent Trends, and Future Perspectives. Nano Micro Lett. 2020, 12, 1–34. [Google Scholar] [CrossRef]

- Oliveira Chaves, L.; Gomes Domingos, A.L.; Louzada Fernandes, D.; Ribeiro Cerqueira, F.; Siqueira-Batista, R.; Bressan, J. Applicability of Machine Learning Techniques in Food Intake Assessment: A Systematic Review. Crit. Rev. Food Sci. Nutr. 2023, 63, 902–919. [Google Scholar] [CrossRef]

- Paliwal, R.; Paliwal, S.R.; Kenwat, R.; Kurmi, B.D.; Sahu, M.K. Solid Lipid Nanoparticles: A Review on Recent Perspectives and Patents. Expert Opin. Ther. Pat. 2020, 30, 179–194. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Spachos, P.; Pensini, E.; Plataniotis, K.N. Deep Learning and Machine Vision for Food Processing: A Survey. Curr. Res. Food Sci. 2021, 4, 233–249. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.M.; Chen, T.Y.; Li, J.S. A Machine Learning-Based Anomaly Detection Method and Blockchain-Based Secure Protection Technology in Collaborative Food Supply Chain. Int. J. e-Collab. 2023, 19, 789. [Google Scholar] [CrossRef]

- Rejeb, A.; Keogh, J.G.; Zailani, S.; Treiblmaier, H.; Rejeb, K. Blockchain Technology in the Food Industry: A Review of Potentials, Challenges and Future Research Directions. Logistics 2020, 4, 27. [Google Scholar] [CrossRef]

- Ulussever, T.; Ertuğrul, H.M.; Kılıç Depren, S.; Kartal, M.T.; Depren, Ö. Estimation of Impacts of Global Factors on World Food Prices: A Comparison of Machine Learning Algorithms and Time Series Econometric Models. Foods 2023, 12, 873. [Google Scholar] [CrossRef]

- Torres-Sánchez, R.; Martínez-Zafra, M.T.; Castillejo, N.; Guillamón-Frutos, A.; Artés-Hernández, F. Real-Time Monitoring System for Shelf Life Estimation of Fruit and Vegetables. Sensors 2020, 20, 1860. [Google Scholar] [CrossRef]

- Khan, M.I.H.; Longa, D.; Sablani, S.S.; Gu, Y. A Novel Machine Learning–Based Approach for Characterising the Micromechanical Properties of Food Material During Drying. Food Bioprocess Technol. 2023, 16, 420–433. [Google Scholar] [CrossRef]

- Mittal, A.; Krejci, C.C.; Craven, T.J. Logistics Best Practices for Regional Food Systems: A Review. Sustainability 2018, 10, 168. [Google Scholar] [CrossRef]

- Ahmad, I.; Benjamin, T.A. Application of Artificial Intelligence and Machine Learning to Food Rheology. Adv. Food Rheol. Appl. 2023, 8, 201–219. [Google Scholar]

- da Costa, T.P.; Gillespie, J.; Cama-Moncunill, X.; Ward, S.; Condell, J.; Ramanathan, R.; Murphy, F. A Systematic Review of Real-Time Monitoring Technologies and Its Potential Application to Reduce Food Loss and Waste: Key Elements of Food Supply Chains and IoT Technologies. Sustainability 2022, 15, 614. [Google Scholar] [CrossRef]

- Stoll, D.A.; Müller, A.; Meinhardt, A.K.; Dötsch, A.; Greiner, R.; Kulling, S.E.; Huch, M. Infuence of Salt Concentration and Iodized Table Salt on the Microbiota of Fermented Cucumbers. Food Microbiol. 2020, 92, 103552. [Google Scholar] [CrossRef]

- Fideler, J.; Johanningsmeier, S.D.; Ekelöf, M.; Muddiman, D.C. Discovery and Quantifcation of Bioactive Peptides in Fermented Cucumber by Direct Analysis IR-MALDESI Mass Spectrometry and LC-QQQ-MS. Food Chem. 2019, 271, 715–723. [Google Scholar] [CrossRef] [PubMed]

- McMurtrie, E.K.; Johanningsmeier, S.D. Quality of Cucumbers Commercially Fermented in Calcium Chloride Brine without Sodium Salts. J. Food Qual. 2018, 2018, 8051435. [Google Scholar] [CrossRef]

- Dupas de Matos, A.D.; Marangon, M.; Magli, M.; Cianciabella, M.; Predieri, S.; Curioni, A.; Vincenzi, S. Sensory Characterization of Cucumbers Pickled with Verjuice as Novel Acidifying Agent. Food Chem. 2019, 286, 78–86. [Google Scholar] [CrossRef] [PubMed]

- Johanningsmeier, S.D.; McFeeters, R.F. Metabolism of Lactic Acid in Fermented Cucumbers by Lactobacillus buchneri and Related Species, Potential Spoilage Organisms in Reduced Salt Fermentations. Food Microbiol. 2013, 35, 129–135. [Google Scholar] [CrossRef]

- Pérez-Díaz, I.M.; Hayes, J.S.; Medina, E.; Webber, A.M.; Butz, N.; Dickey, A.N.; Lu, Z.; Azcarate-Peril, M.A. Assessment of the Nonlactic Acid Bacteria Microbiota in Fresh Cucumbers and Commercially Fermented Cucumber Pickles Brined with 6% NaCl. Food Microbiol. 2019, 77, 10–20. [Google Scholar] [CrossRef] [PubMed]

- Nosratabadi, S.; Ardabili, S.; Lakner, Z.; Mako, C.; Mosavi, A. Prediction of Food Production Using Machine Learning Algorithms of Multilayer Perceptron and ANFIS. Agriculture 2021, 11, 408. [Google Scholar] [CrossRef]

- Bhattacharyya, S.K.; Pal, S. Measurement of Parboiled and Non-parboiled Rice Grain Dimension During Hydro Thermal Treatment Using Image Processing. In Proceedings of the Emerging Trends on Sustainable Technology and Engineering Applications National Conference, Durgapur, India, 7–8 February 2020; pp. 8–12. [Google Scholar] [CrossRef]

- Cheng, L.; Sun, D.W.; Zhu, Z.; Zhang, Z. Emerging Techniques for Assisting and Accelerating Food Freezing Processes: A Review of Recent Research Progresses. Crit. Rev. Food Sci. Nutr. 2017, 57, 769–781. [Google Scholar] [CrossRef]

- Christiansen, M.V.; Pedersen, T.B.; Brønd, J.N.; Skibsted, L.H.; Ahrné, L. Physical Properties and Storage Stability of Reverse Osmosis Skim Milk Concentrates: Effects of Skim Milk Pasteurisation, Solid Content and Thermal Treatment. J. Food Eng. 2020, 278, 109922. [Google Scholar] [CrossRef]

- Valverde-Miranda, D.; Díaz-Pérez, M.; Gómez-Galán, M.; Callejón-Ferre, Á.J. Total Soluble Solids and Dry Matter of Cucumber as Indicators of Shelf Life. Postharvest Biol. Technol. 2021, 180, 111603. [Google Scholar] [CrossRef]

- Lin, K.; Gong, L.; Huang, Y.; Liu, C.; Pan, J. Deep Learningbased Segmentation and Quantifcation of Cucumber Powdery Mildew Using Convolutional Neural Network. Front. Plant Sci. 2019, 10, 155. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Zhu, H.; Guo, W.; Han, X.; Chen, C.; Wu, H. EFDet: An Efficient Detection Method for Cucumber Disease under Natural Complex Environments. Comput. Electron. Agric. 2021, 189, 106378. [Google Scholar] [CrossRef]

- Białkowska, A.; Majewska, E.; Olczak, A.; Twarda-Clapa, A. Ice Binding Proteins: Diverse Biological Roles and Applications in Different Types of Industry. Biomolecules 2020, 10, 274. [Google Scholar] [CrossRef]

- Brandão, V.A.A.; Araújo de Queiroz, R.; Lima Dantas, R.; Santos de Lima, G.; Lima Tresena, N.; de Queiroga, A.X.M.; Barbosa de Lima, A.G. Cooling and Freezing of Cashew Apple Using Computational Fluid Dynamics. Diffus. Found. 2020, 25, 114–132. [Google Scholar] [CrossRef]

- Codina-Torrella, I.; Guamis, B.; Ferragut, V.; Trujillo, A.J. Potential Application of Ultra-high Pressure Homogenization in the Physico-chemical Stabilization of Tiger Nuts’ Milk Beverage. Innov. Food Sci. Emerg. Technol. 2017, 40, 42–51. [Google Scholar] [CrossRef]

- Dai, J.; Mumper, R.J. Plant Phenolics: Extraction, Analysis and Their Antioxidant and Anticancer Properties. Molecules 2010, 15, 7313–7352. [Google Scholar] [CrossRef]

- Lu, Y.; Lu, R.; Zhang, Z. Detection of Subsurface Bruising in Fresh Pickling Cucumbers Using Structured-Illumination Refectance Imaging. Postharvest Biol. Technol. 2021, 180, 111624. [Google Scholar] [CrossRef]

- Ma, J.; Du, K.; Zheng, F.; Zhang, L.; Gong, Z.; Sun, Z. A Recognition Method for Cucumber Diseases Using Leaf Symptom Images Based on Deep Convolutional Neural Network. Comput. Electron. Agric. 2018, 154, 18–24. [Google Scholar] [CrossRef]

- Mao, S.; Li, Y.; Ma, Y.; Zhang, B.; Zhou, J.; Wang, K. Automatic Cucumber Recognition Algorithm for Harvesting Robots in the Natural Environment Using Deep Learning and Multi-feature Fusion. Comput. Electron. Agric. 2020, 170, 105254. [Google Scholar] [CrossRef]

- Sun, Y.; Zhao, X.; Ma, Y.; Guan, H.; Liang, H.; Wang, D. Inhibitory Efect of Modifed Atmosphere Packaging on Escherichia coli O157:H7 in Fresh-Cut Cucumbers (Cucumis sativus L.) and Efectively Maintain Quality During Storage. Food Chem. 2022, 369, 130969. [Google Scholar] [CrossRef] [PubMed]

- Dennis, R.; Cashion, A.; Emanuel, S.; Hubbard, D. Ozone Gas: Scientific Justification and Practical Guidelines for Improvised Disinfection Using Consumer-Grade Ozone Generators and Plastic Storage Boxes. Sci. Med. 2020, 2, v2i1.35. [Google Scholar] [CrossRef]

- Mi, S.; Zhang, X.; Wang, Y.; Ma, Y.; Sang, Y.; Wang, X. Effect of Different Fertilizers on the Physicochemical Properties, Chemical Element and Volatile Composition of Cucumbers. Food Chem. 2022, 367, 130667. [Google Scholar] [CrossRef] [PubMed]

- Cares, M.G.; Vargas, Y.; Gaete, L.; Sainz, J.; Alarcón, J. Ultrasonically Assisted Extraction of Bioactive Principles from Quillaja Saponaria Molina. Phys. Procedia 2010, 3, 169–178. [Google Scholar] [CrossRef]

- de Souza, L.P.; Faroni, L.R.D.A.; Heleno, F.F.; Pinto, F.G.; Queiroz, M.E.L.R.; Prates, L.H.F. Ozone Treatment for Pesticide Removal from Carrots: Optimization by Response Surface Methodology. Food Chem. 2018, 243, 435–441. [Google Scholar] [CrossRef]

- Sabanci, K.; Aslan, M.F.; Ropelewska, E.; Unlersen, M.F. A Convolutional Neural Network-Based Comparative Study for Pepper Seed Classifcation: Analysis of Selected Deep Features with Support Vector Machine. J. Food Process Eng. 2021, 45, e13955. [Google Scholar] [CrossRef]

- Butnaru, E.; Stoleru, E.; Brebu, M.A.; Darie-Nita, R.N.; Bargan, A.; Vasile, C. Chitosan-Based Bionanocomposite Films Prepared by Emulsion Technique for Food Preservation. Materials 2019, 12, 373. [Google Scholar] [CrossRef]

- de Souza, V.R.; Popović, V.; Bissonnette, S.; Ros, I.; Mats, L.; Duizer, L.; Warriner, K.; Koutchma, T. Quality Changes in Cold Pressed Juices After Processing by High Hydrostatic Pressure, Ultraviolet-c Light and Thermal Treatment at Commercial Regimes. Innov. Food Sci. Emerg. Technol. 2020, 64, 102398. [Google Scholar] [CrossRef]

- Moore, J.F.; DuVivier, R.; Johanningsmeier, S.D. Formation of γ-Aminobutyric Acid (GABA) During the Natural Lactic Acid Fermentation of Cucumber. J. Food Compos. Anal. 2021, 96, 103711. [Google Scholar] [CrossRef]

- Srivastava, S.; Pandey, V.K.; Singh, P.; Bhagya Raj, G.V.S.; Dash, K.K.; Singh, R. Effects of microwave, ultrasound, and various treatments on the reduction of antinutritional factors in elephant foot yam: A review. eFood 2022, 3, e40. [Google Scholar] [CrossRef]

- Bräutigam, K.R.; Jörissen, J.; Priefer, C. The Extent of Food Waste Generation Across EU-27: Different Calculation Methods and the Reliability of Their Results. Waste Manag. Res. 2014, 32, 683–694. [Google Scholar] [CrossRef]

- Delfino, J.R.; da Silva, J.L.; Marques, A.L.B.; Stradiotto, N.R. Antioxidants Detection in Aviation Biokerosene by High-performance Liquid Chromatography Using Gold Nanoparticles Anchored in Reduced Graphene Oxide. Fuel 2020, 260, 116315. [Google Scholar] [CrossRef]

- Srivastava, S.; Pandey, V.K.; Singh, R.; Dar, A.H.; Bashir, I. Recent Insights on Electrostatic Filtration and Its Potential Applications in Food Industry. Trends Food Sci. Technol. 2023, 136, 239–250. [Google Scholar] [CrossRef]

- Brodowska, A.J.; Nowak, A.; Śmigielski, K. Ozone in the Food Industry: Principles of Ozone Treatment, Mechanisms of Action, and Applications: An Overview. Crit. Rev. Food Sci. Nutr. 2018, 58, 2176–2201. [Google Scholar] [CrossRef]

- Demirdöven, A.; Baysal, T. Optimization of Ohmic Heating Applications for Pectin Methylesterase Inactivation in Orange Juice. J. Food Sci. Technol. 2014, 51, 1817–1826. [Google Scholar] [CrossRef] [PubMed]

- Pan, L.; Zhou, C.; Jing, J.; Zhuang, M.; Zhang, J.; Wang, K.; Zhang, H. Metabolomics Analysis of Cucumber Fruit in Response to Foliar Fertilizer and Pesticides Using UHPLC-Q-Orbitrap-HRMS. Food Chem. 2022, 369, 130960. [Google Scholar] [CrossRef] [PubMed]

- Sabanci, K.; Aslan, M.F.; Durdu, A. Bread and Durum Wheat Classifcation Using Wavelet Based Image Fusion. J. Sci. Food Agric. 2020, 100, 5577–5585. [Google Scholar] [CrossRef]

- Pourdarbani, R.; Sabzi, S.; Kalantari, D.; Arribas, J.I. Nondestructive Visible and Shortwave Near-Infrared Spectroscopic Data Estimation of Various Physicochemical Properties of Fuji Apple (Malus pumila) Fruits at Different Maturation Stages. Chemom. Intell. Lab. Syst. 2020, 206, 104147. [Google Scholar] [CrossRef]

- Afsah-Hejri, L.; Hajeb, P.; Ehsani, R.J. Application of Ozone for Degradation of Mycotoxins in Food: A Review. Compr. Rev. Food Sci. Food Saf. 2020, 19, 1777–1808. [Google Scholar] [CrossRef] [PubMed]

- Ozturk, S.; Bowler, A.; Rady, A.; Watson, N.J. Near-Infrared Spectroscopy and Machine Learning for Classification of Food Powders during a Continuous Process. J. Food Eng. 2023, 341, 111339. [Google Scholar] [CrossRef]

- Aghajanzadeh, S.; Ziaiifar, A.M. A Review of Pectin Methylesterase Inactivation in Citrus Juice during Pasteurization. Trends Food Sci. Technol. 2018, 71, 1–12. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhang, M.; Mujumdar, A.S.; Wang, D. Non-destructive Quality Determination of Frozen Food Using NIR Spectroscopy-Based Machine Learning and Predictive Modelling. J. Food Eng. 2023, 343, 111374. [Google Scholar] [CrossRef]

- Anaya-Esparza, L.M.; Velázquez-Estrada, R.M.; Sayago-Ayerdi, S.G.; Sánchez-Burgos, J.A.; Ramírez-Mares, M.V.; García-Magaña, M.D.L.; Montalvo-González, E. Effect of Thermosonication on Polyphenol Oxidase Inactivation and Quality Parameters of Soursop Nectar. LWT 2017, 75, 545–551. [Google Scholar] [CrossRef]

- Azam, S.M.R.; Ma, H.; Xu, B.; Devi, S.; Siddique, M.A.B.; Stanley, S.L.; Bhandari, B.; Zhu, J. Efficacy of Ultrasound Treatment in the Removal of Pesticide Residues from Fresh Vegetables: A Review. Trends Food Sci. Technol. 2020, 97, 417–432. [Google Scholar] [CrossRef]

- Yu, X.X.; Liu, M.Q.; Li, X.Y.; Zhang, Y.H.; Tao, B.J. Qualitative and Quantitative Prediction of Food Allergen Epitopes Based on Machine Learning Combined with In Vitro Experimental Validation. Food Chem. 2023, 405, 134796. [Google Scholar] [CrossRef]

- Kheiralipour, K.; Pormah, A. Introducing New Shape Features for Classifcation of Cucumber Fruit Based on Image Processing Technique and Artifcial Neural Networks. J. Food Process. Eng. 2017, 40, e12558. [Google Scholar] [CrossRef]

- Clement, J.; Novas, N.; Gazquez, J.A.; Manzano-Agugliaro, F. An Active Contour Computer Algorithm for the Classifcation of Cucumbers. Comput. Electron. Agric. 2013, 92, 75–81. [Google Scholar] [CrossRef]

- Sabzi, S.; Pourdarbani, R.; Rohban, M.H.; García-Mateos, G.; Arribas, J.I. Estimation of Nitrogen Content in Cucumber Plant (Cucumis sativus L.) Leaves Using Hyperspectral Imaging Data with Neural Network and Partial Least Squares Regressions. Chemometr. Intell. Lab. Syst. 2021, 217, 104404. [Google Scholar] [CrossRef]

- Pandey, N.K.; Mishra, A.K.; Kumar, V.; Kumar, A.; Diwakar, M.; Tripathi, N. Machine Learning Based Food Demand Estimation for Restaurants. In Proceedings of the 6th International Conference on Information Systems and Computer Networks (ISCON), Mathura, India, 3 March 2023; pp. 1–5. [Google Scholar] [CrossRef]

- Chen, J.Y.; Lin, Y.J.; Kuo, W.C. Pesticide Residue Removal from Vegetables by Ozonation. J. Food Eng. 2013, 114, 404–411. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, X.; Liu, S.; Wang, R.; Guo, J.; Chen, Y.; Ma, X. Wireless Food-Freshness Monitoring and Storage-Time Prediction Based on Ammonia-Sensitive MOF@SnS2 PN Heterostructure and Machine Learning. Chem. Eng. J. 2023, 458, 141364. [Google Scholar] [CrossRef]

- Lin, Y.; Ma, J.; Wang, Q.; Sun, D.W. Applications of Machine Learning Techniques for Enhancing Nondestructive Food Quality and Safety Detection. Crit. Rev. Food Sci. Nutr. 2023, 63, 1649–1669. [Google Scholar] [CrossRef]

- Srivastava, S.; Pandey, V.K.; Singh, R.; Dar, A.H.; Dash, K.K.; Panesar, P.S. A Critical Review on Artificial Intelligence and Robotic Vision in Food Industry. 2022. Available online: https://www.researchgate.net/profile/Vinay-Kumar-Pandey-2/publication/367180170_A_Critical_Review_on_Artificial_Intelligence_and_Robotic_Vision_in_Food_Industry/links/63c64905d7e5841e0bd4c293/A-Critical-Review-on-Artificial-Intelligence-and-Robotic-Vision-in-Food-Industry.pdf (accessed on 11 April 2023).

- Ban, C.; Jo, M.; Park, Y.H.; Kim, J.H.; Han, J.Y.; Lee, K.W.; Kweon, D.H.; Choi, Y.J. Enhancing the Oral Bioavailability of Curcumin Using Solid Lipid Nanoparticles. Food Chem. 2020, 302, 125328. [Google Scholar] [CrossRef]

- Ropelewska, E.; Mieszczakowska-Frąc, M.; Kruczyńska, D. The Evaluation of the Usefulness of Textures from Cross-Section Images Obtained Using a Digital Camera and a Fatbed Scanner for Cultivar Discrimination of Quince (Cydonia oblonga Mill.). Food Control 2022, 131, 108447. [Google Scholar] [CrossRef]

- Villacis, A.H.; Badruddoza, S.; Mishra, A.K.; Mayorga, J. The Role of Recall Periods When Predicting Food Insecurity: A Machine Learning Application in Nigeria. Glob. Food Sec. 2023, 36, 100671. [Google Scholar] [CrossRef]

- Han, J.; Zhang, X.; He, S.; Jia, P. Can the Coronavirus Disease Be Transmitted from Food? A Review of Evidence, Risks, Policies and Knowledge Gaps. Environ. Chem. Lett. 2021, 19, 5–16. [Google Scholar] [CrossRef] [PubMed]

- Bouckaert, R.R.; Frank, E.; Hall, M.; Kirkby, R.; Reutemann, P.; Seewald, A.; Scuse, D. WEKA Manual for Version 3-9-1; University of Waikato: Hamilton, ON, Canada, 2016. [Google Scholar]

- Frank, E.; Hall, M.A.; Witten, I.H. The WEKA Workbench. Online Appendix for Data Mining: Practical Machine Learning Tools and Techniques, 4th ed.; Morgan Kaufmann: Burlington, MA, USA, 2016. [Google Scholar]

- Alabdali, T.A.M.; Icyer, N.C.; Ucak Ozkaya, G.U.; Durak, M.Z. Effect of Stand-Alone and Combined Ultraviolet and Ultrasound Treatments on Physicochemical and Microbial Characteristics of Pomegranate Juice. Appl. Sci. 2020, 10, 5458. [Google Scholar] [CrossRef]

- Barba, F.J.; Parniakov, O.; Pereira, S.A.; Wiktor, A.; Grimi, N.; Boussetta, N.; Saraiva, J.A.; Raso, J.; Martin-Belloso, O.; Witrowa-Rajchert, D.; et al. Current Applications and New Opportunities for the Use of Pulsed Electric Fields in Food Science and Industry. Food Res. Int. 2015, 77, 773–798. [Google Scholar] [CrossRef]

- Barbosa de Lima, W.C.P.; Nascimento, L.P.C.; Lima Dantas, R.; Lima Tresena, N.; Silva Júnior, J.B.; Santos de Lima, G.; Barbosa de Lima, A.G. Heat Transfer in the Cooling, Freezing and Post-freezing of Liquid Food: Modeling and Simulation. Diffus. Found. 2020, 25, 37–53. [Google Scholar] [CrossRef]

- Bhattacharjee, C.; Saxena, V.K.; Dutta, S. Novel Thermal and Nonthermal Processing of Watermelon Juice. Trends Food Sci. Technol. 2019, 93, 234–243. [Google Scholar] [CrossRef]

- Gu, R.; Yun, H.; Chen, L.; Wang, Q.; Huang, X. Regenerated Cellulose Films with Amino-Terminated Hyperbranched Polyamic Anchored Nanosilver for Active Food Packaging. ACS Appl. Bio Mater. 2020, 3, 602–610. [Google Scholar] [CrossRef] [PubMed]

- Menichetti, G.; Ravandi, B.; Mozaffarian, D.; Barabási, A.L. Machine Learning Prediction of the Degree of Food Processing. Nat. Commun. 2023, 14, 2312. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).